Crystals, the Gulf of Mexico Blowout, and the new 'Top Hat' Dome

Posted by Heading Out on May 12, 2010 - 10:26am

The situation in the Gulf, in regard to the Deepwater Horizon fire and oil spill continues to evolve. Since my last post on this, the size of the operation has continued to grow, with some thought now being given to dredging barriers along the coastline. What I thought I cover a little today, among other things, is the problems that occur when oil leaves a hot reservoir and suddenly enters a pipe on the floor of a very cold sea, causing some of the constituent chemicals to crystallize out. To illustrate this, I took a picture of one of the pipes that used to sit in my office, since it helped visualize a problem we had been given, and is along the lines of that now facing BP.

You will note that the crystals have reduced the effective diameter of the pipe down to about 1.5 inches, cutting the flow the pipe can carry by 75% (roughly). These are but one example of a number of different chemicals that can precipitate out in the pipes that carry oil from the reservoir, where it is hot, up through colder zones as it rises through the different pipes on its way to land. There are two different aspects to the problem that I want to cover since it relates to the formation of methane hydrates in the capture box that BP had fielded at the end of last week.

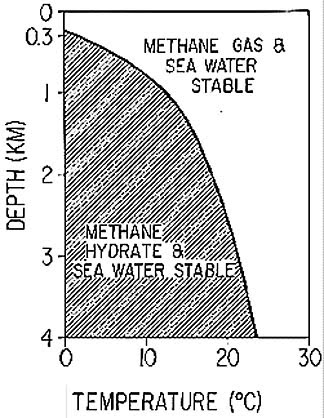

The first of these is on the growth of the crystal hydrates within the confinement box that BP had lowered over the middle leak in the riser. However, rather than dig back into my notes, I am going to suggest that those who want to understand the chemistry/physics go to The Obligate Scientist. He uses a plot from the USGS to illustrate the conditions that transition methane gas to methane hydrate as a function of temperature and pressure (depth in the ocean).

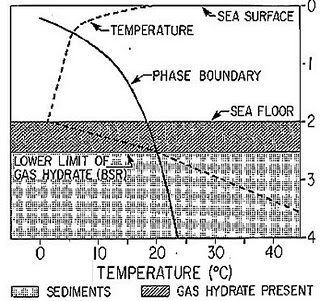

To which, to give it current relevance, the USGS have added what happens at the sea bed, exemplifying this with a seabed at 2 km deep, while in this case it is only about 1.6 km. However the temperature is still sufficiently low to cause the hydrates to form.

The temperature of the fluid is critical, as can be seen, but for the temperature to reach that level requires a certain amount of residence time, for heat transfer to take place. Unfortunately in constructing the box the way that BP did, while providing stabilizing plates that would stop the box sinking into the sediment, these also act as heat radiators, ensuring a very rapid heat loss to the surrounding sea and a faster drop in temperature for the gas, accelerating the formation of the hydrates.

As I mentioned above there are two problems that then arise. The first of these is the immediate constriction of the flow path, as the first figure shows, the second is that if the crystals were to break off, or grow freely to that size and then enter the flow channel, then unless they are all smaller than about 30-40% of the flow channel diameter, then they will jam together and block the flow channel. (I have photographs somewhere of a pair of particles, both nominally less than half a tube diameter wedged together in the middle of said tube and effectively blocking it – hence the rule of thumb).

So as the crystals grow they both reduce the flow channel itself, and also increase the risk of total blockage. Now it might be suggested that if the speed of the fluid were increased that this would not give the crystals time enough to form and cause the above problems. These are three, originally similar sized nozzles through which water was fed at 40,000 psi. (It is used in industrial cutting) The top orifice was totally blocked after 48 hours of operation using untreated tap water, the center orifice is largely closed after 104 hours using softened water, and the bottom orifice is still clear after 200 hours using de-ionized water. The water velocity was around 2,400 ft/sec and, as you may note deposits still grew.

Keeping deposits from clogging feed lines is thus a tad more complicated than it may first appear. And while I note that BP is now apparently planning on lowering a second smaller cap into position, there may need to be other modifications (such as an inner liner of Teflon to insulate the flow from the radiative metal of the box) that have been added (perhaps an internal heating system) to help alleviate the problem.

The Unified Command Center has noted the following update to the resources mobilized to help with the spill:

Total response vessels: more than 290

Boom deployed: more than 1.1 million feet (regular plus sorbent boom)

Boom available: more than 1.4 million feet (regular plus sorbent boom)

Oily water recovered: approximately 3.6 million gallons

Dispersant used: approximately 372,000 gallons

Dispersant available: approximately 180,000 gallons

Overall personnel responding: approximately 10,000

There was a “real time” transcript of the press conference that BP held at noon (6 pm in the UK) in which they commented that the second dome that they will try to cap the well with is going to be much smaller (about the size of a barrel) and that this should be tried within three days , and if that doesn’t work they are thinking of tapping into the pipe to drain the oil without seawater contamination. One of the problems, apparently has been the high gas content of the oil. Much higher than had been anticipated.

The box is being made smaller so that warm water (from the surface) can be poured over it to keep the temperature above that at which the hydrates form.

Now they've gone from "one extreme to the other". The "top hat" dome is 5ft tall, 4ft wide. Warm sea water will be pumped down. As they lower the dome it will already be operational - hooked up to a ship on the surface. It will be more difficult to place but they will succeed.

It should be in place by the end of the week.

What a beautiful picture of Barium Sulphate crystals!

Can they chip or dissolve these off I wonder and then crush and use them in Medicine to do 'Barium enemas'?

Wouldn't that be ironic!

Barium crystals clogging up a pipe, used to check why our pipes internal are 'clogging up'?

Barium is a particular oilfield problem deposit - no acid will touch them, or so the acid treating companies have told me. You might not want the mix you get from the pipe though - it has gypsum, scale and the barium all mixed together. I have found that treating with microbes (bacteria) is effective for treating to prevent the deposition, however.

http://www.patentstorm.us/patents/6331513/description.html mentions organophosphoric acid.

Having failed at this prediction of a spill being unlikely

http://www.washingtontimes.com/news/2010/apr/30/document-bp-didnt-plan-m...

Having failed to date at stopping the spill

Now we are assured that the new plan WILL SUCCEED. Such hubris. But I hope they are right.

I think they were talking about the placement of the box, not the success, as a predictor. I mean, they hope it will work, and the are certain it will be placed. The two are different.

At least that is my take on it. Not that anyone is asserting that the plan will succeed in stopping the flow.

Craig

How could BP not have known that this problem would occur with the first containment?

I think they did -- an article posted here, before they lowered the first container, mentioned that the riser would have down-flowing pipes to carry warm water and maybe some antifreeze to the box.

The surprise was that the "chimney" would become clogged with crystals before they could even hook up the riser.

Very interesting, HO, thanks for the post.

Barium sulfate (BaSO4) is, among other things, a respectable oxidizer; it is even used in some pyrotechnics. Properly mixed in the right proportion with hydrocarbons, it could pose a real explosion hazard. Is that ever an issue in this context?

No, as a general rule, sulfates are not significant oxidizers. BaSO4 is used in fireworks because the barium gives a bright green color.

I believe the picture is only intended to illustrate that growth of solids in oil pipelines can be a real problem, not to suggest that BaSO4 had any role in the Deepwater Horizon incident.

That's right - the points I wanted to make is that crystal growth can block a pipe in a couple of different ways, and had the pipe to show how the crystals - it was not meant to suggest that Barium Sulfate had anything to do with this particular disaster.

One might ask where the barium sulfate is coming from that is blocking oil pipes in the North Sea. Probably from drilling muds that often employ barium sulfate as a component. See: http://en.wikipedia.org/wiki/Barium_poisoning

House hearing: Gulf of Mexico oil spill and Offshore Drilling now on C-Span.org.

Uh....that pit volume change log looks kinda strange....According to the work boat captain they had stopped displacing mud several hours before that (5pm)....

Is that indicative of taking kicks? Or starting to "produce" mud? or is that normal?

toller -- I'll have to study the log later but to answer the "mud production" question: It's difficult to tell if the well is loading while you're pumping mud down the hole. But pretty easy to tell once you stop: when you shut the pumps off the well will still flow a small amount for a minute or two. But if you see a steady stream then you know something is puching the mud up. And the only time that happens is when the well is flowing back: oil/NG/water/drilling mud or any combination there off.

This was the bit they just highlighted if I saw the screen correctly.

http://energycommerce.house.gov/Press_111/20100512/Halliburton-Last.Two....

Yeah...but if you look up mebbe 1/3 the way down the log the pit volume is all OVER the place....

In the testimony on the negative pressure test they said that they had 1400 psi on the standpipe and 0 psi on the kill lines.

If you look at Column 2, you see Choke 1 and Choke 2 pressure which I assume are the kill chokes under the BOP. I assume this is the topside ocean floor of the annulus between the drillpipe and the casing, but measured on the surface.

If my assumption is correct, at catastrophic failure that pressure never responds even though the standpipe pressure is 6,000 psi.

FF

OK, should the kill lines have had 1400 PSI on them? They weren't activated at that time, IIRC those are activated to kill the well so they can slowly circulate out the kick But 1400 PSI on the standpipe seems a signal that something is leaking into the well.

tow -- I need to study this a bit. I normally don't watch the mud tanks too closely. I'll probably bounce the data off an engineer or two. but this is waht I see: the upper log shows the SSP. This is the stand pipe pressure and in about 4 minutes it went from less to 500 psi to over 5500 psi and then the recording stops. The SSP is the pressure of the mud flowing back up the well bore (need to check to make sure there isn't another potential pressure source.) This may be very telling in that this may be the best indication of the blow out coming at them. As far as the pit volumes it's less clear.

Rock-

If something can build to 6000 psi it must be closed off. A valve is shut. That is my question.

FF

Just FYI 20:10 - 20:30 and the area around 21:20 are the area Im looking at....OTOH I can barely read an SP log, so it may just look strange to me (considering that they werent pumping out the riser)...but maybe there was something totally unrelated going on in those areas.

It looks like they reversed mud out of the hole then. Five full scale reversals would be 500 barrels. I can't remember what the testimony of the boat crew chief was as to the volume he was going to take on.

Inside 9" ID pipe (the top of the tapered string), I get about 12 feet per barrel. So that would be 6000' of mud or other fluid out of the pipe.

The other interesting time starts at 21:10 where it looks like they are taking fluid out of the tanks.

A lot of info here.

FF

The Damon B. Bankston, owned by Tidewater Marine, had received about 3,100 barrels of drilling mud from the Deepwater Horizon through a hose connecting the two when the process abruptly stopped, short of the 4,500 barrels scheduled to be transferred, Landry said.

http://www.chron.com/disp/story.mpl/business/7000866.html

Interesting point, at this time the gas goes up to 80 units, not high but it is the only gas on the sheet, but the flow out stays relatively level, and pumps stay the same so I still say the pit level change is pumping mud from another pit.

Sorry...obviously meant SPP...stand pipe pressure

Tollertwins

When you are displacing to sea water at the end of the well, you have fluids going everywhere. They were taking mud back to the pits, they had been transfering to the boat. They need sea water to displace the mud, depending on the lay out of the pits, they may have to fill pits with water before they pump it. Some rigs can take sea water directly to the pumps. They could have been flushing pits. We do not know it the pit totalizer was set for all pits, just active pits, or anywhere in between. What concerns me is the steady gain while pumping between 20:34 and 21:10.

The sharp movement at 20:10 to 20:34, looks to as a transfer from another pit. The rapid decline at 21:10 to 21:18 looks like a transfer out of the pit or pits.

Tx for the explanation!

The gain you mention appears to continue after the 21:10 'pit shift', too.....

So based on another of your posts further down, it sounds like since the well had essentially been shut in, there might not be anybody monitoring telemetry, either....

This whole thing is just truly tragic....

Looks like the last standpipe pressure recorded was 6,000 psi.

How??

Great Post

FF

My guess would be that the flowing tubing pressure from 18,000' would be that high or higher. Remember that I'm not an engineer even though I sometimes play one on TOD. But I'm not sure there's a mud pump on the rig capable of reaching that pressure.

That is amazing that it would build that quick wide open.

You can really see the hook load lighten and the corresponding Weight on bit increase. I wonder if any of the physicists could tell us whether the pipe was in motion. The blocks have not changed position.

FF

FF

One of the statements said they closed the annular, and this pressure build up is an indication that the BOPs were closed. At 21.44 an increase in the flow out, means fluid is coming up the riser. This the same time of the sharp increase in the SSP. To me looks like a annular failure. The annulars were good for 10,000psi, I believe this well was higher than that.

For such a sharp increase SSP, something down below gave way, casing parted, seal assembly ejected or cement ruptured.

As for the Top drive, it is rated for 7500psi and the pumps would be the same with the correct pistons and liners. I doubt they would have had these installed drilling in what I suspect are soft formation. Most like 6 1/2" liners with relief valves set at 5000psi. Unless they had a gate valve close on the pumps then one of the first things going wrong would have been the relief valves returning to the pits.

No reading on the C&K, line up must not have been opened to the gauge or they were closed. Pits show a steady increase. Where from with no flow out?, Trip tank which should have the line up, not the mud pits, looks like it and a couple of top ups rather than a steady increase from the well.

That is my quick take on it.

I got it

So the drillpipe is hooked through the top drive to the mud pump and the pop off on the mud pump opened---- here came the gas.

That was the nastiest f'in timing ever, no??

You are da man.

FF

FF

It is easy to look at these graphs and work out what should have been done, but I get the feeling they had it in their mind the well was dead and trying to work out what could have been causing their strange pressures. When you have an unbalanced "U" tube all sorts of strange things can happen. We know the final result they didn't.

It appears they have closed the annular and monitor pressures on the SSP, not realizing the danger they were in. Good practice for a high pressure well would have been shut ram, and hang off, open Choke valves on the BOP, close the IBOP (ball valve at the top of the drill pipe) monitor well on choke gauge. This way they would have 15,000psi protection.

The way they shut in had a 10,000psi annular, mud pump relief valves most likely set at 5000psi, wash pipe, a potential leak point, also 10,000psi, mud hose 7,500psi and a mud manifold rated at 7,500psi. Easy to see in hind sight, but I am sure they though were only dealing with an imbalance in the "U" tube and trying to get a handle on it.

Having said that at 21:47 something let go big time, and even Transocean are say that most likely there was debris in the BOP that caused it not to seal.

21:49 it was all over.

BP's "What We Know" statement (prepared for the House committee on May 6) and Chairman Waxman's explanation of that statement

BP: What We Know

--Before, during or after the cement job, an undetected influx of hydrocarbons entered the wellbore.

--The 9 7/8" casing was tested; the 9 7/8" casing hanger packoff was set and tested; and the entire system was tested.

--After 16.5 hours waiting on cement, a test was performed on the wellbore below the Blowout Preventer (BOP).

--During this test, 1,400 psi was observed on the drill pipe while 0 psi was observed on the kill and the choke lines.

--Following the test, hydrocarbons were unknowingly circulated to surface while displacing the riser with seawater.

--As hydrocarbons rose to the surface, they expanded, further reducing the hydrostatic pressure. The well flowed, and witness account suggest that the Annular Preventer in the BOP and the Diverter were activated.

--An explosion occurred, followed by a power failure.

--Witness accounts suggest that the Emergency Disconnect System was activated.

--The rig was evacuated.

--The BOP system failed to work as intended. Flow was not contained, and the Lower Marine Riser Package did not disconnect.

--Modiflcations have been discovered in the BOP.

--Leaks have been discovered in the BOP hydraulics system.

--BP launched an investigation which is ongoing.

Investigation Themes

--Cementing--design and execution

--Casing--design and installation

--Casing hanger--design and installation

--BOP-- configuration, maintenance and operation

--Well Control Practices.

From Rep. Waxman's opening statement:

We recently received a document from BP called “What We Know.” It was prepared on May 6 and it summarizes what BP knew about the spill at that time....

The first bullet says: “Before, during or after the cement job, an undetected influx of hydrocarbons entered the wellbore.” What this means is that there was a breach somewhere in well integrity that allowed methane gas and possibly other hydrocarbons to enter the well.

The second bullet says: “The 9 7/8” casing was tested; the 9 7/8“casing hanger packoff was set and tested; and the entire system was tested.” BP explained to us that this refers to a positive pressure test in the well. What this means is that fluids were injected in the well to increase pressure and to monitor whether the well would retain its integrity. The well passed this test.

Rigs like the Deepwater Horizon keep a daily drilling report. Transocean has given us the report for April 20, the day of the explosion. It is an incomplete log because it ends at 3:00 p.m., about seven hours before the explosion. But it confirms that three positive pressure tests were conducted in the morning to early afternoon.

The next bullet says: “After 16.5 hours waiting on cement, a test was performed on the wellbore below the Blowout Preventer.” BP explained to us what this means. Halliburton completed cementing the well at 12:35 a.m. on April 20 and after giving the cement time to set, a negative pressure test was conducted around 5:00 p.m. This is an important test. During a negative pressure test, the fluid pressure inside the well is reduced and the well is observed to see whether any gas leaks into the well through the cement or casing.

According to James Dupree, the BP Senior Vice President for the Gulf of Mexico, the well did not pass this test. Mr. Dupree told Committee staff on Monday that the test result was “not satisfactory” and “inconclusive.” Significant pressure discrepancies were recorded.

As a result, another negative pressure test was conducted. This is described in the fourth bullet: “During this test, 1,400 psi was observed on the drill pipe while 0 psi was observed on the kill and the choke lines.”

According to Mr. Dupree, this is also an unsatisfactory test result. The kill and choke lines run from the drill rig 5,000 feet to the blowout preventer at the sea floor. The drill pipe runs from the drill rig through the blowout preventer deep into the well. In the test, the pressures measured at any point from the drill rig to the blowout preventer should be the same in all three lines. But what the test showed was that pressures in the drill pipe were significantly higher. Mr. Dupree explained that the results could signal that an influx of gas was causing pressure to mount inside the wellbore.

Another document provided by BP to the Committee is labeled “What Could Have Happened.” It was prepared by BP on April 26, ten days before the first document. According to BP, their understanding of the cause of the spill has evolved considerably since April 26, so this document should not be considered definitive. But it also describes the two negative pressure tests and the pressure discrepancies that were recorded.

What happened next is murky. Mr. Dupree told the Committee staff that he believed the well blew moments after the second pressure test. But lawyers for BP contacted the Committee yesterday and provided a different account. According to BP’s counsel, further investigation has 3 revealed that additional pressure tests were taken, and at 8:00 p.m., company officials determined that the additional results justified ending the test and proceeding with well operations.

This confusion among BP officials appears to echo confusion on the rig. Information reviewed by the Committee describes an internal debate between Transocean and BP personnel about how to proceed.

What we do know is that shortly before 10:00 p.m.--just two hours after well operations apparently resumed--gas surged from the well up the riser and the rig exploded in a fireball....

Very interesting. Was there any more description of what BP and Transocean were debating?

Today's WSJ is reporting

Deepwater Horizon Well Failed Key Test

If I heard correctly, one (of two) batteries read 18 amps (it wasn't "dead" as the press report) instead of 27 amps according to testimony however while it was agreed this should have been noted routinely and acted upon earlier it likely (my interpretation of what was said - but they were not ruling anything in or out at this stage) was not a factor in the incident but nobody could explain why it hadn't been acted upon.

Halliburton just produced logs showing the well coming in during the last two minutes before telemetry was lost which they recorded remotely. Transocean confirmed that they were not recording telemetry remotely themselves but others were.

It seems my comment about the age of the BOP was relevant. I wonder if it had old rubber O rings that crumble at the temps (near 32F) found in deep water?

Tom

The BOPs may have been 10 yrs old, but they under go rigorous preventative maintenance. Every 5 years they are totally stripped and inspected by Cameron personnel measuring every important dimension, crack testing and total rubber replacement. At the 2 year intervals pretty much all the rubber parts are replaced. The main ram seals and annulars are inspected each well and changed out if there is any concerns. To pull a deep water BOP to repair a ram seal or to replace an annular can be a weeks work, at $500,000 per day is $3.5mil. An expensive piece of rubber if not changed at the correct time. Due to cost of unplanned repairs a lot of work is done between wells while th eBOP is on surface. Some deepwater rigs have 2 BOPs to allow more time for maintenance

As for the leaks, BOPs have been know to have hydraulic leaks, the fluid they use is a water base fluid and, it is a constant lose system. Therefore when a ram is functioned the used fluid goes to sea. Depending on the severity of the leak and its importance the BOP may have to be pulled.

is the report that a drill collar can prevent proper bop operation accurate? ie: 10% of the time, the bop probably won't work?

Perhaps I missed it but I can't tell when during the testing process did BP start to displace the mud. The primary purpose of the test is to determine if it's safe to displace. It almost sounds like they began displacing before they completed the test to determine if it was safe to displace.

True....workboat captain seemed to indicate that they were displacing the riser at 5pm, and then shut down that activity till 9...that is the point that he called in for a status update.

Q: whether the comment in the "James" interview is correct...e.g. that if the annulus was leaking, even plugging w/ mud in the hole would only have delayed the inevitable....

toll -- did the capt actually say they were displacing the riser or just that they were pumping mud down to him?

Not entirely sure....just found this again...but it IS media - so dont know if the 'resume pumping out riser' is just 'resume' mebbe...

http://www.chron.com/disp/story.mpl/business/7000866.html

Shortly after 5 p.m. that afternoon, the rig unexpectedly stopped pumping drilling mud out of BP's Macondo well to the vessel Damon B. Bankston, parked alongside the rig. This was one of the last steps the rig was taking to secure the well and temporarily abandon it so BP could come back later to extract oil from it.

The Damon B. Bankston, owned by Tidewater Marine, had received about 3,100 barrels of drilling mud from the Deepwater Horizon through a hose connecting the two when the process abruptly stopped, short of the 4,500 barrels scheduled to be transferred, Landry said.

When calling for an update at 9 p.m., he was told that rig crews soon would resume removing drilling mud from the pipe-like riser connecting the rig to infrastructure on the sea floor.

I like how all these statements leave out the important bit of information. You do a negative test by displacing a heavy fluid (mud)to a light fluid, (water). Without knowing what fluids are in the choke & kill or the drill pipe, and how much, the pressure reading are nearly meaningless. Not stated but the BOP must have been closed. Zero on the C&K means to me that they contained mud. While the 1400psi on the stand pipe (drill pipe) is the differencial caused by putting water down the pipe, but how much water? Was the 1400psi reading changing or static.

I see from Transocean statement to the inquiry, sorry don't have a link as it was emailed to me, but I am sure someone will have it posted by now, wonderful graphics,amazing casing string design but short on factual depths, but they suggest what I have said several times before.

"We also do not know

whether the BOPs were damaged by the surge that emanated from the well beneath

or whether the surge may have blown debris (e.g., cement, casing) into the BOPs,

thereby preventing them from squeezing, crushing or shearing the pipe."

BP got a gamma ray scan of the interior of the BOP - anyone know what they found? Has there been an increase (or decrease) in flow from the leaks over the past week? BP must know - anyone heard? Why haven't they released photos (let alone video) of the leak at the kinked riser by the BOP stack? They say its smaller - what harm in showing?

Push-

I agree. If you have seawater in the drillpipe to 5,000 and mud in the kill line tied to the backside of the well then measuring pressure at the surface the difference due to hydrostatic gradient would be 1400 psi or so. .052*(14-8.65)*5000.

FF

Rockman....

Your posts are extremely informative. I'm in Upstream IT - totally appreciate the information and insights.

That goes for all the other guys who work rigs and do engineering, too!

Seriously HO. I don't know how you crank these posts out so fast (having attempted it myself in the past). You are seriously talented.

Thanks for keeping people informed on energy fundamentals.

Thanks, Nate, though I fear you overestimate my abilities. It took, for example, the combined efforts of myself, a secretary and a student half-an-hour to find that pipe (guess who found it) and with much of my research and teaching being in related fields over the past 40-odd years some of this comes from notes I already have. But a lot more is coming from the comments and the direction that those who are posting them give to help us all understand what happened, and is happening. Those comments and the insights are the real value.

As I said very early on it's not often I get to be one of the smarter guys in the room. Just unfortunate that it's about such a horrible event.

Why don't methane hydrate crystals form in the bits of pipe above the sea floor and self-seal the above sea floor leaks?

I also wonder about BP's explanation of the blockage. If the pipe at the top of the containment box had been closed, I would have expected that the oil would have displaced the water in the box, since the oil/gas mixture is less dense that sea water. However, since it appears that the pipe was open at the time the box was lowered onto the riser pipe, the oil would have flowed out the top of the box and sea-water would have leaked around the bottom, providing the H2O needed to form the clathrates. Without water to form the clathrates, I think that there would not have been such a large problem with blockage. But, the containment vessel did not have a valve (or valves) on top, so we will never know whether it would have worked.

The next approach with the smaller "cap" would feed the oil directly into the pipe to the surface, which has been said to be heated to prevent the formation of clathrates. This approach might work, especially as the "cap" appears to have some ports which could be employed for injection of other substances, such as air or methanol.

E. Swanson

I would guess the oil coming out is quite hot and it's not clear how much gas is coming out at this stage. If little gas is coming out gas hydrates may not be formed.

In this vast flood of data, any ideas on how much gas is coming out of this well now?

Not as much out of the well as from the Senate... ;>)

My prediction on Congressional action is some sort of oil industry version of Sarbanes Oxley. More transparency in the application and preparation process, plus maybe an adverse impact report of some sort going through the down side scenarios from drilling, in each phase of the progress through capping the well when it is closed.

More legal work; more regulations, and of course more opportunity for creative gifting to Reps and Senators.

Or am I being overly cynical?

Craig

Conservatives snicker about corruption but the conservative Roberts SCOTUS has decided that corporations have the sacred 'free speech' right to bribe legislators so it's completely phony hypocrisy for them to bring it up.

Libertarians also believe in the 'right to bribe'.

Even McCain dropped support for McCain-Feingold campaign control bill.

It's a sick system but conservatives like that.

It justifies their instinctive hatred of government but also reassures them that their money power will let them dominate the rest of society.

Man who live in Glass House should not throw rocks...a lot of the current mess with are in with the housing bubble was caused by liberals like Barney Frank and Chris Dodd who got tons of donations from "special interest" groups who wanted "reform" whereby anyone could get a mortage. And the issues of FNMA also comes up where by a buddy of Barney gets a 400K/yr job to run the whole thing into billions of debt. If you look at the data you will see the big brokers on Wall Street and large corporation contribute a lot more towards liberal candidates than conservative candidates so how exactly are conservatives "owned"? There is way more than enough blame on both sides of the aisle, no one can claim they are not involved. McCain-Feingold was far too restrictive and let to the massive growth of the PACs which were little more than thin disguises for wealthy interests. At least with the new laws you'll know where firms like Exxon, Wal-Mart, Microsoft and others stand on the issues instead of hiding behind the PACs they funded. It doesn't mean I like the special influence game, but at least I know the players this way

Yeah?

What about Bush's 'ownership society'?

In 2002, President George W. Bush signed the Single-Family Affordable Housing Tax Credit Act. Dubbed "Renewing the Dream," the program would give nearly $2.4 billion in tax credits over the next five years to investors and builders who develop affordable single-family housing in distressed areas.

On December 16, 2003, President George W. Bush signed the American Dream Downpayment Act, a new program that provided grants to help home buyers with downpayment and closing costs. The act authorized $200 million dollars per year for the program for fiscal years 2004-2007.

Rethugs controlled Congress from 2002-2007.

Freddie and Fannie were intended to to sell mortgage-backed securities on the market. They require that mortgages conform to their requirements--20% down payment, credit score and debt to income ratio.

Freddie and Fannie were nationalized in 2008 by Bush in 2008 due to massive defaults on ARM mortgages.

Freddie has ~800 billion in assets and Fannie has ~900 billion in assets.

The invention of ARM mortgages was back under Raygun(Sen.Jake Garn R-Utah).

In 1995, Freddie Mac began receiving affordable housing credit for buying subprime securities, and by 2004, HUD suggested the company was lagging behind and should "do more."

Freddie Mac was put under a conservatorship of the U.S. Federal government on Sunday, September 7, 2008.

Your conservative memory (or lack of knowledge) conveniently forgot that the Republicans created and managed this disaster.

You scream about Dodd and Frank but totally ignore that the deregulation of the mortgage security markets entirely a conservative show and you who claim to know the players did not know that!

Typical conservative...'disaster?..it MUST have been Bill Clinton or Barney Frank ..or Chris Dodd.'

'Unthinkable! No conservative would ever do anything so irresponsible'

Typical wingnut.

I got better things to do with my time that deal with liberal talking points to try to shift blame. You guys NEVER do a thing wrong. When Obama and you jackasses run this great nation into the ground with outlandish spending, overwhelming in debt, monstrous over-regulation like cap and tax, stupid judiciary, governing on "feelings", etc. we'll be looking just like Greece but there won't be anyone to bail us out.

I love getting lectured by hypocrite-conservatives about 'librul' fiscal irresponsibility.

Total BS w/o context that GWB was fighting the war in Iraq and bailing out banks (still think that was a bad idea), and Reagan/Bush destroyed the former USSR both costing mega-$$$. I also notice you said it came from zFacts.com but where did they get it? And also total BS when you don't have things like the unemployment index there as well. Lower employment and lower economy means less tax inflows versus payments outflows that accounts for much of the jump the last 2 yrs of GWB. But look at Obama in 2 yrs..it's a vertical line! Don't say he "inherited it" thats complete BS. He could have taken any GWB budget "extras" out Day 1 but didn't and then added to it by doing things like buying GM, putting out the "porkulous package" and nonsense, and of course still paying for Iraq/Afghanistan after he promised he would "bring the troops home". Project this spendling like a drunken sailor forward a few years, add in "ObamaCare" and it'll blow the top off the chart. So where is the money going to come from to pay for Obama's plans? The patient was in critical shape but hanging on and now is barely alive and could die anytime.

Iraq/Afghanistan is nothing like Korea(Truman,Ike) or Viet Nam(LBJ, Nixon) and the debt dropped over those years.

Ronny/Bush had some tough opponents like Nicaragua Panama and Grenada.

Loved how Raygun stood up to terrorism in Lebanon in 1982.

Strange how you credit Raygun for 'destroying the Soviet Union'(with the imaginary Star War program--boo!) which fell in 1989 (but forget Raygun slept thru Al Qaeda which was formed in 1988).

Again your conservative mind prevented you from noting that the chart ends Feb 27 2009 with Obama being in office for a month an a half.

The conservative brainwash seems to have cut your IQ in half.

But you CAN recover your mind..if you really want to.

First, turn off FOX News and stop listening to Michael Savage.

Then take an aspirin and lay down in a quiet room.

"I got better things to do with my time that deal with liberal talking points to try to shift blame. You guys NEVER do a thing wrong. When Obama and you jackasses run this great nation into the ground with outlandish spending, overwhelming in debt, monstrous over-regulation like cap and tax, stupid judiciary, governing on "feelings", etc. we'll be looking just like Greece but there won't be anyone to bail us out."

Interesting you mention that, Curious. You could have easily substituted Bush for Obama and Conservative Talking Points for Liberal in that paragraph, and you would be just as right. For what it's worth, I'm kind of disapointed in what's happened to our Republic. And you can find all sorts of villains; conservative, liberal, democrat, republican, corporate, special interest...who have had a hand in it's devolution. If it were up to me, I would start establishing eco-communes with an anarcho-syndicalist framework to prepare for the coming societal clusterf***. Either that, or start my own religious cult. I mean, it worked out so well for the Rev. Moon and his Unification Church...other than the bit about going to jail for tax evasion, that is.

Pete Deer

Well, you could join Scientology, they don't care about your political leanings ;) I hear they got ways to get around that issue of taxes too!

I'm just as mad as you are about things, but the people to really blame are ourselves. After all we voted the people into office that did things that have harmed us. Human nature is such that promise us we'll get some sort of personal benefit from something and we are all of a sudden all for it without even understanding how it works. We have become a nation of entitlements and until we break that habit very little is going to change REGARDLESS of which party runs the show.

A big part of the formation of the methane hydrates is the release of the gas from pressure which creates cooling. The gas must still be in pretty good pressure at the point where it is coming out of the leaks if it is forming the hydrates - the water has to be cooled below what the seabed temp is and the oil and the gas as released should still be pretty warm if not hot until the pressure is released, creating the cooling.

No, the seabed temperature and pressure are well within the clathrate stability zone. You don't need gas-expansion cooling to form clathrates: the oil and gas just need to transfer their heat to the seawater.

And say what you like about water, it's *really* good at cooling stuff off.

x -- My guess would be that the pressure is high enough to blow thee crystals out as they are formed.

You gotta have water to make a hydrate.

In the riser is only oil and natural gas, until the very end, and the NG will be in two forms:

(a) gas above the oil layer

(b) dissolved in the oil layer (which is floating on top of any water)

So any contact with water will be limited until free of the pipe.

http://bp.concerts.com/gom/crater_plume.htm

see the white bubbles on top of the dark oil?

The water probably only reaches into the riser until the first hump or two.

I would think that oil and NG was purging the riser under high pressure when things blew, i.e. blew any hydrates out with the seawater.

(n.b. the the "mud" was oil-based").

Great stuff as always, HO.

One hydrate problem they may be having is at the orifice, in this case the kink in the pipe. As a fluid runs through a restriction orifice the static pressure will reduce as the fluid velocity increases until the pressure minimum and velocity maximum are reached at a point known as the vena contracta, which usually resides just downstream of the smallest flow area in the orifice. The loss of static pressure in the fluid causes a temperature loss (refrigeration effect). This can bring the fluid well into the hydrate formation zone even if the conditions at the outlet of the orifice are not in the hydrate formation zone.

I've seen this happen to valves in NG service where upstream and downstream of the valve are clear of hydrates but the valve itself is blocked. I think something like this happened to the first dome as hydrate crystals attached to the walls in the same way they might attach to a valve body and grow very quickly. They don't "melt" instantly even if the surrounding conditions are slightly outside the hydrate formation zone.

As to the "top hat": If they can suck the fluid up into the heated riser quickly enough, and keep the "hat" itself warm enough, it might work. Managing hydrates can be a tricky thing, and they are not easy to predict without detailed fluid constituents, and even then it is tough.

Valve and HO,

Can't the formation of hydrates be prevented by eliminating the water?? If only oil and gas are captured in the top hat (by letting some of the oil leak out the bottom sides of the capture device along with seawater), won't that prevent hydrate crystals? And shouldn't they be using hot light oil to warm the device rather than seawater?

Yes. Hydrates can only form in the presence of water. The smaller dome may have some benefit in that regard. I doubt they would entertain the idea of pumping more oil into the ocean, but they may use methanol or ethanol (basically anti-freeze) which inhibits hydrate formation and will shift the "hydrate line" left on the chart.

Dave,

You had these pipes in your office for a reason. What kind of research were you doing? What did you learn?

Gail:

I think that is cheating (I had told her that I didn't think (would be willing to bet) that anyone would catch that). We were asked to look at ways of removing the crystals. If I can reply in more general terms (since the specific details of those tests are proprietary to our customer) it is possible, and not uncommon to use high-pressure water jets as a cleaning tool down-hole to clean off, for example, the screens that hold back broken rock (sand) around the well. The performance of the jets is reduced as the depth of the well increases, and one way to get around this is to increase the flow by increasing the jet diameter, or adding long-chain polymers to the jetting fluid. One of the important things to do is to clean the surface of the metal with the jets, since this increases the nucleation time, and increases the time between cleaning operations.

HO or anyone who can answer,

I have not seen anyone address the recent news reports (I may have missed it of course) about the leaks changing to much more gas and less crude.

My question is "What does this imply for fixing the leaks and/or for what kind of evolution is going on in the potential problems with this disaster."

Does this change have potential downside issues associated with it? The news reports paint it as an imporvement. But is it. Or is the threat now evolving to other problems that require different fixes than are currently planned?

What does this imply about the oil reservoir itself?

That kind of stuff.

Txs, Wyo

Wyoming,

Not an expert but a couple of thoughts here.

1) IF the oil/gas ratio is changing, it could be that the production zone has a gas cap on top of oil. Just speculation but permeability to the oil flow may cause the well to start to bridge over while the section with gas at a higher permeability continues to flow. If so, that could be a good thing.

2) On the other hand if the Gas flow is actually increasing, that will be dispersed in a water column rising to the surface. Depending on currents, etc, that could be less than good. If the gas concentration gets high enough in the water, it could change the water density and buoyancy for rigs and vessels in the area could be threatened.

ej

Wyo -- If true one answer would be a drawdown of the reservoir pressure. The lower pressure would allow more NG to come out of solution. But I also question how well they can monitor such a possible change.

Rockman,

If the well is unexpectedly having lower pressure from just a few weeks of a 5K bbl/day wouldn't that mean that there is likely much less oil in the reservoir than originally thought?

Wyo

Not really WYO. Given how the well started flowing it would not have surprised me if pressures had gone to zero by today and there was no flow at all. There could still be a 100 million bo down there under high pressure but the well bore might have collapsed (called bridging over).

Let us all pray for a bridgeover!

Then the focus can really shift to the clean-up.

"...about the leaks changing to much more gas and less crude."

i have NO idea what it means... but what i heard on cnn/wolf blitzer was... that BP is saying... the has leak ALWAYS been MORE NG...

and yes... they are saying that's a good thing... they're sating it'll just disappear [paraphrased]...

BP finally released a video to cnn... but i listen on xm... but they say it shows 50% =/- natural gas...

BIG THANKS TO ALL THE EXPERTS PASSING ALONG THE 'NUTS 'N BOLTS' TO US LAYMEN...

Any update on the size of the spill evaluation ?

Is it as shown below or really much worse ?

http://newsimg.bbc.co.uk/media/images/47791000/gif/_47791601_oil_spills4...

HO:

Very informative, thanks. But I think some of your statements lack theoretical support. Referring to the heat transfer in the Macando (sp?) situation as radiative is surely inappropriate. Radiative means that the mechanism of energy transfer is the emission and absorption of photons. And that the photons are capable of traveling some significant distance between emission and absorption. Photons (the quanta of electromagnetic radiation) are not transmitted by concrete or wood or steel. And only very restricted bands of wave length are transmitted in water (seawater included). Seawater also contains floating biomass that scatters and absorbs radiation, thus limiting the distance of transmission.

It is much more plausible to believe (IMHO) that massive production of hydrates is happening on the surface of the oil blobs as the blogs form at the leaks. (Surface layers of the blobs are very cool because the surface is in thermal contact with the ocean water.) The hydrate crystals are not visible because the lighting is wrong for them to show in the camera pictures. They rise slowly because of bouyancy. They pretty much fill the seawater at depths below the hydrate stability line. As the box was lowered, its open bottom collected a full load of crystals on the way down. It was already fouled well before it got anywhere near the leak of oil.

Other places where radiation is mentioned need to be re-thought. The observed facts are not in question, whatever they actually are, but radiative heat transfer should not be invoked in the explanation.

There are three mechanisms for heat transfer: conduction, convection, and radiation. Conduction is the slowest and is only important in situations where convection and radiation cannot happen, such as brick walls, and the solid, non-porous strata of the Earth. Convection is heat transport by matter moving from a hotter region to a cooler region. It is much faster than conduction, and totally overwhelms conduction where in can occur. Radiation moves heat at the speed of light (it IS photons that actually carry the energy), but it can only happen in vacuum or in a region that is transparent or translucent for some wave length bands. Seawater is not particularly transparent. Sunlight does not penetrate below about 1000 ft. (All deep water ROVs carry lights in order to make their cameras useful.) More theory is available at wikipedia heat transfer entry.

If they had had the recovery line hooked up to the box when they lowered it, they could have pumped hot water down and blown out the hydrate crystals, it would seem to me.

I believe that is what they are planning on doing with the "Top Hat" though it is not clear at the moment, since the photos available don't show any connections from the top of the "hat."

If they send it down there unconnected aren't they just sending another rock candy dangler into the flow to be iced-up again?

then couldn't they weld heat sink fins onto the riser, growing the crystals quickly and intentionally to completely block the flow? or is the dome not heavy enough to seal against reservoir pressure to the seabed? and were there any efforts to close the BOP with auxiliary hydraulic power?

"... weld heat sink fins onto the riser ..."

Why try this? The old riser is a pile of junk on the seabed. It will never be used again, and might reasonably be left there to slowly disolve over the next few thousand years. Sea level will never FALL enough for it to be a hazard to navigation.

I think an easy fix to hydrate formation will be found once we have harmonized theory and ground truth fact. Then it might become technically feasible to re-start development of deep undersea oil. Now it is 'temporarily' halted. On geologic time scale, our civilization is temporary. Above ground issues, collapse of civilization due to lack of adequate oil supply, etc.

The greatest danger, IMHO, is that we will fix on an explanation for how to proceed with deep water development that is merely conventional wisdom, but, in fact, bad science, and leads us into an even greater disaster.

Could not agree more.

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in... [4.8MB]

The BP graphic shows Top Hat with two methanol injection ports entering the roof cone. The riser pipe appears to be insulated.

Seems like the best place for the Top Hat is right on top of the Blowout Preventer. Since the length of riser between the BOP and the leak only serves to cool the crude the best place for the Top Hat would be right on the BOP. If the BOP were built with an attachment mount for the Top Hat it could be lowered right onto it and connected and sealed. The Top Hat would then capture hotter crude before it could be cooled. Not only that the BOP stack itself could be pre-built with heating elements built-in so in an emergency they could be plugged-in and further keep the crude above hydrate crystalization phase.

The (first) top hat is being deployed over a break in a part of the riser that is laying on the sea floor.

5,000 bpd will take about ten hours to flow through 5,000' of 21" pipe. So while the oil may be hot at the BOP, it will certainly be as cool as the surrounding sea water at the leak where the dome is.

Wouldn't it be tragic if all this took was a simple bypass pipe in the Blowout Preventer stack with a connection mount and valve.

Interesting comment from Cameron that they do not deny that that the BOP emergency shear was initiated from the rig (and presumably confirmed by the BOP) but that (if I heard correctly) there is then a one minute period before the rams fire. He seemed to be suggesting that if comms was lost within that one minute the shear rams would not initiate even after confirming the instruction.

I'd assumed that if you hit the BOP emergency button that things would happen virtually instantly. Is there really a one minute window (hydraulic charging?) where the command could be "reset" or did I misunderstand? Even if that turns out to not be a problem in this case (or if it does) this seems a major potential problem.

Got the impression the Representatives were astonished at just how many things it was known could go wrong. One comment was "How can you call a device 'fail-safe' when it has 260 known non-safe failure modes?"

Good question, the 1 min delay could be for several reasons, to pressurize the accumulators to power the rams, or it could be a safety means to prevent accidental engagement. I lean towards the later as it sounds like a "deadman" type switch where it has to be held down until the accumulators discharge and the rams start moving then it's all over and the switch position doesn't matter. If anytime in that one minute the switch is in the OFF position the order is cancellled. Loss of communication may be considered as an OFF position. They may have to look at the design specs to be sure. The deadman concept has been in use a long time, and is used on all locomotives to stop the train if the deadman is released.

That is certainly not what I picture when I think of a deadman switch. To me, the deadman should be "loss of communication" where only a signal keeps an event from happening and if that communication is lost, internal logic in the BOP should be to activate. If I hit the BOP switch, there shouldn't be a feedback system, it should activate immediately. If that means the accumulators have to be continuously charged during operation, so be it. I hope this is just a miscommunication of the actual event, because wow, that would sure scare me as an operator. If I hit an ESD, BOP, or any emergency switch, its not cause I have 60 seconds to wait.

As I recall the BOP Accumulators are charged, I don't know if they are fully charged though and if the charging is a standard # or varies by type of well, hole size, etc.

Your version of a "deadman" is what in embedded weapon systems work we called a "watchdog", if your watchdog isn't "kicked" on time it starts up a chain of non-interruptable events to safe the system. However in this case where the BOP Rams going off due to s signal glitch or something (recall it is 5000ft under water) where the kick was missed you get a really bad thing happening where all of a sudden get your pipe, riser, casings, etc. are sheared off and you gotta fish the ends out and redo costing beaucoup bucks and nothing was wrong. Closing the BOP is for a really bad thing happening or going to happen. I also don't think BOPs are that "smart" but others who are more expert can say for certain. Somehow I don't see this switch as a big red button on the drillers board that says "Panic" but as a switch that sets of some events that take a bit of time to occur.

So you're a fail-unsafe kind of guy?

"In emergency press button and hold for 60 seconds while on fire."

Sort of, more of a break glaas and pull alarm. Fail-safe means IF equipment fails it is in a safe configuration or it "safes" the system. BOPs are fail safe meaning the rams have ways to be closed if stuck in an open mode and fail to seal the hole. Those backup systems also seem to have failed which says catastrophic failure of the BOP occured perhaps due to more pressure than it was designed to handle. How and why they are activated is a different issue. Press and hold for say 10 seconds may be all that is needed, or no-communication in X seconds (but I don't think BOPs are that "smart") you just can't have it going off on stray signals or every small outage of signal. You have to balance the risk of damage due to a false alarm with the risk of misssing a real alarm. You can design systems that handle both cases quite well.

Still it seems to me that if the Emergency Disconnect/Shear Sequence was initiated from the floor or control room then the Blow Out Preventer should continue to carry that out autonomously under the circumstances. We are not talking about a "glitch" initiating an EDS here, we are talking about a presumably error checked valid emergency command being received. A subsequent loss of comms after a valid Emergency Disaster Shutdown should not be able to reset the sequence - which, if I understood Cameron correctly, it can.

If this was what happened (and we don't know as they were discussing possible failure modes not necessarily what they think actually happened) then it seems a BOP acoustic remote would have helped here. Previous info from BP had suggested to me that it would not as they had confirmation that the BOP Disaster Shear was confirmed by the BOP but the Cameron testimony has clouded that issue for me if it perhaps just never carried out the validly commanded sequence until much later when the Deadman finally triggered.

The emergency disconnect can be done in 23 secs,ie close shear rams, retract stabs and disconnect LMRP (top half of BOP) all with one hit of the button. You better mean it when you hit it because there recall on the demand. Your off.

That's what I would have assumed - that there was no way to cancel a valid EDS but the Cameron testimony suggested otherwise. Just cut comms or power and the BOP goes back to sleep waiting for loss of hydraulics (possibly as late as the rig sinking) as well as power and comms before self initiating despite having received and confirmed receipt of the fact that it was in a Disaster Scenario. That sounds totally incomprehensible to me if true.

I am sure Cameron know a lot more about the system than me, but the system does have its own UPS, which I am sure was functioning. This is just for the panels and comms. All the physical power comes from stored pressure. Now if you lost comms, I can see the sequence stopping as the brain power is on the rig not 5000ft below the water. But as I said before we could get off in 23 secs which is less time than closing the annular.

Undertow

There are API regulations on the time a surface stack and subsea stack are required to close the rams and annular. The subsea is stack is basically 15 sec more than the surface stack. I should know these numbes off the top of my head as it is in the exams we take every two years. I know someone will correct me if I get it wrong.

To close a surface stack ram 30 sec, annular 45 sec

To close a subsea stack rams 45 sec, annular 60 sec.

In the days when subsea stacks were fully hydraulic the extra time was required, as the water depths increased the operation got slower, so the industry changed to MUX and now fibre optic for its controls, now the deepwater stacks actually close quicker than a land rig, the API requirement stays the same. From my experiance a ram on a fibre optic BOP takes less than 15 secs in operation to seal on the pipe.

The lastest SAT image from NASA: http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/state_oil_on_s.... Are we really supposed to believe that all of that has come from a leak which can be covered with that "top hat." Please BP, don't insult my intelligence.....what is really going on down there?

Seems there are some experts here, and I have been unable to get BP to answer this, or any media to ask.

Can anyone tell me why we have not drilled holes around this well, planted explosives, and capped the well under tons of rock?

Is there too little rock? Is there any solid rock?

Seems to me that between the wellhead at 5k feet, and the deposit at 18k feet, there must be a layers of solid rock.

Why has it not been discussed, and if it has, why is it not an option?

Two problems ibi. The biggest is that there are no rocks out there. It's rather sloppy mud for a coupls of thousands of feet. Second, blowing a pipe apart isn't going to seal it. Might even increase the flow.

staggering

Greetings all,

New to the site, not new to the issue being discussed. All the approaches being used are sympmtomatic of why these things happen in the first place.

Environments like the on being dealt with need "flexible" solutions and I use that word in it's broadest aspect.

Please see:

www.squareandc.net

A potential solution to the Blow-out.

Regards,

Wow just wow.

There's no way I would argue with that.

If we can only convince mother Gaia to heal herself...or something.

I liked "Apply technology in homeopathic doses".

Well there's plenty water to dilute the technology I suppose.

Glad it resonated Badgerb.

Please spread the word.

Greetings from India,

Would like to redirect the thinking here a little towards a little tangential thought process.

For a peek into what I mean, please visit the web-site mentioned above www.squareandc.net

Hostile environment, poor visibility, too many unknowns, uncharted waters (engineering-wise, technology wise, almost every which way).

If I may be a little opaque but very very pertinent, this is a problem caused by newtonian thinking.

May I suggest a little Viktor Schauberger?

How do you create action at a distance in a situation such as this? You move water the way the ocean moves water.

How do you get the air above to play a role and clean it at the same time? Hmmmmm.... food for thought.

Like cures like. So, how can a gusher control a gusher? Think about how the earth has created this tremendous pressure in the first place. Mirror it and work backwards, gently.

All the bludgeoning approaches being discussed will not work. Cannot work.

We have to think differently, circularly, spirally.

The answer is there, it is not easy (such a complex problem) but it is eminently solvable.

And due to it's nature, it takes care not only of the gush, but the spill (to the degree that it has not dispersed or been dispersed fully).

Will post more, but we need to change the thinking, away from millions of psi's and billions of gallons.

Think like the butterfly flapping it's wings.

Such sayings do not survive generations without having more than a grain of truth!

Regards,

VivekAnand

may i suggest that if you possess a solution to this catastrophe that you post it so that it can be examined, instead of redirecting traffic to your website.

every minute counts, share.

Greetings Kimyo,

All solutions cannot be put into simple words. Or simple flow-diagrams. Those are always simplistic. Cap it, put a riser a lowerer, pump this much of this and that.

And truth be told, too much dissection of what is clearly a non-traditional approach will rob it of the energy it needs to hold.

On a problem of this scale and magnitude, my solution is akin to the philosopher's stone. Alchemical engineering if you will.

Some things are best kept under wraps. The redirection to the site is to energise a meme that might lead the right eyes/ears to it.

I hope my allusions to Schaugberger, circular, spiral thinking etc., are hints enough to think away from the linear solutions path.

If there is a general feeling of "get on with it", I will happily step back. Nothing to gain for me here.

Regards,

VivekAnand

I'm not such these are hydraulic rams. I know the tensioners are high pressure air. I can't say for the BOP. The drill ship I was on only had high pressure air. Now if these rams are activated by air and there is any water in those lines they will freeze. It should be dry air but there is no garanty the air was dry.

I believe the actual Rams are Hydraulic (simply the easiest way to get to the forces needed.) The pumps for the hydraulics I believe are air powered. This would also answer another question of why from the time they hit the kill switch on deck does it take one minute for the rams to fire. You press the kill switch this opens the valves on the air cylindars attached to the pumps, the pumps then take one minute to pressurize the accumulators, after the accumulators are charged the vlaves then open to the cylindars of the rams and are supposed to give the force necessary to shear through or smash the (pipe/casing?) well closed. The drawbacks of course are that if hydraulic lines are damged or you loose enough air tanks, you won't have enough pressure to either run the pump or get the accumulator to sufficent pressure to work correctly.

I seem to recall in the testimony today that one of the questioning Congressmen stated that there was a reported leak in one of the hydraulic lines to the accumulators. To which the relevant official stated that they had been tested within the last two weeks, and if there had been a leak since then that the charging pump would have kept kicking on to maintain the pressure, and it did not.

Specifically there was a loose fitting on a hydraulic line. They put dye in with the submersible and identified the leak. Pretty hard for a fitting to get loose on its own a mile down under the sea - suggests bad maintenance the last time it was overhauled and must have been failing tests the whole time it was on the job.

Yes and no. Thermal cycles or thermal shock can cause bolts/nuts to loosen as can vibration. BUT if the right torque was applied when it installed there would be no loosening in either case. This sounds like a way out story as how did the ROVs tap into the lines? I thought they were kinked shut? If this line was leaking why didn't the accumulator pressure drop and force it to be topped off by monitoring systems unless of course such systems were not in use.

It was in the testimony today - quoted many places, for example:

"In Kenner, La., where a separate hearing is being held as part of a U.S. Coast Guard and Interior Department investigation, Michael Saucier of the Minerals Management Service testified the government isn't required to inspect the BOPs as they are built and when installed. Operators are required to test the devices every two weeks, and Saucier said the MMS monitors those tests. He said the agency relies on drillers to ensure the device is working properly.

A 2001 report by Transocean, which bought the BOP from Cameron, indicated there can be as many as 260 failure possibilities in the equipment, which is supposed to be the final safeguard against a well blowout by clamping down and sealing a gushing oil well, said Stupak, chairman of the panel's investigation's subcommittee.

"How can a device that has 260 failure modes be considered fail-safe?" asked Stupak.

Stupak said when an underwater remote vehicle tried to activate the blowout protector's devices designed to ram through the pipe and seal it, a loss of hydraulic pressure was discovered in the device's emergency power component.

When dye was injected "it showed a large leak coming from a loose fitting," said Stupak, citing BP documents. He said officials at Cameron, the company that made the preventer, had told the committee the leak was not believed to have been caused by the blowout because other fittings in the system were tight."

http://hosted.ap.org/dynamic/stories/U/US_GULF_OIL_SPILL?SITE=TXDAM&SECT...

Aircraft fittings have multiple mechanisms to ensure they do not loosen. Why would these be different?

HO-I've been looking for some operational info re: the accumulator banks-The must be Nitrogen charged. Is that correct ? And do you know the charge pressure? THNKX TP

From Yahoo News, just now:

BP caves to pressure, releases first video of oil gushing into Gulf

Finally.

Earlier today we reported on how BP was coming under heavy pressure from the media, Washington politicians and the general public to release underwater video footage of the oil spewing into the Gulf so that a better assessment of its potential damage could be made. ABC even asked White House spokesman Robert Gibbs if the Obama Administration could pressure the company. BP held firm.

But now, the beleaguered energy company has released a 30-second clip and publicized the move on Twitter.

Watch it:

-----

http://www.youtube.com/watch?v=WYFYVNvgg-A

Oil and gas stream from the riser of the Deepwater Horizon well May 11, 2010. This video is from the larger of two existing leaks on the riser. This leak is located approximately 460 feet from the top of the blowout preventer and rests on the sea floor at a depth of about 5,000 feet.

-----

It's believed that getting a glimpse of the gushing oil would allow experts to more accurately estimate the amount spewing into the Gulf each day. Up to this point outside specialists like Ian MacDonald, a Florida State oceanography professor who specializes in tracking oil seeps in the ocean, have been forced to base their projections on satellite images of the oil slick. The accuracy of such estimates has been challenged due to the fact that chemical dispersants, sunlight and the powerful Gulf tides are believed to have made large swaths of the oil difficult to detect. McDonald, for one, believes as much as five times more oil than is currently estimated could be in the Gulf.

—Brett Michael Dykes is a national affairs writer for Yahoo! News

Looks like that's a video of a video. Anyone got a link to the original file?

FWIW, the YouTube video is what BP released, announcing it via Twitter:

-----

Video release: Oil and gas stream from the riser of the Deepwater Horizon well http://bit.ly/cKTcAO (via @Oil_Spill_2010) #oilspill #BP

-----

The bit.ly link goes to the YouTube video I linked to.

From BP's site: http://www.bp.com/gulfofmexico

The video (under "response in video" -> "Oil and gas stream from the riser of the Deepwater Horizon well - 11 May 2010")

http://bp.concerts.com/gom/crater_plume.htm

Same video as the one on YouTube that I linked to above (also now on CNN).

Based on this video, I'm going to have to revise my earlier estimate of the leak rate. That estimate was based on a still photo: using this video I can do a better job of estimating the velocity of stuff coming out of the pipe.

The gas is definitely moving faster than the oil in this video: by watching the motion of blobs and billows of oil, I make the ejection speed of oil to be about 1 m/s, about twice what I estimated before. This image shows the pipe geometry better: things are shaped a little differently than I assumed, but the cross-sectional area of oil as it exits is still about 0.03 m^2.

So that makes a flow rate of about 0.03 m^3/s, or 16,000 barrels per day -- well above BP's reported estimates. As before, this is only a very rough estimate, good to within a factor of 2 or so.

Does anyone recall or have a link to the earlier still photos of the leak? I am quite sure the rate of flow has been increasing. The times article excerpt posted below says BP now knows that the BOP stack is restricting the flow (though the percentage in relation to the riser kink may not be known they should now have a ballpark estimate) - at least for the moment. The article mentions three ideas for shutting down the flow at the wellhead and says they may try the 'junk shot' regardless of what else they do. This suggests to me that there is some considerable urgency in reducing the flow rate asap. I would expect the cutting action to increase with the volume of flow.

How do you know the volume ratio of the gas to oil, seems to me oil flow rate is impossible to calulate without an accurate estimate of this ratio.

I eyeballed it. Looking at the video, you can see that the upper half of the jet is high-speed white stuff (gas), and the lower half is low-speed black stuff (oil). So I estimated the speed of the black stuff and multiplied by half the cross-sectional area of the pipe. This is, of course, not very precise: I could easily be off by a factor of 2 or so.

when bp says 'primary' leak i wonder if they mean 'the leak with the largest flow' or if they mean 'the leak we found first'.

I was picturing the flow more as an oil matrix filled with gas bubbles, does anyone know whould the gas/oil be be neatly separated or more of a foam?

I'm curious about the gas flow and what'll happen if/when the "tophat" is installed. Seems to me that the flowrate is pretty large even when it's coming out of the riser at seafloor pressures (2300 psi?).

If they try to contain that flowrate inside a 10' or 12" riser, can anyone estimate the velocity when this stuff expands to atmospheric pressure?

Without doing any calculations, it seems to me that the back pressure involved is going to start pushing most of the oil back down the riser and out the bottom of the "tophat". Any oil that stays in the riser and comes out the top will be moving at a pretty ungodly speed.

Can somebody (PLEASE!!?) prove me wrong?

GOR at one point reported to be 3000....dont know if that is volume ratio or not.

toll - GOR is normally reported at cubic ft/bbl. It's the ratio of NG disolved in the oil. I suspect the 3000 GOR represents initial reservoir conditions. What's flow out of the system today might be very different.

From the photo in the newspapers tonight, it would appear that the end of the pipe is clear of obstructions.I guess the problem is closing the leakage in the face of the extreme pressure in the pipe.

i was faced with this problem some years ago, not on the same scale to be sure, but the same problem just the same.

A drain plug had been removed from a full oil tank, and oil was pouring out. the pressure in the tank made it impossible to locate the plug in place into the hole, so that it could be screwed home safely.

The contractors where thinking like BP, trying to cover the hole against the high pressure, which didn't work.

The solution was very simple really, and once the correct tool was made, the leakage stopped.

"From the photo in the newspapers tonight, it would appear that the end of the pipe is clear of obstructions."

I believe that is incorrect and in fact it has the drill pipe coming out of it down in the mud - that's the pipe they cut off and capped a few days back. Oil was coming up the well through the drill pipe, through the BOP and on out to its severed end. Now that that is capped the remaining flow is coming through the BOP outside the drill pipe and into the riser. They can't cap the riser because the well pressure will blow it up if they did.

As to why they can't unbolt the riser from the BOP and cap it there - maybe the flow of the leak is a problem, maybe that end of the BOP stack is too damaged to mess with...

BP knows the answer to all these questions, but so far they haven't said AFAIK

CNN has it on their front page with the caption:

First video of the gusher.

http://www.cnn.com

Actually, the one on YouTube is clearer.

If you look carefully at the video at http://bp.concerts.com/gom/crater_plume.htm

you will see the yellow color of the riser on both the left and underneath of the gas and oil emissions.

It looks like the riser was torn cross-wise, and split down lengthwise about a foot, then torn cross-wise again.

In these (dark) pictures:

plume_2

plume_1

they claim a 12" long wrench (with a rope tied around it) for scale.

Since the riser is 21" in diameter, the end is obviously torn up considerably.

Especially visible in the plume_1 picture.

A lot of force to tear a steel pipe like that.

Plume_1 you can also see what appears to be the drill pipe bent 90 degrees heading off to the left. So NO, the riser is not clear of obstructions, there's a bentup drill stem in there (the 1st leak they capped off).

The plume_2 picture you can tell that if the wrench was lowered down until the top was level with the top of the riser pipe, the bottom of the wrench would be level with the mudline along the lengthwise torn section of the riser.

Our ship had about 5-6 air bottles. They were about say 10 – 12 feet long. Very heavy wall. The compressors were 5 stage Ingersoll Rand. They were built like a radial engine. The 1st stage had a piston about 2 inches around and the final stage had a piston about one half inch around. The discharge was say about ¼ inch tubing. To pump the bottles up took days. The compressors were air-cooled. We worked on those compressors continually because of the seals would fail or a compressor would overheat and complete overhaul was necessary. Today the compressors are rotary either wet or dry depending on the client. One compressor may have been down and the operational one rickety. It may have been that the maintenance crew had a compressor down for overhaul and the tanks were not up to their operating pressure. A good look at their maintenance records would be enlightening.

I know sometimes the onboard 3rd assistant-I’m assuming there was a licensed engineer on board-would leave a machine for overhaul to the relieving engineer because there was not enough time to complete the task before crew change. So it may be events conspired against this rig. The high-pressure air was down at the same time the rig got into trouble.

If there were a licensed engineer on board, the logbook would be a good place to look. Of course, the written log is at the bottom of the drink. But in this modern time they may transmit the log via satellite daily to shore.

Many times the rig does not keep enough spare parts on board so that the engineer will order the parts and then after weeks the parts will arrive. Of course the machine is down for weeks until the parts arrive. Everyone has to sign off on the purchase.

OK, so what is this "riser insertion" all about? Does that mean that the "tophat" failed?

http://www.flickr.com/photos/deepwaterhorizonresponse/4601914103/sizes/o...

[file size warning]

That leak is really going (video)! If I had to guess I'd say the situation is getting worse rather than better.