Is 70,000 barrels a day a possibility for the oil spill?

Posted by Gail the Actuary on May 14, 2010 - 10:15am

NPR is now reporting that the oil spill could be 70,000 barrels of oil a day, which is considerably greater than the estimate of 5,000 barrels per day currently being reported. What is the view of Oil Drum readers regarding the likelihood of the higher estimate being accurate? According to the story:

The analysis was conducted by Steve Werely, an associate professor at Purdue University, using a technique called particle image velocimetry. Harris tells Michele Norris that the method is accurate to a degree of plus or minus 20 percent. That means the flow could range between 56,000 barrels a day and 84,000 barrels a day.

Another analysis by Eugene Chiang, a professor of astrophysics at the University of California, Berkeley, calculated the rate of flow to be between 20,000 barrels a day and 100,000 barrels a day.

We also know that the oil tends to mix with water to produce a "chocolate mousse" mixture. The controlled flow rates of wells drilled by BP's at its Thunder Horse platform (another deep water platform) seemed to produce oil of 40,000 to 50,000 barrels a day, when the wells were in maximum production based on the graphs below from this post:

Natural gas production is in addition to the oil production shown on these graphs, bringing the barrel of oil equivalents up somewhat (10% - 15%) from this level. This Deepwater Horizon well is different, so this may not have particular relevance.

What are readers views on the likelihood of higher oil spill estimate being correct?

When I saw the first images of the leak I remember thinking, "That looks a lot bigger than the quarter-inch hole posited at The Oil Drum."

I know it's in this thread -- but can someone please remind me -- what is the inside diameter of the pipe from which all this oil is escaping -- I've read 6 3/4 inches -- one rig worker in an mp3 interview said 12 3/4 inches -- an NPR story yesterday reportedly implied the pipe was actually 6 feet across -- yikes !!

Video images are tough to scale. Can the worlds oceans actually be destroyed through a 6 3/4 inch pipe?

As posted downthread, I was listening to NPR this morning (Friday) and heard someone say that the riser pictured is only the casing, and that the actual oil/gas flow runs through a 9" pipe inside the riser.

Have been seeing consistent reports that the interior of the yellow riser from which the oil is flowing is 20 inches. http://www.npr.org/templates/story/story.php?storyId=126809525&ps=cprs

or 53 cm. O.D. http://www.cbc.ca/world/story/2010/05/14/gulf-of-mexico-spill-0514.html

Even with a 9" drill pipe coming out of it that would leave ample room for inserting a 15cm. (6 in.) pipe-in-a-pipe diversion attempt.

The end of that inside drill pipe had been capped earlier leaving the 2 leaks of oil, one out of the riser casing outside the drill pipe (video) and the other at the BOP.

the 20 " looks about right if you look at the halliburton wellbore diagram posted yesterday.

It may be (although no one has said AFAIK) that the leak is flowing through the valve (BOP) at the wellhead within a 7" drill pipe. This pipe runs on out through the larger 21" riser pipe and out some distance beyond it's broken end. Most of the flow is out the broken end of the riser as can be observed in the videos now posted online. Early on the drill pipe was cut off and capped to prevent oil from leaking there. It is a pretty good bet that the drill pipe is badly cracked or broken off within the riser near or at the BOP where the riser has a pretty dramatic kink - thus the flow we see is traveling mostly through the riser until it exits at the broken end.

Seeing what happens to an annular in a very similar kind of situation, and given the internal BOP X-ray pressure readings estimate of 8,000-9,000 given by TinFoilHatGuy it seems if that was converted to total static pressure those annulars would have been hard pressed to hold.

After they were opened I'm figuring they were well on their way to begining to look like the pic I linked above from gcaptain and Undertow. So the well has to be leaking from both the inner drill pipe and the riser housing from how I understand the setup, b/c if the shear had closed successfully AFAIK all would be moot, and since a lot of that cutting and shredding is outer of the string some of the leak begins in the outer riser portion of the BOP.

This leaves us with the question you (and I and all lot of others) have been wondering; Is this drill string broken, eroded, split just within or somewhere after the BOP inside the riser where it cannot be seen? Perhaps the X-ray pressure drop estimate within the BOP given by TinFoilHatGuy is of value here. 8-9k underneath 450psi above seawater outside.

Tempting to say that almost all of the restriction exists from the BOP to the outer riser, that the flowrate was diminished a bunch when the cap was placed on leak #1 due to sealing the drillstring, and that the junk shot basically has to plug the shear ram area or to simply plug the annulus scoured out by the opening of the annular and disintegration caused by the blowout.

Tempting except for the fact that BP was quoted repeatedly as saying they didn't expect capping leak #1 to significantly diminish the overall output by much. So far that call seems spot on.

Source please

Don't have a cite, can't remember where I saw it (may have been a blog, don't think it was NPR), but I did read a story or a post that said the pipe was 5 (as I recall--not 6) feet wide.

No leak.

1,000 barrels

5,000 barrels

might be 100,000 barrels

70,000 barrels

If I have a pipe of given size and I know the flow pressure and the specific gravity and temperature of the outflow. Should I not be able to calculate a flow rate? What am I missing?

I watched a video of the purported failed casing spewing petroleum and methane gas -- and wondered of the same.

This? It's not the one the calculation is based upon.

http://www.youtube.com/watch?v=2JTM2QyAfCI

But *do* you know the pressure?

Yes. Where the video is taken the pressure is 2240 PSI.

We're not talking pressure upstream of the blowout preventer here, we're talking pressure after it's gone through the pressure drop at the leak in the BOP.

The video permits us to guesstimate volumetric flow by (1) seeing the velocity at which it's expelled from the drill pipe, (2) knowing the interior diameter of the drill pipe that the flow is coming from and (3) assuming that it's high-Re (turbulent) rather than laminar flow in the drill pipe.

Q [m^3/s]] = v [m/s] * π (D/2)^2 [m^2]

where Q is volumetric flow, v is velocity, and D is the pipe interior diameter.

I should have said pressure *gradient*. Tinfoilhatguy seems to be suggesting that one could calculate the flow rate from first principles based on the forces acting on it. To do that, you need the pressure upstream of the BOP ... or whatever choke point is controlling the flow rate.

The calculation you're proposing is the same as what the scientists in the NPR article did, and which I have done elsewhere in this thread.

The pressure upstream of the BOP is at least 8,200 PSI above the 2240 PSI at the seabed, and probably higher due to what Rockman calls "geopressure." That pressure is dropped across an orifice of unknown area formed by damage or blockage within the BOP. Once you calculate the flow based on the flow velocity from the video, you can guesstimate what the area of the orifice is. Increasing flow(remember, the flow was thought to be near zero for the first few days after the disaster began) means that that orifice is being eroded and is increasing in area.

GOR

In an earlier thread I did a poor man's particle imaging velocimetry by eyeballing the video frame-by-frame, and came up with about 16,000 BPD, give or take a factor of 2.

After reading a little more, I realize I underestimated the diameter of the riser pipe, which would bring my calculation up to 30,000 BPD or so -- again, give or take a factor of two.

This is lower than NPR's scientists' estimates, but every calculation I've seen agrees that the true flow rate is much more than 5000 bpd.

One way to look at it: for a flow rate of 5000 bpd, the oil would have to be coming out of the riser at about 25 cm/sec, roughly the speed of a tortoise in a hurry. Look at this video. Does that look like 25 cm/sec to you?

So the report of telemetry link to a ROV was not accurate?

Where's the math on the fluid flow and what are you assuming for the GOR?

Math details:

Pipe diameter is roughly 16 inches (0.4 meters), estimated using this photo with 12-inch wrench for scale.

From video, looking at motion of black stuff (oil) *only* and ignoring the much faster white stuff (gas), black stuff goes 1 pipe diameter in about 0.4 seconds, giving a speed of about 1 m/s.

Notice flow out of pipe is separated: gas in the top half, oil in the lower half. To get oil volume, multiply area of lower half of pipe times oil velocity:

0.5 * pi * (.2 m)^2 * 1 m/s = 0.06 m^3/s = 30,000 barrels/day

Possible errors of 50% or so in oil velocity, cross-sectional area of oil flow, and in the assumption that the black stuff is 100% oil, for a cumulative factor of 2 uncertainty.

0.06 m^3/s translates into 5184 bbls/day according to the conversion I have

1 m3 = 6.2898105697751 bbl

Edit: missed the conversion, however given the 2 phase flow occuring I don't believe your equation is enough.

how 'bout using the garden hose method ?

how many garden hoses does this look like ?

multiply garden hose result x 171 bpd to 342 x bpd, corresponding to 5 gpm for inner city garden hoses to 10 gpm for suburban garden hoses, respectively(i'm not making this up, i have actually measured these rates). of course, size matters in all aspects of hoses.

0.06 m3/s

60*60*24=86400 s in a day

thus 0.06*86400=5184 m3/day

And thus 5184*6.29=32607 barrels a day.

Ouch!

i don't have a definitive link, but every resource i've checked listed the riser's diameter as 21". don't know if that is inside or outside diameter. shouldn't you run your calcs based on the actual size of the riser as opposed to a guesstimate using a monkey wrench as a guide?

Most pipe is sized in approximate OD for that large diameter, but I would say that it is nominal 22" pipe but measures 21" on the ID (0.500" wall). Not likely to have large pipe sized in odd numbered OD's.

One photo showed a 12" wrench near pipe and someone guessed pipe to be 16", but 12" wrench is usually a little longer than 12", plus end of pipe may be slightly deformed to look smaller.

My guess on flow out of riser unobstruted is 16,000 bbl per day or about one cubic foot per second. If pipe is 21" ID and half of pipe is ejecting oil (balance of volume is gas) then cross sectional area of oil is 173 in*2, and 144 in*2 for each cubic foot, as oil looks to be moving at 1.00 ft per second or 0.33 meters per second.

Note that at 5000' depth if half the volume out of pipe is gas, then at surface of the GOM the gas would have 340 times the volume of the oil, or about 1909 cu ft of gas for each barrel of oil. BP is losing $150,000 per day in escaping gas, $1,200,000 in escaping oil, or about $500 million per year in total lost energy after they kill the well.

my hopelessly out of date halliburton cementing tables lists 20" o.d. k-55 133 lb/ft casing with an i.d. of 18.73" but only has a collapse resistance of 1500 psi. totally inadequate for 2350 static pressure at 5000' sea water depth. not much help.

someone more ambitious than i can probably find a current version of halliburton cementing tables online and free. sometimes refered to as the "little red book".

Looking at the video, I see a big decrease in gas flow over the duration of the video clip. A lot of gas at beginning and almost none at the end. The flow is not steady over the elapsed time of the video. I wonder how representative the clip is of the average of an hour or so. Also flow does not seem to be uniform across the outlet of the pipe. More flow from top. Almost none from bottom. It might even be water lying still along bottom. What one uses for the cross sectional area of the flow is surely less than the area of the pipe. But it is very hard to pick a number that one can believe in. 50% errors are a good guess, IMHO.

Answer to Gail's question about how accurate it is: Not very accurate, but a damn site closer to the truth than 5000 bpd.

It looks to me like the flow is coming out of a small hole constriction several pipe diameters upstream of the field of view. It is spreading out from that hole and also rising within the pipe due to bouyancy.

It is hard to get accuracy, but one can draw some very valuable conclusions even from a very inacurate measurement. This is not good. And it doesn't need to be exagerated at all to make a case for serious reconsideration of BAU.

ThunderHorse reports the managed flow output from five (5) wells, I think. This is one well, but unrestricted flow. It could be more, or less, than ThunderHorse.

I had been thinking that if the flow had increased from 1000 to 5000 bpd in first week, it was very puzzling why it stopped increasing and stayed at 5000. Now I don't have to worry about explaining that.

Is this the only source of the leak? I thought there were at least three places where the oil was leaking from. Am I remembering wrong?

There are two points now leaking. There were 3, but one has been capped.

Using your method on the first part of the video where the stratified flow occurs and eyeballing the velocity I got about 33,000 bpd. And the annular flow that follows it is likely to be an even higher flowrate. For sure that flow is nowhere near 5,000 bpd.

And BP obviously has known this from day one.

Are you accounting for a change in gas solution from say 2,500 scf per barrel to say 1,000 scf per barrel in your analysis?? And the velocity component that adds to the effluent?

And a formation volume factor at discharge of 1.73 Reservoir barrels per stock tank barrel.

FF

From the video the only thing you can determine is the rough flow of oil at the ocean pressure at that depth. Say about 2500 psi. That flow would be almost all oil, which is why I used the stratified flow part of the video. 33,000 bpd would be a conservative number for that. How much gas would evolve in the oil from 2500 psi to atmospheric you'd probably know better than me.

That flow would be almost all oil

What is your basis for this statement?? Do you know the bubble point of the reservoir. Tengiz is about at this depth and it is around 3,660 psi. With the high GOR, I would expect a high bubble point.

Still there is a significant "explosion" of gas being liberated from this oil on "flash vaporization" from the pressure inside to outside the pipe. This energy is not due to Bernoulli's equation or nozzle flow and I want to know how it is being accounted for in the calculations.

Edit for Tengiz bubble point

FF

Here is Standing's Correlation for the Solution Gas Oil Ratio versus pressure from 15 to 13015 psi for a 3,000 GOR bubble point oil at 250 degrees Fahrenheit reservoir temperature. It comes from my reservoir simulator. The calculated bubble point is 7,556 psia.

You guys are likely brilliant but way out of your expertise area.

http://img199.imageshack.us/img199/6496/standingscorrelation300.jpg

FF

FF - my one PVT class was a LOOONNNGGG time ago! Bubble point is the pressure where the soluble gas comes out of solution?

Is the implication here that a lot of the volume is solution gas coming out of solution and not 'flow from reservoir' per se?

Toller-

You are correct on all counts. The thermal (temperature) changes make this a 3 dimensional problem--- that curve needs to be a surface.

If you have every written reservoir simulation software to track through the bubble point, you never forget the mathematical difficulties/instabilities it creates.

and that is only for a black oil model, a compositional model, aside from being nearly worthless without a history match, would be more complex.

Was listening to NPR this morning and heard someone say that the riser pictured is only the casing, and that the actual oil/gas flow runs through a 9" pipe inside the riser.

Skytruth did a similar analysis based on coast guard observation of the slick. They came to 25 000 barrels a day. (http://blog.skytruth.org/). It is expected that half of light crude will evaporate after on day. This gave an estimate of the leak at the bottom at 50 000 barrels a day.

I'd bet my salary this leak wasn't north of 20,000 bbls/day. An unfrac'ed well with restricted flow through a partially closed BOP into open ocean when the Gulf's best frac'ed controlled wells can barely managed 50,000 bbls/day.

70,000 bbls/day are just laughable.

Some people just want this disaster to be worse than it already is to fuel their agenda.

I should not even worry about it. In the path, but what shows up, shows up.

"best frac'ed and controlled" means that they are presumably maintaining pressure control on the reservoir, and thus limiting flow.

Presumably, the particle velocity analysis data is reproduceable... I know some of the methods they are using, and they are pretty simple, solid stuff.

If you know the size of the cross section of the pipe, and the velocity of material coming out of the pipe, you can measure flux. Period, full stop.

The errors in the analysis are introduced via the following factors: losing track of a particle and over-estimating its velocity; turbulent flow increasing apparent velocity; and mis-measurement of distance from the flow itself, which will cause the velocity measurements to be improperly scaled.

How much is your salary? Because I would take that bet... that well is pumping out more than 20k bbl/day, easy. 20 thousand barrels a day is 580 gallons a minute... that's well within a reasonably good fire hose capacity, and looking at that video, that's what I see.

1000 gpm (water) can be forced through 2,500 feet of 5" fire hose with a pressure of 150 psi... I think the pressure is a bit higher in the reservoir, and the well bore is minimum 7 inches (probably more at this point).

Over estimating velocity - maybe

overestimating the amount of oil in the flow - definitely (most of the flow will be gas that disperses the oil making the oil look like a higher percentage)

I'm gonna maintain my upper limit.

The non industry people also need to google "oil formation volume factor" or Bo. It is the relative volume of oil at pressure divided by its volume after shrinkage (at atmospheric conditions). For a 3,000 GOR oil, it could be pushing 2.00. So all your at pressured flow estimates will be cut in half as gas continues to evolve at surface.

FF

I‘m not an oil guy but I doubt a factor of 2 here.

From the last kink/obstruction in the riser onward, the oil pressure will be pretty much equal to the water pressure. Plus any pressure differential necessary to push the fluid through the pipe. This differential should be rather small, compared to formation pressure at least.

Eyeballing the diagram you posted above, at 2500 psi, the gas remaining in solution is ~800 ft³/b. At least that‘s how I think the diagram should be interpreted.

I do not know what remaining "shrinkage factor" this would result in (1.2-1.3 maybe).

Of course temperature will be different (probably much lower than 250F, maybe even close to water temperature), and the time the gas has to separate might play a role too.

Assuming that 2200 ft³/b (under atmospheric pressure) has separated, and that the gas is compressed 160 fold, and a shrinkage factor as above, I get a gas to oil volumetric ratio of 2 to 1 (volume to volume, not ft³/b).

Consistent with what we see in the video.

Rainer

You got part the oil part of it but since the differential across the pipe leak is small then the bottomhole pressure is likely below the bubble point as is the near wellbore area.... so gas is being liberated continously from the bottom of the well to the top and in the near wellbore region of the reservoir.

Gas is breaking out in the near wellbore region due to this pressure reduction and the gas saturation exceeds the critical gas saturation so the relative permeability to gas is nonzero and free gas is flowing from the reservoir as well as the dissolved gas you are accounting for. The free gas will likely be a larger contributor. Muskat's Method is an ordinary differential equation solved by a fourth order Runge Kutta method to calculate gas saturation versus pressure in such a reservoir.

Good Luck.

FF

You still betting your salary on it?

Because I want to fix my roof and rewire the basement.

;p

While I'm dying to know what the real number is and hope BP can get a flow meter in the pipe they're inserting, I doubt we'll ever really know the real number.

But sure, my salary that will never be able to be claimed by anyone on the internet is hereby bet.

It's a bet!

You're unclaimable virtual salary vs my anonymous and unimpeachable credibility!

Sure thing.

But, more seriously:

The estimate of total fluid flow through the end of that pipe are probably close to accurate.

70 K is probably high, but 20 K is probably low.

Your point about percentage of oil vs gas is quite well taken.

What's the percentage, by volume, of gas vs oil in a freely flowing, newly produced reservoir? That's not even close to my area of knowledgeable discussion, but I am guessing that since a) it's (obviously) a gassy reservoir, and b) the gas is continuously expanding as it rises through the well and depressurizes, and c) gas in the oil is released as the oil rises in the well, that the percentage of gas is high.

What's a good guesstimate? 50%? 75%?

Say it's 75% gas, 25% oil by volume. If the total fluid flow is 50k barrels per day, and 75% of that fluid flow is actually gas, we're still talking 12,500 barrels of oil per day.

The question is, assuming your salary is higher than mine, are we betting my salary vs your salary, or are we betting your salary, full stop. Because I can't afford that, and I really do need to fix my roof.

All these big numbers are a little hard to picture. If the flow is 75% NG, and the flow is 10,000 barrels/day...uhhh..quick math, lots of assumptions...we're just shy of 1000 standard cubic feet per second of gas at the surface. Would that be detectable? Or does it get spread over many acres and then get lost in the chop?

is your upper limit for the total of both leaks? or just the one we've seen video of?

I would be betting on the total flow rate from the well.

over at latoc there is a poster who spent the last week out in the gom with the recovery effort. his information seems to confirm a minimum of 26,000 bbls/day, much more likely:

"I was out in it. Ten 300T vessels skimming AT the incident site - not further away - could not keep up with the oil release despite skimming 2-4000 bpd EACH! We weren't even close."

http://www.doomers.us/forum2/index.php/topic,67590.msg1037142.html#msg10...

on the permitting, bp said max flow was 160,000bpd, are you factoring in that information?

The barrels they are skimming are probably barrels of oil-water mixture--and the substantial majority of this mixture is probably water--so the amount of oil they are removing from the ocean is much lower than you are thinking.

he discusses that in another thread - "OK, good question, once the mix/or slurry comes into the holding tanks it's decanted, a procedure where they pump off the water just underneath the oil to get a higher concentration. We were getting somewhere around 85 to 95% product before pumping it to the barge."

I'm not hearing much about the toxic volatiles in the air. As these blow ashore, how can they not render the Gulf Coast uninhabitable?

EPA is monitoring volatiles, particulate matter, and H2S at several stations in Placquemines and St. Bernard parishes. They say that when wind is right, VOC (total volatile organic compounds) is high enough for some people to smell, but still safe. If someone wants to put the data into graphical form, here it is:

http://www.epa.gov/bpspill/air.html

The wind has been out of the south and southeast for several days here in New Orleans; I can't smell it, but several friends say that the air smells a lot like weak diesel fumes.

The supercritical pressure for methane is 673 psi, so above that pressure (and I estimate that at 5000 feet, the pressure exceeds 2000 psi - which is way above the critical pressure), methane is acting as a liquid, not a gas. So I would not place your bet based on that assumed factor.

Retsel

So the outflow density or temperature does not matter. I thought maybe if there was a gas component to it, but school was so long ago. Why can't they just telescope a hand held meter into the stream via ROV?

Any time BP felt like it they could use an ROV to stick a pitot tube into the oil jet and get a velocity profile. That would get them a within 5-10% of the flow rate.

Any time BP felt like it, they could release all sorts of info that would help independent analysis of this thing, even just longer film clips of the outflow. Instead, they prefer to claim that there is no way to determine the flow rate.

I am guessing that, if the flow rate is variable, they chose a clip that minimizes the flow rate.

BP themselves have admitted that the flow rate could be 60,000bbl/day, so I'm guessing that it is much higher than that.

It seems to me that if you want to make a calculation based on visual observation, you need the diameter of the pipe from which the flow emmanates. That it was constricted earlier should not matter. So, you look at the 21" pipe, measure velocity, and use the oil stream you have to get a BPD estimate.

I am not sufficiently mathey/graphey to extrapolate from this, but the comment earlier about it is only 9" and it went through the BOP seems irrelevant to me. Wat matters, again, is flow where it can be measured, from pipe that can be measured.

Many weeks ago (far too many, IMO) a figure of 52,000 BPD was bandied about, with no one denying. I would therefore place the actual flow at not less than 52,000.

Craig

I'll bet with Greq on this one.

You know the Bernoulli Detective Agency is really good if they can differentiate the fluid flow inside that pipe from the thermodynamic expansion of that gas crude oil mixture possibly going through the bubble point and a 150 degree temperature drop at the exit.

What component of the velocity is flow and what component is expansion and gas liberation??

FF

Is it possible because of the large temperature drop from (presumably)the BOP to the end of the pipe that some gasses are actually condensing back to liquid at depth?

Yes it is a mess

I'm sure you meant "fuel" as a pun, right?

Just curious, who are those people and what exactly would their agenda be?

As for the disaster, I was listening to some journalist on NPR yesterday, quite convincingly argue (not that I bought his arguments) that this spill really wasn't all that bad and that the Gulf would easily absorb the oil and nature would take its course and everything will be just fine and dandy.

For the record, your worst case scenario of 20,000 bbls/day, sounds pretty damn dire to me.

And while I'm not much of an expert, I do think that 70,000 bbls/day is probably a gross exaggeration, However I also think that neither the 20 or 70 thousand bbls/day means very much to the public at large.

Maybe the MSM should put this mess into perspective by just telling J6pk in terms they can relate to. How about, "The Sh!t has really hit the fan this time, folks, and while the turds aren't quite as big as they might have been, they stink about as bad as any we've ever smelled and if your livelihood depended of the Gulf waters you better get yourself a bigger paddle because the one you lost when you were just up sh!t's creek, probably wouldn't have cut it anyway! So, you might want to consider reassessing your agendas...

Good luck!

Good call.

I suppose there is the disturbing "scientific agenda" that should also concern us.

Isn't that all about finding out the truth? Scary prospect that.

http://suchabastard.files.wordpress.com/2008/08/shitcreek.jpg

Those are *BIG* paddles but have you seen the creek?!

That's why you need more than one!

A high pressure reservoir is normally "throttled" back in production quite a bit for several reasons, including stability of the reservoir rock (supposedly a major problem at Thunderhorse), potential water coning, economic processing equipment (don't size for a short lived maximum production) and more.

With continuing sand erosion for almost a month, there is every reason to believe that this well is producing more oil than it ever would as a BP production well.

Alan

Where in the f is the oil??

All the flow rates increase increase increase But I haven't seen a picture yet of a solid oil slick...

It reminds me of the difference between production and reserves in a deepwater discovery.

An article this morning says all the recovery efforts after separation have yeilded a whopping 1000 barrels.

FF

It was supposed to have hit the beach in Florida 3 weeks ago.

http://www.aolnews.com/nation/article/wheres-all-the-oil-and-wheres-it-g...

I suppose I could write an article about the general idea of dispersion?

Or could we have a discussion on this?

I get a feeling that people have all sorts of problems with this concept. For example, for all the carbon emissions that occur, people still complain about where it all goes, pointing to that the level in the atmosphere is only around 400 parts per million. By gOD, you can't even see that! That is what dispersion and diffusion and drift causes, an effect that results in a rise in the overall background, but not necessarily anything you can immediately see.

This in fact may also be the one physical law that will save the day. If material disperses enough and natural processes break down the oil and byproucts, we could eventually dodge a bullet.

An article would probably work, but it should be not too long, and include as much a possible in terms of practical implications. There is a danger in going over everyone's head. People do like an article on a topic as a backdrop for their discussions.

One thing people get in their heads is that somehow complexity plays a role in how material disperses.

Scientists can come up with all these sophisticated models with detailed finite element grids (going over peoples heads) when in reality all these models converge to the same thing and one can use fundamental entropic arguments to arrive at the same result.

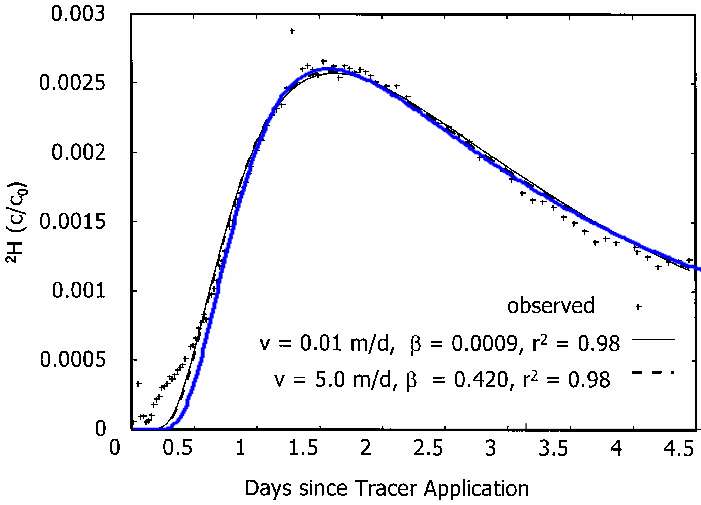

A case in point is the path of a tracer solute through a porous material. This paper documented a case where they could change the simulation parameters wildly and come up with pretty much the same result:

Biogeochemical Models in the Environmental Sciences

I think it all boils down to the concept of entropy. I tried my hand at coming up with a fit to the same empirical curve they provided for soil water movement; and with a single maximum entropy-based equation got just as good agreement (see the blue curve).

The point is that all the complex calculations in the world are often pointless when you are dealing with a situation with a high degree of disorder. The situation simplifies enough that one can use universal approaches to describe the result.

I don't understand this idea of going over people's heads. Apparently lots of people are very impressed by linking to some study by scientists who use supercomputers and days of compute cycles to arrive at some conclusion, yet remain wary of someone else that comes up with the same result with minimal effort.

I will likely submit something but not dumb it down. Fearing that ideas will go over people's heads are what got us into these situations in the first place. Ignorance is a dangerous concept.

Another case in point is the entire atmospheric CO2 debate. We always genuflect to the climate scientists who wield either huge supercomputer runs or detailed theoretical math to justify their conclusions. Yet in the end, one can simply use logic and some probability concepts to arrive at the same conclusion. This is what I wrote about here:

http://mobjectivist.blogspot.com/2010/05/how-shock-model-analysis-relate...

I would like to put something together along these lines. I will decide whether to post it on my blog or on TOD when I finish. In my experience TOD has this huge wait time (often two weeks) on publishing posts by people not in the inner circle of TOD editors. I will get a day turnaround if I post it myself and then just place a link here.

Wait times vary. HIgh technical articles that have a lot of HTML issues can be delayed because of the HTML issues. Right now, we are running a lot of oil spill articles fairly quickly.

Oil can also spread so thinly on the surface of water to be barely visible. But people tend to believe that their eyeballs are high quality scientific instruments that can detect anything that is significant.

http://en.wikipedia.org/wiki/Oil_spill

Even a slick this thin would be damaging to the ecology of life on the surface.

Given BP have come out and said the GOM is so big that this slick won't harm it, it's not surprising some people actually accept such bullshit reasoning. It is after all, far more amazing to see a volcano erupt and conclude it emits more GHGs than it is to consider all those seemingly clean airliners flying daily.

here it is:

http://www.boston.com/bigpicture/2010/05/disaster_unfolds_slowly_in_the....

I have already seen those pictures. I don't see anything in there that is not 99% water... maybe the ones right at the rig.

You have obviously never cleaned a one barrel oil spill out of a creek. I unfortunately have.

FF

I agree with your thinking; if that much oil was actually being released, then the Gulf should be covered with it. It seems that there are three reasons of why the Gulf is not covered with oil (assuming that a lot more than 5000 bbl/day is being released).

One reason is that a large portion of the oil is probably not making it to the surface (per a marine biologist). It may be stuck in the thermocline boundaries somwhere down in the Gulf.

The second reason why much of the oil is not observable from the surface is because of the oil dispersants that are being used, both down at the well head and at the surface. What is happening is that much of the oil is affecting sea life deep down in the Gulf, not just at the surface.

The third reason is that the oil is lighter in gravity than most crude oil and the Gulf is warm, so somewhere between 20 to 30 percent of the oil is likely vaporized at the surface of the Gulf.

Of course, some of the oil is being burned or skimmed off the surface of the Gulf.

Retsel

Maybe because there are no private planes and helicopters allowed over the spill area? Maybe because there are no private boats allowed near the spill area? Maybe because the fishing boats involved in the cleanup/containment operations all needed to sign a contract to shutup? Government and BP are doing a good job in keeping the nasty pictures out of the press...

The lower picture shows what sand cut can do to a malfunctioning BOP

It seems that at least 1 restriction exists, that the restriction(s) are subject to sand cut and that the trend in estimates has been continually upward.

Of course we are not looking at a full on flow of the 53 cm. or 21 in. riser diameter. But it should be noted that we are looking at video of flow rate that is 4 days old and is subject to ,mostly upward, change so far.

There is one other trend ,which is perhaps somewhat subjective, but may signal an accelerating flow rate. There is continual slippage in the design and effectiveness of operational fixes. My emergency response red flags go up a bit when mitigation efforts seem to be constantly behind the curve.

72K BPD going vertical...Wild Mary Sudik..Oklahoma City, 1930

http://en.wikipedia.org/wiki/Oil_gusher#cite_note-12

Hey, driller guys... Do you still use the Hughes bit?

Thanks

Will this help?

YouTube video of these 2 boys from Alabama who have an idea about tackling the oil spill.

http://www.youtube.com/watch?v=k5SxX2EntEo

Donald Long

Pensacola

Engineering is all about the scale...

So they used 1/4lb of hay for a small cup of oil. That's about 20,000 tons of hay required per day for 5,000 barrels. Then they have to deploy it over the slick, let it agitate for several hours maybe? Then scoop up 40,000 tons of hay/oil mix and dispose of it somewhere.

That's a lot of hay.

--- Hay Hay Hay ---

A lot of Hungry cows this winter &

more imported beef

They could offset coal in the steam plants. Take

the Bio fuel credits - to offset FF consumption.

wait - Tar bails? Sorry ...

Probably quickly consume all the hay on the continent

That video is making its rounds as if it's a novel discovery. Straw was used in the 1969 Santa Barbara spill.

'Some people just want this disaster to be worse...'

And some people (namely BP) go out of their way to obfuscate.

How come it took weeks for the public to see this video?

How come no-one seems to know the diameter of this pipe?

How come no-one seems to know what type of calculations BP uses to arrive at 5000 bpd?

This is a very public disaster, and I assume that BP will be quite happy to have thousands of volunteers enlist to clean up beaches and limit the damage. But somehow everything that is going on down there needs to be shrouded in secrecy.

"How come it took weeks for the public to see this video?"

I'm not sure it did... the version I looked at on Youtube has the date on the film and although blurry it looks like it wasn't filmed until 5/12, and I think it went public the next day.

BP may have known earlier that it was flowing at that rate (whatever it may be) indicated on the video, but maybe not.

Or maybe they released a May 12 video to make it appear they just found out.

"This is a very public disaster" - yes but not public enough. BP doens't want to release certain information, claiming some kind of proprietary rights, I think; but it seems to me this emergency is too important to allow that and they should make much fuller disclosure to the government and public. Also, maybe it should be declared a national emergency, not just a group of state emergencies.

Minimizing the oil amount as they have done (if purposeful) is sort of like the kind of "honesty" of admitting to stealing $5 from someone while at the same time not telling them about the $75 you also took from them, which you have in your other pocket. That's even worse than normal dishonesty. Should be criminal to do that.

If its that high I'd like to see an aerial of it "breaking the surface".

Does anyone have a link to video of leak surfacing?

It should burn.

FF

I found this intriguing but I would not call it breaking the surface.

http://blog.al.com/live/2010/05/gulf_oil_spill_news_links_alab.html

why would it need to 'break the surface'? the outflow appears to be horizontal, yes? the currents are pretty strong in 5,000ft of water, too.

Any references or links to what the currents are on location - and on surface vs subsurface?

I don't know maybe gravity.

The currents are pretty slow at that depth at least to 3200 ft. We have RT data from Shell Ram- Powell platform at 29N, 88W down to 3200 Ft:

http://www.ndbc.noaa.gov/station_page.php?station=42364

Though an interesting side note: The Pelican research vessel http://blogs.nature.com/news/thegreatbeyond/2010/05/oil_spill_science_ma... found some possible oil stratifying in the water column with gaseous evidence of high microbial activity at 3,000 feet. Implying that microbes are feasting on oil. Likely the comparisons to Alaska are moot, since the gulf ecosystem is much more dynamic at its latitude, as long as the oil remains off shore.

Look what I found. A video from BP that I haven't seen linked on this forum or elsewhere, showing the failed deployment of the 100-ton dome.

http://bp.concerts.com/gom/cofferdam_video.htm

Shows a view of the outflow from a new angle, and a whole lot of puffy black clouds going up the side of the dome rather than inside.

Until I watched that my comprehension of the flow was nonexistent. Now I can feel another wave of doom engulfing me.

I'm amazed and still trying to get my head around it.

For 70,000 bbl/day =2000 gal/min the velocity out the 16" pipe would be 500 in/sec. The oil flow doesn't look nearly that fast. The white gas stream is definitely faster. If so, it would be coming out as a jet straight out the pipe - not so, it is coming out at an angle.

Consider this 16" pipe as same area and flow as about heavy duty 500 garden hoses flowing 4 GPM /hose. Stick a hose with that flow rate in a bucket and you will get alot more mixing turbulence than shown in the picture.

I SWAG 20,000 bbl/day ratioing the flow coming out to my experience sticking flowing pipes into tanks.

Doublecheck your math, I think you may be off by a factor of 10 somewhere.

And dang, am I the only guy in the room who likes the metric system?

Oops, divided by dia instead of area. I get your 1 m/sec.

What are you, French or something?

Exactly, regarding metric. In metric, I could do the calculations involved here in my head. Maybe that should be the first improvement to the field of engineering in the US that should be applied. Consider it a safety issue.

Nothing annoys me more about US science and engineering than the persistent use of that retarded system we invented over here that is Imperial.

"My car gets forty rods to the hogshead and that's the way I likes it."

On April 1st I sent some water use estimates (via eMail) in the US standard unit "Acre-feet/day" instead of m3/sec.

Reykjavik was not amused.

Alan

I couldn't agree more!

I guess I was lucky enough to have been brought up in a metric world, to me anything else just doesn't make sense :-)

Since I'm a scuba diver I'll give this practical example of how metric really helps keep it simple stupid! When I first started diving we didn't even have an underwater air pressure gauge we had a J valve reserve which you opened with a lever once you started to feel it getting hard to breathe. We only knew our fill pressure at the compressor. Dive computer? Fuggedaboutit!

Now try this calculation in your head when you are already under the influence of a little nitrogen narcosis...

Here's the calculation in metric:

Lets say I have a pair of 10 liter Cressi scuba tanks filled to 200 atm pressure which equals about 4000 cubic liters of breathing gas. I want to know for aproximately how long I will have air at a depth of 20 meters.

If my Surface air consumption is about 20 L/min and knowing that every 10 meters of depth equals 1 atm of pressure, I have 3 atm of pressure at that depth so my consumption is 3 times surface consumption or 60 L/min.

Say I know I want to leave about 1000 cubic meters for decompression and ascent so I now divide the remaining 3000 liters by 60 L/min and have a rough idea that I'll have about 50 minutes of availabe air for bottom time.

Now here is the same calculation without the benefit of metric.

I have a pair of 610.2 cubic inch scuba tanks filled to 2844.7 psi of pressure which equals about 244,095 cubic inches of breathing gas. I want to know for aproximately how long I will have air at a depth of 65.6 feet.

If my Surface air consumption is about 1,220.5 cubic inch/min and knowing that every 33 ft of sea water equals 14.2 psi of pressure, I have 42.6 psi of pressure at that depth so my consumption is 3 times surface consumption or 3661.5 cubic inch/min.

If I want to leave about 61023.75 cubic inches of air for decompression and ascent so I now divide the renmaining 183071.25 liters by 3661.5 cubic inch/min. and have a rough idea that I'll have about 49.9 minutes of availabe air for bottom time.

So which calculation would you rather be doing if your life depended on it? ;-)

Your second calculation is a great example of carrying a silly number of digits and not rounding properly like you did in the first one. What on earth does the measurement system have to do with the fact that you used nice round numbers for everything in the "metric" calculation? Multiply any SI unit by PI and then use it in your head.

Ok, I admit I was putting the second calculation in a less than flattering light by doing that. However even if you round to the next significant number the point remains that doing the calculation in metric is much more intuitive and much less susceptible for making gross errors. I don't know about you but I have ten fingers and can easily do multiplication and division by tens in my head.

There is a reason science generally uses the metric system.

Of course, the true strength of the metric system for mental arithmetic is that all the conversion factors are powers of 10.

But in addition, it so happens that many common measurements are nice round numbers in the metric system. Some of these are deliberate (the density of water, its freezing and boiling point, the size of a human), and some are accidental (sea-level pressure, the acceleration of gravity), but it's true nevertheless.

This is indeed a huge advance on acre-feet, etc. However the truer strength of the metric system is the relationship between length, area, volume (capacity), and weight (mass). So one litre of water weights one kilogram, and occupies 1000 cubic centimetres; one cubic metre weighs one tonne, etc. Very elegant.

The downside of metric is the lack of ancient and very useful names for shorter measures. A kilometre easily replaces a mile, one metre easily replaces a yard, kilos for pounds, litres for gallons - but we lack handy names like "foot", "inch", "ounce", "cup", etc. "He missed the putt by 15cm." is just not quite as smooth. The persistence of acres in real estate indicates that hectares have not been a success so far.

The traditional units are handy for rough use. In timber at least the informally defined "metric inch" and "metric foot" are used, being 25mm and 300mm respectively. So what was 8 feet of 2x4 is now labelled a nominal 2400x50x100mm.

Unfortunately I was brought up when schools taught metric but in the real world mostly imperial units were used, so now I have trouble visualising metric sizes, but am equally uncertain over how many ounces are in a pound for example. And don't ask me about chains and rods ;)

Except that the standard U.S. 8 foot 2x4 stud is actually 92.625 inches long by 1.5 inches deep by 3.5 inches wide.

This makes it 2343 x 38 x 89 mm.

The traditional systems of measurement are just full of little traps for the unwary like this.

Let's say you go to an oil cleaning plant and drive a truck load of oil across a scale. It weights 44,000 pounds. You drop off a sample at the office, and dump your load into the tanks. Then you drive back across the scale and your truck nows weighs 11,000 pounds. The girl at the office tells you the oil was 35 degrees API. QUICK! How many barrels of oil are you going to bill them for?

You are under a lot of time pressure because you only have a pencil, a piece of paper, and the trucks behind you are starting to honk at you. There's one truck a minute driving across the scales and they know that time is money.

Alternatively, you drive the same truck across the scale and it is 25,000 kilograms. You drop off a sample, and dump your load. When you come back, your truck weights 5,000 kilograms and the girl tells you the density of the oil was 850 kilograms per cubic metre. How many cubic metres of oil did you just deliver?

You have a pencil, paper, and the same honking trucks. Which scenario would you prefer?

This is something of a real-world example, because we did this kind of thing in the Canadian oil industry. The American Petroleum Institute had an incredibly complicated procedure for gauging oil tanks and calculating the volume, correcting several times for temperature in the process, whereas we just used to weigh the trucks.

I know this isn't your point, but why on earth would this plant do its billing by volume rather than by mass?

Driver's note to self: postpone all oil deliveries until late afternoon; schedule truck maintenance and vacation time for February.

In general, you ship oil by mass and sell it by volume. However, if you have the density you can translate between mass and volume with a simple, 4-function calculator (in the metric system). If you have the density and either the volume or the mass, you have (almost) everything you need to determine the price.

Company's note to driver: The plant operates 24 hours per day, 365 days per year. You will drive whenever we tell you to drive and take your vacation whenever we tell you to take your vacation.

The interesting thing about these guys is that you can call them up at 3:00 AM on a Sunday morning, and not only will they answer the phone, they will be *cheerful* when they answer. The reason is that if you call them at 3:00 AM they know that they are going to make a lot of money that day.

Because we all know everything that uses metric units always comes out in neat round numbers, right? Let's say the truck weighed 24, 973.8 kg, and after you dump it it weighs 5,278 kg, and the oil density was 847.3 kg/m3. Quick, whip out that pencil. The SI system is great, but it does not magically make all numbers come out even.

You will note that I rounded both the metric and Imperial measurements in the interests of keeping things simple. With a little more study, you could determine that the metric and Imperial measurements were more or less the same. However, it's not totally obvious to the layman that 35 degree API oil has a density of 850 kilograms per cubic metre.

You wouldn't measure truck weights to 0.1 kg nor oil densities to 0.1 kg/m3. The equipment is not that accurate. However, you would normally use one or two decimal places in calculating oil volume in m3.

For instance, in the example you gave, the truck would contain 19,695 kg of oil, which if you divide it by the density of 847 kg/m3 would give you 23.25 m3 of oil. Anybody who can do long division could figure that out. If you converted it to imperial by multiplying by 6.29, that would be 146 barrels.

However, if I said the truck contained 43,419 pounds of oil, and the API gravity was 35.5 degrees API, what would you do? (Hint: the answer is 146 barrels)

If you were shipping water to the water disposal plant, it would be even simpler: 19,695 kg of water would be 19.7 m3 of water. And the driver would find it useful to know that 19.7 m3 of water weighed 19.7 tonnes.

Ever since I heard about peak oil I've thought one of the good things about sliding down the back side of Hubbert's Peak might be that we (in the U.S. and any place else that lags behind) finally convert to the metric system once and for all. That, and more cuddling. Definitely more cuddling.

Yes, there will definitely be more cudgeling.

Remember, GH, that there are two places you need to check on to estimate total flow. If both are about the same (and, the laws of physics say they should be pretty close), then you need to doublt what you see in one flow.

Craig

Unfortunately I cant see the video....Is the cofferdam down? E.g. are the black clouds oil or possibly sludge from the bottom being disturbed?

tt, from what I see in the video oil appears to be coming out from under the cofferdam, and flowing up the side. Almost like a black mold. It appears to be fairly thick, and clings to the sides of the cofferdam. It does not appear that there is any disturbing of the bottom sediment.

I know nothing about all this, but I started thinking about how one might calculate it and this led to some (possibly stupid) questions for those that do:

1. Does all the oil come to the surface, and how quickly?

2. If it comes fairly quickly, days or even weeks, couldn't one take samples at the surface throughout the spill zone to come up with a total of how much has reached the surface?

3. Knowing the delay to reach surface, could one then make an estimate of the total so far, and therefore the average rate?

4. Has this been done?

Question 1: No, it does not. I heard a story today from a research vessel in the Gulf - oil down at 1,300m. Although I haven't seen anything current in the press I believe BP is injecting dispersants at depth into the flow and this may be a contributing factor. This means that surface estimates are going to have significant error - underestimating the volume of the leak. Consequences for the environment - unknown. There are bacteria at depth that make a living from oil seeps and support communities of other organisms - bonus time for them... hopefully the dispersants aren't toxic to these organisms.

Question 2: Because of reasons above, no, you can't calculate the spill volume - however it is probably handy to know how much is reaching and floating on the surface for other reasons. I believe people are making such measurements.

Question 3: No, for reasons stated above.

Question 4: See above.

How much of the oil is reporting to the surface, vs flowing subsurface?

See the vertical profiles in slides 11, 12 of:

"Deepwater Blowouts: Modeling for oil spill contingency, planning, monitoring, and response." Mark Reed et al.

These seem to show most hydrocarbons in the middle between floor and surface.

Are there any published reports of the oil density for Deepwater Horizon blowout? Or estimates of gas/oil fractions?

thank you for signaling this.

Following the paper, the main part of hydrocarbons are still trapped between 300 and 700m , and this is scaring.

The oil spill moedels I've seen are used to evaluate spilling on the surface (mostly from tankers).

A few days after the blowout (using satellite pictures) a 20.000 to 30.000 flow was evaluated from oil spill models, ad now I'm wondering if they was using a version of this OSCAR model (which is able to model seafloor spilling) or another.

Bottom line: the flow is more than 5000, for sure. How much more, is directly linked to the political and economical convenience of the responsible.

Thanks, David.

BTW... as to the dispersants... don't they just 'dissolve' the oil? I mean, it doesn't go away. It just goes into solution, and mixes with the sea water. Right?

And, if that is true, all you are really doing is makinmg it less visible. The oil is still there. And, if it is damaging to marine life, that might even make matters worse.

I mean, imagine a shellfish that makes its living filtering sea water. Suddenly, there is oil in the water - small blobs, to be sure, but oil. And it coats your gills. That would be bad, right?

It seems to me that they are being quite cavalier about this.

Craig

Craig

"It just goes into solution, and mixes with the sea water. Right?"

Dispersants are a fancy name for SOAP or Surfactants

They help the oil breakup into smaller droplets so they "disperse".

The oil is still there - just not as obvious.

ITOPF Dispersants See figures etc.

Microbacteria eventually feed on it.

Nature Fighting Back Against Gulf Oil Spill

Re "don't they just 'dissolve' the oil?"

Oxygenated fuels such as Ethanol, methanol do dissolve in water.

David

The New York Times is also finally reporting on the question of the size of the spill. It's taken an awfully long time (given that this issue has been reported on since day 1 here on TOD) but it's good to see that the MSM is finally catching on.

Size of Gulf Oil Spill Underestimated, Scientists Say

5000 or 50000 thousand does not really change the urgency or the approaches to stop or mitigate does it? It makes for good press for the people predicting the end of the world as we know it.

I would think ,given the amount of gas, that the range predicted by the profs in the article would be much wider.

it doesn't make a difference in terms of the mitigation effort.

it does make a difference to the people of the gulf coast, their lives, their plans, their future.

and, it's just 1 of 2 leaks, we don't have a flow calculation on the second leak.

I believe that's the BP party line. That it doesn't really matter. Why? Because it best suits their PR angle which is all they seem to be worrying about when it comes to public information. But I think it does matter a great deal when trying to evaluate the impact.

Low-balling assumes they fix the leak(s).

It's hitting the coast, they can't dink around with low-balling it much longer.

I have a question. Wide varying estimates are being made. Fair enough. Much of the volume coming out of the pipe is gas which significantly complicates estimations.

My question, is all that gas from a separate pocket the well is in? Or is it gas that was trapped in the oil under great pressure (22,000 feet below sea level) and is now released because the oil is only 5,000' bsw?

If that's true, then wouldn't the oil (black flow) still contain a statistically significant amount of gas that will get realeased as the oil makes its way to the surface?

And if that's true, then wouldn't the actual amount of oil in the black flow be less than it appears at this depth? Wouldn't that skew calculations as well? In other words instead of half the pipe flowing oil as it appears, maybe only a quarter (or 1/3 or ...) of the pipe is actually oil?

"Statistically significant" is the operative phrase as that is all we have going for us. If you look at it from the perspective of 70,000 barrels per day and this goes on for 2 weeks, it will put the volume at 1 million barrels. This will essentially place the size of the reservoir at the 50 percentile rank of all reservoir sizes in the USA. I don't have statistics for the GOM by itself. So then we can look at a place like the North Sea, and a comparable outflow of this rate for about a year would place it at a 50% rank for that set of fields.

As I said elsewhere in this thread, take a look at the rank histograms of oil reservoir sizes and you might get a upper limit gauge on potential outflow.

The point is that the initial investment in offshore areas is much larger so that has at least something to do with the expected size. Someone will set up a stripper well in their backyard and be happy to get a barrel per day, but that will never happen offshore.

Size of Oil Spill in Gulf Underestimated, Scientists Say

That put's it at the 95th percentile of all USA fields and bigger than average in comparison to a North Sea field. This may give something of a limit to think about.

The oil has gas in it, sort of like soda water. When the pressure is released, the gas bubbles out. There is a release from the reservoir as it enters the pipe; another release as it leaves the riser; and, finally, yes, the pressure at 5,000 ft would keep some of the gas in the oil. It would not make a big difference. If you doubt that, open a clear bottle of club soda, and let it go flat. Then measure the difference in volume. Not that much.

The main factor as it goes up from the reservoir is that it does become a gas, and displaces some of the oil, so that it acts to reduce total flow of liquid to the extent of that volume. As the bubbles come out of solution on the way up through 5,000 ft of water, there is nothing to minimize the total voluem of the oil, though, since it is not in a restricted area.

Right now it sounds to me that it is rising part way, and it is being hit with reagents to break it up and allow the oil to dissolve. That way, the sea water becomes an oily mess, sort of like your dishwater in the kitchen sink does after you have done a load of greasy dishes. There is no oil floating on the surface, and yet you would not want to drink the stuff in the sink.

Craig

The particle image velocimetry appears to provide the best quantitative estimate of velocity of the flow out the pipe. One major uncertainty is the oil fraction.

Particle Image Velocimetry See Steve Wereley's home page.

See Wereley's book: "Particle Imaging Velocimetry

However, here the velocimetry appears to be inferred from the video which probably degrades the accuracy.

Size of Oil Spill in Gulf Underestimated, Scientists Say"

Note missing data and description of BP's feeding a pipe in to draw off the oil flow:

Missing data causing rig reconstruction mystery

That last article, if accurate, is hugely, devastatingly damning.

I am having trouble understanding the supposed events here. Are we to believe BP and Transocean shut Halliburton out of the room while they discussed the cement? Meanwhile Halliburton went off in a huff and ran their own test which showed everything was "OK". Inside the closed room BP and Transocean then hallucinated their own test which was also presumably "OK" but had no knowledge that Halliburton were doing things behind their backs without telling BP or Transocean? I just don't get it.

In order, yes, we can believe that. It happens a lot that the rig operator and overall overseer of drilling and HSE (Transocean) and the leaseholder and overall responsible party (BP) would, in fact get together on their own without a subcontractor to discuss the results of a given set of tests... that's pretty normal. To then apparently throw out the results of those tests based on some "other tests" that noone has seen and no one will admit to conducting or analyzing.... that's not normal.

Halliburton didn't run off in a huff according to this account, nor did they conduct any more tests according to this account - they had already conducted their tests, showing that the well was not sealed properly - according to this article, they waited for BP and TransOcean to let them know what the plan for proceeding was.

Inside the closed room is where, if this account is truthful and accurate, the big, big trouble happened, and where the people who made that decision probably ruined their careers and their lives... IF the article is accurate. That's where, apparently, the results of the Halliburton pressure tests of the cement job were deemed not relevant, the "results" of some "other" test, so far not in evidence in any reports or data... were used to justify displacing the drill mud with sea water and running the cement plug in the top hole.

Ok, on re-reading the lawyer's statement it can be read that way (no Halliburton second test) but my first reading of it was that he claimed Halliburton had conducted their own second test unlike BP/Transocean who conducted a claimed "phantom test".

Tow -- I’ve sat in a company man’s office more than once and observed very similar “conversations”. And I’ve seen service company hands (including myself) ordered to leave a meeting so the remainder of the conversation would be private. I’ve been there when the company man got some onshore managers on the speaker phone and closed his door so no one could listen. Having a service company do some sort of CYA procedure is also not uncommon. As I mentioned earlier I’ll usually follow up with an email to document my position. There are some very territorial aspects of life on an offshore rig that could make many folks a little uncomfortable. Ego is a very strong component in these situations. You don’t find many non-Alphas who take to the life style/stress you’ll find in offshore operations. Thus conflicting opinions are not uncommon.

Some may have even noticed my monumental efforts to check my ego at times.

RM, I hadn't noticed - I'll be sure to be on watch now that you've given the heads up :)

The line between confidence and hubris can be thin at times. Confidence and decisiveness are a requirement for success when the going gets tough - and that includes the confidence to back off when appropriate - and the confidence to tell the higher-ups to lump it when its appropriate. Batting 100% is not a human characteristic either.

Obviously all reservoirs are different.

My opinion is that no one ever gave a damn about trying to understand the statistical distribution of oil reservoirs. Millions and billions of dollars go into the industry and all that comes out are useless heuristics, with no fundamental understanding behind the numbers. But of course, how else could it be -- oil companies run the show and they have to protect their own proprietary information.

That said, this is the best estimate of a rank histogram of reservoir sizes in the USA:

There are well over 10,000 defined reservoirs/fields in the USA with anywhere from 10,000 barrels to almost 10,000 million barrels.

The solid black line is a model fit using entropic dispersion that I outlined here:

http://www.theoildrum.com/node/6255

Of course this doesn't tell you anything more than what we can expect as a typical reservoir size. So what would I guess for this particular reservoir? Heck if I know. It doesn't really matter in the greater scheme of things, as far as peak oil is concerned. But now that this spew has the potential to wreak havoc, we just have to know!

Isn't that weird how things work out?

Seriously, all the historical oil production information should be made public knowledge, pronto. All we have to emulate is the procedure tha the UK and Norway do, and place all the information on the internet.

So this is what the size distribution looks like for the North Sea:

http://mobjectivist.blogspot.com/2008/10/estimating-urr-from-dispersive-...

Like I said, I can do a pretty good job of understanding the size distribution from a statistical point of view, but to try to guess the size of a single reservoir, you have to do careful monitoring of reserve growth over time.

http://www.theoildrum.com/node/4311

Jean Laherrere has conducted numerous fractal analyses. e.g.

Estimates of Oil Reserves 2001

Laherrere does a pretty good job of empirical curve fitting but this "Fractal analysis" is pretty lame heuristics in my opinion. Most of that kind of math comes put of the Mandelbrot/Taleb fractal school where they just talk and nothing ever fundamental, as far as a derivation from first principles is concerned, comes out of it.

Fractal analysis = heuristics.

Got anything better than Laherrere?

Sure. See the links for a model based on rate dispersion and the maximum entropy principle.

This is arguably better than Laherrere because it actually uses ideas from probability and physics. I say "better" reservedly of course because you can't really argue against heuristics, as a heuristic by definition actually has no basis to argue against. All masters of the heuristic do is represent the data as a curve.

Sounds like one of those pitches you hear, from shills trying to sell a "scientific" system for picking horse races, or even lotto.

WHT:

I have worked with rank/abundance data before getting interested in peak oil. It occurs in ecology in the study of biodiversity, and in looking at statistical data about the population sizes of nations, etc.

In my work I followed the biodiversity literature and plotted the data on a semi-log paper, log for y axis, and linear for x axis.

Could I get your data so that I can replot it that way? Or could you do a special replot? As I write this, I have the wild idea that

the individual reservoirs might correspond to the rise and fall to extinction of individual species of micro-biota. Have you thought of that as a possible cause for the distribution?

You might want to look at the first link I put in my comment. I already made the analogy to biodiversity and have it worked out reasonably well. I also talk about city distributions.

Likely that the distribution oil has at least something to do with the cycles of biota. My model assumes a uniform distribution of these waves through history. (The biodiversity analogy is between metacommunities and local communities) Otherwise the distribution follows from a maximum entropy distribution of reservoir aggregation rates. I welcome any additional help on these topics because it's pretty interesting and I don't think anyone has worked it out quite so simply.

Web,

Your "cycles of biota" idea is interesting but there are some big problems there.

The fossil record doesn't uniformly preserve the record of biota. There are large variations in depositional environments which leave some very significant gaps. A particularly frustrating one for paleontology is, "Romer's Gap", as an example. That one "happened" at the beginning of the Mississippian Period. We must presume that things were happening at that time, but we don't have much record of it to examine. Same problem throughout much of the Jurassic Period; not enough deposition going on. Deposition in the marine environment (where oil is formed) is strongly affected by erosional factors in the terrestrial environment, which will vary widely over time for any number of reasons. There is also significant variability over time in the creation of anoxic, shallow sea bed environments which are a necessary pre-condition for the preservation of the biotic sediments which ultimately will become "oil".

There obviously is a pattern between biotic environments and oil formation, but the geological record only provides the coarsest imaginable resolution.

Thanks for the feedback.

Impulse response functions sufficiently smear out any variations over time so that only the overall power-law behavior remains. Any smearing or disorder that occurs in nature is appropriately modeled in terms of entropy. And entropy is defined as a probability which won't necessarily show much structure.

So you have to account for the lack of structure in the power-law curve before you can start ascribing effects due to fine details in the biological record.

The math is straightforward but fairly novel. I have applied it to much more than just this topic. A few days ago, I posted an updated application to the characterization of the impulse photoresponse of amorphous silicon.

http://mobjectivist.blogspot.com/2010/05/characterizing-mobility-in-diso...

This shows some structure in the power law in the form of extra inflection but only because the geometry of the detector is clearly defined. That is what dispersion due to entropy and disorder results in, and makes it difficult to weed out the causal and deterministic factors. And we are talking on the scale of microseconds here (not eons)!

Same goes for the atmospheric CO2 impulse response. Even though carbon emissions have only recently occurred in the historical record, we are seeing the results as rising CO2 levels in which one can make out the inflections, but they already have started to smear.

Compare this against processes that have been evolving over millions of years.

One of the huge challenges in anyone trying to deny the ideas behind the theory of entropic disorder is that they will essentially have to disprove it over all the different application domains. Entropy exists in all sorts of natural behaviors and certain artificial ones and it happens to show much universality. It is the great leveler of deterministic theories.

Does anybody have any guesses about the GAS flow rate?

From what I've seen of the flow out the end of the broken riser, and doing some back-of-the-envelope calculations, it appears to me that ANY attempts to collect the entire flow are doomed to failure.

Based on some numbers I found in another TOD thread, it sounds like the gas-to-oil ratio may be as high as 3000 cu ft/bbl. If that's the case, even if the oil is only flowing at 5000 bbl/day, that's one HELL of a lot of gas!

If they can't put any back pressure on it (for fear of rupturing whatever connection they can make into the end of the riser) they're going to get some pretty spectacular velocities when this gas expands to near STP at the surface.

I'm convinced that, unless they separate out the gas AT DEPTH (where it's volumetrically handleable) they're not going to be able to do ANYTHING with the flow once it gets to the surface.

I keep hoping that I've missed something and that I'm just wrong, but nobody's corrected me yet.

I don't think you are wrong. Without some median stage, they can't do it. If hydrates don't get them, the velocity will.

I think the "junk shot" is the only chance of stopping this thing short of a successful relief well.

The real solution is the relief well. Anything else is just twiddling thumbs while they wait for that. This side activity creates the impression that they are doing "all they can" to fix it quickly, and there's a small chance it might actually work.

I guess it also helps if people get involved to think they are doing something, rather than just watch the oil creep up to the coast.

Tinhat posted a link above to an AP story saying that at the spill site, "At times, the fumes have become so intense it has caused a burning sensation in the nostrils and nausea. Workers have been wearing respirators while on deck." Another AP story yesterday or the day before mentioned the need for respirators at the spill site (can't find that one right now).

http://blog.al.com/live/2010/05/underwater_chemical_spraying_o.html

Yesterday I tried to convert 5k bbl/day into something I could get a better handle on, and came up with two and a half 40-foot shipping containers per hour. In the evening I walked my dogs about a mile from my truck and looked back, trying to imagine that volume per hour traveling a mile up through open ocean and resulting in conditions so bad that respirators would be needed.

Maybe some industry people who've been on-site at blow-outs could comment on whether the conditions reported by AP correspond better to 5k bbl/day, or 50k. I realize that gas is mixed with the oil, and I imagine that could greatly influence surface conditions.

If the military can remotely operate "predator drones" why are there not special craft the purpose of which would be to scoop up a certain amount of oil and then carry it back for unloading to a "mother ship" parked some distance away in a safe location for its crew?

Big Oil appears to be way behind the military in its technology.

You learn when things go wrong. N. T. Obot

HOG:

(Did you chose your handle so that it could be shortened in this way?)

I think I see your point. To drive it home a bit, I ask:

Remind me, please. When was the last time the military turned a profit and declared a dividend?

Well of course the military only returns its dividends to its owners, who are not us common folk. As for "when", well, certainly in feudal times when the purpose of a military was to protect a baron's landholding from costly raiders. Also to the British in defending the Suez canal last century. 'Course it seems to me quite obvious that defence is no longer the purpose of a military, so then the computation becomes very complex. But then, defence was clearly never the purpose of the British military controlling India for 250 years either.

Ok, here we are arguing, figuring, and betting salaries and all that - good sport! BUT - BP has submersibles down there 24/7 with video and lots of fancy equipment. They CLEARLY have the capability to produce high quality video of BOTH leaks AND to sample the stream to analyze/estimate gas content. They UNDOUBTEDLY have video taken since the spill started that could shed light on whether the rate is increasing or not and if so then by how much.

I am willing to wager they RIGHT NOW have pretty reasonable estimates of the flow - and if they don't then it is ONLY because they DON'T want to know for fear someone else will find out.

Anyone want to make a wager on why this information has not been shared to date?

Here they release a bit of video and we have estimates within 24 hours making it to the press - a really hard task isn't it? By releasing video from which it is possible to make estimates but about which good, intelligent people can disagree what purpose is served?

Prove me wrong BP - do a little homework and take some responsibility for this mess.

Remember this 5k bbl/day estimate (I think it was upped because the slick had gotten so large so quickly and the 1k estimate was no longer credible) has been floating around in the press for many days now and the figure is just a back-of-the-envelope calculation based on rather poor data - why has no one bothered to provide a more accurate estimate?

IP, You are likely right and for those exact reasons. The USA oil industry has gotten away for years with keeping discovery/reserve/production numbers close to the vest. It is all IP and trade secrets, IP. Somewhere our government got it in their heads that this would improve the competitive marketplace.

So BP has work going on in the North Sea and they are forced to report everything they do, but not in the USA, And the USGS or MMS doesn't do anything to help the situation.

BP is not in the business of disclosing intelligence, it's in the business of making money. Better to direct these questions to NOAA and MMS who are paid by US taxpayers to act in our interest.

Exactly

" (I think it was upped because the slick had gotten so large so quickly and the 1k estimate was no longer credible) "

I recall that first reports were actually that the BOP had worked, and there was no oil leak, whatsoever.

I am torn between three views: