Deepwater Oil Spill - Top Kill Update, Restarting the Mud, and Comment Thread

Posted by Heading Out on May 28, 2010 - 9:28am

New thread, please redirect to http://www.theoildrum.com/node/6538.

As I write this, I see see that the monitoring ROV is back in position to watch the leaks as BP, perhaps, is about to restart pumping mud – if they really are.

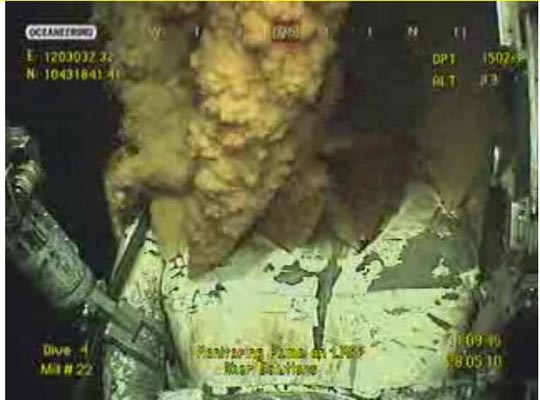

Piece of "junk" (?) in the riser crack, as BP apparently work to reduce the size of the path through the BOP.

Note that this piece has had to pass through the BOP, and it is sealing the BOP path which is more critical to success. It could also be a piece of the rubber from the annulus seal that broke loose and got caught in the riser. Without knowledge of what BP is trying it is hard to decide, but the flow looks to be still gas and oil without mud, and I would expect that BP would have to use mud as the carrier if they were injecting material into the flow, so this could just be a piece of seal that got caught. If you can't tell where it is, it is in the crack to the immediate right of the center line (without the paint) on the riser. (The view has changed)

UPDATE 1: Mud is clearly visible in the change in the look of the flows out of the riser. But at the moment it does not appear to be under the pressure of the flows on Wednesday. (This could be because it is being pumped in at a lower pressure, or it could be that they have sealed some of the leaks in the BOP and that is cutting back the driving pressure at the riser).

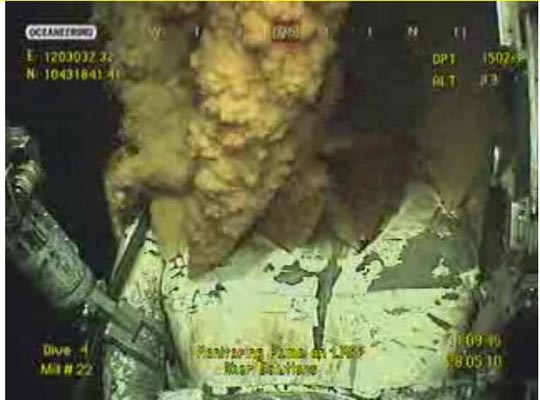

Leak shot at 10:25 pm Central

The problem we saw on Wednesday night with mud being heavier than oil and thus settling more readily and obscuring the view, is also evident.

UPDATE 2: 12:18 AM So it appears that BP have injected "rubber strips" into the flow, and that some of these have lodged in the BOP, reducing the flow channel, while one made it through and is trapped in one of the leaks in the bent portion of the riser.

Now what may happen is that they will slowly increase the mud flow/pressure to a) find out how much the leak rate has been reduced and b) to make sure that the restrictions in the flow channel are stable, and won't blow out. (If they do then they will have to repeat the process). Once they have a sure reduction in leakage then they will re-generate the higher pressures that overcome the pressure in the reservoir and start forcing the oil and gas back down the well, as the mud begins to fill the pipe.

The mud seems to have a slightly different texture from last time, so they could have increased the mud weight so that when the column of mud is re-established that this time it weighs a little more and overcomes the slight pressure imbalance that they were left with the first time they tried this.

Now is a good time for caution and, though the fill time may be reduced because of the smaller leak rate into the Gulf, they may still pump at relatively only slightly higher pressure that that in the reservoir, to slowly sweep down the well, getting into the necessary channels, and giving time for the oil and gas to be pressed back into the rock that it came from.

The CNN shot however shows that we are back with oil and gas apparently coming out of the leaks at the top of the riser, which is no different than the conditions before they started pumping mud into the well last evening. So the second filling of the well has apparently all been washed out, and they will try again later. The comment from BP was that this might take another couple of days.

UPDATE 4: 10:24 AM Well, I am not sure that the CNN feed was actually live and there are other stories catching their attention at the moment, but there is a Youtube recording of what took place (h/t Jessica in Pensacola).

UPDATE 5: 11:09 AM The feed has gone back to the riser, and we are back to the oil and gas flows that we were saw at the beginning. Not quite the same shapes as earlier, so perhaps the block in the BOP was partially effective, but BP have now apparently filled the well twice and failed to get enough weight into the mud to hold the driving pressure from the rock. They could try again with a higher density mud, I am presuming that the second shot had a higher weight than the first, and that while the first left a small pressure imbalance, that the second was closer, but as yet no banana. (Though the Admiral did say that they had stabilized the flow). My presumption is that they will mix up another batch and try again - though whether they will try another junk shot is not clear.

Flow at 11:09 am

The way in which you try to stop leaks is that you put the big stuff in first. If you can get enough of that to stick, it still leaves large flow channels, and so the second shot uses smaller pieces that fit into the gaps. Then you try smaller shots etc until you get as good a seal as you can. Doing this to plug water flows into tunnels can take several shots to get a total seal, working with sequentially smaller sizes of particles.

9:52 pm the camera is focusing on the cracks in the riser, and it seems that they may be injecting rubber pieces one of which is now stuck in one of the cracks in the riser. (Not very securely it seems)

Note that this piece has had to pass through the BOP, and it is sealing the BOP path which is more critical to success. It could also be a piece of the rubber from the annulus seal that broke loose and got caught in the riser. Without knowledge of what BP is trying it is hard to decide, but the flow looks to be still gas and oil without mud, and I would expect that BP would have to use mud as the carrier if they were injecting material into the flow, so this could just be a piece of seal that got caught. If you can't tell where it is, it is in the crack to the immediate right of the center line (without the paint) on the riser. (The view has changed)

UPDATE 1: Mud is clearly visible in the change in the look of the flows out of the riser. But at the moment it does not appear to be under the pressure of the flows on Wednesday. (This could be because it is being pumped in at a lower pressure, or it could be that they have sealed some of the leaks in the BOP and that is cutting back the driving pressure at the riser).

The problem we saw on Wednesday night with mud being heavier than oil and thus settling more readily and obscuring the view, is also evident.

UPDATE 2: 12:18 AM So it appears that BP have injected "rubber strips" into the flow, and that some of these have lodged in the BOP, reducing the flow channel, while one made it through and is trapped in one of the leaks in the bent portion of the riser.

Now what may happen is that they will slowly increase the mud flow/pressure to a) find out how much the leak rate has been reduced and b) to make sure that the restrictions in the flow channel are stable, and won't blow out. (If they do then they will have to repeat the process). Once they have a sure reduction in leakage then they will re-generate the higher pressures that overcome the pressure in the reservoir and start forcing the oil and gas back down the well, as the mud begins to fill the pipe.

The mud seems to have a slightly different texture from last time, so they could have increased the mud weight so that when the column of mud is re-established that this time it weighs a little more and overcomes the slight pressure imbalance that they were left with the first time they tried this.

Now is a good time for caution and, though the fill time may be reduced because of the smaller leak rate into the Gulf, they may still pump at relatively only slightly higher pressure that that in the reservoir, to slowly sweep down the well, getting into the necessary channels, and giving time for the oil and gas to be pressed back into the rock that it came from.

UPDATE 3: 9:30 AM The latest report from the Gulf

Hayward told CNN BP engineers had injected a "junk shot" of heavier blocking materials into the failed blowout preventer of the ruptured wellhead, and would also pump in more drilling "mud"- all part of the top kill procedure being attempted.Admiral Allen also noted at that time that the leak had been stopped, but that they were not sure that they could sustain the halt in flow. However at 8:10 am, Sterling925 who was watching and commenting on The Oil Drum saw some sort of event occur around the BOP.

"We have some indications of partial bridging which is good news," he said.

"I think it's probably 48 hours before we have a conclusive view," he added.

Chaotic images - looks like an explosion!and from SteinarN

09:14 et 5/28/2010

It looks like A LOT of gas is coming up from the seabed around the BOP. Considering the large water pressure and the possibly large area this gas is emanating from it ought to be a large flow. This indicate the integrity of the well is not good?Unfortunately I did not see any of this and haven't been able to see the BOP apart from one short shot since, though in that shot it did not appear to have any problem. The PBS viewed ROV at the moment is working with a chain, while the ROV that was monitoring the plume is now staring out into the ocean.

The CNN shot however shows that we are back with oil and gas apparently coming out of the leaks at the top of the riser, which is no different than the conditions before they started pumping mud into the well last evening. So the second filling of the well has apparently all been washed out, and they will try again later. The comment from BP was that this might take another couple of days.

UPDATE 4: 10:24 AM Well, I am not sure that the CNN feed was actually live and there are other stories catching their attention at the moment, but there is a Youtube recording of what took place (h/t Jessica in Pensacola).

UPDATE 5: 11:09 AM The feed has gone back to the riser, and we are back to the oil and gas flows that we were saw at the beginning. Not quite the same shapes as earlier, so perhaps the block in the BOP was partially effective, but BP have now apparently filled the well twice and failed to get enough weight into the mud to hold the driving pressure from the rock. They could try again with a higher density mud, I am presuming that the second shot had a higher weight than the first, and that while the first left a small pressure imbalance, that the second was closer, but as yet no banana. (Though the Admiral did say that they had stabilized the flow). My presumption is that they will mix up another batch and try again - though whether they will try another junk shot is not clear.

The way in which you try to stop leaks is that you put the big stuff in first. If you can get enough of that to stick, it still leaves large flow channels, and so the second shot uses smaller pieces that fit into the gaps. Then you try smaller shots etc until you get as good a seal as you can. Doing this to plug water flows into tunnels can take several shots to get a total seal, working with sequentially smaller sizes of particles.

I don't understand. If they've stopped the oil flow up from the well and they are not pumping at this exact moment, what in the hell is gushing out at high pressures? How does that make any common sense at all?

Exactly. What we're watching doesn't compute with what they're saying, as far as I can tell.

i assumed they were still pumping ... but i'm not as up to speed on this as most.

Should the weight of the mud be enough to hold the oil back, and if so for how long?

BM -- The weight of the mud would only stop the flow if there was a 18,000' tall column of it putting pressure against the flowing reservoir. The mud weight could be 165 pounds/gallown instead of the 16.5 ppg they are pumping and it won't stop the flow unless the can keep it in the csg. And that's the problem; as long as the well is flow out at thousand of #'s of pressure anything they try to force into the csg is immediately pushed back out. What is more critical than the MW is the amount of pressure the mid pumps can exert. But that leads to the basic problem: the seal is leaking so the higher they raise the pump pressure the faster they push the mud out of the leaking seal. And that doesn't appear to happening...not even close.

Bill Nye the Science Guy says they need 400 tons of force inside a 21" diameter pipe (the riser) to counteract the pressure in the well. Any thoughts? If I understand him correctly, there is not a 1:1 relationship in drilling fluid meeting oil and gas in the pipe. Because of dilatancy, they are able to push the drilling fluid past the oil and gas (even if they are not able to impede the flow with an equivalent amount of pressure). In time, the drilling fluid will start to build up from the bottom, closing leaks, and eventually start to fill up the pipe until it reaches the top. Does this sound like a fair description?

http://www.cnn.com/video/?/video/bestoftv/2010/05/25/jk.bill.nye.science...

They keep reducing the flow of mud to see if it is working: if mud is reaching the bottom of the well, if there is a balance of pressures in the pipe, or if mud is moving in the pipe and forcing more oil out of the top of the riser through the malfunctioning BOP.

idyl -- Not debating Nye's idea but remember the source of the oil/NG is not the riser. The flow is leaking from the well head/BOP. The riser leak is a secondary leak. Stopping all the oil coming out the riser would just get the flow going out somewhere else if I understand the situation correctly.

If they were to stop all the secondary leaks in the riser, and if the cap that they put on the end of the riser were to hold, then the riser would inflate with oil and gas (and maybe some mud), AND the pressure in the riser would rise towards what is present inside the BOP. It would never get to that pressure because the riser would burst first.

They really need to plug the primary leaks that are inside the BOP, IMHO. Any junk that gets through the primary leak(s) and shows up at a leak in the riser, just shows that they are trying, but without success.

Yes ... Nye was probably incorrect to use the 21" size of the riser pipe for his calculations, he should have used the well casing diameter size at the farthest location from the rig (which I understand to be some 7"). Does this mean the pressure in the well would be higher moving through a smaller diameter pipe, or lower?

For the top kill procedure to work, as I understand it, they have to be able to place drilling liquid at some location down the well bore, and then keep adding more until they have enough weight to counteract the pressure coming from the reservoir. Too little mud and they will get "balooning" ... which would indicate the procedure is working, but needs more mud. Too much mud and you would get negative pressure that would suck in seawater from the leaks at the top of the BOP.

So clearly, based on visual inspection of BOP, they don't have enough mud to balance out pressures in the well bore. Whether they have balooning or other pressure variations in the well bore (indicating something is going on as a result of the introduction of drilling fluid) ... we don't yet have these results.

I also have wondered about the mud density decision. Obviously there is some minimum required density based on downhole pressure and column height. But if the density is too high is there a danger of something like pipe failure or mud loss into the formation?

ld -- the well can exist in only one of two states: it's either shut in (not flowing) or it's flowing. In a standard drilling op it's easy to tell: you shut your mud pumps off. Do that and the well either doesn't flow back or the fluid continues to flow. The problem we have interpreting the videos is that we don't know the status of the mud pumps at anyone time. Additionally, we need to be seeing all the known leak points. Just because we see flow stop at one leak doesn't mean the well stopped flowing.

Yesterday morning at this time Allen said the same thing -- it had been stopped. In fact, there had been no pumping for over 8 hours and the huge gushers continued at the leaks. I'm a layperson, but how is that comment not laughably pathetic? And, how is this not the same thing right now on this morning? The well is stopped? Look at it -- no it's not!

Check out Matt Simmons and another drilling exec.

BP has missed the biggest leak They suggest booting BP and bringing in the US NAVY and SUPERTANKERS. We have got the wrong people working on the "fix".

I suspect Simmons' doomer side is showing, I'm pretty sure he wants to see this disaster continue. As inept as BP has proven to be, replacing them with the Navy would only make matters worse; unless they've developed a special oil-well-killing torpedo...

I don't think Matt Simmons is calling this one right. I think the idea that BP has missed the biggest leak is nonsense. If that idea is way off base, it makes one wonder about the others.

The correct link for Dylan Ratigan/Matt Simmons is http://www.msnbc.msn.com/id/31510813/#37384670

I can't really tell what Matt is getting at. He seems to be under the perception that the bent piece of riser we keep seeing is not at the BOP. But it is, right?

Yes, it is. Seen it with my own eyes more than once when a ROV has backed out from a closeup of the riser plumes to a wider shot and there's a great big giant huge BOP right there where it should be.

Rockman,

Couple questions been nagging me about your fireplug analogy yesterday. I thought from the diagrams that mud was entering from the choke and kill lines, and they were from the manifold, the new pipe carrying mud inserted there. So it would seem they have tightened fittings all the way into the BOP. Not so? The analogy suggested to me 2 hoses w/0 fittings just spraying at each other, trying to find the stronger. Also, if this ever works, is the cement plug set on top of the new mud in the casing, or do they have to somehow set the cement plug at the bottom of the 18K hole at the producing formation? Much more difficult it would seem.

And a last one, working with only 3" irrigation pipe, if I don't want to trudge up the hill to shut the flow, I can sometimes install new risers/pipe by pulling a downhill plug, and rushing to put it all together during the pressure drop. As a last chance gasp, any idea on whether cutting the riser at the bend would give them enough drop/time to get the mud going down? It sounds far fetched to me, but thought I'd ask.

doug -- I don't have a clear picture of the plumbing down there. But if they had fittings that were securely tightened and could hold the pressure as the kill pill was pumped then it would mean they had the well shut in and there would be no flow even before they started the kill pill. That doesn't appear to be the case. The fact that they pumped more than 30,000 bbls of mud into a csg string that could hold no more than 1,400 bbls of mud if it were completely filled tells you how poor those fittings must be holding.

"how poor those fittings must be holding"

Rock,

Could it not be that there is a gigantic hollow space around the bottom of the production casing because

sand from the producing region has been blown up and out of the well during the continuing blowout?

The 30000 bbls of mud fell down through the production casing and dropped into that void at the bottom (?).

The reason that there has not been dramatic increase in flow rate during the past few days is that sand erosion has stopped. Sand erosion has stopped because the void at to bottom has gotten big enough that flow inside the producing layer is now spread over such a wide area that it no longer picks up sand on it way toward the open end of the production casing.(?)

I've seen this in movies before where they use a video loop to trick you into believing what you're seeing is in real time. The question is, do you trust them?

Who knows what's really going on down there.

I sincerely hope this current procedure works, but I have some serious doubts that it will. That's some serious pressure, and the injection points are smaller diameter than the exit points. Makes it hard to see how this is supposed to happen.

Just some random ideas for other approaches, to be kicked around and criticized:

1) Does the BOP have some kind of actuator that could be forced to close the bore? If it's jammed, is there any point that some kind of charge could be tapped in to blow it shut?

2) Someone in an earlier thread was talking about how medical stents work and wondering if something similar was possible here. I'm wondering if a kevlar/steel mesh bag could be fabricated which could be introduced through one of the 3" lines and then filled with cement inside the BOP to close the bore.

3) Lastly, the nuke option. A tactical nuclear fission device, introduced into a bore hole parallel to the well and at a suitable distance, say a few hundred feet deep and a few hundred feet away. The concept is to achieve a blast that would crush the pipe and fuse a couple hundred feet of sea bottom over the well.

The nuke option was discussed here several weeks ago. I suggested a series of offset compression blasts to collaspe the pipe. I think we all agreed that there were too many uncertainties. I also suggested drilling a few thousand feet below the sediment layer, get near the well and attempt to create a collapse with a large explosive. This wasn't well received either. Perhaps, if these guys get desparate enough......

I'll try to answer:

1) It seems the BOP partially shut. The remaining opening has almost certainly been eroded to a larger size. The erosion means even if it could be closed (I think it actually is after hydraulic repairs) it would still leak. And keep explosives away from this thing.

2) Very interesting idea. I doubt it could be designed, fabricated and tested for this event, but worth further study I would think.

3) Just.....no. No. NO.

I've been thinking about a stent-like approach as well, although it might be easier to drill a hole at the top of the BOP (through the bent-over riser that we've been watching leak for the last two days), threading an expandable "stent" down into the BOP until you're below something that could serve as a seat, and then expanding it into a mesh that would cover the opening with a grid small enough to catch whatever you then pump in with the mud.

Certainly would be simpler than threading a stent down through 5000 feet of 3" tubing.

I was assuming whatever you needed to introduce through the fitting would just be done at the BOP by one of the ROVs, same as they attached the tubing in the first place.

Peter -- very intuitive. We aleady have "stents" in the oil patch. They are expandable cement packers. Picture a hard rubber bladder attached to the end of drill pipe. Run the ECP into the csg to an appropriate depth. The oil/NG will continue to flow up the csg. When in position start pumping cmt into the ECP and it swells to close off the entire diameter of the csg. A couple of problems though. First, the obvious: the csg has to be completely open. have to have the BOP wide open and the broken drill pipe removed. Second, I'm not sure if any of the existing ECP's can handle the pressures involved.

Rocky, that sounds like one of the problems that were neglected before they started doing DW drilling. They are doing things at a depth where the technology either does not work, or has not been tested. They were tempting fate! And, fate rose up and bit them.

I have finally managed to convince one of my children that we are now witnessing the beginning of the end game, in the Age of Oil. Until now, he has been a technocopian.

What do you figure are the odds on at least one of the RWs succeeding?

Criag

zap -- I think the odds of a RW killing the blow out is 100%. The real question is will it take 3 months or 1 year. The RW will work...eventually.

And to reduce that time, even by one day, I advocate four relief wells (at a mere $100 million each per incomplete RW).

Four RWs are, on average, more likely to finish early than two RWs (or the "just one" RW BP wanted to drill).

The odds of "disaster" hitting any one, or even any two RWs in this specific case, are discouraging high.

And a disaster could be a week long, a month long for a four month long delay !

Alan

PS: Drilling RWs is work for the 33 deep water rigs and crews that are being pulled out of the GoM. More is better ;-)

i agree. 2 of them can work as RW's and the rest on drilling production wells to get the product that is destroying the GOM. there is only a finite amount down there. Produce it ASAP. Obama nationalize them now. Assign them a drilling site in Macando. The oil rig folks need work and we need this oil for something other than its currently misaligned mission of turning the GOM into a slim pit. If they are all working in close proximity they can be efficiently trained and monitored if there is to be future DW drilling, which I am against. Draft Rockman and a few of his compatriots to oversee the operation. Might as well dream for something positive. The dreams I have been having lately have all been nightmares.

Thanks, Rock. The 100% makes me feel better, especially coming from you. The 3 months to a year - not so much. Old man Murphy has really been screwing with this thing from the get-go.

::sighs::

Have a good day, if possible.

Craig

Not sure how effective a stent in the central casing would be if the oil is leaking out the annular region

Putting the cement packer down the well would be excellent.

The shear rams on the BOP have cut through and partially collapsed the riser pipe inside the BOP.

Inside the riser is the (partially cut?) drill string.

The issue is whether the crimped riser is an obstacle to removing the drill string and replacing it from the surface with either a conventional tool or another device such as the cement packer. In any event, with the drill string downhole mud can be injected from the bottom of the well up. Well pressure would assist in driving the mud upward toward the well head.

Going the other direction appears to require more pressure than the BOP, riser or downhole casings can take. The mud is only going down halfway then escaping into the formation. More pressure means more mud into the dirt. Basically, as I understand it, the mud crew is working against an endless kick.

18,000 feet of heavy mud from the bottom up should stem the flow by itself, then concrete at the bottom and through the kill and choke lines.

I as well was thinking about a stent, that I have. I also thought about a spring they shoved up my inside through my penis (ouch!). The tool straightened it out and, once inside, on letting it go it formed a coil. When they went in to get it the tool straightened it out again and they pulled it out. The surgeon then held it up in front of me and said "This is new, Boston Scientific". (Harvard teaching hospital)

However that is just by way of an aside. What I'd really do is concentrate on getting 'junk' that can close the flow area within the BOP from the upstream side. It must go into one or both of the 3 inch pipes and then lodge within the BOP body. To keep it simple I would try a device consisting of two rubber balls with some quite strong wire in between them (different thicknesses could be tried). The rubber balls would consist of a larger slightly less than the I/D of the mud pipe, and a smaller. The idea would be to get them into the pipe with the larger leading. It would then pass through like a piston with the wire and smaller ball following. The wire length and flexibility could be varied so it can negotiate bends and joints in the pipe. A 'test rig' BOP could be set up to try this. Now the intent is for these rubber balls and wires to become entangled within the BOP once they are injected. If spring wire were used in would bent somewhat once it was in a free space within the POB. The intent is to stuff a lot of these in so that a wire mesh type structure is obtained. (Afterthought is the wire could be barbed, to some extent, but see remark about the sacred 3 inch pipes - with joints)(Another afterthought is the second rubber ball could be just a ball of wire - that's even simpler. The main point is for the leading ball to be the piston propelling the assenmbly down the pipe with the force of fluid behind while it does not propell the second ball and cause the whole thing to jamm.)

I do not care about the riser leakage paths. They are secondary. This is to reduce critical flow areas within the POB so as to allow sufficient mud pressure (circa 10000 psi?) to reverse the flow of the oil/gas column.

Now, once you have all these pieces of entangled wire you can return to junk that is more like flat pieces of rubber that will lodge in the mesh. Their may even be a goey cement like substance you can add however you cannot compromise the integrity of the 3" feed pipes. They are sacred.

Having got the inside clogged up you should be seeing a rise in pressure from underneath as you reduce the flow of oil/gas and get lesser friction losses coming up the pipe - even without pumping mud. It will get to reservoir pressure minus the head of oil in the pipe once it is stationary. Now I do not think you will get as far as that however you have now set the stage for pumping either mud or sea water that will increase the pressure at the bottom of the BOP to the point where it will stop the oil/gas upward flow.

Either you will get there or you will blow out the restrictive material. If the latter you start again.

Now it is a nicety if you can then get sufficient mud down the drilling for its head alone to stabilise the flow. Once it starts going down the pressure required within the BOP will reduce. That should help the integrity of the 'flow restriction mesh'. That perhaps is the advantage of using mud rather than sea water. Over twice the head.

If the SG of the mud is sufficiently high (and I gather it can be tailored) then the column could be sufficient to hold the well pressure with the pressure at the BOP being that of the sea (no mud pumping needed).

I would not think this a perfect seal as the mud would continue to drop down into the reservoir and be replaced in the pipe with the lighter oil/gas however you then have a situation that you can fine tune until such time as a) you can mount another valve on top of the POB, then close this and cement and/or b) wait out the secondary well.

Enough for now.

Good ideas, erd. I just hope the BOP has retained sufficient structural integrity to stand the increased pressure, though if it hasn't it doesn't really matter since there seems no better plan that I have read to date.

ISTM that BP should have thought this whole thing through years ago. I mean, the presence of a BOP infers the realization that blowouts happen. And, any manmade manufactured item is susceptible to failure. Therefore, a means to seal this well should have been a part of initial engineering. Of course that would mean spending money on safety, wouldn't it? Oops. Sorry! I take it all back.

::sarcasm off::

Craig

Come on Brooklynite only two of your three suggestions involve blowing something up!

There's a subtle difference between propellant charges (like the ones used in airbags, ejection seats, and other single-use actuators) and explosives. Obviously, the correct solution would have to be engineered. Unlike the third suggestion, the first isn't a demolition job.

Now the ROV shows "Monitoring Plume on LMRP, and it's traveling through clouds of stuff with rocks floating by - wasn't LMRP the "Lower Marine Riser Package"?

emm... what's going on? ROV getting pounded by mud asteroids or something

They moved the camera at about 9:10. It had been looking at the leaks in the riser, then it lifted away and moved to the left.

ah allright, I just tuned in and it looked like something blew up or so. still, haven't seen this much debris in the water yet.

I think why do I have this feed up and then something spectacular happens. It looked like the asteroids were in an oil plume.

Chaotic images - looks like an explosion!

09:14 et 5/28/2010

Top of the riser let go? ROV is back in his cage it looks like.

EDIT: maybe not. Might just be surveying the plume.

Lots of debris flying around. Cement job going down, perhaps?

I don't think so. Something happened. They got the ROV out of there post haste.

Never saw that part. Others have since written that they saw the riser pop, followed by an O&G release.

I hope those white objects are not Hydrates

It looks like A LOT of gas is coming up from the seabed around the BOP. Considering the large water pressure and the possibly large area this gas is emanating from it ought to be a large flow. This indicate the integrity of the well is not god?

Any coments from the experts?

Was watching - monitoring ROV turned camera away and then whoosh -- the chunky debris has me suspecting a sizable rupture in that kinked and perforated section of the riser.

Edit - suspect ROV operator is still hanging on hoping for enough visual to be able to back out.

Is it correct to say that even in an almost-killed well, residual gas rising will expand in the hole and increase surface pressure at top of hole?

Again - if someone recorded the stream, it would be real nice to have it uploaded somewhere. I would love to see what happened there again from the beginning.

You can't tell me they cannot pan that ROV camera into view of what is going on. It would appear we are seeing what they want us to see...nothing.

Nope...nothing happening here folks...move along.

None of these ROVs are down there for the sole purpose of filming the action for us, we just get a dupe of the same feed the ROV operators are seeing. I promise you, none of the ROV guys are doing anything other than everything they can to do the jobs they have to down there.

Now all that considered, there has to be someone, probably a humanoid PR droid who doesn't know a wrench from a hammer, in a control room somewhere acting as director, picking which of the many video feeds gets piped out to the public. If you have to invent a conspiracy, blame that bastard. The ROV operators are being stressed to the point they might not even know their live feeds are being piggybacked and sent out for the world to watch.

Yes, I recorded the whole thing. A ten-minute clip of which I was finally able to get on you-tube, here: http://www.youtube.com/watch?v=CEKmYWErGy4

...since you asked. There's more on either end, but that's the heart of it.

Certainly BP will claim this is all normal, we just have to wait a few more days...it looks like hell to my carpenter eyes.

Gas has to follow PV/T so the answer is no. That relationship has to stay constant.

Thanks for the answer. Coffee not working well this morning. Plaques in the brain don't help much either LOL.

Edit. I should say, a mostly killed well with an open top, which is what we have. I was trying to be hopeful that continued flow out the riser might still be compatible with a killed well. Which I doubt is the case, but I do hope it.

I am aware of the likelihood of the behind-cement leaking into annulus at a casing hanger complicating the effort. It doesn't look good. I suppose blasting mud down into it like a fracking effort is what would be needed. Such a bigger chance of losing whole column into weaker formations.

Is it correct to say that even in an almost-killed well, residual gas rising will expand in the hole and increase surface pressure at top of hole?

An "almost killed well" is like "a lttle bit pregnant.

A WELL IS DEAD WHEN THE PUMPS PUMPING IN ARE STOPPED AND NOTHING IS FLOWING OUT TOP OF WELL

Was there a disconnect at the base of the lower marine riser package?

CNN is back up with 6 monitor view

No. ROV2 is checking out the LMRP now... looks intact.

The ROV is at 1470 meters now, it was at 1507 meters. Maybe they just had to move it out of the way and it kicked up a bunch of debris in the process.

I hope that is what happened.

Hopefully all the activity on the MAC hosting this stream at PBS was someone recording the event.

Is it just me or is that the weirdest current flow you have ever seen? It appear there are some pretty forceful updraft and downdraft current flows...almost like some form of suction or vortex.

I am wondering if something did blow, the resulting upflow could be creating the wild looking residual current flow we are witnessing?

Crazy.

I think the ROV is back in the cage and we are seeing the wave motion of the ROV boat.

In the CNN multi-view you can see they are screwing something on/off with the ROV robotic arm. Not sure what it shows tough.

It may be they have long abandondend "Operation Top Kill 2: Junk Shots" and are already preparing LMRP - no official communication about it anywhere...

http://www.deepwaterhorizonresponse.com/go/doc/2931/564231/

Does anyone have an idea what ROV2 is doing? It has been turning bolt or something clockwise on part that I havent seen before, perhaps somewhere lower down on the BOP

I don't think just shutting off the pumps will immediately stop the flow of mud from the riser. There is still a mile high column of mud in the tubing going up to the surface that would either have to be valved off of it would drain out through the riser leaks.

Don't know how long that would take but it could be a while if there is no valve.

The "manifold" the C/K lines are fed from I would believe includes remote operated valves or may even be choke valves. That manifold connects via drill pipe to Q4000 topside.

long time lurker, just signed in.

@ rockman, headingout et al.

Last night I was showing my son the problem with pushing mud against what appears to be a 2x pressure differential and a he came up with an idea.

Here it is:

If they have a place to push mud, apparently 4 valves they have control over.

use one of the lower valves to release/ relieve pressure from the flow.

use one of the upper valves to pump cement into the flow(upward) and once the cement has blocked/filled to BOP slowly close off the 'relief' valve.

I'm a network guy so I yield to the oil engineering section on this one.

I couldn't find a major red flag. If they have control of 4 valves it makes some sense. I'm just not sure why they didn't try to reduce the pressure on the main bore.

thx,

woerm

You aren't going to be able to reduce the pressure in those valves to initiate flow vs continuing on up the riser. Not to mention you are perpendicular to the flow stream with much smaller flow orifaces.

woerm -- What you're describing is the basic method for killing a shut in well. The problem with the blow out is exactly that: there are no valves to close to stop the flow. If there were you would simple attach a kill live to that valve and pump in at a pressure exceeding that of the flowing oil/NG.

I believe that we have moved on to "Top Hat" phase. They are trying to get us into the holiday news cycle. They were cagey on TV this morning. Definitely not being transparent.

Can someone with technical background comment on what they may be working on atm? Is it the top of BOP? Can't make out the depth either.

Was gonna say the same thing. That looks to be some sort of guide or something the ROV is attaching. Guessing something to do with the saw they'll use to cut the top off. Just a guess.

So what are we looking at now? I am not sure where on the BOP that ROV is working. Since they are tightening a bolt I don't think they are getting ready to saw off the old riser, but I may have that exactly backwards.

Any thoughts?

To me that looks like a fitting for some sort of instrumentation - pressure gauge, temperature, sample port, whatever.

This may have been posted in an earlier thread

http://www.csmonitor.com/USA/2010/0527/BP-oil-spill-harrowing-escapes-of...

It looked to me like the ROV attached a rigging ring to a riser section. Later it looked like the ROV picking up a come-a long.

Got a glimps of ROV2 from ROV1 as it moved into position

RoV2 appears to be just below the level of the kink in the riser and is still turning. It is turning something on the flange that connects to the kinked part just above

I think I saw very briefly the kink in the riser still leaking like before. But the view wasnt good and moved quickly away.

ROV 1 then moved to same position on opposite side of riser and seems to be startng the same procedure on that side.

Rov2 then seemed to finish and backed off showing the full BOP still intact

He might just have picked up a saw.<-- I must be starting seeing things.Where he was turning stuff whas the top of the BOP under the riser pipe, as you could see as it moved back.

Here is video of what happened earlier, certainly looks like something came apart...lots of debris falling. Watch to the point of about 1 minute 14 seconds into it.

http://www.youtube.com/watch?v=AadjMspXMAA

Thanks!

I think BP have moved on with the LMRP attempt.

A few minutes ago when the live feed was showing the view of debris suspended in water from the camera of "BOA Deep 1" the text at the bottom of the screen was "Monitoring [...?] on LMRP".

I found this screenshot to confirm: http://twitpic.com/1rtag8

Based on the description of the attempt found here:

http://www.rigzone.com/news/article.asp?a_id=93712&rss=true

"This would first involve removing the damaged riser from the top of the BOP, leaving a cleanly-cut pipe at the top of the BOP's LMRP. The LMRP cap, an engineered containment device with a sealing grommet, would be connected to a riser from the Discoverer Enterprise drillship and then placed over the LMRP with the intention of capturing most of the oil and gas flowing from the well and transporting it to the drillship on the surface."

I infer that what we are looking at right now on the live feed are the operations of removal of the TOP of the BOP.

Wish I had a screen capture of that screwdriver - screwing - underwater - a few minutes ago.

Is that a metaphor for this oil spill and bp's "appearances of transparency"?

Nobody wants to risk any more face. Every possible operation that can fail is outright rejected. The problems surrounding this well are growing and this kill mud is missing the crack to the annulus. All the mud added will flow out through BOP or the Drill Pipe. The mud in the lower part of the well below the DP open end is static. The casing below and around the float shoe is plugged.

Time to cut losses and break some eggs.

Replace the broken bent LMRP with the BOP stack on Deepwater Enterprise.

Allow topflow through the C/K lines on the lower BOP. Rig to produce flow from new riser.

Go fishing to catch the DP stuck in the lower BOP and then open Lower BOP and remove that drill string.

Run into hole with perforating tools and cut up the casing above payzone. Kill the well.

Cement plug the entire well and abandon.

BP you are wasting more time.

All this for:

1. Short cementing on casings and liners.

2. Short on cement plugs.

3. A total disregard for anomalous BOP tests.

4. Short on time waiting on cement.

5. Short on mud as they unload to transport. Replacing the mud with sea water on a live well.

6. Short on bottoms up circulations.

7. Short on experience with onsite rep.

This is the only solution now. They are quickly losing this well to erosion. It's time to open the well up to full flow and divert it to allow tripping to bottom and perforating the casing to allow mud then cement to be circulated to kill the well. Top kill won't work because of the annular flow not allowing any mud to make it into the well. They cannot hold back pressure to allow mud to be bull headed into the well. This was blowout was caused by a culture of big company attitude to save money and hurry up. Thanks for screwing up a fine business British Petroleum. We will never be able to recover from the black oil eye we have taken.

+1000

Given:

1. The first attempt to deal with the blowout failed when the 100 ton capture box filled with methane hydrate crystals when sea water mixed with the oil/gas mixture, which blocked the flow of the oil/gas mixture through the riser pipe to the sea surface.

2. The top kill method of injecting drilling mud into the lower portion of the blowout preventer (BOP) failed when the escaping oil/gas mixture carried the drilling mud upward and out of the BOP.

Question:

What would be likely to happen if the mud pumps, top kill lines, manifold, etc. were used to pump large quantities of cold seawater into the lower portion of the BOP? If methane hydrate crystals could be produced inside the BOP, they might stop, or at least slow the flow of oil and gas. If the flow could be stopped or slowed, the top kill drilling mud method would have a better chance of success.

Is this suggestion practical enough to be worth trying?

newbee, I'm not an expert on drilling, but I am a mechanical engineer. Your idea is intriguing but I can imagine a few problems, just based on normal engineering principles.

1. The melting point of many liquids can be functions of pressure. I don't know how that works with hydrate crystals, but water becomes a little bit harder to freeze at elevated pressures. It could be that, if the hydrates clogged the BOP, the pressure inside would increase, the melting point could also increase, and thus the hydrates could melt again.

2. Another important point is that the oil coming up from the reservoir is very very hot. This is probably both because of geothermal heat at the bottom and also because of friction after the oil's long, high speed trip up the pipe. So there might be enough heat in the oil stream to prevent hydrates from forming until they get into open water.

3. Even if neither of those effects prevented the formation of your sealing ice, I doubt soft ice crystals could mechanically seal a high pressure leak. This leak is considerably more powerful than a jet engine (across a very small area of course), powerful enough to scour steel. It stands to reason that the escaping liquid would also scour away ice crystals as they tried to form. Plus, that scouring action produces heat, which would also work against the ice.

Again, I'm not an expert on drilling, but that's my initial engineering reaction to your proposal.

I do wonder, however: If they were able to pump mud down at a high enough rate to displace the oil back down the well, effectively turning the oil leak into a mud leak, why can't they pump in water and turn the oil leak into a water leak until the relief wells are complete? This would also prevent additional sand-scouring of the BOP hardware and riser pipe...

I'm sure there are many reasons this isn't feasible, but I'd be curious to see what they are.

Whoever writes the CNN Breaking News emails has a very bent sense of humor. Just received this:

quote

BP's top official upgrades impact of Gulf oil spill from "very modest" to "environmental catastrophe."

All of western civ to BP officals,

"DUH"

I only have a couple minutes this morning.

This is based on what BP has said about their forward looking plans - but BP's transparency seems to be like looking through a clean pane of glass - covered with black paint.

If the top kill is successful the next step will likely be the installation of a second BOP which would mean they have to either remove the riser and/or LMRP so they have a fitting to latch the BOP.

If the top kill is not successful then they will proceed to attaching the LMRP "top hat".

Both of these procedures require cutting the broken riser.

So if I was the project manager I would go ahead and install my clamps for the saw and maybe the saw itself to save time later on.

Bottom line is that if they are installing the saw it doesn't actually indicate anything about the success or failure of the top kill.

Thanks for posting.

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/top_kill_strat...

Bottom line is that if they are installing the saw it is probably a clear indication that top kill has in fact failed and they are preparing for the top hat.

Cheers,

Jerry

If the Top Kill is a failure and it appears it is, we will have to wait 30-60--?? more days (at 500,000 gallons or more per day) for the kill well(s) to come into play.

We have X gallons per minute at Y pressure coming through the BOP. And we have inlets into the pipe below the BOP (where the mud has been inserted).

The mud is not working, is expensive, is as toxic as the oil is, is finite. Certainly not 30-60 days worth on hand.

My thought is, if the mud is not working, why not start pumping sea water in instead through the mud lines. X+1 gals of seawater at Y+1 pressure has to displace/replace at least SOME of the oil coming up from the reservoir.

So instead of 500,000 gallons or more per day of oil escaping for the next 30-60 days, it might be brought down to 250,000 gpd, or even if only 499,999 gpd, it would be worth it (not to BP maybe, but really, who cares about them at this point).

my guess is they are goin to us the come along to pull the lmrp into place over the bop and use the enterprise to choke the flow enough to get a kill on the well to pump cement to it

If we're talking about the LMRP cap that I've heard has been built and is on-site waiting for installation, the connection between the old riser stub and the new riser will HOPEFULLY exclude most of the water, but it won't hold much pressure.

It MAY allow capture of some of the oil - hopefully more than we were getting through the RIT - but it won't be any use in killing the flow.

OTOH, if they can somehow stab a new BOP on top of the existing one - I don't know how they could make THAT joint pressure-tight - there is a possibility of choking off flow there.

ND: they zapped comments before I could answer your question about Z42. Yes. Correct universe.

Craig

That's funny - thanks for lightening things up a bit - this situation certainly calls for a little comic break now and then!

I have said before, these guys are clowns. Not funny, though.

I alternate between numb shock, and near tears. I have good friends in Houma, Lafayette, and Big Easy. They are not answering their calls.

Craig

If they can contain and collect the oil at the surface, it really won't matter if the relief well(s) take 3 months or 3 years.

Hey Comfy, you sitting down in that chair of yours? I'm sorry to interrupt all this fascinating underwater viewing of the spill and the scintillating technical and engineering discussion around mud and BOPs and ROVs and all that other good stuff. How bout a major F'ing Reality Check!!! Read some of this stuff:

http://www.marine.usf.edu/oil-spill-2010.shtml

Well, it seems that the very thing that was my absolute worst case possible nightmare scenario is being confirmed bit by horrible bit. I'm beginning to wonder if the BP execs should be tried for crimes against humanity...

The plume of dissolved oil stretched 6 miles down, said David Hollander, a USF chemical oceanographer and lead investigator for the project. This is the second oil plume to be discovered by scientists, and it marks the first time such plumes have been detected after a spill, Hollander said.

So Comfy, how ya gonna collect that?! Maybe the engineering folk have a few ideas...

Look, I'm on your side. There should have been something in place BEFORE THIS EVER STARTED to collect anything leaking from a deepwater well and keep it isolated from the water column all the way to the surface where it could be collected and disposed of. I'm a layperson, but IMO as soon as they realized the BOP wasn't able to shut in the well, they should have cut off the riser to isolate it to ONE source location, and used the as-yet-to-be-invented device.

The decision to use dispersant in deep water should land somebody's ass in jail.

EDIT: If the oil comes to the surface in one small location, even within a square mile, it can be dealt with. If it's allowed to spread out and pop up at random over a 500 square mile area, we're fucked. If it's dissolved into the entire water column over a 500 square mile area, well, my best solution for that is to sit in the corner and cry.

Sorry I jumped on you comfy, watching this whole thing unfold has been very traumatic.

It's ok dude, I know you from your comments. If I thought you were a crazy person I wouldn't have bothered to elaborate. My comment you replied to was short and didn't give a lot of context, and it's not clear that the emphasis should have been on:

The point is that with current tech, they can't. That's the part we have to figure out if we're going to keep drilling for oil.

See here: http://www.theoildrum.com/node/6501#comment-628432

Speaking of volcanoes, there are two major eruptions going on since the oil "eruption." One in Ecuador, another in Guatemala. Probably just coincidence? But surely removal of large amounts of oil could have some seismic effects.

Hi all, first time poster to the forum, but I have been lurking for a few months in an effort to learn a little about the industry. I had intended to seek employment in the petroleum sector upon graduation next semester(GLY BS)... rethinking that now with Obama's announcement, yesterday.

Anyway, on the meat of the post: To those thinking of a solution to this problem employing explosives, Here are a couple of photos of what a seafloor looks like after a seismic wave passes through unconsolidated clastics(calcilutite, calcisiltite). Turbidites behave in the same manner. This structure is mapped over about 40,000 km/2 in Kentucky and Virginia.

http://www.flickr.com/photos/30726183@N05/4647733808/

http://www.flickr.com/photos/30726183@N05/4647118701/

Now, I don't what is on that seafloor within a 50-100 km radius of any blast that occurs, but there will probably be a lot of liquefaction of the beds near the surface

EDIT: I tried posting this several minutes ago, but my laptop thought otherwise. If a duplicate, delete, please.

It also looks like BP needs to go back to booming school, that is actually send people to the classes.

NSFW salty language from some one who apparently has actually had to go to the classes

It sounds like a documentary but the language is. well, terse.

http://www.youtube.com/watch?v=Vx8kMXufu3w

they make a few points I've noted from past experience watching folks lay out booms that didn't work.

Testimony from Transocean employee, Chris Pleasant. who finally hit the EDS (from the live hearing on CNN web). When he reached the bridge he announced his intention to EDS. Captain told him to calm down and not activate EDS. BP Company Man Vidrine then told him to hit EDS ("Get us off Chris") out of the hearing of the captain - which he did. In later questioning he stated that he had authority to activate EDS himself and would have done so against the captain's instructions even if Vidrine had not given the go-ahead. Approximately 4 or 5 minutes later the captain told him to EDS and was told that it had already been initiated.

Further testimony. When he arrived on bridge lower BOP annular was closed but upper was open according to panel.

Second pressure test was done after anomalous results on first pressure test. Toolpusher Jason Anderson and others were of the opinion that first test anomaly was due to a "U-tube" but he could give no more information on this. second negative pressure test was apparently "good" as far as everyone was concerned.

New witness Gregory Mesh of mi-swaco now testifying.

Edit: Senior Toolpusher now testifying. He had been entertaining guests but spoke to duty Toolpusher Jason Anderson at 9:20pm who assured him that second negative pressure test was good and displacement activities were proceding normally. After hearing this he went to bed satisfied all was ok. At about 9:50pm he got a call in bed from driller Steve Curtis on the drilling floor to say they had a major problem, needed help and that Jason Anderson (testimony: considered one of Transocean's best well control experts) was shutting down the well. Before he could get to help there was a massive explosion.

Also testified that be believed up to that point they (BP/Transocean combo) had one of the safest operations there could be. Stated that he had never felt pressure from BP to cut corners. He stated the discussion (not an argument as some reported) earlier in the day was about performing a negative pressure test. The method favoured by Jimmy Harrell (Transocean) was agreed upon by all.

They are zeroing in on something. The Transocean lawyer is going nuts.

Yes the Transocean lawyer made sure he didn't answer what he thought happened in the last few minutes. T Boone Pickens said last night on Larry King that the blame aimed at BP is misdirected (I know many most strongly disagree but I'm just quoting what he said). He also said that when all is said and done we will see that plain and simple human error in the heat of the moment likely caused a major problem to become a disaster (and that it was something to do with the BOP) but these things happen very occasionally (even the most experienced pilots can crash a plane due to pilot error he pointed out) and we have to live with that he said.

He was certainly sounding like he knew something which has not been made public. Did someone on drill floor mistakenly open a closed BOP annular, which was containing a blow-out below it, I continue to wonder?

What I don't think most people realize is that disasters like this don't occur by the gross negligence of one individual or one company most of time. Its usually a combination of small, seemingly inconsequent errors that build up until the control of situation is lost and the dominos all fall down. So many people want to believe hte narrative that it was BP's fault that the whole thing went to hell, when the reality is that BP made an error (not doing a CBL, an admittedly hard to interpret log before displacing the mud), Transocean made an error (failing to ensure the BOP's complete integrity), Halliburton made an error (I'm not giving them a complete pass on their cement job), Camermon could have made an error (a different design BOP may not have failed). The combination of these seemingly small errors led to a disaster. The investigation will determine what the root causes of this accident are, but people need to realize that complex disasters don't boil down to simple causes.

Looks lik they have a "rigging crew" of ROV's at work right now. It appears they are attaching hook points and a setup for a crane to grab onto. This would all seem to be prepping to cut off the riser. Could still be days before they decide to cut off the riser, but they would be ready to start.

A few minutes ago somebody posted a link to the camera showing this operation--in a very clear view on a German Web site--but that post has vanished. Not sure why it was taken down, but here it is again:

http://www.bild.de/BILD/news/2010/05/28/quelle-am-meeresgrund/was-sprude...

What is the box-like thing the robots are attaching hooks to?

As I said before, they just embedd the feed from BP.

Here is the direct URL:

http://mfile.akamai.com/97892/live/reflector:46260.asx?bkup=46260

CNN hearings a lot more interesting atm though.They have an actual employee up now instead of some "higher up" guy spinning around.

It is a container for tools and equipment for the work of the ROVs. On the deck of a ship this container is filled with items needed by ROVs and then they plunge the container to the seabed.

That looks (just guessing) like a toolbox/equipment box from the surface. Which if they are attaching the hooks to it, makes what I said earlier make no sense.

I know this has been discussed to an extent already, but can someone knowledgeable speak to the record of relief wells (assuming now that this is going to have to be the answer) - seems like it will take 3-6 months or so at a minimum to complete the wells from what I have read so far, but how guaranteed is it to work? What will the effect be on reducing the pressure of the oil/mud now coming out of this busted well, etc.? Just curious to learn more here...

I've managed the drilling of 4 of them in my career, all successful as planned. I might add that none of them attempted to mill into casing but were targeted to be 50 ft from the bottom of the blowing well. When one gets that close or sooner sometimes, the bottom falls out of the relief well and its katy bar the door to pump mud to keep up with the lost returns into the blowing well. You have to be set up for that occurrence as we were and all went as planned with the kill happening on the first encounter. Keep in mind there will be a pressure sink in the formation around the blowing well which will aid in sucking the mud from the relief well. If you can flood the blowing well from the source of the BO, i.e. the formation that is producing or blowing, it won't make much difference whether the flow is up a cased well or around the casing(annular flow). It takes mucho planning to have the pumps on hand and the mud volumes required to kill a blowout from a relief well.

Given the high pressure of this formation and the possibility that it is a supercritical petrogas (as one commenter called it), does that make a relief well here more difficult than usual? How much more difficult, if so?

EDM,

very interesting comment. Do I have this straight. drill down just below the bottom of the blowing well and intercept the petro-gas flow going to the blown well. pump mud etc. from relief well into the flow resulting from the blown well and let that pull the mud up into the bottom of the blown well. sounds very elegant to me. Use the force of the reservoir to do the work for you. Currently, all plans being implemented or proposed go against the a very powerful flow. This approach appears superior to the relief well approach currently be implemented. Your four successful projects, were any in the DW environment with these kinds of pressures? Please excuse my ignorance. just a curious, very concerned old man. If you saw my comments last evening i have been encouraging taking a look at the down hole location for shutting this thing down. This looks like a solution that might work. What do you think Rockman, Heading out?

Haven't seen any video of the pipe since what appeared to be some kind of burst @9:20 am

Which pipe? More info please, just now waking up here.

Check out the vid that jessicainpensacola posted above...looks like something blew.

CNN is showing the multi-video display. Riser looks the same as it did last night.

RT @BP_America: Operations on top kill procedure continue. Estimated that full top kill procedure could extend for another 24 to 48 hours #oilspill #bp

Original Tweet: http://twitter.com/BP_America/statuses/14911724245

Any word about what happend earlier? Was there an explosion or is it just speculation? And is that impacting their Top Kill plans?

Thanks as always goose I appreciate the information.

Nothing else from the BP feed really (http://twitter.com/BP_America). They continue to lack transparency.

I mean, learn from freaking NASA, people. Tell us that ROV2 has an itch that ROV5 is going to scratch in 15 seconds--and from what angle--preferably with X, Y, AND Z coordinates. (Don't want to fall into the whole Wrath of Khan trap. *snicker*)

Guy who posted the vid clip said he thot that they were trying to knock mud off of the ROV.

Looks like things are getting pretty violent down there. I do not envy those guys who are operating those ROVs

if anyone's IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

prof.

why don't they simple arrange a flexible conduit, made from heavy oil resistant material and buoy it and anchor it to the surface of the gulf floor. an inverted cone/conduit to direct the oil/gas stream to the surface? it could all be directed to a series of booms that would corral the oil for collection by supertanker.

it won't stop the leak but at least it will allow it to be collected while the relief well is drilled.

Or just use the webchat version, download nothing.

http://webchat.freenode.net/

type your nick and #theoildrum

So that's better than being here?

CNN's Oceenering Video Portal is showing a shot of the top of the riser. Not sure how to interpret other than the holes look bigger.

So would it be reasonable to infer that debris from the junk shot broke through the holes in the riser pipe and widened them on the way out?

In one of the minor leaks, it appears some debris is constricting the crack. But overall very little change from yesterday, and it doesn't appear they are currently pumping mud either.

I should add, we are staring at these pinhole leaks on the bent riser. The major source of pressure loss is on the end of the riser. BP stated this am the junk shot was mildly successful, so I imagine they are recalibrating again for another, hopfully more success run later today or tonight.

I think they are on the right track now. I never did understand the logic behind the mud only "battle of rate flows". think of it like a tire with a small nail hole. they insist on inflating it with an overwhelming air supply. those familiar with the tire plugging additives ("slime" etc) know the first action is to plug the hole with particulate bridge material, then the added pressure can proceed to fill the tire.

I may be understanding things wrong, it seemed the original "junk shot" was portrayed as a means to push junk DOWN the bore in hopes of plugging the bore pipe. the same impression was taken away from the understanding of the mud only attempt. It seems a better attempt would have been to include some small amount of "junk" in with the mud. this would let the rubber chunks bridge the bop top leaks (the nail hole in the leaking tire analogy). then the preponderance of mud applied would be more effective to push down the oil column in the bore. it seems the old methods and usual ideas of standard "pumping mud" ignore the fact that there is a pressure relieving leak that does not allow the great mile column of mud pressure above to perform as they accustomed to.

The public's understanding of what is happening is based on technical information that's been through several rounds of the 'telephone' game with non-technical people.

I wouldn't assume anything you're hearing has anything to do with reality.

Gosh there sure is a lot of conflicting information out there.

We're told that the mud has, perhaps temporarily, stopped the flow of oil and gas. Yet CNN has a headline that would seem to indicate that they are NOT pumping mud at the moment but will resume doing so later today. But we can see that there is still high pressure flow from the holes in the riser which would indicate that the well is still flowing. Nobody seems to be telling the same story this morning.

BP and Coast Guard are doing a terrible job communicating status of the operation. No wonder people are beginning to distrust everything said. Sort of makes some of the armchair analysis that appears here pointless (but very interesting never the less).

FWIW: Like many of the people posting comments the last few days, I'm just a tourist here. I want to thank those with experience and know-how for their contributions (HO, sheldon, ROCKMAN, et.al.). I have to admit I am sorry you guys are sort of being drowned out by the number of commenters that have appeared once people discovered The Oil Drum is one of the few sites that provides any sort of analysis of the oil spill activity of the last few weeks.

It has been an incredible learning experience for me. Thanks.

-g.b.

If any measurement method could verify that fist 40 feet of well bore below BOP is free for drill pipe then

Clean cut well pipe below BOP. Remove BOP.

Oil/Gas flow increases to absolute maximum of well capasity > 50 000 bb pr day.

If well pipe below BOP has an diameter of 30"

Make a 60 feet pipe with outside diameter of 30.1"

Fill that with liquid nitrogen make weak seals at both ends.

Attach valves at top.

Lower the cold pipe which now has a diameter of 29.5" due to the cold nitrogen.

The pipe will slide down the existing well bore 40 feet.

The oil will push out the nitrogen thru the weak seals and the pipe start expanding as it heats up.

Now is the new pipe held in place mostly by extreme friction and a little help by its own weight.

Wait until pipe is finished heating up.

Close valves at top gradually and oil flow is stopped.

Have valves made ready below closing valves to pump in mud and when well is killed open valves go in and plug it.

After lurking a while, I decided to open an account here, so, first of all - Hello everyone and thanks for the great info so far.

Now let me say a few words to your suggestion, 8ball. I am no petro guy, but I have some experience with cryo-tech, albeit rather on a lab-scale than on a huge engineering scale. However, the problem I see here is the same as with other LN2 suggestions I have read in the last couple of days: How to get the stuff down there? If you just fill the pipe that you want to use for the press fit at the surface and lower it, you gotta take into account that the LN2 will boil off before you are halfway there - you got no insulation at all and it probably will take hours to get it into position. By the time you reach bottom, your pipe is at ambient temperature again. I have seen often enough how fast the stuff boils off when you start cooling down a cryomagnet from room temp to LN2 temp, even if it is encased in a Dewar. Lowering a Dewar is out of the question, too, as you need vacuum insulation to keep the LN2 liquid. That would simply be crushed by water pressure. Some engineer may correct me, but I just don't see a way.

Apart from that, even if you get the pipe down, the top valve will restrict the flow as soon as you lower it into the bore, exerting an upward force. How can it be forced down 40 feet against this pressure? Then there is the issue of embrittlement. As much as I like the idea of simply building an interference fit, but I don't see how it could be done.

You could bring the LN2 down in the large containers it comes in from the factory (200 or 300 bar) and use it to chill the structure at the bottom only. Those container bottles will have no problem withstanding the pressure at depth. Regarding containing a vacuum at that depth is equally difficult as containing atmospheric pressure like the inner sections of the ROV's: there is just 1 bar pressure difference between atmospheric pressure and a vacuum... while every 10 meters of water column equals 1 bar.

You are thinking of gaseous N2 - that comes at 200-300 bar. Liquid gases are largely pressure-free, you usually have an overpressure valve on the container that blows off evaporated gas. I am no expert on ROVs, but I doubt that they have any significant internal spaces held at 1 bar. Steel is awfully bad under compression load, so it would be way more sensible to equilibrate pressure.

Round (steel) cillinders are very capable of handling compressing load. Submarines, a bathyscaphe are designed as cillinders for that just reason. An ROV will have some airtight pressure free compartments, mainly for electronics, batteries and cameras etc.

Liquid nitrogen is stored in containers and evaporates slowly due to heat flux coming in from outside the container. The vapor causes the pressure in the container to rise from the initial 0 to e.g. 200 bar after which a safety valve will bleed the excess pressure. So a full container will be almost all liquid nitrogen and a little bit nitrogen gas. The internal pressure is higher then the surrounding pressure at depth so there really is no problem in getting LN2 down to that depth.

The top of the well bore is almost certainly not free of drill pipe.

How exactly are you going to get liquid nitrogen down to the bottom of the gulf of mexico?

gb -- let me offer a summary of where I think we are right now. I think I have all the facts but if not someone will point out the error. One confusion seems to be the source of the oil/NG leak. Some focus on the oil/NG coming out of different sections of the riser. The riser isn't the source of the oil/NG. It's coming out of the well head/BOP. Some of that flow may be entering the riser and leaking elsewhere out of it. But if every hole in the riser were plugged the same amount of oil/NG would be leaking into the GOM from the well head/BOP. As far as the top kill working I don't think we can tell that ourselves from watching the video. The top kill is a simple concept: pump drilling mud into the well head/BOP at a sufficient pressure to stop the oil/NG flowing out. If the connection between the well head/BOP and the line carrying the mud wasn't leaking then this would be a standard kill process: increase pump pressure high enough to push the oil/NG back down the csg into the rocks at the bottom of the well. But the connection apparently leaks like a sieve. An earlier report indicated they had pumped 30,000 bbls of mud down. But the csg in the blow out can only hold a max of 1,400 bbls of mud if it were completely filled. Obviously most of the mud leaked out.

Can we tell if oil/NG is flowing out of the well or if we're watching the drilling mud leaking out? We can't because we don't know exactly when they have the mud pumps working or not. Of course, BP knows. If they have the pumps off and they see something flowing out of the well head/BOP it can only be one thing: oil/NG. More importantly they would also know they haven't killed the well. If the pumps are on they will see lots of stuff flowing. Be it the mud leaking or the oil/NG continuing to flow is anyone's guess at that point. And killing a flowing well is exactly like being pregnant: you either are or you're not. You can't partially stop a well from flowing. If you did get some kill mud down the well but if it's still flowing then that mud is coming right back up and out the well. That is the basic definition of a blow out. If you've gotten enough mud down the hole to stop the flow then you've stopped the flow. But it might not be stopped for good. Any NG that might still be escaping into the well at the bottom can mix with the mud and lighten it enough to cause the head to be lost and begin the well flowing. Such "gas cut mud" is often the cause of many well control situations.

Again, maybe I missed something so please, anyone, point it out.

If the gas content were high enough (or if it's some kind of gas phase down there), what would keep the mud from running out the bottom and into the reservoir until the well was open again? The heavier liquid could hold down a lighter liquid (if they don't mix?), but I don't see what would prevent a gas from just bubbling through it.

Does anyone know what the well head pressure is?

Weeks old data, 8,000 to 9,000 psi below the BOP, seawater + 400 psi above the BOP.

Alan

Thanks Alan for info. Ya BOP not a wellhead my mistake

Not exactly sure what is going on down there, but I swear I saw one of the ROvs doing a seabed survey, then it started shaking violently, it panned over to one of the leaking riser pipes which had a huge plume coming out, and the screen went black. Now we are seeing a perfectly clear video. Why do I get the feeling we are watching old video right now? Theres no way things cleared up that quickly.

BP needs to fire their PR firm. They have no credibility left with me at all after this. Same for Thad Allen.

If I told my boss things were working over and over and their were live web cams clearly showing the contrary I'm pretty sure I'd be walked out the door in no time.

Good thing we at least have the webcam feeds, huh? How much worse would it be had people here (and elsewhere) not been so vocal in their protests?

Kinda reminds me of the scene at the end in Animal House, where the frat's "deathmobile" is driving into the stands, people are screaming, and Kevin Bacon is holding is hands up screaming "all is well...all is well."

Sorry for the intrusion, I've been following and reading since only last night. A huge wealth of knowledge and information and for that I thank you all.

Now to my question. If they stopped pumping yesterday and they are not currently pumping today, what exactly is spewing from that bent pipe? It doesn't look like oil, colorwise at least and it looks like the stuff that they said was mud. But if they aren't pumping or they have stopped the leak, what exactly is the yellow/brown stuff?

BP pumps the mud down the well. When they stop pumping, the well pressure pushes the mud back out through the leaks. They say they were testing the process, but now I'm not sure what they are doing. They seem to have attempted a junk shot to try and slow the leaks. Doesn't seem to be working to well yet.

So it is mud, wow how, since they are supposedly not pumping that's a whole lotta mud still in there. I am so confused.

roadchild,

Don't get the wrong impression from the videos. The stuff you're currently seeing venting probably contains a little bit of mud, but it's MOSTLY oil-gas mixture.

From what I understand, it looks deceptively red/brown because is is broken into a pretty fine dispersion by its high-velocity exit through the side of the riser.

Thanks for the explanation newdood, I guess I was just being hopeful.

This situation is just so beyond depressing.

My guess? A mix of lies, over-simplifications, misunderstandings and CYA.

:)

I'm inclined to be in full agreement.

"pumping out lies...best comment of the day