The bright future of solar powered factories

Posted by Rembrandt on August 8, 2011 - 10:20am

Most of the talk about renewable energy is aimed at electricity production. However, most of the energy we need is heat, which solar panels and wind turbines cannot produce efficiently. To power industrial processes like the making of chemicals, the smelting of metals or the production of microchips, we need a renewable source of thermal energy. Direct use of solar energy can be the solution, and it creates the possibility to produce renewable energy plants using only renewable energy plants, paving the way for a truly sustainable industrial civilization.

A large share of energy consumed worldwide is by heat. Cooking, space heating and water heating dominate domestic energy consumption. In the UK, these activities account for 85 percent of domestic energy use, in Europe for 89 percent and in the USA for 61 percent (excluding cooking).

Heat also dominates industrial energy consumption. In the UK, 76 percent of industrial energy consumption is heat. In Europe, this is 67 percent. I could not find figures for the US and for the world as a whole, but these percentages must be similar (and probably even higher on a worldwide scale because many energy-intensive industries have been outsourced to developing countries). Few things can be manufactured without heat.

Solar panels and wind turbines are no producers of heat energy

The importance of heat in total energy consumption sharply contrasts with our efforts to green the energy infrastructure. These are largely aimed at renewable electricity production using wind turbines and solar panels. Although it is perfectly possible to convert electricity into heat, as in electric heaters or electric cookers, it is very inefficient to do so.

The importance of heat in total energy consumption sharply contrasts with our efforts to green the energy infrastructure. These are largely aimed at renewable electricity production using wind turbines and solar panels. Although it is perfectly possible to convert electricity into heat, as in electric heaters or electric cookers, it is very inefficient to do so.

It is often assumed that our energy problems are solved when renewables reach 'grid parity' - the point at which they can generate electricity for the same price as fossil fuels. But to truly compete with fossil fuels, renewables must also reach 'thermal parity'.

Though today in some locations it may be as cheap to produce electricity with wind or solar energy as with gas or coal, it still remains significantly cheaper to produce heat with oil, gas or coal than with a wind turbine or a solar panel. This is because it takes 2 to 3 kWh of fossil fuel thermal energy to create 1 kWh of electricity, so it is at least 2 to 3 times cheaper to make heat by simply burning the fossil fuels directly than to use an electric renewable technology at grid parity.

Manufacturing wind turbines and solar panels requires heat

This means that solar panels and wind turbines will have to become two to three times cheaper than they are today in order to reach thermal parity with fossil fuels. This might sound reasonably possible, especially if you expect fossil fuel prices to rise. But consider this: even though they are intended to replace fossil fuels, renewable energy sources like wind turbines and solar panels are in fact dependent on a continuous supply of fossil fuels.

Solar panels and wind turbines do not need fossil fuels to operate, but they do need fossil fuels for their production. You won't find any factory manufacturing PV solar panels or wind turbines using energy from their own PV solar panels or wind turbines. Why not? Because it is very inefficient (and thus utterly expensive) to convert electricity into heat. Yet to make solar panels and wind turbines, to produce steel and silicon for instance, heat is what is most needed. This means that the production costs of solar panels and wind turbines will be affected negatively by rising fossil fuel prices.

The same goes for batteries, which are an essential element of electric cars and renewable electricity storage, and for many other modern green technologies, like LEDs and heat pumps. They require heat for their production, and this heat can be delivered at least 2 to 3 times cheaper by burning fossil fuels than by using wind turbines or solar panels (cheap electricity from hydropower plants is also an option, but has limited potential). This is a fundamental problem, because we will have to produce new wind turbines and solar panels every 20 to 30 years, and new batteries every 5 to 10 years.

The same goes for batteries, which are an essential element of electric cars and renewable electricity storage, and for many other modern green technologies, like LEDs and heat pumps. They require heat for their production, and this heat can be delivered at least 2 to 3 times cheaper by burning fossil fuels than by using wind turbines or solar panels (cheap electricity from hydropower plants is also an option, but has limited potential). This is a fundamental problem, because we will have to produce new wind turbines and solar panels every 20 to 30 years, and new batteries every 5 to 10 years.

Renewable source of heat energy

The missing element in our sustainable energy strategy is a renewable source of thermal energy. Geothermal energy produces heat, but for now it is mostly economical in regions that lie on the boundaries of tectonic plates, as there temperatures are higher closer to the surface. Biomass is another option, but it faces many problems. If we were to try to provide an important share of heat demand by burning biomass, we would quickly come up against the limits of what the planet can produce. There is only one source of heat energy left, and it is a powerful and inexhaustible one: solar energy.

We tend to see solar energy as yet another way to generate electricity, using photovoltaic panels or solar thermal power plants. But solar energy can also be applied directly, without the intermediate step of generating electricity. Basically, harvesting direct solar energy can happen in two ways: by means of water-based flat plate collectors or evacuated tube collectors, which collect solar radiation from all directions and can reach temperatures of 120 °C (248 °F), and by means of solar concentrator collectors, which track the sun, concentrate its radiation, and can generate much higher temperatures. These can be parabolic trough systems, linear concentrating Fresnel collectors, parabolic dish systems or solar power towers. Almost all of these technologies were developed at the turn of the 20th century.

Solar thermal power versus solar thermal heat

The problem is that we mostly use this technology for the wrong purpose. In today's solar thermal plants, solar energy is converted into steam (via a steam boiler), which is then converted into electricity (via a steam turbine that drives an electric generator).

The problem is that we mostly use this technology for the wrong purpose. In today's solar thermal plants, solar energy is converted into steam (via a steam boiler), which is then converted into electricity (via a steam turbine that drives an electric generator).

This process is just as inefficient as converting electricity into heat: two-thirds of energy gets lost when converted from steam to electricity. This is one of the main reasons why the use of solar thermal energy to produce electricity is only cost-effective in deserts.

If we were to use solar thermal plants to generate heat instead of converting this heat into electricity, the technology could deliver energy 3 times cheaper than it does today and become cost-effective also in less sunny regions. The crucial difference between solar thermal electricity and other renewables producing electricity is that solar thermal actually starts with heat energy. Thus, contrary to other renewables, the cost of heat energy using the technology is far lower than the cost of electricity, and so it can compete with burning fossil fuels at the thermal level.

Low temperature solar heat

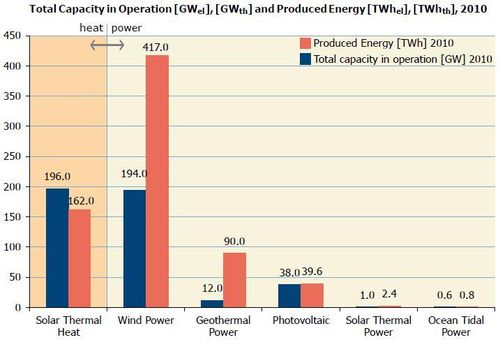

This can be demonstrated by flat plate collectors and evacuated tube collectors, which are used for domestic hot water preparation and (to a lesser extent) interior space heating. This technology is used without any conversion losses and is cost-competitive with fossil fuels almost anywhere on Earth. According to the 2011 update (pdf) of the International Energy Agency's Solar Heating and Cooling Programme (IEA-SHC), solar thermal heat is now the second most important renewable energy source following wind, and a much more important energy source than photovoltaics and solar thermal power plants. Almost 60 percent of solar thermal heat capacity can be found in China and another 20 percent is in Europe. The US and Canada (where the main application is to heat swimming pools) account for less than 9 percent.

Sweden, Denmark, Spain, Germany and Austria have the most sophisticated markets for different solar thermal applications, including large-scale plants for district heating and a small but growing number of systems for air conditioning and cooling (using an absorption chiller). By the end of 2009, 115 solar supported district heating networks and 11 solar supported cooling systems were installed in Europe. Canada, Saudi Arabia and Singapore have also built a few large-scale solar heat systems for producing hot water, space heating and cooling.

The potential of solar heat for industrial processes

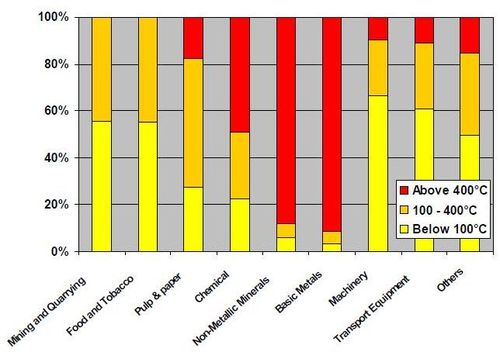

Without a doubt, solar heat for domestic purposes should continue to be encouraged and a lot of potential remains. But it does not stop there. According to a 2008 report (pdf), which analyses the situation in Europe, the potential for solar heat in industrial processes is even larger than in the domestic market. About 30 percent of industrial heat demand in Europe is below 100 °C (212 °F), which could be delivered by commercially available flat plate collectors (< 80 °C) and evacuated tube collectors (< 120 °C) currently used for domestic purposes.

Another 27 percent of industrial heat demand requires medium temperatures (100 to 400 °C or 212 to 752 °F), which could be reached by improved versions of these collectors (up to 160 °C, see this document) and by commercially available solar concentrator technologies now mostly used for electricity production: parabolic troughs, parabolic dishes and linear concentrating Fresnel collectors.

This means that at least 57 percent of heat demand in European industry (or almost 40 percent of total industrial energy demand) could be covered by available and cost-effective technology using an inexhaustible renewable energy source that has no ecological disadvantages whatsoever. The capital costs (and embodied energy) of this would be much less than replacing a similar amount of fossil fuel energy use with solar panels or wind turbines. And of course, it could be done anywhere, not just in Europe.

Solar heat in industry: existing applications

At low and medium temperatures, solar heat can be used for industrial processes in several ways. It can provide warm water for processes like bottle washing or chemical processes. Secondly, it can provide hot air for drying and baking processes, for instance in the food and paper industries. Thirdly, it can generate steam that can be fed into steam heat distribution networks, which are widely used in many industries. The interesting thing is that in all these applications, the existing industrial machinery and distribution infrastructure remains in place. Only the energy source is replaced.

At low and medium temperatures, solar heat can be used for industrial processes in several ways. It can provide warm water for processes like bottle washing or chemical processes. Secondly, it can provide hot air for drying and baking processes, for instance in the food and paper industries. Thirdly, it can generate steam that can be fed into steam heat distribution networks, which are widely used in many industries. The interesting thing is that in all these applications, the existing industrial machinery and distribution infrastructure remains in place. Only the energy source is replaced.

Some manufacturers have started marketing their solar concentrator technologies for the use of heat generation in industry, in addition to their application as electricity generators. Examples are Sopogy (a Hawaian company that sells modular parabolic trough systems - picture above), the Solar Power Group (a German company that sells linear concentrating Fresnel collectors) and HelioDynamics (an American seller offering similar technology - picture below).

Installations for the use of solar industrial process heat are still rare, but they exist. German heating systems manufacturer Viessmann installed 260 m² of its own flat plate collectors on its factory in France to provide hot water for a chemical process, taking a first step towards producing renewable energy using renewable energy. A solar thermal plant based on 1,900 m² of parabolic troughs provides steam for a pharmaceutical plant in Egypt. A similar solar thermal plant was built for a dairy plant in Greece. A food processing facility in California has 5,000 m² of parabolic troughs to produce steam used in the manufacturing process. Several industrial applications of solar heat have been built in India, using both flat plate collectors and concentrator technologies.

Installations for the use of solar industrial process heat are still rare, but they exist. German heating systems manufacturer Viessmann installed 260 m² of its own flat plate collectors on its factory in France to provide hot water for a chemical process, taking a first step towards producing renewable energy using renewable energy. A solar thermal plant based on 1,900 m² of parabolic troughs provides steam for a pharmaceutical plant in Egypt. A similar solar thermal plant was built for a dairy plant in Greece. A food processing facility in California has 5,000 m² of parabolic troughs to produce steam used in the manufacturing process. Several industrial applications of solar heat have been built in India, using both flat plate collectors and concentrator technologies.

A solar concentrator system called ARUN - a Fresnel parabolic reflector with point focus that delivers temperatures from 80 to 400 °C - has been installed in six industries, ranging from a dairy plant to an automobile manufacturer (picture on the left). India also has several large solar cooking facilities for community kitchens (schools, hospitals, factories, religious centres). The largest one consists of 84 parabolic dish systems reaching temperatures of up to 650 °C and producing up to 38,500 meals per day. The largest solar process heat application to date was recently installed in Hangzhou, China, where 13,000 m² of solar collectors on the roof of a textile factory provide hot water for a dyeing process. The Global Solar Thermal Energy Council is continually updating its list of new industrial applications of solar heat.

A solar concentrator system called ARUN - a Fresnel parabolic reflector with point focus that delivers temperatures from 80 to 400 °C - has been installed in six industries, ranging from a dairy plant to an automobile manufacturer (picture on the left). India also has several large solar cooking facilities for community kitchens (schools, hospitals, factories, religious centres). The largest one consists of 84 parabolic dish systems reaching temperatures of up to 650 °C and producing up to 38,500 meals per day. The largest solar process heat application to date was recently installed in Hangzhou, China, where 13,000 m² of solar collectors on the roof of a textile factory provide hot water for a dyeing process. The Global Solar Thermal Energy Council is continually updating its list of new industrial applications of solar heat.

Renewables building renewables

The remaining 43 percent of industrial heat demand in Europe is above 400 °C (752 °F). These include many of the industrial processes that we need to manufacture renewable energy sources (wind turbines, solar panels, flat plate collectors and solar concentrators) as well as other green technologies (like LEDs, batteries and bicycles). Examples include the production of glass (requiring temperatures up to 1,575 °C) and cement (1,450 °C), the recycling of aluminum (660 °C) and steel (1,520 °C), the production of steel (1,800 °C) and aluminum (2,000 °C) from mined ores, the firing of ceramics (1,000 to 1,400 °C) and the manufacturing of silicon microchips and solar cells (1,900°C ).

These temperatures can be achieved by solar concentrator technology. Linear reflectors (parabolic trough systems and linear concentrating Fresnel collectors) are limited to temperatures of about 400 °C, but point concentrators can reach higher temperatures. These include parabolic dish systems, solar power towers, and solar furnaces - which are basically a combination of power towers and parabolic dish systems.

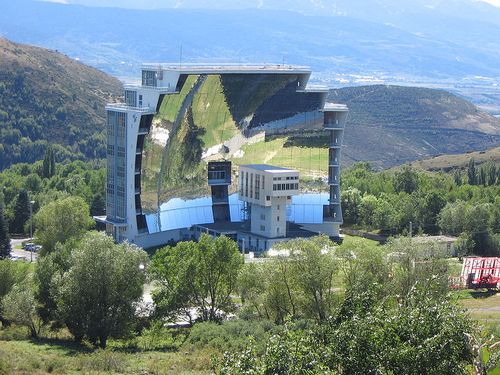

Solar furnaces can produce temperatures up to 3,500 °C (6,332 °F), enough to manufacture microchips, solar cells, carbon nanotubes, hydrogen and all metals (including tungsten which has a melting point of 3,400 °C). These temperatures can be achieved in just a few seconds - see this short video of a solar furnace melting steel. The most powerful solar furnace is the one at Odeillo in France, built in 1970, which concentrates the light of the sun 10,000 times and has a power output of 1 MW.

Solar furnaces can produce temperatures up to 3,500 °C (6,332 °F), enough to manufacture microchips, solar cells, carbon nanotubes, hydrogen and all metals (including tungsten which has a melting point of 3,400 °C). These temperatures can be achieved in just a few seconds - see this short video of a solar furnace melting steel. The most powerful solar furnace is the one at Odeillo in France, built in 1970, which concentrates the light of the sun 10,000 times and has a power output of 1 MW.

More than 60 heliostats (only one is seen on the picture above, in the lower righthand corner) direct the rays of the sun onto a parabolic mirror of more than 1,800 square metres, from which they are concentrated on a focal point with a diameter of only 40 centimetres in the tower in front of it. A similar solar furnace stands in Uzbekistan, built in 1976, but it is slightly less powerful due to lower solar insolation in the region. The picture on the right shows it in action, melting metal.

More than 60 heliostats (only one is seen on the picture above, in the lower righthand corner) direct the rays of the sun onto a parabolic mirror of more than 1,800 square metres, from which they are concentrated on a focal point with a diameter of only 40 centimetres in the tower in front of it. A similar solar furnace stands in Uzbekistan, built in 1976, but it is slightly less powerful due to lower solar insolation in the region. The picture on the right shows it in action, melting metal.

You don't need such an enormous structure to achieve high temperatures. Several smaller solar furnaces have been built, often using only one heliostat. They reach similar or only slightly lower temperatures (usually between 1,500 and 3,000 °C) than the giants pictured above, though at significantly lower power outputs (between 15 and 60 kW). They can perform most of the same processes as the large solar furnaces, but processing smaller amounts of materials or chemicals.

You don't need such an enormous structure to achieve high temperatures. Several smaller solar furnaces have been built, often using only one heliostat. They reach similar or only slightly lower temperatures (usually between 1,500 and 3,000 °C) than the giants pictured above, though at significantly lower power outputs (between 15 and 60 kW). They can perform most of the same processes as the large solar furnaces, but processing smaller amounts of materials or chemicals.

Examples of smaller solar furnaces can be found at the Paul Scherrer Institute in Switzerland (pictured below right), the National Renewable Energies Laboratory in the USA, the Plataforma Solar de Almería in Spain, the German Aerospace Center in Germany, and the Weizmann Institute of Science in Israel (a solar power tower). They have concentration ratios between 4,000 and 10,000. In solar concentration, the temperature is proportional to the degree of concentration, whereas power will be proportional to size and efficiency (which is mostly determined by temperature).

Solar energy improves product quality

Solar furnaces not only have the potential to replace fossil fuels for the energy-intensive production of construction materials, chemicals, and high-tech products like microchips and solar cells, but they also offer additional benefits because of their pure combustion and selective heating capacities. A 1999 research paper describes the manufacturing of silicon solar cells using a solar furnace, concluding that "solar furnace processing of silicon solar cells has the potential to improve cell efficiency, reduce cell fabrication costs, and also be an environmentally friendly manufacturing method. We have also demonstrated that a solar furnace can be used to achieve solid-phase crystallization of amorphous silicon at very high speed."

As opposed to low and medium temperature processes in industry, where only the energy source is replaced and the machinery and distribution infrastructure can remain in place, most high temperature solar heat applications require new machinery. Furnaces and kilns have to be rebuilt. Some efforts have been made. The Paul Sherrer Institute in Switzerland designed several solar powered lime and cement kilns (pdf), and research concluded that they could become cost-competitive with a fossil fuel powered kiln (pdf) following some further technological improvements. Again, the quality of the product turned out to be better using solar energy, eliminating combustion by-products.

Low-tech, open source solar concentrators

Though existing solar funaces prove that anything could be produced using direct solar heat instead of fossil fuels, this is not yet possible in a cost-effective way (it is cheaper to use fossil fuels). However, since solar furnaces could produce all materials needed to build more solar furnaces, they might become cost-effective even without technical improvements if fossil fuels become more expensive.

Though existing solar funaces prove that anything could be produced using direct solar heat instead of fossil fuels, this is not yet possible in a cost-effective way (it is cheaper to use fossil fuels). However, since solar furnaces could produce all materials needed to build more solar furnaces, they might become cost-effective even without technical improvements if fossil fuels become more expensive.

Moreover, the capital costs of solar concentrators are decreasing quickly following some recent innovations aimed at simplifying the technology. These might not only lead to cheaper high temperature solar heat concentrators in the future, but they also make the use of solar heat for medium temperatures more affordable and competitive today.

The most spectacular example is the Solar Fire P32 (picture above and pictures below), a solar concentrator developed in 2010 by the French NGO the Solar Fire Project. It is an open source design (joining forces with the Open Source Ecology project), but the machine can also be bought for 7,500 euro - less than the price of an urban wind turbine.

The Solar Fire P32 is built using simple, abundant and non-toxic materials. Contrary to most other modern green technologies, there is no need for rare earth metals or advanced tools that are not found in an average metal workshop. Essentially, this is a renewable source of heat energy analogous to home made windmills used to produce mechanical energy.

The Solar Fire P32 is built using simple, abundant and non-toxic materials. Contrary to most other modern green technologies, there is no need for rare earth metals or advanced tools that are not found in an average metal workshop. Essentially, this is a renewable source of heat energy analogous to home made windmills used to produce mechanical energy.

The machine can deliver up to 15 kW and can reach a focal temperature of 700 °C (1,292 °F), enough to melt (and thus recycle) aluminum, the material that is used to make its reflectors. This means that you could use a Solar Fire P32 to make another Solar Fire P32. Or almost. The receiver and the supporting structure are made of steel, which requires a higher melting temperature to recycle. However, the structure could as well be made of wood, bamboo, organic fibre or aluminum, and the steel receiver could easily be scavenged material. The use of glass improves the workings of the device, but is not strictly necessary.

The Solar Fire P32 is composed of 360 small mirrors with a total surface of 32 square metres, focusing sunlight on a steam boiler above them. The steam can be used directly to purify large quantities of water, boil milk, produce edible oils, make charcoal, bake bricks, make paper, and so on.

Increasing energy autonomy

The steam can also drive a steam engine to directly power a water pump, oil and grain mills, cotton spinning, or any other stationary application requiring mechanical power. Connected to a steam generator, the machine can also generate electricity (up to 3 kW). These two last applications involve conversion losses, but they are interesting additions for those who want to achieve energy independence, especially in regions where there is lots of sun but no wind. The machine can produce heat, electricity and direct mechanical energy.

The steam can also drive a steam engine to directly power a water pump, oil and grain mills, cotton spinning, or any other stationary application requiring mechanical power. Connected to a steam generator, the machine can also generate electricity (up to 3 kW). These two last applications involve conversion losses, but they are interesting additions for those who want to achieve energy independence, especially in regions where there is lots of sun but no wind. The machine can produce heat, electricity and direct mechanical energy.

The Solar Fire P32 is - in the first place - aimed at developing countries and designed to be cost-effective compared to burning coal and wood, reducing deforestation and pollution, increasing energy autonomy, and providing an energy source at the scale of traditional practices and small industries. It has been built in Mexico, Cuba, Burkina-Faso, Mali, India and Kenya, but also in Texas, France and Canada. Obviously, the design could also be useful in the developed world, where the supply of fossil fuels might not remain as easily accessible as it is today.

Simplifying technology

Apart from the additional equipment that is required to generate electricity, conventional solar concentrator technologies demand heavy capital investments for several reasons. Parabolic trough systems and parabolic dish systems require curved mirrors that are expensive to produce. Moreover, these mirrors cannot be manufactured locally and often have to be transported over long distances, increasing costs further. In both systems the curved mirrors are large and heavy, requiring rigid frames, strong foundations, powerful hydraulics and sophisticated tracking systems to follow the sun. In parabolic dish systems, the heat engine or steam boiler is part of the moving structure, increasing weight and thus making things even worse.

Apart from the additional equipment that is required to generate electricity, conventional solar concentrator technologies demand heavy capital investments for several reasons. Parabolic trough systems and parabolic dish systems require curved mirrors that are expensive to produce. Moreover, these mirrors cannot be manufactured locally and often have to be transported over long distances, increasing costs further. In both systems the curved mirrors are large and heavy, requiring rigid frames, strong foundations, powerful hydraulics and sophisticated tracking systems to follow the sun. In parabolic dish systems, the heat engine or steam boiler is part of the moving structure, increasing weight and thus making things even worse.

Solar power towers - which were invented in 1878 - solve some of these issues: they use nearly flat mirrors and all mirrors share one stationary receiver. But, they require the construction of a large tower building. Last but not least, all of these systems have very high land requirements because of overshadowing issues. Linear Fresnel concentrators use (mostly) flat mirrors, have simpler tracking systems and are more compact, but they can only reach temperatures of 250 °C (using relatively low-tech materials) or 450 °C (using sophisticated technology).

The Solar Fire is a Fresnel parabolic reflector with point focus, just like ARUN - but unlike that machine it is placed horizontally and the receiver does not have to be turned together with the mirrors, resulting in light weight and high wind resistance. The machine uses slightly curved mirrors, achieved by mechanical bending which can be done on the spot. Sun tracking of the mirrors is done by hand, eliminating the need for electronics and electric motors altogether (multiple mirrors can be turned at once using hand operated wheels). This might sound crude, but for industrial applications the machine has to be supervised anyway.

The Solar Fire is a Fresnel parabolic reflector with point focus, just like ARUN - but unlike that machine it is placed horizontally and the receiver does not have to be turned together with the mirrors, resulting in light weight and high wind resistance. The machine uses slightly curved mirrors, achieved by mechanical bending which can be done on the spot. Sun tracking of the mirrors is done by hand, eliminating the need for electronics and electric motors altogether (multiple mirrors can be turned at once using hand operated wheels). This might sound crude, but for industrial applications the machine has to be supervised anyway.

And because it is open source, it can be further improved by anyone. Eerik Wissenz, the designer of the machine, thinks this is the only way: "Companies pursuing patents for solar collectors have fallen into a complexity trap. Since solar energy is free it is far simpler to add 5 percent more surface area instead of creating complex machines too expensive to be commercially viable. Solar fire concentration is so simple it cannot be patented."

Low-tech solar furnaces

High temperature solar furnaces can be low-tech autonomous systems, too. One example is the large magnifying glass used by Sundrop Jewelry, which reaches high enough temperatures to melt coloured bottle glass into handcrafted jewelry. Of course the power output is low, making this installation useless if you want to produce industrial quantities of glass. But it shows that solar heat can be used on any scale.

Another example is the Solar Sinter Project by Markus Kayser, in which glass is produced using only sunlight and desert sand. I would like to quote the artist here: "Whilst not providing definitive answers, this experiment aims to provide a point of departure for fresh thinking".

Another example is the Solar Sinter Project by Markus Kayser, in which glass is produced using only sunlight and desert sand. I would like to quote the artist here: "Whilst not providing definitive answers, this experiment aims to provide a point of departure for fresh thinking".

Storage

How can you power factories using an energy source that is not always available? Solar insolation varies throughout the day and the seasons, and there is no sun at night. Moreover, solar concentrator technologies only work with unscattered sunlight, which means that a passing cloud stops energy production. This raises two questions. Some industrial processes work fine with intermittent energy supply, but how do you guarantee an uninterrupted supply of energy to a process that requires it? And what do you do when there is no sun at all for a week?

There are three ways to deal with the intermittency of solar power. The first solution is to design hybrid systems: make solar and already existing energy sources work together. This is how most of today's solar thermal power plants work. In this scenario, which offers a solution for both short and long term storage, industrial processes are powered by solar heat whenever it is available. When it is not, solar energy is instantly replaced by fossil fuels or electricity. It is not an ideal solution, but it could save large amounts of energy. And we don't need new technology to make it work.

The second strategy is to store solar energy so that it can be used to smooth out industrial processes (analogous to a flywheel for smoothing out mechanical processes) and to guarantee energy supply on cloudy days or at night. Storage of heat is much cheaper and more efficient than storage of electricity. The most low-tech way is to store heat in well-insulated water reservoirs - another technology that is more than 100 years old. The disadvantages are that you need quite a lot of space, and that water storage only works up to a temperature of 100 °C (212 °F). There are more compact ways to store heat at higher temperatures, for example by using ceramics or phase-changing materials (certain salts). These storage media are already used in one solar thermal power plant, but they would be even more efficient if used in a thermal only system. Innovative technology could further improve heat storage.

The second strategy is to store solar energy so that it can be used to smooth out industrial processes (analogous to a flywheel for smoothing out mechanical processes) and to guarantee energy supply on cloudy days or at night. Storage of heat is much cheaper and more efficient than storage of electricity. The most low-tech way is to store heat in well-insulated water reservoirs - another technology that is more than 100 years old. The disadvantages are that you need quite a lot of space, and that water storage only works up to a temperature of 100 °C (212 °F). There are more compact ways to store heat at higher temperatures, for example by using ceramics or phase-changing materials (certain salts). These storage media are already used in one solar thermal power plant, but they would be even more efficient if used in a thermal only system. Innovative technology could further improve heat storage.

Storing work instead of energy

The third way to deal with the intermittency of solar heat is to store work instead of energy. We let our factories work when the sun shines, and only when the sun shines. Just like we wait for a sunny day to do the laundry, we could wait for a sunny day to bake bricks, recycle metal or produce smartphones. Industrial production would be concentrated in summer months. Of course, there is a price to pay. Industrial production would be lower. But considering the fact that our energy and environmental problems are largely caused by overproduction and overconsumption of goods, this is not as far-fetched as it might seem.

Combining all three strategies could be a solution. In that scenario we would run part of our factories only when the sun shines (and when the wind blows), using heat storage, fossil fuels, biomass or electricity to smooth out industrial processes if necessary. Critical goods could be produced continuously combining solar heat and heat storage, fossil fuels, or biomass. Of course, not all climates are blessed with enough sun to make solar heat a viable option to power the whole industry. But since many people are now talking about outsourcing electricity production to desert regions, we could just as well move our factories to regions where there is plenty of sun. It is much more efficient to transport manufactured goods over large distances than to transport electricity.

Solar powered enhanced oil recovery

As always, a sustainable technology can be used for unsustainable purposes. Solar heat is a great way to get more oil out of fields that are now considered exhausted. Getting that remaining oil out using gas would cost more money and energy than the oil could return, but using a free source of energy changes everything.

At least one company specializes in this application. Glasspoint, a US firm originally founded to use solar heat for drying gypsum wall board, has seen remarkable growth promoting "Solar Enhanced Oil Recovery".

This has been tried before, but they use an innovative technology: parabolic trough mirrors suspended from the ceiling of enormous glasshouse structures that are equipped with robotic cleaning systems. Because they are protected from wind, sand and dust by the greenhouse, the mirrors can be made extremely light and without protective glass layers - lowering their costs and increasing their efficiency. The steam that is generated by the solar heat is pumped into the oil reservoir. The more sun there is, the more oil will come to the surface. Only 20 to 40 percent of an oil field can be recovered using standard techniques, but as much as 60 to 80 percent can be recovered using solar heat. In the end, solar heat could thus increase fossil fuel production and CO2-emissions.

Kris De Decker (edited by Rachel Meyer)

Sources, inspiration & more information:

- The thermal problem and the solar (thermal) solution, Eerik Wissenz, 2011.

- Concentrating Solar Concentrators at the Build it Solar Site. Lots of links to DIY-projects. Thanks to Paul Nash.

- High temperature solar collectors, Robert Pitz-Paal, in 'Solar Energy Conversion and Photoenergy Systems'.

- Direct Use of the Sun's Energy

, Farrington Daniels, 1964.

- Task 33 - Solar heat for industrial processes, Solar Heating and Cooling Programme, International Energy Agency.

- Potential for Solar Heat in Industrial Processes (pdf), Claudia Vannoni, Riccardo Battisti and Serena Drigo, Task 33

- Process Heat Collectors - state of the art within task 33/IV (pdf), Werner Weiss and Matthias Rommel

- Solar thermochemical process technology, Aldo Steinfeld & Robert Palumbo, 2001

- Solar Heat Worldwide 2011 (pdf), SHC, Werner Weiss & franz Mauthner, may 2011

- The Value of Concentrating Solar Power and Thermal Energy Storage, National Renewable Laboratory, 2010

- Understanding solar collectors, George Kaplan, 1985

- Global Solar Thermal Energy Council.

- So-Pro: European project on solar process heat

- European Solar Thermal Industry Association

- The European Alliance SolLab

- SolarPACES

- CSP- how it works

Thanks, very informative.

Yes, a wonderful article.

BTW, see the campfire-driven fridge (that could be solar powered) developed by Adam Grosser here:Adam Grosser: A new vision for refrigeration (youtube video). (In 2007, Adam Grosser presented his research of a new, very small, "intermittent absorption" refrigeration system for use in third world countries at the TED Conference. The refrigerator is a small unit placed over a campfire, that can later be used to cool 3 gallons of water to just above freezing for 24 hours in a 30 degree Celsius environment.)

>In 2007....

That's over three years ago, so where's he at now with his project?

Probably stuck in 1927 with David Forbes Keith next to the Crosley IcyBall. http://crosleyautoclub.com/IcyBall/crosley_icyball.html

As this is about using 'heat' to do 'work' http://www.energy-concepts.com/isaac - the ISAAC Solar Ice Maker.

If one wants one today - http://crosleyautoclub.com/IcyBall/HomeBuilt/HallPlans/IB_Directions.html

ISTR a scheme like that written up (Home Power?) which used CaCl2 as a solid sorbent for NH3 (here's a paper). This eliminates the need for a water separator. Bulk CaCl2 seems to sell for about 10¢/lb ($200/ton).

I think the lessons here are:

So who's mass producing the equipment we're discussing and where is it commonly used?

Nobody's making it. Currently it's too cheap to use conventional refrigeration and batteries. But such systems are simple enough to be built by amateurs, and in a crisis situation you can bet they would be.

A bit of a discussion about that over here: http://www.theoildrum.com/node/8255#comment-827179

And I note that you've been straightened out regarding the technology requirements. Absorption systems were commercial products in the 1920's, and could have been built with 19th-century materials and practices. All else that's needed is the knowledge that it can be done.

I'm not your average noob when it comes to refrigeration tech. I'm a former HVAC installer and refrigeration and heating serviceman.

Absorption systems are still commonly manufactured as small propane powered units in motorhomes and campers, and large scale commercial and industrial refrigeration systems.

Great. How does that address the issue of what people would do if e.g. electricity was intermittent (as it currently is not) and they wanted their refrigeration to be reliable?

Much less material and less awkward to simply power a regular refrigerator with some PV.

How do you do this if several million people suddenly want PV too? How do people invest in all that PV if they can't afford to maintain their electric grid? Pushing PV as a civil-defense measure might work (keep things running if storms or sabotage take the grid down), but once the problems hit it's too late.

The beauty of absorption systems is that they are dumb. They require no high-tech parts or sophisticated fabrication techniques. They can be built from junk. If you are looking for a fallback which can be implemented with local resources in a period of disrupted financial systems or supply lines, that's the way to go.

Oh sure, they're fantastic systems, yet all you can link to is instructions on how to make one. No citations that anyone in the world is mass producing them. They're fantastic systems, yet no one wants to take the plunge and mass produce them. Not even for charity for people in developing countries.

I wonder what the reason for that is....

"How do people invest in all that PV if they can't afford to maintain their electric grid?"

How will a society afford to maintain an ammonia manufacturing plant if they can't afford to maintain transmission infrastructure?

Interesting question. Maybe concern about high pressure, noxious gas within the home? Can efficiency figures be met? I don't know but it does seem odd that if they are so good that we do not see them on the shelf. Mind you, look at all the kicking and screaming to get efficiency up for normal fridges, maybe it isn't that odd.

NAOM

Good little subthread here.

I know the specialist service guy for RV absorption fridges in Calgary. He does a great business servicing these things. He also has a separate company that builds small RV trailers - and the fridges he puts in there - 12V marine fridges, that can be powered by a 30W folding solar panel and one car sized deep cycle battery.

His opinion - despite the apparent simplicity of the absorption fridges, they are just too high maintenance/low performance.

Now, this is not to say an absorption fridge can't be made reliable, but I think the key thing would be to move away from ammonia to some other less toxic, easier to use material.

If the performance parameters are such that it only needs to provide refrigeration, rather than freezing, then perhaps there are more options available.

Since no one has taken the plunge to produce such systems, maybe this would be an appropriate candidate for some government funding. Get a new, ammonia free, design made, at both small and large scale, and then start implementing them. There would be a large market in the southern US for these systems on all sorts of buildings, from schools to military bases. Given the large amount of fuel used by the military for A/C at bases, they might well be interested in joint funding for small, portable sun powered units.

I doubt we'll see any such action from any of the existing refrigeration companies - they are too heavily invested in what they currently do.

Although ammonia isn't something you want to breath high concentrations of, it's not environmentally harmful. It's a byproduct of our metabolism in small concentrations, and you might get a good whiff of it while turning a dry compost pile. It's not uncommon for folks putting only grass clippings or similar in a pile, to create an environment more favorable to bacteria that produce a lot of ammonia.

My first experience with an absorption system was as an HVAC installer working a remodel of a home in Bel Air Estates, an exclusive community in Los Angeles. I went to cut the refrigerant lines to let out the refrigerant, and was surprised to find they were steel. Not yet having been trained in refrigeration tech, I got a metal blade and proceeded to cut the lines. The resulting cloud of ammonia prompted a visit from the LAFD and the neighborhood evacuated.

This was in 1980, before refrigerants had to be recovered.

There was a time when natural gas powered absorption refrigerators were relatively common in homes. As far as what your friend says, I think the weakest link in an absorption system is the burner. Usually something a simple cleaning will take care of. Following is a link to a company selling absorption refrigerator/freezers recommended for PV: http://polarpowerinc.com/products/refrigerator/index.htm

The following site has answers to just about any question one might have about absorption systems, although it looks like a natural gas industry website (annoys me): http://www.gasairconditioning.org/index.htm

Any encouragement to burn more fossils annoys me.

You can make ammonia by decomposition of urea. It's also a widely-used agricultural chemical and doesn't require an intact just-in-time delivery system.

You want a new one? Here's a product description.

There's currently no market for absorption backup systems, because the people who need backup are using generators instead. Folks who are predicting a fast collapse ought to realize that people will shift to make use of what's available; if gasoline goes away, the generators won't work but the rocket stoves will.

Edit: Here's an NYT blog item on liquid-dessicant dehumidifier systems. Conditioning air with less electricity (or possibly none, if the system is regenerated with solar heat) is one way to have more good out of less FF use.

New Solar Refrigerator Prototype from Chile

Kris,

A very interesting article, but I question your statement.

A large share of energy consumed worldwide is by heat. Cooking, space heating and water heating dominate domestic energy consumption. In the UK, these activities account for 85 percent of domestic energy use, in Europe for 89 percent and in the USA for 61 percent (excluding cooking).

About 40% of energy consumption is derived from oil used mainly in transportation with a small amount used for heating and electricity production. Another 30% is derived from burning thermal coal to generate electricity. A small amount of coal is used to produce cement and steel. About 20% energy consumption is from natural gas, approx a third being used to generate electricity. An additional 5% is from hydro, nuclear and wind delivered as electricity. Biomass accounts for <5%,used mainly for heating and cooking.

While space heating, hot water heating and cooking dominate dominate domestic energy consumption in some regions, air conditioning is also important and much heating and cooling uses electric heat pumps. Some cooking (microwaves,electric ovens), electric kettles, lighting, refrigeration use electricity.

The energy used to recycle aluminum, copper and other base metals is minor compared to the electrical energy used in initial electrolytic production. In US and EU a lot of steel comes from recycling scrap in electric furnaces.

It is simply not not worth mentioning the heating and cooling of buildings, when thinking about our energy future. Buildings must be built to require no energy at all to keep their temperature comfortable. It is easy possibly to build a house requiring less then 10% energy for this purpose, compared to current average, at no extra costs.

There is another area with great potentials for the future. Many of our materials are produced by high temperature industrial procedures, while similar materials are created in living creatures at body temperature. Using such bio-chemical procedures in industries, may reduce heat requirement a lot and may also make solar heating more feasible.

Unfortunately the future is going to contain pretty much all of the buildings that exist now - and those buildings are going to have to be heated and cooled. They represent a large investment and can't be replaced immediately as if they never existed.

They can be insulated.

Assuming a building has a sound skeleton sitting on a sound foundation and has an economic purpose, i.e., a tenant, then investing in insulation is practical and easy.

Whether or not the interior design and mechanical systems are renewed, it is a straight forward job to increase dramatically the thermal resistance of the walls:

1. Remove old cladding, as necessary

2. Install impermeable membrane continously over wall sheathing

3. Install brackets to hold semi-rigid stone wool insulation and to hold cladding

4. Install insulation

5. Install cladding: cement board; corrugated steel...

Conceptually similar methods are regularly employed to add insulation to all sorts of roofs.

Thus, what you have is a building structure now waterproofed, with a continous layer of 'external' insulation and therefore no thermal bridging to supplement whatever was the preexisting insulation value.

We should be glad we have all these older buildings around, already standing.

Reaching the zero (or near to zero) heating/cooling energy requirement is easier with newly built houses. However, it is still possible to make wonders with old houses.

Just some examples of extreme old houses:

http://erg.ucd.ie/pep/pdf/I3_Stefan_Oehler.pdf

http://www.viking-house.co.uk/passive-house-renovation.html

Our house is also more than 100 years old. We are near to finish renovating it with 20 to 30 cm thick insulation, triple glazed windows and with heat recovery ventilation. Our modest target is to reach the 30-40 kWh / m2 / year heat requirement.

Energy need of buildings is really no reason for headache. It is the only area, where requirement for external energy source can be nearly eliminated with low tech methods. Transportation, industry and agriculture is much harder problem.

Can you possibly link to the heat recovery ventilation system you are installing.

If not I'll eventually search Google.

I don't know what bdi is putting in, but you might also search on "air-to-air heat exchanger." e,g, http://www.smarthome.com/3033A/HE100-Air-to-Air-Exchanger/p.aspx

The HE100 seems to have a cross-flow heat exchanger. Countercurrent is better.

There are heat exchangers made from plastic and metals, but a new direction is to make them from paper-like materials, to allow recovery of air humidity not only heat.

Thanks for the link. As an HVAC tech in the plains states I'm just trying to keep abreast of technical innovations.

Worst job I ever had. I hated crawling, working in tight spaces, but most of all, I loathed working with fiberglass.

Most of the HVAC systems I saw were absolute crap.

We have chosen Stiebel Eltron LWZ 170 (http://www.stiebel-eltron.de/en/privatkunden/erneuerbare-energien/produk...)

A look at you link and further links from a Google search indicates this is a German product.

I have not found explicit confirmation of this technology being available in US ... will keep my eyes open.

At any rate, you seem to be on the cutting, if not the bleeding, edge of application of the technology.

Good for you !

Thanks for the reply !

I am just an enthusiastic amateur from Hungary, applying passive house techniques on the reconstruction of our house.

Passive house is a standard developed in Germany. They build houses with no (or almost no) heating/cooling by applying only low tech solutions. (actually, the heat recovery ventilation machine is the only active component, also not too complicated: a heat exchanger, two ventilators and some electronics) It is a well tested system, with tens of thousands of houses already built with this technique mainly in Germany and Austria. Surprisingly, it is not necessarily more expensive than building a traditional house.

If you are interested in it, you can start at wikipedia (http://en.wikipedia.org/wiki/Passive_house) and external links at the end. Passive House Institute is also present in the US now.

If building a new house, I think it is stupid not to make it at least a passive house. If someone is brave enough, may target zero energy house, which will be the standard in Europe for new buildings from 2020. (2018 for public buildings)

I am familiar with Passive House specs in general from Germany.

Thanks for the personal info, as I am at the moment, mostly an enthusiastic amateur as my professional capacity only nets me about 40 hours a year. This is working on very, very staid and traditional US residential heating and cooling systems.

Unfortunately the future is going to contain pretty much all of the buildings that exist now - and those buildings are going to have to be heated and cooled. They represent a large investment and can't be replaced immediately as if they never existed.

As far as cooling is concerned you can certainly use PV power on your roof.

And thinfilm PV-module costs start meanwhile at $0.90/W: http://pvinsights.com/

And if you don't have a heat pump and no insulation and need some warmth, you can always dress for the season.

[edit]

I also question the premise of the article. HVAC systems are pretty efficient compared to thermal+heat exchanging alternatives. Also, I've done a fair bit of work in the PV industry, there are no thermal steps required for thin film PV and for silicon PV, the thermal steps mostly uses electricity (induction furnaces). Today it makes more sense to use natural gas fuel reverb furnaces, but if the price of natural gas rose 2x, then silicon refiners could easily switch to electrical alternatives. Finally, the premise that manufacturing solar requires heat and thus PV can only be manufactured without fossils when it becomes 2-3x cheaper is truly flawed. PV is currently expensive not because of the embedded energy but because of all the non-energy expenses (labor, supply chain inefficiencies, depreciation, etc). This is clear when you consider that the energy payback of PV systems can be under 1 year and is almost always under 2.

On a much higher level, I reject the premise that the world needs low tech solutions for our energy problems. When you see how efficient modern solar manufacturing facilities are, you realize that any energy crises would only increase demand for the product rather than force the facility to shut down.

Then why don't you use solar panels to produce solar panels?

Because they aren't currently at grid parity compared with the lowest cost base load electricity. As soon as this is no longer the case, PV electricity (along with whatever other electricity generation is available on the transmission side of the grid) will be used to produce solar panels. You don't believe that making PV panels from wind generated electricity (as happens in parts of the world today) means that the manufacturing of PV panels is deeply flawed do you?

You mean that there are PV solar panel manufacturers using only wind turbines to produce their PV solar panels? Would be great. I am curious to know them.

Back 'round the 1st go on this 'energy shortage' there was a Massachusetts company making solar PV which bragged (just before they were bought out by what became BP Solar as I 'member) they were using their off spec PV to power the plant.

I believe you're referring to Astropower, (in Delaware), who at one time had the largest PV array on a building in the U.S. Astropower went bankrupt, the assets were sold to GE,

and somehow now Motech (a Taiwanese company) is in their former module assembly building.

http://guntherportfolio.blogspot.com/2006/08/astropower-decline-of-solar...

http://guntherportfolio.com/2010/10/motech-solar-modules-made-in-delaware/

BTW BP solar has shut down its Fredericksburg Maryland plant as of late too.

http://www.bp.com/genericarticle.do?categoryId=2012968&contentId=7059551

While I'm responding (quickly)...

Re the "1999" paper of using solar heat for making PV cells.

(a) it's from 1996 (went online in 1999 - the year of the dot com boom/crash).

(b) that was a long time ago in PV land - nobody uses gold contact anymore, etc.

(c) any manufacturer worth their CAPX (Capital Expenditures) is going to be running 24x7,

and solar heat is hard to store, especially at diffusion furnace or ink firing temps temps (800+ deg. C).

(d) modern furnaces for PV use are all electric, so they are clean and can be precisely controlled

(1996 is a long time ago in PV equipment land, 3-4 generations of most things)

(e) many processes in current, industrial PV production are only electrically powered

(silicon nitride deposition for Anti-Reflection Coating and surfaced passivation is either Plasma Enhanced Chemical Vapor Deposition or sputtering as one critical example. Another is that edge isolation of the junction is commonly done with an electrically powered laser.).

(f) the experiment led to the development of Rapid Thermal Processing, using high intensity lamps to do all this stuff, with better controllability, and on demand 24x7.

Solarex of Frederick, Maryland, partly powered their production with their own product. SOLAREX FADES AWAY, Green Energy News, March 27, 2010, Vol.15 No.1. I have 8 SXP-44's (polycrystalline PV) that today produce the same amount of power that they did 20 years ago when new.

You mean that there are PV solar panel manufacturers using only wind turbines to produce their PV solar panels?

Besides that you won't find anyone, who solely uses coal power to mine and ship coal and to produce coal power plants either...

This car factory is wind powered:

http://www.easier.com/6475-third-wind-turbine-for-ford-dagenham-s-low-co...

This Chinese PV-module manufacturer has a 1000 kW PV facade:

This tire manufacturer has a 7400 kW PV system on its roof:

http://www.zub-kassel.de/news/article?id=445

This car manufacturer has a 11800 kW PV system on its roof:

http://www.pvresources.com/en/top25bipv.php

I was not asking for car manufacturers or tire manufacturers using solar energy. I was asking for PV solar panel manufacturers using wind turbines and solar panels to produce their solar panels. You post a picture of a Chinese PV-module manufacturer that has a 1000 kW PV facade. You give no link or additional information. So, what I would like to know: does this Chinese factory uses these solar panels to produce its solar panels? Or does it use them to operate the lighting and the air conditioning?

That's a weird reply. We have fossil fuels on one side, and renewables on the other. Coal plants rely entirely on fossil fuels - what kind of fossil fuels has no importance. If renewables rely on fossil fuels, however, they cannot be an alternative to fossil fuels. But whether solar PV panels manufacturers are powered by wind turbines or solar panels or any other renewable energy - that has no importance.

The point is that simply because a factory doesn't use energy produced from the product it manufacturers doesn't mean that the energy technology isn't sound. As was mentioned previously, coal excavation primarily uses electricity only a fraction of which comes from coal plants. Nuclear uses very little nuclear power in the construction or operation of nuke plants. Many people who work at bicycle factories drive to work.

Muscle builders used to think they should only eat protein because "you are what you eat". This is narrow thinking and should be avoided.

In Europe, nuclear power uses quite a lot of nuclear power for doing the uranium enrichment - the facility is in France and the French grid is about 80% nuclear. But I appreciate this isn't quite the point you're making.

It can be helpful to reduce the pictures and link to larger ones, since they may create bandwidth issues for some members.

All the best,

K.

What makes you think that all the citations you provided are disconnected from the grid and getting all their power from intermittent solar and wind?

I don't care if they get all their trons from the panels. It would be nice if the plant was net zero, i.e. exports as many trons as it imports. But, even so, purity of source is a standard we won't have to meet for several decades. Its usually used as a mechanism for dismissal.

Fetuses, rely on their mothers bodily functions. Infants rely on their parents for years. Should we abort all fetuses, because they are not in isolation viable at conception?

The Japanese and the Algerians have a project "Sahara Solar Breeder" to make PV from PV and sand.

Sounds interesting? Something I have long thought MENA should be investing their vanishing oil wealth in.

Linky??

here is a link http://www.diginfo.tv/2010/11/24/10-0135-r-en.php

Because electricty is fungible. Makes much more sense to use the grid for 24/7 poower. Many high tech processes require 24/7 operation, and the avoidance of heating/cooling cycles for equipment. Now if a solar manulfactuerer wants to greenwash, he could always build/finance a utility scale PV plant that produces the same annual output as the plant. But the PV supply chain is distributed. Producers of solar silicon are usually not producers of panels. Then you purchase mounts glass electrical connectors etc. So you end up with an industrial microcosm of general industrial production.

This question usually devolves to argumenting that PV is impure, because it is difficult to purify the supply chain. That probably won't happen until fossil fuels aren't used at all in the wider economy.

Neil, it is true that many heat processes are powered by electricity, but that does not take away the fact that these are heat processes, which could be powered more efficiently by solar energy. The numbers mentioned show the significance of heat energy in industry and households, regardless of how this heat energy is produced - they speak for themselves, no?

You mention air conditioning and cooling: these are probably the most interesting applications of solar heat, using (for instance) an absorption chiller. Cooling is mostly needed when the sun shines.

The metric shouldn't be converting PV electricity to heat. Rather, it's more appropriate to compare the best thermal generation from solar to the best fossil application. For example, solar water heating is much more efficient than using PV to heat water. It's also MUCH cheaper. Folks China, Greece, Egypt, already do this and even rick folks in the US use solar water heating for their pools, homes, etc. I think similar arguments could be made for CSP for industrial applications, mid-level concentrating systems for light industrial applications, solar ovens, etc.

"Cooling is mostly needed when the sun shines."

Mostly. I'd argue it's most needed when there's heat+humidity, which often means clouds at some point in the day, and a major loss of generation from solar when it's obscured by clouds. It's always going to need some sort of backup.

Well, smartass, there's always a need for backup ... like the stored solar energy in any variety of things, including fossil fuel.

I can testify, that where I live (Calif), peak elec demand closely follows the rise in temps in July and Aug. We're using many thousands of megawatts for AC in CA right now. I think absorption cooling could be a great solar application... and make ice so cooling can continue into the eve. Like a lot of things, the high initial cost is holding us back especially while morons are saying cut cut cut. We need to invest invest invest in solar.

It would be nice to see some packaged systems for evacuated tube solar absorption chillers going into homes and businesses everywhere. I haven't run across any lately

>and make ice so cooling can continue into the eve

Actually I believe ice is made for all of the following day and into the evening. Example: Enough ice is made on Monday afternoon to be used for Monday night, all of Tuesday, and perhaps into Tuesday evening if necessary. I'm not a total noob at debating this subject. The following is a block away from me, and uses a thermal storage A/C system: http://i.imgur.com/gbf3d.jpg The image is of Eastside High School, Lancaster, Ca. The solar installation is part of the largest PPA agreement with a utility and installed at multiple locations within a school district in the United States.

IMO, the approach we're taking involves an unsustainable consumption of materials and doesn't sufficiently solve the issues with incinerating fossils for energy.

I'm one of those damn pro nuclear power guys. If I didn't think it was a superior alternative, I'd be all arguments in favor of solar and wind.

I'm one of those damn pro nuclear power guys. If I didn't think it was a superior alternative, I'd be all arguments in favor of solar and wind.

Even if nuclear is a superior alternative, that does not mean it is *always* a superior alternative.

Nuclear is only feasible in large installations, that seem take take a long time to build, needs a supply of fuel, and also create a waste storage/security issue. It also needs highly skilled people to build operate and maintain, and decommission thee facilities, let alone handle them after Fukishima type incident.

Solar systems can readily be built at small scale, in a short time, have no waste, and do not need highly skilled people.

This makes them ideal for remote and/or low tech places that have lots of sun - which just happens to describe many third world countries.

Do you really think nuclear is a "superior alternative" for politically unstable places like Libya, Egypt, Somalia, Ethiopia, Nigeria, Afghanistan, etc or earthquake/tsunami prone places like Indonesia, New Guinea, Solomon Islands, Haiti etc?

That's a nice pic, but I'm not sure what I'm looking at. You say PPA so I assume it's a PV array. I said I'd like to see some solar thermal absorption chillers working.

>That's a nice pic, but I'm not sure what I'm looking at.

So it's actually a crappy pic, which I'd acknowledge. There's actually a lot going on there. The school is one of California's latest (cost over $200,000,000), and the solar topped canopies are a popular trend. The one agreement involving the imaged school, is actually one of a 10 school project. California has some of the most ambitious renewables mandates in the world, so there's an explosion of renewables installations. One of the gimmicks used to meet the mandates are power purchase agreements (PPAs), and the installation of solar topped canopies at California schools have become a popular method and location for those. I think there's at least 20 school installations just in my town, and at least 60 across the state.

Perhaps tomorrow I'll image some windfarm porn. Also near me is one of the largest wind resource areas in the world, and there's some major expansion of it going on. Over the weekend I drove past the area where all the equipment is being staged. Monopole sections, nacelles, and blades all lined up in one location.

IMO, the approach we're taking involves an unsustainable consumption of materials.

Actually, a thin-film silicon PV-module contains about 0.6 gram/m2:

http://www.sciencedaily.com/releases/2011/05/110506165312.htm

That's about 0.6 gram silicon for a 100 W thin-film panel.

At 1500 sunhours/year and 30 years lifetime, that's 7500 kWh/gram silicon.

For comparison: Current nuclear power plants only produce 38 kWh/gram uranium.

And silicon is non-toxic and available in abundance (28% of earth crust):

Carbon is at 0.03% and Uranium235 at 0.0000013%

The 0.6 grams of silicon is minuscule compared to the balance of the panel; one might as well rank PV panels by GJ per gram of dopant.

U-235 releases about 6.5*1010 J/g when struck by thermal neutrons (including the losses to U-236 formation), so that figure must be starting from natural uranium and include the conversion losses from heat to electricity.

Fast-spectrum reactors make ~100 times as much uranium usable, and thorium reactors will utilize about 99.85% of thorium (about 0.15% winds up as Pu-238 after 6 neutron captures).

Of course, both sides of this are rather ridiculous.

The silicon argument reminds me of the oft repeated statements by hydrogen enthusiasts that it is the most common element in the universe--true, but utterly irrelevant as our access to vast clouds of the stuff millions of light years away is...rather limited.

On the uranium side, one must always wonder what is left out of such calculations:

the energy to find, mine transport, process the stuff?

the energy needed to decommission the plants?

the energy needed to 'safely' store the spent fuel for essentially ever?

the energy needed to evacuate citizens from ever-widening exclusion zones after the inevitable 'accidents'?

the energy needed to pay industry shills to make ridiculously optimistic claims about their toxic industry on sites like this?

...

Of course, both sides of this are rather ridiculous.

I agree (however, the problem with hydrogen is not the abundance-issue, but the cost-of-electrolysis-and-energy-consumption-issue).

But sometimes it just needs to be pointed out, that renewables actually need very little material, since this 'uranium-beats-everything' gets really tiring, especially given the fact that a gram of silicon can produce significantly more electricity than a gram of uranium.

But important is the fact that PV-modules start meanwhile at $0.90/W (and still falling): http://pvinsights.com/

(My efficient household is at 300 kWh/person and year. So with less than $300 of PV-modules per person, I can power my household for the next 30 years and even give some extra electricity to the grid - compare this with your health insurance bill for the next 30 years...)

Is this the whole of your argument?

The energy per gram of material?

And to what end? Ignoring the lack of "good" locations for fission reactors, ignoring the known demonstrated failures of Man to be able to operate fission plants safely - how does this energy fact address the long term lack of 'economic'

Phosphorous, the erosion of topsoil, idiots playing games with fiat money? At what point does "growth end" on a finite planet?

Stating "the material has this much energy per gram" is on par with the

http://economics.about.com/od/termsbeginningwith1/g/assume_a_can_opener.htm joke.

For those that might be interested in California's CAISO state power generation, they also report out the contributions by wind and solar to the grid in MW:

http://www.caiso.com/Pages/TodaysOutlook.aspx

It shows that today, using some cherry picked times:

Midnight to 4am, 2GW from wind.

10a to 2p, 400MW+ from solar.

etc... ;)

For my thoughts on the discussion:

1. I am not so concerned that an individual plant or office is net zero

2. I am interested in larger-scope communities getting more and more contributions from renewables.

CA is generating ~5% renewable from wind and solar. What percentage is imported hydro? Seems there is plenty of room to grow.

Well, it's not really 5% from wind and solar (a little less than 4%). It could be a lot more than in the next few years if funding comes through for a bunch of approved projects.

A few things:

- The Cal ISO area is not the whole state... 80+ percent. Major utilities not part of Cal ISO include LA County DWP and SMUD (Sacramento Municipal Util Dist).

- For any point in time, wind varies from nearly 10 percent (like around 4am sometimes) of the load to around zero. Yesterday happened to be a big day for wind. A good day we get about as much as geothermal. Yesterday we got almost 50% more from wind than geothermal (32 gwh v. 22 gwh) in Cal ISO area.

- California has a lot of hydro installed ... around 14,000 megawatts. Capacity factor is not very high (depends on season) but I think it averages ~25 percent.

- Large hydro is not included in the 33 percent RPS mandate. If we hit the 33 percent target (doubtful) in 2020, we'll actually be closer to 50% renewables (depending on weather etc... lots of rain and mild temps can double the percent contribution of hydro). Last year large hydro made 14.6% of elec power generated in-state. Other renewables contributes a similar portion, but this is mostly geothermal, small hydro, and biomass.

see http://energyalmanac.ca.gov/electricity/total_system_power.html )

- We get some WAPA power, which is mainly federally owned hydro (10,000 megawatts to 15 western states ... see www.wapa.gov ). This goes to municpalities for stuff like mass transit (BART get WAPA power).

- We also get some power from the largest nuke plant (Palo Verde) in the US, which is in AZ and part owned by CA utilities.

- Hydro imports can be substantial but depends on weather. Last year not much imported hydro -- less than 4%, mostly from the north (WA and OR).

In my local area EMBUD, it appears a great deal of effort is going into making biogas from sewage. There is enough biogas to run the plant and add power to the grid, which reduces fees to ratepayers.

https://www.ebmud.com/our-water/wastewater-treatment/wastewater-energy

Interesting times for power generation. I cannot believe we used to dump all this energy down the drain literally in the past. We were running waste treatment plants with electricity made from fossils when our waste had plenty of energy content.

Apparently water distribution in CA uses 10% of electricity in the state. That seems like a ripe area to exploit with intermittent renewables, which can pump water when the sun is up or the wind is cranking. Of course in the old days wind was used to move water around. This should be the way things go in the future as well.

Actually, water distribution use less than 10% of the electricity, but total water related energy use is much higher;

The Calif energy commission looked at this in a 2005 report on California's Water-Energy Relationship and found;

The single biggest energy consumer is actually heating water, followed by "supply and conveyance" meaning the aqueducts. Urban distribution and sewage collection and treatment are decent users too.

Bottom line - if Californians learned to use less water, and less hot water, they would save a lot of energy. The author of this report concluded that if they want to save electricity, they are better of changing toilets and showerheads than light bulbs. Getting rid of some of those lawns wouldn't hurt, either.

Yair...I've said it many times and it's probably boring but why don't the Yanks use Aussie style solar water heaters...simple low-tech that works. The one on my roof has worked with no maintainance for over twenty years.

[edit]

I can't give you figures, but a lot of in state hydro is along the California and Los Angeles aqueducts. They generate electricity where they can, but the aqueducts also consume a lot of electricity. California's single largest draws of current are electric motors used to pump water along the State Water Project.

Sounds like an instant invitation to work on a redesign with pumped Hydro storage that will both store renewable energy sources, and then reapply them directly as pumped (nee, gravity fed) water to satisfy a greater portion of the system's needs.

Pumped hydro schemes already exist as part of The State Water Project. Like most pumped hydro schemes, it's primarily used for excess nightime generation. The Castaic Lake/Pyramid Lake scheme. Water isn't pumped and stored for days of use, it's pumped and used the following day.

Ideally, you want to use what you generate, since you don't take X excess MWh of generation, use it for pumping water, and then get it all back. When we're discussing renewables, we're discussing a large amount of material and cost used to generate relatively small amounts of power.

>A small amount of coal is used to produce cement

Also used is petroleum, natural gas, and increasingly tires. I can't envision it done with solar or solar providing the heat directly or indirectly for any industrial process that requires very high temperatures from WITHIN a kiln used to heat non metallic substances. Many industrial processes that source electricity for the heat required, are processes that take more hours than the sun shines in a day.

"The energy used to recycle aluminum, copper and other base metals is minor compared to the electrical energy used in initial electrolytic production. In US and EU a lot of steel comes from recycling scrap in electric furnaces"

Aluminum and other metals can't be recycled into high quality alloys unless the feed material is pure or is already the alloy desired. Only the highest grades of copper can be made back into the highest grade of copper without electrolytic refining to produce a pure product. Bare bright copper can be made melted back into copper pure enough to produce wire from, but tin plated wire is often made into bronze alloys. It would have to be electrolytically refined to produce a high quality product. General steel scrap isn't made into high quality steel alloys. Too many contaminants. Primary iron from ore is made with coal.

Sure, I can envision some commercial and industrial processes powered by solar....some of the time. I'd be willing to bet that all the solar on a Costco's roof can't provide all the energy required for just its food court.

"General steel scrap isn't made into high quality steel alloys. Too many contaminants." This is incorrect.