Anaerobic Digestion (AD) in Ontario – A Regulatory Obstacle Course

Posted by Stoneleigh on February 15, 2007 - 11:59am in The Oil Drum: Canada

The Ontario government has recently been emphasizing its green credentials, particularly in relation to small-scale renewable generation, in the run up to a provincial election this fall. The Standard Offer Program (SOP - previously discussed here) is claimed to provide a framework for bringing a substantial array of new embedded generation on to the grid - generation based on different energy sources and varying widely in size. This is exactly what needs to happen if Ontario is to avoid a painful energy squeeze in the future, due in part to the approaching decline of natural gas supplies in North America. However, achieving it is proving to be far more difficult than one might reasonably expect.

The Regulatory Landscape

The Ontario Power Authority (OPA), which administers the SOP is clearly intent on minimizing the cost to Ontario electricity consumers by strongly favouring the cheapest renewable alternative. However, this position is at odds with the priorities of other government agencies, notably the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA), which is keen to promote various forms of farm-based generation as a means of securing rural development. In addition, the Ministry of the Environment (MOE) has its own priorities, which are not necessarily in accordance with those of other agencies. Zoning and taxation are also issues. The net result is the development of a regulatory obstacle course threatening to derail the development of valuable technologies such as anaerobic digestion. Given the considerable collateral benefits of agricultural biogas production, such an outcome would represent a significant own-goal.

The Benefits of Anaerobic Digestion

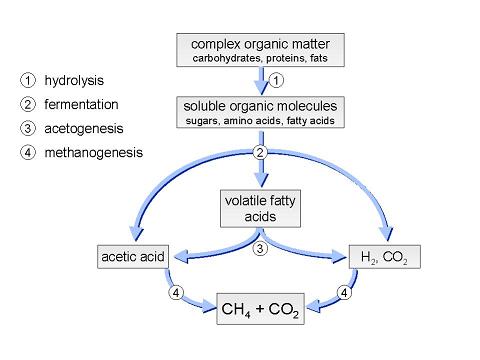

Anaerobic digestion (AD) is well established in Europe and is increasingly being developed in America (see for instance the Agstar Handbook and software from the US EPA or this Minnesota case study). In combination with power generation from the resulting biogas and waste heat recovery, it has significant potential for recovering energy from agricultural operations in Ontario. Approximately 4-5 kWh per milking cow per day (equivalent to 2-3 kWh per head of dairy livestock per day) can typically be generated, meaning most farmers for whom it would be economical to install a system would be able to cover their own electricity demand with a surplus available to feed into the grid. In winter, the recovered heat would also typically be sufficient to provide for all the heating needs of the farm, including heating the digester itself in order to maintain the required temperature range.

AD also has a number of important collateral benefits that have made its development a priority for the farming community.

- Improved manure management

- Pathogen reduction (typically 95% or more)

- Reduced greenhouse gas emissions (methane, nitrous oxide)

- Reduced odour (90% reduction of VFAs)

- Chemical fertilizer substitution

- Rural economic development

- Treatment of off-farm organic waste streams as co-substrates

Combining digestion of manure with other wastes - green waste, commercial food waste, waste fats and oils, grease trap residues - can enhance methane production, typically by up to a factor of four. The surplus power available for sale is therefore greatly increased and the economics of the project substantially improved. At present, farmers may also be offered a tipping fee to take off-farm materials (tipping fees currently paid for composting or landfill are $40-$90 per tonne), although that is unlikely to continue once there is competition for energy-rich waste streams. AD of these off-farm waste streams is a very much better option than the landfilling, which often occurs now.

According to OMAFRA, a fully developed AD sector is predicted to result in $1.4 billion of investment in Ontario agriculture and infrastructure, with an anticipated $434 million in annual income for farmers in exchange for generating 2% of Ontario’s power demand. However, a string of bureaucratic obstacles stands in the way, and is proving to be a huge source of frustration for early adopters and their backers.

Grid Connection Obstacles

For projects under 50kW which are planning to net meter, the connection process is straightforward, however, most AD systems, including any based on co-substrates, would be larger than this. For larger systems, the process of establishing a grid connection is extremely long, complicated and expensive. Although time-scales are set by the Ontario Energy Board (OEB) in the Distribution Code - 15 days for an initial feasibility study and 60 days for a Connection Impact Assessment (CIA) and Connection Cost Estimate (CCE) for generation less than 500kW - these time-scales are not even close to being met, partly due to the avalanche of applications resulting from the dash for wind under the SOP. Projects currently submitting an application to Hydro One - the relevant utility in almost all cases as it deals with rural Ontario - can expect to wait for months before their application will be assessed.

The initial feasibility assessment is free, but the CIA costs in excess of $3000 and the CCE in excess of $4000. After completion of the CIA and CCE, a cost recovery agreement will be offered, based on deep entry. In other words, the prospective generator is liable for the full cost of all necessary distribution system upgrades, however far downstream these may occur, and however disproportionate they may be to the economics of the project. Once the necessary upgrades have been performed and paid for, which could potentially extend the timeline considerably, a connection agreement would be offered.

Hydro One is legitimately concerned about the potential for islanding, for which the standard solution would be a $200,000 transfer trip scheme to ensure that feeder lines are not energized when power is restored after a momentary outage (the typical restoration time is approximately 1 second). If a feeder line is energized and significantly out of phase on reclosure, equipment damage is on the feeder side is a distinct possibility. This problem could potentially be addressed by increasing the reclosure time - to perhaps 5 seconds - in order to ensure that the embedded generation would have sufficient time to disconnect. Hydro One has so far been disinclined to do this, however, as restoration time appears to be one of their reportable performance measures. Insisting on a transfer trip instead for a $300,000 farm-based AD project, would render almost all such projects uneconomic.

A working group has been set up between the Ontario Federation of Agriculture (OFA) and Hydro One to discuss ways of moving forward, but solutions will take time.

Power Purchase Obstacles

Embedded generation with a two-way connection to the grid can choose to net meter or to sign a 20-year contract under the SOP. Net metering would not be an attractive option for a generator commonly out-producing his own demand, as any surplus power would have to be put on to the grid for free. Most prospective biogas generators are hoping to sign a SOP contract, but the rate currently being offered is not attractive.

Critics of the SOP point out that the program is essentially designed for commercial wind power as the lowest cost form of renewable energy. Although the SOP rate of 11 cents per kWh is supplemented by 3.52 cents per kWh during peak period - a supplement for non-intermittent generation - the overall price still averages out at only about 12.5 cents per kWh. OMAFRA’s work suggests that an effective price of 13-22 cents per kWh, depending on the project, is required to make AD economic under prevailing conditions in Ontario. The OPA is said to be considering a price review within two years, which could significantly disadvantage early adopters. In practice, potential AD generators may well decide to wait for the price review before committing themselves to a 20 year contract, which could substantially delay the adoption of AD technology.

Renewable generation projects may be eligible for additional incentive programs intended to enhance their viability - for instance the proposed federal ecoenergy renewable power program which would provide an additional cent per kWh for renewable generators larger than 1 MW. However, under the SOP contract, the provincial OPA is able to claw back half of any such incentive. This form of regulation at cross-purposes adds pointless complication to the process.

An additional complication is the demand charge for demand customers using more than 50kW. Whereas smaller demand customers pay an energy charge, a fixed charge and a distribution charge proportional to their energy use, larger customers pay an energy charge, a fixed monthly component and variable amount proportional to their peak power consumption rather than their energy use. The variable component is referred to as the demand charge.

Essentially, the distribution charge, comprised of both fixed and variable components, represents the utility’s cost recovery strategy for installing a standard connection, which the standard demand customer does not have to pay for up front. Generators are, however, expected to pay the full cost of the connection upfront. Hydro One is apparently planning to apply the demand charge to the generator’s own demand, despite the fact that the generator will not in practice be drawing his peak demand from elsewhere, but generating it himself locally. This would arguably amount to generators double paying for the cost of their connection - paying upfront as well as per billing period thereafter. This aspect of the cost structure would make a very significant difference to the economics of AD projects.

Designing AD projects to include handling off-farm high-energy waste streams would make projects viable at a lower price per kilowatt hour for the electricity sold. However, attempting to obtain permission to process off-farm materials opens another regulatory can of worms.

Zoning and Taxation Obstacles

Property tax assessments are under the control of municipalities, meaning that tax liabilities as a result of changes in land use can vary. Although the OPA currently only advises potential generators to contact their local municipality for details, they have previously advised prospective generators that establishing a grid connection for the purpose of selling electricity is likely to result in the farm being zoned industrial and taxed accordingly.

In addition, the inclusion of off-farm wastes in the project design is likely to result in rezoning of the farm as a waste disposal site by the municipality, even though the materials to be handled would mostly be harmless food wastes. As rezoning is a process open to public consultation, and the label of ‘waste disposal site’ is an emotive one, the opportunity for local opposition to develop would be considerable. The level of regulation, and therefore the cost, would increase substantially, assuming the project was allowed to proceed at all.

Environmental Obstacles

AD based on the use of co-substrates requires certificate of approval from provincial Ministry of the Environment (MOE). However no regulations have been developed to deal with the situation despite on-going discussions since 2005 between the MOE and OMAFRA. To date, OMAFRA has agreed to fund, at significant cost, a waste pasteurization facility and a gas flare at one prospective site in order to gain approval. Despite these concessions - the cost of which will have to be built into the project funding for all subsequent projects as OMAFRA will only cover the first one - a certificate of approval has yet to be issued for any project.

It is likely that legislation will be required in order to establish an appropriate regulatory framework for AD with co-substrates. However, such legislation would be controversial and is unlikely to be introduced in the run up to the Ontario provincial election due in the fall of 2007. The regulatory delay would therefore be expected to continue for at least another year, if not longer depending on how high a priority the next government places on seeing AD become established.

The Issue of Insurance

Insurers are becoming increasingly sensitive to potential risks and are increasingly likely to impose high premiums on any activity that could be considered unusual. Although AD is an established technology in Europe and has not proven to represent an insurance risk there, the industry here may choose not to take experiences gained elsewhere into account.

Resolving the Regulatory Obstacle Course

The current regulatory impasse is effectively preventing the development of an important technology by withholding permissions and imposing disproportionate costs at every turn. This fractured and contradictory state of affairs clearly does not serve the interests of Ontario. Although there are informal working groups attempting to diffuse the various conflicts between the priorities of the different bureaucracies involved, it is unlikely that a full resolution will be possible in the absence of political will at the provincial level. The province requires a coherent policy on AD, based on a comprehensive professional assessment of risks and benefits. It needs to integrate the various regulatory strands in order to ensure that the priorities of various regulatory bodies are not in conflict and that the overall regulatory burden is reasonable.

Marotti32 has posted on TOD about similar initiatives in Germany. These were implemented under what I understand to be a "Feed Law" that required the German utilities to purchase power generated by small scale PV and bio-reactors.

It would seem that some of the same technical challenges would have been addressed in the the German initiative. Do you know of any technology transfer between the two nations?

Kudos for posting this by the way. I live up here and this is the first I have heard of this initiative.

Cheers!

The Standard Offer Program (SOP) is equivalent to the German feedlaw, although the guiding idea is quite different. In Europe, the point of advanced renewable tariffs under a feedlaw is to exploit as much of the existing renewable potential as possible, using a wide range of technologies and deliberately encouraging distributed development. If one RE technology is more expensive than another, a higher tariff would be paid, or if the energy source to be exploited is more diffuse in a particular area, then a higher tariff would be paid in order to ensure that the potential of all areas is developed.

This leads to a completely different distribution of renewable generation than one would expect under the North American circumstances where comparative advantage is the guiding philosophy. Here, there are only two tariff bands - one for solar PV and one for everything else, regardless of cost structure. Even the inclusion of a solar tariff was a hard fought battle, and the level chosen is insufficient to provide a return on investment. The renewable tariff was set with wind power in particularly windy areas in mind. Almost any other RE technology would struggle under this pricing regime, but if the point is to build only the cheapest possible RE capacity then that is not seen as a problem.

The issue of self-reliance versus comparative advantage in relation to renewable generation was discussed more fully here:

Standard Offer Contracts - the Future for Renewable Generation?

Kudo's for bringing this up as a topic.

I don't know if a digester will neutralize the herbicide clopyralid, but this could be a downstream concern for using the sludge. I think most farmers are aware of the problems with clopyralid but if used by unscrupulous hay suppliers would give a the sludge a bad name. Clopyralid has been found to pass through a cow and remain active in the resulting compost.

http://www.jgpress.com/BCArticles/2002/020257.html

Thanks for pointing this out - I'll pass it on to the farmers I know. If I can find out any more information I'll get back to you.

Great stuff, Stoneleigh. In the last paragraph you state: "The current regulatory impasse is effectively preventing the development of an important technology by withholding permissions and imposing disproportionate costs at every turn."

Are you able to order the obstacles facing implementation of AD technology according to their significance?

Earlier you state: "OMAFRA’s work suggests that an effective price of 13-22 cents per kWh, depending on the project, is required to make AD economic under prevailing conditions in Ontario." And I note that you indicate that this situation would change if off-farm waste was brought into the equasion. Like many, I hesitate when I see appeals for what appears to be an subsidy. On the other hand, AD appears to be dealing with several externalities of concentrated meat and dairy operations. I wonder, if the cost equasions included an assumed carbon tax for all the electricity purchased by the OPA, does AD without an off-farm waste stream become competitively viable?

Also, I wonder about the scale of farm operations appropriate to use of AD technology. What is too small? Is anything too large?

You would probably want at least a hundred milking cows. As an example, there is a local farm not far from here with 140 milking cows that runs a 50kW generator using manure alone. The net metering connection for that size generator is much simpler than would be the case for a larger system under the SOP. Many larger projects are planned - some tied to other endeavours such as ethanol production.

I'm afraid I can't answer your carbon tax question. The problem isn't really that AD would need a subsidy - the problem is that mains power in Ontario is essentially subsidized, making it difficult for alternatives to compete. The price AD would require to be viable is not that different from current electricity pool prices, and if natural gas shortages were to push up the price of power in a few years time then AD under a 20 year contract would look cheap. When you consider the externalities that AD addresses, it would look even cheaper.

Ranking the obstacles would be difficult. Probably getting a affordable grid connection regime up and running would be the first priority. Once the cost of grid connection was predictable and consistent, it would be much easier to estimate at what power purchase price projects would be viable.

Thanks again for a most informative posting, Stoneleigh. I note that you have set this discussion mostly in the context of dairy operations. Is there any reason AD is not applicable to feedlots?

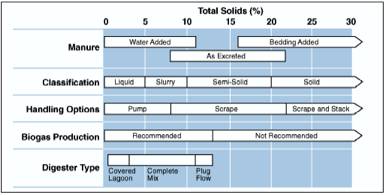

AD can be used with various farming operations, but it is more compatible with some manure management systems than others. Total solids content is a very important parameter and different manure management systems produce waste at very different solids contents. I've added a figure to the story on this point (under The Benefits of Anaerobic Digestion) because I don't know how to put graphics in comments.

Essentially, there are different digester designs (covered lagoon - unheated and so not applicable to northern climates - complete mix and plug flow), each of which works with a different total solids content. Raw manure is excreted with a total solids contents of 8-25% depending on type of animal. For swine the figure would typically be 9.2-10%, for beef cattle 11.6-13.0%, for dairy cattle 11.6-12.5%, and for caged laying hens 25%. Manure can be diluted by process waters, misters, spilled drinking water or washing water, or it can be thickened by air drying or the addition of bedding materials. When designing a digester, all water in the manure-handling system and all processes affecting the total solids content of the resulting manure must be accounted for in order to choose the appropriate digester technology.

Flushed manure with less than 3% solids cannot be processed to produce energy in the heated digesters necessary in the Canadian climate. Complete mix digesters are suitable for slurry-based manure management systems, which result in manure with a total solids concentration of 3-10%. Plug flow digesters are used where the manure to be handled has a higher solids content, typically 11-13%, than for the complete mix design. Plug flow digesters are suitable for use on dairy farms as long as they do not use flush systems, but not for swine operations as the total solids content of swine manure is insufficient for this method of handling.

Here in Vermont we've found that there is great potential in small hydropower projects, using existing small dams, many of which used to produce power decades ago. But it turns out that regulatory hurdles add up to an expense of about $600,000 just for getting the needed permits for one project. There are currently efforts in the state legislature to streamline the permitting, we'll see what happens. Some people blame the utilities, saying they stand in the way of distributed generation. There is some of that, but I also think that the regulations were set up in an era of centralized generation and the resulting absurdities are un-intentional. But what's the best way to improve the situation?

Dams are a hot potato.

First of course you have the movement of fish, which is blocked.

And second you have the impact on everyone downstream. Riparian Rights is the legal doctrine.

And then you have the liability issues if the dam fails, or does something wrong.

Having been peripherally involved in dam litigation, it can go on for years.

Adding a power plant to an existing dam raises none of the above issues, yet it still creates massive paperwork headaches in the US ! Likewise for "run-of-river" schemes except for the riparian issues for that section of river bypassed.

I have heard it said that any hydropower plant under 5 MW in the US cannot afford to pay for it's paperwork. And excuse used in Yosemite Park for an 1890s waterwheel. 2 MW of historic generation equipment dumped in a landfill, wheel left for visual impact & "history". It now just spins uselessly. Zero impact on stream, but less paperwork.

Best Hopes for Less paperwork,

Alan

National Park Service did this just before California electricity crisis.

This is a very important point Alan. In fact it really can't be stressed strongly enough. There is a substantial gap, in terms of project size, for renewable energy, where projects are currently being rendered non-viable purely by regulatory barriers to entry. The issues are not technical - they are purely political.

Small systems (50kW and below) are feasible here, if they are associated with a comparable load, because they can set up a net-metering arrangement fairly easily and cheaply. Above that size the regulatory burden (and it's associated cost) is completely disproportionate for projects below a certain minimum size, a size which would vary by jurisdiction and by renewable energy technology. Unfortunately, the gap is where most of the community or farm-based initiatives would fall.

I'm tempted to write another post specifically on this issue, but I'd have to do a lot of research first. I'm also planning to write something on islanding.

By the way, did you hear that the planned Ottawa electrified light rail scheme was derailed by political interference? It might be reconsidered as the jilted construction company is threatening to claim damages against the city for breach of contract, but everything is still up in the air at the moment.

For small hydro, I would STRONGLY recommend MhyLab at

http://www.mhylab.com/fr/index.html

High quality & innovative designs that can be built in small machine shops (CNC capability required).

Smallest they have ever done was 100 watts; largest 1 MW (limit as a non-profit so as to not compete with commerical firms).

Yes, I have been following Ottawa. (I supported the subway section in downtown but I understood & respected both positions). STUPID is about as kind a remark as I can make for recent developments.

Best Hopes,

Alan

I made a floating gasometer connected to a methane digester running on cow manure and chopped grass. However I haven't scaled it up as it seems like a lot of work for modest amounts of gas. Biomethane appears to be a niche for energy recovery, not a prime time energy source. Away from 'hot spots' like dairies, landfills and sewage farms it is unlikely that methane could power the materials handling requirement. How many of these places run their vehicles on methane?

Remember that we already pay for garbage and sewage removal, subsidised fuel in a sense. Those fees help buy diesel for trucks and grid electricity for large pumps. That's what makes it economic to generate small amounts of electricity onsite and recycle some leftover solids to farmland.

Some claim that methane 'needs' to be burned as it is a stronger greenhouse gas than CO2. Large human assisted methane emitters (ie not natural swamps) should be carbon taxed and let them work it out, maybe passing the tax on to customers.

As Stoneleigh pointed out, burning the methane to produce power lowers the emissions from what would otherwise be a total waste. Methane released to the atmosphere has 21 times the warming potential of CO2, so reducing even small-scale emissions is worthwhile. In BC, the Environment Ministry estimates that methane release from landfills accounts for 9% of provincial GHG emissions on a CO2 equivalent basis. Recovering methane from municipal landfills has become standard practice.

Sewage treatment is another potential source of electricity. Most of Canada has completely ignored this possibility because treatment systems were designed when the resource values in sewage weren't important. Victoria, where I live, has had only quarter-inch screens on their effluent for decades and is finally moving towards wastewater treatment. Since the region is starting from scratch, there's a movement to extract energy from the sludge in much the same way as Stoneleigh has described. Several cities in Sweden produce methane and/or electricity and/or district heat from sewage sludge, fuelling the municipal bus fleet and making a profit in the process.

The obstacles to AD at Ontario farms do look discouraging. What may emerge is a more centralised approach to agricultural waste disposal at the district level.

Indeed biomethane is energy recovery not an energy source, but there is a great deal of energy available to be recovered, especially if high energy off-farm wastes such as chicken fat can be digested.

Running vehicles on the methane produced (once it has been cleaned) is being done in Europe, and the idea is being discussed here as well.

Nice work Stoney - very informative.

For further reading I would definately reccommend taking a look at what the Brits are doing in Dream Farm 2 - a project run by the Institute of Science in Society http://www.i-sis.org.uk/DreamFarm2.php

They're using a new type of underground AD seen here: http://www.organic-power.co.uk/

I've also spoken with the guys at Microgy: http://www.environmentalpower.com and they have a couple of AD sites in operation in the US.

www.defendscience.org

Small scale digester - posted on TOD ealier by someone else. I researched the use of forest litter and C:N ratio is 30:1 which is what was stated as the nec. for this man's digester. Interesting reading...

http://journeytoforever.org/biofuel_library/methane_pain.html

The French guy's system was interesting. He seems to have solved the reaction temperature control problem with a sealed tank within a compost heap. As always the question is 'does this help a lot of people ?' He appears to need a big acreage of forest to harvest or let grow. I gather cutting, chopping, loading, stacking and emptying is all done manually. Interesting that he said brushcutting reduces wildfire hazard. I agree except it's tough on understorey ecology ie tweetie birds.

"As always the question is 'does this help a lot of people ?'"

Boy what is a loaded question. Obviously we will need to power down hard, and as my wife would ask is it just two of them(?) and how big of house(?) and, and, and....

You are right I figured roughly 500 US acres to do this. The work to cut and manually grind 50 tones of biomass? He must use a tractor/machinery.

I figured his "tank" to be 3,000 US gallons.

Thanks for bringing the subject up!

I have no figures or details to share but just briefly will tell you that in Sweden biogas as fuel for cars and city bus-service is working. Biogas is typically produced in cooperation with sewage treatment, landfill or foodindusty waste. It is either available for filling up your car locally resembeling a gas station or biogas is pumped into the fossilgas pipeline grid.

I have been driving a Bi-fuel vehicle for more than a year now, it has double fuel systems. It ignites on petrol and switches over to methane as the engine is sufficiently warm. If the methane tank (20m3 -200bar) goes epty petrol kicks in seamlessly. A special contract with the Gas company ensures that I always use biogas, if i fill up on pump with fossil gas they pump the equivalent of biogas into the fossil grid to make up - just as in the green electricity contract.

This soulution allows my car use to be carbon neutral, costs like a Prius and on a larger scale helps converting methane emission to CO2 emission which lessens greenhouse effect.

I have had no technical problems for the past 35000km.

This area has great collective transport by bus. Most are biogas.

For me its hard to understand why this technology is not spreading faster.

Cheers

Hi,

I am very interested by your comment, but I have a question: Can you tell me where axactly they drive on biogas in Sweden?

If I am not mistaking, Your car is driving on natural gas (which is very common in a number of Countries), would the pollutants in the biogas not cause maintenance/failures of your engine and hence is the claim?

Furthermore, I believe there are just few car manufacturers who will warrant their cars for the use of Biodiesel, and since biogas is a number of years behind as a carfuel on biodiesel I am not surprised that it's not spreading faster, because people would probably loose their warranty. Now this is only my impression, so if I am wrong let me know. I am also very interested in other comments in this area.

Cheers

Do not dismiss another use for Anaerobic Digestion

Butanol, the 4 carbon alcohol that can be made from sugar beets, or any plant with sugar/starch content including cheap, easy to grow crops and other plant waste that can be raised easily in northern climes. Butanol uses a bacterium instead of yeast, the well known and long isolated Clostridium_acetobutylicum, used since WWI. It is processed by Anaerobic digestion using this bacterium in much the same that brewers use yeast.

Butanol can be mixed with gasoline without modification or run straight in the place of gasoline with no modification to infrastructure, and will mix with ethanol in the same way that gasoline can. While Vinod Khosla and the rest wasted time and money with ethanol, DuPont Corp and BP went with the easy money. The alcohol wars are only beginning, and while ethanol has the early jump start, it looks like they are being gained on from behind FAST.

http://www2.dupont.com/Biofuels/en_US/index.html

http://en.wikipedia.org/wiki/1-Butanol

http://www.greencarcongress.com/biobutanol/index.html

http://www.butanol.com/

http://i-r-squared.blogspot.com/2006/05/bio-butanol.html

The bug that makes it:

http://en.wikipedia.org/wiki/Clostridium_acetobutylicum

http://www.epa.gov/biotech_rule/pubs/fra/fra003.htm

Roger Conner (self appointed SOBB (Supporter of Bio Butanol) :-)

Remember, we are only one cubic mile from freedom

Roger,

I had no idea that Acetone was made this way. For some reason I always assumed it was a petroleum distilate.

Thanks, I think you are onto something here.

D

One of the great challenges in Canada is the over regulation of everything....Canadians suffer under a burden of over 550,000 Pages of laws, rules and regulations.....In most jurisdictions in Canada it would cost you a fortune to deviate from the accepted norms.....