Visit to Shell's Brutus Off-shore Oil/Gas Platform and New Orleans Facility

Posted by Gail the Actuary on November 26, 2007 - 4:30pm

On November 9 and 10, the American Petroleum Institute (API) invited several bloggers to visit Shell's facilities in New Orleans, and also its Brutus Tension-leg Platform, 165 miles south of New Orleans, in the Gulf of Mexico. The purpose of this post is to tell you a little about my trip.

(More below the fold).

First, I need to disclose that API paid for my trip.

API has underwritten Gail Tverberg’s travel expenses to attend the Shell location tour in New Orleans. Gail is not required to blog about API initiatives. The only requirement as a condition of underwriting these expenses was to include this disclosure of this relationship on her blog.

There were only three bloggers on this trip:

• Mark Hemingway of National Review

• Margot Gerritsen who teaches energy resources engineering at Stanford University

• Gail Tverberg of The Oil Drum

Also on the trip were Jane Van Ryan of API, Ignacio Gonzalas from Shell Oil, and plus two women assisting Jane with the trip.

Visit to Shell Facility in New Orleans

On Saturday, November 9, we started by having lunch together and talking a little about the reason for the trip. Shell and API would like to be more open about oil company operations and would like to have at least a few bloggers understand their operations better. Also, we talked a little about their view of the future of oil production. I would describe the views of both Ignacio and Jane to be "peak lite" views. With rising demand, and many of the older fields now in decline, they have real concerns about developing adequate energy resources to meet tomorrow's needs.

After lunch, we visited three areas in Shell's New Orleans facility that are involved with visualization of new sites and monitoring of existing oil fields. At each of these stops, we saw specially prepared presentations on how the centers operate.

Our first stop was SEPCoVE 3-D (Shell Exploration and Production Collaborative Virtual Environment). This is a virtual reality center where a team of specialists can meet to study a particular field's structure and plan a course of action. The room has a curved 24 foot screen. People viewing the images wear special three-D glasses, to get a better 3-D effect. We were told that Shell has about a dozen rooms like this around the world. The visualization centers were developed by the same companies that make 3D animation for amusement park rides. We saw some seismic 3-D images, so got a little feel for what the teams are looking at.

While in the SEPCoVE room, we heard a little about Shell's ventures into newer sources of energy. One they are particularly optimistic about is a shale oil extraction method using heating and freezing. It seemed to me that it was likely to be very energy intensive.

Next we visited the Shell/Halliburton Real Time Operations Center (RTOC). This is a center that can monitor up to 12 critical fields at a time. This is a large room filled with 75 monitors and 12 large screens. One of the goals in both SEPCoVE and RTOC is to minimize down-time of drilling rigs, since they are very expensive.

Third, we visited the Production Operations Management Center (POMC). We were told that a better name would be the Production Operations Monitoring Center, since what this group really does is monitoring, rather than management. In this room, a large number of less critical fields are monitored, to make certain that they are operating within expected parameters.

Part of the reason for POMC is to get maximum use from the limited number of people trained to do this kind of monitoring. By having both the recent graduates and the more experienced workers together in the same room, it is possible for the more experienced to help train the less experienced, and to leverage their knowledge to handle a large number of fields at a time.

Trip to Brutus TLP

Saturday morning, we took a helicopter to visit the Brutus Tension-Leg Platform (TLP). A TLP has four "hulls" (like legs) at the corners, and is tethered to the sea floor by 12 "tendons". The facility makes all its own power -- generally from the natural gas it produces -- and desalinates sea water for drinking.

We had a beautiful day for the visit--temperature in the upper 70's, sunny, with little wind. On the day we visited, the platform was perfectly still. We were told that on windy days, it moves in figure 8's. The platform cost a little under $1 billion to make, and was designed with a 30-year lifetime. The management of the platform spent the day showing us around. This was much more attention than I had expected.

One of the first things I asked was how much Brutus was producing. I had read in the literature that it began operation in 2001, and was designed with a maximum capacity of 100,000 barrels of oil and 150 million cubic feet of gas per day. I was told that the previous day's production was 28,000 barrels of oil and 40 million cubic feet of gas. This production may not have been entirely representative, but it was clear that the platform is producing quite a bit less than it was designed for. We were told that Shell has plans to add some type of gas lift in the second quarter of 2008, to enhance recovery.

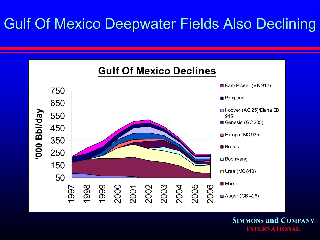

When I got back, I looked at Matt Simmons' slide from the Houston ASPO conference regarding Gulf of Mexico production.

Click to enlarge. Brutus is the black sliver starting in 2001. It rises to a quick peak, and starts declining, like the other GOM sites shown on the graph. On the trip, I was told that other Shell GOM sites are also planning some type of secondary recovery, starting in the next year or so. If I understood correctly, many of these are to be water injection.

It seems to me that Gulf of Mexico production will drop to non-economic levels for many of these fields within the next few years, even with secondary recovery methods. I asked whether the Brutus platform could be moved to another location, since it still has most of its 30-year lifetime left. I was told that the only way this would work is if a new location is found that is of approximately the same depth (2,985 feet) as the current location.

At this point, few new drilling sites are opening up in the 3,000 foot depth range. I expect that this is one reason that Shell (and others) are very interested in getting the portion of the Gull of Mexico near Florida opened up for exploration. If further Gulf exploration is delayed for 15 or 20 years, it may be necessary to start over with new platforms. By that time, onshore pipelines may also have deteriorated with disuse, and trained personnel may be unavailable.

The facility was much nicer than I had expected. Workers have rooms with bunk-beds, a desk and a television. Each room has a private bathroom for the two workers in the room. (I was told that this is unusual--most platforms have group bathrooms). The dining room is open for snacks as well as meals, and offers several choices of entrees. There were a couple of large gathering rooms, with large television screens. I noticed a "Wii" video game box next to one. No alcohol is permitted on board, and random drug testing is required. We were told that our group doubled the number of women on board, so about five out of the 90 or so workers on the platform must be women.

It seems like the Brutus platform would be a good place to work, at least for the next few years, before its operations cease. Workers spend two weeks on the platform, then two weeks on shore. Pay is good enough that some live in other states, and fly to New Orleans for two-week tours of duty. (If air travel becomes less available, workers may have to move closer to the platforms.) During the two-week tours of duty, the workers work 12 hours on, and then have 12 hours off.

Safety is given a very high priority -- we were told that there is fewer than one injury per year on the platform. One program that seems to work well is requiring any worker who sees a co-worker doing some activity in an unsafe (like forgetting safety goggles) to immediately counsel the co-worker on his behavior. There is no retribution against the person doing the unsafe activity. The number and types of these events is tabulated, and used in designing future safety (re)training sessions.

Ignacio from Shell took a number of pictures on the trip. His pictures can be found here.

These are a few pictures from the trip. Most will enlarge when clicked.

This is the helicopter we took to the platform. The 165 mile trip took about an hour. Margot from Stanford is standing in front with a microphone. She made a narrated movie of our trip, and plans to post it to her site.

This is a picture of the drilling floor. We watched the pipe drilling operation for several minutes.

This is a picture of a worker holding a drill bit. There are three rotating heads on it, and plus some nozzles.

This is a picture of one of the platform hulls. The bottoms of these have ballast tanks whose volume can be adjusted to keep the platform floating correctly.

This is the view from inside one of the hulls, looking downward. The hull is several stories tall.

This is one area in the dining room, with a selection of cereal boxes, a microwave, and a soup pot.

Hofmeister Speech/Town Hall Meeting in Atlanta

After I got back from the New Orleans/Brutus trip, I went to see John Hofmeister, president of Shell, speak in downtown Atlanta on "Meeting the Energy Challenge". He was in town for the last stop on a 50-city tour, giving this speech and conducting town-hall meetings. I would guess there were 300 or more attendees - all of the chairs were taken, and people were standing in the back of the room. Most of the invitees were from the general public, and were not peak-oil aware.

Mr. Hofmeister made what he called several outrageous statements. He said that the energy market had stopped working, so that increased price was not leading to increased supply. He blamed this on a variety of factors - greater demand from China and India; countries subsidizing the cost of fuels; resource nationalism; and oil exporters acting in their own self-interest.

Another "outrageous" statement he made was, "America is the only oil-importing nation that prohibits the development of its own resources." He credits this prohibition with moving jobs out of the country and worsening the balance of payment situation.

He went on to talk about various alternatives to oil production that are being considered (including hydrogen). He asked the audience for their input regarding alternatives in the town-hall session that followed. I thought Shell was to be commended for bringing the issue of energy security to the American people in the 50-city tour. I was disappointed that Hofmeister didn't mention peak oil as a concern, and didn't go into any pros or cons of the various alternatives.

http://science.reddit.com/info/61h6w/comments/

thanks for your support.

Well it looks like I was a bit late predicting the rapid decline of deep water gulf production :)

The short five year production profile is about what I expected thanks for the graph. Also what I find VERY interesting is that the platform was build for a 30 year life span. Did you find out if thats just a natural result of how its designed ? I'd have to think so. If they had known production would have been short i.e about 5 years would they have spent the money ?

Now that they know that production profiles are short will they spend more money ?

Overall from reading your post I get the feeling that they expected to produce a lot more oil for a lot longer out of this platform.

Thanks !

I am sure that they hoped to get a longer lifetime in the current location. I am sure that they hoped to move it to one or more additional locations as well.

The platforms have to be sturdy to withstand hurricanes, so pretty much have to be built for fairly long lifetimes. Brutus didn't have any problems with the 2005 hurricanes.

Gail, thank you for an interesting report.

As Royal Dutch Shell was a pioneer in expanding "Scenario Planning" in the late 1960's, it would seem reasonable to expect Mr Hofmeister to be well-informed regarding Peak Oil. Either he doesn't want to rock the boat, or Shell has lost its lead in strategic planning.

PLAN, PLANt, PLANet

Errol in Miami

Sounds like a fine day out! I suspect the statement about the rig being limited to that water depth is not quite accurate. These rigs may have several refits in their lifetimes and be reconfigured for different conditions. Besides, given current rig shortages, most new rigs would find work in other areas of the world - subject to reasonable contract terms and length of tenure.

The comment about "America prohibiting development of its own resources" is plainly intended to be controversial and just daft. Yes - the US limits some areas, but consider the current Baker Hughes rig count figures: 1762 out of 3124 rigs drilling in October 2007 were drilling in America. Put another way 56.4% of all rigs in the world are drilling in the US. It is riddled with wells! Compare that rig count with production as a world percentage.

I was told that there is a range around the depth at which a TLP such as this one can be used, but that it definitely is not suitable for deep water. If I understood correctly, the weight of the long pipes reaching to the sea floor would be a problem. I know that there was some weight that was a problem.

The rigs that are used in deep water are smaller, and are not tethered to the sea floor. They bob around in the waves a fair amount, more like a ship.

I think you understood correctly Gail.

Longer legs (tendons) would be required for deeper water, but the extra weight would require greater buoyancy. The buoyancy tanks would allow some range of operation, but if you need to fit bigger tanks you have then effectively built a new TLP.

Gail, are you sure about this? Drill ships are, of course, not tethered. But they have GPS and must keep their engines always pushing against the wind to keep them in the exact same spot, else the wind and waves would snap the drill pipe. A platform, unless it was tethered, would need engines and propellars, always running, to keep the platform in the exact same spot.

Ron Patterson

This was the impression I received - more from the point of view that the workers liked living on the tethered ships better, because they were more stable. I am sure you are right that they would need engines pushing against the wind and current. I don't know how effective the engines would be, especially in offsetting the waves coming by.

It seems like I saw some sort of device that that allowed Brutus to bounce a little more than the pipes (or vice versa). It may be that there is some similar device involved with deep water platforms.

Gail, it is the design of the platform that keeps the it from bobbing up and down like a ship would do, not the tethers. The platform's four very deep hulls or legs, make it very slow to respond to waves, averageing them out so you get very little up and down action because of the waves. A much smaller platform would naturally be much more succeptable to wave action.

The tethers have some slack in them and this allows the platform to move up and down with the tides as well as swells and waves.

Steel tethers are only good for up to 1500 meters (4,920 feet) but Composite Carbon Fiber tethers allow a platform to be tethered in 3,000 meters (9,840 feet) of water.

I think you misunderstood the workers on the platform. All platforms, that are not standing on the sea floor, are tethered.

Ron Patterson

I am wondering on the very deep sea platforms if there is a difference between the drill ship and the platform. The drill ships or drilling rigs have to be very stable, but the platforms may not have to be.

I mentioned below that some of Brutus's wells are subsea wells, that are not directly below the platform. They are linked by flexible tubing to the platform.

With very deep sea platform's, I am wondering if all of the wells are of this type. They are originally drilled by some specialized drilling rig, but then they are linked with flexible tubing to a platform, that may be at a distance.

Brutus has a total of 12 tethers, three for each hull. My impression from the diagram I saw was that the very deep sea platforms may have only one tether.

That may very well be the case. The smaller platforms have only one hull, and due to the flexability of the tubing they may need only one tether.

I really don't see how the tubing could be the tether but perhaps they have some special desing in the tubing that allows this. We need someone in the oil business to answer these questions.

Ron Patterson

I think the tubing and the tethers are two separate things.

You can find all this information via Google, Ron, if you care to look.

Bob, please don't lecture me about using Google. I have googled "Tethered oil platforms" and every other combination imaginable. I found nothing but the links I have already posted except one about tethering offshore wind farms.

I know how to use google and I do use it extensively. If I ask a question, you can be damn well assured that I have already googled it and did not find a satisfactory answer.

Thank you for your sarcastic comment anyway.

Ron Patterson

Ron:

I've found some interesting things here: http://www.offshore-mag.com/resourcecenter/os_poster_series.cfm

I hadn't looked at this site. Offshore magazine, Oil and Gas Journal, and LNG observer all seem to be affiliated. You have to have a subscription for some things on the site, but you can get quite a lot of free stuff, including a big poster with all kinds of statistics about the various off-shore oil platform.

"I found nothing"...

Hey, Ron, I was about to apologise, but I find thousands of links for your query. Also I easily found many explanatory links for oil platform, drill ship, semi-submersible platform, tension leg platform etc. Therefore I find your claim hard to believe.

I stand by my claim these things are easy to find, but I did assume the level of skill required in searching was low.

Rather than speculate about what you do not know, why did you not declare you had no good information? I think you are a bit pissed because I called your bluff. ;)

Right Bob, google (Tethered Offshor Oil Platforms) and you get 78,700 replies. None of them are even remotely related to the discussion. There are thousands about offshore oil platforms, or oil, or platforms, or thethered but nothing that even came close to answering our question. Except the one I posted which I found by using Google. But it did not completely answer the question. It was only about carbon fiber tethers and how they were made. I could find nothing addressing the question Gail and I were discussing. Nothing Bob, but if you can find a page discussing how platforms are tethered, how deepwater smaller platforms are tethered, and whether the platform is allowed to move or not, then please post it.

Bob, did you actually look at any of the pages? Or, as I suspect, you just saw the number of pages that fit at least one of the words in the search phrase? Then you replied that you got thousands of hits? It doesn't matter if you got a million hits, what matters is what information was on the pages.

Do the search again Bob. Then tell me which page answeres the question Gail and I were discussing. Then tell me how many pages you had to examine before you found it. I examined, not thousands, but dozens that looked the most promising. NONE of them even remotely addressed the question Gail and I were discussing.

Why are you such a dick head Bob? Must you always be so damn sarcastic. This is not a list where we try to put each other down. We are trying to gather information that pertains to peak oil but there are always a few really smart asses in the crowd who try to show their superiority by being an absolute smart ass.

Ron Patterson

Ok I will try to find time to cover a drilling 101 since there are a lot of questions being raised here about TLP systems, Dynamic positioning, Marine risers, rig types, drill bit sizes etc.

I will try to put it together and email to TOD.

May take a couple of days , cos we are a bit busy at the moment :-)

You might send it to me. My e-mail address is GailTverberg at comcast dot net.

tried to email you without success.

Excuse the cumbersome links.

Notes on Drilling Rigs

Further to Gail – the – Actuary’s recent visit to a Tension Leg Platform, here is a brief guide to Rig types. There are several types: mobile and fixed installations

Geographically Mobile General Depths

1. Land Rig Land and shallow islands

2. Barge Inshore and swamps

3. Jack Up To water depths of ca 100m

4. Anchored Semi submersibles To Water depths of ca. 500m

5. Semi submersibles using dynamic positioning To water depths of 2000m

6. Drillships, again using dynamic positioning To water depths of 3000m

Geographically Fixed

1. Jacket Platform

2. Tension Leg platform

3. Floating production platform

A useful schematic of a basic land rig can be found here, And the article is worth reading in full.

http://images.google.co.uk/imgres?imgurl=http://www.exxonmobil.com/Corpo...

Here is a useful introduction from the UKOOA Website:

How oil is formed:

http://www.ukooa.co.uk/education/students/origins.cfm

How oil migrates and is trapped:

http://www.ukooa.co.uk/education/students/move.cfm

How the search commences:

http://www.ukooa.co.uk/education/students/searchog.cfm

Drilling:

http://www.ukooa.co.uk/education/students/drilling.cfm

How oil is produced:

http://www.ukooa.co.uk/education/students/production.cfm

Looking at each in turn.

LAND RIGS (and Barges)

Have not really changed much in principle for the last 60 years. Though they have grown larger in size to accommodate drilling to greater depths.

Basic components are a hoisting system (Derrick); A prime mover – usually a diesel engine that provides electric power to the lifting system and to the rotary table which enables the rotation of the drill pipe and supplies power to the mud pumps for the circulation of drilling mud.

A series of tanks store the drilling mud. This is pumped down the drill pipe from surface and through the nozzles of the drill bit. Drilling mud used to:

1. Lubricate and cool the drill bit.

2. Provide a pressure at depth that is at least equal to any pressures in the formation that have or are being drilled.

3. As the drill bit breaks up rock formations into cuttings, these are carried back to surface in the Annulus by the drill fluid. Shaker screens at the surface separate the drilling mud from the rock cuttings in order to reuse the drilling fluid.

JACK UP RIGS

If you take the basic package as described above and add accommodation and storage into a large barge and also add three or four legs that are jacked down to the sea bed and the barge is then jacked up above seal level then you have a jack up rig:

http://images.google.co.uk/imgres?imgurl=http://www.dockwise.com/files/v...

As you can see from this picture, they can be lifted and transported over long distances and can also be towed over short distances.

Jack ups are shallow water dwellers. Such as the southern and central north sea, inshore GOM.

SEMISUBMERSIBLES

If you take the drilling package, accommodation modules etc and build them onto pontoons, and then you can tow the rig around, fill the pontoons with water and anchor them to the sea bead while the rig floats. These beasts live in water depths of up to ca 500 metres. They are useful in the deeper areas of the North Sea and Atlantic margin.

Here is a typical Semi and you can clearly see the pontoons:

http://images.google.co.uk/imgres?imgurl=http://www.allum.no/images/bing...

DEEP WATER SEMISUBMERSIBLES

Larger and more powerful than the usual semi sub, these are built for deeper water where the depths do not allow full anchoring to the sea floor. They are controlled and held in position by propulsion units on all sides or ‘Dynamic Positioning ‘Again, they are usually towed into position by tugs.

Here is the Leif Eriksson:

http://www.jotun.com/www/us/20020225.nsf?OpenDatabase&db=/www/us/2002022...

DRILLSHIPS

The self contained drilling and accommodation modules are housed in the hull of a ship. They can move under their own power and maintain position over the well being drilled by dynamic positioning. These are the beasts of deepwater.

http://www.marinetalk.com/articles-marine-companies/art/Ultra-Deepwater-...

All of the above are MOBILE and are used for exploration and appraisal. In some cases, a Jack up can act as a production platform as well.

In order to maintain control of the well and ensure returns of drilling mud to the surface, you need two specific pieces of kit:

MARINE RISER – a pipe from the rig to the sea floor. In order to cope with heave and tide on a floating system, then the Marine Riser is fitted with a TROMBONE JOINT which allows movement in the vertical. These risers latch onto the BLOW OUT PREVENTER

On a guide base on the sea floor sits the Blow out preventer. This is a series of hydraulic rams that can close around the drillpipe or in extreme cases shear through the drillpipe.

Here is a nice schematic of all types as seen from the sea floor: It includes a TLP

http://images.google.co.uk/imgres?imgurl=http://www.offshore-technology....

Platforms which stand on the seabed are fairly self explanatory. They have production pipe work from wells and also a marine riser system for drilling over a template of slots on the sea floor.

TENSION LEG PLATFORMS

Where water depths are too great to construct a jacket, TLP systems are a solution.

This details design and construction pretty well:

http://www.offshore-technology.com/projects/ursa/

The buoyant platform is anchored in place by TENDONS. 32 Inches in diameter with a wall thickness of 1.5 inches. In total, the tendons weigh 16000 tons There are 16 tendons with four at each corner. The TLP is capable of drilling and Producing.

FLOATING PRODUCTION PLATFORMS (FPSO) Are basically ships.

Here is AKPO, Offshore Nigeria:

http://www.ship-technology.com/projects/akpofpso/

LETS LOOK AT ARCTIC RIGS (SAKHALIN, Shallow water, Ice bound most months.)

Here is one solution:

http://www.hydrocarbons-technology.com/projects/sakhalin2/

‘’MOLIKPAQ (PA-A) PLATFORM

The Molikpaq offshore platform is the centre of the Vityaz Production Complex. It is a converted drilling rig that was first used in Arctic waters offshore Canada. In 1998, the Molikpaq was towed to Korea where it was upgraded for the Sakhalin II Project. It was then towed from Korea to Russia where a steel 'spacer', manufactured by the Amur Shipyard was retro-fitted to the bottom of the Molikpaq so that it could be used in the deeper offshore waters at Sakhalin Island. The structure was specially constructed for use in severe ice conditions. The completed steel and concrete substructure was filled with sand permanently anchoring it to the seabed.

During Phase 2 of the Sakhalin II Project the Molikpaq platform will be connected to the new pipeline infrastructure allowing year-round production.

Molikpaq sits 16km offshore, north east of Sakhalin. The platform is 120m wide, weighs 37,523t, and is home to over 150 people. Molikpaq is ballasted down with 278,000m³ of sand. In the winter, offshore temperatures, with the wind chill, drop to -70°C.

LUNSKOYE (LUN-A) PLATFORM

The LUN-A platform will be located 15km off the north eastern coast of Sakhalin Island, in 48m of water. This is a drilling and production platform with minimum processing facilities. Oil / condensate and gas separation, including gas treatment for transport to the LNG plant, will be carried out onshore at the Onshore Processing Facility (OPF). This platform will produce the majority of the gas for the LNG plant. Construction was started in July 2003 and production is scheduled to begin in the first quarter of 2007.’’

AND NOW CANADA – THE HIBERNIA OFFSHORE FIELD:

http://www.offshore-technology.com/projects/hibernia/

DEVELOPMENT OF HIBERNIA

It was decided that the Hibernia field would be developed using a special gravity-base structure, strong enough to withstand a collision with a one-million-tonne iceberg (expected to occur once every 500 years) and a direct hit from a six-million-tonne iceberg (expected just once every 10,000 years).

Hope this helps.

Will do some basic notes on drilling a well later.

Very interesting! Thanks.

My e-mail should work. The most common mistakes are putting a period between my first and last (there isn't any) and misspelling my last name. Most people can't believe that the first two letters are "t" and "v". My surname is Norwegian.

My e-mail address is also given when you click on "gail the actuary" in the staff section.

I thought of another reason my e-mail may not work. I have had difficulty with some overseas e-mails. I see you are in the UK.

Try this one instead:

info at tverbergactuarial dot com

Thanks.

Will try again next time.

Here is some basics on constructing a well:

DRILLING A WELL.

Let us start with a Semi-submersible, say working in the North Sea. Lets start with a vertical well.

Key Components.

The Semi is in position over the guide base, anchors are positioned, the initial spud phase of the well is complete and the 26 inch conductor has been driven into the loose sands and clays at the sea bed.

The Marine riser is latched on to the Blow out preventor and the Riser travels all the way up from the BOP on the sea bed up to the underside of the Drill Floor. The trombone joint on the Marine Riser allows for the vertical movement of the Marine Riser. The riser is suspended in place using steel ropes. The riser is connected to the rig circulating system through a flow line.

The Schlumberger online glossary is a superb tool for looking up terms.

BOP

http://www.glossary.oilfield.slb.com/Display.cfm?Term=BOP%20stack

RISER

http://www.glossary.oilfield.slb.com/Display.cfm?Term=drilling%20riser

The Equipment on the Drill floor

http://www.glossary.oilfield.slb.com/Display.cfm?Term=rig%20floor

The Derrick

http://www.glossary.oilfield.slb.com/Display.cfm?Term=derrick

The Travelling Blocks

http://www.glossary.oilfield.slb.com/Display.cfm?Term=traveling%20block

The Top Drive

http://www.glossary.oilfield.slb.com/Display.cfm?Term=topdrive

The Rotary Table

http://www.glossary.oilfield.slb.com/Display.cfm?Term=rotary%20table

The drill crew make up the Bottom Hole assembly (BHA) in sections starting with the drill bit, drill collars and stabilisers and perhaps an Measurement While Drilling tool.

Drill bit

http://www.glossary.oilfield.slb.com/Display.cfm?Term=bit

Drill Collars

http://www.glossary.oilfield.slb.com/Display.cfm?Term=drill%20collar

Measurement While Drilling tool

http://www.glossary.oilfield.slb.com/Display.cfm?Term=measurements%2Dwhi...

When the BHA is made up then Drill pipe is added

http://www.glossary.oilfield.slb.com/Display.cfm?Term=drillpipe

Drilling fluid is mixed to the correct properties (yield point, gel strength, oil water ratio, density, viscosity etc by the drill crew and the mud engineer.

Drilling fluid

http://www.glossary.oilfield.slb.com/Display.cfm?Term=drilling%20fluid

Mud Engineer

http://www.glossary.oilfield.slb.com/Display.cfm?Term=mud%20engineer

The mud is stored in pits and can be pumped down the drill string using very large triplex pumps which form part of the circulating system.

http://www.glossary.oilfield.slb.com/Display.cfm?Term=circulation%20system

So, we can start drilling. The drilling fluid lubricates the bit, removes cuttings back to surface and helps maintain well bore stability.

The Mudlogger and Wellsite Geologist analyses and describes the cuttings. And construct a log.

http://www.glossary.oilfield.slb.com/Display.cfm?Term=lithostratigraphy

http://en.wikipedia.org/wiki/Mudlogger

At the start, the hole diameter is fairly large and when a certain depth is reached then

Drilling is stopped. This is section Total Depth or TD.

Why Stop?

The hole sections need to be cased off at intervals to avoid , hole collapse, hole washout, squeezing etc or because the next section may contain formations that are over pressured and the safe way to control the well if a kick occurs is to have the looser, less competent beds sealed off behind casing and cemented in. The bit is tripped out back to surface, and Casing is run.

http://www.glossary.oilfield.slb.com/Display.cfm?Term=casing

The casing string is a lesser diameter than the drill bit that has just been used to section TD. The BOP’s are re-latched after testing, the riser re latched and a new drill string and BHA with a smaller diameter bit is made up, run into bottom. The casing shoe is drilled out and a few feet of hole drilled. A formation Integrity test is performed by pressurising the formation up in order to see if the formation could stand the pressure of a gas or fluid kick. http://www.glossary.oilfield.slb.com/Display.cfm?Term=formation%20fractu...

Drilling continues to the next section TD.

Typically, Well bore diameters are as follows: (In inches)

BIT , CASING

17 ½ , 13 3/8

Next section:

12 ¼ , 9 5/8

Next section

8 ½ , 7 (usually by the time you are at 8 ½, then you are at the reservoir)

Any further sections:

6, 5

The casing setting depths are planned by the Company Geologists, Drilling Engineers at the well planning stage. Variations occur due to formations coming shallow or deeper than prognosed, but when that happens there is a significant amount of communication to ensure optimum setting depth.

http://www.glossary.oilfield.slb.com/Display.cfm?Term=drilling%20procedure

At final TD , the Open section of Hole is logged.

http://www.glossary.oilfield.slb.com/Display.cfm?Term=logging%20run

http://www.glossary.oilfield.slb.com/Display.cfm?Term=wireline%20log

Depending upon the type of hole (Exploration, Appriasal , Development, ) then well is plugged and abandoned or completed as a producer.

This next link is very good and I wish I had spotted it before the last post:

http://www.naturalgas.org/naturalgas/extraction_offshore.asp

All drill ships and semi-submersibles will be equipped with a motion compensation system to address the problem of vessel motion in a sea way. All drilling systems need to be motion stabilzed.

On the systems that I am familiar with the entire drill floor is suspended on a set of compensators with one situated at each corner of the drill floor. These act to raise or lower the drill floor in order to counteract vessel motion. In effect the drill floor remains fixed in space and the drilling vessel pitches around it.

Motion compensation is required as without it vessel motion would be transferred to the drill string. This vertical motion may initiate a pumping action (swabbing)that increases the liklihood of a loss of well control. In the pictures from your trip I cannot see any motion compensation equipment. I have never worked in GOM but suspect it is a bit of a millpond - on the Grand Banks we rode out 70 footers (after disconnect and hang off) and a TLP would be unable to deal with this range of motion.

The drill string reaches the seafloor through a riser system. This is not used to secure the vessel; it is just a closed conduit between the VL and the BOP on the sea floor.

Drill ships and semi-subs will normally be anchored and the anchor system can be tensioned to maintain VL lateral position. In severe weather VL thrusters will also be used to counter sea motion and in some deepwater systems Dynamic Positioning using thrusters is all that is used as water depth precludes running anchors.

Sorry to hear you didn't have to go through offshore survival training to get offshore - the heli ditiching module is lots of fun!!

Cheers!

Maybe you can address one of my questions on offshore platforms.

How does the industry intend to compensate for movements of pack ice when placing these in the new spheres opened by Arctic thawing? Impossible, there won't be offshore platforms in the Arctic, or does perhaps Statoil have some expertise in this area?

IIRC, one newspaper article I read a while back seemed to suggest that there might not be offshore platforms in the arctic. The article talked about subsea wells with flexible tubing, connected to an underwater hub. It seems like the underwater hubs would have to be pretty deep, to stay out of the way of icebergs.

The folks with the most experience in arctic waters would be those who worked for Dome Petroleum and HBOG (both now defunct). Dome built gravel islands atop its locations and was looking at harsh environment jack-ups before the bottom fell out of the market in the mid 80's.

The arctic is relatively shallow and the ice is largely floating floe or pan ice. The bergs are calved from the glaciers on Greenland and the folks with the most experience in dealing with those are working Hibernia and the adjacent locations. Hibernia is a GBS platform and this was designed to withstand a direct iceberg hit; when it finally occurs we will have an answer to what happens when irresistible force meets immovable object.

The floating units have explosive links in their anchor cables so they can sever these and move off location if this is required. Problem is it is very difficult to project the future track of an oncoming berg. I remember days staring at an oncoming mountain of ice. You don't want to cut and run to the left because the berg may go over there. And you don't want to run to the right because maybe it will mosey down that way. Safer to just stay where you are and face it down. A long drawn out, very slow moving, high stakes poker game.

My hunch is that if they do drill the arctic they will use jack ups for deep water and build gravel pads and islands along the coast. Given current environmental projections, ice will not be a problem. You can get short steep seas but generally these are not a problem.

You are making the assumption that there will be wildcatting in the Arctic. I appreciate all the graphs that Stuart and Euan churn out (WHT's article is a doozy) but what we are talking about is not pools of oil but great big pools of money. If there were a few hundred billion dollars sitting in a corner of Kansas, how long do you think it would sit there before it walked off, or got claimed? Not long at all. If there were several hundred billion dollars just under the Florida coast do you think everyone would just sit back all relaxed and talk about how we got to preserve the scenic view? Do you believe the oil industry is unable to buy the government it wants?

The oil industry pumps dollars and they have no hesitation about using this cashflow to ensure access to even more money. If there was oil in the Arctic, Dome and HBOG would still be operating today and rolling in cash. There is a lot of stranded gas up there but all this talk of oil is a chimera. It's all rumour oil. The fact that no major is rolling heavy equipment into the arctic, or fighting tooth and nail to secure a lease offshore Florida, suggests there is not much worth fighting over. Why would you spend billions cooking up muck in Alberta if you could just go punch a nice clean hole in the ocean and let untold billions flow into your accounts? Where is the romance in driving a dump truck?

There is no slack in the tendons, they are rigid steel pipes 32in across and 1.25in thick. The whole point of the design is that the tendons are kept in permanent tension by anchoring to the sea bed at one end and the buoyancy of the hulls at the surface. If the platform moved up and down the tendons would break - they are not designed to carry a compressive load.

All this stuff is on the Shell web site btw.

Great post. The Simmons' figure is for U.S. Gulf waters. The U.S. is buying from Mexico's declining production. Any studies or thoughts on what Mexico can hope to find in the Gulf?

I used to be invited to the API weekly conference calls, but I got dropped apparently (no invites for many months).

I could have taken the streetcar down (or walked, it is 1.2 miles) to One Shell Square. Sorry I missed it, but I am not on API's good list anymore it seems. (Was it the questions I asked ?)

Alan

Thanks for that report on your field trip, Gail. Fascinating stuff.

Gail:

Thanks for the insight about the huge investment risks that oil cos. such as Shell are making in the Gulf of Mexico. I have seen drill bits close up at a company that rebuilt them. I am surprised at the small size for such a deep well - same size as for a 500 foot well.

One comment about Hofmeister's statement "the energy markets have stopped working". I believe he is correct in making this statement because the free market is not applicable to the global oil trade anymore. State owned oil companies are largely controlling the export price by limiting what can be produced and who they will sell it to. Case in point is Venezuela and their decision to supply certain friendly countries at discounted price while restricting the amount available to the US through open markets.

Too bad Shell did not give a status report on the oil shale project and their involvement in expanding Canadian

tar sands production, both of which are lagging in producing expected amounts of oil.

It's very strange, when I studied Economics 101, I learned that the market system was a way to ration (finite) resources. I never studied more, but it seems when you get to Advanced Economics, the market system turns into something that is supposed to produce infinite resources.

Of course, what Hofmeister means by "stopped working" is "not providing unlimited profits for the Shell corporation".

Oil companies have always been pretty myopic about their business. When electric lighting killed the market for kerosene lamps, the oil companies were heading for extinction - until someone invented the internal combustion engine, creating a whole new market for them.

Hofmeister should heed the advert occasionally shown on the left: "innovate or die".

I agree that he may have had profits in mind when Shell's Hofmeister said that the markets have ceased to work, meaning for them; but the cause is the same.

His comments about US restraining exploration is greatly exagerated. Much more land has recently been available for exploration in US west, especially for gas.

Regarding oil companies losing business around 1900: they did have other oil products besides kerosene, like oil used to power locomotives on the western RR's starting around 1900. Also a lot of oil was used for lubricanting machinery, including RR axles. But the big user became the ICE which caused greatly increased oil demand after WWI. Without that demand oil cos. would likely never have gotten so big so fast, quickly surpasing the RR's in financial strength.

Free Markets are maybe desirable, but we've sure never seen one.

Free for whom?

The resource nationalists are practicing a kind of free market when deciding when and at what price they are willing to sell oil. So resource nationalism might be a matter of husbanding a limited resource for maximum benefit to the nation that "owns" the oil.

The great market failure is beyond the ken of Hofmeister and Company.

The great market failure is that we have decimated our own life support system without bothering to understand our relationship to it.

By depleting resources and dumping toxins into our environment, we have kicked off the Sixth Great Extinction, which is very likely to include our own species.

That's a humdinger of a market failure.

It seems odd to be stuck talking about reality in terms which exclude the most important aspects of the reality in which we live.

But good public relations propaganda controls thought by controlling the terms and scope of the conversation.

Isn't that what these trips with bloggers are ultimately about? -- What do you think, Gail?

I think one of the great failures is of the eduction system. It hasn't understood how important the energy system is to the world's functioning, and to how temporary the current energy system is. The discussion of energy and its impacts fell between the various disciplines. It also hasn't understood that economic "theory" is a collection of poorly tested hypotheses, and has given it far too much weight. The education system didn't understand all of the ecosystem problems 50 or 100 years ago, which is when we probably should have cut way back.

I wouldn't worry too much about API controlling the terms and the scope of the conversation. They can add their bit to the conversation, and try to get people thinking about issues, but I don't see them doing any controlling.

Thanks for that perspective, Gail!

I'm just back from working all day -- no computer access -- plus dinner with family.

After 10-12 hours or so, I finally get to scan through TOD.

I agree -- in fact we've managed to screen out some of the most important information related to our species survival, while making mountains of fantasy out of molehills of wishful thinking, and then basing our culture on the dubious superstitions we've generated.

Asking good questions is always difficult, and usually a good indicator that one is about to be laughed at, shunned, or crucified. Or all of the above.

It is a bit comforting to consider that API will not be able to control the terms and scope of the conversation regarding energy, global warming, and our collective future.

You're right, the drill bit that the worker is pointing at in pic no. 3 below the fold is no bigger than the bit that the well driller used to drill the 600-foot-deep hole for our ground-source heat pump. In pic no. 2 below the fold, showing the drilling floor, the rack of extension tubes at right are about the same size as the ones the well driller used on our geo system. Basically all the same equipment, the offshore rig just needs a bigger support system... Great post by Gail.

A 600 foot deep hole for a ground source heat pump? Why bother? The energy cost of moving the water up from such a depth would seem to make it not worth the bother. Why not just do a shallower horizontal closed system?

Most likely the 600 foot hole is not 600 feet to reach water, but the column of water created (probably 500-550 of the 600) is needed for the Geothermal exchange to work properly. In fact, depending on the design, 75%-100% flows back down the hole, and with a circular loop, the pumping requirement is actually less than circulating the thicker glycol solution through several thousand feet of Polyethylene pipe. Also, using a deep well keeps your water temperature higher, making the unit run 25-40% more efficient than with a closed buried loop.

One question I wonder about is how dependent ground source heat pumps are on electricity. I am not certain how soon we will be seeing frequently electrical outages - outages have begun in some parts of the world, and may be only a few years away in some parts of the US. We had scheduled blackouts in California when one of their nuclear plants was down a few years ago, so this is not as far-fetched as one might think.

They run on electricity, but far more efficient than anything else. So in the case of a long term outtage, as I get sometimes, I have a PTO Generator for my tractor. Also I have a woodstove which I use much less than I used too prior to the Geothermal install. Also, when running backwards for Air Conditioning, they are far more efficient than the best Air conditioner out there. If these installations became main stream, the conservation of electricity in the summer would be very significant. And could alleviate electricity grid loads in the summer. Just another part of the conservation solution.

I am thinking about this more from Liebig's Law of the Minimum.

There are a lot of nice conservation efforts that will work, as long as we can keep some minimum level of electricity going. Once it is out frequently, the conservation measures aren't likely to work either.

"Case in point is Venezuela and their decision to supply certain friendly countries at discounted price while restricting the amount available to the US through open markets."

Venezuela does trade small amounts of oil for Cuban medical personnel and has provided discounted products to some poor countries, also in small amounts. It has also signed a long term supply agreement with China (where it will be available for the likes of US automakers). Is this what you mean by "restricting the amount available to the US"? It sounds more like a mix of smart policy and Christian charity to me. Customer diversification is always smart policy. Moreover, nobody in their right mind would want to be dependent on the (sinking) purchasing power of the crumbling empire.

By the way, where was the free market during the haydays of oil discovery? Does Texas Railway Commission ring a bell?

tfo -- this recent article by George Monbiot for The Guardian might help to answer questions about how much the "Free Marketeers" are really for a free market at all.

http://www.guardian.co.uk/Columnists/Column/0,,2197186,00.html

Monbiot traces the writing of the self-proclaimed "libertarian" Matt Ridley -- also the head of a certain Northern Rock Bank in England -- who stated that he had no need of government at all, and that he could scientifically demonstrate that humans do better without government and a "free market" without government regulation or "interference."

When Northern Rock recently tanked, they went crawling on hands and knees to ... the Government (!) ... to arrange for a huge 16 billion pound bailout. Now a leading businessman is calling is calling for it to be nationalized to avoid insolvency.

The Free Market superstition is pervasive and may very well be fatal. Monbiot offers some clear-headed suggestions as to how the checks and balances of civilization must be promoted, not whined away by those who have no idea that they are cutting off the branch upon which they themselves sit.

This gets back to Gail's comment above about a failure of education.

I'll add to that comment this: "Economic theory as we know it is strictly political propaganda masquerading as scientific knowledge."

A right-wing blogger known as Captain Ed from Captain's Quarters was also invited recently to one of these API/Shell gatherings. So it looks like it is a fairly sophisticated press/marketing strategy on API's part on behalf of Shell. This is what Ed has to say about oil depletion:

http://www.captainsquartersblog.com/mt/archives/015224.php

Of course he doesn't have much to say about the specific trip itself, other than to use it to market the bloviatings of the man that TBogg calls Special Ed:

http://www.captainsquartersblog.com/mt/fastsearch?query=American+Petrole...

I don't think Ed got invited to visit the rig because the old cap'n is afraid of deep water :)

As a non-oil expert I have trouble fending off the charges that the shortage is artificial, the product of liberal restrictions on drilling. So how much potential production has been held back? My list of restricted oil provinces is likley incomplete:

Coastal California, ANWR, Georges Bank, and Eastern GOM. With the exception of ANWR these areas have been offlimits because of local NIMBYisms, not national policy. My guess is the total reserves are not likley very large, but real numbers could be useful in fending off such charges.

For ANWR, try the USGS:

http://pubs.usgs.gov/fs/fs-0028-01/fs-0028-01.htm

http://pubs.usgs.gov/of/2005/1217/

Bottom line... there is a "mean" chance of recovering about 10 billion barrels from the ANWR area (includes a bit more land than just the particular parcel #1002.)

Sounds like a lot... until you realize that the US consumes 7.5 billion barrels a year. As it would take decades to actually produce that 10 billion barrels, the average daily amount (over the life of production) isn't too large.

Not that I'm against drilling there.. by all means drill. At best what can we expect of the outcome - that oil prices may dip a couple of dollars a barrel for a year or two?

That is the problem, or rather, the hard part of the problem for many Americans who otherwise complain about off-limited lands. The sheer size of oil consumption annually dwarfs any reasonable expectation of production from the off-limit areas.

Again, I'm all for drilling wherever... if only to finally answer those who keep whining that the oil problems the US faces are due to restrictions.

I think we are on the same wavelength. I had remembered ANWR as circa 10GB. I don't even have guesses for the other reas. Without numbers it is hard to counter assertions that we are shutting off vast supplies. I think Joe Sixpack generally believes these myths. And that was political and policy implications.

Gail,

"we heard a little about Shell's ventures into newer sources of energy. One they are particularly optimistic about is a shale oil extraction method using heating and freezing."

I thought Shell had given up on this method in CO this last summer as it was not working/profitable. Do they intend to resume, or did I read incorrectly?

I don't think they gave up on this technology. But Shell did not request to the US gov. an expansion of the leased area where the projects sits. This expansion was to be for the next phase of the project, as I recall from an item on energybulletin.net. Also Shell has not issued any progress reports on the oil shale project lately, not a good sign that their tests are producing oil in meaningful amounts at economical price, IMHO.

Lack of available water may be an issue as well in the decision whether or not to expand this technology.

Insufficient water is one limiting factor I've heard. One of my questions is what happens when they leave-the frozen wall is constructed to prevent groundwater infiltration/contamination during extraction. The tech has been apparently proven on much smaller scale construction sites. When the wall is no longer frozen, then what-the shale is resolidified and won't mix? Sounds like a great plan, but I doublt all the liquids and gas will be pumped out. Any plans to address this?

Thanks for the clarification. Further search found this:

"Shell spokeswoman Jill Davis said the withdrawal of a permit on one of its three oil-shale research and demonstration leases was done for economic reasons: Costs for building an underground wall of frozen water to contain melted shale have "significantly escalated."

"We are being more cautious and more prudent," Davis said. "Because of the nature of research you have challenges. With that in mind, it is taking a little longer to build a freeze wall than we planned."

Davis stressed that the withdrawal of the mining permit does not lessen Shell's commitment to continuing research at its Mahogany Research Project between Rangely and Meeker and eventually building demonstration projects on its federal leases.

"There is a very active program up there, and that will continue," Davis said. "

http://www.denverpost.com/extremes/ci_6155257

Does anybody else see the insanity of building a gigantic freezer so you can cook the shale? In order for the freeze wall to be far enough away from the cooker it must be extremely long compared to the area being cooked.

"Davis stressed that the withdrawal of the mining permit does not lessen Shell's commitment to continuing research at its Mahogany Research Project between Rangely and Meeker and eventually building demonstration projects on its federal leases."

Yeah, they're committed alright. They just don't want to pay for it.

SubKommander Dred

Good question. I have a cousin who is a Peak-Oil-aware attorney. He lives in Houston and worked on a study on that very issue. According to him Shell was having a lot of problems and bailed out. He didn't say it like he thought it was temporary, although I admit to not questioning him more deeply. Between the turkey and rambunctious children it was not a good time for that level of conversation.

Great post Gail. Brings it home for the non-techies who lurk here, myself in particular.

Gail,

Regarding the Simmons chart you show, am I correct in assuming that what is being depicted in it is the decline of currently producing rigs, not rigs coming online?

The reason I say this is because there is no mention of the big BP rigs, "Thunderhorse" or "Mad Dog" production.

Correct me if I am risreading the chart.

Thanks,

RC

This chart shows historical production, not any estimate of future production.

I believe Thunder Horse never came on line. It was damaged in early 2005 before it started production, and is not expected to go on line until mid-2008.

I'm not sure why Mad Dog is omitted. It seems to have had a little production, but perhaps it is too little to show on the graph. It started production on January 2005, and was up to production of 50,000 barrels per day by early 2007. Production may have been lower in 2005 and 2006.

http://www.petroleumnews.com/pntruncate/1819520.shtml

Roger, I think this is just a chart to show the decline rate of deepwater rigs. I don't think it was ever intended to represent all rigs. The Gulf of Mexico produced, before Katrina and Rita, about 1.5 million barrels per day. This was the figure the EIA used when giving us their weekly reports of how much production was down due to the hurricanes. That was in the summer of 2005. This chart shows about a quarter of that production so it obviously left a lot of platforms out.

I have no idea what the GOM produces today but I think it is a good deal less than 1.5 mb/d. However Atlantis just came on line.

Then Thunder Horse will come on line late 2008 and be up to speed by the third or fourth quarter of 2009. This however will not get the US back to pre Katrina levels of production. Recent US production was under 5 mb/d while pre Katrina US production above 5.5 mb/d.

Ron Patterson

You are right - the chart does say deep water fields in the GOM. Do you have any idea where one can get the corresponding information on all fields in the GOM.

If would seem like the shallow water fields would have been drilled earlier, so may be farther along on the depletion cycle.

Other than Hofmeister's absurd speech, it sounds like you had an opportunity to see a lot of people working pretty hard and honestly out there. I think it's good to keep in mind that most people in the oil industry are just doing their job, and trying to do it well.

I don't think thats ever been a issue. In fact my concern has grown as I've gained a better understanding of the oil industry. We are incredibly good at extracting oil. In my opinion oil extraction and semiconductors our are two most advanced industries if you look at the entire petrochemical industry then its by far our most advanced industry. By advanced I mean more than just high tech its also advanced in the sense of the art of oil extraction.

i find it very interesting that the API, and especially Shell, would arrange this trip. bringing visitors onto offshore platforms does not happen every day (it's quite rare, at least based on my north sea experience).

i think some API members, presumably especially Shell, have decided that bloggers can say things that they can't say themselves (because the markets would punish them). they wouldn't have accepted someone from TOD if they hadn't accepted a benefit to them.

the result is that bloggers can help raise the public awareness until one day (still a long way off) when everybody knows, those large reluctant API members can finally admit the problem and nobody will be surprised. (although i still think exxon is in a completely different category to Shell/BP/Chevron etc who would like to say something but still feel they can't quite do it).

great to see this happen..

Thank you for posting this. I think that the importance of the blogsphere is clear to the seven sisters. Amazing pictures; to think our civilization depends on these activities is unreal.

Gail, great report. I have a few basic questions. On such a platform as this, what is the relationship between drilling and production? Are both occurring simultaneously, or are they temporally interspersed somehow? Are new holes being drilled all the time, or is there just one main hole which keeps getting redrilled? How deep are the holes? Do they go straight down and then turn into angled or horizontal runs?

As I understood it, there were eight holes going more or less straight down, under the platform, but then turning angles out in different directions. These were drilled first, and some (all?) are in significant decline.

In addition, the platform also has the capability of having up to eight "sub-sea" wells. The sub-sea wells are at a distance from the platform, and are linked by tubes. They actual number of sub-sea wells they have is smaller - three, if I remember correctly. Each of these is producing something like 4,000 barrels of oil per day.

Another "outrageous" statement he made was, "America is the only oil-importing nation that prohibits the development of its own resources." He credits this prohibition with moving jobs out of the country and worsening the balance of payment situation.

What in God’s name is “outrageous" about that? Is it accurate or inaccurate? If it is inaccurate then it is “outrageous." We prohibit development in oil rich areas of Alaska, offshore California, the Eastern Gulf, and the East Coast. It seems to be a pretty accurate remark to me.

“The comment about "America prohibiting development of its own resources" is plainly intended to be controversial and just daft. Yes - the US limits some areas …”

I suggest you spend a bit of time Googling the estimates of petroleum in the prohibited areas. Nowhere in the continental USA or the current offshore USA where development is allowed is there thought to be the kind of reserves that is in the prohibited areas. Drill as many new wells as you want in Texas, Louisiana, Wyoming, and California; they will not give you reserves or the daily production that is waiting to be developed in Alaska for example.

"Outrageous" was the label Hofmeister used.

I think that one area they are interested in is the Gulf of Mexico, near Florida. Also, most of the rest of the outer continental shelf. The USGS has some fairly optimistic estimates out for production in some of these areas. This is a link to a 2005 report.

Sorry about that, I should have noticed a quote within a quote.

I have often thought that existing oil/gas drilling platforms could help us go green by adding facilitites to capture energy from wave motion beneath the platforms or by a type of geothermal energy capture technology that uses the temporal differential between the surface water temperature and the water temperature at a certain depth.

Thoughts?

My impression was that the platform is fairly specialized. There is a lot of equipment for separating oil from gas from water, and also the drilling equipment. The platform then generates its own electricity, and has a place for housing a fairly large staff. I doubt that much of this would be needed for wave motion and geothermal technologies.

I think that wave and geothermal sea water technologies are likely to be unmanned, or perhaps have a small staff for geothermal. It seems to me that wave technology would be more like windmills - lots of them, doing a relatively small amount each.

A couple of technical questions:

Does anyone know where these drilling platforms are manufactured? New Orleans, Houston, or ???

Also, is the oil moved to shore by pipeline, or ship?

thanks in advance,

Oz

Oz,

If you click on the link I gave for the platform, above, it gives more information about it.

The hull of the platform was manufactured in South Korea. The deck was manufactured in five modules in Louisiana. It was all put together in Texas.

There are separate oil and gas pipelines for sending the oil to shore.

Hull fabrication is almost always done overseas, with Korea being the #1 choice.

Oil field specific work is done largely in Louisiana, although bits & pieces are done elsewhere. It is a major industry here with several shipyards.

Some international competition but I understand that we still do most oil field specific fabrication for offshore drilling and production here.

Best Hopes for for Local Industry,

Alan