A Visit to Chevron's Kern River Heavy Oil Facility

Posted by Gail the Actuary on February 10, 2009 - 11:06am

Recently, I visited Chevron's Kern River Heavy Oil field, near Bakersfield California, as a guest of the American Petroleum Institute. Kern River is an extremely old field, discovered in 1899. The oil flows a bit on its own (API=13), but really needs to be heated to be easily extracted or to be shipped by pipeline. After more than a hundred years of pumping, most of the available oil has been extracted--a total of a little over 2 billion barrels has been extracted. The additional amount that can be extracted will depend on the price of oil and how well Chevron can minimize costs.

The site produces about 80,000 barrels a day from 8,000 producing wells, meaning that on average, each well produces about 10 barrels of oil a day. In order to make money with this type of operation, Chevron must be very efficient in everything it does--reusing equipment whenever possible, using the best techniques possible to find the remaining pockets of oil, and prioritizing the workload of the employees, based on which activities are most likely to produce a profit, and which activities are not cost effective.

In the recent past, production has been declining at 2% or 3% a year. Chevron's goal in the near future is to hold the decline rate to 1% per year. No one knows how much additional oil can profitably be produced, but rough guesses were in the 200 to 500 million barrel range. This range equates to 10% to 25% of the oil produced to date as possibly being economically available for extraction.

In this post, I will tell you a little about what I learned on my trip, and also offer some thoughts on whether heavy oil is likely to be a panacea for peak oil.

What a person sees at Kern River

I was surprised at the appearance of Kern River field. As far as one can see, there are thousands of oil producing wells bobbing up and down. Besides oil wells, one sees electric power lines and many types of pipes. The area is very arid, so there is little vegetation.

There are much better photos in the Kern River Basin Tour video(3 minutes) taken by professional photographers the day we were there. The API website also has a page with still pictures and copies of the presentations from which I took most of the images in this post. In case you are wondering, I am wearing a blue jacket in the photos. I am not in the video.

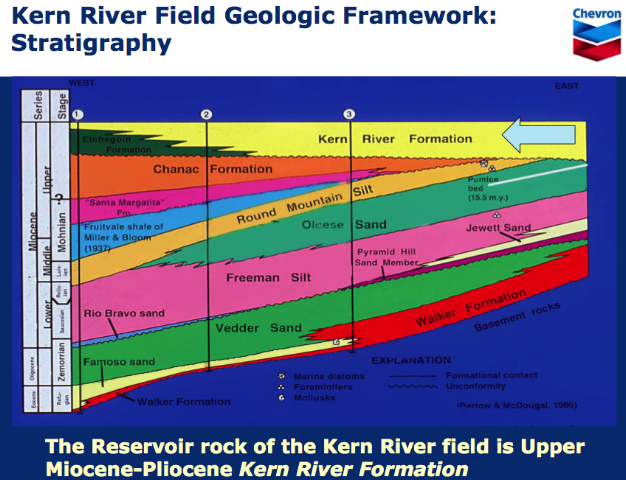

Geology

For those interested in geology, this is the slide we were shown of Kern River Stratigraphy. The oil is found in nine separate layers, the deepest of which is only 1,500 feet deep. The material that the oil is trapped in is very sandy, and one of the challenges is keeping the oil wells from becoming clogged with sand. The oil and water mixture that is extracted is about 90% water.

Extracting Oil Cheaply

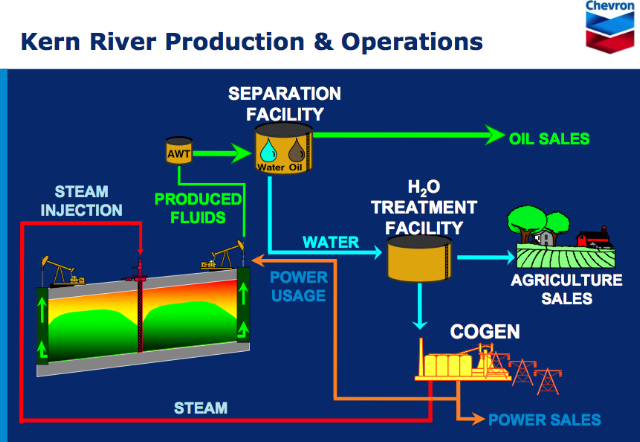

This is a diagram we were shown of Chevron's operations. The technique Chevron uses to heat the earth to better extract the oil is called steam flooding. Besides the operations we would normally think of, Chevron generates electricity, most of which is sold to a local electric utility, and recycles the excess water it extracts so that it can be used for agricultural purposes.

Natural Gas

In order to generate steam for steam-flooding, Chevron purchases a large amount of natural gas. This gas represents about half of the operating costs of the facility, so it is important that it be used efficiently.

Starting about 1985, Chevron began to get double use of its natural gas by using the excess heat from the steam-generation process to generate electricity (co-generation). Using this approach, 300 MW of electricity is generated. The Kern River field uses 36MW of this, and the remainder is sold to a local utility. Since Kern River generates its own electricity, Chevron is assured of a constant supply of electricity for the facility, even if there are rolling black outs elsewhere. Also, the sale of this co-generated electricity is a significant source of the base electrical power for California's grid.

Through co-generation, Chevron is able to attain approximately 80% efficiency in its use of natural gas. Recently, Chevron has developed boilers for steam generation that are themselves 85% efficient, removing the incentive to add additional cogeneration capacity.

Water

Since the oil-water mixture that is extracted is approximately 90% water, the question is what to do with all of the excess water. Chevron's approach is to treat the water and reuse it, partly for its own use in generating steam, and partly to re-sell for agricultural use. A small residual portion remains, which is re-injected below the water table in regulated locations.

Other Approaches for Keeping Costs Down

To keep costs down, Chevron reuses equipment as much as possible. If a pump jack is not needed in one location, it is moved to another location. If an oil well is no longer producing oil, the borehole can still be used for surveillance of ground temperatures (to see how the steam is heating the area) and for other measurements that will help determine whether there is still remaining oil in the area.

When new monitoring techniques are developed, Chevron adds new controls to existing equipment, rather than starting over with new equipment. For example, we were shown tanks used to measure the proportion of water and oil coming from individual wells. Some of the oil tank were set up so that a worker could use a measuring tape to measure the depth of the oil in the tank. These old tanks have been retrofitted with new electronic controls that measure the proportion of oil and water.

Most of the oil in the oil-field has now been drained. The challenge now is to find the remaining pockets and drain them as efficiently as possible. Chevron has developed a 155,000,000 cell imaging model of the field that allows them to target those areas most likely to have oil remaining. Each of the 155,000,000 cells represents an area 50 feet x 50 feet by 2 feet deep. This model is based strictly on borehole data, not on seismic imaging. Besides whether or not the cell is likely to have oil, the model gives other information, such as whether the area has been heated to the optimal temperature.

In trying to minimize costs, one issue of concern is precisely how long in each 24 hours a given pump jack should be pumping. If the area is heated by steam, the area will continue to drain, whether or not the pump jack is moving. Pump jacks are put on timers and turned on and off as needed, so as to use as little electricity as possible to pump the available oil out.

Another issue is heating the ground to precisely the correct temperature. As one can see from the graph at the bottom of the figure below, viscosity does not decrease much after a temperature of approximately 230 degrees is reached. The challenge is to heat to precisely the correct temperature, and no more, so as to not waste energy needed to make heat.

Historical Production

The graph in the above figure indicates that production was quite low until steam flooding was introduced about 1965. A peak in production of 141,000 barrels a day was reached in 1985, when cogeneration was added. Since then, production has been declining.

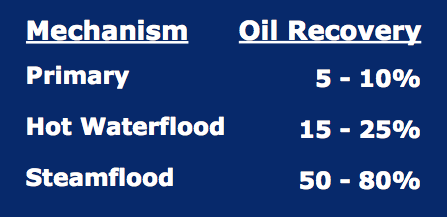

The proportion of heavy oil originally in place that can be removed varies greatly with the approach used. We were shown this table of the percentage of oil originally in place that can be extracted with various methods. Clearly, steam flooding is a major improvement over gravity drainage and hot water extraction.

Nearly all of the producing wells at Kern River are vertical wells. Recently, Chevron has begun using a small number of horizontal wells as well. Horizontal wells only make sense if the bypassed oil lies in a horizontal pattern and if the soil for the entire length has been adequately heated by steam. If only part of the soil has been heated, the oil does not flow sufficiently freely to make the horizontal well useful. We were told that one horizontal well started with 500 barrels a day of production--truly outstanding when the average is only 10 barrels a day.

Costs, etc

When we asked about marginal production costs, and the answer was, "We can't tell you that." We were shown a slide that does give some partial indications, however:

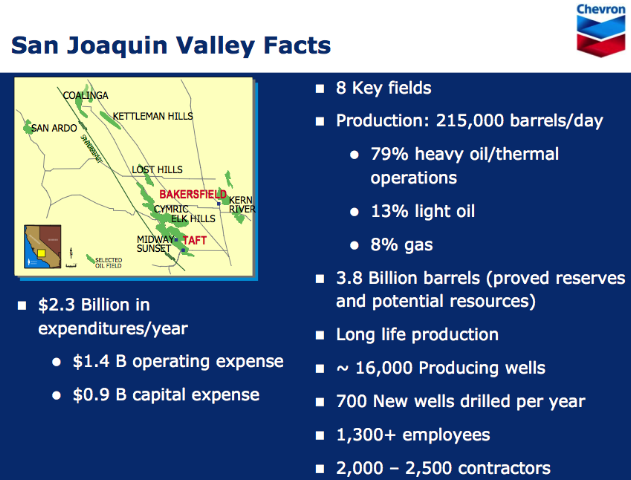

Kern River is part of the San Joaquin Valley. Using figures from this graph, we can calculate some averages for the valley as a whole. Kern River's costs no doubt are somewhat higher, because its oil is weighted more toward heavy oil than that of the valley as a whole, and its average production per well is lower than for the valley as a whole.

According to the slide, there is a total of 215,000 barrels a day of oil produced in the San Joaquin Valley, of which Kern River amounts to about 80,000 barrels. The exhibit indicates that operating expenses are $1.4 billion a year and capital expenditures are $0.9 billion a year. 215,000 barrels a day is equivalent to 78,475,000 barrels a year, so operating expenses amount to $17.84 a barrel and capital expenditures amount to $11.47 a barrel, for the San Joaquin Valley as a whole. The selling price for San Joaquin Valley oil is several dollars below that of West Texas Intermediate, so these costs are approaching the current price of oil, if WTI is about $40 barrel.

The costs for Kern River would be higher, so the most expensive capital expenditures are likely getting squeezed. It was clear from our discussion that any decision on drilling or allocating workers time is made only after carefully considering the implications for profitability. Some of the deeper areas of the Kern River Field which are harder to heat have been by-passed in the past. Cost considerations will determine whether it makes economic sense to drill additional wells in this area. Because of this, I would expect the price of oil to have an impact on the decline rate--the lower the price of oil, the fewer projects are economic to undertake.

One factor that keeps costs down for Chevron is lack of debt. Chevron has accumulated capital over the years, and is able to run its operations without debt. Also, the fact that it has been able to buy a huge amount of oil drilling equipment at low prices over the years is helpful. Since this equipment is fully paid for, it does not affect current costs.

Implications for Drilling Other Heavy Oil

Chevron is involved with quite a number of different heavy oil fields around the world, in areas such as Venezuela, Indonesia, and the Middle East, and the techniques it has learned are no doubt helpful in these areas as well.

It seems likely that the costs in these other oil fields will be higher, because Chevron does not have the benefit of building up a large inventory of equipment at low prices, in years past. Also, if another company is actually drilling the wells, it may not be as well capitalized as Chevron, and need to obtain debt to finance the large up-front costs. This will also tend to raise the cost. In some cases, companies may not be able to obtain financing, so new or expanded heavy oil production may not be an option.

Another consideration is natural gas. The way Chevron is currently running its operation, natural gas is needed to create the steam for steam-flooding. If natural gas is not available in adequate quantities, it may not be possible to extract the heavy oil.

A third consideration is the speed at which the oil can be extracted. There is more than 1 billion barrels of oil still in place. Something less than 3% of this can be extracted in a year (comparing production to remaining oil). If new heavy oil fields are put into production, it is unlikely they will produce a huge amount oil in a single year.

The Kern River oil field, as huge as it is, produces something like 1/1000 of total world production. If one wanted to replace lost oil production due to decline of say, 4 or 5 million barrels as day, it would take a huge amount of infrastructure. To replace a decline of 4 million barrels a day would require the equivalent of 50 additional Kern River oil fields each year. The capital expenditure, if nothing else, would be overwhelming.

Because of these considerations, I don't see heavy oil ramping up to replacing declining production of freer flowing oil. There may be some growth in heavy oil, especially if the price of oil rises, but it is hard to see it ever growing to replace lighter oil.

Can steam-flooding be used to greatly increase the recovery on other-than-heavy production? I am sure we would have heard about it if it were the case--it is not a new technique. Steam flooding "works" on very heavy oil, because the oil is too heavy to flow otherwise. The oil seems to be very loosely bound in what is close to sand in Kern River, so steam-flooding yields a very high percentage of oil in place. If the oil is deeply embedded in stone with a different structure (permeability, porosity), the results will likely be quite different.

Good article, Gail, as usual.

While they mention that there is 3.8 billion barrels of proven and potential, I wonder how much is 'proven' (PD and PUD), probable, and possible.

It would also be nice to understand the EROEI of the steam flooding they are using.

I wonder how much of the equipment they have there is approaching replacement time, ada Simmon's Rust Never Sleeps.

Did you get the sense in any way that they were trying to 'steer' you to a facility they wanted to use as an API exemplar, or did you get to pick the facility?

I didn't get to pick the facility.

I felt the Chevron management was very open and honest with us. If they wanted to steer us to a "good" facility, they would have taken us to a start up facility, where hopes were high for ramped up production. I never heard any hype about seeing another peak at Kern River or other things that sound like they are out of a commercial. The management clearly put a lot of time into this, and were willing to answer our questions.

A lot of what is left as yet-to-produce in the world is heavy oil, or very heavy oil. I thought it was interesting to get to see this facility, to get an idea of what is involved in such production.

Clearly the EROEI will depend on whether you can use a given piece of infrastructure for 10 years or 40 year or 80 years. Chevron has managed to keep some very old equipment in operation, and this affects their cost structure. One thing that helps the EROI is that the oil is not very deep. Vertical wells cost somewhat over $100,000 each; horizontal wells are about double this. Chevron is able to get good prices, because it doesn't need the newest, fanciest equipment. Its contracts are short term, so it can quickly change to get better prices if they are available.

Gail,

I suspect the "500,000 bopd" is a typo. Perhaps 500 or 5000 bopd?

With regards to the proven vs. other categories the inplace reserves are pretty well proven. With the amount of well control they have it wouldn't be too difficult to generate a fairly accurate map. But how much is "proven - economically recoverable" is another matter. When reservoir engineering auditors offer a future production forecast it always has a price forecast included in the model. One reservoir might have 500,000 barrels of proven "producible" oil at $80 per barrel but only 50,000 barrels proven at $30 per barrel.

Even if prices drop below Chevron's production costs for a time they would continue producing for longer then many might expect. Several reasons: waiting for prices to recover; waiting for new (probably deeper) drilling to find new production (drilled by Chevron or a sub-lessor from them); and lastly, to delay a huge environmental plug and abandon liability. Removing all the equipment, plugging the wells and cleaning up the areas to regulatory specs could cost many millions of $'s. About 15 years ago a client bought a S La oil field from Shell which had not been commercially productive for year but was still producing 500 bopd. Luckily for Shell they found a sucker to take a huge abandonment liability off their hands. Fortunately for my client I found an even bigger sucker to take it off their hands.

I corrected the amount to 500 barrels a day. Clearly if the whole field produces something like 80,000 barrels a day, one well can't produce a whole lot.

One thing they mentioned is that if they turn off the electricity for any significant length of time (I am guessing months rather than hours), the wells start to fill with sand. Thus, if Chevron is ever going to produce oil from this field, it needs to do so now. It really can't stop, wait a few years, and start over again, because the cost and time involved in reworking all the old wells would be prohibitive for the small production per well.

You make a good point about the cost of abandoning a site like this. It seems like this cost could be greater than just keeping it going, and not adding any new wells as old ones deplete. With their fancy software, they can find some very good pockets, so these are what they are targeting now. I would expect these pockets are still quite profitable, so they will keep on. It is hard to know what they do when these pockets run out--like you say, find a sucker to take the site off their hands.

With the number of bankruptcies we see now days, I wonder what the state of California will do if it finds a bankrupt owner in charge of Kern River, at the time it ceases operations.

Agreed, but that's been BAU to now, so no reason not to expect it.

Kern River produced 30.8 mb in 2006, equating to 84,383 kb/d, according to the California 2006 Annual Report of the State Oil and Gas Supervisor. This is one of the excellent publications made available from the CA Energy Commission. Here is a graph taken from that Annual Report:

So much for increased cost leading to greater production. Or other factors were at stake that impeded more crude from being extracted - the switch to ULSD in 2006, for instance. Again, read some of the EEC's publications, such as the Spring 2006 Petroleum Fuels Price Spike - Report to the Governor, to familiarize oneself with the multitude of factors at work in the economics of the hydrocarbon industry. It's nothing like the public perception of fat cats lighting up cigars with $100 bills and laughing as they effortlessly gouge us day in and out.

Kern River might not be the most likely candidate for this wondering now but plenty of other currently producing resource extraction sites are. Those nasty little long term considerations economists used to sweep under what they called the 'social cost' rug. I've been away from formal schooling for a while, what is the term that is being used to hide these kind of future liabilities these days?

Thanks for the very enlightening post Gail. It would be interesting to compare what is done for cost control at a handy beat up old field near Bakersfield to what is done at a beat up bunch of remote ones in the Prudhoe area (I know it produces light crude but the cost conrols could be compared in some fashion). The old deferred maintenance model of cost cutting has proved problematic up there in the past.

Luke,

They're not sweep under the rug by economists for US public oil companies. Today those companies carry huge negative values on their balance sheets compared to the old days when they were ignored to a degree. This is especially true with offshore fields. But you don’t have to worry about a big offshore operator ducking that liability by selling to some smaller operator who later files bankruptcy. On Federal leases the property can change hands a dozen times and all those subsequent owners can file bankruptcy. But the liability always remains with the original lessor if no one else can pay. Exxon, Chevron et al can run but they can’t hide from those costs. Depending on water depths costs can run as high as $20 to $40 million. Two big liabilities with all fields are "NORM" and PCP's. Norm is naturally occurring radioactive material. In reality everyone else calls it dirt. I'm not kidding. But if there is any amount of NORM on oil field equipment and casing it has to be disposed of as per expensive regulations.

PCP was a common additive to lubricants for years. Like all lube some drips to the ground. After 20 or 30 years a significant amount can accumulate in the soil. And it takes major (and expensive) remediation remove it. For decades those Chevron pump jacks slowly leaked PCP onto the ground. Unless Chevron has already remediated the soil there are PCP levels in the ground that likely exceed reg standards by 10 fold or more. Just another reason to delay abandoning the field as long as possible.

Rockman,

Thanks for the info, your up close and personal knowledge of oil operations is really a great plus. Thanks again. I wasn't aware the liability stayed with the original offshore lessor if all subsequent lessors failed. What happens if original lessor has ceased to exist before the field is finished and all subsequent lessors also go bellyup? A lot of what iffing I know.

I'm guessing carrying that huge negative value on the balance sheets (for reclaiming oil sites) carries a huge tax advantage in one or more areas, (taxable real property value?) but that is just a guess.

PCPs are to be taken seriously but I wouldn't doubt NORMs danger are somewhat overblown. Radioactivity gets a certain amount of irrational response added to its real threats in a lot of situations. One case that comes to mind was what actually occured at Point Hope AK when they were planning to nuke a harbor up there (Operation Chariot was the project's code name, it was to be a practice run for an H bomb excavated sea level Panama canal). Fortunately the harbor was never nuke excavated--that would have made an ugly long lasting mess. What was done in the prep work leading up to it was that a few pounds of soil gathered from the downwind area of a Nevada (or was it New Mexico) above ground nuke test were sprinkled on the tundra. I think they were trying to see what kind of migration patterns the soil had. The amount of radioactive material spread was miniscule compared to the area it was spread over. But by the time it was cleaned up, revisited and on and on the attention that little bit of radioactive soil gathered was gargantuan.

The scenario so many at this site envision (I don't envision a collapse without violent trauma that would leave plenty of floating and otherwise spilled oil myself, so keeping energy supplies up one way or the other seems a real good goal) would almost certainly leave the mess at the finish. What government would be there to force or manage any kind of cleanup?

What I do see as likely if the U.S. weakens substantially is that all environmental laws that make any critical resource more expensive will be gutted, the cleanups will mostly occur on paper. Proper management of campaign contributions would certainly seem a way to hasten such legislative change along.

'Social Costs' if memory serves me correctly encompassed all the expenses that were never picked up by the private sector. Polluted land and water and long term health and genetic damage have been addressed substantially in the last several decades, though the social cost of man induced climate change has only recently shown up on the radar. Those costs could well be incalculable with any degree of accuracy for some time to come.

PCP is an illegal drug. I assume you mean PCB (polychlorinated biphenyl).

I was pretty sure that was what he meant also but I figured someone would catch it (couldn't entirely trust my memory of the proper initials), PCB has left some ugly transformer storage yards.

"I wonder how much of the equipment they have there is approaching replacement time, ada Simmon's Rust Never Sleeps"

Hi Will, I can't give you hard facts and #'s on your question, but I drive through the Kern field many many times each year and have noticed a lot of new equipment going in, one sees brand new and far larger pumps either replacing the older ones or going in as they drill new wells in the field. Rusted dead pumps are still visible, but fewer each time - so I think the replacement is happening.

Great article Gail, I drive through the heart of the Kern field so often and have so many questions - you've answered some of them, thanks.

Thanks MacDuff, I wonder how much of the rest of the infrastructure there is new (i.e., manifolds, piping, tanks, pumps, boilers, etc).

Anyone have any clues to the EROEI of steam injection/etc there or at other heavy (sour) oil sites?

Gail

Thank you for the post, there are interesting observations. What strikes me (and you noted as well) is that despite little or no debt and equipment that is mostly fully amortized (ok, maybe not the cogen), the Kern field appears to be at the margins of current oil production costs. The picture of the Kern field brings home a Matt Simmons comment to the effect that 'there is plenty of oil in little pockets, but what we need are more super-giants.'

That makes heavy oil a tough proposition in new field development. On top of that, not many refineries (particularly U.S. refineries) are built to handle heavy crude. So you have higher costs at the wellhead, and upward cost pressure at the refinery to cover retrofits or new construction. Seeing, as we now do, that consumers will reduce demand at $4/gallon+ for gasoline or diesel, heavy oil seems like a big investment gamble along the whole supply chain. All this before we touch on climate change.

You are right about the higher costs at the refinery as well.

Also, if the oil is too thick to flow, pipelines with heating stations along the way need to be built, to keep the oil flowing. The need for these pipelines reduces the options as to where the oil can be sent to be refined. It pretty much needs to go where the special pipelines are. In the case of Kern River, the heated pipeline seems to run north to Sacramento. I don't know where the cost of the heated pipeline shows up.

Gail:

Excellent posting.

I especially appreciate the implications of your final two sentences (above). Those sentences speak to at least two very significant issues:

(1) the geologic complexities that are the reality in all oil fields and which are front and center in every past, present, and future effort to determine how much it will cost to recover the not-so-easy-to-get oil in a given field anywhere in the world, and

(2) the continued need for geologists trained to examine core in the detail needed to determine the precise nature of the pore spaces in a given stratigraphic interval, and the interconnectedness of those pore spaces. Seismic information doesn't provide such details, only a methodical description of core, and of core samples in thin section examined with a polarizing microscope, or a scanning electron microscope, and/or other appropriate analytical equipment, can do that.

It's interesting to consider how much is obviously known about the petrophysical properties of the several producing horizons in the Kern River field given its age, and how long it took to grasp that information and how many individuals contributed to the understanding of the geology of this field over the decades. Then, it's interesting to ponder how little we really know about these same petrophysical properties in fields that have been producing for far shorter periods of time, and then finally, how very little we really know about the details of porosity and permeability in promising basins that haven't even been drilled yet.

Thanks again for this detailed report on your visit.

I know that in the past, the big increases achieved in Kern River have been used as a reason to believe that enhanced oil recovery will result in huge increases in production elsewhere. This was never mentioned on our trip. The focus was very much more on the here and now of how to make the current production work in view of the low prices available in the marketplace. I was aware that this connection had been made in the past, and wanted to make readers aware that I don't see the technology as a universal fix-all.

One thing that has changed over the years is that originally the field was broken into a huge number of sub-fields, all under different owners. Gradually there has been consolidation, so that now Chevron owns the whole thing. The consolidation has permitted the use of more sophisticated tools for finding the last remnants of the oil, and for finding more efficient ways of extraction. Even with consolidation, production hasn't increased, except temporarily, when new processes were introduced (particularly steam flooding and co-generation). The co-generation seems to have allowed the owners to do more steam-flooding with a fixed amount of purchased natural gas.

Gail,

Excellent post. Kudos for taking the time to get a close-up view.

I agree that heavy oil can never completely replace conventional production.

What it can do is provide a cushion while we transition to something else.

" If natural gas is not available in adequate quantities, it may not be possible to extract the heavy oil."

Natural gas is cheaper per BTU, and much more convenient to burn, so it makes perfect sense that Chevron would use it currently, but if it was unavailable wouldn't you just burn part of the oil production?

Nick,

Unrefined crude oil, especially heavy oil as the Kern River crud, is generally a poor fuel. It might even be impossible to burn it as bunker fuel in CA and not violate state air quality regs.

There are billions of bbls of residual crude (and much better quality the Kern crud) in coastal Texas counties. All would require expensive secondary recovery methods but there will come a time when prices reach a level that those efforts would be initiated. I was actually putting together one such proposal when prices collapsed. But as someone else mentioned, though some day much of this by passed oil will be produced, it will never occur at a combined rate that can overcome the national decline rate. But as Gail points out, it may offer a small cushion.

"Unrefined crude oil, especially heavy oil as the Kern River crud, is generally a poor fuel."

Sure - very dirty, and a pain to handle.

"It might even be impossible to burn it as bunker fuel in CA and not violate state air quality regs."

Yes, Nat Gas will always be preferred. OTOH, there's no sign of NG not being available. So, the question is, when would Gail's problem scenario of NG not being available arise? I think it might arise either when prices of oil and gas become much higher in the US, or in places like Venezuela, where people are sometimes less worried about air quality.

During the tour, Chevron did mention that before natural gas was used, they attempted to burn the oil itself. It wasn't very satisfactory, but it was used for some time.

The fogginess you see in the picture near the top of the post is apparently a usual condition at this time of year. If a company burned oil to run boilers, it seems like one would get a horrible version of smog. According to this website about the San Joaquin Valley:

No question, we can understand why Chevron would prefer NG.

If NG got very scarce, oil would also be very expensive, which would allow Chevron to bid for NG. OTOH - in true scarcity conditions, pollution concerns would recede in priority, facilitating a return to burning the crude.

I just have a hard time seeing how the "If natural gas is not available in adequate quantities, it may not be possible to extract the heavy oil." scenario would be a significant risk.

I am thinking about if heavy oil production is done in other parts of the world. For example, Saudi Arabia seems to have quite a bit of heavy oil, but not much natural gas. Piping it in is sometimes a problem.

I think KSA has quite a bit: per http://www.eia.doe.gov/cabs/Saudi_Arabia/NaturalGas.html

"Saudi Arabia has the fourth largest proven natural gas reserves in the world, estimated at 253 trillion cubic feet (Tcf)...the majority of gas fields in Saudi Arabia are “associated” with petroleum deposits, or found in the same wells as the crude oil, and plans to increase production of this type of gas remain linked to an increase in oil production...an estimated 13 to 14 percent of total production is lost to venting, flaring, reinjection and natural processes"

KSA has traditionally capped the domestic price of NG so low (at $.75) that supplies were barely adequate, but that's easily fixed.

Elsewhere, if NG was limited, I still don't see why they wouldn't just burn some of the oil, with or without some light refining.

You and I know how to fix the low price, but if that is part of the social agreement, it gets difficult to fix.

I know getting adequate electricity generation tends to be a problem in the some of the Middle East, and natural gas is used for electricity. I think you are right about the low price being an issue.

The oil that comes out isn't that great for burning. It really needs to be refined first and the appropriate portion brought back.

When I visited the Shell's Brutus offshore platform, I discovered they were burning some of the natural gas from the wells for electricity. Another reason may be that natural gas tends to be a fair amount cheaper, for the same energy value.

"if that is part of the social agreement, it gets difficult to fix"

Fortunately, the KSA NG consumers appear to be industrial/commercial, not the average citizen. I/C owners may be disproportionately influential, but they're much easier to communicate with about basic economic issues, like "we need to charge more for NG, in order to increase NG production, in order to maintain oil exports".

Yep Nick....I think you hit that price nail right on the head. Forecasting prices is often a bigger risk factor in analyzing any oil patch project then geology or reservoir engineering but it's especially true in most secondary recovery efforts. As gail pointed out above, a big chunk of the operating cost for the Kern crud is the NG fuel. True for nearly all EOR projects: they all need substantial enegy input from some source. It's great when oil prices go up but if there's a proportional increase in NG prices it can become a even trade off...or even worse.

"these costs are approaching the current price of oil"

As far as cost vs revenue goes, if Kern generates 300MW and sells 264MW, that's a significant revenue source.

264MW at $.04 per KWH would generate about $3.20 per barrel of revenue (264,000KW x 24 hours x $.04 / 80,000 BPD), which would make a noticeable difference to the overall profitability of the field.

Anyone know how much the CA ISO is paying generators for power these days? Is $.04/KWH a fair estimate? I know CA has much higher rates in general than most of the US.

Also, I wonder what revenue Chevron gets from the recycled water?

I don't know how much revenue they are getting for the electricity. They were saying that the revenue for baseload was not very good. They could actually get more for having a plant on standby for peaking power, and not selling anything.

It is my understanding that at this point they sell half of the Kern River generated electricity as baseload, and sell half for peaking. There is also some co-generation capability in other San Joaquin Valley facilities operated by Chevron, bringing the total available for sale for the San Joaquin Valley to something over 600MW. To be comparable to the San Joaquin Valley totals on the chart, you would probably want the full 600MW.

My impression regarding the recycled water was that they didn't get much for it, at least in comparison to electricity. We were not given copies of the presentation regarding cogeneration and water recycling. My impression was that the water they ended up with was still not quite up to specifications in some regards (oil was out, but some natural contaminant was difficult to remove), so it had to be diluted with "regular" water, before it could be used for irrigation. This reduced the value of the water, and made them happy to get something for it, even if it wasn't a whole lot.

" the revenue for baseload was not very good."

Yeah, that was my assumption - I think $.04 is a fairly low rate for CA.

"at this point they sell half of the Kern River generated electricity as baseload, and sell half for peaking"

That suggests a higher average than $.04/KWH, as IIRC wholesale peak rates can get as high as $.20 in CA. If they get an average of $.08, then that's $6.20/barrel, which is 1/3 of the operating cost and allows recovery of perhaps 2/3 of the NG cost. That's pretty good.

"They could actually get more for having a plant on standby for peaking power, and not selling anything."

Can they shift more to peak?

"To be comparable to the San Joaquin Valley totals on the chart"

Yeah, I was just using the Kern 80K BPD.

"My impression regarding the recycled water was that they didn't get much for it, at least in comparison to electricity."

That makes sense.

regarding the water...if the oil yield is 80,000 bbl/d and the water cut is 90%...one gets about 100 acre feet per day of water. I suppose that is a lot of water, but at $100/acre foot (wild guess, dunno what ag water goes for), that is $10,000 per day less the expense of treating and moving it. AT $30/bbl, the oil is $2.4 million per day.

"the water they ended up with was still not quite up to specifications" might be the understatement, and the producers are happy to get rid of it at any price.

Ag water in southern Santa Clara County is $275/af. It's probably cheaper over in the Central Valley, but not by a lot.

Between $.04 and $.05 per KWH seems a reasonable estimate based on Bloomberg's quotes for West coast spot electricity.

Thanks.

Dear Gail:

I found your article very interesting, as heavy oil production is a significant contributor to my local economy in the Uintah Basin of Utah. Could the Uintah basin be a good candidate for this style of secondary recovery? NG is locally available and common in deeper formations of the basin 6000'+, and heavier crudes are common in shallower formations 3000'-5000', heavy oil refining capacity is available in Salt Lake City. We also have a Coal fired power plant in the basin so electrical infrastructure already exists for if a cogeneration plant were built. Could the ability to drill and produce one's own supply of natural gas, gas being 1/2 the operating cost offset the capital expenditures associated with startup cost? Chevron has shown it can profit with 8000 stripper wells, the majority of wells in this area still produce at greater rates without steam flooding, however due to the higher pour points of the crude production rates could be greatly enhanced by steam flooding. I’m a younger geologist and not an economist, and not familiar with how economic viability is determined. To me I see potential; however, I don’t have the experience of Rockman, and some of the other regular posters, and would appreciate your insights on this matter.

Thanks again for the interesting article.

Someone would need to look at the details of each individual situation. It would seem like whoever is currently operating the heavy oil production would have looked at what alternatives were available in their particular situation.

cat,

I'm not very familiar with your part of the world but even if a similar EOR effort would work I suspect you would still have to overcome the transport issue. Getting the product from the U basin might just add enough expense to hinder interest. But also it can be just a matter of the local players not focusing on efforts which are working elsewhere. Sounds odd but I've seen that lack of technology transfer happen before.

Maybe you can stir some capital source up and get something started out there. Especially if you make the cogen side of the equation work well.

The Chevron Pipeline runs from Salt Lake City up to Spokane, so at the very least there's a cheap method for piping refined product to the NW. I imagine it's running at capacity already, though, but if UT production is declining new fields in the Unita could fill the gap. The Canadian Association of Petroleum Producers does a very good job of keeping track of potential pipeline expansions and might have some info on prospects for new lines out of the Rockies. One quite grandiose proposal is a BIG pipe direct from the Alberta oil sands to southern CA, which well might cut through UT - check it out, I think Kinder Morgan's the main pusher for that one.

Good catch Dude. Speaking of tar sands p/l's, have you heard anything recently about the Chinese financing such a line to the Pacific coast. I saw one very short report about 2-3 months ago.

As you probably know, Berry Petroleum which operates a good portion of Midway-Sunset the other giant [but also very very very old] heavy oil field in California's Central Valley is ramping up its Uintah Basin operations.

Berry's Midway-Sunset steam flood operations are also co generation facilities. Steam floods require scale, which may not have been present unitl now in the Uintah Basin [just a guess.]

If the economics look good, expect that Berry will opt for co generation.

A couple of general questions:

How deep are the typical wells in the Uintah Basin?

What is the typical pour point? [I remember what I think were semi trucks hauling Uintah Basin crudes having heaters on board -- back in the late 70s / early 80s -- I don't think they would have gone to that extreme unless the crude if left unheated was going to be very difficult to handle by the time they made it to Salt Lake.]

Is the old Plateau [in Roosevelt?] refinery still intact?

[edited to clarify / fix typos]

I think the co-generation approach is an interesting idea, as it points to Chevron's interest in coupling oil production and geothermal energy - maybe a first step of an oil company moving from oil to renewables. (In fact Chevron Corporation is already the world's largest producer of geothermal energy since they acquired Unocal Corporation in 2005).

The huge amount of hot water pumped up with the oil production gives a great opportunity to produce electicity at little cost. However as far as I remember a major obstacle is that the flow rate from a single oil well is still too low for a geothermal facility.

More information about this technology can be found at the Southern Methodist University.

It may be with 8,000 wells in one location one can do more though. It is an interesting idea.

What about using the waste energy from a nuke plant to create the steam?

One day we might see countries with large heavy oil reserves trading their oil output for nuclear technology (based on Thorium in a molten salt reactor or the Hyperion nuclear battery?)

Nick.

"What about using the waste energy from a nuke plant to create the steam?"

Easier, faster and cheaper to use the nuke plant to power plug-ins and EV's, which are going to ramp up faster than nukes will.

I suspect we may need to reduce coal CO2 emissions much faster than we need to increase oil production - we're going to need all of the low-CO2 generation we can get, from nukes, wind, solar, etc, etc.

Looking around I read that 4.2 'barrels of steam' at 350 psi is needed per barrel of Kern River Oil API: 4.2 bbl x 350# per bbl x 1200 BTU/#=1764000 BTU per barrel

and a barrel of oil has 5800000 BTUs or 30% of output energy. That's an immediate EROI of 3.3.

If the Kern Oil field could produce +120000 bpd($3 million per day-heavy oil), the steam could easily be produced by a standard 1 GWe powerplant(converted to thermal operation) which would normally sell a day's worth of electricity for $2.4 million dollars. OTOH

with $5 per MSCF gas the steam cost would be ~$1500000 per day.

"That's an immediate EROI of 3.3."

Which needs to be adjusted for energy quality - one of the usual problems with E-ROI. First, NG is less expensive per BTU than oil, because it's less useful, and 2nd and more importantly, roughly 2/3 of the NG cost is covered by the sale of the cogenerated electricity, which takes advantage of the very high-value high-temperature NG combustion vs the lower-value low-temperature steam.

That suggests an adjusted E-ROI of 10.

According to Gails article the 'San Joaquin' oil fields(including Kern) produces only 8% natural gas. 8% of a barrel of oil--464000 Btus from 17400000 Btus used to make steam 5800000/(1740000-464000)= EROI=4.54 only as an 'immediate',

upside estimate.

Turning primary energy into electricity is the worse thing you can do in terms of EROI: Say you take 1 BTU of gas to produce 3 BTU of oil (EROI=3) and burn that oil to generate 1 BTU of electricity(electricity generation is~33% efficient).

Your way is frankly idiotic; burn 1 BTU of gas to get 1/3 BTU of electricity out.

But don't feel bad--at least half the people who posts here is don't 'get it' either.

Kern Valley produces essentially no natural gas. It is the "other part" of San Joaquin Valley that has the lighter oil and the natural gas. The natural gas Kern Valley uses is piped in from elsewhere, I believe.

Turning primary energy into electricity is the worse thing you can do in terms of EROI: Say you take 1 BTU of gas to produce 3 BTU of oil (EROI=3) and burn that oil to generate 1 BTU of electricity(electricity generation is~33% efficient).

Thermodynamics is about turning heat into work. Cogenneration, (combined heat and power or CHP), is about extracting high quality energy, skimming it off the top so to speak, and using some of the heat that would otherwise be wasted at the condenser (the latent heat of vaporization). A technical discussion of this is too long to go into here, but with a Mollier (temperature-enthalpy) diagram you can calculate the amount of energy that can be extracted by condensing the steam through a turbine generator versus having a back pressure turbine exhausting at 350 psi and compare that to simply prodcuing 350 psi steam. The efficiency of generating power with steam going from 1200 psi to 350 psi is probably on the order of 75% (including boiler feed water pump) rather than the much lower overall efficiency of a condensing cycle.

A BTU by itself is meaningless in terms of energy quality. No work can be extracted from a BTU at ambient temperature. To be useful, BTU's have to be turned into work, or the potential to do work, such as electricity, potential or chemical energy.

To make mechanical work you can't exceed the efficiency of the Carnot cycle which for most materials is limited by the temperature of the sink and the temperature of the source (usually around 33% efficient). If you believe that you can generate power with 75% efficiency(on the Rankine cycle), I have a perpetual motion machine you may be interested in investing in.

The most efficient advanced ultra high temperature gas turbine in the world is only 60% efficient with a recuperator.

http://en.wikipedia.org/wiki/Carnot_heat_engine

To recover heat depends on the effectiveness of the heat exchanger which is also dependent on temperatures differences. A boiler generally is 75-85% efficient.

With cogen you can recover heat energy but you can't make a power plant more efficient than the Carnot cycle. You can't recover more than a little energy with tricks like the Kalina cycle or back pressure turbines.

Geez Louise, somebody(other than me) needs to start educating folks around here!

You totally missed the point about the difference between the total cycle with condensing steam versus the partial cycle with a backpressure or extraction. If you eliminate the low temperature end and the associated condensing with lost latent heat, you eliminate most of the inefficiency. The top end of the cycle is the most efficient part.

The high efficency I was referring to is based on the incremental energy of producing 1200 psi steam versus producing 350 psi steam. Calculate the power prodcued and divide it by the difference in heat input.

You need to use a Mollier diagram to see this. The theoretical maximum efficiency is found by following the constant entropy line from the inlet (1200 psi) conditions to the final pressure condition (350 psi) at the actual temperatures. The difference between the theoretical and the actual power can be accounted for by the inefficiency of the turbine generator.

The fact is that, neither one of you, or for that matter just about anyone posting here, really gets it!!! The ground has shifted under our feet!! We need only to look above (about 3-5 miles) for a colder location to reject heat from our thermal engines.

EVERYTHING YOU LEARNED ABOUT WORK PRODUCTION FROM TERRESTRIAL HEAT SOURCES IS WRONG!!! The earth's surface temperature is no longer a valid basis for exergy calculations. In fact, thermal energy at the surface of the earth can become an energy SOURCE--SEE

http://www.scitizen.com/screens/blogPage/viewBlog/sw_viewBlog.php?idThem...

Any thread or conversation on this website that doesn't understand this concept might as well be discussing the number of angels that can dance on the head of a pin.

Stop defending your old bones--there is no longer any meat on them!!

What are the implications--1) we can phase out the burning of coal within 5-10 years, 2)Places on earth which have been deprived due to lack of energy sources now find themselves with a virtually boundless source of energy for electricity production, e.g., from CAPE, thermal energy from seas or lakes, geothermal (including Chevron's Kern River)--India, China, Israel, Gaza, Egypt, Iran, Romania, Philippines, Gaza, etc. (Western Hemisphere, too)

No more wars for oil will be needed, or the necessity to develop nuclear power for ANY reason.

EVERYBODY NEEDS TO WAKE UP NOW AND UNDERSTAND THIS!!!

We need to adopt energy policies that take this into account. Clue in your colleagues, managers, scientists, etc., and contact your Congressmen and women.

We need the AVE-force to be with us. (Thank You Louis M. Michaud, P.Eng.--inventor of the AVE Concept--http://vortexengine.ca)

So, what are the technical details of scaling up the model to reach the upper atmosphere? How high, what diameter, what materials and how much energy can be produced?

I've thought about using the upper atmosphere as a heat sink before, but never in terms of what would be required to actually accomplish this. I assumed there would be enormous technical and cost barriers.

Similarly, there is the heat of the earth's mantle lying several miles below.

As depicted in the overview page at the website, with respect to size, you might think in terms of hyperbolic (natural draft) cooling tower for typical nuclear plant, being able to produce about 100 MWe from about 500 MWt (say 100m across, but only 50 m high).

No exotic material will be required--concrete, steel (for heat exchangers, expanders), plastics etc., but the "stadium" required will consist mostly of open space. The heavy power generation equipment would be located on the "ground floor" which conducts air from the outside into the center of the device. Other layers can be added (to protect the inner rising core and maintain reduced pressure through increased centrifugal force) by spinning them, mechanically, using deflectors, onto the outside of the vortex using channels placed above the ground floor. These higher levels could also contain heat exchange equipment, but perhaps perhaps might use aluminum to reduce weight. This is a fairly non-corrosive environment.

The "trick" to utilizing the upper troposphere as a "heat sink" is to "reorganize" up-flow over a region into a single, voluminous stream, which rises with reduced resistance due to the vorticity employed, as compared to the typical convective updraft you would find on a summer day--see http://tornadochaser.net and click on CAPECLASS tab. This allows it to rise faster than it would otherwise, advecting less air from the cooler surroundings, which otherwise would cause entropy increases and loss of potential work.

Those of you wanting more information should read everything at the vortexengine website, including the presentations and the FAQs.

Pulled this paragraph from your above linked page. 'Eventually' has not been given the quantitative of value of 5-10 years as far as I know. R/D has a way to go with the AVE (atmospheric vortex engine). Religious fervor likely will not push the production phase forward that much.

The short answer is: That was Then (one year ago), This is Now.

The climate and energy crises are worse than thought (Australia's burning up--we've past "peak oil"). The first AVEs still should use waste heat from existing power plants, since they can't all be shut down immediately, anyway.

We didn't have a financial meltdown then and the economy wasn't cratering. Steps are being taken to correct it, but are they going in the wrong direction and will they be effective enough? We need more people working, but it would be much better if they were employed in efforts that would be sustainable over the long term. AVE plants could be a big part of the solution.

R&D on new aircraft or carriers probably had a "way to go" in 1941--then came Pearl Harbor.

President Roosevelt didn't put us on a war footing because he had "religious fervor". Reasonable, knowledgeable people knew what could be done, and then they went ahead and did it. Within 6 months, the US won the Battle of Midway, thanks to carriers and dive-bombers.

If there is anyone here with "gravitas" who doesn't think this technology will work, let him/her go on the record and give a valid scientific reason why he/she thinks it won't. Otherwise, please find a way to endorse or promote the program. Thank You.

Actually I thought the tech looked interesting a couple of years ago when I first saw it drawn up, has it been built to full scale anywhere yet or been scheduled to get there soon? The 4 meter model is a ways from what is needed to get this done in the time frame you suggest but it is getting closer.

To put all our hope in a new unproven technology does seem an act of religious faith to me, and your post had the fervor part down. I certainly agree we aren't moving fast enough and no promising leaf should be left unturned. My fervor subsided back when America gave its answer to moving toward a more sustainable future by giving 'we can all live like kings' Reagan a resounding victory. At lot of damage has been done since then, its going to be much harder to turn things around now. We may not have a lot of time but changing things will still be much more of a slog than a euphoric leap.

One of the carriers you refer to was handily (lots of unproven theories on how and why that came to be) on the other side of the island December 7, 1941 while the obsolete battleship fleet was tied like sitting ducks two by two at Pearl with only one boiler up in each to save fuel. The other Battle of Midway carriers were all in service elsewhere that day. New R/D didn't win Midway, we used stuff that was already built and was working. Plenty of R/D was pushed forward by the war and helped us gain final victory, but never did we put all of our hopes in a single basket.

Point Taken on the war scenario--maybe the analogy could have been better--I was just trying to point out how quickly huge industrial movements can be implemented when the motivation is sufficiently large.

As you admit however, R&D made winning the war a lot less costly than it might otherwise have been. One big advantage we gained was the invention of the "proximity" fuse which caused shells to go off when coming close to a target, even when they didn't actually hit it.

I'm not suggesting we put all our hopes in a single basket. I'm just suggesting that we could, within a year--two at the most, and without spending any more than we do before 6 A.M. every day in Iraq, thoroughly

test and develop this technology.

What have we got to lose?

No arguement on what sufficient motivation can bring about. How to convince all who need convincing that the motivation is already sufficiently large is the tricky part.

Sorry, you're reversing the burden of proof. It is up to the proponents to prove it WILL work, not on us to prove it WON'T.

I've gone to the site and looked at the video. What I saw was a rather lazy plume emerging from a cylinder near the side of a building, looking like a science-fair tornado machine. Lazy plumes won't cut it; you cannot extract useful amounts of energy from the trivial pressure differences they produce. Among other bits of proof not met by the proponents, I can count:

Without all of that, the proponents have nothing of merit. I would much rather see the construction of convection towers a la Leon O. Billig's proposal in "Defeating the Son of Andrew"; we can be certain that they would work, and they would cool the surface while producing both electric power and fresh water.

Quoth majorian:

True. Also irrelevant, for reasons which have been explained to you. In this case, the 350 PSI steam going to the injection wells is the heat sink for the Rankine cycle. The energy extracted between the boiler and the injection wells goes largely to electricity (some of it goes to conduction losses); if the plant is a combined-cycle unit, the efficiency of the gas-turbine section would be unaffected.

It's sad, but it appears that you have a tiny bit of knowledge with no understanding of how it fits together or how to apply it (two sides of the same coin). This blindness pervades your comments here. Maybe you should get yourself an intro thermo book and do some studying, or take up a new hobby.

"Turning primary energy into electricity is the worse thing you can do in terms of EROI"

I'm baffled - how does this relate to cogeneration at Kern River?

" burn that oil to generate 1 BTU of electricity...Your way is frankly idiotic; burn 1 BTU of gas to get 1/3 BTU of electricity out."

Again, this isn't what Kern River does: they burn gas to generate electricity, and use the lower temperature waste heat to create the steam they need to produce oil. This gives them two valuable products: electricity plus the oil.

You can burn gas to create low temperature steam, or you can generate electricity and then create steam. If you do the latter, you get high value electricity plus the steam. This is at least twice as valuable. In the case of Kern River, they're getting decent prices for the electricity, so it's probably roughly 3x as valuable as the steam alone. Another way of looking at it is that the cogen reduces the cost of the steam by 2/3, effectively reducing the energy input (adjusted for quality) by 2/3 as well and tripling the E-ROI.

Are you clear on the concept of co-generation??

So you prefer the following;

You take 1 BTU and turn it into 1/3 of a BTU of electricity plus 1/3(?) of a BTU of cogen heat to which you can turn into 1 BTU of recovered oil using a EROI=3 process. I'll let you in on a little secret, heat transfer is never

more than 75% efficient and usually much less efficient with all the pumping, heat loss, etc. If you can reuse 50% of the waste heat, that's pretty damn good.

OTOH, I take 1 BTU turn it into 3 BTU of recovered oil via a EROEI 3 process, of which I take 1 BTU and turn it into 1/3 of a BTU of electricity plus the 2 BTU of recovered oil I already got.

You got 1/3 BTU of electricity and 1BTU of recovered oil(with cogen heat).

I've of 1/3 BTU of electricityand 2 BTU of recovered oil(without any cogen heat).

Seems I am up 1 BTU of recovered oil!

I'd say Kern river is doing cogen because they need the electricity, not because it is profitable.

"I'd say Kern river is doing cogen because they need the electricity, not because it is profitable."

According to the Original Post, Kern River produces 300MW, and only uses 36MW, or 12%.

No one is going to burn oil to generate electricity: the oil is more valuable for other things. That's why oil is normally more expensive per BTU than NG.

I'm afraid you don't understand cogeneration: the electricity and the waste heat are worth more than the heat alone, even with handling losses. Further, one btu of electricity is worth more than the larger number of BTU's of natural gas needed to generate it: that's why we use NG to generate electricity.

Do you really think cogen has no value, and that Chevron is incompetent when they choose it?

Never? People who actually deal with HSRG's assume 75% as a matter of course, and that's after the energy of the topping cycle has been removed. A package boiler will start with a much higher gas temperature and be able to recover more heat for the same cost.

Heat transfer is 100% efficient; heat cannot be destroyed. Heat capture can be lousy, though.

Here's where your obliviousness to your lack of knowledge really shows. Let's make some more reasonable assumptions:

(s=1.6018 BTU/lbm-R, h=1379.1)

Out of 1 million BTU of gas, the cogenerator will produce roughly 360kBTU of electricity and 480kBTU of steam; starting from 50 F and atmospheric pressure, the Δh in the boiler would be 1361 BTU/lbm. If the efficiency of the steam turbine is 90% of isentropic [1], we'd expect about 15% efficiency in the steam cycle. The outlet steam would carry about 408kBTU.

So, out of the 1 mmBTU of gas @ $6, you'd get:

If you can sell half the electricity at peaking rates, you can get much greater revenues. That's how a cogenerating plant works.

[1] isentropic output state: quality=0.954, h=1132 BTU/lbm

Another company involved with heavy oil : Berry Petroleum. http://www.bry.com/index.php?page=oilprices

This is the graph of Heavy Oil prices (Midway Sunset) shown at the link you provided. It looks like the current price is in the upper $20s.

Is there any interest in Petrobank's THAI (Toe-to-Heel Air Injection) process?

We probably need an update on that. My impression was that they were burning some of the oil in place to provide the heat. To get the heavy oil to burn, they were blowing oxygen (or oxygen fortified air) into the path of the planned burn.

It doesn't seem like the method would work very well at Kern River, where the majority of oil has already been produced, and the task is to target the bypassed areas. It may be a possibility in some other areas, though.

Bill,

Actually air injections projects had their heyday in the 60's. Various arrangements such as your THAI and top down approaches. For those not familiar with in situ combustion (a "fire flood") air or pure oxygen is injected directly into the oil reservoir. There it combusts (burns) with the oil to produce pressured gases and heat. The heavy oil reservoirs benefit from both. Other light oil fields gain from the pressure increase that forces the oil out. These fields are pressure depletion drives and often recover less than 20% of the oil before reservoir pressure is reduced to non-commercial levels.

Though ISC or steam injection are well known in CA the most commercially successful efforts have been in south TX and north La. There are a billion+ BO in S TX that could be recovered by this method even during lower price periods. But ISC is a "dead language" in this part of the world. Literally the folks that understood the process in these parts are now dead for the most part. I wasn’t kidding our young geologist from the Uinta Basin about the various application of EOR for the heavy stuff that, while common to CA, are not considered in his part of the world. I tried for the better part of 10 years to get TX companies interested in the ISC approach but the typical response was “That only works in CA”. As I said this was despite the fact I could show the most successful projects ever conducted in the US were in this part of the world. Oilmen can be just as parochial as any other biz types. I did find one very small operator using N2 for an injection gas in some S TX fields. He knew about air injection but it “scared “ him so he chose not to use the more efficient process.

THAI is actually somewhat different from the older fire flooding. I wrote an article about it back in 2007. It has been tested now somewhat more, so it would be good to do an update. With THAI, the path the fire follows is definitely directed. When I wrote the article, I thought it was air blown to keep the fire moving in the correct direction. It seems like since then I have heard that it doesn't burn well enough unless the oxygen content is higher.

Gail,

The fuel source (the crud) isn't going to be a problem regardless of the depletion state. ISC only cokes around 8 - 12% of the oil by volume. Even in a well drained section of the reservoir there will be an adequate amount of residual oil to burn.

In terms of steam injection and fire floods THAI is something of a last resort for such heavy oil reservoirs as Kern River. A classical fire flood is actually a re-pressuring of an oil trap in which oil mobility is not a major issue. The heavy oil can't be readily "pushed" like the lighter grades. As you learned the THAI is designed for a short distance recovery. You probably also discovered what I suppose you could call the mother of THAI: huff and puff recovery. In this case steam or air are injected into the reservoir from a well. The injection is stopped and oil is pumped back out of the same well. And the cycles is repeated until additional recoveries drop below economical levels.

There have been pilot projects where two horizontal holes were drilled one above the other in a heavy oil reservoir. Typically steam was injected into one while the other was pumped. I’m not sure if these efforts turned out commercial or not. I’m sure the process worked to a degree but even two relatively shallow horizontal wells are going to be expensive. If fact, it’s not uncommon that special requirements lead to the completion costs of such wells to be greater then the drilling costs.

And yes, oxygen content is critical in any ISC effort. Not so much the amount needed for combustion as the ability for the air to reach the fire front. For those not familiar with fire floods it's essentially a crude cracking process. As the air (or oxygen) is injected it pushes oil away from that well. This begins a coking process: the residual oil left behind is what burns with the lighter fraction being pushed ahead in the front by the increased pressure. In the heavy oil reservoirs an additional aid is that the increased temperatures reduce the viscosity of the oil and is thus easier to flow. The nature of the heavy oils is such that it can be difficult for the oxygen to reach this burning distillation front: insufficient oxygen and the fire literally goes out. And just like with a campfire, it's a lot easier to keep one burning then trying to restart once the flame goes out.

The next 3 trillion barrels from Total.

http://www.spe.org/spe-site/spe/spe/meetings/RDC/2007/Sabbag.pdf

Looking at the Total presentation, it looks like upgrading heavy crude is a big part of the plan. Upgrading is currently very NG intensive:

One of the issues is finding an alternative source of hydrogen.

That's a typo.

The hydrogen upgrader

requires 650 scf of natural gas per barrel of syncrude. In the field SAGD requires around 1200 scf which is less than Kern thermal which seems to require ~1800 scf per barrel maybe Albert SAGD flows better?

At any rate you add them up and you get around 2500 scf of natural gas to make syncrude from insitu oil sands that has the same energy as 5800 scf of natural gas so 5800/2800= EROI of 2 for what it's worth.

1 mbpd of mined bitumen probably takes about .25 Tcf of natural gas, insitu probably .8 Tcf. Canada produces about 6 Tcf of natural gas/consumes about 3 Tcf.

You could always get the steam and hydrogen from a nuclear power plant.

Electrolysis/compression is 50% efficient, so to make .002 tons of H2(upgrade) per barrel would take .16 Mwh of electricity per barrel and to produce 1600 pounds of steam per barrel would take ~.5 Mwh of heat.

Since the efficiency of electricity is 33%, it would take a total of 1 Mwh(.16/.33+.5) thermal per barrel syncrude (which contains 1.6 Mwh of energy). So 1 mbpd would take (15) standard 1 Gwe nuke plants to replace natural gas at the tar sands which now produce 1 mbpd. Canada has 110 Gwe of nukes.

What I copied was directly from the Total presentation. The full title of the presentation is "Extra Heavy Oil & Bitumen Upgrading: One Way towards the next 3 Trillion Crude".

One of the things they mention is nuclear.

"Canada has 110 Gwe of nukes."

Canada has about 10 GW of nuclear. See http://en.wikipedia.org/wiki/Nuclear_power_in_Canada

Just checking.

"One of the issues is finding an alternative source of hydrogen."

NEXEN, up in Aberta, (will) produce enough synthetic natural gas from the bottom of the barrel, after OrCrude (deasphalting process, to supply clean fuel for the power plant and steam for the field:

and for hydrogen as well--see

http://www.opticanada.com/technology/integrated_orcrude_process/

A very accurate article, Gail.

I run a Canadian junior with operations "nearby on the Bakersfield Arch" ...

For those who have never seen Kern River from Panorama Drive in Beautiful Uptown Bakersfield (where the rich folks like Jeb Clampett live), it is what Hollywood imagines an oil field looks like, pump jacks and power lines stretching into the heat haze over the northern horizon.

Kern River is known locally as the world's oldest EPA clean-up operation, because the original discovery was based upon oil seeps into the Kern River, and so much oil has been pumped and steam-flooded out since 1984 that the sands are now “clean”. The sands are very porous (35%), very permeable (measured in Darcies, not milliDarcies), and being very young, are very poorly consolidated. Sand production, especially when starting pumping a new well, can be a very serious problem. DO NOT RUN THE DOWNHOLE PUMP AT MAXIMUM RPM ON STARTING THE WELL. LET THE PUMP RUN AT LOW RPM FOR A MONTH AND LET THE SAND BE PRODUCED SLOWLY AND STEADILY WITHOUT JAMMING THE PUMP.

The field was unitised by Getty in the 1960's, who (legend has it) introduced the use of metal and steam flood to the field. The pump jacks previously used by the mom and pops were made of wooden railroad ties, with sacks of rocks used as weights ... Getty was acquired by Texaco in 1984, and then Chevron acquired Texaco in the mid 1990's.

The field is Chevron's pride and joy. There are three light aircraft overflights a day to check for obvious production mishaps.

… The cogen is a real money-spinner for Chevron.

... Chevron sells the water to ranchers, but I believe the trace boron (?) content turns grapes yellow …

Chevron shot the first ever 3-D seismic program over Kern River in the spring of 2007, while the field was in operation. That really took some planning, technology, and processing (and money). No idea what they found … However, we still do not understand the up-dip trapping mechanism at Kern River, a permeability barrier of some sort.

û The well spacing is very close by Canadian standards, approximately one well per 50 yards. It must be stressed Chevron’s technology is tailored to the field conditions, and that it is not necessarily directly transferable to other operations.

û Horizontal drilling under such conditions (close well spacing) is rather pointless. It has been tried elsewhere on the Arch, not always very successfully It is not a panacea.

û “Chevron’s lack of debt does not keep operating costs down …” Gail, you should know better than that!

û Chevron will not be shipping production equipment from Kern River around the world to its other heavy oil fields, but it does use Kern River as a training ground for other heavy oil operations (in competition with its Canadian heavy oil operations). .

û The gas for Kern River, I believe, comes down PGT from NE BC via Westcoast / Duke. So only when NE BC runs out …

û … Uh no, heavy oil will NOT be able to ramp up to replace medium or light crude.

û ... The abandonment costs are always included in the economics at the forecast end of production … I don’t think Chevron’s going bankrupt, but they do have a serious legal problem in Ecuador right now, that I think they have inherited from Texaco.

û Kern River is so mature that using a new technology like THAI is probably not economic.

û Oxy made a major acquisition on the Arch about 2 years ago, and has cleaned up the previous operations, which looked like a scrapman’s dream. California allows grandfathering of old facilities, so they are mot moved unless absolutely necessary. There is a certain very old oil tank on the side of a certain hill which I am waiting to collapse …

û “In the past, the big increases achieved in Kern River have been used as a reason to believe that enhanced oil recovery will result in huge increases in production elsewhere”. Uh, no. You’ve been reading USGS again, haven’t you.

û The San Joaquin is oil prone, with gas in the deeper central part of the basin (East Lost Hills blow-out, anybody???). The oil and gas basically runs out north of Fresno. The Sacramento Basin is gas prone, but it is mature, and I think the gases have low BTU contents.

û If anyone is looking for many more Kern Rivers to maintain US production volumes, dream on.

One of the things that we like about the area is the abundance of electricity supplies for the downhole pumps. There are three other ~30 MW co-gen facilities at Jasmine, Mount Poso and Poso Creek on the Arch, and there is a main PGE transmission line running north to south (or vice versa) down the east side of the San Joaquin Basin. Mount Poso co-gen is coal fired using coal from Utah that is trucked ~15 miles from Bakersfield. I think Jasmine and Poso Creek may be coal fired as well.

There are no polar bears or grimsley bears, and no freeze-up and break-up, but when (if) it rains (in December, January and February) the mud turns to gumbo and operations come to a halt for a few days.

What we do not like about the Arch is that it is a cell-phone dead zone … you’d think in California of all places …

Thanks for your comments. Glad you think the article is accurate.

Clearly debt has a big influence on cash flow. Also,the interest on debt has to be paid somehow.

I understand insurance accounting pretty well. I am not as clear on what numbers are being presented on presentation slides--if they are on a cash or accrual basis and precisely what is included. I like it better if I can look at actual financial statements so I know what is what.

Great details Harry. Back in the day I did my grad thesis on one of those deeper turbidite fields in the SJB at the same time (mid 70's) Tenneco began poking for the deep gas. Thus I’ve always had a fond place in my heart for such distant activities. It’s probably also why I’m the 1 out of 1000 geologists in TX who’s familiar with thermal recover techniques

Harry/Gail -- are you familiar with progressive cavity pumps as an alternative to electric pumps? Wonder if Chevron has deployed any? A very simple and ancient design: An Archimedes screw rotates inside the production tubing and lifts the oil out. Ideal for producing very sandy production streams. If seen run times increase from 60% to 98% in S TX when the electric down hole pumps were replaced with PC pumps.

I have never heard of progressive gravity pumps. There is a Wikipedia article about them, though, I see.

My impression is that everything is as uniform as possible at Kern River, to make easy repairs and substitution, so I expect they are not using them.

Gail,

Looks like most of Chevron's pumping is done with sucker rods at the end of those pump jacks. Those aren't as problamatic when it comes to sand producitons as using electric downhole pumps. Sorry if I confused the conversation. The question was more focused at Harry.

This was an interesting and informative article. An excellent piece of reportage.

And the follow-up comments were very useful as well.

Jean Leherre e-mailed some comments with some graphs he produced. I will make a little post about them, so those who are not checking comments at this late date will see them.

According to Jean:

The decline since 1999 is about 6%/a and the remaining 450 Mb can be produced up to 2100 (0,1 Mb/a) but likely economically stopped around 2060 (1 Mb/a).

Progressive cavity pumps were used by Total (Sincor) to produce extra-heavy oil of Orinoco at initial rate of over 1000 b/d/well