On burning wood, coppicing and pollarding

Posted by Heading Out on September 4, 2009 - 10:15am

The power plant on our campus is set up so that it can burn either coal, natural gas or wood feed stocks. At the present time the natural gas lines are blocked, since the trends of increasing price made it uneconomic to use within the boilers. However the plant uses around wood for 40% of the feed, and has for a number of years. It helps, both with pollution control, and with the overall plant economics (oftimes being cheaper per kwh generated). We are located adjacent to a national forest and thus there is a ready supply of material.

This practice is beginning to catch on, as Bloomberg notes:

Using biomass for power and heat -- mainly from poplar, willow and pine trees -- grew by 25 percent during the past two decades, according to the International Energy Agency, the Paris-based adviser to 28 oil-consuming nations such as the U.S.

Industrialized nations got 4 percent of their energy from biomass in 2006, the most recent data available from the IEA. That was the equivalent of 151 million tons of oil.

Chips of wood stumps and branches, heated to 400 degrees Celsius (750 degrees Fahrenheit) at the Novus furnace, are as efficient as coal and cheaper: European Union rules don’t require carbon-dioxide permits because the trees absorbed a like amount of the gas before harvest, making them carbon-neutral.

Now in relatively small quantities this is a viable program, and for domestic heating wood has long been a fall-back supply (we buy several cords each winter to burn in our tile stove).

It is particularly useful as a supply in those parts of the country where solar and wind energies are not going to be locally available as viable resources (long-term, long-distance transmission of generated power is an issue I’ll duck today).

However, before everyone rushes out to get a stove, furnace, or even a fireplace it is worth reminding folks of some historic facts (some of which Bloomberg also catches).

Generally you burn up a tree a whole lot faster than you can grow a new one. Out of that reality grew the European practice of coppicing where the young limbs of the tree are harvested back to just above the stump, and the stump thenn allowed to regrow limbs. (The practice dates back to before Henry VIII.) Trees such as birch may, for example, be harvested every three or four years, while the basic root of the tree may survive for centuries.

The alternative practice is known as pollarding where the tree is first allowed to grow to some height, and then the limbs are cut back. Because the growth then occurs at a later stage in the tree life, the trees will mature in a way that coppiced trees won’t though the production can come faster. It is used where livestock could come in and eat the coppiced limbs (Henry VIII passed laws about fencing the coppiced plantations, thereby enclosing parts of the forest). Both practices were common in Europe with their need for fuel and fencing material, oak and willow being commonly harvested this way, and the characteristic tree shapes are a feature of landscape portraits by artists such as Gainsborough, Knight and Price. It is a practice that, though laudatory for many reasons, has fallen into abeyance, since it is, among other things, very labor intensive. It is suggested that less than 3% of modern woodland is coppiced. There are some attempts to regenerate the industry.

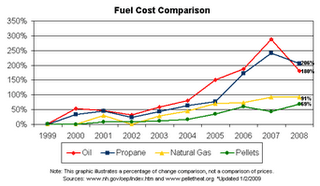

Short of these land management and wood harvesting techniques, wood can only be expected to supply a limited amount of fuel before it too runs out. Pelletizing the waste products from wood manufacture has created an industry that can, again, supply a limited market with fuel. Until recently the price has been relatively stable in comparison with other fuels.

An average household is anticipated to use some 2.67 tons of pellets a heating season, and they have advantages of being cleaner and simpler to operate than the wood that heats me at least three times (stacking, moving and burning).

Were the whole nation to turn to wood, however, then as happened in Europe in previous times, the cost of the fuel could well skyrocket. I have mentioned in earlier posts that King Edward I (Longshanks) tried to ban the burning of coal back around 1306, but the costs for wood were so much higher, that the ban was ineffectual, as were subsequent bans by monarchs such as Elizabeth 1. And even today one finds that there are those who would rather burn coal than wood. The stove that we have can be adapted (using two grates in about 2 minutes) to burn coal, however, as yet we have not examined that option.

The Bloomberg article notes that one supplier of pellets has already sold this year's supply, and with 800,000 households (I suspect many, like us in more rural parts of the country) already using wood, overall supplies may also become tighter. And, in Europe RWE is building wood-fired power plants, and eighteen months ago a large-scale plant opened on Teeside in the UK.

This 30 MWe plant uses 300.000 tons of woodchips a year.

The wood for the station comes from four separate sources. Around 40% of the 300,000t a year total is recycled wood from UK Wood Recycling. This is received, stored and chipped on a nearby, separately owned site at Wilton. A further 20% comes to the site already chipped as offcuts from sawmills. SembCorp is working with the Forestry Commission to bring another 20% from north east forests in the form of small roundwood logs – items sometimes left on the forest floor after routine tree felling operations.

Finally, 20% comprises specially grown energy crops in the form of short rotation coppice willow. The company Greenergy is supplying the wood, to be grown by farmers and other landowners within a 50-mile radius of the site.

The new plant required the growth of around 7,500 acres of coppice in the area, an activity that is creating local wildlife havens.

As an example of the benefits available to local farmers is the case of the Corrigans near Middlesborough and the power plant. They have three 25 acre willow plantations, the first of which has just come to first harvest. Once dried it will be shipped to Wilton and bring in around $20,000. As the plants mature this harvest is expected to increase. There are other advantages

He said: "There has been a dramatic increase in insect and bird life especially snipe, woodcock, lapwings and reed bunting as well as pipistrelle and long eared bats and three species of owl.

So we have found a couple more words that you should probably add to your energy lexicon. And they provide not only fuel, but also jobs.

(long-term, long-distance transmission of generated power is an issue I’ll duck today)

Well, it's apparently not an issue for Brazil (short-term that is).

http://www.abb.ch/cawp/seitp202/06c9cd09d993758cc1257601003db274.aspx

Yay, a Swedish export product. ;-)

Btw, I should add that pollarding is almost extinct in Sweden but coppicing seems to be fairly simmilar to growing shrub willow on farmland and that is slowly turning into a regular "crop" on excess farmland. (Yes I know about "excess" farmland and the future need for more food)

I'm curious as to why pollarding is relatively rarer than coppicing when the article implies a faster growth rate with the latter. Is it the labour involved, or the quality of the wood?

I suspect it because coppicing, by it nature, produces cash income earlier.

Will be interest to hear the answer.

Update: Also, being on unviable farm land, there is not push to use pollarding in an integrated mixed farming operation.

Pollarding has traditionally been used primarily as a source for winter feed for animals, at least in Sweden. You dry the branches with leaves on for a couple of day, and then stockpile them in the barn. Give to your sheep in winter as supplement to hay. Come spring you cut up the dried branches and use them for firewood.

Pollarding is very work intensive, and is only economical on a small scale subsistence farm, and extremly difficult, nay impossible, to do with large scale equipment. Pollarding is a craft.

We pollard twenty something trees on our homestead, but just as a feed supplement. The branches are to thin to bother cutting up for firewood, but I do drop them into the pile that will be hacked up and sold to a powerplant nearby. But it's not economical, takes too much time.

Coppicing can easily be done with large scale machinery, and thus requires very little work. It is also much easier to do manually. To coppice a single bush with a chainsaw takes about 2 minutes. To pollard a tree can take hours, even with machinery, although I usually do it manually for safety reasons.

Thanks for the historical perspective. I had been coppicing a line of mulberries without knowing that this was what I was doing.

My main concern about wood burning is the air quality issue. In an urban landscape, a lot of even relatively clean-burning stoves can quickly lead to high level of particulates and other problems. As the father of an asthmatic kid, and knowing that more kids in my area miss school because of asthma than any other reason, I can't look at this as an abstract or unimportant issue.

Links to some "glossy paper" but accurate Swedish publications:

http://213.115.22.116/System/TemplateView.aspx?p=Energimyndigheten&view=...

http://213.115.22.116/System/TemplateView.aspx?p=Energimyndigheten&view=...

Biomass energy is very big in Sweden, especially per capita since we got a small population and lots of forests.

RE : Farmer with three 25 acre willow plantations. I wonder exactly how they are drying their willow chips? Also transportation factors is a key issue that I am interested to see discussed while on this topic. You also covered two of three potential user groups of wood for burning - residential and commercial, centralized power producer. A third, decentralized commercial process heat and power generation is a mode I noticed widely applied during a visit to Sao Paulo, Brazil recently.

Our own 60 acre farm is now producing native plants for restoration purposes. We grow lots of our local willow species from seed and also as stakes harvested from coppiced trees. I've calculated energy derived from 15 acres would provide energy for water pumping and product refrigeration. However current cost of energy is not (yet) high enough to justify investment in equipment and labor. We are interested in and experimenting with the use of biochar in our agricultural practices. This coming September 19 and 27 we are testing a batch kiln capable of making biochar with yield of 1000 lbs per burn. Interested persons near us in Western Washington are invited.

You dont need to dry the willow chips if they are being burned in a large multi MW boiler with flue gas condensation that recovers the heat lost in evaporating the moisture. The flue gas condenser can be used to heat district heating water or for drying higher value wood chips with less ash content for making pellets. You can also of course use the condenser heat for drying willow chips to make them storable and saleable to smaller boilers.

Its possible to combine electricity generation with the steam, district heating with the hot water and drying with warm water to get a very energy efficient plant. I made a rough design for such a plant four years ago but it did not result in an investment since my economical thinking were too defensive.

You can also mix the willow chips with peat to lower the corossion rate of your boiler.

The current situation generally is to build big power stations next to big coal deposits.

Forests, by their nature as solar energy collectors, are defuse sources.

So you need to rearrange power distribution in some way, possibilities are:

Options 1 & 3 require investment in the transport networks to haul the wood to its point of combustion (energy cost in hauling the wood). Let my push rail here :)

Options 2 & 3 require investment in the power grid to 'haul' electricity from the wood's point of combustion (energy lose from the grid increasing with distance).

There is always the more holistic option of moving the people/use closer to the energy source. But hey, why break 250 years tradition and stop the move to centralisation & urban living.

Yes. Decentralize. It is, after all, scale that is a big part of the problem.

Two other points come to mind.

cfm, The Growlery, Gray, ME

Three points.

By their defuse nature, these alternate energy methods are decentralising. Can't run this kind of economy with 6% of your population in the primary industaries (3% in farming forestry and fishing, 3% in mining).

Actually I had assume it was going to be farming. Give that forests in National Parks are locked up and the remaining forests on public lands are becoming less accessible for wood harvesting, I assumed any growth in wood production would be both farmed and on private lands.

The second point lead to me last point.

Peoples concerns about energy production replacing food production are both real and to be ignored. The last 90 years (the years of using fossil fuel powered tractors) are the anomaly.

Before the 1920s, farmers always balanced food production with other competing land uses. This is what classical mixed farming is all about. The farmer was always balancing how to use his paddocks. Wheat vs sorghum vs cotton vs pasture. Pasture for dairy cows vs beef cattle vs sheep for wool vs sheep for meat vs draft animals vs hay. Hay for cattle or meat sheep vs wool sheep vs draft animals vs sale (for other peoples riding & draft animals in the cities).

Even over the last 90 years, this trading off has still been going on, just not for energy. Over the last 90 years food production was been traded of with fibre production (wool & cotton), grape production for wine, hopps, tobacco and lots of other product not consumed for their nutritional value.

The markets may not work to get fair returns or farmers, but they do work as a method of tell farmers where to focus their production.

Willow and poplar wood gets 17-19MJ/kg. Miscanthus produces 19-20 MJ/kg and switchgrass 18-20 MJ/kg.

http://www.biofuelsb2b.com/useful_info.php?page=Typic

http://cta.ornl.gov/bedb/appendix_b/Bioenergy_Feedstock_Characteristics.xls

Trees produce 3-6 dry tons of renewable biomass per year while switchgrass gets 3-10 dry tons per acre and miscanthus gets 4-15 dry tons per acre.

Grasses can also be pelletized.

http://pelheatblog.com/2008/02/12/miscanthus-pellets/

That would mean that you could produce up to 74,130,000 MJ or 20.6 GWh per km2 with miscanthus or almost 4,000 TWh (total energy) with only 2% of the area of the US.

The downside of grasses is the high ash content. High ash content = high mineral requirements.

A diverse mix of native "weeds" beats out the monocultures if conditions are suboptimal (link). Its not clear from the article abstract if the biomass grown in the test plots had a lower ash content, if they were truly "low input" I think they would have to be.

Not according to the table above, repeated below.

http://www.biofuelsb2b.com/useful_info.php?page=Typic

miscanthus 1-3% ash

switchgrass 6% ash

poplar 1.2% ash

willow 1-5% ash

coals are rated as low ash coal <8% ash

medium ash >15%, <8% ash

a high ash coal is >15% ash

Since we're talking about 50%(!) co-firing coal biomass ash seems

minor.

Monocultures could be a problem in the future but right no there's too little biomass IMO.

Underutilized resource, agreed. Much better to displace NG and fuel oil in residential and commercial heating applications with biomass than to incur massive capital expenditures turning same into liquids.

Premium hardwood pellets currently have an ash content of less than 1%, but its a limited resource as its waste from furniture factories. The problem with grasses is the high silica content that causes clinker buildup on surfaces in the firebox. Miscanthus is seldom as low as 1%, that would probably be for hybrids harvested late winter -- some minerals leech out if it stands a while.

Every btu of ethanol replaces 10 Btus of petroleum and 95% of

the input energy is provided by biomass with an overall efficiency of 45%.

Therefore 1 ton of biomass(16 GJ of wood) would produce 7.2 GJ of fuel but uses only .8GJ of fossil fuel.

Compare this to finished fuels like gasoline, LNG or CNG which are net energy negative; 1 GJ of gasoline comes from 1.25 GJ of fossil fuel(petroleum) but 1 GJ of ethanol comes from .8GJ of fossil fuels(cellulosic ethanol uses very little fossil fuels).

http://www.nrel.gov/biomass/pdfs/39436.pdf

Your way 100 BTUs of wood saves 100 BTUs of oil/coal/gas or my way 100 BTUs of wood saves 45 BTUs of fuel/ethanol.

The fact is that the US residence and commercial uses 2 quads of petroleum and 8 quads of natural gas versus 27.9 quads of gasoline and diesel from petroleum.

So at most you could save 2 quads of heating oil which would come from 2.5 quads of petroleum.

How much cellulosic ethanol could be produced?

A gov't report says that 1 billion dry tons of biomass could be sustainably harvested.

http://www1.eere.energy.gov/biomass/pdfs/final_billionton_vision_report2...

Assuming 10,000 MJ per ton,

10,000 MJ x 948 BTU/MJ x 45% x 1 billion dry tons = 4.2 quads of cellulosic ethanol requiring .8 quads of fossil fuel.

Remember, people, majorian accuses other people of innumeracy.

Interested, people? Think!

NREL says the petroleum to fuel rato is 10:1.

Why does NREL say that?

Are NREL scientists really innumerate?

Or is Space Cadet E-P who forgot to divide by 2.8?

http://www.nrel.gov/biomass/pdfs/39436.pdf

"Every btu of ethanol replaces 10 Btus of petroleum" and "the petroleum to fuel ratio is 10:1 for ethanol" are not equivalent statements.

Correct.

Let me rephraise that.

1 BTU of petroleum used to produce 10 BTUs of ethanol

replaces 11.7 BTUs of petroleum used to produce 10 BTUs of gasoline. Net savings--10.7 BTUs of petroleum for the same

energy.

http://www.nrel.gov/biomass/pdfs/39436.pdf

Ah, it's all about petroleum, not the natural gas used to make the ammonia for fertilizer or run the distillery to concentrate the products. I guess those don't count if you're innumerate (or a propagandist).

Just think: if you made the agri-chemicals and ran all the equipment on natural gas, it would still suck energy-wise but the ratio of output to petroleum input would be INFINITY to one.

</sarcasm>

Peak Oil is first about oil.

Corn ethanol requires .1 Btu of oil and .6 Btu of natural gas or coal per Btu of fuel according to Nrel.

http://www.nrel.gov/biomass/pdfs/39436.pdf

By law up to 15 billion gallons per year of corn ethanol can be made or 1.14 quads which would require .114 quads of petroleum (.05 mbpd) and .68 quads of natural gas(.68 Tcf) or coal.

So by corn ethanol we can save 1 quad of petroleum or a little less than .5 mbpd.

With 1.3 billion tons of biomass we would produce 3.5 billion barrel equivalent or 20.5 quads of fuel[cellulosic ethanol], which would require 2.05 quads(1 mbpd) of petroleum and 2.05 quads (2 Tcf) of natural gas (or coal).

So by cellulosic ethanol from 1.3 billion tons of biomass we save net 18 quads of petroleum(8.3 mbpd) and spend 2 Tcf of natural gas.

If we do both corn ethanol and cellulose we would save 8.8 mbpd

for using 2.68 Tcf of natural gas (or coal)--- or we would gain

19 quads of liquid fuel for using 2.73 quads of natural(12% of domestic natural gas consumption).

The US has 237 Tcf of natural gas proven reserves and a resource mean of 526 Tcf of 'undiscovered' natural gas.

The US has 21 Gb of proven oil reserves with a resource mean of 75 Gb of oil resource. The US produces less than 2 Gb/yr of domestic oil(5mbpd).

Suppose the US were 100% cutoff from foreign oil,

corn plus cellulosic ethanol would produce 3.6 Gb/yr

--a bit less than 50% of US oil consumption (21.6 quads of fuel) per year using 2.73 Tcf of gas(13% of current domestic prod.)-- and .38 Gb/yr of oil produced (20% of current).

Now obviously the US has'nt the infrastructure today to produce

that much ethanol but assuming a 14.4% per year compounded growth rate, in 30 years we would go from 5 billion gallons per year(.38 quads/yr) to 280 billion gallons(21.6 quads per year).

It's only 50% of the petroleum we use per year today but it will last a long time.

I just want to note how utterly bat-guano crazy you are.

With most of the latter required for the distillation process. It is better to look at fuel paths which do not require distillation. It would also be good to eliminate inputs of nitrogen and phosphorus, which are not needed in the product. Ethanol made from corn fails on all criteria.

But blenders are already butting up against the 10% limit for standard gasoline. You're not going to get to 15 billion gallons without an increasing fraction going to E85.

You're not even getting your own numbers right. The NREL multiplier you quoted for gas/coal is 0.6, so the required input would be 12.3 quads. Note that this is more than half of current natural gas consumption of ~23 quads/year.

Not even close. Your numbers are all wrong, even if we assume your sources are right.

It would be far simpler and cheaper to just make high-economy NGV's and run them directly on the natural gas (if we had it), eliminating all the overhead of growing and processing the corn. If corn stoves could burn the corn at more than 55% efficiency (I found a quote of 60%), they could displace more than 1 BTU of natural gas for every BTU of ethanol the corn could make. The displaced NG could run vehicles. This eliminates a lot of processing as well as the subsidies. Not that I expect the poster child for innumeracy to be able to figure that out on his own... or even follow the arithmetic when it's being spoon-fed to him.

280 billion gallons at 3 gal/bu requires ~93 billion bushels. The record US corn harvest is around 12 billion bu. Growing 93 billion bu at 200 bu/ac would require 465 million acres of cropland; this is roughly 5 times as much as has ever been planted to corn in the USA, and is roughly equal to all land cultivated in the USA.

Let me repeat this (not for you, you're too far gone, but for those out there who might be tempted to take you seriously):

YOU ARE TOTALLY BAT-GUANO CRAZY.

Wrong again Space Cadet Second Class E-P.

http://www.nrel.gov/biomass/pdfs/39436.pdf

The chart "Energy required to produce fuels" on page 3 of the booklet shows that you need about less than .1 Btus of oil and less than .1 Btus of natural gas/coal for cellulosic ethanol, so .1 x 20.5 = 2.05. As most people know, cellulosic ethanol requires less fossil fuel than corn ethanol.

The reason I used 15 billion gallons of corn ethanol is that the

Congress limited corn ethanol to 15 billion gallons in the 2007

energy bill.

http://www.allbusiness.com/energy-utilities/renewable-energy-biofuels-et...

Of course, I never said anything of the kind.

I said 15 billion gallons of corn-ethanol plus 20.5 quads of cellulosic ethanol from the 1.3 billion ton biomass scenario which works out to ~280 billion gallons of ethanol, as NREL says on page 4 of the booklet under chart "The 1.3 billion-ton biomass scenario".

SpaceCadet doesn't really describe you well enough as it suggests mere ignorance without your pomposity, menace and grating negativity, E-P.

So henceforth you will be named (by me)---Darlek E-P.

Ah, you changed the assumptions without listing them. BTW, you should not be using a 6-page brochure intended to be printed on glossy paper as a reference. There are no data tables or citations for sources. The least-authoritative source you should be citing is a white paper... unless 6 pages of pretty pictures is the most complex thing you can handle.

Of course, you can't even get that right. A 50% biomass-to-ethanol efficiency (omitting fossil inputs) would yield roughly 7.5-8 million BTU of product per ton of input (biomass at 15.8 million BTU/ton). That is about what the advocates are reporting as their theoretical efficiency, and it comes to approximately 100 gallons of ethanol per ton. You could only get 130 billion gallons out of 1.3 billion tons... if you can get all the processes working, which appears to be a ways off if the schedule slips and bankruptcies of cellulosic ethanol companies are any indication.

But let's assume it's feasible. Should you? Let's be generous to ethanol, and assume that engines tuned for it can achieve 80% of the volumetric fuel economy of gasoline engines. The USA's 3.1 trillion vehicle-miles per year would require 175 billion gallons of ethanol, or about 13.6 quads. That's an average of 17.7 MPGe, or about 4400 BTU/mile. At a generous 30% average drivetrain efficiency this would deliver about 1320 BTU/mi (390 Wh/mi) to the wheels. This takes 135% of your 1.3 billion tons of biomass; you have some 26% of your demand left unsatisfied, and nothing left over for other purposes.

Suppose instead that you chose electricity instead of ethanol as your medium. 20.5 quads of biomass is processed in the field to pyrolysis oil at 65% efficiency, yielding 13.3 quads of oil. This is burned in combined-cycle gas-turbine powerplants at 60% thermal efficiency, producing 8.0 quads of electricity (2.34 trillion kWH). Transferring this over the grid and to wheels at 60% efficiency delivers 1.40 trillion kWh at the wheels. At 390 Wh/mi, this is sufficient to drive 3.6 trillion miles, requiring just 86% of your available biomass. You have 14% (328 billion kWh) left over for other purposes.

The previous calculation assumes no improvements in vehicle efficiency over today's fleet. If the average electric vehicle is as efficient as the GM Volt (250 Wh/mi at the wall), demand would only require 860 billion kWh at the generators, leaving about 540 billion kWh for other purposes. The leftovers come to roughly 145% of all renewable electricity put on the US grid in 2008.

Of course, you can add wind power or nuclear to run your electric car if your biomass supply runs short; wind and uranium can't help you if you're burning ethanol no matter how much you have.

In brief, cellulosic ethanol makes no sense. Ethanol is a way to keep transport running on liquid fuels so that the oil companies continue to own the market when the ethanol makers fail. It has enormous opportunity costs and should be deep-sixed immediately.

No, it's far better applied to the guy you see in the mirror.

So who to believe in, nrel scientists or a nuke/electron economy cornucopian Space Cadet?

Everything goes back to the efficiency of either lightweight hybrid cars at 50 mpg-gasoline or EVs at 2.56 mi/kwh(your number)?

Okay, lets look at running the hybrid on cellulosic ethanol from biomass at 33 mpg(1.5 GGE) versus grid electricity from a plain old 30% fossil fuel plant, with battery charging at 75% efficent per Ulf Bossel equals 22.5% efficient.

BTW, your example of bio-pyrolysis is wrong.

First, 1 ton of biomass converts to ~50 gallons of bio-oil(which contains water), the rest is char and CO2. I will unrealistically assume burning the char completely covers the conversion of biomass to bio-oil.

UOP processed 2250 gallons of bio-oil in an oil refinery into 1010 gallons of gasoline and 250 of diesel or 1260 gallons of actual fuel --56% so 1 ton of biomass produced 28 gallons of 'bio-gasoline' which is the energy equal to 42 gallons of ethanol in energy. Versus +60 gallons per ton of cellulosic ethanol.

So your overall efficiency for bio-oil assuming biomass is 17 million BTUs per ton is 42 x 78000/17000000 = 20% not 65% as you state.

http://www.ars.usda.gov/sp2UserFiles/Program/307/biomasstoDiesel/RobertB...

The oil industry likes bio-oil because it needs their refineries for upgrading(any process energy input required is not included of course).

(1 gal/75700 BTUs)/33.33 mpg = 2271 Btu per mile.

2271 BTU per mile/45% efficiency = 5047 primary Btu/mile

If I use your .39 kwh/ mi or 2.56 mi/kwh,

3412 BTUs/kwh/2.56 mi per kwh = 1333 Btu per mile.

1333 BTUs/mi / 22.5% = 5924 Btu per mile

So at you 390 wh/mi an ethanol powered hybrid beats a grid electricity (charging batteries) from a conventional steam plant.

You need special 60% efficent plants and super-efficent bio-oil

conversion to make your fantasy numbers work.

Not too impressive, E-P.

Oh, believe NREL. Just don't believe what you quote out of context.

We could go to the Tesla roadster at 200 Wh/mi (5 mi/kWh) if you like, but I thought that was too optimistic for a back-of-the-envelope analysis. I was trying to be fair to your thesis, after all (not for your sake, but for the people reading this—you are a lost cause).

Why? You are no longer comparing two uses for the same feedstock, with systems tailored for that feedstock.

You are full of it. Dynamotive reports 85% conversion to liquid and char. I have found other sources claiming ~70% yield of liquid by mass, with 65% of the input energy contained in the liquid. Here is one finding 66 wt % yield from maize stalk. Other sources claim yield as high as 79 wt %. The density of pyrolysis oil is approximately 1.2. 1 short ton yields ~1400 lb oil, which comes to ~530 liters (~140 gallons).

The rest of your analysis is based on the numbers you pulled out of your butt. Excrement in, excrement out.

No upgrading is required to use pyrolysis oil for boiler fuel or turbine fuel. That's why I used it in my hypothetical example.

There is nothing special about them; they are available as commercial products.

Why shouldn't I use your number of 2.56 miles per kwh(390 wh/mi)?

A Feb 2008 test for Tesla got 3.1 miles/kwh at an EPA range not 5 miles per kwh. That works out to 4891 Btu/ mi versus 5047 for a 50 mpg hybrid. Well, I have a EPA 56 mpg Insight hybrid which works out 4506 Btu/mi.

http://en.wikipedia.org/wiki/Tesla_Roadster

Your Dynamotive report showed the overall efficiency of biomass to gasoline/diesel as 'approximately 25%..the highest ever reported'; I said 20%.

And you said 65%?

LOL!

http://www.dynamotive.com/2009/04/22/renewable-gasoline-and-diesel-from-...

Er..no. GE listed bio-oil nowhere in their long list of fuels. You're ignoring that bio-oil has a lot of water in it; it's HHV is 16-26 MJ/kg where as ethanol is 30 MJ/kg.

http://www.uaex.edu/Other_Areas/publications/PDF/FSA-1052.pdf

http://www.gepower.com/prod_serv/products/gas_turbines_cc/en/downloads/G...

Nothing special except the odds of getting electricity from a few state of the art plants instead of regular coal fired plants burning biomass are very low.

But assuming the 60% efficient GE CCGT turbines were using your 25% efficient Dynamotive bio oil they'd produce 25% x 60%= 15% efficient electricity.

You're welcome to, for the sake of argument (though you should recognize that it is based on a deliberate over-estimate of ICE drivetrain efficiency and is thus biased high). What you shouldn't use is the 33% efficiency figure for existing powerplants.

The Wikipedia page claims 135 Wh/km (217 Wh/mi). But everyone already knows that you don't, or can't, read your own references.

And I'm not talking about conversion to gasoline, which is not required to run gas turbines. Not that anyone would expect you to grasp fine distinctions like that either.

Conversion to 75 wt % bio-oil translates to energy efficiency of 70%. I used 65% to allow for other losses and to be generous to the case for ethanol... which still loses badly.

Why should they? Nobody is asking for it yet, so they haven't designed a fuel system and combustors for it. But your reference does say this:

Crude oils are listed in the graphic on page 5, and pyrolysis oil is nothing if not a crude oil. Bio-oil burns just fine in gas turbines.

Look in the brochure where it talks about "steam injection". That can be used for NOx control. Fuels with a high level of inert products are no problem; see the graphic for blast-furnace gas and air-blown syngas.

It's 25% conversion to bio-gasoline and green diesel, not bio-oil. Nobody would insist on processing all the way to motor fuel just to burn in a gas turbine. Except you, that is; you're just not good with distinctions.

Bless you, Heading Out!

Two of the practices I am beginning to learn are coppice and pollard. I have an interest in labor-intensive but effective ways to provide food, fuel, fiber, etc. on a small scale. I am encouraged that the species you mention include some of those that grow on my little New England acre.

I did have an unusual visit this summer by a deer, who browsed not only the strawberries (they grew back, no worries), but also some pollarded maple (and other maple saplings).

Oh dear, yet another misplaced burst of enthusiasm for coppicing or pollarding.

These do not actually increase your wood harvest beyond what you get by allowing trees to grow to full size. Maybe even decrease it, because many tree species do not like being coppiced or pollarded. Most conifers don't. European birches don't either, despite what the author says. Possibly North American birch species are more tolerant - I don't know about these.

The advantages of coppicing/pollarding are (1) you start collecting your wood harvest sooner, and (2) the wood is in small-diameter stems, easy to cut with light hand tools and light to carry.

The disadvantages are (1) the wood you harvest is useless for furniture, housing or any other form of high-value construction, and (2) there is a drain on soil fertility, long-continued coppicing possibly leading to phosphate deficiency.

Transatlantic readers should be aware that the short rotation willow coppice referenced above takes up good farmland & requires enormous subsidies. It makes even less sense than corn ethanol in the USA.

Short rotation willow do indeed take up good farmland but it do not require more subsidies then the worlds highest CO2 taxes and a subsidy for green electricity when it is burned in combined heat and power plants.

The Swedish research for the most efficient energy crop in different regions in Sweden indicate that it often is the best available choise for us.

The major problem has been that too little has been grown to keep dedicated entrepreneurs busy with dedicated planting and harvesting machinery and enough production volume to make it continously available for use. You get low and uneven pay for the woodchips if they only are available every other year and few entreprenuers with an uneven schedule and long distances between customers makes for expensive harvesting. Manny farmers have thus been burned by zero or negative economical yields for good crops.

I must confess that I share your skepticism. I'm hard-pressed to believe that all that twiggy stuff in the pictures actually amounts to a significant amount of fuel, compared to the heavier trunk sections & limbs that one can obtain from mature fast-growing trees. One of the key metrics would seem to be pounds per acre per year, expressed as a function of harvest interval. Any data available on that, anyone?

As I understand it, all that twiggy stuff becomes thicker trunks, over time, especially with thinning.

Is there a difference in phosphate depletion from coppicing rather than harvesting full size trees? Anecdotally it seems that that "limb wood" produces significantly more ashes than "trunk wood" though I've never weighed and measured.

These do not actually increase your wood harvest beyond what you get by allowing trees to grow to full size.

But isn't it easier to coppice that to cot down a mature tree, especially with hand tools? You also don't need to deal with the roots and trunk of the mature tree, though the coppiced stump can get huge. As the tree remains young, through coppicing, the tree can last for a huge amount of time.

I don't know about useless for anything other than firewood, but if firewood is your primary aim, then coppicing sounds ideal. I'm not sure why it would lead to phosphate deficiency. Do you have any links on that?

According to this article there do appear to be some advantages, especially when some of the trees are left as "standards."

I'm sorry, coppice-with-standards is even more obsolete than pure coppice. At least as practised here. The problem is that the "standards" grow huge branches, so you get curved timber. This was fine for craftsmen to carve out the oak framing for the battleships of long ago, but there's no market for curved timber nowadays.

To explain the phosphate depletion issue: most of the nutrients are held in the living tissue of the tree - the leaves, twigs, bark and sapwood. In conventional forestry, it's mainly the heartwood you are taking away, and this is dead tissue, just cellulose and lignin: the tree has removed all the nutrients it possibly could. Admittedly the forester takes away some sapwood and bark too, but only a small proportion. In contrast the coppice harvest is almost entirely sapwood, bark and twigs - and maybe the leaves too, if for animal feed. It wouldn't matter if the ash was returned to the site, of course, but that's extra work for a benefit which is only seen in the very long term. Human nature being what it is, the ash is usually not returned.

I don't have any web links for the phosphate issue, but see any good forestry reference book which covers coppicing. For example our UK Forestry Commission Bulletin 62 Silviculture of Broadleaved Woodland, ISBN 0-11-710154-0.

The harvesting yield from coppiced sweet chestnut in Southern England averages 5-6 cubic metres/hectare/year (see Practical Forestry for the Agent & Surveyor ISBN 0-86299-962-6). In terms of dry timber that's about 3 tonnes/hectare/year. Similarly for coppiced hazel. These are unimpressive figures, though chestnut coppice produces valuable fencing poles so may still be economic. For comparison, conventional forestry gives me 16 cubic metres/hectare/year of spruce (about 6 tonnes dry timber/hectare/year) on land which is wet, infertile, windswept and far poorer than anywhere in Southern England.

Coppicing makes sense if all you've got is mediaeval hand tools. But I sincerely hope we never regress that far.

Totally OT, but you might be amused to know that my brother and I spent the summer after I got my Bachelor's degree (1965) helping to lay out roads through the forests (as they later became) but the bracken as then was, around St John's Town of Dalry, in what was then Kirkcudbrightshire.

Thanks for the information, and the sources.

Welcome to the Oil Industry & Scottish Forestry Club - we now have 4 members! Your forests may have been harvested by now - in that part of Scotland rotation lengths are down to only 35 years in places, because the growth rates are so good. Similar to Ireland, and I do have a free weblink for that if you're interested: www.coford.ie/iopen24/pub/nf2040608.pdf.

I should possibly mention whole-tree harvesting, a much more promising avenue than short-rotation coppice. The idea here is that you take the main trunk to the sawmill as usual, but then you also pull out the stump and chip it, together with the branches & stem top. You get approximately the same tonnage of wood chips as of sawlogs. Although chips sell for much less than sawlogs, it's a useful bonus. Here is another weblink: http://www.forestresearch.gov.uk/stumpharvesting. It's not very positive, but then our Forestry Commission is not a very positive organisation nowadays. Admittedly phosphate depletion is - as with coppice - of genuine concern.

Thanks - being in part of the US that does not have enough wind or solar, but living in a national forest, the question of how we use it keeps coming up.

I'm not sure that dependence on firewood is a step in the right direction. In Australia a lot of firewood is cut from dead trees or heavy fallen branches, though at the detriment of birds that nest in hollows

http://www.environment.gov.au/land/pressures/firewood/woodlands.html

Given the need to reduce the ferocity of wild fires near homes perhaps undergrowth could be collected with brush hog type machines. That biomass could be torrefied (scorched) and sold for wood stoves. I've experimented with making charcoal briquettes from torrefied straw but I found it difficult to get an even result. Again forest thinning will disadvantage certain fauna, notably 'tweetie' birds. And as with ethanol once you demand the harvesting machinery make its own fuel (not petroleum diesel) it doesn't look so good.

I believe the answer to winter heating is passive building design with frugal heat pumping of smaller volumes of air.

I have only a little formal training in forestry but my reading and what training I do have indicates that the cutting of dead and hollow trees is one of the worst possible ways to manage a woodland in respect to wildlife in general and many species of birds and small mammals in particular.

If you own woodland where fire wood is gathered it is much better to just cut down some healthy younger trees.

In some jurisdictions it is actually unlawful when logging to cut trees that may serve as den trees, and dead trees are the primary foraging sites for some birds.

And speaking as an experienced old hand at gathering firewood,I can say with great confidence that a living green sound tree cut far enough in advance to dry yields far higher quality wood and that your reward in btus per hour stacked in your woodshed will be very substantially enhanced by cutting the green tree.

The very simple reason that this is true is that most dead trees are already substantially colonized by fungus well before they die.If you take a good look at the wood of say a typical oak tree that has been dead for a couple of years,you will see that the sapwood is already visibly decayed,and the sap wood may comprise over half volume in smaller trees. A crown left on the ground for one season after is worth a third less for firewood in my estimation than one freshly felled,and one left for three years is almost worthless-unless there is nothing else available- except for the thickest portions.

Keep in mind that large diameter wood must be split or too heavy to handle conveniently and that wood too small takes too much time to gather.As general thing I try to cut trees that are roughly from six inches to twelve inches in diameter as this minimizes the splitting and I work the limbs up down to roughly two inches in diameter,sometimes smaller.

The trick is to learn a little about the ecology of your particular woodland and have a management plan.I cut firewood with two goals in mind, to thin the woods and allow future timber trees to grow faster and to maximize wildlife habitat.

Cutting your wood green and putting it in a shed or at least covering to season is by far the best way both in terms of net heat yield per hour and woodland ecology,at least in areas with mixed temperate zone forests.

These remarks may not apply in other parts of the country with other kinds of trees and climate.

My personal guess is that except for the fact that your can accelerate the harvest of firewood in small quantities with only hand tools if necessary it is not worth while to coppice except in areas where wood is in short supply and labor is dirt cheap.

Unfortunately it looks as if if these conditions may prevail in many many places in the not too distant future.

Pollarding trees that can also serve as living fence posts around the perimeters of pastures and for partition fences might make a lot of sense where firewood is scarce.. A few decades back it was common to see such living "bobwire" fences on small mountian farms such as my Momma's home place.

When land was bought and sold, it was common practice to just unroll the wire along the property lines and nail it to as many trees as practical,saving a lot of hard work cutting posts and digging post holes.Then the land was cleared and put into crops or pasture as time permitted.

You can still find stretches of such fences in the woods even now sixty or seventy years after they were erected and decades after the land was allowed to revert to woodland,and some are still in use.

It is generally very good practice to be rather skeptical of the value of the first five feet or so of any tree around an old country homestead as it may contain nails , pieces of chain,staples, bullets, barbed wire, end even horseshoes and other embedded metal objects which were nailed to the tree for various reasons or sometimes no apparent reason at all.

Delivering such a log to a small local mill lacking the metal detectors used to detect such objects is a good way to ensure that the mill operator will not buy from you again and might even result in somebody being very seriously or fatally injured.

That depends what machinery you use. Goats are remarkably adaptable, though they don't yield combustible fuel.

It is quite feasible to run engines on woody matter using gasogenes. That might change the economics.

Torrefied biomass might be too friable to make good wood-stove fuel. Large sizes would break too easily, and you'd have dust. You'd still have the problem of bulk handling. Pyrolysis oil ships better and can be delivered in tanks with a little tube going into a burner inside the stove. It has about 85-90% of the heating value of ethanol (and more per unit volume), so that may be something to look at. It would require setting up a new industry, though.

One of the big problems with most of the value calculations I see is that they do not take into consideration the NET heat value of the fuel. ie the heat that actually heats the home instead of going out the exhaust stack.

Propane furnaces are 90+ percent efficient in converting the available BTUs in propane to home heating BTUs. Wood pellet/corn stoves operate in the 50% to 70% range of efficiencies. (I have found no truly independent testing of this)

I just calculated the NET BTU for both propane at current prices and at 90% efficiency and the NET BTU for wood pellets at the current local price at 70% efficiency and propane came out much cheaper. Plus with propane the supplier delivers the fuel and supplies the storage tanks. With wood pellets the buyer has to haul them, stack them, provide storage (indoor) for them, haul them into the dwelling to fill the hopper twice daily, empty the ash bin daily or weekly and shut down the unit the clean it at least weekly. Why would anyone want to do all that extra work (and added hauling expense) and pay more per NET BTU?????

The reason is that most people do NOT take the time to calculate the NET BTU value/cost of the available fuels before spending their hard earned money. I can give you no rational explanation why they do this?

And, in calculating all fuels I included geothermal heating, which is by far the cheapest source of heat. So I contracted for propane for my shop this year and am putting in a geothermal heating system for the house and putting the wood pellet/corn stove in storage for this heating season.

My wood pellet stove burns between 1.5 and 2 40 pound bags of wood pellets per 24 hours with an average of 180 heating days per year. that is 10,800 to 14,400 pounds of wood pellets (5-7 tons!). You have to be in pretty good shape to haul, unload and stack 14,000 pounds of wood pellets.

I made up a graph that lets me easily view the cost per 100,000 NET BTU for any of the primary fuels at a wide price range for each fuel. Makes it very easy to see which is the cheapest fuel to use each year.

I found that purchasing cut/split wood for a wood stove to be far and away the most expensive fuel at current prices of $75-$125 per "pickup load" (about 800 pounds of wood in most cases that I looked at). Makes even high priced propane/fuel oil look dirt cheap by comparison. My take is that if you can't cut, haul and split your own wood, don't get a wood stove. My guess is if most people buying wood knew what they are paying per NET BTU, there would be more than a few lynchings.

Where I live seventy five dollars in the off season will get you an older model full size "long bed " Ford or Chevey loaded with first quaility oak split and stacked too if the truck can be driven right to the spot you want your wood.

This is a load heaped up in the middle and with the back end of the truck so depressed the axle is bumping into the frame,but the wood is generally free or next to free to the guys who cut it-mostly it is the leftover crowns from logging.Sometimes the loggers get a few bucks for using thier equipment to drag the crowns to an easily accessible spot.

Strictly a cash word of mouth business of course,these guys are netting ten bucks max an hour if they have a really good day.

If they have truck or chainsaw problems,they are in the hole maybe for the entire seasion.

Lots of people don't realize it but such sideline survival businesses keep a lot of por folks in blue jeans and cigarettes and are one very important reason so many country guys drive big pickups.

Right this minute I'm hearing gunfire and the yelps of hunting dogs. The trouble is that is in a 180 acre woodlot belonging to other people. The owner just drove up in a ute/pickup but thought the better of confronting the hunters. Maybe fewer critters will mean small trees get a chance to grow into big trees. In rural areas Downunder slow burning hardwood sells for about $A150 a tonne delivered close by. The woodlot owners managed to get an old six wheel drive Studebaker truck stuck on a ridge top recently. It's all done for booze money, not a living.

The owner must be a real wimp unless he thinks maybe the hunters are growing dope.I have seen a little old lady that didn't wiegh ninety pounds soaking wet evict a whole crowd of hunters from her property with nothing but a sharp tongue and a hot temper.

Since the area where I live is getting a little crowded and hunting opportunities are dwindling,it is common for local landowners to have to chase off uninvited hunters,who are of course violating the very most important rule of all in outdoor shooting sports,which is respect of other's property.

I have never heard of a case of a hunter threatening a land owner or refusing to leave when told to do so,although I am sure this must happen occasionally when some urban redneck(most likely drinking) who never expects to return to the nieghborhood is told to scram.

The ranting lefties have gotten people so scared that they think if somebody is carrying a gun he must be a bloodthirsty depraved murderer looking for a man or woman rather than a rabbit or a deer.

More likely the guy is not willing to go into the woods under any circumstances for fear of getting lost if he loses sight of his car or reluctance to snag his slacks on a briar vine.Or maybe he will be back with the no tresspassing signs and hammer and nails.

The sad thing is that the end result is no trespassing signs everywhere these days.When I was a kid I could walk all day in any direction without needing to ask permission first,although it was understood that you were to have at some point maybe ten years back asked if it were ok to hunt the various nieghborhood farms. It was never refused,and it never occured to the landowners that somebody would throw out trash or spin thier truck around in a corn field or leave a gate open and let the cows out.

Hours later it looks like they can't call the dogs back. The access road the hunters used belongs to a multinational paper company not the road used by the woodlot owner. I'll suggest the company changes the locks.

No idea what your local laws are but here ours are based on 18 and 19century realities that dogs ran loose and can't read.A hunter can't deliberately send his dogs onto another's property w/o permission,but the law recognizes that rabbits and deer can't read either,so the dog can tresspass but for the man with the gun it's a no no and results in a serious fine for a second offense and a very serious fine possibly jail time for a third offense.

In many areas and for certain species hunting with dogs is not allowed,and hunting itself is now banned in most heavily populated areas.

A sawmill near me is in the planning stages of building a wood fired power plant ( Seneca, Eugene, Or US). The catch is that the mill wants to haul all of the logging slash from the forest to burn, rather than relying on just bark/sawdust/mill ends. Most slash is currently burned or left in place. Long term, this takes even more nutrients from the forest soils, it would be like a farmer taking all crop residue off of a field.

For Jebus's sake, why are we talking about burning wood again? Some people seem to have an atavistic attraction to the concept, something to do with the Homo Erectus campfire urge. The bottom line is that burning wood produces a large range of airborne carcinogens as well as particulates, as we pointed out in a previous TOD article on this topic. I've personally had to flee suburbs where many residents used woodburning heaters because of the detrimental effects to my and my family's health. A pox on wood burning! What'll we discuss next — perhaps how we can slaughter a few excess whales and start lighting the streets with their blubber?

Hidden cost in wood burning: Pollution

WHY IS WOODBURNING AN AIR POLLUTION PROBLEM?

Conceivably it is because some of us live in states where there is insufficient wind energy or solar power to adequately provide for the populace, but there is a significant amount of biomass. Not everyone has the luxury of living in a state where all the power can be supplied from those two aforementioned resources - do you?

Me? I was smart enough to relocate to milder climes. Why don't you? Alternatively, look at insulation, warm clothing in layers, blankets when sitting watching TV, and microwaveable heating pads.

I read you have fireplace Nazis in the bay area that go around and smell the air. Sorry but that's a bit much.

Individuals spewing lots of particulates into the air and harming the health of their neighbors is more than a bit much.

Sure, we'll all move to the Bay Area - you'll have a place ready for us won't you? Your assumption that your present climate is somehow fixed is laughable.

I'm not worried about the carcinogens pumped into the air by my efficient wood stoves. Your chart shows that most of the problem comes from crap stoves and fireplaces. Fireplaces are not a serious heat source anymore, and most people don't know how to get any heat out of one anyway. Anyway, there are far more serious issues to attend to, primarily climate change and ecosystem destruction. So wood heat works for me in my present situation, and since I have no interest in moving to California, then you won't be bothered by my wood smoke.

Now for reality - there is no energy source that will work for all of us. There is no way to provide energy in the amounts we've obtained from fossil fuels without serious impact on the environment.

But no state has a sufficient amount of biomass to adequately provide for the populace.

We need more than wind and solar too. We need nuclear and geothermal.

You don't have these issues with wood gasification power plants.

Please,

Just look at your own graphic, only 1.4 is from epa stoves, which I am sure that anyone who would read the article would know to use. Mine is 75% efficient and produces little to no smoke. I also maintain my own wood lot and am carbon neutral. Have you look into the carbon footprint of shipping all that water around your state?

There's an interesting stat in the latest EIA report on page 13. Total quads from renewables exceeded nuclear power in May 2009. This is great ammo against the argument that renewables will never account for very much energy.

http://www.eia.doe.gov/emeu/mer/pdf/mer.pdf

Drax, owner of the largest coal-fired plant in England (caveat: I own a few thousand pounds worth of shares in them, on which I've lost a few hundred pounds over the last nine months), is planning a 300MW biomass-fuelled plant. They have tried co-firing small amounts of biomass at their main 4GW plant and seem to be contemplating getting up to 5% if they can find the supplies.

Much of this is because the British regulations mean that burning a ton of wood gets you carbon credits (which you'd otherwise have to buy with money) enough to allow you to burn a ton and a half of coal.

The intended source for the biomass is 'short-rotation coppice' which is I guess the same as described here. But supplies are very much the issue; they are talking about importing waste wood from Sweden and even from Canada.

The problem I have with co - firing is that the wood ash becomes contaminated with coal ash. I stand to be corrcted but coal ash is high in heavy metals so not suitable for returning to the land?

On a micro scale I return wood ash from buring poplar, sycamore, and horse chestnut to the 100m2 allotment plot I rent

Wood including "wet" wood and pieces of wood and tree-shell contains 20 GJ energy per ton. My research found that per acre we can get 2 tons of such wood sustainably from a natural forest and 5 tons per acre from artificial forests specially planted for wood containing high wood yielding trees. So, 40 GJ per acre is a good estimation. Since gasoline contains 33.4 MJ per liter therefore its equal to 1197 liters of 1197 liters or 7.5 barrels if those barrels contains gasoline only or if the entire energy content of barrel is equal per liter of gasoline. World consumes 30 billion barrels per year which accounts for 40% of all industrial (i.e. non-food) energy consumption. The total 75 billion barrels equivalent require 10 billion acres of forest which is 133% of world's arable land. Simply put, wood is a good source of energy if you are willing to live a 18th century life style, that is burning wood for only direct warming needs and some for electricity. In Pakistan we use 300 kwhr electricity per house per month and on average each house contains 5 people so its 60 kwhr per month per person or 720 kwhr per person per year. This is equal to 129.6 kg wood which needs 0.0648 acres. Add in energy usage by govt, it would be something like 0.1 acres. Note that industrial energy usage is not accounted.

Affluenza starts with the first car, so do heart ache

Can someone point me toward some information on the actual practices of coppicing and pollarding? How does one go about doing this without killing the tree, what species does it work on, etc. It's something I would like to learn more about and consider as a possible method.

Right now my main goal is to get black locust replanted back up on my hill, as previous clearing and poor logging practices have left the woods in pretty bad shape. I've got a lot of black locust down by my house, and for my purposes it's about the most valuable wood there is. I have a lot of ash to burn now, as it is all dying, but that won't go on forever. However, I do have a fair amount of oak too, though I seldom cut it - perhaps these methods would be useful.

A few pointers are here, though not very comprehensive. I think low ash content would make Poplar a good choice, my thinking is that low ash content = lower mineral requirements. Hybrid popular may be something to consider, it was all set to save forests from clear cutting a while back because of its fast growth. It didn't because its structurally too weak for lumber, but who needs structurally strong firewood?

Hybrid Poplar,

http://forestry.about.com/od/silviculture/p/hyb_poplar.htm

Thanks - I've got lots of poplar. It's pretty much a weed here, but I actually like it for firewood because it's so easy to cut, split and stack. I don't know how it would take to coppicing.

Assuming you mean yellow poplar also known as tulip tree some times it is excellent firewood in certain respects.It burns cleanly, is very easy to split,does not drop off a lot of bark particles that must be vacuumed up ,etc.

It grows fast and it will regenerate from the stump almost every time.

The problem is that is is not a dense wood and per unit volume it is not nearly as good as heavier species such as locoust,hichory, maple,or ash in terms of heat content.This means it is not a god deal if you buy by volume or cut your own a long way from home and incur serious hauling expenses.

The bottom line is that it's great fuel but not nearly as good as the other species mentioned because you must cut and handle more wood to get the job done.Most frugal farm type people do burn whatever poplar is handy if it is not good timber quality simply to avoid wasteing it.The extra work is a very minor issue if you don't have to haul it very far and have room to store it,as the larger volume is partly compensated by ease of sawing and splitting.

Back in the days when my Mom cooked on a wood fired kitchen range she actually preferred poplar above all other wood because when it is split into small pieces it ignites fast,burns hot and clean ,and burns out fast-properties much appreciated in the kitchen,especially in the hot months.

The whole issue of ash content is pretty much irrevelant unless you live in a densely populated urban area and have a lcal smog problem.Put the ashes in your garden or scatter them on your lawn or just give them away once you have a big can full, somebody will be glad to takle them.