An Updated Look at Lithium Production

Posted by Heading Out on February 19, 2010 - 10:08am

Just over a year ago, and spurred by an article in Time, I wrote a post on the possible global supply of lithium, which is used in renewable batteries, and a major choice for use in the batteries of electric vehicles, such as the Chevy Volt. Since the story has acquired more recent interest this week, and with new information, it is worth re-visiting the topic.

I began the original post by noting that our first introduction to these batteries was in our role as an Explosives Lab when we found out - in a series of experiments a long time ago - that they can blow up if handled wrongly. And it turns out that such a risk is still around, though not that common. But to put the event in context:

Fifteen incidents in the last two decades were serious enough to warrant a decision to re-route a plane or perform an emergency landing, according to FAA data.

For instance, in 2008, there were nine battery accidents resulting in two minor injuries. To put that figure in perspective, that year 3.3 billion lithium batteries were transported on 77 million flights, including 56 million passenger and combination passenger/cargo flights.

Based on that data, one's chances of being on the same flight with someone who suffers a minor injury because of a malfunctioning battery was about 1 in 28 million in 2008. In comparison, the one-year odds of dying from a car accident in the U.S. are 1 in 6,584, according to the National Safety Council.

Since we also look at processing, I became curious about where and how the lithium is mined. Recently, however, h/t to JoulesBurn, there was an article by Jack Lifton explaining some additional production issues. So what I thought I’d do is to integrate some of this additional information into a more up-to-date post.

It turns out that most lithium comes from salt lake deposits such as those in Chile and Bolivia.

The biggest deposit in the world lies in the Salar de Uyini, Bolivia, which is also the world’s largest salt flat. A quick look through Google Earth gives the location, with the white in the picture being the salt flat, and not snow. La Paz, the capital of Bolivia is at the top.

The lithium is found in the crystallized salt, and in the brine that underlies the crust. As the world gears up to demand more, Bolivia is determined to keep as much of the “value added” part of the processing to itself. Thus the intent has been that the state would initially act alone in industrializing their deposits, and not look for foreign partners until 2013. Unfortunately its attitude has not drawn a lot of excitement from the world press, since there appears to be more than enough for current demands available from elsewhere.

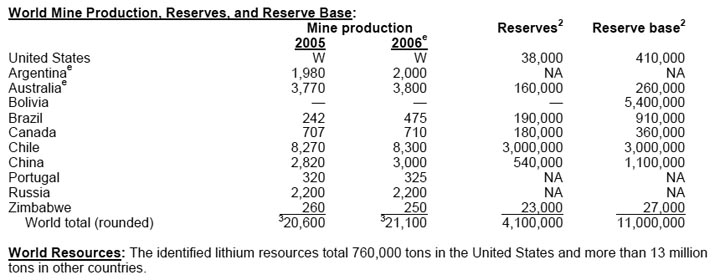

Chile provides 61% of lithium exports to the US, with Argentina providing 36%, says the US Geological Survey (USGS), with Chile having estimated reserves of 3m tonnes, and Argentina about 400,000 tonnes. . . . . . Lithium production via the brine method is much less expensive than mining, says John McNulty, analyst at global bank Credit Suisse. Lithium from minerals or ores costs about $4,200-4,500/tonne (€2,800-3,000/tonne) to produce, while brine-based lithium costs around $1,500-2,300/tonne to produce.

Melting snow from the Andes Mountains runs about 130 feet (39.6 meters) underground, into lithium deposits, then gathering into pools of salt water, or brine. The brine is pumped out from under salt flats such as Chile's Salar de Atacama, and spread among networks of ponds where the desert sun and high altitude provide a beneficial environment for evaporation.

It takes about a year for the brine to reach a lithium concentration of 6%, when it is shipped to a plant to be purified, dried and crystallized into lithium carbonate, which then is granulated into a fine powder for battery makers. Lithium stores a very large amount of energy for its volume, which makes it perfect for electronics.

Unfortunately for those who are expecting electric cars to spring out of the woodwork in the next few years (remembering that the President’s plan calls for 1 million plug-in hybrids by 2015) Mitsubishi estimates that the world will need 500,000 tons per year at full ramp up. The Salar di Uyuni deposit in Bolivia holds at least 9 million tons, although the country has, in total, perhaps as much as 73 million tons. The only progress to date is a pilot plant that was intended to produce some 40 tons by the end of last year, as it geared up to full production, with the product coming from brine processing. The world supply of lithium itself is considered to be 28.4 million tons, equivalent to 150 million tons of lithium carbonate. The USGS has estimated that the deposit can produce about 5.4 million tons of lithium, relative to a total US reserve base of 410,000 tons. With the slump in the world economy last year demand dropped, and so lithium producer SQM SA has recently dropped the price 20% since there is more than enough to go around.

Of course that all depends on how Chinese demand changes in the next short while.

In terms of how much lithium goes into a battery, it is about 20 lb for an EV, and about 0.1 oz for your cell phone. However there are other industrial uses for lithium, so that at present only about 25% of world production ends up in a battery.

Part of the problem with the Bolivian deposit, as Jack Lifton noted is that the deposit is contaminated with magnesium, which is also true at the Atacama deposit in Chile, except that while the Mg/Li ratio there is 6.4 to 1, the deposit is 0.15% Lithium. At Hombre Muerto the Argentinean deposit, the Mg/Li ratio is down to 1.37 to 1, making it easier to produce, even though the grade is lower, at only 0.062% Li. Unfortunately the Bolivian deposit has only a 0.028% lithium, while an Mg/Li ratio of 19.9:1 so that it has both a poorer grade, and a higher Mg content. To add to these disadvantages, being high in the Andes means that evaporation is not as fast, and so processing costs go even further. This is especially true since the lake apparently floods every year, slowing evaporation even further.

So put it all together, and, for the moment, the production of much lithium from Bolivia might be a bit further in the future than they currently expect. Which is perhaps why the plant gets being pushed further and further into the future. By November last it had been put back to 2014. (And the claim that the technology will all be homegrown is a little more suspect.)

. . . companies like Japan's Sumitomo and Mitsubishi, and South Korea's state-run Kores -- Korea Resources Corporation, are helping the government find the best way to extract lithium from Uyuni "free of charge," but will be the preferential buyers of Bolivia's lithium carbonate.

Lithium is also produced from coarse grained igneous rocks called pegmatites, with spodumene being the most common. American mines were in the Carolinas, but closed since brine processing is cheaper than the mining and processing of the hard rock.

Geothermal power plants draw hot brine from underground as a power source, and these brines can contain dissolved minerals. Thus, for example the seven Geothermal plants at the Salton Sea are reported to be able to produce up to 16,000 tons of lithium per year. The facilities are better known as a source of zinc (pdf). However the potential as a source of lithium is becoming increasingly recognized.

Thanks for the update, Dave!

I think the thing that strikes me about the EV hype is that no one has stopped to think that to get enough lithium to scale up the batteries, one will have to go to a whole lot lower grade ore--and that ore will be a whole lot harder to mine. The result will be lithium that costs a whole lot more, so that a set of batteries for an EV will cost a whole lot more. One guess might be $50,000 batteries that last 10 years instead of $10,000 batteries. It seems like that would be a deal-killer for scaling up EVs.

What we need is lots of cheap lithium, and that seems to be what is lacking.

I strongly suspect this is a non-issue. Lithium has, historically, been an element with quite a small industrial demand. I believe the major uses have been lithium grease, a high temperature lubricant, and as a source of tritium for thermonuclear weapons. There has been a tiny amount used for pharmacological purposes, and small amounts in various industrial processes.

But even today, with a lithium battery in about five billion phones and tens or hundreds of millions of laptops, most being scrapped every two years or so, the usage of lithium for batteries is still less than 30% of world production.

It appears that virtually all current production is from accidentally discovered deposits. There is nothing exceptional about any of the deposits mentioned. The Salton Sea geothermal source is a clear example of an accidental discovery. Someone looking for other minerals does a chemical analysis of a brine and publishes the result. Years or decades later, someone looking for lithium does a literature search, and finds a report of some small lithium concentration (it is 0.1% in the Salton Sea brine) and a new source of lithium becomes available.

I know many geoscientists all over the world, and read a lot of geological literature, and have yet to hear or read of a single person deliberately searching for a lithium deposit. In contrast, there are tens of thousands of geoscientists actively searching for oil and natural gas worldwide.

We can confidently say that no more cheap oil will be found, because we have searched diligently almost everywhere in the world for decades.

We cannot say that no more cheap lithium will be found, simply because there has never been a serious search for it.

It seems like the existence of co-products is a big thing that keeps the price down. If lithium is found based only on a serious search for lithium, it is a lot less clear that salable co-products will be part of the package deal--so prices are likely to be higher, I would think.

Interesting article but like all the other shortages we face " We'll burn that bridge when we get to it"

Gail - assuming that lithium EV batteries will cost 50,000 dollars is a bit unreasonable - they will increase in cost to find an equilibrium point somewhere between their current price and 50,000 dollars. The actual flowrate of EV batteries will be limited by this, of course.

Can anyone clear up what world supplies of Li are? I see two conflicting (to me) sentences in the above post:

"The Salar di Uyuni deposit in Bolivia holds at least 9 million tons, although the country has, in total, perhaps as much as 73 million tons"

"The world supply of lithium itself is considered to be 28.4 million tons, equivalent to 150 million tons of lithium carbonate"

Is the 73 million tons in bolivia 73 million tons of lithium carbonate or lithium metal?

Does anyone have any information about the amount of lithium that can be recycled from a battery once it is worn out? Do the batteries contain any other rare metals that may be more problematic than lithium, and if so, how much worse are the batteries that do not contain these rare elements.

Furthermore, who says that massive deployment of EVs is really the answer? Giant makes a nice bike for $2000 that uses lithium ion batteries to assist the rider - it won't work without input from the rider. This is not future technology, this is now - I have no idea how the batteries hold out with time, but I know a few bike shop employees and they know people who have the Giant E-bike. I'll keep TOD posted. I've test ridden one - they are a lot of fun.

In any case, if industrial civilization keeps going (unlikely, but for the sake of discussion let's assume it does), silicon-air batteries (or another metal-air battery) will be able to replace lithium eventually. I would say that silicon reserves are sufficient for a long time; the issue is just the energy required to manufacture the silicon-air batteries.

To borrow someone else's catchphrase, best hopes for sane use of technology rather than attempts to replicate ff-powered society using batteries.

This point does not get as much attention as it should on TOD: Energy and resource consumption only can improve quality of life so much. In North America, many people are on the flat part of the curve. Arguably, the curve peaks and then dips; many people are living in the dip - they would actually be happier with less consumption. Where exactly the peaks and dip(s) are is a matter for debate - but I know that the Internet and electric lights do more for my quality of life than a car would. You could even say that North America is actually suffering as a result of excess energy.

http://lithiumabundance.blogspot.com/

Note "Western world" though, and obivously there is a price aspect to any given level of quantity.

"In 1976 a National Research Council Panel estimated that Western World lithium reserves and resources totaled 10.6 million tonnes as elemental lithium.

Subsequent discoveries, particularly in brines in the southern Andes and the plateaus of western China and Tibet have increased the tonnages significantly. Geothermal brines and lithium bearing clays add to the total.

This current estimate totals 28.4 million tonnes Li equivalent to more than 150.0 million tonnes of lithium carbonate of which nearly 14.0 million tonnes lithium (about 74.0 million tonnes of carbonate) are at active or proposed operations.

This can be compared with current demand for lithium chemicals which approximates to 84,000 tonnes as lithium carbonate equivalents (16,000 tonnes Li).

Concerns regarding lithium availability for hybrid or electric vehicle batteries or other foreseeable applications are unfounded. "

The real trick is to price lithium in terms of energy. How much energy does it take to bring lithium to market? What percentage of this has to come from fossil sources?

At the moment I see the deal killer is the bad power grid. The amount of watts needed can't be delivered with the present grid. Many locations are near capacity - adding transport isn't going to help.

A technology like room-temp superconductors *might* be enough of a reason to spend on creating a new grid. So would a 'new' transport model like the RUF.

http://nextbigfuture.com/2010/02/quebec-physicist-talks-confidently-of.html (room temp superconductor)

http://www.ruf.dk/

If the eestor people are able to deliver on their 'ceramic battery-capacitor' - the Lithium won't be a problem. Same with the 'hydrino battery' that was to be in cars by 2007. The grid will still be an issue.

The grid can deliver much more than it's handling now, especially if the load is levelled (heat dissipation runs as root mean square, so peaky demand maxes it out faster than constant load). Off-peak load is particularly easy to handle. Further, if off-peak loads rise and off-peak prices rise with them, this will generate the revenue to upgrade the lines and transformers.

Are all these percentages by weight or by atom count? Are the weights given of lithium alone or of lithium compound? One thing to remember with lithium is that, with an atomic weight of 6.9, it is a very light element compared to say iron at 55.8 or even oxygen at 18.0 and a low percentage by weight may be a much higher percentage by atom count, or conversely, that even a pure lithium compound may have only a small fraction of lithium by weight.

From the numbers give, if my math is correct, the cost of brine based lithium is as little as $1.50/kg ($1500/tonne). If ore based it is as much as $4.50/kg ($4500/tonne).

If an EV takes 20 lbs, that is about 10kg or $15 to $45 in lithium cost and obviously represents almost nothing of the total cost of the battery. If every adult in the world drove such an ev, about 5 billion X 10 kg = 50 billion kgs = 50 million tonnes. If Bolivia alone has 73 million tonnes of the cheap stuff and the world presumably has multiples more of the slightly more expensive stuff, I don't see how lithium will ever be limiting. Unlike petroleum, the lithium is not consumed. When the battery wears out the lithium is totally recycled just as lead is recycled in conventional batteries.

I recommend reading the articles on lithium by Jack Lifton at Seeking Alpha. He is bearish on the geological potential of many of these deposits, making for a good counterbalance to the hype surrounding them - sort of a Li Colin Campbell. I should mention that, after reading a few of his pieces and doing some checking around, that miners don't seem recalcitrant about working in the Uyini, impurities and all; they're just waiting for Evo to open the doors. Concerns about energy/water don't seem to matter to them, either.

The fact that (as noted above) Li is a coproduct of extraction of other more commercially desirable minerals is important, too. I recall a comment in a story here from a person working in the miners about gallium, and how all that was required to boost extraction was to slap $50 million of kit onto existing Al mining facilities.

Excellent article...thanx

While i think a 250 million vehicle fleet of Lithium powered vehicles powered by Thorium is pure fantasy, i could see a small fleet for the upper class/rich/elite and government officials, their friends and girlfriends and wives.

The more realistic use in my book would be LiPo batteries for electric bicycles. I have no idea how much lithium would be needed for a bicycle capable of going 20 miles or so on a charge, but i bet it would be a small fraction of what a car would need.

From Lithium Mining Stocks List + Sector Overview Chart. No breakdown of batteries by application type, but sales of eBikes are 23 million strong for 2009, 90% of that in China. I agree that they are a big part of the future, being within the reach of the most cash-strapped. The end of the "Tyranny of the Trunk" is what I tell people. Usual caveats apply - good luck electropedalling through a Snowmageddon like the US east coast is enduring - but for most of the year you're in business, no matter how out of shape.

Indeed, bicycles seem to be a far more efficient and responsible use of lithium for electric powered transport.

Cost to charge must be proportional to battery size. Ride on!

I hope your comments and guesses are better in areas I know little about ;-)

Current price is $500 to $700 / kwh - though Nissan supposedly has even lower price for their Nissan Leaf. Let us take $500 / kwh. Since 24kwh battery is said to use 4 kg of Li - 1 kwh would use some 170 gm. Taking metalic Li price as $40 / kg, we are looking at some $7 / kwh. Let us make that $10/kwh.

So, currently only 2% of the battery cost is because of Lithium. How much would that have to increase to make the battery cost 5 times ? (Lithium price needs to go from $40/kg to $2,040/kg or 126 times)

We can cross check this using information from here. "They showed that you need 1.4 kg of lithium carbonate per kilowatt hour of battery." That gives a cost of $11 / kwh (using $8/kg).

http://evworld.com/article.cfm?storyid=1180&first=6240&end=6239

http://www.transportation.anl.gov/pdfs/TA/149.pdf

IIRC Li is ~$4 of the cheaper ~$400/kWh batteries available (~$8/lb as of 2008/2009). If we increased Li price by an order of magnitude in order to exploit new resources it would only increase battery prices by ~10%.

I'm wondering what figures people are using to estimate lithium demand for vehicles.

I've been seeing the number of 80 grams per kWh of battery capacity. (80 grams is 11.5 moles of Li-7, which is 6.9e24 atoms or roughly 1.1e6 coulombs worth; that makes roughly 1 kWh of capacity, give or take.) If every pre-recession US light-duty vehicle purchase (~17 million vehicles/year) had a Chevy Volt battery pack (16 kWh, 1.3 kg lithium) that would require the mining or recycling of 22 million kg of lithium per year. That's 22,000 tons of metal, about 130,000 tons of Li2CO3. To get world consumption under the same scenario, multiply by roughly 4. That's a world of pure PHEV production for less than 100,000 tons of lithium per year.

The Tesla Roadster only has 60-odd kWh of battery capacity. Where does this 500,000 ton number come from? And where does the EV-World article figure its numbers? It overstates the lithium requirement by a factor of 3 or 4.

Salton Sea geothermal brines are enough to Volt-ize most new US vehicle sales; certainly enough to hybridize everything sold in the USA, including commercial vehicles, from ONE source. Current lithium carbonate prices amount to roughly 4.5 kWh per dollar. Current lithium-carbonate prices are about 0.27 CENTS per gram of metal. Yes, that's CENTS; multiply by 80 g/kWH, and it's about 22 CENTS per kWh of battery. We do not have a lithium shortage. We can multiply the world price of lithium by ten, and it still won't affect the price of batteries much. You have to multiply it by 100 to be a serious part of the cost, and other factors would still account for 90+% of today's price. Once the price gets high enough to mine the seas, that's it; it can't go any higher. Relax! Don't worry! (Apologies to Charlie Papazian.)

It would be interesting to see what the comparison between say methanol and electric storage is from a power density as well as a cost point of view. Both are storage methods for energy, and methanol (or an analogue) arguably requires smaller changes to infrastructure .

Regards

WeekendPeak

Off the top of my head I would say methanol stores about 20 megajoules (5.6 kwh) per kilogram and LiPo batteries about 0.4 MJ/kg. That gives methanol a 50 times advantage.

The other issue is vehicle purchase price not just fuel. If EVs or PHEVs cost $40k and a methanol or synfuel car costs $20k the advantage is compounded.

Don't forget about operating costs. Initial costs are fine and all, we need 'em, but don't exclude how much it's costs to fuel a synfuel car versus a PHEV. With the synfuel at $3/gallon and the car at 30mpg, that's an extra $15,000 over the warrantied life of the PHEV pack (~150k miles). Over the actual life the PHEV/Synfuel car are probably neck and neck since the PHEV would also need less in the way of maintenance. The longer they were operated, the greater the advantage for the PHEV, and vice versa. The cheaper the synfuel, the greater the advantage for the synfuel car, and vice versa.

After the lithium is mined and made into batteries it enters a pool of available lithium through the recycling of batteries. The greatest part of demand for "virgin" lithium will be the initial manufacture of batteries. Over time more and more lithium will be recycled. My question is how long can we reasonably expect the stock of lithium to last through mining and recycling? If the US went to lithium for all automobiles, not likely soon, that would be about 200 million vehicles times 20 pounds or 2,000,000 tons. Some fraction of the stock would be "off line" in the manufacturing process. Then to scale up to the global fleet would currently be about 10 million tons with maybe 10% off line?. That's 11 million tons. Hmm. That leaves no lithium for anything else. If the efficiency of recycling is 98%, just guessing, then after 35 recylings we have about half the lithium left. Also, not all lithium will be recycled. Some will get lost. When 5.5 million tons have been mined, we'll be at Peak Lithium.

It seems that recycling lithium is quite energy intensive:

http://www.green-energy-news.com/arch/nrgs2009/20090035.html

US taxpayers are helping with the ramp-up to lithium recycling:

http://www.toxco.com/docs/Toxco%20DOE.pdf

Lithium recycling is not without its hazards. Toxco has had some setbacks:

http://www.toxco.com/index.html

Toxco recycles small batteries and needs to do that efficiently. When we talk about large prismatic batteries, I think they should be able to use better methods.

First, after the initial use in EVs the batteries can be used for storage at utility levels. Then it can be recycled.

http://www.recyclingbizz.com/glass/LA906624.html

DurangoKid -

Yes, any sort of a recycle loop is never 100% complete, and a certain fraction gets permanently lost in a variety of ways. However, if an auto lithium battery has an average operating life of 10 years (just guessing), then your 35 recyclings would take place over a period of roughly 350 years.

However, as a previous poster commented, the exploration for lithium reserves has up to now been a more or less incidental thing, often involving the search for other minerals. As such, how much economically recoverable lithium there is in the world is nowhere nearly as well defined as global petroleum or coal reserves, and even those are of questionable accuracy. So, I suppose what I'm saying is that for now I would take those stated lithium reserve estimates with a great big grain of salt (pun not intended). And just as with fossil fuels, the easy-to-recover reserves will be exploited first and then the less attractive ones will be worked.

No, not by a long shot. For one thing, lithium is not consumed by battery production. For another, lithium is available from both minerals and sea water. Unconventional sources will set a higher floor on the price of Li-ion batteries, but even 100 times today's price is so far below today's battery cost that it does not represent a constraint.

Are these quoted figures (below) pure lithium as used in batteries or just mined agregate with a certain % of lithium? (there is a quote for "lithium carbonate")

"Mitsubishi estimates that the world will need 500,000 tons per year at full ramp up. The Salar di Uyuni deposit in Bolivia holds at least 9 million tons, although the country has, in total, perhaps as much as 73 million tons. The only progress to date is a pilot plant that was intended to produce some 40 tons by the end of last year, as it geared up to full production, with the product coming from brine processing. The world supply of lithium itself is considered to be 28.4 million tons, equivalent to 150 million tons of lithium carbonate."

Also, it would be interesting to add a table with the amount of lithium that goes in various batteries/ applications in relation to other characteristics such as weight, cost, battery life, other chemicals, etc. It would certainly help get a more practical grasp of this material.

Seems like theres is a ever growing demand for portable electric devices, so lithium for electric cars perhaps is not the only concern.

Out of a resource of 28.4 million tons of lithium resource?

Bad news for Li-ion cornucopians, but more broadly speaking

indicative of the depletion of dozens of rasre elements we have become addicted to.

Stationary sodium sulfur batteries have the same energy density as lithium ion batteries and we will never run out of salt or sulfur.

http://en.wikipedia.org/wiki/Sodium-sulfur_battery

For more mobile applications like cars, zinc-air batteries

have been proposed (470 wh per kg versus 518 wh per kg in Li-ion). The world reserves of zinc are around 1900 million tons per the USGS.

If/when the NIF is successful and controlled fusion energy becomes a reality the main purpose of lithium will be the production of tritium for thermonuclear reactions.

https://lasers.llnl.gov/programs/nic/icf/

Then Katie bar the door as the cornucopians will go nuts.

HO quotes Mitsubishi at 500k tons/year, this is the original source for this figure, I think: 500,000 Electric Cars Would Take 10% of World Lithium. Only. | SolveClimate.com

Doesn't Obama's announcement of the 1 million PHEV goal pre-date this article, though? Perhaps they mean 500k EVs per year. Or are more realistic. Goals on the board are 300k+ Volts, and 10ks/year of Leafs Leaves/Prii. Rest are cottage industry efforts like Tesla. BYD may have made some inroads by then; their PHEV has been a big flop, however. But they may do better overseas with standard hybrids.

Here's where the action is: The Future of Electric Vehicle Batteries: Lithium Ion & China

Wait a minute, scratch that, that's 500k cars not tons. What's your source, HO? Apologies if I missed it in the OP.

Leaf production goal is 150k vehicles built in TN. This will be a ramp up; bets are that a $25-30k vehicle won't find such mass acceptance as these volumes would warrant.

Also: Hertz to Offer Nissan Leaf as a Rental - PriusChat Forums

4 kg per car(for 24 kwh battery-100 mile range Leaf) x 500000 cars = 2000 tonnes(10% of present production) so 500000 tons does look like a typo. However 500000 is nothing.

The US hybrid market is <300000.

The US new car market is 8 million cars and 8 million trucks and SUVs(2008).

EVs will be a tiny market.

But the idea of EVs is that they will replace passenger cars/trucks/SUVs.

80 million cars were sold worldwide in 2008.

4 kg x 80 million = 320,000 tons.

29 million tons/320,000 tons per year=9.

If EVs are going to save the world then they will for 9 years.

OTOH, a hybrid uses 10% of the lithium as a EV so hybrids will last for 90 years.

EVs will drain the world of lithium.

I'm with you there, barring vast expansion of the resource or successful upgrade in the recycling process. Good posts about that above; I wonder how much additional energy demand a full bore recycling industry for Li would add.

Using data from Hybrid Center Scorecard, which compares hybrid performance to typical conventional ICE cars in each class, hybrids improve on mileage as follows:

Given that Prii are 48% of total US hybrid sales this is skewed a bit higher than the number for the total. But 2005-2009 sales only amount to 0.66% of a 246 million auto fleet in the first place. We don't use the whole fleet on a daily basis, of course, but even so the total savings in gasoline is quite low - finished motor gasoline supplied over that period was:

9159

9253

9286

8989

9002 (tentative, my calc)

So at their 2007 peak of sales (see graph below) gasoline consumption increased. Other factors swamp the impact of hybrids.

Hybrids as a % of sales were

2009 2.71%

2008 2.38%

2007 2.16%

2006 2.83%

2005 1.21%

So it's a good sign they are holding on to their popularity, at least. But sales are down in any case. Another good resource is the Hybrid Market Dashboard | Hybrid Cars, which provides a handy graph of historic sales:

"Hybrid" at this stage means US+Japan, too. 2009 sales by market:

Build Your Dream, indeed.

There is a decent case to be made for PHEVs instead of EVs. With a smaller battery they save a lot of oil.

In other words, if the battery production capacity (and the money to be spent on them) is constant, it is better to spread it across multiple PHEVs instead of one EV. That would save more oil, since most of the trips are below 40 miles, which can all be electric miles.

ps : EVs, PHEVs are not really comparable to Prius type hybrids. Afterall some non-hybrids have nearly the same mileage as a hybrid.

I'm not denying that, just pointing to the paucity of their numbers. 60k Volts entering into a 246 million strong US vehicle fleet will save about 2 bbl/day, assuming they run all electric all day. About 3/4 of the US work force drives solo every day, let's call that the non-essential part of the fleet in constant use - a very liberal estimate, around 106 million. Even so, you're only up to ca. 5 bbl/day saved. This is with 8900 kb/d of gasoline consumed and full 60k sales. Throw in the Leaves if you want, it's still a tiny fraction of current gasoline use, and as my link shows, BYD's PHEV was a disaster commercially; what shape will car shoppers being in financially in two years? (PH)EVs have a long way to go, and we have yet to see whether they will sell in commercial meaningful numbers. The DOE is correct in forecasting far greater sales volumes from more conventional hybrid designs.

And longer if their batteries will be recycled...

Anyways, there doesn't seem to be a natural gas, gasified coal/wood, biogas, Hythane or ammonia shortage anytime soon.

So who cares - one 90 year old might just take this instead:

http://www.cngpower.eu/en/impressionen10.html

Check your math.

29 million tons/320,000 tons per year=90.625.

Also, there are other battery technologies that are already in use. The current Prius has a NiMH. Most NEV/Golf Carts are Lead Acid. These still get people around.

The total energy requirements to power the class of vehicles at the high speeds consumers currently expect is not available without fossil fuels. There are plenty of battery options for more reasonable transport alternatives that will be in line with the available energy supplies.

Another Alpha Seeker, John Petersen , is constantly boosting lead acid tech. His pieces may be of interest, as well as the comments accusing him of being a shallow stock pumper.

Petersen is an ex-director of a lead acid battery company - constantly bashing lithium batteries and EVs. He completely ignores peak oil (whenever I've brought up PO, he doesn't respond). He is like the guy who would constantly pump CRTs and bash LCDs as too expensive 5 years back.

Oops. My bad--90 years is right.

Nickel is not very abundant at 130 million ton world resource.

Lead is too heavy for cars.

A 16 kw lead battery(40 mile range) would weigh more(extra 821# in a 3000# car) than a Li-ion battery.

http://www.altenergystocks.com/archives/2009/05/why_advanced_leadacid_ba...

That's roughly twice as much lithium as required to transfer the charge in the battery. I don't claim to be an expert on the chemistry, but I have to wonder if that's accurate.

At today's Li2CO3 prices, even 160 g/kWh is only about 55¢/kWh. You'd have to multiply this by 100 to be a serious impediment to the wholesale electrification of ground transport.

I still try to imagine lithium batteries for 10 billion people. Enough for mobile communication devices (laptops, phones, whatever comes down the pike) and personal vehicles and those vehicles needed to build and maintain the huge infrastructure that will be required to make all of these things functional.

Does anyone ask what the demand will be as the population grows and as individual expectations for more electronics and transportation devices grows and grows?

Is there really enough lithium? At what true cast? At what dollar cost? Is recycling lithium batteries energy intensive?

My link, quoted above, states that Li batteries are cooled to -325f prior to being shredded. That takes a lot of energy to do on any sizable scale.

How much is a lot? Is it more energy intensive than mining? Couldn't it be done anywhere at anytime, say using off peak (wasted) hydro or nuclear?

As with other metals, I'm sure that it is much more efficient than starting with virgin ore. It occurs to me that recaptured co2 could be used as a coolent. I'm sure Toxco has pretty good numbers on the total energy costs per ton.

Heat capacity of lithium is 3.5kJ/(kg*K).

Cooling 1 ton of lithium by 220 K requires: 214 kWh.

If you do this with wind power at 5 cents per kWh that energy costs $11 or $107 per ton at a process efficiency of only 10%.

(Keep in mind: Mining lithium costs apparently around $4000 per ton.)

In other words:

Last year alone the world installed 37.5 GW of new wind power.

To cool down 500'000 tons of lithium by 220 K at only 10% efficiency requires about 1 TWh or roughly 30 hours of full power work of those new wind turbines installed in just one year.

Since Toxco cools the entire battery to -198 C, not just the lithium, before shredding it, your calculations of energy and cost are extremely low.

The obvious solution to the problem of shredding incompletely discharged batteries is... heat-sink them in something like icewater, pierce or otherwise short them, and let them burn. You're recovering lithium from the completely reacted products anyway, so it doesn't matter.

If this recycling is done on a large scale at a centralized location, it probably could be done in a uilding pumped full of nitrogen with remotely operated equipment- this might actually cost more in terms of energy though.

But I think maybe purified nitrigen is dirt cheap , as the market for t is small-the air seperation plants seem to be mostly going for oxygen and argon as thier primary sellable products.

If this recycling is done on a large scale at a centralized location, it probably could be done in a building pumped full of nitrogen with remotely operated equipment- this might actually cost more in terms of energy though.

But I think maybe purified nitrogen is dirt cheap , as the market for it is saturated-the air seperation plants seem to be mostly going for oxygen and argon as thier primary sellable products.This seems to be the case when you buy bottled gas at least -nitrogen and co2 are almost free , after the cost of handling and distributing the cylinders is accounted for.

As far as the mobile communication devices go, no problem.

I heard on the radio this morning that mobile communications providers (phone companies) now claim over five billion subscribers worldwide.

That means at least five billion mobile devices, almost all of which use lithium ion batteries. Not counting the billions of devices sitting in a drawer somewhere in case the new one breaks or is lost (I've got four of them myself).

"I still try to imagine lithium batteries for 10 billion people"

I have a hard time imagining any viable approach to transportation for 10 billion people that relies on individual automobiles, although lithium battery-based electric cars seem to be about as close to a plausible scenario as you can come up with based on what is known today.

Indeed, this may cause some issues - given the fact that an increase in cars already caused problems in the past.

But luckily, there are alternatives:

I'll take the bus. I bet you could make a big hybrid bus that uses biofuel and lithium. Better yet just build electric rail like France and screw batteries all together.

My question regarding all of the discussion regarding Lithium production is, what are the ecological consequenses of production?

I find that many of these sorts of discussions seem to focus on purely the technical aspects. My other comment is that it is ludicrous to speak of 10 billion people using these sorts of technologies. The sheer energy requirements needed to "service" even 6 billion people seem to be impossible from what limited reading I have done over the last couple of years.

I am of the opinion that a lot of other factors will interupt this rather optimistic view.

Best hopes for a gentle power down.

This post is now "green" over at Slashdot, meaning it has a chance to be fronted. Upvote if you are so inclined:

http://slashdot.org/submission/1176542/An-Updated-Look-at-Lithium-Produc...

Also, here's the reddit links:

http://www.reddit.com/r/energy/comments/b44mq/an_updated_look_at_lithium...

http://www.reddit.com/r/Green/comments/b4448/an_updated_look_at_lithium_...

http://www.reddit.com/r/environment/comments/b444a/an_updated_look_at_li...

and here's the SU link"

http://www.stumbleupon.com/submit?url=http%3A%2F%2Fwww.theoildrum.com%2F...

My recollection is that Li-ion technology has one big flaw that is not mentioned much.

The batteries have a life-span of approx 3 years from date of manufacture, regardless of numbers of cycles or depth of discharge.

It is related to temperature though. Higher temps - faster deterioration.

So even if you use your EV sparingly, for essential journeys only, it will degrade as much as if you used it heavily.

This is very different from our working experience with NiCd or Lead-acid technology. I think it needs to be taken in to account

when looking at lifecycle costs etc.

My gut feeling is that this is just another big cornucopian vision that isn't going to happen.

Ben

As I understand it that depends on how they are treated. How to prolong lithium-based batteries

Not sure how differently larger scale batteries perform compared to laptop etc.

Besides, a lot of the guidelines are impractical. Wasn't it Bill Gates who said that battery tech has to be improved 100 times.

Here in the USA many people are looking for a single technology to be made that will solve our energy and pollution issues related to transportation.

We mostly, absolutely do not want to change the way we drive.

We want techno-magical products we can buy,

We want these techno-magic products at even lower dollar cost than we pay today.

Politicians and MSM hype "the next big thing" and so people sleep on, thinking that "they" are taking care of it.

"You want the truth? You can't handle the truth!" (Movie reference)

The problem of overshoot is complex, but requires us humans to change from the inside out.

Lithium batteries is another hyped "fix" like hydrogen and ethanol.

We can only solve our problems by consuming less and lowering our population. Truth does not sell.

We cannot engineer a habitat as rich and hospitable as the one we've experienced for ten thousand years or so. We cannot engineer our biosphere. We can do some effective things, like saving as many species as possible.

People do not want to be told the truth, they want false hope and the "carrion comfort" provided by our electronic cocoon.

Maybe a few breeding pairs will survive the bottleneck, but it looks like our business and political "leadership" are Hell-bent on spinning blatantly false visions of tomorrow as being just like today, but with everyone having more and more energy and stuff, and with infinite progress brought by techno-magic.

The lithium battery hype is just part of the techno-magic illusion.

Today it was revealed that over the past 18 months tens of thousands of computer systems have been hacked and that access to the data of these compromised systems "was complete". The hacked systems include the US Federal Govt., Fortune 500 companies, credit systems, etc. "The most effective botnet of all time".

http://www.npr.org/templates/story/story.php?storyId=123856178

By far, the most Googled story of the day: Tiger Wood's apology.

People really don't want to know.

Our imaginations are truly bound.

Who bothers to step back and look at the whole big picture, and then to ask whether or not this is the way it will be tomorrow?

We need to see in entirely new ways.

We keep trying to re-invent the car.

We are unable to see the future without "two cars in every garage."

And so we go extinct.....

Hi Beggar,

I'm with you - all this talk about batteries for cars is pretty frustrating.

More efficient, lower cost batteries is great and there are probably many critical services that can benefit from advances in this area. But cars! Cars are ruining the planet - it is not just about batteries - it is about the entire process of extracting resources, energy for manufacturing, pollution and waste issues, road building and maintenance, etc. Perhaps a neighborhood electric vehicle (ie fancy golf cart) is OK, but beyond that we should be focused on how to transition to a car free world (not holding my breath until then).

Yup.

Instead of "Who Killed The Electric Car?"

We need to ask: "Who killed the Homo Colossus?"

(Homo Colossus being William Catton's term, I believe.)

Homo Colossus did it. First ecocide, then massive homicide within the species fighting over diminishing resources, then suicide as the complex systems needed to support Homo Colossus completely disappeared.

Question: will some sort of Phoenix arise out of the toxic ashes?

Will homo sapiens survive or evolve somehow?

Only time will tell.

it is about the entire process of extracting resources, energy for manufacturing, pollution and waste issues, road building and maintenance, etc.

Not really. Cars are 99% recycled, and manufacturing largely uses electricity. Road building is a very small % of our energy consumption.

Wind and solar powered EVs would be very, very sustainable, very low impact on the planet.

Hmmmm ... if you had followed GM Volt news even casually, you would have found out the truth. This is from the document I linked at the post below. You can find very detailed information in gm-volt.com.

The people quoting 3-year lifespans are thinking of lithium cobalt oxide batteries, as used in current laptop cells. That's not what the Volt will use; it's a completely different chemistry.

That really depends on the chemistry. A lot of the older lithium cobalt cells, especially in early laptops, were like that. The newer stuff tends to be better. I have cell phone batteries from ~2006 that are still functional, although they seem to be at ~half of their original capacity. As was mentioned, controlling temperature for LiCo cells can greatly prologue life. For instance the BMS in the Roadster pushes the lifespan from ~5 years to ~10 years.

Other types of lithium cells, for instance lithium manganese or lithium iron phosphate, still age, but don't have the same ~3-5 year lifespan in terms of aging. LFPs can supposedly last a few decades, and IIRC LiMn cells last about half that.

I drive an ev powered by LiFePO4 cells. Molecular weights: Li, 6.939; Fe, 55.847; P, 30.974; O, 15.999. Percentage Li by wt: 100*6.939/(4*15.999 + 30.974 + 55.874 + 6.939)~ 4.4%. The cells in my car weigh about 440 lb and store 20.76 kWh energy. Lets say about 1/3 of this is the LiFePO4 paste on the cathode and the rest is the thick plastic case, electrode, and copper and aluminum terminal materials. That gives about 0.04*440/3 ~ 6 lb of Li. A Prius hybrid uses only about a 4 kWh battery I think, so roughly 1/5 as much Li. A converted Prius plug-in hybrid uses a 6 to 8 kWh battery typically, so roughly 1/3 as much Li (I know the Prius doesn't currently use Li-based batteries but many of the conversion kits do). I have a range of about 65 miles 50/50 highway/secondary road driving. A "city" car doesn't require any more than this. Lets say we build 10 million cars per year with 20.7 kWh packs, using about 60 million lbs of Li, or about 27,000 kTonnes Li. SQM in Chile produces 32.6 kTonnes LCE/year, Chemetall in Chile 22.5, FMC in Argentina 16.6, Talison in Australia 12.8, and China 9.9 (LCE is lithium Carbonate Equivalent, the form lithium is sold in). I think we can do it. My cells are projected to last 3000 cycles or about 10 years, at which point they have 80% of their original capacity and can be used for other energy storage applications which use less current (wind, solar). The lithium can also be recycled, as Japan has started doing. If most people who live in cities drove such a car for most of their driving (it is estimated 80% drive less than 40 miles/day) fossil fuel use would be greatly reduced. Mine is powered completely by solar panels, which also power the house, except for 200 gal fuel oil per year for heat (need a heat pump).

Here is a very useful document by the Electrification Coalition (includes Nissan, A123 etc).

http://www.electrificationcoalition.org/535928473533888957466293/EC-Road... (very large - but good information on many things EV)

There is a full sub-chapter devoted to Lithium Batteries. Li batteries contain very small amounts of Lithium - something like 1%. 100% of it is recyclable.

US production stopped as the mining company found Chile to be cheaper. Chile provides 50% of current production and Bolivia with the largest known reserves doesn't produce any lithium.

If you can't decide whether its NiMH or Lithium that will win out but still want an investment then Cobalt might be a good option as I've read its found in both type.

'Geovic Mining' will be opening a large very low cost operation in Cameroon soon -loks set to become the SQM of the Cobalt world.

Nick.

(Disclaimer: I like the look of them so much I own a few...)