Heading Out's Oil Spill Update - Including Oil Spill Discussion - May 7

Posted by Heading Out on May 7, 2010 - 10:23am

Sorry for the switch-- this is still the thread for oil spill discussion, but now includes Heading Out's update as well. It is hard to keep too many threads going at once, and we like to be able to discuss as many current issues as possible. - Gail

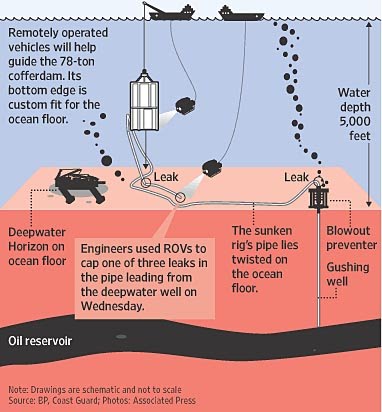

The last two days has seen what appears to be some progress in the capping of the Gulf oil leaks. BP is currently lowering the 100 ton dome that is intended to cap and capture oil from the middle leak of the three. The open end of the riser was also closed on May 4th by fitting a valve to the end of the pipe and closing it. There are however, two different results from the different methods of treating the problem.

Plan for sealing the second leak in the riser.

The oil is flowing out of the well, through the Blow-Out Preventer stack (BOP) which is mounted on the sea bed and into the pipe that would have initially carried the oil to the surface and the drilling rig. When the blow-out occurred, natural gas flowed up that riser, and was ignited as it left the pipe, on the platform. To help with understanding I am going to include a couple of items that I have been sent to try and give a better picture of the overall situation as well as where we are today.

Firstly, to help with some of the discussion on the structure of the rig there are a couple of pictures, first of a sister rig while aboard a ship, so that you can see the pontoons, and then with the Deepwater Horizon in the water.

When the rig is in the water the lower parts are submerged, and only the legs and platform are above the water.

When the fire began it was fueled by the initial flow of oil and gas that came up the riser from the wellhead on the sea bed, through the rig floor and engulfed the drilling mast. As I noted earlier, there is some indication that the ignition came after the power to the rig was cut, and then the emergency generators kicked in. However, initially, as can be seen from the form of the fire, the fuel was coming up the pipe from the sea bed.

Over time, the vessel began to develop a list, as the fire continued to be fought

And by this time, on the second day, the heat had burned out parts of the aluminum structure (see the helipad for example)

The rig, as you know, sank shortly thereafter.

I am going to add some illustrations to help those of us who don’t do this every day understand some of the terms and conditions that are referred to either in discussion or in the media. (Thanks to Roland V).

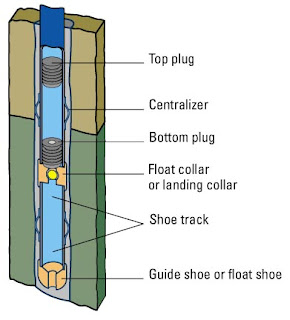

The first of these is the casing shoe, which is the piece of pipe that is threaded onto the bottom of the casing to help guide it into place.

Some of the components used for the casing and cementing of a well (Schlumberger)

Some of the components used for the casing and cementing of a well (Schlumberger)

The other area that I want to address is where the well starts on the sea bed. Remember that when we are drilling a well mud is used to cool the bit, clear the cuttings and stabilize the walls of the well. Well this normally flows up around the outside of the drill pipe, but when it gets to the sea bed it is captured between the casing that was initially set into the sea bed to stop if falling into the hole, and the high pressure drilling pipes. Thus when one looks at the area around the wellhead there are actually several pipes going into the ground.

The first of these is a relatively low pressure outer casing, that holds the surrounding ground in place as the well penetrates through it and down towards the rock with the oil in it. Within that there is a second, higher pressure tubing that will carry the fluids down to drill the well, which may be an additional 20,000 ft deeper (at 1 psi per foot rock pressure perhaps) and which must contain the oil and gas flow that will then come from that site. As an example, you can see, from this view of a Cameron assembly, through a window in the lower pressure casing to the higher pressure fittings inside.

It can also be seen in this drawing of a section of a competing design from Vetco

Notice that there have to be seals between the high pressure drilling/production line and the lower pressure confinement casing/housing. Should high pressure fluid get into the space behind the outer casing, then it could be sufficient to crack it, and there is not always monitoring equipment in place, subsea that can check to see that this has not occurred.

There is also a passage so that the drilling fluid which flows down the central bore to the bit, can also has to come back out of the hole, and be confined as it is carried out of the well and back up to the rig where it is cleaned of cuttings and re-circulated.

It should be born in mind that the BOP sits on this assembly, and that the lowest leak is about 50 ft above the BOP, so that there are apparently no leaks in this section of the structure, as far as I can determine, at this time. The current condition of the riser above the BOP has been badly distorted by the collapse of the pipe to the sea floor. And the difficulty in fitting a cap over the assembly can be estimated from the condition of that area.

Photo of the top of the BOP (I have color corrected the image)

Photo of the top of the BOP (I have color corrected the image)

When the production casing is floated into the well the high-pressure drill pipe is removed, and the production casing floated into the well. It will have the assembly shown in the earlier picture, and will be sealed at the joints along its length so that the cement flows down to the shoe, and then fills the bottom of the well, and then flows back through the gap between the production casing and the rock walls, displacing the mud and filling that gap. The intent is to ensure that all the oil and gas will be forced to flow through access holes that will later be inserted through the production casing and the cement liner, using shaped charges.

There are a couple of considerations when the wells get this deep, the first being that the rock is very hot at that depth, and so the cement chemistry has to be carefully controlled to ensure that it stays liquid long enough to totally fill the gap that it is being injected into. The second area of concern lies with the pressure at which the cement is injected. Because the rock is under a lot of pressure initially, and can also be quite weak, the cement must be injected at a pressure that will be enough to drive it up along the gap, but not at too high a pressure. If the pressure is too high, then the rock around the well can be cracked. In that case some of the cement can be pumped into the crack, and the full volume fill may not be achieved, and the circulation path for the cement back to the well head may be lost.

The shape of the wiper plugs are slightly different to those that I showed in the earlier post.

The plugs are activated by first causing the plug releasing ball to be locked into the plug, sealing the flow passage, and then the pressure of the cement/driving mud will push the plug down the casing, wiping the walls as it goes. When the plug gets to the bottom of the well, the ball in the bottom plug is pushed out, and this allows the cement to flow into the gap (annulus) around the casing.

Some of this additional explanation, as I have said, is more to help fill out the background to the ongoing story.

At the present the large cap is being lowered to the second leak, and we may not know if this works until Monday. It has one advantage over the first step in the process. When the initial seal was put over the end of the riser, it closed the open end of the pipe. However the riser was split in two additional places. It is the intermediate leak that is the current target. When the pipe was capped the pressure driving the oil up out of the ground did not change. As a result, since the other two leaks are still open, all the oil that was going out of the three holes is now flowing out of two.

However when the intermediate cap is placed over the riser it will capture some of the oil, and depending on how the pressure in that cap is controlled, by drawing the oil to the surface, it might be possible not only to capture that portion of the spill, but also to reduce the pressure at that point a little, relative to the third split, so that the flow from it is also reduced a little.

It has been suggested that this idea is relatively novel, and the patent on the idea is relatively recent about 2000) though it appears to have been quite successful at shallower depths. The technique is a variation on the Riserless Mud Recovery System (RMR) that has been successful in a number of earlier wells, though at shallower depths. We will wait to see how it works this time, though I can't at the moment, see why it should not.

Piggy Oil Companies:

I do not think oil companies clean up the oil because they care about the environment. I think they just want the oil back! If our economy gets any worse, we are just going to look at an oil spill as an opportunity for cheaper gas. We will all drive down with our tanks and clean it up ourselves. However, to add insult to injury, the oil companies only have to spend up to 75 million for the clean up. Which I am sure they will just make it back by charging us more at the pump. Leaving them with zero accountability. Let me guess, the American Tax Payer has to pay anything that goes over 75 million? THAT’S CALLED A BAIL OUT! Apparently, the oil companies are also too big to fail. I think there should be a law that says that oil companies have to give American’s free gas that is equivalent to whatever they spilt. Now that sounds more fair to me! However, they instead make a 10 BILLION DOLLAR profit. When gas went up in the 90s, President Clinton responded “It looks like someone is playing politics.” Who knows, maybe that was the day that a law being passed that stipulated they had to pay more than 75 million. Maybe they rose the gas rates to remind the President that they have the power to create and economic crisis, with one stroke of a pen. HOW DARE THESE OIL PIGGIES HOLD OUR PRESIDENTS AND THE AMERICAN ECONOMY HOSTAGE WITH THREATS OF ECONOMIC SABOTAGE!

Piggy Banks:

But there is a bigger spill on the horizon my friend. This spill is going to effect every coast line in America. It is called the GREAT FORECLOSURE SPILL! It will also keep bubbling and bubbling and bubbling foreclosures. It is still going to happen, even though the American Tax Payer funded TARP with a potential 581 BILLION DOLLARS as BAIL OUT money to the piggy banks. I mean if the government is in the lending business, why not have just loaned it to the American homeowner directly? I mean these piggy banks caused the whole mortgage crisis in the first place. TARP gave one bank $45 BILLION DOLLARS! Now that bank is potentially “playing politics” with the modification process. While dealing with the piggy banks, President Obama and Bush had the same look of fear on their face as President Clinton did with the oil companies.

HOW DARE THESE PIGGY BANKS HOLD OUR PRESIDENTS AND THE AMERICAN ECONOMY HOSTAGE WITH THREATS OF ECONOMIC SABOTAGE!

I dedicate to both the Piggy Oil Companies and Piggy Banks the following song by George Harrision and John Lennon. Appropriately titled “Piggies” I invite you to listen to it on youtube as you read the words

http://www.youtube.com/watch?v=NTmeHM-Hojg&feature=related

Have you seen the little piggies

Crawling in the dirt

And for all the little piggies

Life is getting worse

Always having dirt to play around in.

Have you seen the bigger piggies

In their starched white shirts

You will find the bigger piggies

Stirring up the dirt

Always have clean shirts to play around in.

In their ties with all their backing

They don't care what goes on around

In their eyes there's something lacking

What they need's a damn good whacking.

Everywhere there's lots of piggies

Living piggy lives

You can see them out for dinner

With their piggy wives

Clutching forks and knives to eat their bacon.

I AM FIGHTING BACK!

You can read my story or show your support in your comments at: Unitedlawgroup.com

under the John Wright vs. Bank of America Lawsuit

Please send an email to BofA CEO with “I SUPPORT JOHN WRIGHT VS. BANK OF AMERICA” : brian.t.moynihan@bankofamerica.com

Sincerely,

Johns-wright@hotmail.com

At least try to get your facts straight. It is OK to be against the oil companies, and you are certainly entitled to your own opinions, but you are not entitled to your own facts. Facts are facts.

If the oil is recovered quickly it can be cleaned and input into the refinery process but the price a refinery will pay for that oil is very low, if anything, and certainly way less than the cost of recovering it.

If the oil has weathered beyond a certain point it can not be used in a refinery and the normal process of disposal is a controlled burn at a land fill. This is an additional cost that BP will have to pay for in addition to recovering the oil. Hopefully they will locate a waste fueled power plant that can utilize the remaining oil but I'm not aware of any such power plants on the Gulf Coast.

BP is NOT limited to $75 million for the clean up and environmental damage. Their liability is unlimited - they have to pay the entire cost.

The $75 million is a limitation of economic liability - to pay fishermen, motel owners, etc who have been economically damaged by the spill. And BP has stated they will not hide behind that limit. For that we will have to wait and see.

Meanwhile a number of politicians and commentators continue to take the $75 million of out context and misrepresent what the law actually says.

It pretty much degrades to asphalt, and I'm sure it could be used for that, but fortunately there isn't a large market for refined petroleum products collected from spills. I just saw a CNN video of supposedly the first tar balls washing up on a barrier island. Looks even more like asphalt than the petroleum that regularly washes up on Southern California beaches from natural seeps. I'm used to seeing that, so that didn't look very alarming to me.

I am doubtful that BP will assume full responsibility for this event. Until they are convinced that the cannot rescue the well, yes... and so long as the economics show a profit. However, my background tells me that there is some slight of hand going on here. BP PLC is a limited liability company. It is publicly traded, and it does distribute profits to shareholders. However, there are also BP America and BP Global that I know about. Other BP's, well, I expect there are some more.

The PLC is the entity used for risky ventures. If they make a great profit, wonderful! BP Global, or whoever is major shareholder with the public, takes the lion's share, I am sure. OTOH, I work with tax laywers who specialize in asset protection every day. They create these limited liability companies for this purpose. Profits go to shareholders; if there is a major loss, bankruptcy is no big deal and they get on with life!

Believe me, if this cleanup would mean a huge loss, you will see BP PLC filing Ch-7 faster than an oil slick on the GOM!

Craig

They know they can't rescue the well - all they can do is throw money at it until they kill it.

The cleanup will mean a huge loss, already estimated into the billions of dollars.

BP is legally on the hook for the cleanup and the transferring of assets and/or bankruptcy to get out of that would probably see top executives facing jail time.

In addition it would probably put the BP group out of business. Even though they are a British company by far the largest single portion of their assets, oil fields, reserves, etc are in the US and just about all of that channels through the MMS and US government, regardless of which legal entity they are using. Default on this could get them blackballed, not only in the US but probably by other governments.

Where they have some wriggle room is in economic damage claims which are limited to $75 million. They have said they will honor legitimate claims without regard to that limitation - but time will tell.

They also have a couple partners that will probably be hurt worse than BP because they are smaller - Anadarko at 25% and another small company at 10%.

They may, or may not, have some recourse against Transocean, Halliburton and Cameron International. Other than that they are self-insured.

We can hope you are right, and they have to pay. OTOH, I am not sanguine about it. We are speaking about legalities, and courts. The Courts of the U.S. are owned by the corporatocracy - the legalities would be clear as to limited liabilty. No Court in the land would set precedent that this limitation could be broken.

Yes, BP would be blackballed. They would set up a new corporation, new name, new spin and go on with life absent the bit they pay out here and the few assets that are actually held by BP PLC. Just my opinion, but based on seeing quite a bit of this played out in courts over 25 years or so.

Or do you think that John Roberts and Clarence Thomas would rule in favor of the little guys, the fishermen say, against their buddies?

Not bloody likely!

Craig

Corp vs Corp anything can and does happen though, and a large chunk of the liability will be of that type.

Wright4ulg,

Perhaps you've noticed that oil prices have fallen by about 13% over the past week? Or that oil and gasoline prices fell by something like 70% in late 2008? From this you should be able to conclude that oil companies can't simply raise prices to cover costs.

No private business should be allowed to go above a certain level, lets say 1000 employees or $1 billion revenues. There have to be a limit. What is the maximum number of slaves owned by a non-royal-family person in rome? perhaps 500. Today's corporations' owners own a hell lot more slaves. They are slaves because they are almost fully depending on incomes from their jobs and often its very very difficult to maintain even half the living standard when you are fired. The next employer always ask what happened to your previous job.

If we have to be slaves of large corporations since large corporations are needed for progress, for example oil exploration and production company have to be big and so is the case in many other fields too, then let us be slaves of govt rather than a private business owner. A govt is obliged for many things like providing free education and medical that a private business owner is not. A govt can be brought to justice in many different ways including elections, protests, strikes and even revolutions but its very much hard to bring a private business owner to justice especially when the entire law system in modern world is controlled by money, you have very little chances to win a case in court if you can't hire an expensive lawyer, true witnesses can be silenced and fake witnesses can be introduced. On top of all that media is private corporations and in most likelihood would support a private corporation after some back-office deal and your individual voice would be unheard in the noise generated by media.

What to do? Govts should own and control all large corporations, large being a relative term should have a precise definition like the one I proposed above. Govts itself should be mostly run at local levels where people know each other and very little intervention should be made from top levels of govt. Also all govt owned corporations should have their own laws which are passed by govts and should be hard to change to enforce stability and ensurity.

When you have a large corporation, say having 200,000 employees its true can't be run at a local district level simply because of its size and also because of vast geographical area it operate in. Still a govt owned organization run even by a federal govt is much more likely to be useful to general public than a privately owned business.

Its often said that a govt run organization would be less efficient and more likely to run in losses than a privately owned business. It would not be the case if employees are given a share in profit, a significant share like 20%. Also a corporation should be given chance to run independently without political interventions from govt and only when it break a law its brought to a court by govt. A corporation should be brought to court only when it break a law, a corporate law made by govt and which is not often changed. In the routine run the corporation should run by engineers and everything need to be documented. Infact most inefficiency would be gone once the control is given to engineers from the economists. Thats counter intuitive to economists though but thats how reality works. Better still if engineers at the upper positions are bound to have an economist degree too. An economist degree in context is mostly a mba.

"...No private business should be allowed to go above a certain level, lets say ..."

thurs or fri... an amendment to the financial reform bill by sen tester (D) montana... failed... including two republicans - shelby & corker - who voted yes...

the amendment would have limited the size of financial institutions based on a formula based on their outstanding liabilities and / or a percentage of gdp...

the amendment was introduced in the senate... to limit the size of banks... and the democratic majority... aided by two republicans... could have passed it filibuster proof... but... the of the democratic majority... of 57-8-0r-9... less than 35 democrats voted for the amendment.

there you have it... "...No private business should be allowed to go above a certain level, lets say ..." NOT. the U.S. Senate - just said NO.

next idea? (sarcasm).

Rumour is, the 700 points down in 15 minutes at Dow Jones on thursday, is linked with the bill. Precisely banks and other large corporations who do almost all the trading shut down their computer which resulted in lack of buyers and prices had a free fall. More details here. We been telling since almost a century that europe and america is controlled at throat by jews, alas...nobody there listen.

On one of the posts, someone had quoted an eyewitness as saying he saw the drill floor vanish and then the generators sped up and exploded. I think that was the way it went. I’m in no tying to discredit an eyewitness’s account to this horrible event. This is just my opinion and an alternative viewpoint.

The generators were probably had a large electrical load. This may have been from the rotary table, mud pumps, or other large electrical machinery. When the explosion occurred the electrical load was suddenly dropped from the generators and consequently, the gas turbines sped up until the governors could grab it and bring the speed back to normal speed. This would take several seconds. I have been on ships where large cargo pumps or lifting of the BOP would suddenly come on line with the result the generators would bog down and the lights would dim until the governors can bring the generators back up to speed. This takes several seconds.

I don’t think the gas turbines could over speed. First, the heavy generator because of its large inertia would not allow the gas turbines to over speed. Second, the gas turbines have an over speed trip. After about 10% over speed the turbine will shut down.

Once again this is just an opinion. An eyewitness is pretty good in a court of law.

I agree. If you were ever in a hydro-electric generating station when the line breaker opened (as in an electrical storm) or a generator breaker opened you get a real speed up before the governors can slam the water doors shut. It is a real thrill if you are close to the unit.

In this case the sequence of events before and after the gas ignition will be examined very closely. If there was physical destrucxtion of any part of the electrical system that probably would be all the spark that was needed. It would be good to pinpoint the point of initial explosion but likely there was too much destruction. Not even worrying about doing forensics by ROV at 5000'.

Hopefully they will interview the eyewitnesses in a non-adversarial situation. Stress can colour the accounts even if the person is trying to be totally honest.

Thinking about the eleven families who are grieving today.

I have seen the explosion of the internal combustion engines attributed to the air intake suddenly changing from pure ocean breeze to an explosive mixture of air and natural gas. I think this process could happen faster than an engine over speeding due to loss of load. Maybe an explosion in the intake manifold could explain what observers report.

The specs for the deepwater horizon show it had 6 large wartsilla engines powering large ABB AC generators to create power for the propulsion motors and equipment on the rig.

Emergency power was handled by a much smaller 3408 Caterpillar unit.

I have to be careful what I say because I work for Caterpillar on design and engineering of these particular engines and packages. I can say this though:

The Petroleum versions of Cat engines are equipped with extensive safety features to avoid all sorts of bad things from happening. Specifically they have lots of automatic shutdown systems. With most diesel engines an off switch by itself wouldnt be enough to shut off an engine that is breathing natural gas into its intake manifold. So for this reason we also include what are know as "air shut offs" which act as simple gate valves to slam shut the supply of air into the intake manifold when engine overspeed occurs (or when anyone hits the big red button). With these in place it is in-theory impossible to overspeed and destroy the engine.

I cant tell if the witness was describing the main engines - or the much smaller single Cat engine, but I do know that the smaller Cat engine shouldnt have been able to overspeed like that if the air shut-offs actuated. Of course we also know that the cement casing shouldnt fail, Nor should the BOP. I would imagine that the Wartsilla engines are also protected by similar systems (i'm fairly sure its mandated by government regulations)

If an air shut off device failed (or was improperly installed) its easily possible that a diesel engine could overspeed not from having load removed but simply because the govenor is no longer controlling the supply of fuel. The fuel is no longer being supplied by the engines fuel system but by the enviroment the engine is in. In addition it ought to be apparent that diesel engines are not designed to run on natural gas and with high compression ratios found in diesel engines natural gas tends to be quite destructive to the engine due to detonation of the air fuel mixture in the combustion chamber. The 3408 engine would have been rated to run at 1800RPM to generate 60Hz electric power for the emergency systems (mostly lights and comm equipment). That particular engine will stay together until about 3500-4000RPM.

Phil,

Would the Cat unit be sitting cold and only set to start on auto if the main power failed? If so should I assume a delay in starting similar to a transportation unit while the glow plugs heat? It is unclear but there doesn't seem to be that kind of delay in the events as described but that could be clarified in more detailed interviews in the future.

Also, I have never seen an MG unit react to a load dump but again would not be surprised that it would be similar to having full throttle on a tractor for instance and then hitting the clutch. The ICE will definitly overspeed and activate any speed governors the same as a NG rich air intake might cause. In the end it would still activate the safety systems you describe. All of this probably is of little concern in finding out how the blow out happened but is perhaps very important in finding out why the explosion happened and how to make other rigs safer.

I also find it difficult to accept the generators went into overspeed and destructed. The T-G sets (turbine-generator, or diesel-generator) are designed to withstand overspeed for at least 30 seconds on full load rejection (loss of connected load). But the protection and control would have disconnected and started shutting down in under one second. More likely the appearance of generators destructing was they were blown off their mounts and then blew apart.

All the electrical and instrumentation devices on the rig would be explosion proof or intrinsically safe. 99% sure the circuit breakers would be vacuum bottle type, so no external spark there. However, cable(s) could have been ripped loose, or even an extension cord ripped from the explosion proof receptacle, and these could have caused the igniting spark.

But, in all my ignorance, I'll still maintain the drill string and riser had lost its grounding bond, (probably from the severe kick), either partially or completely, and the static charge caused by the high pressure water and gas rising up to the surface arced to another part of the rig. Just a WAG, but with the stated pressure the saline fluid and gas were under resulting in enormous velocity, the static charge could easily have got to 20,000-50,000 volts. Short air gaps can arc over at 2,000 volts.

"However, cable(s) could have been ripped loose, or even an extension cord ripped from the explosion proof receptacle, and these could have caused the igniting spark."

This is a very plausable cause of the ignition if the reports of massive physical damage preceeding the explosion are correct. A possible sequence could be main generators trip off line, back up tries to do its job and arcs out through damaged conductors or the arc and ignition could have happened during the event that knocked the generators off line in the first place. I hope that eventually the real causes and time line will become public knowledge.

That would make sense. In the four-stroke cycle while the piston is compressing the air-fuel mixture it would prematurely ignite, or possibly the hot cylinder walls - especially in diesel - would ignite the air-ng mixture while the piston is starting the compression part of the cycle. As each piston is in a different part of the cycle, the gross effect on the ICE would be to blow the pistons and engine apart. Essentially, igniting at least 1/2 of the cylinders at once while the piston are out of position.

Concerning the remaining leaks, there was a monitored radio transmission to the effect that...

"The box was about 4,000 feet (1,200 meters) underwater before dawn Friday, with another 1,000 feet (300 meters) to go, Coast Guard Petty Officer Shawn Eggert said."

http://www.marconews.com/news/2010/may/07/giant-box-close-being-over-oil...

Buoys are placed on the bottom to aid in placement of the box.

If the dome placement or pressure leaks around the perimeter kick up a bunch of sediment would this not put operators at full stop until they can see again?

Best hopes the results of the operation does not cloud the remote view of the scene too much.

The media says buoys but I'm sure they mean short baseline subsea acoustic transponders which can be used for extremely accurate positioning on the sea bed. They look a little like bouys when they are placed on the seabed by the ROV with the transponder floating up a foot or so above the weight holding it to the bottom.

The mud anywhere near the mouth of the Mississippi is very deep, sometime a hundred feet or more, and very soft. It will certainly kick up and I'm sure they will be all stop until it clears. The time of clearing is dependent on the current and could be from 30 seconds to 5 or 10 minutes. This will probably have a number of time during the positioning of the dome.

It is one of several reasons why it will take several hours to lower the dome the last 50 feet.

They will do everything slowly and methodically to try to avoid any mistakes and minimize the risk of damage to any of the equipment.

I'm curious if the Discoverer Enterprise is standing off and already lowering the modified drill string down to about 4,000 feet or more so they can move over the top of the dome after it is in place or if they will wait until they a stable on position before they start to lower the string.

Deep water operations are S-L-O-W. For instance if it turns out the ROV needs a special tool that was not sent down originally the time to get to the surface, install the tool and return to the bottom is a minimum of at least 2 and probably 3 hours.

shelburn, thanks for that very helpful explanation.

About Enterprise and that modified drill string, re the discussion yesterday about getting the flow established once the box is set and seems to be funneling things along, what do you think the procedure will be to establish the flow and get the seawater in the string out of the way?

It just seems that any restriction when the string is attached is going to encourage the overpressure from the well to find another way around and through the silt.

I don't know the specifics about establishing the flow but as oil enters the drill string it will displace the water in the string and establish the buoyancy necessary to start the flow. I doubt this would take more than a few minutes once the top of the dome if filled with oil.

If there is any gas entrained in the oil then that will greatly accelerate the process and controlling the pressure and flow will be required.

It is certainly possible that they have some contingency plans involving pumps or N2 injection or something similar. The one thing I'm certain of is that the starting the flow has been considered and reviewed.

Incidentally, I haven't noticed any gas in the photos/videos on the internet but then I don't think they have shown many pictures of the highest leak where the gas would go.

Thanks again.

Couple more questions if you have time.

Does the virtual representation in the bottom clip 'capturing the leaking oil' (similar to HO's diagram above) on this site match with your understanding of generally where the first dome will be applied?

http://www.examiner.com/x-48107-Gulf-Oil-Spill-Examiner~y2010m5d7-Oil-Sp...

Also just for reference. Does this video of the leak (which starts at 2:15 in this clip) probably represent only oil w/o gas entrained?

http://www.energyboom.com/policy/underwater-video-oil-pipeline-capped-gu...

Once sealed to the seabed, it will take a couple of days to get everything hooked up, Pack said. Then, it will take time to "get the balance of liquids right." That's because as the oil flows out of the ground and travels higher up the pipe, gases that are beginning to come out of solution can form hydrates. These hydrates are like ice crystals and can reduce the internal diameter of the pipe and so block it (like plaques blocking an artery). In order to prevent the formation of hydrates, warm seawater is being pumped down in the space between the drill pipe (where the oil is flowing to the ship) and the outer pipe.

from this /Live Science article.

So it appears the entrained gas coming up from that depth is a tricky entity.

I was having a bit of problem with your back of napkin calc in your post farther down. The 33 feet of freeboard you are refering to--is that how much dome must be below the leaking pipe to form the seal that will force the hydrocarbons up the riser, or the amount of pipe that must be above the sea to get flow from the pressure differential, or just the distance from the water to the works and of no real significance. I read it twice but was a little too dense to follow your path.

The 33 feet of freeboard is just my guesstimate of the distance from the ocean surface to the piping on board the drill ship. That last little bit is probably a 12 to 15 psi reduction in the pressure at the surface - assuming it is 100% oil with no gas.

thanks

best drawing I could find. I do find it all a little confusing as a BP spokesman says the tricky part is sealing the box to the bed and you and other point out there is no way it can be sealed or it will blow the box off the bed (or as I posted another day the pressure will push a hole through the mud around the box unless somehow the seawater column in the pipe can be drawn up enough to keep the pressures in check). This drawing definitely show the mud seal above the door. I'd certainly like to see a better diagram of what is really goint to happen. Those two smaller blue arrows seem important but from where do they originate or did the artist screw up and have them going the wrong direction and they were supposed to be coming from the outer riser casing as the warm mix being pumped down from the surface..but that doesn't make sense as it is supposed to be a glycol mix so I would assume it would be in a more controlled loop. Like I said I'm a bit confused.

Best, or at least the prettiest, drawing I've seen.

It is frustrating trying to get good information through the media filter.

This looks like a good drawing but it shows it installed over the end of the drill pipe which has been capped.

The area around the mouth of the Mississippi is just a huge delta of super soft, super deep mud. The flaps - properly know as mud mats - are standard for anything going into that bottom. Even offshore platform templates in that area sink about 100 feet into the mud until the mad mats at the second level hit bottom and then they are piled in.

If you look at the drawing it shows the leak in a position where it would be well below the mudline.

As I believe it is designed I give it a 50%+ chance of working, probably a higher chance of partially working.

If it is "sealed" to the leak and the bottom I would reduce that chance to less than 5%, maybe to 1%.

Stabilizing the dome is critical and the penetration into the seabed will help that. Certainly the photos I've seen of the dome do not show any attempt to make it capable of sealing to anything. But it would be easy to take the concept it has to be stable on the bottom and say "sealed to the bottom".

It is also highly probable that the BP spokespeople, including upper management, don't understand the technical details and can easily use the wrong word when under pressure from the media.

I don't think most of the media is deliberately malicious, they are usually ignorant of the technical aspects and don't properly fact check because they are trying to beat a deadline. The people who do know what is going on don't like to talk to them because what they say ends up being distorted so the reporters end up interviewing dozens of pseudo-experts and people holding dead turtles from beaches a hundred miles from the spill.

New method:

BP Lowers Dome in Effort to Catch Oil,MAY 7, 2010, 7:45 A.M. ET, WSJ

Another article on top-kill

http://www.wdsu.com/news/23469509/detail.html

Regarding the cavalcade of contingencies preceding ultimate shutdown the BP CEO seems to me to be doing his level best to manage expectations.

“This will not work perfectly at all when we first do it,” Hayward said."

Bloomberg has what seems a fairly good recent summary of the blowout, but I would appreciate what others think. It has a graphic for the relief wells to be drilled, which unfortunately I can't get to enlarge.

It puts the Macondo field in perspective, although stating Thunderhorse is producing at 300,000 bpd and is the second largest US producer...

http://preview.bloomberg.com/news/2010-05-06/bp-s-deepwater-horizon-rig-...

Never mind, the link below is better than mine

The graphic can be found on the BP site:

http://www.bp.com/gulfofmexico

Unfortunately I cannot find the path to it right now, the direct link is:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

Was this ever posted anywhere on Oil Drum?

Whistleblower: BP Risks More Massive Catastrophes in Gulf (April 30, 2010 - Truthout)

A former contractor who worked for BP claims the oil conglomerate broke federal laws and violated its own internal procedures by failing to maintain crucial safety and engineering documents related to one of the firms other deepwater production projects in the Gulf of Mexico, according to internal emails and other documents obtained by Truthout.

The whistleblower, whose name has been withheld at the person's request because the whistleblower still works in the oil industry and fears retaliation, first raised concerns about safety issues related to BP Atlantis, the world's largest and deepest semi-submersible oil and natural gas platform, located about 200 miles south of New Orleans, in November 2008. Atlantis, which began production in October 2007, has the capacity to produce about 8.4 million gallons of oil and 180 million cubic feet of natural gas per day.

---

Last May, Mike Sawyer, a Texas-based engineer who works for Apex Safety Consultants, voluntarily agreed to evaluate BP's Atlantis subsea document database and the whistleblower's allegations regarding BP's engineering document shortfall related to Atlantis. Sawyer concluded that of the 2,108 P&IDs BP maintained that dealt specifically with the subsea components of its Atlantis production project, 85 percent did not receive engineer approval.

Even worse, 95 percent of Atlantis' subsea welding records did not receive final approval, calling into question the integrity of thousands of crucial welds on subsea components that, if they were to rupture, could result in an oil spill 30 times worse than the one that occurred after the explosion on Deepwater Horizon last week.

Full article here:

http://www.truthout.org/whistlelower-bps-other-offshore-drilling-project...

Is the lingo a little mixed up? 2,108 P&ID's?? (Process and Instrumentation Diagram) These are a master schematisc for the processes at a facility. Although I'm not an oil rig expert, given the size and systems on the rig I would expect maybe 20-30 P&ID's. Maybe a few more for the generator plant.

I think they are referring to Instrumentation loops, or loop drawings. That count sounds about right. In typical practice loop drawings are not signed off by a P.E. (P. Eng. up here in the GWN). Matter of fact, I don't think I've ever seen loop drawings signed by a P.E., but I don't work on oil rigs so take it for what its worth. Maybe I did see some for the Army Corp of Engineers signed off...

However the welds are a different story. Sounds like a contractor design-build job to me. This corner gets cut all too often and this is what happens. Not a shameless plug for professional engineers, but we are taking donations.

Start holding contractors to the same professional and public welfare accountability of P.E.'s and we'll see a whole different attitude.

This is slightly updated from yesterday’s post but I thought I would post it again for those who might have missed it.

I have been playing with some very rough calculations and trying to develop analogies that are understandable to laymen about what has happened and what is/can be done.

I’m not a downhole expert so I’ll leave that side to Rockman and others with the necessary experience.

I do have some relevant background as I retired a few years ago after almost 40 years in the offshore industry primarily in the underwater service side so I am very familiar with the ROVs, in fact some of the ROV operators currently working on the BOP used to work for me. I also was involved in building an oil capture and recovery dome (actually a pyramid) in much shallower water and was also involved in the Exxon Valdez cleanup and environmental surveys several years after that incident.

First off there is every indication that the BOP was activated and at least partially worked. It is almost a certainty that the “leak” is inside the BOP and as that oil leaks through the BOP it then finds its way through the damaged riser and drill pipe where it will exit out any open end or damaged area.

Therefore trying to repair the leaks in the riser does not decrease the flow but it can reduce the number of places where oil must be captured which is why they capped the end of the leaking drill pipe.

Every deepwater work class ROV has a sector scan sonar. Sonar can pick up oil leaks that the naked eye cannot see. The picture of oil bubbles painted on a sonar screen is like fireworks going off.

There was an ROV survey of the BOP and riser within hours after the rig sank. At that time there was no indication of any oil leakage from the BOP. And everyone breathed an extremely large, and extremely premature, sigh of relief.

Estimates made about leakage are primarily done from aerial surveys and satellite photos and are notoriously inaccurate as is clearly stated in the USCG manual on reporting oil spills. The gravity of the oil, the temperature, weather, currents, time, weathering of the oil and other factors all have a major impact on the size of a slick from a given amount of oil.

For example; if you are on a lake in very still water and pour a gallon - not a barrel, a gallon - of gasoline over the side in a matter of minutes you can have a slick covering a square mile – which will evaporate just a quickly, especially on a hot day. If you do the same with heavy crude like the Exxon Valdez spill it will probably take 500 barrels to cover that same square mile although with the fullness of time it will end up covering an area many times larger, and will take months to dissipate in the absence of heavy weather. This sweet crude is somewhere in between.

It was sometime the night after the sinking that oil leaks started appearing from buckles and holes in the riser. This was stated to be about 1,000 barrels per day. I would read that to mean the leak was between 250 and 3,000 bpd. And a 5,000 bpd leak is probably between 2,000 and 10,000 bpd. Until there is some way to measure the flow like running it through a pipeline it is impossible to have any accurate measurement of the leakage.

Factoid: If you assume that there over 5,000 psi of downhole pressure at the BOP - and everything I have heard indicates it is substantially higher than that - then a 1/4 inch hole is large enough to “leak” 5,000 barrels a day. That “leak” would probably cut off your arm if you passed it in front of it.

There is almost certainly sand in the oil and as that sand passes the leaking portion of the BOP it acts as an extremely high pressure sand blaster eroding away the area around the leak and enlarging it. So there is a perfectly rational explanation why the leak would escalate from 1,000 bpd to 5,000 bpd to ???.

Nobody was lying about the volume. The leak was, and is, getting worse.

How much is 1,000 bpd? It works out to 30 gallons per minute, about the output from 3 garden hoses running wide open, or about enough to fill a smallish backyard swimming pool in 24 hours.

Let talk about the dome a little. It would appear from the photos that the dome is designed to be large enough to encase the BOP if the broken riser were removed. It has mud mats 16 feet off the bottom so obviously the idea is to let it sink into the mud and seal the area around the leak.

It is to be connected to the drillship with a 6-7/8” drill string. I wore out a whole napkin making these calculations but if you assume the specific gravity of the oil at 0.89, the specific gravity of sea water is 1.026, the depth of 5,000 feet (actually this is of little importance in calculating the maximum flow), a freeboard of 33 feet to reach the drill ship deck piping you should be able to get about 24,000 bpd on the ship using the natural buoyancy of the oil. Most of my numbers, especially the specific gravity of the oil, are conservative so the actual output could be greater.

If there is any gas entrained in the leaking oil that will change the whole picture as the gas will expand approximately 150 times going up the drill string and act as a giant airlift so the problem won’t be getting the oil up the pipe but throttling back the flow onboard the drillship. Luckily, about the only place in the world you would expect to find the proper equipment just laying around is on a deepwater drillship.

The expanding gas also has a substantial cooling effect, enough to freeze the water entrained in the stream. So the design of the drill string has been modified t include a warm water jacket and methanol (antifreeze) injection.

They have a potentially dangerous situation separating the oil, gas and water but since the Discoverer Enterprise has processing equipment on board they should be able to handle that safely. The Enterprise also has dual draw works and drill floor so they are equipped to handle the drill string to a second dome.

This is obviously a disaster and it is quite possible that a human error or series of errors, coupled with possible equipment failure are to blame.

Does BP have culpability due to trying to move too fast? At over $500 a minute they certainly have the incentive to move fast. We don’t know - yet.

Is Transocean to blame for some sort of negligence in not properly monitoring the mud return or some other aspect of cementing process? We don’t know - yet.

Was Halliburton’s cement job faulty? We don’t know - yet.

Did Cameron International’s BOP fail due to manufacturing or design fault? We don’t know - yet.

Is a combination of one or more of the above? We don’t know - yet.

There are unsubstantiated reports that the kick registered over 30,000 psi. If the BOP stack saw that kind of pressure it could be a important factor, both in determining what happened and how to prevent it from happening again.

For those who are appalled that BP had no contingency plans in case of a spill I guess you think the skimmer vessels, the miles and miles of boom and the couple hundred trained oil spill control personnel that you see on TV just materialized out of thin air. In fact they have been on standby for a couple decades. They train, work on small spills and prepare for this type of disaster. As Rockman says; think of them as a fire department, paid for by the oil companies, under duress provided by the US government.

For those who are appalled by the lack of government response consider that the US Coast Guard was underway in minutes after the blow out and their spill response personnel as well as the teams and equipment from the oil industry were already on site standing by before the rig sank.

For a week after the initial incident, from the blowout April 20 until April 28 things weren't going well with the BOP still leaking and the weather slowing recovery operations but it is fair to say that the incident was reasonably "under control". There was no need for Obama to get directly involved, mobilize the Dept of Defense, etc.

On April 29 everything started going to hell, a true worst case scenario. That morning it was obvious the leakage from the BOP had increased dramatically. Even worse the weather changed and strong offshore winds start moving the oil directly towards some of the most sensitive barrier islands in Louisiana. Not only did the wind change direction but by evening it also increased to the point it effectively shut down all skimming and recovery operations and most boom deployments.

The media, which had only superficial coverage up to this point, got heavily involved and disseminated a great deal of information that was technically just plain incorrect.

There is a certainly an expectation that there may be someone to blame for the uncontrolled blow out with its loss of life and potential for extreme environmental and economic damage. But, it is my opinion, with some understanding of the complexities and technical and operational challenges involved, that both the oil industry and the government operational people have responded to the incident quickly and professionally. I wish I could say the same for the media, the politicians and the bloggers.

The only operation after the blow out that I might question was the decision to keep pumping water into the rig. Would it have been better to let it float and let the oil burn? But with the rigs engines and thrusters dead the only thing holding it in position was the riser so the potential of it further damaging the BOP probably played into that decision. It is always easy to Monday morning quarterback, especially if you don’t understand the technical or operational problems, but they have some of the best and most experienced people in the world working the problem.

BP has stated they will pay for the cleanup and environmental damage (as required by law) and will pay any legitimate claims for economic damage. This is a reasonable requirement. During the Exxon Valdez disaster we saw numerous outlandish claims from “fishermen” who couldn’t tell you the difference between the bow and the stern and “landowners” and “tourist industry people” who had never been to Alaska until after the spill.

There is a lot of press about a $75 million cap on BP’s liability. This has been taken out of context as it does not apply to the cleanup or environmental damage – there BP’s liability is unlimited. The $75 million is in reference to economic damage and BP has stated they will not hide behind that limit. Time will tell but at this time I take them at their word.

I’m sure this will require some effort on the part of people filing claims. For instance if you are a charter boat owner or fisherman I expect BP will require you to submit business records proving you are really in that business and substantiating the amount of business you had before and after the event. It is fair and reasonable for BP to protect themselves from scams just as it is fair that those who have been economically damaged by this event be given reasonable compensation.

I have a much greater problem understanding why the 200+ lawyers currently meeting to decide how to split up the pie should be entitled to the hundreds of millions of dollars in fees they will eventually receive.

We are lucky that this happened to one of the very few companies in the world that has the financial resources to pay the billions of dollars this will cost. This is similar to the Exxon Valdez where Exxon, despite their overwhelming arrogance, did pay all the cost of the cleanup but fought paying many of the economic damage claims I thought were valid and all of the punitive damages.

If either spill had happened to a foreign tanker firm or an independent oil company, the taxpayers would have ended up footing the cleanup bill, the people economically affect would have been out of luck and the companies would have already declared bankruptcy.

Great comments - thanks so much.

I incline strongly toward pessimism by nature, but over the past 48 hours or so I have actually found myself cultivating some serious hopes that this particular spill might very soon be under control (say within 2-3 days). How high would you rate the likelihood of such hopes?

PS: I used to post on TOD regularly, but it has been a long, long time.

Even if the coffer dam works there is still the issue of oil flowing from the drill hole, and that means any number of possible problems before they either engage the BOP, install a new BOP, or cut the flow through the two additional drill holes. That is up to three months of work, and hurricane season is coming folks.

This is a refreshing levelheaded response and I thank you for it. Let's hope that the administration and public listen to reason as well and make good dispassionate decisions and not attempt to further wreck the economy by reacting disproportionately to the disaster.

I hope that BP is as transparent as possible with what went wrong, how to prevent this in the future and how they are going to do right by all those affected and that the media doesn't get suckered in by all the ambulance chasers that just want to make a buck off of everyone's misery.

Thank you Shelburn for the best post ever written on the oil spill. It's all I need to know.

Indeed a great report Shelburne. Mucho thanks. And I can set your mind at ease over the water pumped on to the fire. The drilling rig itself has no buoyancy. In fact, it has almost no capacity to hold water. Imagine the steel frame of a building under construction and that's a fair picture. And now imagine that building sitting on two submarines. The subs would represent the two giant pontoons that actually float the rig. Can't sink a sub by spraying water on it. You may recall the statement that the rig was listing at 70 degrees. Obviously no vessel can list at that angle. What apparently happened is that the explosion ruptured one of the pontoons and it filled with sea water. The rig was actually floating on its side and not listing. Eventually the other pontoon ruptured and took on water . That was when the rig sank out of sight.

Rockman –

I have to respectfully disagree with you.

Before I do that let me say that I have followed your posts on Oil Drum for a long time although I have rarely posted myself. I find them highly informative and more than a little entertaining. Your clear and detailed explanations of what happens downhole have taught me a lot.

Although it is possible that a pontoon was ruptured during the explosions I doubt that happened. If it had I think the rig would have sunk much sooner.

The possibility of the cooling water from the work boats sinking the rig depends entirely of the condition of the water tight integrity of the rig when the crew abandoned ship. I doubt they stopped to close all the watertight doors.

I have worked on the design engineering for a couple semisubmersible MSVs and done a bunch of stability cals on them. The same characteristics that make a semi such a stable drilling or work platform in their submerged configuration also make them inherently unstable once they start to list.

A semi has a very small cut water plane when it is in the submerged condition and since the pontoons are below that water plane they do not contribute to the stability of the vessel, they only support the deck load, until the list is great enough to bring a portion of the pontoon to the surface.

On a ship shape the CG (center of gravity) is relatively close to the CB (center of buoyancy) and they have a large cut water plane so they tend to roll a great deal in comparison with a semi. Because a ships hull is wide as a ship rolls its CB shifts towards the side of the roll increasing the uprighting moment. Ship shapes can take a 45 to 60 degree or even greater roll and still want to come back upright.

On a semi the GC is very high and when they list the CB only shifts very slightly (until a pontoon breaks the surface) so it only takes a little uncontrolled flooding, especially if it concentrated in one pontoon, to impart a severe list to a semi.

Once the CG passes the CB the deed is done and the semi will capsize.

As a general rule (with lots of exceptions) ships sink from the weight of water in them and semis (in submerged configuration) capsize from instability, which requires a lot less flooding.

I guess we'll just have to agree to disagree shelburn. Though not a marine engineer I've been on many semis and I don't recall enough water tight areas that would even come close to keeping a rig floating if the potoons breached. I'll just pull a number out of the air and guess that at least 80% of the space on the rig isn't water tight. Not only not water tight but designed to drain to the sea. The mud room alone on a semi probably has more volume than all of the water tight spaces combines. But even your explanation doesn't explain how it sank if the pontoons didn't fail.

But your background in such matters should trump mine easily.

You could certainly be right. If there was not an open path of some type that allowed the water into the pontoons then you are absolutely right.

I would agree with your 80% non-water tight spaces. Normally only the pontoons and legs are considered water tight When you get water in the quarters areas it is a bit late to shut the doors and probably time to start swimming. And yes the pontoons must have flooded or the worst case she would have turned turtle and floated on her back.

But the history of capsized, or almost capsized, semis almost always goes back to a door(s) or valve left open. Thunder Horse almost became such a casualty.

shelburn -- your open door/hatch got me thinking. I know you're aware of keeping water tight while underway. I've only been on a semi when on station and everything was wide open: loading hatches, sliding bulkheads, huge vents, etc. About the only thing going for it is that the door ways always open out so water pressure would tend to push them closed. But it's not difficult to imagine that in the excitment of evac no one bothered to dog them.

Given the events leading to the blow out fit the "Perfect Storm" line I suppose the combination of water spray and lack of water tight conditions could fit too.

All pure speculation for the moment. After the well is killed and the spill cleaned we might get some answers from the rig inspection.

I understand that in the explosion on the drill deck just after the blowout, several heavy motor-generator sets 'exploded' and fell overboard. One of these could have hit a pontoon on the way down. The pontoons are outboard of the edge of the drill deck and are light aluminum structures designed to hold a few atmospheres pressure.

When BP gets arround to inspecting the wreakage on the bottom it may be obvious what caused it to sink. I wouldn't expect to see gashes in the pontoons from their settling on a soft mud bottom or from fire hoses squirting water.

Interesting question for a nautical engineer: how big a hole is needed to sink a drill rig like this in time from April 20th to 22nd?

The entire underwater structure of the Deepwater Horizon is watertight, this includes all of the space below the upper hull (deck box). There were no spaces designed to drain into the sea.

Within the pontoons were pump rooms, access spaces, and thruster spaces. Surrounding these spaces were the ballast tanks (38 in the pontoons and 4 in the horizontal braces). If you look at the floodable space in the pontoons themselves you have the empty ballast tanks and working spaces. Assuming that the watertight dampers and doors were closed (a reasonable assumption), that means that you can only flood a limited volume of the pontoon, which also assumes that the breach is not in a pressed up ballast tank.

With water being sprayed on the main deck, you would get accumulation in the spaces of the upper hull that were breached by the explosion. With free surface effect (imagine a pan filled with water) the water would collect and make a list worse. The torque from this water load would have been concentrated above the center of gravity making the effect worse.

To use numbers stated above, 3 garden hoses can add 1,000 Bbls of water per day. That is approx. 150 m³ of water, or 150 metric tonnes (I love metric conversions). The fire monitors being used to fight the fire could have placed significantly more water than this on the deck over the course of the day.

My guess is that the structure of the upper hull failed after extended exposure to high heat. The rigidity of the upper hull is necessary for the structural integrity of the rig. As the steel in the area of the moonpool is continuously heated, the steel would become weaker until it would no longer be able to supply the necessary rigidity. The stresses on the upper hull probably would have been exacerbated by the unequal loading caused by the list.

Why would a capsized rig sink, since the buoyancy is not in the superstructure? Wouldn't it simply be upside down in the water, with both pontoons at the surface then?

I'm guessing that the burning oil and gas caused the pontoons to lose their integrity and allow water into them. The other problem is that the pontoon were already submerged, so they were half way to sinking on their own regardless of any type of disaster.

There are a variety of images of the sinking here:

http://www.rigzone.com/news/incident_images.asp?inc_id=1

Since list means generally, "to tilt to one side," you're playing with semantics when you describe the drilling rig as floating on its side.

If fire boats spraying water on the drilling rig could add enough weight to sink it, then rain would do the same. It is more likely one of the pontoons was damaged.

Thanks shelburn

cf crude "500 barrels to cover that same square mile"

Any information or guestimates on the area covered by one of the leaks when it reaches the surface after rising from the ocean floor, compared to how it spreads out from there?

What are the practicalities of containing the leak at the surface?

e.g. at what point do the waves become too high or wind or currents to strong to contain an open ocean leak?

david -- the boom system they use in the GOM becomes much less effective in seas of 4' or greater. I gather that was the immediate problem after the spill started. One would think an alternative method might be considered for future problems. A 4' sea is not uncommon in the GOM especially during th winter.

BP indicates they have recovered 5,000 barrels of oil in oil/water mixture with 90% water. i.e. only 1 days worth flow.

WSJ MAY 7, 2010, 4:28 P.M. ET Dome Being Installed In Gulf; Rig Reviews Show Nothing Urgent

I can't really guess what the size of each oil leak is when it reaches the surface. I'd venture it depends greatly on how much the oil adheres to itself during the trip to the surface plus the currents it encounters on the way up amd the amount of entrained gas which will expand greatly thereby spreading the oil stream.

What I can say is that the oil can move as much as a mile away from the leak area before it reaches the surface and as currents change they could be chasing it all over. The depth of the leak certainly compounds the problem. Also where the oil surfaces is a dangerous area as the oil may be thick enough to ignite, not to mention the gas, and the fumes are dangerous to any one close by.

Weather is a major factor. It is relatively easy to recover a spill from a calm body of water.

On the other end of the spectrum a storm is Mother Natures way of cleaning up a spill. In Alaska areas that were prone to heavy storms were essentially clean after one winter while protected bays and inlets still have oil deposits more than 20 years later.

A number of years ago a tanker broke up on the Scottish coast during a North Sea winter storm. Heroic efforts by the British Coast Guard and the salvage tug crew saved most of the crew members but the tankers was completely destroyed and all the cargo spilled. There was a great fear of a massive environmental consequences. But after the storm abated there are almost no sign of the oil, the power of the storm had effectively dispersed all the oil and cleaned the rock beaches and cliffs.

Probably the worst case is what we have seen in Louisiana. 4 to 8 foot waves that push the oil past the booms (actually most of escapes UNDER the boom) but without the larger waves and white caps that will disperse the oil in such a way the environment can handle it with minimal damage.

At over $500 a minute they certainly have the incentive to move fast.

The $75 million is in reference to economic damage

Well that seventy five million dollars is over a hundred days rig time at that rate. The Gulf economy hurt by such an event could hardly equal a hundred days rig time...right. A bit of a disconnect between the value of minutes to the oil company and the value of months to the many small businesses and their employees affected don't you think.

Some people did very well cleaning up Captain Joe's spill (there is a gas station/RV park a few blocks form the Valdez waterfront unabashedly named Captain Joe's). Many Alaska fisherman who finally got a settlement twenty years later didn't come out smelling all that sweet though I'm guessing their lawyers did.

you must live in the 'burbs.

shelburn said

A may be damned if you do, fer sure damned if you don't proposition.

While people think of steel ships as fire proof, then contain all kinds of burnables. And in this case, lots of burning oil that keeps coming.

The fire can weaken the steel enough that it can then collapse or bend, possibly tearing openings, which allow fire and/or water to penetrate the vessel further.

As a fire moves around due to wind and/or fuel consumption, the steel warps, and then can tear as it cools now that it is softened.

So just letting it burn basically means it will sink sooner or later,

especially in a case where the flaming oil is at the water line.

Red hot steel at the waterline, then an odd wave (falling debris from above?), and possibly rip! - now you've got a hole - and flaming oil is now inside along with a path for water in (or air out).

Great pics of crumpled rigs after blowouts -> fires on land at:

http://www.energyindustryphotos.com/oilfield_blowout_photos_and_rig.htm

Check out the sagging drill pipe on the rack beside the remnants of the rig in the 1st picture. Burning oil isn't hot enough to melt steel, but it can soften it enough so it will sag under its own weight.

Same same with the Deepwater Horizon, except to run away you had to walk on water or jump in a lifeboat.

There were also explosions, flinging debris around, that could have punctured ballast tanks, or dented/stressing things that later broke open.

I'm not familiar with the ballast controls, but the electrical problems could have inadvertently activated valves to do the wrong thing as well, but that seems too fast for what happened.

Flooding with fire water is always a concern, but a lot of it in a fire this big is going to evaporate or run off the decks.

I think the rig was doomed without a huge amount of foam to smother the ocean surface, which was likely impossible given waves and currents.

The reason to keep spraying it down would be that if the BOP had been able to be activated and the oil cut off, the vessel might have been saved.

And something might have happened down-hole to cause the flow to decrease, and allow re-boarding, remember - they were missing 11 men, would want to recover bodies if possible.

Fire is the 2nd leading cause of ship loss after stranding.

Though it can take a couple days to sink a flaming ship - the Achille Lauro sank in 3 days from uncontrolled fire:

http://www.ssmaritime.com/achillelauro.htm

You say there is every indication that the BOP was activated. What are some of these indications? Sorry if I missed this info in an earlier discussion.

There have been quite a number of references to the fact the BOP was activated. The green lights turned red, etc.

There are numerous places on the rig where it can be activated and those controls should have all worked up until the fire burned the control system umbilical. I believe it can even be activate from the Houston office.

As the well blew for a short while before the fire, and any rig person's immediate response would have been to hit the BOP switch, it would be hard to believe that it wasn't activated.

But obviously when activated it did not work as designed.

Why? Why, why, why? In the fullness of time I'm sure we will know.

I have noticed that there seem to be many sub-specialties involved in this drilling business. I hope that nobody feels slighted or insulted, my question is could some of these accidents be occurring at the meeting places or joints from one specialist field to the next?

Sort of like at the Battle of the Bulge where the Germans hit where two army's flanks met?

A newer diagram of what is on the ocean bottom:

http://sg.wsj.net/public/resources/images/NA-BF862A_OILSP_NS_20100506192...

This diagram seems much more believable than earlier ones about which I have posted in days gone by.

Partially hidden by the sketch of the dome is a kink in the riser pipe that is not labeled and with no indication that it is leaking. Also the labeling does not indicate that the pipe in the diagram is riser as opposed to drill pipe. But it surely is riser pipe (diameter = 22 inch OD).

Labeling in an earlier diagram placed this kink at 1200 ft above the sea floor. The wreakage of Deepwater Horizon is said to be 1200 ft from the BOP in another source. The total length of riser pipe must have been 5000 ft, so there must be considerable twisting that is not shown. This is not a criticism of the artist, only a warning to someone who might want to draw conclusions from what is shown.

This diagram is sufficiently different in detail from earlier diagrams that I withdraw my earlier comments that were based of details of the seafloor situation. I think we are near enough to experiencing "ground truth" that I don't think it is useful to speculate any more.

A question: assuming this diagram is correct and the end of the riser has been capped and the cofferdam/dome is able to capture the oil from the second leak as shown won't this increase the pressure in the riser - and the flow from the leak by the BOP? Could this lead to accelerated erosion of the rupture there and thus higher flows from that point (both from the increase in pressure within the riser and the cutting action of the gritty fluid)?

I suppose there is hope that the main constriction of flow is within the BOP rather than due to the kinked riser and thus the tendency for the leak to increase would be slowed by the more massive nature of the BOP and its resistance to erosion... or is that reasoning off-base?

Has there been mention of a plan to deal with the leak at the BOP? Or is that site too dangerous to mess with?

Tis True if the cofferdam makes perfect seal then the Reservoir Inflow Performance Relationship (IPR) takes over and the journey begins to where no man has gone before. Keep the choke open and hopefully have a sleeve or some other method to let the oil out of the system prior to launch.

FF

Does anyone know the size of the roof in that thing?? Is it 20X10' feet or 200 square feet or 29,000 square inches or so??

FF

Earlier postings showed it at 14' x 24'. There are more square feet than that because it slants upwards, and that increases exposed surface.

Craig

Thank you so much. So a little over 48,000 square inches. The slant doesn't matter if I remember Archimedes correctly, as you integrate the force over the normal.... I think to get the force on submerged surface. You young guys be gentle on me though because I took fluid mechanics about 30 years ago.

So if it weighs 200,000 lbs, a 5 psi differential will lift its weight, not including the drag to push it up out of the muck.

Interesting.

FF

I agree! It would seem that the thing should get sent right back to the surface!

OTOH, even a small difference might tip it over if it is not precisely lowered.

There are many problems with this device.

Craig

Anything over 2 psi will vent oil out the slots, IMHO. It might tip, but the flaps will help. Who knows, maybe they'll sandbag it?

The engineers have really nice toys for doing a model, I'm sure. We may not be quite sure of the forces with rough estimates, but they are getting that way by now.

I'm more worried about second-order issues -- icing, mud clogs, mechanical issues on planting it, ship-based controls, mud depth, and so forth.

Engineers are smart, and they've had days. If we can rough it out in 10 minutes of on-line breaks, they can do wonders with 24-hour focus.

Is the dome being lowered 'hot', with the plumbing attached? Or will that be connected after the dome is set? Playing in the deep is surely quite an operation - hopefully planning (and a good helping of luck) will put the odds in their favor.

No - one DP vessel is lowering the containment vessel. When it is in place the the Discoverer Enterprise will move over the top and make the connection. Pretty standard procedure for a drill ship.

If you want to play some more with this don't forget to include the buoyancy of the steel, wood and concrete in water. Seawater is 64 lb/cubic foot.

You may well have hit on why the weight of the dome increased from initial reports of about 60 tons to over 100 tons but the size of the dome did not increase.

I took fluid mechanics about 40 years ago but I have always enjoyed helping young people.

If the 40' dome is half-planted in mud, then the 20' remaining, if filled with oil, would exert about 2 psi of lift. The column, if filled with oil and capped at the top, would add 500 psi for the pipe diameter. It would be worse if the pipe partially filled with gas.

But then there is a bunch of pipe holding it down as well.

100,000lbs seems like its in the ballpark of max lift, but I'm pretty sure their engineers can do the math precisely, and if needed they could weight the dome further. Plus, the mix should be heavily water, so the worst case is very conservative.

The problem I see is that this is great, if you are just talking about filling it and letting it run up the pipe. OTOH, it is coming into the bell at pressure. Once the bell fills up, the rest backs up less whatever goes up the stack. Or it leaks out, which is the same thing. If oil is coming in at 550psi, it has to go out with sufficient volume to empty the vessel. How is that being done?

Craig

If the oil is mixed with gas, when the top is closed the gas should collect at the top and force the oil out the windows until the bottom of the gas reaches the top of the windows. At that point you have a lot (almost 300,000 lbs??) of flotation force, which would float the dome. Sure hope I am wrong.

I wonder if that places a limit on how much backpressure will build and then how much additional flow will come out the BOP leak??

FF

Unless there is a strong pump forcing the oil out of the containment vessel, it will indeed increase pressure backwards on the line. At least that would be my take on it. Physics demands it, in fact.

Craig