Threading the needle at the Deepwater Horizon BP oil spill site

Posted by Heading Out on May 16, 2010 - 10:20am

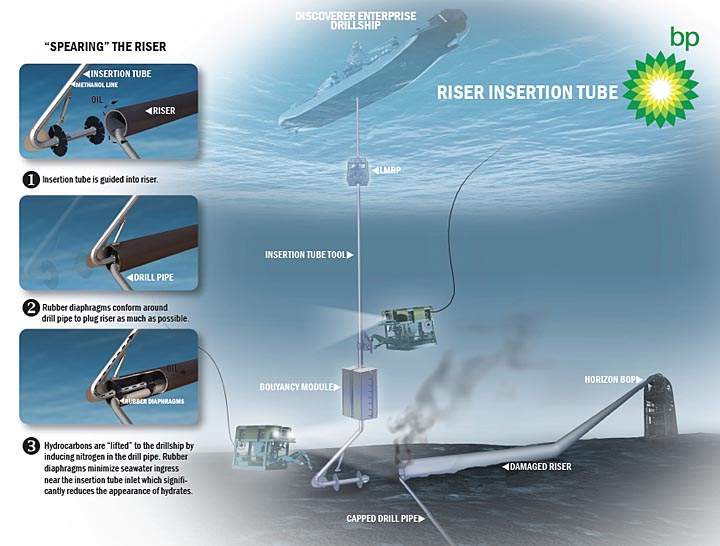

Late on Friday night BP began to try inserting a narrow pipe into the remnant of the riser lying on the sea bed at the site of the Deepwater Horizon site in the Gulf of Mexico. Because there is a better illustration of the process that they are using, I am adding this as a separate post, rather than an addendum to the last one on this topic.

UPDATE: The pipe was apparently successfully inserted, but an accident with a couple of ROV's knocked it back out, so that it will be another nine hours before it can be reconnected. (H/t lowtech architect.)

UPDATE 2: The pipe has been reinserted successfully

Technicians have fully inspected the system and have re-inserted the tool. The tool is fashioned from a 4-inch pipe and is inserted into the leaking riser, from which the majority of the flow is coming. While not collecting all of the leaking oil, this tool is an important step in reducing the amount of oil being released into Gulf waters. The procedure - never attempted before at such depths - involves inserting a 5-foot length of the specifically-designed tool into the end of the existing, damaged riser from where the oil and gas is leaking. In a procedure approved by federal agencies and the Federal On Scene Coordinator, methanol will also be flowed into the riser to help prevent the formation of gas crystals, known as hydrates. Gas and oil will then flow to the surface to the Discoverer Enterprise drillship.

(H/t xazp).

The initial attempt to get the "needle" into the pipe was called off when the equipment shifted in the supporting frame. It is, however back on the seabed, and the attempt to insert it, collect the oil and gas, and bring it to the surface should start later this evening.

The problem arose because the pipe that will carry the oil and gas back up to the ship at the surface (which they confusingly also call the drill pipe) has to mate with the insertion tool which is held in the frame (I imagine this includes the buoyancy module shown) at the seabed. It was the connection of the drill pipe to the ship that could not be made, so they took the assembly back to the surface, and fixed the problem. They are now (late Saturday afternoon) getting ready to make an insertion into the broken riser. The drill pipe is to be "stabbed into" the frame, and the intent is to eliminate any water getting into the connection, to eliminate the hydrate problem.

At the moment they have also started a continuous injection of dispersants underwater, after the three tests were judged to be successful. This has reduced the work needed to control the oil spread on the surface. They pointed out today that the dispersants that they are using were pre-approved before the spill. Distribution of these dispersants had been approved in a more limited application (on the surface), but after the tests were successful, distribution is now approved for use underwater - which actually reduces the amount needed since it is injected into the heart of the spill, rather than spread over the surface after the oil has migrated upwards.

They are, however, becoming a little more concerned about the weather, since changing conditions have made it more difficult to control the spill, since it is currently too rough for skimming and controlled burns - though that may improve in the next couple of days.

They are running the riser and blowout preventer (BOP) on the first relief well today (it is already about half-way down to total depth (TD)), and they should spud the second relief well almost immediately.

Let me close by noting that in the press briefing, Secretary Salazar repeated the line used by Secretary Chu in the past, that his folks are "the smartest people on the planet!" Sigh! Even if they are, you cannot bring folks up to speed on all the ramifications and complexities of deepwater oilfield technologies in a couple of days. It is a blindness to reality, I have commented on before, but let me get off that soap box.

Ok, now it really looks like a vasectomy reversal. I am guessing the LMRP can control flow prior to arrival at surface, allowing final control of methane buildup.

LMRP = Lower Marine Riser Package

Huge oil plumes lurk in deep waters:

http://www.omaha.com/article/20100516/AP/705169893

OIL PLUMES

http://www.reuters.com/article/idUSN1521453720100516

Cheers,

Jerry

Yes, there is much sub-surface oil. Not only have plumes been found, oil contaminated shrimp was harvested from 'oil-free' waters. Who the hell is making that call?

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/fishing_closur...

I guess BP figures that they can risk our health to have to payoff for one less load. BP is so going to be broken down by this. Good, maybe Gulf Oil can come back.

No, they won't go broke. BP knows how to deal with the Great American Lawyer Bingo Machine. They will stall, deny, reapply and do whatever it takes to convince the most of the other side to settle for pennies. Even worse, all kinds of fraudsters will jump on this like sharks on bloodied fish and even further slow things down. Or at best case, they will pay maybe 10 billion dollars to some Oil Spill Victim Fund and that is it.

Few are able to fight this in courts for years to come. Especially if their business went under and are unemployed. Then you will settle for 5000 dollars instead of possible shot at one million years later.

BP is a Public Limited Company under the British Companies Act 2006. I don't know any corporate law but in theory the US government has the legal authority to cease any assets BP has on US soil to cover any liabilities the company has in the US.

But more likely the US government need only have a private chat with the new British PM, as well as the EU 'federal government' - to get them to make a fair deal - as BP is under EU legal authority - lawyers here don't have as much power as the bureaucracy (yet).

And anyway, I don't think you are going to let "a foreign company" walk all over you - politically it shouldn't be a problem to get cross party support to press BP for full a compensation...

What is full compensation?

Fourth largest company in the world. Dissolved and auctioned off to competitors ... assets alone should fetch half a trillion. Enough?

That would be about half of the US treasuries held by the Chinese (who would likely be the high bidders).

I personally think that the MMS should start hearings about revoking BP's license to operate Thunderhorse, given their halfhearted response to this spill.

Best Hopes for tightening the grip on BP's gonads,

Alan

Alan,

I don't know the facts so I can't form an opinion yet on the quality of BP's response to the spill. Can you help me out with this? What caused you to understand BP's response was "halfhearted"?

I know the number of rigs drilling relief (kill) wells is controversial. I don't remember hearing about anything similar. Or are you referring to how prepared BP was at the start of the spill?

Thanks.

PS. Hadn't thought about revoking drilling rights for Thunderhorse. That is one hell of a big stick to hold over their heads if they drag their feet on "we will pay all legitimate claims." Although given the rapid depletion rate, the stick is getting smaller each day:(

$10/hour for "clean-up" crews will not hire an effective group of people for conditions they must work under.

Only two relief wells.

Not bothering to measure (or if measured, share) the flow rate of the leak.

Not revealing dispersant used.

Not hiring every available oceanographic ship to measure and predict undersea plume.

Not being prepared for a spill of this magnitude.

Alan

My favorite is discharging without a permit. This is an undeniable violation of the Clean Water Act. The CEO's of BP, Halliburton, and Transocean should be served with federal felony charges for these violations. I imagine they would plead for a year in Club Fed, do six months, and we have our pound of flesh. Then those CEO's would be made to work cleaning this mess up for the remainder of their working lives, else they would be bankrupted and held personally responsible. I bet their guilt would make them do the deal anyways, but nothing like the threat of financial ruin. Like the threat my neighbors and I face now.

IANAL, nor do I play one on TV, but... Looking at the CWA statute, it almost certainly does not apply. The text states that the law applies inside the "contiguous zone" as defined in the UN treaty on that subject, which extends only 12 miles from the low-water shore line. In this case, the discharge point, and the source of the pollutant, are clearly outside that zone.

Well there must be something that would work. I want a year each. Club Fed is not too bad. They can work on their tennis game. Probably better than most of us coastal folks.

I am a lawyer and according to Wikipedia it covers navigable waters which is what I suspected.

The gulf would qualify if navigable waters are included.

A lawyer that thinks Wikipedia is a legitimate source?? I hope you wouldn't use that argument in court! IANAL and I don't trust Wikipedia as an authoritiative source on anything I can find another place. Since all Federal Laws are published on-line I used Google, and when you Google "Clean Water Act 1972" the link to the EPA where you can find the actual text is the 6th one down the page.

Here is what the law actually SAYS concerning what is called "navigable waters":

To get BP under the CWA you have to use the broadest area in the law called the Exclusive Ecomonic Zone which extends out to 200 miles. All that is required in the EEZ is a plan to be filed with the Government on how the pollution incident would be dealt with. I can find no specific fine defined for the EEZ, only a generic fine specified as:

It appears that the fine is limited to 25K per day and a max of 125K no matter how many bbls of oil are spilled. However..there is an additional fine if Negiligence is involved. There is another place that says fines can't be applied from more than one section of the Act,even if there is a violation of more than one section.

In addition to fines the owner/operator who had the spill has to pay cleanup costs. However, if you bring in the concept of Gross Negligence then the fines grow.

Based on this fine you can see why it is very important to determine who made the decisions that lead to the blowout as that company is paying the fine. And here is a point where the flow rate enters into the picture again as how well it can be determined will establish fines. I don't see a limit on fines when Gross Negligence kicks in. I would say BP is on the hook, but then again BP could try to recover from it's subcontractors who did the drilling. It will get messy. If you want to read it for yourself, here is the link: http://www.epa.gov/npdes/pubs/cwatxt.txt

Actually Wikipedia was right, citing the exact section of the statute you quoted. I just failed to read the entire section on navigable waters. The second part clearly states, as you say, a three mile limit from shore.

Moral of the story. No drilling offshore unless the law is amended to cover all offshore drilling.

Appears to me the law does cover offshore out to 200 miles. But it treats it the same as on-shore which may not be right. The fines are a joke, way too small plus this all has to actually be decided in a civil court action, it's not automatic. As we have seen the Exxon Valdez incident took about 15 yrs to close out. Maybe this one will not take as long as there are no Native American tribes invovled which added complexity to the Valdez case, but nevertheless don't expect a quick summation of damages and claims.

I posted a comment on another thread to count me out. I am a personal injury lawyer with 32 years of experience, the last 28 representing plaintiffs.

If the Exxon Valdez taught us anything is how foolish it is to take on a company so large that it can easily spend a million a month in attorneys fees defending itself and can drag out litigation for decades.

When you take cases on a contingency, it is a good way to go broke.

Thanks!

"Not hiring every available oceanographic ship to measure and predict undersea plume."

Alan, think. Do you really want all the oceanographic ships to be under the control of the evil monster?

They surely could have done this. But they did not, most probably because they did think, and did not want to appear to be the evil monster.

If BP had funded such an effort. directed by, say, the USGS or NOAA, with results made public daily, it would help.

Oceanography is not a specialty of BP, but it is of NOAA.

Alan

Of course BP isn't going to give away information that will be used against it, and certainly will not willingly pay to develop such information. Forcing the suing parties to develop their own information will help reduce the number of suing parties and/or reduce the potential severity of the lawsuits.

The company is in a bad situation and is making choices amongst the numerous lousy options available.

Remember, plugging the hole is just the first step. Cleanup will take years. Lawsuits will take even longer. $50 billion? $100 billion? More? This isn't chump change.

It matters little to BP if the rest of the industry is adversely impacted by their actions. Company survival is the top priority for them right now.

Over-reactive are we?

$10/hr is above minimum wage!!! Putting out boom is not a high tech high skill job. If you added up all the costs versus income I bet a lot of fishermen don't make this wage. You are also not counting what BP paid folks to use thier boats. I suspect the shrimpers and others who are under contract are not working cheap!!

The dispersant was documented. They had to ask the feds what they could use, and the underwater use was a novel idea and they took quite a while to approve that and that dispersant was documented.

Only two relief wells? As many people here from within the business have told you more wells does NOT make the problem get solved faster. In fact it would increase the odds some other bad thing could happen. On land only one relief well is typically drilled and that solves the problem.

Every available oceangraphic ship? Considering those belong to Government organizations this one should be laid on the Governments not BP. Also as someone here who IS an Oceangrapher said there are only a couple ships that can do the work and the work is very time consuming and tracking the underwater plumes could take a very long time.

Not prepared? So where did all this containment boom and ships come from? They were prepared as best can be, you may have missed the discussion early on where the Response Plan is a GOM wide plan where assets come from many companies and are pooled. If this had happened to any other company the response probably would have been the same, maybe worse. If this was a small to mid-sized oil company they may have ended up bankrupt.

Flow rate really doesn't matter except maybe to the engineers who were developing a fix. There was NOTHING different that could have been done or done any faster. Once the spill happened a lot of agencies got in the loop, Coast Guard, MMS, Homeland Security, Department of the Interior and of course the Congress. What did those groups do to help? And if they had known the spill was say 5X bigger would they have done things differently, or just grandstand more?

I feel so bad, now that you've explained things in such a rational way. In fact, I think we should all whip out our wallets and send poor BP a bunch of big fat charitable donations, you know, just to make sure none of their kids will go hungry after the Evil Socialists punish them over a few drops of all-natural oil in that great big giant endless ocean. Who's with me!!? Come on guys, don't be selfish...

If BP had not put saving money ahead of stopping the leak ASAP, they would be spudding four wells.

This is a difficult formation. Initial estimate, per 60 minutes, was 21 days and it took 6 weeks of active drilling.

The same can happen to any relief well, which is why four, suitably spaced far enough apart (say 0.7 miles) should be drilling simultaneously.

Sure is costs more money. But if just two wells are drilled, both may run into significant problems and delay.

No wild well on land is causing the damage every minute, every hour, that this one is.

Spend an extra quarter billion and shut down the wild well ONE DAY, or even TWELVE HOURS sooner and it is BP's money very well spent.

BTW, we should amend the tax code to make all BP expenses and damage claims not tax deductible if they are found negligent in any way, either in causing the blowout or not controlling it ASAP.

Alan

I suspect the shrimpers and others who are under contract are not working cheap!!

$17/hour for quite skilled work and $250/day for the boat, with the boat owners accepting ALL liability for damage to boat or hands.

A pittance ! Far less than normal charter rates, but no one is chartering boats for fishing these days due to the malfeasance of BP.

One may pay a security guard, working in a nice air conditioned environment, and sleeping in his own bed every night, $12 or even $10/hour.

One cannot get workers that will work effectively in the swamp, with the heat, humidity and mosquitoes, manhandling booms for just $10/hour.

Alan

The Los Angeles Times is reporting a higher number, $1500/day, for the boat charter:

http://www.latimes.com/news/nationworld/nation/la-na-oil-spill-boaters-2...

Local fishermen were complainimg publicly and loudly about the low rates.

'

Perhaps BP's PR department (the people in ultimate charge) saw some local news reports and decided to take proactive measures before it went national.

Bad PR to have a hundred plus fishermen complaining about how cheap BP is.

Alan

I am all in favor of suspending BP's license to operate Atlantis and Thunderhorse immediately, until BP can conclusively demonstrate that their corporate culture has changed and they can act responsibly, competently and honestly.

Start shut down ASAP.

Today, they fail all three criteria.

BTW, 60 minutes also pointed out the snafu at Atlantis documents (89% not engineering approved, when 100% are supposed to be).

The oil will still be there later, and sold for a higher price when it is produced, by somebody.

Alan

Get off your enviro-soapbox.

Boat rates - $250 day plus $17/hr..but first you said $10 an hour? Which is it? It also beats doing nothing AND they still get to file claims for lost income. They could make out pretty good. By the way oil platforms are great places to fish, and the boat captains like taking people there as the catch is usually good. Living in NOLA I would think you knew that fishing and oil and really more symbiotic than adversarial.

Oh, by the way fishing boats need diesel fuel to run, and where does the oil for that come from???? So you want to close down a lot of the oil production in the Gulf? OK, do you drive a car, an SUV? Do you wear polyester clothing? Use plastics for anything? If so, watch your cost of living skyrocket. You think the ecomony is bad now, $4/gal gas after Katrina may be back and even higher. I hope you like even LESS jobs being available. So if you are NOT a user of oil then you can talk. Even if you just suspend BP's license they can't produce. You know how long it would take for a deal for someone else to take over? Years and BILLIONS in payment. Oh, well I guess we could have the MMS take over right? I'm SURE the Government can do a MUCH better job.

I'm not saying BP deserves anything but the full punishment allowed BY LAW. Not by what some people with a wild hair and/or an agenda on the Internet think. BP screwed up. They will pay to fix it. End of story.

As for the documents missing thats a concern, but if they were able to call them up via the Internet I'm not too worried. The laws date to the old days when such things as satellite links were not available. Worse case, burn them to a DVD and send them with the next chopper. This is a mountain out of a molehill and really had nada to do with what happened.

If you read the details on this case, it was filed by a disgruntled employee whose claim was investigated internally by BP and they found yes things we missing but it was not nearly as bad as you mention.

I seriously doubt that 89% NOT approved number. Why? Because I've been associated with building things for large companies and the Government. My relative managed production for a company that makes special seals and gaskets for the oil field and his take is the same as mine. If that document is NOT signed off properly we wouldn't build a thing. Why? Because then WE were liable if it broke or if something changed after we built it then WE ate the cost to change and make it right. I suspect a paperwork filing SNAFU not a deliberate attempt to go around the rules.

The $17/hour is for the very skilled labor of boat captain. $10/hour is for riff raff off the street to make a show for the cameras (one cannot hire motivated people for working in difficult conditions at $10/hour, BP just wants some shills for the cameras).

As noted I am VERY much in favor of new laws (no tax deductions for BP clean-up and damages, I do NOT want to subsidize them !), raise the $75 million limit on damages to $75 billion (including treble punitive damages if warranted) and enforcing old ones.

Like lifting the license to operate from an operator that has shown all that BP has shown to date. FULLY justified !

And just why should I step off a soapbox ? BP is about to destroy much of what I love and cherish and hurt people I know and respect.

Alan

PS: I drive a 1982 M-B 240D, manual shift (28 to 30 mpg in the city) but not very far. In 2008, I spent $178 on fuel and $158 on shoe repairs. $14/gallon fuel is quite affordable for me. And I strongly prefer cotton and linen clothing.

And how lomg have you worked for BP?

He joined TOD a week ago when he got this assignment. Probably a freelancer that gets more than $10/hour.

To give him credit, he has motivated me to pass some ideas on to Sen. Landrieu via one of her brothers and some others (good friend has good contacts with Sen. Kerry). Like no tax deduction for clean-up and damages and pull their Thunderhorse & Atlantis licenses immediately. Know several Washington lobbyists and dailyKos as well that I can pass these ideas on to and see if they get traction.

VERY limited contact with James Carville, but I can pass it on to him as well.

Kind of like BPs efforts at plugging the leak; keep throwing different things at it till something sticks !

Thanks for the motivation, Mr. BP supporter :-)

Alan

PS; Removing 450,000 b/day will not have THAT big an impact on prices.

CuriousGeorge, tells Alan to get off his enviro-soapbox.

I say George should quit monkeying around! Should I ever get to meet him face to face I would tell him in no uncertain terms and in much stronger language, than I might be allowed to use here, what I think of him...

So Mr. Curious (I seriously doubt that you are at all curious in the scientific sense). How are you even going to begin to assess the long term environmental impacts of what is begining to be found out about this spill. See Jerry McManus' comment up top: http://www.theoildrum.com/node/6470#comment-624175

Are you going to suggest that the Gulf ecosystem is just going to absorb it all? Or the harmless non toxic dispersants will take care of it and then the microbes will just eat it all up? Right? Move along now no harms been done here because we can't see it yet.

Well George, @#$%^& you!

And you gotta love this little gem of condescension:

Some of us here and I know for a fact that Alan is one of those people are well into the process of personally reducing their FF foot print.

As for me personaly, I drive an old compact car with a manual transmission and a rebuilt engine, less than 5K miles a year and plan on reducing that even further. I will never buy another new car again. As for gas at $4.00 a gal, I think it should be at least $10.00 with another $5.00 tax on top of that.

You are right that that will reduce employment in the current economy but that is happening anyway and will continue to do so we slide or fall off the slope or cliff on the down side of peak oil. In my case, since no one wanted to hire me at 57 when I was laid off a year and a half ago I had to start my own business from scratch. I'm sure quite a few more people will be doing the same.

BTW my business is based on "unsustainable" solar energy...

Hi,Alan, FMaygar,

I have come to trust you two guys over the last year;why?

Well ,partly because although we may disagree on the best way to accomplish something,or which of two possible goals might be the more desirable,our goals and values are basically similar.

The biggest difference is that we might not agree which monkey wrench, or hammer, is best suited to the job at hand.

But the greater reason is that when you comment on things about which I do happen to know a great deal,I never catch you making outrageous or erronous claims.Hence I have gradually come to rely on your comments as authoritative and often base my own opinions on yours, especially if I am poorly informed in some given area.

My own sense of the size of the current oil spill disaster is still fuzzy- but it is obvious to me that it is already enormous and indeed potentially catastrophic in the true sense of the word.

It is also obvious that it will be , already is, a historical turning point.Journalists and historians working in the field of energy in coming decades will refer to it in ways similar to the way thier predecessors responded to the launch of the first Sputnik.

Hopefully our country still has the will and the capacity to mount a similarly vigorous response, in respect to getting our house in order in respect to oil in particular and energy in general.I have made comments here about before about Pearl Harbor wake up events, and the POSSIBILITY that if we are fortunate enough to suffer such events, numerous enough and of magnitudes sufficient to get our collective attention, but mild enough to leave us able to respond in a wartime mode,WE JUST MIGHT skinny thru the coming bottleneck and emerge on the other side more or less whole in the ways that really matter.

When confronted with dealing with a monster lemon, it is good to stop and catch your breath for a minute, and consider the possibility of enjoying at least a little bit of unexpected lemonade later on.

Now I realize just how frustrated you guys are, and sympathize;I feel the same way but not so strongly, being more professionally, physically, and personally removed from the immediate problem.

If some company were to come into my home turf and create such a disaster, I might seriously think about becoming a martyr and giving the exucutive class a little something to think about -maybe a groundsman running over them down , and over,with a hundred horsepower lawn mower, blades engaged of course, during a golf outing.Or a bit of dimethyl mercury in thier sushi, something of that sort.I could probably manage to get a job as a kitchen helper in some fancy club-I've never convicted of anything more serious than drunk in public-and that as a consequence of being a passenger in a car involved in an accident so long ago that it might not even be in computerized records..

It feels good to vent and rant, no doubt about it;and doing so serves a healthy purpose.Some of those of us who are unable to release the pressure might otherwise actually become martyrs.

Let's not give the idiots too much ammo by talking about fifteen dollar a gallon gasoline by edict;it will arrive soon enough in the natural course of affairs, probably within ten to fifteen years in my opinion.

The vast majority of the public, and even a considerable portion of the audience here, cannot distinguish between a rant or sarcasm, and a serious proposal.Our current situation is patently unsustainable of course, but throwing a few more tens of millions of people out of work immediately via a draconian fuel tax will not help in the long run.

The bau crowd loves it when environmentalists make remarks along these lines, and has no scruples whatsoever about using them to the best possible partisan effect.Think James Carville on the other team.

(Personally I think of him the way Texans were reputed to think of LBJ-as in , " Of course he's a xxx, but he's OUR xxx".)

Thanks OFM, you are right I have been probably more than a little hot under the collar recently. I do need to take a step back and cool off a bit. Granted I'm watching that massive underwater plume coming closer and closer to the Gulf Loop Current which would bring the oil into the the Florida Keys, and up the East Coast. Those are the same reefs that I dive. So yeah its very close to home.

OFM, I agree with you 110%. We need a series of somewhat severe, but surviveable crises to awaken the slumbering masses. As a farmer, you are well aware of the adage of how you get the attention of a mule. We had one or 2 wacks upside the head (as a society) and a growing number of people are starting to gaze around, all groggy, and trying to figure out what's going on. There will be (must be?) more of such lurches and then we can begin to get serious about some solutions.

I tend to the optomistic side and believe that it is possible to get through this without having to live "beyond Thunderdome". If our leaders would just suck it up and start explaining what's needed we could be on the way to some solutions. The example of what the US did to change/increase production to win the 2nd world war is all the example one needs. Or, getting to the moon once we we got some gumption and decided to race the commies.

Like mom used to say: "Can't was defeated at the battle of Try".

As an engineer I am pretty impressed with what BP is doing to fix the well. Totally the opposite on how they got to that point. Off shore drilling will go on, but at much higher cost due to regulations and insurance. In the best of all worlds they'll be allowed to drill but it will be too expensive to make money at and they'll stop. (Dream on). Offshore wind is looking better by the day.

As an ex commercial diver who used to do inspections on BOP hydraulic systems back in the day when 500 ft of water was considered deep, I'm not!

Why, you may ask?

Because anyone who puts others at physical risk by not following their own safety procedures should not be considered a hero and does not deserve any respect. The shit hit the fan because they were cutting corners to save time. That just isn't acceptable!

If back in the day if I had been doing tender in the dive bell and didn't switch my diver to the correct breathing mixture just to save some time and he had a seizure and then I methodically go through the steps and save him by doing an extended decompression with all kinds of special gas mixes would you also be impressed?!

I think you misunderstand my comment. I meant to say that BP, et al, are guilty, perhaps, of criminal negligence in causing the situation. However, the technology being used in the remediation effort, ROV's that can weld and construct high pressure plumbing one mile deep, I find most interesting from a purely technical point of view.

Engineering, at it's most basic level, is simply problem solving. As an engineer I am learning some interesting facts about oil production while watching the "best and brightest" attempt to solve a rather unique problem. When this is over, my vote would be for the responsible parties to be hanging from telephone poles. But, as several folks noted during the financial meltdown - that would be letting them off too easy.

I was trying to be brief as us enjuneers are nut gud at Englush. My bad.

Minor correction - ROVs can not weld. They theoretically could put a automatic welding machine in place.

Hyperbaric dry welding has only been developed to about 1,000 feet, the practical limit for divers. While welding technology could be developed to deeper depths it would take a lot of R&D and to date the needs has not justified the expense.

Quality wet welding is only viable to around 150 to 200 feet. Poor quality wet welding can be done deeper. The deepest I know of was a job we did in the Gulf of Mexico at 670 feet over 20 years ago to stop up some habitat leaks - not great to look at - and the metallurgy was probably terrible.

Gud nuf 4 me! LOL!

At least we're on the same page with respect how we feel about what should happen to those responsible.

This is complete horse radish - every single person in the Western world is highly dependent on petroleum and petro-chemical products - that is hardly news. It does not prevent knowledgeable, concerned, and critical people from having a very strong stance against the oil industry, in all sorts of ways.

If I had to choose between the hundred-year destruction of every single thing touched by the oil industry on every continent on the planet, versus living a simpler, horse-and-buggy existence that did not rely on vast oil flows, I would take the horse-and-buggy straight away. But people like Alan (and you and I) have never had that choice - born since WW2. So get smart, and toughen up intellectually, before you write such drivel on here - it is a very critical place.

And how long have you worked for BP? A good question. Everyone knows they did not want the blowout to occur, but I think their behaviour since the accident has been disgusting, but not surprising - corporations run the world.

MMS is run by recycled oil execs... what chance is there they will go after their buddies?

See below for another note about asset management.

Craig

BP PLC is a limited liability company of British origin. I don't know how their assets are held, but typically, LLCs (the American type) are used in risky operations. The profits go to the shareholders (mostly BP's real corporate person), while if things go really bad only the assets held by the PLC are at risk. I work a lot with a lawyer who does asset protection consulting with many high risk groups. This is how they always structure. it is a good way to maximize profits and minmimize losses.

I have been waiting to hear about any other holdings of BP; to date not a word.

I have not yet heard the exact way that BP PLC connects with any other BP company. My guess is it is as stated above, and while they not doubt have significant assets, most of the real holdings are certainly protected. Just wait and see. If things get bad enough, watch for BP to bankrupt with no where near half a trillion US $ in assets!

Craig

In my humble opinion, "full compensation" from BP should include some rather tender bits of anatomy from one or two of the decision makers.

For the purpose of affixing blame for this debacle there seems to be no shortage of "decision makers" responsible. For the most part they seem to be doing pretty much what they do every day -- climbing into their cars and driving to their jobs.

Like junkies who casually blame the dealers for all of the drug related violence there is no select few that may be singled out for scorn in this matter. Consumers make the most important decisions every day--not someone behind the scenes in some corporate office.

Executives get enormously high salaries because (they say) they take the risks that others don't. "...part of the justification for granting executives large incentives to take risks is that, should the decisions be mistaken, the executives will pay a penalty."

http://www.zenit.org/rssenglish-29029

Taking the risk means taking the responsibility when you fail.

If my dog gets loose due to my carelessness and kills my neighbors chickens, I am responsible not my dog. Dogs do what dogs do. Humans who own dogs are responsible for them. Thus Ken Salazar, Obama, Bush, Cheney and the head of Transocean, BP, and Halliburton are ultimately responsible.

Junkies bear some blame, but all to often the dealer is a "pusher" who encourages the addiction. Likewise advertising has encouraged the addiction of driving big autos and all facets of our energy intensive lifestyle. In fact the ad companies do research to determine just what kind of ad will most likely sell the product just as the pusher knows how to get to a young kid. (and tobacco knows what kinds of ads to put up near schools to get kids to smoke cigarettes at any early age).

Before we drop this all on the consumer, lets have Obama, and Putin, and the Pope, and the head of every major country, religion and fossil fuel company come clean with the consumer and let him know what his REAL choices are. If the people are told just how much time Offshore Deep drilling will prolong BAU and how likely it is that further accidents will happen perhaps they will be willing to car pool and take mass transit. Since this has not been tried we can't really know what the consumer would do. Until it is, while I detest the ignorance and selfishness of the American Consumer, I don't see how we can say "oh well, they had to drill because its what the consumer wants."

We do know what the consumers will do. Tomorrow morning they will get back into their cars and drive to work just like they did last week.

Many are very comfortable trying to push the blame on others who make more money than they do but the truth is that their behavior is at the root of the problem and not some sneaky advertizers. Authority may be delegated to politicians and industry executives with high salaries but not responsiblilty.

The consumer is unquestionably the moving force here and nothing will change until his behavior changes. Blaming others only makes BAU seem easier to live with for a while.

That is because consumers have no choice. Any time choice is taken away, it is easy to blame the consumer.

We have had peak oil in the US for 20-30 years now and have done little to find a means of replacing oil.

The big money was all aligned against change.

It still is. Until big money is reined in, blaming the consumer is hogwash.

Necessity is the mother of invention. Big money has made certain that necessity for invention has not had its day.

I get it. Consumers are just powerless cogs in a machine that they have no influence on.

So folks who find it too painful to even contemplate what kind of personal changes they might have to make in their own lives so they could get rid of their cars are going to save the world only by influencing those making decisions at the top?

Of course consumers have choices. I never said they were easy choices. I have made them. I have paid for it but I have done it. It was worth it. All who think change is impossible at a grass roots level are fooling themselves if they think they are somehow going to make a meaningful difference only by making imaginary changes at the top.

How well has that strategy worked out for you so far?

I think changes are needed at every level, and the changes will interact.

Alan

Consumers are powerless cogs. You just haven't realized it yet.

Mussolini said that fascism should be called corporatism because it is the merger of corporate and governmental power. The Italians even had another name: estato corporativo.

When the government and its agencies have become captives of the corporations and when the foxes guard the hen-houses, I am sorry, but you really are a cog.

Maybe you think you have made changes, but I doubt that they would amount to much. And I doubt seriously that most people could make these changes if they wanted to and even had the means. They simply wouldn't know how.

The power of consumers is seen on issues of monumental concern. New Coke comes to mind. Democracy lives.

If consumers will consume more of any particular item all on their own then there would be no need to use costly advertisers to get them to consume. Come on, advertising works to create wants and that is why corporations pay advertisers so much.

With authority goes responsibility. The Water Authority in a city is RESPONSIBLE for providing clean water. The head of the Water Authority is responsible to supervise his or her employees so that they fulfill that responsibility. A parent is the authority in a household of young children and is RESPONSIBLE for their health and safety and training. If they don't fulfill that their children can be taken away. A head of a corporation is RESPONSIBLE to the shareholders to earn income for the corporation. He is also responsible for doing so within the laws of the land. He is responsible to insure that his employees work towards those ends in efficient ways.

Do you really want to live in a world with Authorities who can order things to be done but never held accountable for their actions?????

If the corporations and government level with the people and stop lying about how much oil is left, how bad CO2 is for the environment, how likely oil spills are and how devastating it is to the environment, perhaps they will change, perhaps not. But if the corporations are so sure that they know what the people want regardless of the cost, then why do they lie? They lie because they are afraid that the people will start using less oil if they tell the truth. What other reason could there be?

Agree in general, but with one caveat:

The heads of companies are responsible for their companies, but the heads of government are only responsible for the actions of government, not the actions of everyone in their nation. The government is responsible for its own weak oversight here, but the overall blame for the incident lies with BP.

To continue your analogy, the dog owner is responsible for the dead chickens, but the town's mayor is not.

Yes but if the government had correctly evaluated the risks of disaster, they would have regulated much more. I was going to say this event is like Three Mile Island, but at Three Mile Island only the power plant itself was destroyed. After TMI, the NRC realized that they would have made the nuclear plants much more safer had they fully appreciated the risks involved. I expect to see the same type of response from the government this time.

Risk is probability times consequences and its very easy to get both terms drastically wrong.

I'm sure when the dust settles there will be a new safety regulator that is fully funded by the oil companies, much like the electric power producers pay for the nuclear regulatory commission.

You don't understand the concept of captive agencies.

When Congress or a legislature decides it needs to regulate an industry, often the only people who are knowledgeable come from the industry itself. Additionally, the regulated industry wants people that are sympathetic to it so the industry lobbies to get its people on the agency regulated by it. The agencies become loaded with industry people.

Example, most insurance commissions are loaded with former insurance people. Same with banking and I am sure it would be the same with oil and gas.

So you have the fox guarding the hen-house. No wonder tough regulations don't get written.

True but if the town has a leash law and yet the town's mayor refuses to enforce that law for a few of his buddies and their dogs more than once kill people's chickens or attach people, well then the town's mayor bears responsibility.

In the case of BP and our gov't clearly lobbying has gotten them exempted from regulations that should have helped protect the Gulf. The MMS is entrusted with enforcing laws not giving exemptions, especially to a company that has been shown to be at fault in previous accidents (convicted of a felony in the Texas refinery fire). If the MMS had not given exemptions I would agree with you. But they are responsible for the laws of the land and thus they bear some of the blame. http://www.washingtonpost.com/wp-dyn/content/article/2010/05/04/AR201005...

In our gov't there is often not a clear line between industry and gov't. It is known as the Congressional Revolving Door http://lobbyinginfo.org/documents/RevolveDoor.pdf

Not to mention possible negligent homicide charges, particularly if what Alan reported a couple days ago is accurate.

Seriously, what is full compensation?

Should a gas station (ha!) hurt by declines in tourism be compensated?

Or a hotel, which may or may not have booked it rooms if this didn't happen?

What should the ocean raping fisherman get? They certainly never paid a dime for their catch.

Bhopal disaster

Union Carbide

Still in business

Of course this was India, but still........

I imagine that part of the strategy would be to stall and delay in the hopes that a friendly administration takes control in the White House that would be willing to settle this thing.

Going to be a lot harder this time. The states whose economies are about to tank don't get a lot of revenue from off-shore drilling. Unlike Alaska, they probably will cease the reflexive defense pretty soon.

I guess the crock about the leak rate being less than 20,000 barrels per day can be put to rest. The best estimate so far based on video evidence and not shill opinion has been 50,000 barrels per day and clearly most of it has not hit the surface. This explains why the skimming rate is only 20,000 bpd. It is still months before relief wells hit the target.

All the surface "fixes" have been failures and so will be the latest one.

If the "needle" / "junk shot" / "relief well" efforts fall short, how much oil could conceivably escape under its own steam (I understand there's around 50 million barrels in this particular tank).

Pressure must begin to wain at some point, right?

Concerned Joe

What are the consequences of the gas that is flowing from this blowout. I've read that the ratio of gas-oil is 3000:1.

I'm still no expert in the field, but from what I understand, the Gas Oil Ratio (GOR) is given in units of cubic feet gas per barrel of oil.

That 3000 number is the only one I've seen. Using that with any one of the flow estimates will give you a total gas flow rate coming (mostly) out of the riser. If you pick the 5000 bbl/day flow rate, that computes to something like 15 million cubic feet/day.

Just plugging some numbers in my calculator and assuming that the gas expands close to the Standard Temperature and Pressure (STP) where a cubic foot of gas will actually occupy a cubic foot of volume, they should have a velocity in their 6" riser pipe approaching 600 miles per hour.

I'm trying to figure out how they might be able to put some back pressure on the flow at the surface WITHOUT having the insertion tube blow out of the end of the pipe at the sea floor, but so far no luck

Draw a pressure gradient chart inside and outside the column. Outside, the pressure is solely determined by water depth - atmospheric at the surface linearly increasing to about 2200 psi at 5000ft.

Inside the pipe, it depends on the water/gas/oil mix. If it were water, it would match the outside, but you want little water inside anyway to prevent clathrate formation. If oil, the internal gradient would be about 4/5th of the outside, yielding about 450lb of difference. If gas, the difference is huge -- almost all of the 2000+psi will be seen at the bottom as the column of gas will weigh very little -- and all of that will act to "suck in" the tube, not blow it out.

In fact, to prevent too much water intrusion they will need to throttle-back the flow (probably at the surface?) to attain approximately zero pressure delta inside to outside at the seafloor connection. At equilibrium the straw should be able to "suck up" the leaking oil as fast as it is being emitted.

As they throttle back, the mix will go from almost all gas back to mostly oil, and hopefully no water. This will reduce the gas volume they have to deal with, greatly reduce velocity, and hopefully eliminate clathrates.

Variability in flow composition throughout would seem to be the potential problem -- shifting mixes of gas and oil could cause pressure shifts that the surface ship would have to respond to. Maybe there will also be a partial restrictor near the floor with closed-loop control from pressure sensors inside and outside the straw at the end?

I'm less skeptical than I was, but this is way more difficult than a soda straw.

As they close the valve at the top they should be able to keep quite a bit of pressure in the tube. I'm guessing that "control choke" will be on pressure control rather than flow control because of the fluctuating flow stream. The valve at the top will need to be very fast acting, I would think, to catch the occasional slug. The Broom platform in the Scottish N. Sea has a slug detecting system that signals a fast acting production choke (control valve) and it works very well (pats self on back).

This is way more difficult than a soda straw.

Thanks, Paleocon!

450 psi backpressure available at the top will give 'em some room for control, but I STILL don't want to be anywhere close to the flare(?) on this sucker!

If I was designing things, I would have still put a check valve - maybe something as simple as a flap of rubber over an orifice - at the bottom end. This would allow a bypass if they have to close a valve at the top end so they don't lose the insertion.

I think that the GOR is quoted for the mixture as measured at standard laboratory conditions of temperature and pressure (STP). If the actual measurement is made under different conditions then the raw data is converted to STP for reporting. If this is true, you should not account for the expansion to STP again. That would be double counting of a single effect. Rockman is away for a while. I hope someone else can clarify what the standard practice in the oil/gas industry actually is.

In the post where Rockman explained GOR, he also said that a hydrocarbon resource that is higher than 10000cuft/barrel is usually called a gas well rather than an oil well. So 3000 is quite high gas content as compared to the general run of oil wells.

So what is happening to all this ejected methane? What will it do to undersea life?

Most of the methane will wind up as solid methane hydrate (density 1.04 g/cc), which will settle like snow on the bottom of the ocean (density 1.03 g/cc)...not a big problem compared to the oil. There is an immense amount of methane hydrate in the ocean floor...more than all the coal in the world in terms of energy content.

You are right geek7, GOR is expressed at STP - so under pressure the gas is compressed and eventually goes into solution in the oil.

And yes, 3,000 scf/bbl is quite high for an oil well, "typically" you would find around a tenth of that. But wells can be anywhere along the continuum from zero GOR to (almost) pure gas.

If that much oil has been spilling into the depths of the Gulf since this incident occurred, isn't it a foregone conclusion the Gulf will become a dead zone? Isn't oil going to end up on Florida beaches, and maybe all the way up the eastern seaboard?

What will happen if all that oil at lower depths makes it to the surface at the same time a hurricane is sweeping across the gulf? Couldn't oil be splatted across New Orleans and the rest of the Gulf Coast? What if people are once again exiting rooftops to escape rising waters only to be sprayed with a fine mist of oil? Then it gets hot after the storm subsides and the oil hardens to a stiff shell. We could be washing off people like their seabirds.

Maybe that's too doomerish. Ok, how about the oil gets miraculously scooped up and refined, the profits pay for the oil spill, the Gulf is pristine once again in a few short months, and there are no hurricanes entering the gulf this coming season. There, that's much better.

Hurricanes are largely surface phenomenon - submarines can ride these things out quite comfortably by staying underwater.

Normally warm waters and high winds lead to high evaporation rates, and that is what would keep the clouds supplied with moisture. I suspect that nobody really has any idea what happens when you have an oil slick on the ocean when there is a hurricane in the area.

I don't think you would have oil raining down anywhere however - the hurricane really isn't literally sucking water from the ocean.

I have been through many a hurricane. I can taste salt in the rain 20 miles inland. Surely the salt was 'sucked up' or at least evaporated into the cloud system .

Salt doesn't evaporate, it is wind driven mist lifted by the winds high into the clouds.

I remember now. You can distill water out of a salty solution with heat. Thanks.

I am thinking that in these cases the winds just pick up drops of seawater and blow them inland.

Where I am (far further inland), all we see are the heavy rains where all of the water comes from the clouds, and we get no salt at all.

What are the chances dipersent chemicals are caught in water vapor? Toxic or semi-toxic rain?

AFAIK, we don't know what is really in the dispersants (the formula is proprietary), so it is really hard to say.

Although if I were the right kind of academic with the right kind of equipment, I might try and take water samples and come up with answers to these questions.

What would exposure to oil harm if dispersed along the coast in the form of oil mixed with hurricane rain? I imagine oil might harm the plants, but I also remember using mineral oil as a leaf polish when I was young. I know the oil would probably not travel far from the coast, but I am only 2 blocks off the beach in cheap housing.

I might believe 30 or 40 percent of the surface sheen evaporates in arid dry climates, but in the Gulf at 60-100 percent humidity the air is already saturated.

Likely a greater proportion of the VOC's will settle into the ground level atmosphere and carry across land with the wind.

Mineral oil is no longer advised as a leaf polish because, I have read, the leaf can't breathe.

Mineral oil is no longer advised as a leaf polish because, I have read, the leaf can't breathe.

The oil will have complex effects on a possible hurricane I think. The oil should increase water temperature by reducing evaporation under calm conditions...but in stormy conditions, the oil will not be an effective barrier to evaporation. This might intensify hurricanes via the stored heat in the warmer water. Also, the oil slick reduces the oxygenation of the water.

I think you are being a bit doomerish but if you only go by the media headlines its hard not to be.

As usual the media reports part of the story and leaves out the most critical parts, in this case the density of the oil within the plumes. Although the report said the scientists stated they didn't know the density.

We can make a WORST case estimate based on some things we do know. If we assume the well is flowing at 50,000 bpd for 20 days (from rig sinking to scientists sampling) that would be a total of 1,000,000 barrels. I think this is probably double the actual amount.

Obviously a large portion, probably the majority of this oil comes to the surface, but lets assume 50%, or 500,000 barrels is suspended subsea. The articles says there are a number of these plumes and at several layers in the water column. They mention one is 10 miles x 3 miles by 300 feet thick and I assume that is probably the largest one so again we assume that 50% of the subsea oil is in that one plume. So 250,000 barrels of oil in that plume.

A volume 3 miles by 10 miles by 300 feet is about 1.5 trillion barrels. Assume it is actually an ovoid with missing bits so say a 50% reduction in volume so it is actually a volume of of 750 million barrels.

Using these numbers 250,000 barrels of oil in 750 million barrels of water is an average density of 0.03%. I would be very surprised if it was anywhere near that high. There are probably pockets of higher density.

As I understand it - it's definitely outside my area of expertise - the dispersant breaks the oil into tiny "micro-bubbles", similar to a very fine mist of water in air. The tiny size of these bubbles is why they don't rise to the surface and also why they can be quickly absorbed by oil eating microbes.

The depletion of oxygen is both good and bad. The bad is that if it depletes the oxygen too much it will be detrimental to marine life, the good is it means the microbes are eating the oil at a fast rate. When the oil is "eaten" the microbes will starve to death and the oxygen depletion will stop. I hope this doesn't start a "save the microbes" campaign.

Under these circumstances having whats left of these plumes come to the surface during a hurricane is almost a best case scenario. The power of the hurricane would churn up these micro-bubbles and they would disappear into the atmosphere and the water column.

great little quick calculations... and assumptions... but...

i am offically starting the "save the microbes" campaign...

i will be applying for funding from the BP cleanup funding...

i will be seeking government grant funding...

i will incorporate as a tax exempt LLC...

i will sell t-shirts and coffe cups...

i will appear in larry king...

i will gain "expert" status and be called upon as a consultant in future crises...

i will market a line of children's toys...

in other words... i will use this disaster to "CASH IN"... thanks for the idea!

Bingo. I think you were being sarcastic - but nonetheless, a bazillion people are going to CASH IN on this thing - in actual ca$h, in ideological self-stimulation, in crocodile tears over things they never cared a whit about before in their entire lives, in obscenely gargantuan legal fees, and in countless ways yet to be imagined...

there's three personality types germain to unregulated-free-market-capitalism... (my apologies to the great works of maslow and others)...

1)suckers

2)sociopaths (bordering on psychopathy)

3)sarcasists (i made that up)

#1 is required for #2 & #3 is fun when you either can't or won't take complete advantage of everything and everyone you encounter for the shameless goal of making money...

if i was cashing in... i wouldn't have time to post here... i'd be on the phone... no... better... DRIVING down there... lining up my DEALS... see: balloon boy; s palin; r limbaugh; b madoff; and a host of other noatable and not-so-notable scammers...

Please not Larry King. Do that and I will not buy your cups. Now Colbert....

Shelburn wouldn't that be 750 billion?

Using Shelburns assumptions isn't it about .00003%, so even smaller (again using 50000 barrels per day and his numbers)??????

YES - My bad - it is 750 BILLION barrels

That‘s what you got with those stupid imperial units.

I have a nice little program here that I trust in these matters.

ratz@sebigbos:~$ units2411 units, 71 prefixes, 33 nonlinear units

You have: 3 nauticalmile 10 nauticalmile 300 ft

You want: barrel

* 5.918028e+10

/ 1.6897521e-11

You have: 3 mile 10 mile 300 ft

You want: barrel

* 4.4688196e+10

/ 2.2377274e-11

You have: nauticalmile

You want:

Definition: 1852 m = 1852 m

You have: mile

You want:

Definition: 5280 ft = 1609.344 m

You have: ft

You want:

Definition: foot = 12 inch = 0.3048 m

You have: barrel

You want:

Definition: petroleumbarrel = 42 usgallon = 0.15898729 m^3

So 3 miles by 10 miles by 300 feet is either 4.5e10 (45 billion) or 6e10 (60 billion) barrels, depending on wether you use land miles or nautical miles.

Rainer

Someone earlier commented that maybe we should burn the oil up down deep...seemed funny at the time, but what with the microbes, all that may be needed is to keep them supplied with oxygen. Could it be cost effective to aerate the oil plumes?

Outside the realm of reality

So far in our thirst for oil humanity has drilled a million oilwells and consumed about 1000 Gigabarrels, which works out as 1.000.000 Barrels of Oil over the lifetime of an average borehole. So fifty thousand or 70.000 barrels a day from a single borehole would be the mythical super mega über field, which lays the whole peak oil story to rest in peace.

I am trying to figure out what is keeping this oil from rising to the surface. You can definitely get weird behavior at a thermocline (sudden temperature change), but I wouldn't have thought that something so buoyant as oil could get blocked from rising.

I'm guessing that the dispersants are acting to create a form of deepwater emulsion.

I wonder how well these things can be mapped with surface sonar.

i'm guessing you are right and i'm also guessing they are creating a "reverse" emulsion, oil in water -vs- the "normal" water in oil emulsion.

http://www.onepetro.org/mslib/servlet/onepetropreview?id=00086932&soc=SPE

Except weren't the dispersants only recently OK'ed for deepwater injection? So how could you have deepwater plumes created by something sprayed on the surface?

See my recent post below, under a post by goodmanj for a theory.

Emulsification and separation of fractions (heavier asphalt fractions stay lower longer).

Alan

you need a mechanism to separate out the components...I nominate phase separation as the density of an initially miscible supercritical solution is reduced. more details below, at http://www.theoildrum.com/node/6470/625553

Water layers in a deepwater column are odd things. You can get different layers moving in different directions at the same time. A major factor is salinity - obviously less saline layers are less dense and slide over layers of higher salinity when the two meet. I am not familiar with GOM but my guess is you will get some currents which circulate the gulf, and others coming in from the Atlantic, perhaps with higher salinity and at lower levels which is different to what you would observe at the surface.

Oil particles will tend to rise upwards, but could easily get carried along by subsurface layers while they are making their way to the surface.

A couple of thoughts from someone with an oceanography background:

1) The fluorometers being used to measure petroleum in the water column are *very* sensitive. Someone here was throwing around numbers like "1% oil/water ratio", but a good dissolved-organic-carbon fluorometer can detect organic carbon levels in the tens of micromolar range -- that's in the vicinity of 1-10 parts per million.

2) Even without the dispersants, you can see from the seafloor video that the turbulent outflow is breaking the oil plume up into a cloud of very very tiny droplets. This drastically reduces the rate at which they rise to the surface. Some simple Stokes Law calculations:

1 mm droplets: 0.3 m/s

0.1 mm droplets: 3 mm/s

10 micron droplets: .03 mm/s

.03 mm/s works out to 2.6 meters per day.

As a general rule, any object suspended in water that's invisible to the naked eye is immune to sinking/floating, and will stay suspended in the water column essentially forever.

3) The ocean is full of its own natural dispersants. Cell membranes and other structures in living organisms are made up of molecules which bind with both water and oil, allowing them to mix. In short, the ocean has a lot of natural "soap" in it already.

I did the same calculations this afternoon with somewhat different results.

Diameter 1 mm: 0.05 m/s.

Diameter 0.1 mm: 0.0005 m/s.

You have to enter radius into the equation.

wolframalpha uses water viscosity at 25°C (8.9e-4 Pa/s). At 0°C viscosity is 1.82e-3 Pa/s, I used 1.6e-3 Pa/s since deep water is pretty close to freezing.

Just nitpicking here, this doesn‘t change the validity of what you say.

1 mm droplets: 11 hours to reach the surface.

0.1 mm droplets: 40+ days.

0.01 mm droplets: never.

Rainer

You have assumed that the droplets all have the same density, as if there is only one phase forming the dispesion. I think there may be two or three distinct phases, already separated when the oil leaks out of the riser pipe. Some rises fast (lightest fraction); this is where most of the present surface oil came from. Then there is an intermediate fraction, and a heavy fraction.

I just looked again at the video that goodmanj is referring to in his point 2) above.

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/gulf_of_mexico...

I think I agree with him that the black billowing cloud is not pure oil, but a multitude of tiny oil drops suspended in seawater. There are glimpses of less dense, more tenuous grey cloud showing in spots momentarily. I don't think this could happen if it were pure oil with no water. If it were pure oil in water, it would always have a sharply defined boundary in every frame of the video, I think.

If this is correct, it negates all the estimates of oil flow rates that have been done to date, based on watching this video (including goodmanj's estimate from a few days ago) All these extimates assumed that the black stuff in the image is pure oil. But goodmanj now says otherwise, and on looking again, I agree with him.

But I have no idea how to estimate the amount of oil in a cloud of oil drops. Is 1% oil reasonable? 10%? 0.1%? or what? With this new uncertainty, I am no longer sure that 5000 bpd is wrong. I am sure that the method that was used to arrive at the number was based on flawed reasoning. I am sure that if it turns out to be close to the correct answer it is by luck alone. But it may turn out that serious scientific reasoning will suffer a setback to it public eye. Sometimes when one pulls a number out his lower sphincter it is a good number in spite of its provinance.

His other comments call into question the idea that human applied surfactants are having any effect on the physical condition of the oil in the ocean. I think there is merit to his comments. We need more investigation here.

It looks to me like a multiphase flow. The white stuff is primarily gas with a lot of the light hydrocarbons; the black stuff is the heavier fraction. because of this fractionation, the black cloud is denser than ordinary crude oil.

See my detailed post:

http://www.theoildrum.com/node/6470/625553

I think there is a fractionation happening that is an additional factor besides emulsification.

RE oil plumes.

I know this may be gratuitous speculation, but taking these figures and doing back of napkin calculations...

10 miles X 3 miles X assuming 100 ft thick avg

assuming 1% oil in the volume

I get close to 20 million barrels

divided by 30 days yields something over 60,000 bbl/day

It might give some idea of the magnitude of the spill.

edit: comes to over 600,000 bbl/day slipped a decimal pt. Still obviously in the WAG area. Really need more data to go from WAG to SWAG. I'll bet these folks measuring the plumes have data on the % of oil/water in the plumes.

ET:

Assume 0.1% oil by volume instead. The instruments are easily sensitive enough to detect that lower concentration. Your original point still stands, IMHO. The estimate of 5000 bpd is incredible.

Yeah, I'm running a dopamine deficit right now. Should know better than to try to do any ciphering.

I think most of your reasoning was OK. The problem is that when you picked a number out of the air where the is no way to rationally choose a number, you should have picked a number that made your argument work. You could have said: "We have no idea what percent volume of oil in water is, so let's choose 0.1%" The rule is: If you are going to grab a number out of the air, first make sure it is a good number before grabbing it. ;-)

10 miles x 5280 ft/mile x 3 miles x 5280 ft/mile x 100 ft x 7.48 gal/ft^3 x 0.01 / 42 gal/barrel = 149,000,000 barrels

149,000,000 barrels / 25 days = 6,000,000 barrels a day

Obviously, this plume has huge gaps in it - the content of oil must be in the hundredth of a percent range.

Shelburn, for your example I get

10 miles x 5280 ft/mile x 3 miles x 5280 ft/mile x 300 ft x 7.48 gal/ft^3 / 42 gal/barrel = 45,000,000,000 barrels.

You are absolutely right. I will quit trying to do this on a cell phone while traveling. A total of two mistakes and one typo in the calculation. Final results should be more on the order of 0.001% oil to water vs the 0.03% so about 30 times LESS oil density than I originally calculated.

We are starting to hear concerns about reduced oxygen levels caused by the oil plumes deep under the surface. Such as this quote taken from the omaha.com article linked to above: "While the oxygen depletion so far is not enough to kill off sea life, the possibility looms that oxygen levels could fall so low as to create large dead zones, especially at the sea floor.

"

Is there a solution for this or is the scale of the problem too large? Can air be pumped into the plume from surface ships to increase the oxygen levels? Anyone willing to do the math?

I'm guessing since the plume is a moving target this adds a huge level of complexity. It's not like a bubbler in your fish tank at home:(

Oxygen depletion is generally caused by some process consumping oxygen. In this case we don't yet know what that process might be. A plausible guess is that microbiotic life is blooming because oil is a food source for it. Such blooms happen frequently at the mouth of the Mississippi river, caused by phosphate and nitrate runoff from agriculture in the middle west. Around the Mississippi delta there is a die-off of 'good' life, ie fish and shrimp that people eat. But here, in the deep ocean, it is just a gross violation of the environment that we all ought to find repulsive whether or not there is economic loss. (Sort of like if the astronauts had left candy wrappers and bottle caps on the Moon.)

A technical fix like pumping air into the region would surely have unintended consequences that would be a different form of unpleasantness.

if we can prevent large swaths of ocean from going anaerobic, I'm for it. My guess is that it is probably more energy efficient to pump pure oxygen down there (because the work to compres 5 units of air to 2200 psi is probably larger than the work of purifying the oxygen, them pumping one fifth as much gas down there. It will never make it to the surface if pure oxygen is used. Air could wind up giving sea life nitrogen narcosis.

This sounds almost exactly what I was proposing yesterday. The nitrogen injection should only be needed to start the process as gas coming out of solution should be far more than is needed to drive the flow.

I don’t see a control valve in the system at the bottom. I wonder if they will have enough control by having a valve only at the top. If the pumping action pulls in all of the oil then you can’t tell if it is also sucking in water, and a mile long pipeline clogged with hydrates would be a mess.

From what I picked up in yesterday's thread, there are some flow control components in the LMRP

I think you'd still want the valve at the top, so you can maintain some gas pressure. Roughly, doubling the pressure will halve the gas volume, so the first few hundred pounds of pressure would seem to go a long way.

Track Surface Oil Spill over time

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/gulf_of_mexico...

And with our daily weather forecast we now also get our daily oil spill forecast

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/may_16_17_fore...

With good explanations of the effects of wind, tide, eddy currents, Loop Current, increased water flow in the Mississippi (Nashville rains now going into Gulf), evaporation and more.

Just like "I think this cold front will stall north of us and these easterly winds will ..."

Alan

This is a pretty diagram from BP's communications mavens. Strange how the diagram doesn't even show the leak at the top of the BOP. Stranger still, they have not released ANY photos of that leak.

(Apologies in advance because I'm sure this has been asked a thousand times, but I haven't seen it addressed. I'm reading as much as I can, but can't read everything.)

Why can't the BOP be replaced?

Below the BOP, there's no way to shut off the well, so if they take off the bad one, they'll have completely uncontrolled flow out of the well. Aside from what that'll do to the fish and the birds, it'd make it DAMN TOUGH to try and get a replacement BOP in place.

In addition, there's apparently at least a little section of drill pipe sticking down out of the bottom of the BOP. God only knows (although the drilling people probably have some pretty good estimates) how long that pipe is.

The uncontrolled flow for a finite period until the new BOP is in place seems an acceptable trade off considering it's very possible it will keep leaking at least at the current rate (but more likely increasing with time) for however long it takes to finish the kill well. I do see your point about the old drill pipe (possibly) making it impossible.

If there's a lot of gas in the well, and if the BOP is the controlling delta P in the system, the BOP upstream pressure could be at 10,000-15,000 psi. Would be an interesting experiment to cut that off, but I wouldn't want to be within 10 miles when they do it.

If I recall correctly, from early on BP said they have a second BOP stack on location(on a ship). This was specifically discussed in their briefings as a possibility to put on top of the current BOP. They had stated that the riser had been designed to separate but had not. Had it done so one option was to piggy back a second BOP. I think on here or another site engineers had discussed the problems with the riser and the complications of removing it. Also, if I remember correctly there are/were concerns regarding the condition of the BOP itself. They have done the scanning of the internals and I believe they said they were able to determine BOP's had been engaged but the top shear ram had not completely closed. I do not remember if they said they had diagnosed why from the internal scanning (done with Sandia lab equipment). I believe they said structurally the internals looked to be in good shape. Others have talked about he condition of the kill lines (I believe they are each 3") that will be used if they do a junk shot. Someone else wrote they had heard something about ROV's working on them to improve chance of successful of junk flow. Unless they completely rule out the ability to safely figure out a way to put on the second stack, I wonder if it is still an option if the containment and junkshot/top kill and other options do not work. They claim as different options are vetted and higraded they put them in a priority list. As you imagine some of the actual engineering/ construction and setup is pretty complicated and time consuming.I hope others of you who have better memories or knowledge can fill in what I screwed up here.

What makes this impossible as compared to Kuwait/1991 - is it the water depth and access only via ROVs? What to do with the old drill pipe (noted above)? This particular hole's mix of oil/NG?

Does it make sense to say that if wells at this depth can't be controlled when something goes wrong, there shouldn't be any wells at this depth? At least until the technology catches up?

Here's the latest from Google news on the oil spill:

I'm figuring this article must already be on TOD, but anyway here it is:

http://www.csmonitor.com/USA/2010/0516/Gulf-oil-spill-real-disaster-migh...

Gulf oil spill: real disaster might be lurking beneath the surface.

New research suggests that huge plumes of oil might be spread at all levels of the water column, showing how much scientists don't yet know about the complex Gulf oil spill.

A multi array induction logging tool may be the perfect method of determining the ratio of oil to water in the subsurface oil plumes. There are about 12 orders of magnitude difference in the conductivity of sea water and a pure light crude.

The tool could be fitted with a pressure monitor to determine depth. The tool could then be towed behind a vessel with depth controlled by adding tool weight and vessel speed and cable length, while conductivity is monitored in real time. These tools can be purchased or leased from some wireline co's. By simultaneously recording GPS data a 3D map of the plume could be produced.

Do you think BP REALLY wants to know ?

Or even the US Gov't ?

We have a dozen oceanographic ships in the USA (more abroad). One volunteered and found something. They have asked for more funding and ...

The silence is deafening.

Alan

No but I and a lot of other folks would like to better understand the results of deep water oil leaks. A small groop of retired wirline guys could get this set up in a few weeks.

I'm sure they want to know.

I'm also sure they don't want us to know.

BP officials say they were on the verge of a breakthrough stemming the gushing oil leak in the Gulf of Mexico, but another accident has set them back. Meanwhile, scientists have found huge plumes of oil lurking under the surface of the water.

Officials say they successfully inserted a new pipe into the broken pipe spewing water into the Gulf. That new pipe started sending oil to a ship on the surface, but, just moments later, two remotely-operated robots crashed into each other and knocked the pipes partially apart. The robots were taking photos of the operation.

http://www.npr.org/templates/story/story.php?storyId=126852086

Sounds like some of those guys need to get some sleep.

paparazzi

LMFAO!

xxx ooo

Regarding the dispersants being used -

Full article at link below

http://www.grist.org/article/2010-05-13-want-to-phase-out-a-hazardous-su...