Deepwater Oil Spill - The LMRP Attempt, the "Press Conference," and a Live Open Thread

Posted by Gail the Actuary on May 29, 2010 - 7:30pm

New thread, please redirect to http://www.theoildrum.com/node/6538.

BP is now saying that its Top Kill approach has failed, and it is moving on to LMRP. A few comments from the press:

Top Kill Fails To Plug Oil Spill, BP Now To Try LMRP Cap

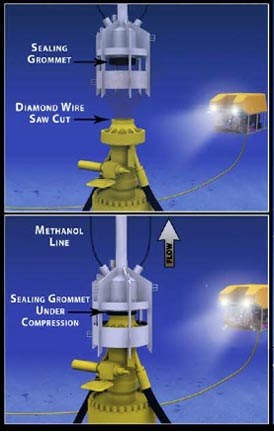

BP said preparations have been made for the possible deployment of the lower marine riser package (LMRP) cap containment system, which would be complex because of the depth of the oil leak.

Deployment would first involve removing the damaged riser from the top of the failed BOP to leave a cleanly-cut pipe at the top of the BOP's LMRP.

The cap, a containment device with a sealing grommet, will be connected to a riser from the Discoverer Enterprise drillship, 5,000 feet above on the surface, and placed over the LMRP with the intention of capturing most of the oil and gas flowing from the well.

Mr Suttles said it should capture "most of the oil" and was expected to last at least four days but "we cannot guarantee success at this time."

Under the fold (click "there's more"), I talk a bit about the Lower Marine Riser Package (LMRP) and what we know at this point. Please elaborate other facts in the comments.

(PG here, and following Gail's post below are HO's thoughts on the press conference...)

This is a diagram that Heading Out posted a few days ago, of the LMRP.

According to Upstream Online:

If the top kill does not work, the UK supermajor plans to cut off the riser from the lower marine riser package (LMRP) and attach another to collect the flow.

The device would be coupled to a flex joint above the LMRP with a sealing grommet to keep water out of the flow and control gas hydrate formation.

The cap also has valves to inject methanol or hot water into the production stream.

BP has already lowered the LMRP cap to the seafloor so it could be deployed immediately after a failed top kill.

Installing the cap would take about four days, Suttles said, and it could be in place early next week.

The LMRP cap would allow BP to capture as much of the flow from the well as possible while it works on other options to kill the well, he said.

He announced Wednesday that BP preferred option in that instance would be to add a second BOP on top of the first.

Heading Out's Thoughts on the Press Conference

BP and Admiral Landry just held a Press Conference in which they said that, based on a decision 90 minutes ago, by the “best and brightest minds” that it was time to move on the next option, the Lower Marine Riser Package (LMRP). BP was unable to block sufficient flow out of the well to make the injection of cement possible, and thus to kill the well. They had made, I believe he said, three attempts to inject material (the junk shots) without being able to get that material to block the passages through the Blow-Out Preventer (BOP). (Unfortunately I missed a large part of his opening remarks, and thus have only the question response to go on at present.) The volume of mud used did not appear to have changed from earlier reports at some 30,000 barrels.

Mr Suttles said that they had given the technique every chance, but could not get it to start to provide an effective seal. They had, however, determined that the majority of the pressure restrictions to the flow of oil was coming from some resistance within the well itself, and from the BOP. Since the riser above the BOP was not contributing much to the resistance, and thus to control of the oil flow, the next plan is to remove it, using a band saw device (of which pictures will be available) and then to lower the LMRP onto the existing BOP. They intend to cut the surface flat that the LMRP will sit on, so that it will give a good, but not perfect, seal. Thus there will be some leakage around the joint, and they will monitor that and use dispersant as appropriate.

The new change should take somewhere between 4 and 7 days to implement. The assembly, which has been constructed, is not the Top Hat assembly built earlier, to fit on the bottom of a riser. Flow of oil from the LMRP will rise up a 6 7/8 inch drill pipe within the riser (the same size as the one currently fitted to the RIT). The riser will also carry hot water down to the LMRP to protect against the formation of hydrates.

He noted that their inability to stop the well “scares everybody” but is reasonably confident (no success percentage estimates) that this will collect the majority of the oil and gas. Because they do not know the flow path of the oil below the seabed, it is difficult to estimate what is actually going on in terms of oil path below the BOP. Thus they are, again, trying something that has never been done before, but expect, based on the RIT, that it will work.

On being asked about the cleanup of the dispersed oil – he pointed out that the reason that the dispersant was used was to break the oil into small droplets. These are small enough to be consumed by the microbes in the sea, and thus there is no plan to do other than let nature take its course. For the oil on the surface, they are getting better at spotting oil pools and sending skimmers to deal with them.

The Admiral drew attention to the article on Hurricanes and the Oil Spill which is available at the Unified Command Web site.

The relief well is about half-way through the rock it must drill (about 6,000 ft below sea level) but progress will slow as the well deepens. A diagram of the LMRP is as shown above by Gail, from one of my previous posts.

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome, 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

PG - Appreciate your years of dedicated service. As many have noted, the lower signal/noise ratio is largely due to people who joined TOD post the DWH disaster. Don't know if it is possible with the blog software, but it would be nice to have a thread where comments are limited to posters who were members before 20 April 2010.

As a noob who is here for the signal, I'd gladly give up my ability to comment if it would help reduce the noise (and because everything else out there seems to pointed 180* from the signal;-)

But...wait...if that rule were in effect now, I wouldn't be able to post a comment supporting that rule...wait...Whoa! I think I just blew my own mind!

(with a nod to Keanu Reeves, who could solve this in a jiffy.)

The noisiest and loudest posters like Cargill are what the references made to signal to noise are about. I don't think you would ever be able to generate as much static as that one does. No one would.

Hi, I wanted to let you know that this is a great discussion thread and I appreciate the varied knowledge base of the people who have contributed to the discussion, especially at the bottom of the thread. I am not not a trained petroleum industry professional, but I do have an engineering background, and I must agree that the LMRP does not not look like the most feasible solution. I think the whole challenge with this crisis is one of pressure and fluid dynamics, and I don't think a riser that is that the same size as the RIT can hold the seal on the LMRP for a 21 inch well pipe that is flowing at 13,000 psi. I may be naive but I think at the least they need to use riser with a bigger dia if they want to release some pressure from the seal. Alternatively I think the BOP on BOP may have more promise than this solution. thanks Arshad

It's done... My worst case was a mil gallons of oil in the GoM for 90 days. I thought that was a really wild pessimistic conclusion but it’s looking real.

Any EXPERTS want to dispute that?

Profgoose -

With some trepidation I'm writing to gently point out that the experts, and the professionals too, seem somewhat at a loss as to what to do for the best about this rogue well, with its unique wreckage and exceptional outflows, sea depth, dispersant downflows, negligence, mendacity, financial stakes, ecology, fisheries, hurricane prospects, political sensitivity, and media coverage, all in the mix. Added to which, Peak Oil is looming up.

Such are the connotations of this thoroughly oiled sort of swan that at least one prominent figure (a former Bush advisor whom it might be crass to name) appears to have gone clean out of his mind with the additional stress.

Given that no visible consensus as to engineering solutions has arisen in over a month, perhaps it is time to look at what might attract agreement and then fashion it into a practical proposal ?

To this end, I'd suggest that it would be imprudent to alter the chaotic wreckage for any connection-based control option without first having deployed a containment-based control option for immediate positioning in the event of any failure that risked increasing the outflow.

The likelyhood of incompetence yielding such a failure is perhaps best illustrated by NASA's problems when someone confused miles and kilometres. The probe reached mars ok, but rather than settling gently into position to start its work, it went splat into the planet. Way to go!

Given that the business plans of even the world's most powerful corporations are grossly unsustainable, which is but incompetence on a grand scale, the probability of further failure, arising somewhere between Haywood and his working minions on site, looks rather nearer to one than zero.

Whether the idea of a containment option may find agreement here on TOD depends on our confidence in the best form of containment that we as a fraternity could devise. Having looked at the parameters for a month there seem to be various distinct requirements that must be met, any one of which may be insuperable.

- Given that oil extraction isn't my field, it is for others to explain and if possible resolve any problems they see.

1/. Ballast must be delivered by chute around the wellhead to provide a stable foundation for the container, (perhaps after the removal of soft silt ?).

2/. The container must be made double skinned and topped with an ample outflow pipe and stopcock, and be large enough to easily accomodate the BOP. Within its heavy framing its inner skin needs to help sweep out any hydrates and so should be conical. Its heavy duty outer skin of marine s/steel must be domed to withstand the delivery of stabilization ballast by wide chute from 5,000 feet. While the two skins are joined onto framing round the outflow pipe, there is no floor between their bottom edges. Connections for hoses for liquid concrete delivery are set around the outflow pipe.

3/. Sufficient barges to deliver say 250,000 Ts of ballast to the site need to be commandeered, emptied, loaded with ballast and sailed to nearby harbours to await orders. Custom-rigged barges able to provide say 10,000Ts of concrete need to be similarly positioned.

4/. Prior to any connection-based option being attempted, the barge fleet and the container's barge are anchored on site, and the container is positioned near the wellhead, with its stopcock fully open and concrete hoses attached.

5/. On the order to deploy the container, the ROVs are used to set cutting charges on all pipework from the BOP and around the site. Once cut away, the wreckage is towed clear and further ballast laid as required. The container is lowered over the BOP to rest on its pad of ballast.

6/. The double skin is immediately filled with concrete which flows onto the pad providing a seal at the container's edges. Ballast is chuted down to bury it to around 3/4ths height, before building a base to that height over a wide radius. The concrete hoses are removed and a concrete pad is laid around the outflow.

7/. Once the concrete has begun to cure, the stopcock is closed, very slowly. It and the outflow pipe are then deeply buried under concrete, before the many remaining barge-loads of ballast are delivered to form a very large mound. An ROV is permanently stationed to patrol the mound on a daily basis, for at least the next decade.

8/. Send the bill to BP.

___________________________________________

Starting with seabed issues, I've both unknowns and uncertainties about the design and deployment sequence sketched above. What seems certain is that neither waiting for the secondary wells nor altering the wreckage to make connections without a plan B seem remotely viable options.

Thus it seems there are now two prime questions to address:

- What is the best containment option that could be deployed ?

- What are the prospects of deploying a reliable containment not as the 'backstop' capacity, but as a distinctly preferable option to attempting an engineered connection to a malfunctioning BOP ?

Hoping these may at least be regarded as fair questions from a layman,

regards,

Backstop

For unknown reasons, BP doesn't appear to be entertaining any ideas that decouple the containment from the extraction. We tried to get them to use containment vessels made from retrofitted barges:

http://www.youtube.com/watch?v=JbUAAHuJUHs

This is gobbledegook oogoo-boogoo - can you please communicate in reasonably understood English? Sheesh ...

Perhaps you mean "reasonably understandable English" ?

As a British commoner I'd observe that your inability to read English written at more than high school level, along with your aggressive response to anything you have difficulty comprehending, occurs on US websites to the extent of reflecting rather badly on the American education system.

I'd suggest perseverance.

Regards,

Backstop

Hey Cargill

Read elsewhere on this thread about the difference between professional levels and non pro being segregated. I'm fighting that move but the likes of your post's are cutting the ground from under my computer keyboard. Might I speculate and suggest that you were perhaps stymied by words such as imprudent.

You really should learn about online dictionaries--http://onelook.com/ and look that one up. But to make my point, perhaps the writer likes that word because it encompasses a lot of concepts and ideas in one roll-up.

adjective: imprudent, lacking wise,self-restraint So, the writer could have said, 'It would not be a good idea to alter the chaotic wreckage' but that fails to convey the idea of the lack of self restraint that is a known hallmark of BP management types who are still living out the fantasies of the wildcatter days. 'not be a good idea' is also rather pedestrian, every day lingo and fails to give an understanding of what the word wisdom implies.

wise, ▸ adjective: carefully considered, also adjective: marked by the exercise of good judgment or common sense in practical matters

So, my dear Cargill, imprudent was really a very good word to use because it really says a lot in just three syllables.

Sincere thanks to everyone sharing their knowledge and providing insight. It's been amazing to follow the development of events here for the past two weeks or so.

For what it's worth, there's some fascinating activity transpiring at the http://interactive.foxnews.com/livestream/live.html?chanId=2 link posted earlier by "JoesBarAndGrill".

While the CNN feed (and most others) are down at the moment, this feed shows multiple views of the LMRP being prepped (Heading Out's diagram makes it very easy to identify different aspects of the LMRP). The ROV capabilities are downright impressive operating under such extreme force.

Good luck to all working on this at the moment. And for my colleagues still awake, check out the feed... it's really remarkable stuff. Take care!

google MIRC and download it

Just a data point: when I did this, my anti-virus program (AVG Internet Security) flagged it as malicious software. I don't know whether or not this was a false positive, but to be safe I didn't install it.

As another option, I discovered that if you use Firefox you can install the ChatZilla extension. If I remember correctly from the other day, it will launch itself the first time upon restarting Firefox, but then after that you can launch it by going to Tools > ChatZilla in Firefox to use it.

Tnx Prof. Goose, HO, Rockman, alii, rube, and all. I’m new to TOD, found you after Deepwater Horizon burned and sank. I know one of the young men killed that day, in the mud crew, and I’ve also put in some time in the GOM oil fields offshore LA and TX. Now I’ve retired to a camp 10 mi inland from the coast, so feel at least partially qualified to add my 2 cents now and then to your one-of-a-kind discussion forum.

But thought and emotion is ramping, no? There are extra voices in the meeting room. Some of you think too many; others work toward fitting them in. Underwater oil gushers beget online yak gushers, pure and simple. Is there a way to persuade comment makers that space and time--be they online, in the human mind, or under or above the waves in the GOM--is a limited resource (I didn’t say peak) and might not want to be wasted.

TOD is not the hot spot for self-expression and narcissism. They pollute it. They compete with TOD information, which includes reports, news, ideas, expertise, experience, wisdom, awareness, and of course opinions (which we all know are as numerous as rear ends, but at least give warm bodies a place to rest upon). Is there a polite way to ask: Please don’t wax here.

I don’t know how to address you “conspiracy heads” and other doomsayers? We should listen to the best of Peak Oil argument, pro and con. We should open up to alternative energy suggestions. We should hear about mitigating corruption--at corporate, government, and personal levels. We should entertain ideas to clean up all our actions. But TOD is not the hot spot to grind an ax. And neither is it a “Keep Your Big Fat Flapping Mouth Shut” site.

Can TOD continue to recommend and strive for balance? Easy does it, as always (especially in crisis mode)? Isn’t TOD looking for the truth? What’s that, you say? It’s wiley. It’s not comfort, not pain, not a swell heaven or hell on earth--but what’s happening now. I know, what’s happening now is debatable. But isn’t that why we come flocking to TOD? Don't we come looking for the truth, in any size, as soon as it becomes available, as soon as any of us notice it trying to escape? Don't we come to pay attention and learn, together, or not?

Conspiracies happen (1. An agreement to perform together an illegal, wrongful, or subversive act.) Any time two or more people get together to plan an illegal act a conspiracy has occurred. Only spontaneous acts of crime or crimes preformed by one person are not conspiracies. To not suspect conspiracies is naive as Julius Caesar found out (et tu Brute?). Doom has happened before it will happen again. Civilizations fall (unless you think the Mesopotanium, Mayan, Roman empires still stand and the Soviet Union is still that rather than the Former Soviet Union). Tsunami's kill thousands or hundreds of thousands, Chernobyl happened. Several hundred thousand were killed in the Haitian Earthquake. Several thousand were killed in the Dow Chemical accident at Bhophal.

Conspiracies happen and sometimes doomy predictions come true. Your "truth" might just be wrong you know. Who should be the arbiter of truth on TOD - you? Environmentalists said such a disaster as Deep Horizon could happen. BP said No and also said therefore exempt us from some precautions so we can make more money. The one's predicting such an event were not listened to and lo and behold they were right and and BP wrong. In fact is certainly appeared that people at BP conspired to hide the difficulty of what they were doing and hide the fact that they were just cutting costs from MSM who was more than willing to be Wink Wink duped into granting exemptions. All the while the lobbyists were conspiring to feed lies and money to Congress. The only other explanation is that the decisions makers at BP are idiots, the decision makers at MSM are idiots, the lobbyists are idiots, and our congressmen are idiots. It is true that the mass idiocy theory seems at time plausible, but come on we all know a whole bunch of conspiring was going on.

Following on from westexas's posting on the thread that just got closed, I'd suggest that 'conspiracy heads' are the biggest issue; at least BP are trying to solve the problem.

As a viewpoint relating immediate discussion back to the main purpose of ToD, I'd suggest that this is a useful experiment to see how the general populous and politicians react to oil related issues outside their understanding. Rather than trust, what we see are wild accusations and loony ideas that run far ahead of any evidence. We also saw something similar with the first oil price spike where conspiracy heads ignored supply constraints to blame 'speculators'.

Now map that across to Peak Oil setting in. What do you think will happen when you start getting supply constrictions at any price? Ones that don't end and hit the pumps?

I'd suggest the evidence from this is a massive blame game based on wild suppositions, together with impractical ideas of how to solve it. Not only will we have 'drill baby drill' on any potential reserve pocket, we'll have attacks on the oil companies for imagined or real deficiencies, political interference, and a sizeable call to "go take back our oil". All of those are serious, but I'd suggest the middle one has not been recognised to date.

Far from allowing the oil companies free reign to get more oil, it seems likely they will get hamstrung by outside forces. We can expect senators playing political pork games to get drilling in their region, even if the chances of success are low. We can expect ration allocation games based on regional politics. We can expect 'commissions of enquiry' poking into oil company processes and history. Frankly, given the age of many in the industry, we can see the possibility of the old hands getting out to avoid the hassle, and because they know the practical situation.

As much as the cyclic nature of price spikes, I's suggest this would seem to be an identifiable stage of a post peak world. Call it the "March of the Idiots" stage in our oil decline.

Oil co's already getting hamstrung all over the world...just gonna get worse, especially if domestic drilling gets regulated to the point where it is unaffordable (and having said that - it obviously needs SOME more oversight). MOST of the oil, and MOST of the production in the world is owned by national oil co's in other countries. And they aren't necessarily all that interested in playing nicely. Russia (one of the largest potential non-Opec suppliers) is getting the reputation of being a mafia-type government, and I have seen talk about 'energy cold war'.

Personally, at retirement I'm gonna move to a moderate climate and try to get as 'off the grid' as reasonably possible w/o going survivalist.

I'm also making myself a hole that I can crawl in and pull in after me.

:>)

The implication seems to be that now the oil companies will be too restricted to go get us the oil we need. Perhaps you've heard of Peak Oil? This thread is all about what happens when oil companies are free to operate with the most minimal of oversight (regulatory capture), and all the easy to get oil has been had. The other thing that happens when oil companies are free to use their best technologies with little restriction in a post peak environment is that oil production rates continue to decline - as Jeffery Brown has so often pointed out concerning Texas in the 70's. It really makes very little difference if a few regions are delayed or off limits in terms of the effects of peak oil. As awful as this spill is given the massive quantities of oil that are leaking, this field is but a tiny thing compared to our appetites.

As far as other countries and companies not playing fair - well, did you expect them to, and do you really believe that the "civilized" industrial west plays fair? On the way from 7billion people to something far less, there will be very few volunteers. The "Great Game" is just a name, it's anything but.

Nice? nah - everybody strong arms everybody else.

Effects of peak oil? No everybody cooperating doesn't change the effect - but it could change the timing, and allow more time for better alternatives being found.

OTOH...did you miss the part where I indicate I'm planning on crawling in a hole and pulling it in after me?

There's no need - we all and up in the hole eventually. Until then, we may be able to do something helpful during the beginning of transition that will make up the rest of our lives.

I know we will use whatever oil we can get to, because we spent a long time building a society and infrastructure that requires it and there is so little time left. But the effect of doing that may have a net negative impact on the survival of those who come after us.

Exactly right! Even if this entire leaking reservoir ends up flowing into the gulf, that would mean an amount of roughly 100 million barrels will have been spilled (based on estimates I've read). A massive amount of oil, until you realize that humans currently use almost that much oil every day of the year (roughly 85 millions barrels per day on a world-wide basis; counting all petroleum-based liquids). So the total output from that entire oil field could have kept the current world economy running for about 30 hours, tops. And that 85 million barrels a day is looking more and more like the high water mark for world oil production.

Gasp!!! Are you trying to say it wasn't all part of the big plan to bring on Cap and Trade? More Globalization? I am sure Alan from big easy will be delighted with that turn of events. He is dreaming of an oil transport free future. We are all going to get government rebates from our new government bicycle program.

Look at Westexas's Export Land Model (ELM) and you will see that oil supply is going to get shorter faster than most imagine, even those that believe world oil production has already peaked.

Basically, oil consumption in oil exporters grows. Saudi Arabia and Russia and everyone else takes care of the home folk first. Since both nations are past peak, production declines a little, but oil exports decline a lot.

Now can the USA outbid China, the EU, Japan for what is left ? All those listed except the USA export a lot of stuff. We don't.

May be a good idea to get a good bicycle before the rush.

Alan

The only offsetting thing would be food. China, EU, and Japan will be importing food. The USA can export food (calorie-wise, if not dollar-wise). Food may be the only thing a country would be willing to trade oil for.

Part of the point of posting the above note is that I don't think its going to end up being down to 'outbid'.

With the level of distrust and hyperbole we've seen over something as commonplace as an oil spill, I'd suggest we as a society aren't going to take the rational route. Its going to be recrimination and military force. Not only are we going to scrap over access to oil, we'll blame any and everyone (probably with an unhealthy dose of "why don't they do this"). The very groups that could potentially alleviate the downslope will get attacked.

Expect a massive built out of coal mining and liquification, and at least a few lynchings. Oh, and expect to see tankers that are going across the Atlantic and Pacific to transport oil to the US to be blown out of the water. Battle of the Atlantic in reverse.

I don't disagree...masses of humans and 'rational' frequently don't belong in the same sentence.

However - just to stir the pot a bit (altho this should probably be on a different thread)...when I started in geology in 1974 (DAMN I'm getting up there!!!) the mantra was "all the easy oil has been found and we only have 30 years of oil left". It's getting harder and harder, and arguably messier, to find and extract...but I still hear 'we only have a few decades of oil left' 30 years later.

But that was true. The production curve lags the discovery curve by 40 years, even though individual oil wells can be brought in faster than that. World discovery peaked in the 1960s, so it was true that the easy oil had been found before 1974. No supergiant oil fields found in last couple of decades except "Cash-all-gone" in Kazakhstan, which will take years, if ever, to produce 1 million BPD of heavy sour at great expense.

PS - I gotta say that one thing that is scaring crap out of me right now is the really deep plumes the scientists have been finding. One is apparently at 10K feet down.

Very bad just in the GOM..but at those depths, I worry about it getting entrained in some of the colder currents and traveling farther than even the loop current goes.

Anybody got a good reference on deep currents and their directions of travel?

You can see the direction and speed of currents down to 3200 feet in the area by viewing the data from Shell's Ram Powell PLatform ( scroll down to "Ocean Current Data") http://www.ndbc.noaa.gov/station_page.php?station=42364

Discussion including deep warter flow:

http://oceanexplorer.noaa.gov/explorations/02mexico/background/currents/...

Relief map:

http://www.gulfbase.org/facts.php

Confined basin walled off by Florida Strait with a deeper connection to the Caribbean Basin. Poorly studied - as are many such things. Now we have a nice experiment going.

There is a pdf here:

http://www.gomr.mms.gov/PI/PDFImages/ESPIS/4/4306.pdf

describing another study.

good articles! thx!

At the risk of being slightly non PC, it seems to me that our policies towards Iran are somewhat short sighted. We encouraged them to develop a nuclear capacity years ago, so as to minimize ELM impact. Now, two successive presidents have decided that nuclear engineering to, according to the wingnut who runs Iran today, produce electricity, is a subtrafuge for THE BOMB. Of course we cannot be certain that religious zealotry would not in fact use that nuclear capacity for such purposes, after all, we did the bomb first, and electricity after.

Still, I can't help but feel that we are a bit flighty and inconsistent, and maybe even justifiably paranoid since we support Israel, and Ahmajinidad has a stated goal to eliminate that State from the roles of sovereign nations. I am still of the opinion that most of our posturing and bluster in the Middle East has to do with oil, not Faith. And, more with money than with mankind.

The end may be at hand, but until then there is a buck to be made, eh?

Courage!

Craig

Your statement is incorrect Ahmajinidad did not say anything like destruction of Israel. Never once did he say that, what he did say was the destruction of the Zionists. The Zionists have the same policy towards Iran. Two very different meanings and distorted by both parties. Israel has never claimed to be a Zionist state that I know of.

I was hoping they will start one of those government rebate programs for one. Kind of like the cash for clunkers thing. Well I guess I will be going to the gun show this afternoon before we run out of ammo too. Prices are going up you know.

From the sound of the doom and gloomers in here on the drilling industry and the oil industry in particular, Future Shock is arriving. Best be stocking up.

Transport will be substantially oil-free in the uncomfortably near future, whether we like it or not. The question is whether we will have a superior alternative to bicycles.

EDIT: The question is whether we will successfully use our dwindling resource base to transition to a superior alternative.

I heard the President actually talking about using oil as a bridge to a non-fossil fuel future in his press conference the other day. Too bad we didn't hear Nixon say it, there was still enough time back then.

The trouble is that the world is using all the oil that the world can produce and the amount it can produce is starting to decline. In order to use oil as a bridge to non-fossil fuel we have to ration its use now. ie in order to build high speed electric rail, lots of solar panels, lots of windmills we need oil as we are not currently geared to do that kind of manufacturing and attendant mining with nothing but electric. So to use our declining energy to bridge we need to reduce the use for other purposes - driving, manufacturing, heating and cooling etc. The question is how do you sell that to the public. First you have to convince them of the reality of Peak Oil.

Per the Hirsch report we need 20 years to prepare BEFORE we peak. Since we have peaked we are 20 years too late

http://en.wikipedia.org/wiki/Hirsch_report#Conclusions

I think that future is one that I'll be long gone for, unfortunately...

I'll do the bicycle when I move to a climate where I don't either die of heat stroke, or get my nice work clothes all gross from sweating on the way to work! Actually, for short jaunts, I might try pony instead.

> 'conspiracy heads' are the biggest issue; at least BP are trying to solve the problem <

What the heck? TOD becoming a public relations channel?

I've followed these discussions, gCaptain, Drillers Club, Congressional testimony, and Coast Guard hearings as carefully as anyone else, and I am convinced BP should be indicted for manslaughter, GoM assets seized as surety for civil damages, and thrown off the lease block immediately. Farm out well control to bid or form a consortium of Exxon, Shell, etc, and have US military clean up the spill.

BP cheerleaders really disgust me, especially here. I signed up to say that. Regards to regulars and editors.

Alan von Altendorf

Hi Alan,

The comment from WestTexas that I believe Gary was referring to at the start of his comment is: "Don't know who is worse--BP apologists or conspiracy heads."

I think if you look at Gary's comment again, with this in mind, it might be you misconstrued what he meant.

On Westexas' question as to which is worse:

Conspiracy heads can be used to shake up the system, perhaps to the point that something breaks and allows some movement. OTOH, BP apologists push towards BAU NOW! More of the same, until collapse!

BP's only redeeming social value, IMHO, is that it pays the wages of a large number of wage slaves --- until it lays them off and transitions into a hedge fund. Could BP purchase Goldman as a way to escape from the oil business?

The ones who really scare me are the conspiracy heads who blame in all on Obama and are also BP apologists. The two positions are not mutually exclusive.

Let me tell you something, I have been following this crisis from day one and I would like to say THANK YOU to TOD!!! This site has really made me OPEN my eyes!

I have a simple question..dont laugh Im a simple man.:)

I have been reading up on the LOOP (Louisiana Offshore Oil Port)...

How much more oil will need to gush into the gulf before it is closed down? Will it close? What are the chances of it closing for a long period of time? Everything Ive read tells me if it does shut down WE are all in for a world of hurt..

Again much thanks to TOD:)

There was discussion about that in the May 7 Drumbeat.

Do you think "breaking" the oil companies is going to improve the circumstances of peak oil any?

I'd suggest BP et al have a major redeeming social value, they keep the fuel flowing on which we depend. Oh, and in BPs case they create their yearly statistical survey that gets used here again and again.

Its easy to make knee-jerk reactions, here's hoping that cooler heads will prevail (although Obama hasn't exactly covered himself in glory, and he's the sanest US president in a long time).

About time the "idiots" marched!

It is extremely shortsighted to defend oil company's. Deepwater is so visible because it is off the coast of America. As you clearly are a long time Drummer and commentator, surely you are aware of Big Oil's messes in lesser known or reported places like the Niger Delta? Massive pollution, use of paid and supported dictatorships to violently quell local opposition?

The absolute plight of East Timor, of course the blight of Oil money on the middle east. The list is extensive and undefendable in any way, morally, conveniently or otherwise.

While you vehemently claim otherwise, your views are those of an apologist for the world's dirtiest industry, driving the worst experiment in "civil"ization.

Strange. Very strange.

If you take the time to go through to multitude of articles on this site, you will rapidly realise that the potential threats faced dwarf any failings of corporate governance in BP you may like to point to.

Really, as these things go, its a whole other order of magnitude.

Focusing on throwing blame around misses the big picture. Saints or sinners, accident rates in complex projects will result in spills, and in themselves they don't change much (I'm going to catch flack for that, but it true). Its how we deal with it that informs the 'peak oil' scale of problem.

Honest, give an afternoon over to reading through the back catalogue of articles - you don't have to apologise for any oil companies to say that corporate malfeasance or otherwise isn't the elephant in the room.

Gary, while I really appreciate the Oil Drum as a resource, this is not the only place in the world to understand peak oil. I'm new here but old enough at life and well read enough and informed to know what I am talking about.

Seeing the thread of your responses down the line, I see that you use circuitous reasoning to drive home the same point, that BP is ultimately doing us a favour.

And then you say things like "At least they are trying" and "trust them" or words to that effect.

Hmmmmmm..... clearly BP is more concerned about legal ramifications and the size of the compensation than keeping the public really informed, as they have every right to be. There are visible lies and obfuscation at every level of this.

I am more convinced than ever of your apologist nature now.

And I do not need to read the back articles here to support that view.

If peak oil is the wall this ugly "uncivil"ization needs to hit, especially the American way of waste filled life, then I say hit it and take it like a man, like a people. You way has been the absolute ruin of most culture and many many people. And of your own people too. I've lived in the US for many years and know it first hand. It is a classic pattern of fall: first Moral, then physical then fiscal then war then bigger war then bust with bloodlust.

I suggest you check out Extreme Fighting or WWF or whatever it is called nowadays to see what I mean.

It's about time it's impact dwindled or died away.

"If peak oil is the wall this ugly "uncivil"ization needs to hit, ... then I say hit it and take it like a man..."

You mean just take it out on somebody else? ;P Seriously though, thank you for your post, couldn't have said it better. The longer this culture keeps on solving problems, the deeper a mess all life will be in, and it's way too big a mess already. Thanks. And a big hat tip to TOD for the coverage of the spill so far.

Hmm, well OK. From the B&W way you write I guess there is no way to convince you I'm apologising for no-one. I'll live.

However, I would suggest that throwing away civilisation as "it's about time it's impact dwindled or died away" rather ignores what that means in both the small and big picture - so I'll leave you with a quote:

"Do not go gentle into that good night."

Gary, A truly in-formed individual knows full well what it means. And I'll say it again for emphasis, it is high time industrialization as we know it disappears and it will not go gently into the night. It has hung on kicking and screaming in the face of all the havoc it has caused and is causing.

Do not want to take up too much space here but maybe it's time for individuals to look into themselves and really really see what in most of their god-forsaken lives is worth saving, to justify that oil must flow? That their life-"style" is too precious and that a jarring interruption of freebasing at the expense of 90 percent of the world's population is just not worth the price?

And yes, it is time for black and white in case you had not noticed. We are at a tipping point not in just oil, but everything. The fabric of everything that this facade is built on is stretched thin, to the point of breaking.

Look around you.... you will see confused OLDers, very few Elders (most are kept away in retirement homes anyways), disenchanted and mostly vapid youth, children (yes, even 30 year old children) having children, a money system spinning out of control, Sportsmen (so many felons, frightening) paid 1000X teachers.... the list is long.

And in a fractal world, it all matters.

So if the Oil spill is what broke the Oily Camels back then I say so be it. Such a weak edifice, it just might crumple with a sigh not a storm and give those of us with ideas for a brave new world some place to breathe, experiment.

And I am not speaking as some air-headed utopian here. There are much better ways and EVERYONE who says it will take too long or cost too much is still caught in this paradigm.

Try living without TV (at all, zero) for 10 years and develop a genuine media free mind-flex, then make philosophical statements that belong to you, not a filterate of other peoples noodling, howsoever wise it may sound or be.

Okay garyp. Here is the first load of flack.

I think this mess in the GOM is not just a BP thing. It is an announcement that maybe, just maybe, we should stop drilling in risky places because we cannot afford the damage that a mistake will bring. How long do you think it will take for the cleanup? What is the ultimate cost here, in terms of lost fisheries, wildlife, and sustainability? It appears more and more that the Gulf Cost of the United States has been devastated. It may be decades before any real restoration can be expected.

Is driving a big damned car or truck really worth that? Hell, No!

We gotta change the way we do things. BAU is dead --- it has drowned in the Gulf of Mexico.

So, I guess I agree that corporate malfeasance isn't the only elephant in the room. It is still a pretty big one, though, and corporate greed that leads to corporate errors in judgment and mistakes is no longer acceptable!

Other than that, it's all good.

Courage.

Craig

Well no, but there are many bigger reasons why that's to be avoided.

Put it like this, oil has spilled into the Gulf before (Ixtoc being the pre-run), and marine life has taken a hit, but recovered. Compare that with the slow, steady, acidification of the oceans and the millennia long impact and mass species die off that results - globally.

Its a failing of our species that we find it easy to get worked up about the local and close to home, and ignore the big elephants. My contention is that focusing on BP and its market-led shaving of safety rules for profit similarly misses the big elephant that its these companies that will be the shock troops of a post peak world - and like it or not they will determine the severity of the downslope. The cultural behaviour that shoots the messenger and at the same time buys the 'big damned truck' is not one that going to play rationally with the consequences of decline. That's the take home that I was highlighting, the same scapegoating that makes it easy for people to cast stones at BP is going to ensure that those shock troops of the oil downturn are going to suffer a "Life of Brian" result.

The problem with scapegoating is that it's a release of anger and frustration which has then disspiated. What worries me is that, rather than taking away the message that there are some tricky trade-offs coming in energy where the populace needs to decide which risks are and aren't justified and over the long haul force governments and corporations to follow these assessments rather than their own, we'll have the populace at large a couple of weeks of ranting about BP and ostentatiously boycotting them and then go back to normal.

In response to Gayrp

Perhaps you did not mean to rationalize the negligently criminal behavior of British Petroleum, but that is precisely what you have done. Using the sophisticated analysis of 'down slope technology' and 'post peak world' to describe British Petroleum will not excuse the fact that BP has destroyed the Gulf of Mexico-I invite you to read the blog http://gulfblog.uga.edu/ to see and understand the extent of the damage done. Or look at all of the pictures and weep, if you may.

http://www.washingtonpost.com/wp-dyn/content/gallery/2010/05/12/GA201005...

I will not stand by while alibis are delivered and a spokesperson (voluntary or otherwise) condones with excuses made for whatever reason, that draw a picture of the rest of society as the culprits who were the enablers motivating BP to engage in the destruction of a whole ecosystem. BP did not HAVE to destroy the Gulf of Mexico in supplying oil to the consumer. They chose to do that. They ignored for weeks, serious 'belching' of the sleeping dragon that was to emerge beneath Deep Water Horizon. They willfully and knowingly (consciously) ignored all of the Government guidelines on safety

http://www.propublica.org/documents/item/bp-internal-investigation-memo#...

Yes, the Government screwed up big time and more on that later. For now let me just summarize, as I see from reading the rest of the posts here that there is talk about this 'conspiracy' theory or that 'conspiracy' theory.

Conspiracy, noun: a secret agreement between two or more people to perform an unlawful act

http://onelook.com/?w=conspiracy&ls=a And yes, more than one person can be in on a secret.

secret, noun: something that should remain hidden from others (especially information that is not to be passed on)adjective: not open or public; kept private or not revealed ("A secret formula")

Putting it all together, by operating in secret (how many folks knew before the dragon blew his nose that BP was running their feathers across it?) BP conspired to destroy the Gulf of Mexico in pursuit of what appeared to be at least 50 million barrels of oil. http://www.bloomberg.com/apps/news?pid=20601072&sid=aawwCXDN1UsM

About those Big Trucks-what if everyone was driving a Prius, or a similar vehilce? Would we as consumers still be playing the 'blame game' when we asked BP to behave as rational adults in supply products, services and have some concern for everyone's safety and well being? You mention market-led shaving of safety rules. Am I to understand that because it was market led, BP's behavior can be given a wash?

To summarize, BP is not in any instance to be cut any slack whatsoever. They made decisions that have changed the world for the worst in a big way. By, the way when you say 'marine life has taken a hit, but recovered' were you assuming that would apply to the present scenario and the ecosystem of the Gulf of Mexico will eventually recover? Even after some animal and plant life is driven to extinction by the foolish acts of a money grubbing, nefarious group of sleezy, rotters who don't give a rat's ass about you or anyone but are only looking to take as many cookies out of the jar as possible even if the rest of us get deathly sick when they puke their guts out from overindulgence?

I have some news you may wish to read.

http://www.usaliberalism.com

I will gladly and courteously respond to all comments made to this post as far as I am able to.

ohregionalindian

There is a good article in the Guardian

about the far greater plight then the

Gulf of Mexico in the Niger delta

http://www.guardian.co.uk/world/2010/may/30/oil-spills-nigeria-niger-del...

Hi Nick,

Thanks for the link, and it is a terrible situation there, has been for a long long time.

And this is the attitude of all big industry in the developing world. Big Pharma, a cozy twin of big oil is equally ruthless. India has been a favourite, rule flouting clinical trial ground for them as have many smaller nations.

Not to forget Union carbide, still fighting in courts not to pay victims for the Bhopal episode.

http://en.wikipedia.org/wiki/Bhopal_disaster

So what I am ranting against is not just big oil, but big everything.

Big is not beautiful we have reached the limit of "size" that we can control.

But ingrained bad habits are hard to let go of.

When I think of big industry, I am most reminded of Gollum from Lord of the Rings.

Preciousssssssss......

Interesting, so when did you give up driving, and your computer and anything else that you use or touch made from plastic? Interesting since almost everything you use or touch used energy to bring it to you. I know it is hard to fully visualize until you don't have it, but alas it is true. Are you fully ready to give up all of your toys? If you are then I suppose we won't be seeing you online much anymore.

Good luck been interesting knowing you and your viewpoints. I have heard there are religious groups like the Amish around the country that try to live without using modern conveniences of any kind, although they do still use a little kerosene for their lamps. Kerosene does still come from oil also however, so even they can't claim to be completely oil free.

Hey wireline,

You seem to be saying: because we all buy products wherein BP may be the original source of materials they were therefor given license or we as the consumers are the enablers for them to go out and commit ecocide.

?

Scoobie Doo moment here; "Mmmm?"

Not sure I follow the logic but again, we as consumers choose to make choices about plastic and purchase that item, (let's pause and think of how many building projects, how many electronics in hospitals, police stations, health clinics, how many airplanes, how many. . . would all shut down while we boycott BP's products that end up in a plastic item) we are then enablers to BP's criminal actions. Actions that now include bringing in the police to make sure we don't see the extent of the destruction of the Gulf of Mexico. http://motherjones.com/environment/2010/05/oil-spill-bp-grand-isle-beach

BP could have chosen to NOT destroy the Gulf of Mexico but they did not make that choice, rather, they deliberately, with chosen speed of their own making, with clear foresight about what they were doing, decided to expose us all to 150,000,000 gallons of toxic sludge and allow it to spread around the world's oceans.

search www.nakedcapitalism.com for May 9, 2010 posts for that link.

BP sent the Schulmberger folks home who were going to run a definitive test showing the drill was flawed, so there would be no evidence of the flaws after-wards.

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/costly_time-consuming_test_of.html

Schlumberger's isolation scanner testing to evaluate wellbore integrity is described at their website.

http://www.slb.com

WE all need to change our lifestyles and we as a society should get control of harmful practices inside of the consumerism behaviors and mind set. Meanwhile Tony Hayward should be preparing to have an excess of free time to sit in the yard and practice his guitar all day long.

http://en.wikipedia.org/wiki/File:Federal_Correctional_Institution_Herlo...

How will they apply pressure to the seal? Is the device goign to fit around the flange and then use that as leverage?

...very carefully. I would imagine that the weight of the unit itself will probably be enough to seal it.

But installing it is a job I don't envy!

The renderings shows latches. This device clamps onto the flange.

I appreciate the work that goes into TOD and the unique information and outlook it has always provided.

I would like to make a suggestion. How about starting a separate thread for the solution suggestions? To minimize bandwidth, perhaps require that all drawings be hosted at one of the internet's many free picture sites? That would provide an outlet for the creative solutions ("Let's stuff all the jelly donuts we can find into the hole! That will help put the entire US on a diet, too!), while maybe allowing the discussions to stick to items related to the current events.

It might be worthwhile to separate out the discussions on local littoral effects into a separate thread, too.

Respectfully submitted,

YAR, will definitely consider that. Honestly, we've just been trying to get through the weekend. :)

But yes, we're going to need a local component to this coverage, as well as solutions throughout. I hope folks aren't too pissy about the tack we've taken, but it was the best way we saw through this.

Christ, I sound like a BP PR guy there. Apologies.

nah, yr doin good

btw, i watch the feed on bp's site and pause yours (when there) to save your bandwidth ...

Seriously, it is not TOD's bandwidth. We just have the video embedded (HTML code). If TOD was actually streaming the video, Goose would be even more excitable. Honking, even.

LOL! (I have to clean off my keyboard now)

Prof. Goose: Self awareness is an adult trait. Thanks for your work and tolerance. As I said in an earlier post, this site is what the Internet is supposed to be. Bye the bye, you're never going to have your 501c (3) status yanked for failing to provide an education to the pubic. Boy, oh boy!

I'll second that. I have some experience blogging on public health emergencies, where we have the same problem of sudden increase in traffic when an outbreak is happening, with many new posters unfamiliar both with the science and with lots of speculation, and we run the risk of overwhelming noise, as stated by others.

While this is precisely the time when sites like TOD is performing a great public service (donation on the way, much appreciate all your hard work!!), I also think the 'hive mind' works best when new posters and non-experts have a place to share their ideas

May I suggest keeping 2 open threads, one for speculations (ie any ideas, rumors, speculations, that are not referenced or linked), and one for asking questions, with a heavy caveat to please make a good faith effort to find the answer first.

Many many thanks again. I have some idea of how much work this is, been there, done that...

What Hiver said. I am one of the medical people with just enough math and science to make me dangerous in a place devoted to engineering and geology, so I will just express my appreciation for what you are doing here and say a hearty thank you.

"May I suggest keeping 2 open threads, one for speculations ..."

I doubt that would work. The newbie speculations tend to be as ignorant of the realities as I was a short time ago, and I can't imagine who would read them, if the alternative of reading Rockman's speculations were available on the other thread. Other old timers would also draw audience to the non-speculative thread. The whole point of trying to post here is to, maybe, have your ideas read and criticized by intelligent experts. (Yes, there are also stupid experts, who tend to populate the news media.)

My two cents on the censorship issue:

The primary problem is not that some wag posted something assinine on the internet.

The difficulty is that TOD's format is not able to smoothly handle a discussion of this character.

TOD is set up in an article & comments format - someone posts an article, then all of us post comments until we lose interest. In this case, however, there is an ongoing crisis and media circus, and the commentary isn't losing momentum in the first hundred posts, or event the first four hundred. New threads cannot be created for these comments because new threads on TOD require an article. So, there is nowhere to put unrelated but otherwise legitimate comments.

The solution really is censorship - Self Censorship. My suggestion: Keep comments on side issues as replies to previous related comments without replying in a new window (the closest thing to a separate thread that TOD's format allows), and follow basic netiquette. If you think your side issue is important enough, consider creating an article. And don't waste a lot of time griping about how people should be posting in alternate threads that do not exist.

A separate article is a good idea, because a separate thread is a good idea, and that's the only way you get a separate thread around here.

Y'all are doing an outstanding job. Nobody with half a brain would think ill of you for tightening up a bit.

If there is an award for Blog Journalism, the TOD staff should receive it!!

If nothing else, this disaster has exposed more people to what TOD has been about for 5+ years now. Perhaps, ultimately, this is the silver lining....broader awareness of our current global energy situation.

I dunno - I'm not sure all the new visitors really appreciate the issue of peak oil and that peak oil is what TOD is about. Which is why I've been trying to re-introduce that subject here and there.

I have been here a long time and this is the first time I am hearing

CENSORSHIP! This I will not be part of. If this continues I am done after several years here. Who cares if the newbies feelings are hurt. Grow up the world is about to get very hard and you will be lucky if you have time for feelings.

This is rather contradictory, let alone confusing ... do you want to run it past us again?

We've lost TOD ...it's become something else. It's pretty sad - but maybe we'll bounce back.

We'll be alright mate, at least Hrothgar is gone

True .. and I hope you're right, cobber!

Blogs go through phases. There's sort of a natural life cycle. No worries, this is perhaps TODs finest hour, and if not, it will 'bounce back'.

Cheers.

I think the LMRP has the most merit of any attempts to quell the leak from the riser/BOP. My main concern is that after removing the restriction of the bent riser with drill string inside, the flow will increase dramatically until the sealing grommet makes and remains in contact. Since the "package" will sit on the cut off and possibly slightly deformed riser stub, nothing will secure it to the BOP except weight, IMO. To prevent the force of flowing fluid from acting to push the LMRP upward the pipe to the surface better be large and held steady at the top.

If I had designed this device I would put about 100 tons of weight around the bottom ring of the LMRP to help hold it down on the BOP. That weight would also act against the pressure fluctuations in the riser. I have had experience designing components for aircraft hydraulic systems that have high pressure, but nothing with this kind of flow and force on components.

I wonder if 100 tons will be enough, assuming that you are using garden variety avoirdupois tons. Once installed, I would imagine that the weight of the unit itself will be enough to stabilize it. But if the opening is 18-7/8", that's just under 280 square inches. If one of the gas kicks arrives during the placement operation...I'm glad it's just expensive equipment that will be around.

(Yes, I know the flow is constrained, and that it's less than 18-7/8" at its narrowest point. This is just for instance.)

If I read things correctly, they aren't trying to plug the top of the BOP with this thing - they are merely trying to attach an contraption that would allow them to capture the oil and bring it to the surface.

I wonder if 100 tons will be enough,

I don't think you need to add any weight at all. It is very similar to the RIT tool in that they are going to provide a path for the oil and gas to flow. So long as they don't block the path, there will be minimum upward pressure that will push the LMRP upward. I think the tricky part is when they try to reduce the flow on the surface.. But since the RIT can stick to the riser without problem, I would think that we won't have problem here.. The more issue is whether the ship on the surface can flare all the gas given that they are trying to capture most of the spill not just part of the spill with RIT. We already see how much gas can come up...

Until BP provides pressures and dimensions no one can really offer well-considered suggestions.

With respect to thst "top kill" solution, a simple topside simulation (or a mental exercise) would show that even with all flow stopped, the amount of mud they could have pumped through those two adapter pipes would just have drizzled down the side of the downside tube. What a waste of time!

Keep in mind that, once the pipe to the surface is full of oil, there's not going to be any pressure gradient blowing oil out into the water at the junction. In fact, there'll be a huge *suction*.

The situation's much like a chimney. Once you fill a chimney with hot air, it creates a natural draft that sucks up more hot air. Now, there is of course high pressure below the BOP, but the flow restriction on the way out means that's not controlling the pressure at the top of the BOP: all that matters is the pressure at the top of the pipe and the buoyancy difference between 5000 feet of oil vs 5000 feet of water.

Anyway, point is, some weight is probably going to be useful to make a solid enough seal to convince the oil to start going up the pipe in the first place, but once the pipe is full of buoyant oil the LMRP grommet is going to suck itself onto the top of the BOP. It'll be like french kissing a vacuum cleaner.

The idea of the pipe having any suction effect inside, relative to the seawater at 5000 ft depth, can't be correct. The density of the fluid flowing up the pipe is less than the surrounding water and that will have a bouyant force to move the pipe upward. However, the fact that the expanding gases, both separated and dissolved will tend to "shoot" the oil up the pipe with increasing velocity as they expand, creating frictional forces against the inside wall and want to lift the LMRP off the BOP.

The interior pressure of the LMRP at the seal will be less than pressure of the reservoir due to the oil flow not being restricted by the bent riser. As pressure in the reservoir (8000psi relative to the sea bed pressure), which is potential energy, turns into flow which is kinetic energy in the form of velocity, the pressure of the oil will drop, but still be far in excess of the surrounding sea bed pressure (2250psi).

As an example of this:

Turn on your garden hose full open at the faucet. Now try attaching a second hose to the one spewing water. You will have a hard time getting the fitting screwed on due to the pressure that is created by the restriction of the second hose. And you will have water squirting out as you join the two hoses.

goodmanj is correct

With the estimated flow, the pipe friction (which is distributed along the length) will be much less than the weight of the to be attached straw.

There could be "suction", or not, depending on the sizes of the pipes,the various numbers of vents, the size of each of the vents, the quantity of oil and gas, and the amount of oil/gas mixture that escapes at the junction;in order for there to be "suction", the pressure of the oil and gas column at the bottom of the pipe must be less than the water pressure at the sea floor.

This is obviously going to be the case IF (once) the pipe is filled with the oil and gas mix, and there is an opening allowing water to ENTER THE PIPES.This necessarily also implies an opening that will also allow a good portion of the oil gas mix to escape into the surrounding water.

If an insufficient amount of oil/gas is not allowed to escape into the surrounding water probably at level somewhat below the level where the water is supposed to enter, the well will pressurize the LMRP to well above the ambient water pressure more or less instantly, and the oil and gas will begin exiting through the holes where the water should be coming in.

Suction is a term that is subject to serious misinterpretation by laymen and trades people.We should really be talking about pressure differences due to differing circumstances.Since the oil/gas coming from the well is lighter or less dense than water, if the pipe to the surface is once full of oil and gas, and the bottom of the pipe is open to the water at the sea floor, the sea water will enter the pipe due to the weight of the five thousand foot water column being greater than the five thousand foot column of oil/gas in the pipe and PUSH THE OIL UP THE PIPE.

You cannot "suck" water up a straw but you can use your lungs to LOWER the air pressure in the straw by expanding your lungs so that some of the air in the straw flows into your lungs.This LOWERS THE PRESSURE in the straw, which was previously exactly the same as the ambient air pressure.Since the air pressure outside the straw remains the same, the pressure difference PUSHES the water up the straw.

The word "suction" should be probably outlawed in any technically accurate discussion.

But the more water that enters the pipe, the less the pressure difference becomes, and at some point the flow oil oil , water, and gas will begin to slow down.

It seems obvious to me that the IDEAL solution would be to clamp the new riser pipe as tightly as possible to the existing BOP , and utilize the pressure of the well itself to force the oil /gas mixture up the riser to the surface.It might be necessary to vent some oil the oil/ gas at the BOP to keep the pressure at a manageable level,meaning below some critical level, which might possibly be done through the existing fittings that were used in the attempted junk shot.

If this could be accomplished, the hydrate problem would be solved, as there would be no water in the riser.

My guess is that this possible solution has been considered and ruled out because the flow up the riser would be so great as to be unmanageable if the entire flow of the well is directed into it.The riser would probably start doing weird things like whipping around; it might actually break; or the irregular pulses of expanding gas might be too much to handle at the surface.

It may also possible that the folks in charge think the BOP and/or the existing pipes just below it are in such poor condition that allowing the oil to continue to continue to flow through them under high pressure will cause them to fail soon, and that a leak proof connection is therefore ruled out.This would not have been a problem in the junk shot scenario if it had worked, as there would have been no further abrasive erosion of the pipes once the flow stopped.

I can't see that it would be all that difficult to securely fasten the new plumbing to the old although doing so would obviously take some extra time.

If it were possible to make the riser pipe big enough, and to keep it from freezing up, it would be possible to capture the entire flow through it using the pressure difference due to the difference in the density of the water and the oil.

This leads me to wonder why it would not be possible to use a y type connection , or connections, and use two or three or even more risers to carry the oil to the surface and so capture nearly all of it.This presumes of course that the hydrate problem can be licked by either heating the pipes or injecting antifreeze, or both.

Sorry, I posted in nontechnical language to try to keep this thread readable. Not trying to show off here, but I have a PhD in climate physics: I know how the hydrostatic equation works. When I said "all that matters is the pressure at the top of the pipe and the buoyancy difference between 5000 feet of oil vs 5000 feet of water", what I meant was:

Above the BOP, the flow velocity is weak enough, and the pipe diameter large enough, that the friction force is small compared to the weight of the fluid. If friction is negligible, pressure and gravity forces are the only terms in the vertical Navier Stokes equation, and we have the hydrostatic relation:

dP/dz = - rho g

This is true for both the oil in the pipe and the water outside:

dPoil/dz = - rhooil g

dPwater/dz = - rhowater g

So the pressure *difference* can be found by subtracting these:

d(Poil-Pwater)/dz = - (rhooil - rhowater) g

For demonstration purposes, let's assume rhooil is constant. It doesn't have to be.

Poil - Pwater = (rhowater - rhooil) g z + C

The constant of integration is the pressure difference at the surface. Unless BP deliberately provides backpressure to prevent the oil from escaping out the top of the pipe, this will be zero.

Poil - Pwater = (rhowater - rhooil) g z

Plugging in some numbers (g = 9.8, rhowater = 1024, rhooil = 870, z = - 1524) we find the oil pressure is lower than water pressure by 2.3 MPa, or 23 atmospheres. So that's 23 atmospheres of "suction". And that's a minimum: if the pipe has some gas in it, and it will, the pressure will be higher. In fact, so high that BP may want to add some surface backpressure to control it.

This calculation is true no matter what the geometry at the BOP is: all that matters is the forces in that 5000 feet of riser.

The one caveat is, this calculation assumes that there's enough of a constriction in the BOP or in the formation that the flow velocity through the pipe is slow enough to render friction negligible. By my calculations, which I won't bore you with, that's true up to a flow rate of around 100,000 barrels a day.

How much extra work would it be to cap the newly cut pipe stub with what amounts to an upper riser flange piece that slides over (caps)the existing pibe with very little difference between the outside diameter of the cut old pipe( I think it is 21inch)and the inside diameter of the "cap" piece. The lower edge of the "cap" could be welded to old pipe , or one of the ROV with an attached hydraulic arm could apply circumferential pressure to the junction of the old pipe and new (think hose clamp for a visual) but with obviously enough PSI to hold the junction.

If the new pipe piece has a flange head, that flange could be bolted/welded by the robot submarine to a matching flange head on the LMRP...securing it indefinitely. Any takers on that idea?

I think that might work but for the fact that the riser is bent right at the BOP and it is deformed immediatly above the top ring of the BOP. Not much round pipe to work with. Good idea to use annular crimp connection, but if flow is constrained the force on the connection may be over 1000 tons, which is a lot for a crimped slip joint even if welded. Force on the weld would be 34,000 lbs per linear inch, so a thick pipe (3/4 inch minimum) and full fillet weld would be required (maybe use type 10011 weld steel).

In the future, maybe they will make the first 20 feet or so of riser extremely strong, so if the riser bends or breaks, it bends or breaks 20 feet above the BOP and not right above the BOP. Then you have some undamaged pipe to work with.

I am quite surprised they hadn't learned this lesson some time ago.

I hope deep sea drilling will be permanently banned. It is obvious we don't have the technical maturity to quickly address any problems.

Ofcource, once the effects of peak oil become apparent, the drilling will resume ...

From another angle, I am not sure that there will be enough demand if the credit crisis and peak oil cause economic collapse. I think you may get your wish regarding offshore drilling -- be careful what you wish for :)

Sadly you are correct. In a sane world, when the effects of peak oil became apparent, oil use would be curtailed and sustainable sources of energy invoked.

Of course, as you said, we are lacking sufficient 'technical maturity' to do that, aren't we. We will, in all likelihood, go merrily along, espousing growth and BAU even as we plunge blindly over the precipice of Hubbert's Curve.

Craig

Yair...I had always assumed the riser/production pipe would have passed through a structure on the seafloor...think a platform supported by a tripod or tankstand like structure.

I had imagined a main control valve and connect/disconnect mechanism would have been at the elevated position with the BOP below on the seafloor.

It seems to me I must have seen that situation maybe in a picture of a North Sea well...it would have been useful here.

Very good question nbnewtrain-

I have asked BP for the proposed length of the remaining stub and it's expected condition. No response.

I have some reservations about the 1,000 ton force number. How did you calculate that number?

None of us have enough information to accurately compute the force from the riser after it is cut. However, if the inside diameter is 18-7/8", that's about 280 square inches. 1,000 tons (US) would be over 7000+ PSI applied evenly across the entire opening.

I have seen many pressure numbers discussed in TOD since this blowout started. I would not suggest that the pressure will exceed 7000 PSI, and don't have the numbers available to really make any assertions.

But if an expanding gas kick came through while they were working over the remaining stub following the cut, it could set back the operation days or longer.

IMHO I would have retrofitted the old top hat with heating lines first, even only as a backup to this plan. But none of us have enough information to do anything but guess.

BP should have grasped the clathrate problem before deploying the tophat. The 'tophat' may have been constructed to contain the amount of oil BPs own PR stated was escaping; so it doesn't have the capacity to handle the flow...but it could...they could have pulled it up, installed heating lines and enlarged the pipe in a matter of a couple of days and dropped it on the well. Instead, they spent days threading a small line into one of the leaks in order to try to save the oil but that technique makes no sense to me. Why would the government let them do that and keep doing it for days while the plume continued?

In my opinion, their entire effort has been and continues to be committed primarily to limiting their liability and saving the well...or simply wasting time until the relief well is completed. They said the 'next' plan was ready to go if topkill failed, but apparently it isn't. Now they are talking about another week to get it in place. In the mean time we aren't allowed to see the other thirteen or so video feeds because watching might create confusion or even precipitate another failure? Is that what I heard? That can't be right.

First off this well is history, period, it cannot be saved and never will be. They will tie into the bottom pump the mud to kill it, cement will then be pumped and it is a done deal. They probably will attempt to clean off the top of the well as well, and that will require a little more cementing. Put a plaque on it mark do not disturb.

As far as the time goes...well, while I think I can sympathize with your impatience in these things, reality is, it takes time to tighten a bolt, turn a wrench, lower a pipe, etc. I am trying to be simplistic here about mechanical operations, but that is basically how it goes. Have you watched any of the videos? I know you carping about not being able to see all 13, or whatever, but I have watched the ROV's at work, cutting splicing, reconnecting etc. My hat goes off to those guys running them. While I know I have the capability to do it, I don't have the patience, they are doing that stuff hour after hour to get the job done. Sadly my friend it just takes time to do the physical aspects of any job.