The BP Deepwater Oil Spill - Why Top Kill May Have Failed and Monday Open Thread 2

Posted by Heading Out on May 31, 2010 - 6:15pm

Please transfer discussion to http://www.theoildrum.com/node/6558.

The Top Kill attempts have failed, and the Government has given its response.

He (President Obama) said US Energy Secretary Steven Chu was leading a team of "the world's top scientists, engineers and experts" in devising a contingency plan should the "top kill" attempt fail.

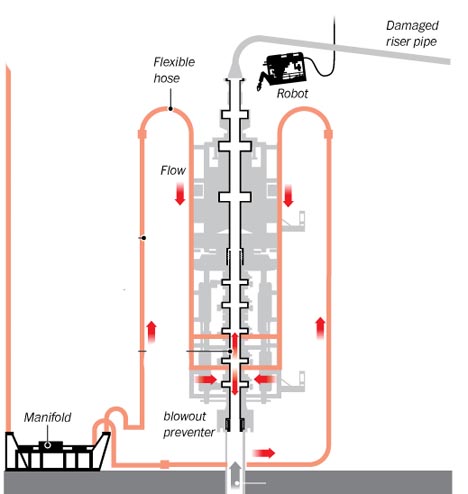

But while waiting for that, and for the Lower Marine Riser Package (LMRP), I thought I would spend a few paragraphs discussing why Top Kill may have failed as a substitute for my tech talk tonight; you can find that under the fold by clicking "there's more."

(The last post has a very technical discussion of LMRP, check that out there and in the comments.)

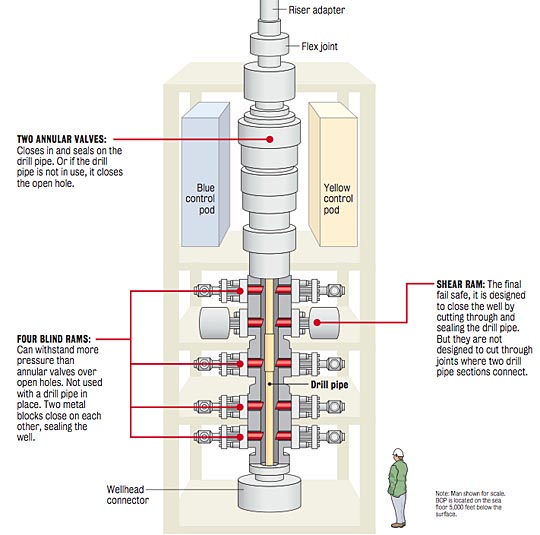

In a couple of earlier posts I wrote about how it was necessary to fill the gaps that ran through the Blow-Out Preventer (BOP) either with spheres and triangles or with wire (string would act similarly). To refresh your memory, in the initial simpler analysis, I had put up a simple sketch of the BOP and well, to show how the blocking particles were injected.

Simple approximation of the situation

Now, unfortunately that diagram left a significant part out, and that is that there are three sets of pipes leading down into the well. These are the well outer casing, which, surrounded by a layer of cement, holds the BOP in place. Then there is the production casing, which had just been set to the full depth of the well. And then there is the drill pipe that, at the time of the incident, extended down 8,367 ft from the platform, or roughly 3,367 ft below the BOP. That drill pipe (DP) had previously been used to locate the production casing at the bottom of the well, and itself now rode inside that production casing. In most normal operations it is closed at the bottom by a drill bit, but (and I’ll come back to this later), it had just finished the cementing of the production casing into position, and once it detached from that and was being pulled from the well, it was an open pipe all the way up to the rig floor. And in that condition, it could be used for other things. By pulling mud out of the DP and transferring it to the mud pits (or standoff vessel), the level in the riser would fall and be replaced by seawater flowing in at the top. Unfortunately this also lowered the weight of mud in the well, and that is what caused the oil and gas to flow into the well.

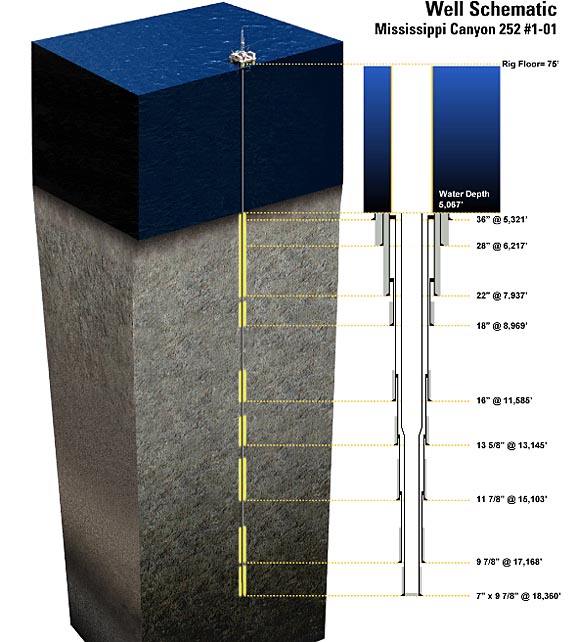

Outside of the DP is the casing and cement segments that make up the outer lining of the well. The diagram presented in Congressional testimony, shows these various pipes, except for the central drill pipe.

Casing and cement down the Deepwater well

BP do not know, but believe that the oil is getting into the well through the cement wall at the bottom of the well, and probably rising up the well through the empty space (annulus) between the production casing and the outer lining of the well. However the oil and gas may have broken through the bottom of the cement plug and be rising up within the production casing, in which it is also rising through the DP once the oil reaches its lower end. It could also reach the bottom of the DP by flowing up the annulus then go down the production casing to the bottom of the DP and then back up into the BOP.

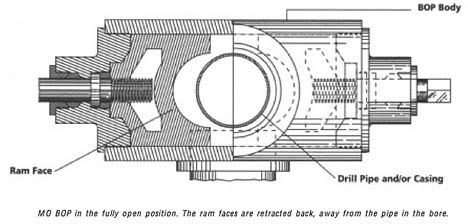

Most normal blowouts occur when the well is being drilled, and mud is flowing down, through the drill bit, and then back up the space (the annulus) between the DP and the rock wall. Thus, when there is a blowout, the oil and gas that flow into the well normally flow up this outer passage to the rig, and give the spectacular fountain of oil. The BOP was invented (by Harry Cameron and Jim Abercrombie) to stop that flow and to protect the crew at the surface. Because the flow is normally up the outside of the drill pipe, the initial BOP designs were rams that pushed seals across the flow path through the BOP, and sealed against the side of the DP.

BOP open allowing flow through the annulus (ASME )

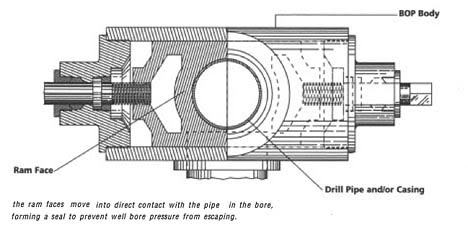

BOP closed against the pipe, sealing the annulus (ASME )

A BOP could have two of these mounted so that one sealed to the production casing in the well, and one to the drill pipe, but if underwater then the production casing is tied back to the Wellhead Collet Connector, and then the only tube running through the BOP will be the DP, to which they will seal.

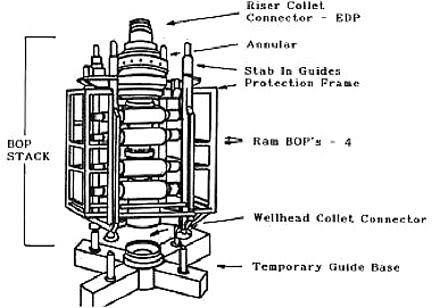

BOP connection to casing at the seabed (PCCI report for MMS)

The problem that this leaves, in the current situation, is that the pipe that runs through these two seals is open at the bottom to the oil flow. So how can the flow through this be stopped?

The answer is to mount a top ram set that has a set of shear cutting blades on it, that will cut through the pipe and seal the full face of the well.

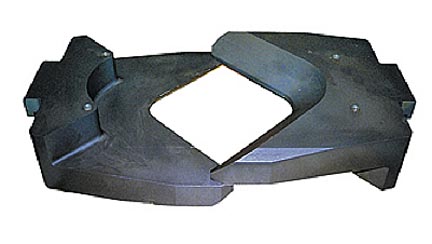

Shear blades to cut through the DP and seal the well (Varco )

The DP should shear, but would be held in place by the grip of the annular sealing rams below.

In this case it seems to be recognized that for some reason this shear event did not totally succeed. Thus the pipe was not totally severed and the two shear plates did not fully move over one another to complete the seal.

Now this is where the problem arises, because, in part, that pipe is still open at its lower end. If the leak is around the outside of the pipe, through a gap that has generated between the pipe and the annular seals, then the use of the junk shot to fill the cracks and gaps could conventionally have worked. But the configuration of the rams on the Deepwater Horizon had changed from the initial simpler configuration to add seals for occasions where the drill pipe was not in place.

Ram layout on the BOP (Times Picayune)

And the "junk" is being injected at the bottom of this stack.

Section through the BOP, showing the anticipated mud flow path (initially from BP)

If the leak is coming up through the remnants of the drill pipe then life is complicated. It can’t all be coming up through an undamaged pipe alone, since it was the far open end of that which was successfully closed at the beginning of the remedial steps, but if it is coming through the pipe and leaking out at the shear rams into the annulus that feeds into the riser, and out to the sea, then putting sealing particles into the bottom of the BOP to seal the cracks could have sealed some of the leakage around the DP trapped in the shears, but not that flowing through the shears in the remaining pipe section.

The reason that it can’t is that the access to that flow is occurring 3,367 ft below the riser, and there is no easy way to get the sealing particles down that far. If they are mixed with mud and pushed down the well to that level and then released they have a different problem. The hope when they were released into the well was that the flow of the current would be enough to carry them up to the cracks that they could seal. But if they have to be carried down to the zone where the oil remains, then their density may be sufficiently high that they get into the flow without enough speed to lift them up into the BOP, instead it will cause them to sink to the bottom of the well.

The materials that BP tried included materials that might float on the surface, and might not be dense enough.

Those materials, including fibrous pieces of rope and chunks of rubber, were supposed to force more of the mud down the wellbore, but ultimately it did not work.

Rubber has a specific gravity of 0.91 and rope varies from 0.9 to 1.4. But remember that at that depth any buoyancy from air entrainment would be lost.

In other circumstances it might have worked, If they could have dropped the DP out of the shears perhaps, but they couldn’t and it didn’t. So on to the LMRP.

UPDATE: Thinking about this a little more, I had two more thoughts. The first is that once the LMRP preparation cuts off the riser and the bent drill pipe, then the full weight of the pipe below the shears may come onto the section in the shear jaws at the moment, pulling them further out of alignment and increasing the flows. It could also cause the pipe to drop out of the jaws, pulled out by the underlying weight, and hopefully not distorting them too much so that in the best of worlds they could then be cranked shut.

One could also, once the bent riser and pipe had been cut, go in down the pipe bit that extends up, go down past the annular seals with an abrasive jet lance (most of the flow is around the DP as we have established above) and cut it off, right above the shears. Then partially open the shears, drop the pipe out, and close them again. If they move all the way closed, without the obstruction, then the well may be sealed.

A *very* sincere thank you to all who have donated thus far. It will help with the increased costs we face (see point 3 below).

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes.

6. Do not be afraid to go back and read the last couple of threads yesterday and today before you start on this thread. They were really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 400 comments, as it's really unmanageable. Lots of good stuff in there though.

yup, about time i donated something to this site. been here a couple of years. haven't donated yet, cause i promised my children that i would not donate something to folks i never seen, or that come to my door. When you get my age you will get that lecture too. just talked to my daughter and told her i was going to send your folks a few pennies. She knows, cause i tell her about all the marvelous things i learn here and that it is like PBS, which she approves. going to come in the mail though. So be patient. We will be writing checks in the next couple of days. They don't trust me on the computer. You know credit card and that sort of stuff. Thanks for a very valuable service. Many of my old friends are gone. like to think of ya'll as sort of....

Rube: Ain't this Internet thing great? It keeps our old minds alive and active. I gladly have and will pay money for that. Once in a while, I think about what life would be like now for me without it. And, just like the great New Yorker cartoon: "Om the internet, no one knows your a dog." I don't even have to wear my teeth. I hope you had a great Memorial Day weekend. Keep safe. And keep posting. We have something to say. E L

E L, I was thinking this exact thing! That places like this keep our minds agile as we grow older! "Energy and our Future" - it's also about "mental energy" - and nothing like good conversation to keep those neurons happy on both sides of the brain.

Kudos again to this wonderful community! To its moderators and its contributors. I think you've done wonders coping with all the new people and trying to sort out the wheat from the weeds among us newbies.

TheraP: I've had to drop the "er" from "older." But that doesn't make any difference at theoildrum.com. All I can say for sure to one and all: DONATE, DONATE, DONATE what you can. We're all going to need the five steps of grief counseling as we move through Peak Oil. We're still in denial as a nation, er... make that planet. Next, dealing with planetary anger. Stay safe and keep commenting TheraP. This Peak Oil/grief thing is not gonna be easy. E L

Again, Thank you...

The top kill failed because you have an open pipe below exerting a large pressure upward. You have several smaller orifices through which the mud is (was) being pumped at a lower pressure, lower flow. At the top, you have a bent over pipe with several leaks in it, there is another leak in the riser pipe and the originaly broadcast footage was of the open end of the riser pipe.

Essentially - for those of you famliar with plumbing, you had a small hose running into one side of T, a well with nearly four miles of dirt/rock and a mile of ocean above pushing down on it running into the bottome side, and then a hole on the top side of the T of unquantified size.

I've heard several estimates of the flow rates, from a total of 5,000 barrels a day to an estimate by a Purdue fluids PhD of 70,000 barrels a day (+/- 16,000 barrels) running out the open end of pipe. They didn't show much footage of the bent riser pipe or the other break until they (BP) stated they were getting 5,000 barrels a day into a ship. We need three live feed cameras, not one to properly estimate flow.

I would not be one bit surprised if we find out that there was 125,000 barrels a day rushing into the GOM at the peak. Once they remove the kink in order to lower the LMRP on top, I wouldn't be surprisedd if the flow increases to 150,000 barrels per day.

I do agree with others that it will be very difficult to accurately lower the LMRP onto the cut pipe, and when that is actually done, I wouldn't be surprised that the thing pop's straight off.

When CNN had the fluids PhD on giving his estimate, it came to light that the riser pipe is 22" around - with a 1" pipe thickness, 20 inches of flow. It is easy to see that the flow was easily over a barrel a second. What is not easy to tell is how much of the flow was oil with methane entraped in the fluid.

What was the mud pumping capacity? If the mud pumping capacity was not equal to the leakage rate, "Top Kill" would fail straight away.

"Top Kill with Junk Shot" failed because the holes in the riser pipes were too big and the junk just went right through. The valves through which the mud flowed were smaller than the holes in the riser pipe making it impossible to send junk down big enough to plug these holes.

This is good and bad news. It seems the only hole though which the oil is flowing is right up the drill pipe, not through the annular between the well pipe and the drill pipe. We still do not know if the footing of the wellhead/BOP is strong enough to hold the well down under full pressure. The whole BOP could pop right off if shut, or shut too quickly.

Even worse, depending on what layer of rod/clay/sediment the leak is actually occuring at, the changes in flow when trying to stop or slow the flow may result in fracturing, quickened errosion, and larger and less controlable leaks.

This does not mean that the Gulf can sit around and wait for the releif wells to be completed.

It does mean that - should blowing up the hole, nuclear or conventional - be tried, it should be tried sooner rather than later so as not to effect the drilling of the two or three relief wells that will eventually inject mud and concrete into the base of the well to completely kill it.

Dumping Redimix is an issue. How long does it take for the concrete to begin to really set-up? If it is still in the downpies or in the only valves they have access to on the BOP when it sets-up, then the problems will be compounded. Also 3,000 PSI Redimix will not hold back 7,500 PSI oil.

If the LMRC can be placed properly, the "Top Kill" mud could be shot down the hole and recirculated again with (hopefully) much lower leakage rates. We may find that one we put a couple miles of mud and a mile of concrete on top of the oil, it will stay put.

The best case would be to drop the drill pipe and find that the sheer actually closes and the top kill culd be done without leakage out the top, other than perhaps the methane gas sneaking by. Depending on the types of plugs available, perhaps even the methane could be held down.

One does not have to be an expert in the oil field to understand the basics of what is going on down there once explained. It is simple if one has a scientific education and has worked on many different kinds of systems in one's life.

One thing for sure, this hasn't happened to Chevron, Petrobras or others carrying out deep water/deep strata drilling and Transocean had a perfect safety record on the Horizon until now. The only actor that seems to have a lot of accidents is BP - not to say that Tranocean should have told the greenhorn at BP to shut up and listen to the experts on the rig.

Safety procedures certainly have to be written into law and enforced by inspection. Accident still may happen.

Maybe a dollar per gallon tax will cover the costs of experts to sit on their hands until the next accident. Maybe an additional dollar per gallon tax will get Americans to invest in more efficient and less environmetally damaging forms of transportation and energy production. (Good luck with that - right?)

We must remember that the "relief wells" may not do the trick, either. Months away-- they(2 drillings so far)need to hit the exact drill point that opened these hell gates. That is, the drills have to slant drill some 19000 ft. or more below the floor bed itself and interface with a 7-9 inch bore at unbelievable psi!!

The relief wells themselves could interface with a zone which, by August, has been blasted into a much wider hole, which will include ancient geological debris, etc. In theory, at least, this roaring wound may be unstoppable by us mere mortals.

A question arises: As per Albert Camus, are we facing the void in a silent, unaswering universe?

I wonder how much control they will have at the BOP connection. I understand they don't expect a perfect seal with the "grommet" so I expect they will try to keep some positive pressure inside the "hat" relative to the ocean pressure. If they can control the pressure in the "hat" closely, they can minimize the leakage, however if they get a negative pressure, they will suck in seawater and may block the whole thing with hydrates.

I expect the entire thing to be filled with methanol before they try a connection.

I would think that once the marine riser and the drill pipe stub is exposed, the drill pipe could be dropped downhole by releasing the pipe ram and/or the shear ram. Next, it would be possible to remove the riser stub from the riser adapter and stab in with a new riser with a valve above the adapter.

I am not conversant in sub-surface BOP's but I would imagine that it would be necessary to add weight to the riser adapter and turn right to ultimately release it when the drilling operations have been completed and prior to the retrieval of the BOP stack.

Is this correct?

given that the DP has no tool tip on it, i wouldnt think turning would be necessary.

for that matter assuming we can reasonably manipulate the DP, it would probably be easier to lift it several feet, cut the top foot or two then drop it back down. though considering the pressures at the well head i'm not sure that would be possible, further more as i understand it the Shear rams are believed to be damaged.

If peeps are going to be mucking about with the drill string, why not connect drill pipe from the surface to it and push the bit of pipe to the bottom of the well and kill it with mud?

If the oil/gas is gushing out of the drill pipe, the check valves on the kill and choke lines can be opened enough to reduce prssure/flow out of the drill string so more pipe can be added to it. Once the drill pipe is connected ordinary mudding practices will stauch flow up the casing. More drilling mud or concrete can be pumped into the well through the choke and kill lines.

The more I read the more likely it is the flow is mainly coming up the drill pipe through the BOP. That means the casing below the drill string @ 3,000 feet below the ocean floor can withstand reservoir pressure safely. This conclusion can be made if the drill string is the leak as the top kill temporarily sealed both the drill string and the upper casing(s) above 3,000 feet.

Now, get to work!

Wow steve, you wanna kill another 11 people trying to do that? If so than Get to work!

Please read: Open the check valves on the kill and choke lines on the BOP to relieve pressure on the well.

Read this, too:

http://www.offshore-mag.com/index/article-display/23675/articles/offshor...

I think the risk is manageable if there is enough drill pipe in the hole and mud flows to the bottom and back up the production casing to the BOP. Then a concrete plug can be set prior to having the entire casing plugged with concrete.

While we are on the subject of top kill I wonder why BP just didn't pump ordinary redi- mix concrete into the hole? Slump one or two @ 6" concrete lines from the surface and the well would be filled with gravel up to the point where the drill string ended and solid concrete above. A gallon of 5,000 psi concrete weighs about 20 lbs.

I expressed concern on the earlier thread about cutting the DP loose and letting it drop (several thousand feet) to the bottom. It's a heavy sucker. What damage could it do? Would it interfere with drilling-in the relief well?

the question Mr G is; 'Drop or Pop'? Nobody knows! The blind rams might be holding the DP in place with all the oil and gas blowing through it.

Some people think it might pop out of the well and rocket out of the water, like Moby Dick.

Some other people think it might skedaddle to the bottom and have to be fished out. Nobody knows becuase nobody can guess what is up with the BOP.

Are the shear rams on top or on the bottom? Did the SR's cut the riser, production casing and drill string? Can the SR's be fiddled with manually?

Did the annular work? Did the blind rams work? Is the drill string hard tool steel or softer mild steel? Without knowing exactly what the various components are and what worked and what didn't the exercise is just that?

Doesn't matter much anyway as the real solution is the relief wells and us just talkin' you know what I mean?

My call would be to leave the DP where it is. Too many unknowns (as you made clear) and it may be reinforcing the BOP. These new pictures (of how contorted the BOP is) tell me they need to go easy. For all we (they) know, the DP is all that's holding things down.

The BOP on the sea bed right now is highly compromised, was questionable to begin with (and they knew it) and attached to a set of casing that has had a non-functioning (burning, sinking, floundering) very large drill ship torquing on it for two days via the riser, and has sustained a blowout, whatever erosion is still taking place, and had junk blown into it repeatedly, plus the strain of this wild well. It's probably not a good idea to do anything with it other than pray it doesn't shoot off like a pop gun, or just fall off like one of those tall wax candles that Zorro is always slicing thru in the movies.

Cutting the drill pipe any any point adds to the risk of that pipe falling to the bottom of the well and fracturing whatever is there - a concrete seal, supposedly but who knows for sure. Any of these actions could lead to a greater pressure wild well spewing into the gulf. I'd hate to see that entire drill pipe string shooting up the riser and into the bright blue sky like Spindletop.

It's fine to speculate about what might work, but shutting in the well via THIS BOP sounds extremely risky to me. If there were a way link a riser to it, and i know they are saying they will try - they ought to also think about later encasing the whole original BOP in cement somehow as a next step. The damn thing is broken, and could fail at any point.

As you gents build you BOP/DP scenarios, one perhaps worth considering is that there is a section or two of production liner up in the BOP. Brainstorming that might be interesting.

A 20" + riser squished like that? Wow that footage is amazing today.

Look at the rate that Oil is coming out of them holes. Wow thats a huge volume. 20 000 bbls seems about right IMO.

Im going to hate to see the flow rate once they cut the riser below that huge restriction. Its going to be ripping into the ocean at 100 000 bbls a day. Anyone have a clue how they are going to land this LMRP? As soon as they get it close to that amount they arent going to be able to see anything? I think its going to be impossible to land that over that little piece of pipe.

No kidding! Now that we're getting a 360 deg view of the riser just look at how much oil is coming out the "backside," i.e. the side of the riser we didn't see during the top kill. It's spectacular, in a gruesome sort of way. My god, and to think, even more oil is coming out of the busted pipe end.

So there's been a ~1 hr long dance with the this rope the ROV is holding... anyone know what's going on?

What would that do to the DP? Still whole, or busted?

when cutting with a saw the item to be cut should not vibrate unduly. Therefore the wrap/tie. Notice when the cutting is getting done, the other arm is pulling on the line to keep it taut. Blades can shatter, being its no doubt a diamond tipped blade its pricy

Has anyone ever worked with a well under pressure before ie Snub?

One will learn really fast that a BOP means Blow out Preventer. The key word is Preventer. You start opening and then trying to close them rams or bag with out being equalized you might as well just be doing your work without BOP's on. The rubbers on them rams blocks would be so far gone it would be trying to close a block that isnt going to seal anything. Come on now people think just a little tiny bit?

Just heard on CNN that they won't be attempting it until sometime between Wednesday and Saturday. They have one on standby that is a little different design should the first one not work out.

I have been following the Deepwater Horizon story from a bit of a distance. I am not an oil man or oil industry expert by any means. But seeing the multiple failed efforts to plug the leak, along with the continued low-balling of estimates of the magnitude of the leak on the part of BP and the U.S. Federal government, I can't help but be a bit skeptical about a few things. To me it seems that BP's efforts are constrained by its desire to protect its profits from damage at all costs. I think they're just dinking around. I wonder - not that I think this would ever happen in our country at present - but what if money was no object; how quickly could this leak be stopped?

By "stopped" I mean stopped - without any regard for whether BP could use this well afterward. How could it be that "money was no object" in stopping the leak? One of two ways - either assume that BP has unlimited resources, or assume that a government (such as the U.S. government) had the guts and the strong moral sense to seize BP's assets and liquidate the company entirely in order to pay for the quickest and most effective means of stopping the leak. In other words, someone with a backbone and means of enforcement would have to make BP an "offer they couldn't refuse." What sort of engineering solutions would be available then? And how quickly could they be implemented?

It's an academic question to be sure, since it's not going to happen. But considering such a question would at least provide us with a "delta" between what could happen if those in charge really wanted to stop this mess versus what's happening now.

http://www.nytimes.com/2010/05/30/weekinreview/30rosenthal.html

What people forget is that even when technology works it doesn't work like in the movies.

In real life things just take days, weeks, months, even years to actually do. Those pesky laws of physics and causality keep getting in the way of having your problem fixed Right Now. In real life Scotty can't change the laws of physics no matter how much he might wish to.

The kill wells will fix the problem within a matter of a few months, which is pretty darned quick given the history of past blowouts and the technical difficulties involved in working at these depths.

If anything at all works between now and then we are talking technological miracle territory, and as has been said before: "If you rush a miracle worker, you get lousy miracles".

Hi TH,

Due to damage in the well, this well can never be used to produce oil again.

TH, I know you said your not a oil man or a expert and you really should of stopped there.

You think that BP just loves this well ripping into the ocean that they have to eventually clean up? You dont think they have the best professionals in the world working on this thing right now?

Every thing they have tried, they have a very small chance of really working is the honest to god truth. They know 1 thing. The relieve wells will work. They have minimum 2 months to try as many things in the meantime to hold out hope that they are going to get this thing limited and then they can progress with the clean up efforts. Really sad story, but to think someone else could do a quicker and easier job without know the oil and gas industry is just being silly IMO.

"Really sad story, but to think someone else could do a quicker and easier job without know the oil and gas industry is just being silly IMO."

And yet, often we typically are pleased when knowledgeable people with fresh eyes but little domain experience come in.

Think Steven Chu.

Think Feynman and the Challenger.

Think Emperor's new clothes

Yes, I understand that us noobs have overrun The Oil Drum. But just telling people that asking questions is silly, is well, not the way to raise signal to noise ratio.

"Yes, I understand that us noobs have overrun The Oil Drum. But just telling people that asking questions is silly, is well, not the way to raise signal to noise ratio."

Yes, Im a noob on TOD, even though a long time lurker. I just thought I could pass on a little help having killed 1000's of wells and working on (drilling and service) rigs for many many years.

I just couldnt help myself when someone says they know no nothing about the industry than make big assumptions. Ill refrain myself and stick to the just commenting on the expertise that I know.

I have been involved in some offshore crisis in the drilling business. Fortunately all ended up OK and much was learned by our company. My feeling is that this crisis has likely been very poorly managed by BP due to the intense management, government, and public pressure. There are far too many experts involved to make sensible, timely decisions. I cannot blame BP. i have seen this in action, albeit on a smaller scale. In all cases, once management see what was happenning and assigned the right focussed group to solve and carry out the solution, it got solved. All the others are put away somewhere else where they can do less damage. Don't get me wrong. There are no doubt some world class experts but they need to assmeble a small team with the right skills and then give them the authority to get the job done and problem solved. I think BP should have been where they are 3-4 weeks ago.

And don't forget - relief wells can take several attempts. Luck has a lot to do with it. Yes, a relief well may eventually work but it can take a very long time and many attempts. We need to get 100% of this oil diverted to a tanker now and not wait for a releif well to get there.

Going over extremely well-covered ground can be tiresome indeed - we could discuss whether it is "silly" as well. Firstly, it has been well enunciated on here (repeatedly) by many experienced posters, that the well will be closed permanently, and that BP's strategies are not (cannot be) based on a desire to re-use the well for production. I suggest new posters read some history on here first.

Secondly, the US Government cannot just seize the entire assets of BP (or any number of its subsidiaries), and it makes it a lot harder when BP is not even a US-registered company. The President (and other layers) are subject to the rule of law, and if they wish to sue BP in the future, then there are procedures for doing that, and buckets of lawyers to assist. This has also been discussed here at length.

The idea that BP is withholding some efforts on the basis of costs is pure nonsense. Your analysis is just not credible. I hope it is better applied when you are on whatever the day job is. This well will never be used for producing oil. And neither will the relief wells.

The answer would be the length of time to drill the relief well. Sorry for the answer .. have been on exactly one Project prior to working Offshore and Subsea Projects with unlimited budget and a lot of government "opening of doors" .. rebuild of Angus Nitroparafin Plant .. producer of 90% of nitro for jet fuels (and more mundane racing car fuel) in the world. Plant blew .. we did total tear out/analysis of remaining plant/design/procurement/rebuild in 6-1/2 months .. normal time for this type project 18-24 months. They would of been out of jet fuel way before then which is why we got "open doors", the air force without fuel if you get my drift.

Money can only do so much .. can't drill faster. You have shops, engineers, riggers basically on 24 hours shifts now, have the top people from every country/company on loan/24hr call.

Used to use the pregnancy problem .. making 9 women pregnant will not get you a baby in one month to explain this .. more people, more money does not always work.

What determined how many relief wells to dig?

I do believe that BP would gladly write a $1B check to stop the leak, and that they have they have the best technical talent working on it. But there are still some cost issues.

The costs to sort this out are currently estimated to be more than the total annual GDP of the majority of countries in the world.

I'm not sure if that is "money was no object", but it certainly is not "dinking about".

Right from the start BP volunteered to pay for everything although they could have hidden behind a $75m cap for the clean-up. Also contrast the actions of most of the other companies involved (and for that matter US gov agencies) - nothing to do with us and/or filing for limited liability protection in court.

I am certainly not saying BP are great, but uninformed witch-hunts without a trial are just not helpful.

Nope, TH. I'm not an oil person either but I am in an industry that includes much technology. The folks working on this issue are putting forward a first-class effort. I've done a lot of technical projects myself and it takes one to know one I guess but I surely don't have any complaints re their work.

TH, as others have said you ARE seeing an all-out, best minds on the task, no expense spared effort to stop the oil from flowing into the Gulf.

Here is the tragedy - a very bad accident has happened (killed 11 good, hard working people right off the bat) and the best technology and information that can be brought to bear is just WAY short of being more than minimally effective. The proven route to fix the mess is drilling relief wells down to the bottom of this one and filling it full of cement. Too bad that to do this safely will take a couple of months. We (our collective oil consuming society) have been drilling oil and gas wells in water so deep that there is no technological fix when an accident happens. The technology to drill the wells and recover gas and oil has been developed to the point that we can drill 5,000 deepwater wells in the Gulf of Mexico mostly without incident BUT when the 5,000 and 1st blows out it becomes crystal clear that there has been no similar improvement in the technology to mitigate an accident. When the Ixtoc well blew out in 1979 basically the same set of tools was used trying to bring it under control - with similar results - and that well was in only 160' of water.

Undoubtedly that will now change - and the changes will benefit the industry and public world-wide, but it took this highly visible catastrophe right off the American coast for people here in the States to understand the risks that were being taken with our common resources in order to keep our oil-driven economy afloat. Tragic isn't it?

Now we can all watch a bunch of cute robots and their operators struggle to deal with a very very difficult problem, and any thing they try may end up allowing that oil to leak out faster. The current operation will certainly increase the rate of flow, but it may allow them to be able to capture most of the oil and gas - if it works. If they just sit back and wait for the relief wells to be drilled the oil will continue to leak faster and faster anyway. So we should all wish them luck, and after all, they really are working for the collective 'us'.

Perhaps we need to be a little more temperate here ... for weeks now we have heard that the "best minds" and the brightest professionals are on the task. Well, I think it should be qualified to (perhaps) "the best technical expertise in the off-shore oil industry", or something similar.

When I went to university (back in the dark ages), the brightest and best certainly did not go anywhere near the mining and energy sectors (despite the 70s boom) - they became surgeons, lawyers, dentists, history professors, stockbrokers, architects, whatever ... so perhaps BP has access to the best geologists, engineers, and well-drilling technicians ... let's hope so. Would have to be more useful than having a lot more lawyers.

A lot of really bright people went into economic geology, chemistry, and related fields back in the '70s anyway, and people with a technical bent don't become lawyers/brokers/bankers and the like - aerospace maybe.

Nice to see your more temperate post.

My post was more than temperate ... I'm certainly not insulting those working on this issue - I'm sure they have great expertise indeed in their field. But the oil industry is but one area where some of the best and the brightest might go, and I think it's a bit of a stretch to over-state their brilliance, compared to the rest of the world's bright people. No-one doubts their intellectual and technical best endeavours, of course.

"My post was more than temperate" I was agreeing.

Your qualification noted and entirely appropriate.

The technical fixes being attempted - mitigation of the flow of oil, relief wells - are something the industry is good at. That said, the problem is that this stuff should have been worked out 30 years ago, but it takes a highly visible catastrophe near American shores that is directly damaging to people in the States for both the industry and the public here to figure out that this has been an accident waiting to happen - and that it has been happening elsewhere all along but nothing was done about it.

The spill response is abysmal though - nothing sexy about cleaning up an oil slick and the technology is antiquated and the effort poorly coordinated.

Dentists!

OMG why hasn't anyone thought of this yet?

Just recruit some dentists and history professors and several dozen whatevers, then we really will have the best minds working on this! I'm gonna email this to BP right away.

LOL - yes, dentists could apply some serious Novocaine to the BOP and solve everything painlessly! Would work - and then you pay the bill. Might need some orthodontics as well, just to beef up the profit margin.

No - my LITTLE point was, I was getting a little tired of the "best minds" meme in post after post, I'm afraid. Sure - I assume some bright people work in the oil patch, no doubt - but seriously, it isn't rocket science, and never has been - so all these allusions to the B&B, let alone NASA and Apollo 13 - just a tad over the top - wouldn't you agree? There are lots of very excellent B&B people not in the oil patch ... all I'm saying.

And frankly, given the giant cluster-f on this gig - you'd wonder about the people on the job - I would anyway ... but carry on.

I don't agree with what you are saying. When I came out of college some years ago with a freshly minted PhD looking for a job in industrial R&D there were very few organizations that had a reputation as good as Exxon's central research. Bell Labs maybe was the only one that you could point to as clearly being superior. Exxon had plenty of money to support anything you could come up with and this attracted a lot of the best engineering minds in the world.

Over my career I've gone to a number of symposia where oil industry funding paid for cutting edge research - fluid mechanics in porous media, separation processes, you name it. The fact is that the economic stakes are so high in this industry that getting the best is an investment well worth while for them.

So yeah while drilling a well is an exercise in applied mechanics and geology that doesn't mean that is the only thing going on in these companies.

Bill Gates (yes, that one)once said that Microsoft's fiercest competitor was Goldman Sachs. Why? Because both companies were after the best minds. And that's what business is all about. And look what happened.

End of August. The only way to do it for sure is a relief well, which is drilled down and intercepts the blown out well, and you then plug the blow out. In theory, that would take two months, then again, this well was supposed to take about that long, and ended up taking tfour months, so the probably should drill several relief wells, and hope that one of them is done on schedule. That's all money can buy you, not faster, just a better chance of sticking to your schedule.

And there is some hope that one of their kludges will work, and get things under control more quickly, but who knows?

I'm watching the video feed. People should realize that the skill of the engineers and technicians is breathtaking. We are seeing stuff akin to what NASA does. Cutting pipes by robot at 5000 ft. bsl in a controlled manner is bleeding edge technology. The sad part is that nobody will get an award, a Nobel Prize or a research grant. If anything, BP will be reviled and hated in the mainstream media. Things are to the point that BP can almost do nothing to fix its reputation and this is terribly unfair.

We are witnessing the destruction of wealth and assets and reputation and we may never be certain if anyone really screwed up. If it was a problem with the cement job and with the design of the drill pipes in the well, perhaps the same stuff worked elsewhere and this particular well kicked too hard with methane and natural gas and it was unlikely that the impact could have been assessed and the design compensated. I guess something was under-engineered in the well but should someone be blamed? I dunno.

The good thing is that the public will have a new appreciation about what is involved to get them their gasoline. I've learned a ton the last few weeks. Next time gas goes up in price, I will not be too upset, assuming it is not OPEC sourced.

KUDOS to the people int he petroleum industry. You all rock!

Yesterday the BP American guy said it was like performing open heart surgery on television -- apt analogy.

YES, what he said.

I'm amazed at the video of the ROVs working on this problem. The technology and effort, both physical and technical and scientific, is akin to going to the moon, except (as someone wrote in an earlier thread) not as glamorous. The stakes are high and these guys deserve credit for their efforts on our behalf.

To go a mile under the ocean and tackle these problems with remotely controlled devices is breathtaking to watch and I can't help but understand that the oil industry has brought us to this point and made all this technology possible. Every little link in the chain that connects my consciousness with these events, from the plastic keys of my computer (petroleum based) that I sit in front of here in my air-conditioned living room in Appalachia, through the air via a wireless router to the internet to those ships in the Gulf to the video feeds coming from the cameras of the ROVs, has been made possible by OIL and by the oil companies that take it from the Earth. I know there are people out there giving their absolute best efforts to this problem because all of our interests are entwined. Be cynical and say what you will about oil companies drinking our milkshakes and/or greed and/or negligence and chances are you'd be right on many points, but it is undeniable that being alive at this time, at the peak of the Age of Oil is awesome. At least for most of us reading these posts.

Godspeed and best of luck to all the folks in the Gulf trying to shut down this blowout. This is an amazing forum, too.

The financial implications of this spill on downstream projects cannot be understated. Risk takes on new meaning when Congress lifts caps on liability which the public will demand but its clear that this type of incident can occur again given the demand side for oil and gas but only Nation states will have the financial backstop to cover the scope of this type of spill since the costs are well beyond any driller including BP. The idea that insurance could be arranged while possible but sooner or later an incident will test the financial ability of they parties that signed on and my guess is that taxpayers would be required to provide the bulk of the clean up costs.

"but only Nation states will have the financial backstop to cover the scope of this type of spill" I agree. By nation sates, I think you mean mean taxpaying voters. I have not thought through the implications of this statement, but: 1) soaring government debt 2) bond vigilantes 3) voters that want it all but scream "Tax Cuts" and 4) peak oil. Talk about a witches' brew for a political and financial blow out.

well, more or less controlled - you missed little ROV wiggling a bracket back & forth this am cause couldn't get it cut all the way .... but still ... pretty amazing

Winter -- I’ll use your question to give a brief summary, with the permission of the editors, for the benefit of the newbies who seem to be showing up hourly.

Above all else this tales goes with a very BIG IF: if we have a accurate picture of how the incident began then here goes: they had run production casing from total depth back up to the well head/BOP. Cement was pumped down the drill pipe to the bottom of this casing and forced back up between the csg and the rock. The reason for this cmt job is to isolate the oil reservoir. This cement seal would be the only barrier preventing the well from “coming in “ (flowing oil/NG up the csg). Prior to pumping the cmt the weight of the drilling mud kept the reservoir from flowing up. The backpressure stopping the flow was a result of an 18,000’ column of heavy drilling mud.

Before temporarily abandoning the well BP was required for safety reasons to set a series of cement plugs in the production csg to ensure the reservoir would not leak to the surface until they were ready to produce the well. To make the eventual re-entry of the well easier BP “displaced” the riser (that 20” tube that connected the well head/BOP to the drilling rig on the surface of the GOM) with seawater and thus removing the heavy drill mud from the well. But they did this before setting the top cmt plug which would have kept any oil/NG from flowing up should the csg cmt fail. This is why testing the validity of the cmt job was extremely critical: the column of seawater could not produce a sufficient backpressure to prevent the oil/NG from rushing to the surface. If the cmt didn’t hold there was a 100% certainty of the well flowing oil/NG. There has been much discussion about the interpretation of the tests conducted on the cmt, the nature of the cmt, who has ultimate responsibility for certifying the cmt job. Likewise the reason for waiting to set the top cmt plug until after displacement has been speculated by others. I’ll leave those debates to others. But a good cmt job wasn’t the last safeguard.

There is a standard procedure for determining if a well is flowing. The same protocol for a cased hole as when drilling. I don’t know for a fact but I wouldn’t be surprised if this procedure had been done more than 100 times as this well was being drilled. The mud pumps on the rig push drilling mud down the drill pipe, which then returns to the surface between the drill pipe and the csg or open hole. Though this will sound simplistic this is the primary method to tell if a well is kicking (flowing): you shut the mud pumps off. For oil/NG to flow to the surface it has to push the mud out of the hole ahead of it. If you turn the pumps off and the mud stops flowing out you have a static well. If the mud continues flowing out the return line the well is coming in and a blow out is on the way unless you stop this flow. In addition to visually seeing the mud flowing out, there are various mud tanks that have the mud flow volume measured automatically.

Again, IF we have the correct story, the mud returns were not being monitored. I’ll leave the details of why they weren’t monitoring the mud returns to others. Why the cmt failed is a separate issue from not monitoring the mud returns. Had they seen the mud flowing they could have shut the well in (closed all the return valves on the rig). The oil/NG might have still flowed all the way up but it would have not escaped to the drill floor and exploded. Killing a shut in well is a standard procedure and practiced often. Once the well was shut in they could have replaced the light seawater with heavy drilling mud via the drill pipe and stopped the flow of oil/NG from the reservoir. But they did not become aware of the well coming in until it as too late.

The failure of the BOP to stop the blow out is a completely separate issue I’ll let others expand upon. Likewise with the various efforts to stop the blow out and collect the oil spill.

As usual the rest of the TODers are free to add, modify and adjust this summary. My hope was to reduce some of the redundency required to bring our new memebers up to speed.

Thankyou sir.

The sub question you responded to earlier was more of a generality, but I appreciate your input on that also.

Ex post facto, it is a clear fact that the cement job was faulty.

There are a number of procedures in the oil industry to confirm that a good cement job was done. It appears that BP did not do all that it could to confirm that they had a good cement job before replacing heavy drilling "mud" with seawater (this was the proximate trigger of the kick, blowout, explosion, fire, sinking and polluting the Gulf).

Positive pressure tests, negative pressure tests and cement bond logs (tools on wire dropped into the well, I think they use radiation) are the tools to confirm good cement jobs.

The cement used was quite unusual for this depth well, nitrogen filled cement (like shaving cream consistency).

Normal wait after pouring cement is 24 to 48 hours to let it set. Reports are that BP pressure tested the cement 10 hours after pour (blowout was 20 hours after pour). Pressure testing can involve 2,500 psi pressure and some SPECULATION is that early testing may have affected the cement.

Does nitrogen cement set faster ? No confirmation on TOD either way except "doubt it".

Some pressure tests failed, but altering the test and repeat gave a pass.

The people to do a CBL (cement bond log) were on the rig, but were not asked to do one (or some other dispute arose). In any case, a CBL was not run.

It should be noted that drilling rigs like this cost about $500/minute (rental + people) and running tests takes time.

Hope that helps,

Alan

What strikes me about all those issues is apparently no one raised an issue with the cure time or the lack of a CBL or number of centering devices, etc. They all trusted that they had the well under control. Disagreement apparently was around the negative test, but it was done. I agree that all of these decisions may have been tragic errors. I'm still not convinced there was anything criminal or negligent about them.

Greg -- I agree with your sentiment in general. But IMHO opinion not checking for mud flow is always negligent. And I would deem it so even if it weren't a critical stage. When I'm drilling I make sure flow is checked even when we stop pumps to connect a new joint of drill pipe. Even if there's nothing to be concerned about. I'm not the only one. But attitudes vary. The most important take away about checking for flow is that it costs nothing to do. CBL's, pressure tests, BOP tests, etc all cost rig time and thus cost money. Checking for flow while displacing would have taken one hand watching the mud pits. You know I like simplistic examples: checking for flow is no different then clicking your seat belt when you get into your car. Might seldom need it but when you do there is no substitute.

I'm still unclear if they noticed mud returns and were initially unconcerned, failed to watch excessive mud returns or were watching mud returns, saw what was happening and tried to reverse the seawater displacement and then something happened (why did the mud pumps stop?) and then they were hosed?

In any case, assuming they were not watching mud returns, I guess you have to distinguish between best practice (before the accident) and ordinary practice (before the accident) and base their judgement not on what the most conservative practices were, but what the most reasonable liberal practices were to determine negligence (I could be persuaded to believe simple negligence in not following best practice, but would be very skeptical about going after them for gross negligence let alone criminal gross negligence if industry failed in general to see the critical importance of watching mud returns during the plugging stage).

I would expect that this is a wake up call to industry to change their minimal practices (if that is what BP was doing), but nailing the first one caught with an excessive penalty and letting the rest slip by would do no one any favors. Find and fix the root cause rather than just fight the symptom.

I wish I was able to watch all of the interviews and understand what happened. Has the site posted a link to archived videos of the MMS Invetigation? I've missed about half unfortunately (damn job getting in the way).

http://www.c-spanvideo.org/browse?date=2010-05-28

http://www.c-spanvideo.org/browse?date=2010-05-29

All very interesting, sad, fascinating, informative.

Greg -- the story line is that they were distracted with shuting down ops and offloading mud. To be honest that has been total supposition as far as I can tell. But I know what it’s like on a rig at that point and it is plausible. I think we’ll have to wait for the formal investigation to get confirmation. But I would readily bet you lunch that checking flow is being beaten into every drill crew in the USA on every rig every day. But it’s SOP for some of us. I mentioned the other day about an 18,000’ well in the La. bayous last January. I had flow checked on every connection. And double-checked b a second hand. And then had it triple checked personally by the company man. I’ll confess I’m not perfect. But I try to be.

Hi Greg,

Try the main C-Span website.

Use the search box in the upper right and enter "Deepwater Horizon"

I think you will get a list of the hearing videos that you are looking for, but I"m not sure they have all the various hearing.

Greg, not sure if you have this already, if you do, I'm sure many others will find it interesting.

BP provided the Energy & Commerce Committee with a preliminary report of all events leading up to the blow out on the day of the accident. It is a great way to keep oriented as to what happened when and to learn more about what aspects of the procedure are troublesome.

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

Note, this is a 48 page PDF file

Thanks PriorityX, that's very helpful.

Alan

Traditional Cement Bond Logs are acoustic tools.

Thanks !

Alan

Alan

My understanding (third hand from inside BP) is that the plan was to run the CBL with the completion rig. If true, this would not be unusual as there is normally a specialist switch from open hole logging to cased hole logging and for better or worse (much worse in this case) this is normal in many cases. I wasn't there but if there were any doubts as to the cement job, pressure tests, etc. it would be a no brainer to fix the problem before T&A. I noted in a previous post my suspicions concerning why they ran a tapered string and not simply a 7" liner and tieback. (I suspect it was perceived to be a more cost efficient method.) The small volume of cement and long trip down the hole plus a less than ideal cement plug arrangement that had to wipe both casing sizes is more apt to allow mud to bypass and contaminate this small volume in the 9 7/8" casing. The ECD would have all been reduce thereby reducing losses, etc. etc. In addition you could have run a liner top packer for an extra barrier to flow. The engineering just cascades.

Thanks Rockman. You always cut through the confusion. After searching around the web I am still unclear regarding the difference between casing and liner. (Sorry it's so basic.) If you have time and the inclination, would you help me with where I've got this wrong. Casing is hung from the wellhead. When the casing diameter is reduced they hang a smaller casing and typically put in a temporary packer, then cement the area above and below this "joint" between the two casings and the borehole. Also if they encounter porous/fractured strata they do a "squeeze" job with the same process to inject cement between the borehole and the casing for some distance above and below the porous strata. Another question I have is how do they determine just how far above and below? When they did this final cement job was there a continuous "liner" of cement from TD to the wellhead, or just up some hundreds or thousands of feet from the bottom? If you get to this, many thanks for your time. Hell, many thanks - regardless.

RP – Simpler than most would think. Csg is run from the bottom of the current hole all the way up to the wellhead. A liner is run from the bottom of the current hole only up to the bottom of the previous csg run. You may have seen reference to a csg hanger. That’s the device used to connect the liner to the previous csg run. You understand squeeze jobs also. You also squeeze bad cmt jobs to fix them. As to how high to run the cmt you have to understand the primary purpose. You don’t really need to cmt the csg to hold it in place…it ain’t going nowhere. The purpose is to isolate zones, such as the reservoir leaking oil/NG in the blow out. You run enough cmt to prevent it from flowing up or down.

Thanks again Rockman. Sounds like liner is a bit more lightweight than is casing and is temporary, until the more sturdy casing is placed and cemented. A protective measure to keep the DP free and clear while work continues. 'Nother dumb question - so liner is pulled and stacked/reused (like DP)?

RP -- rarely is liner/csg salvaged offshore. The rig time usualy is greater than the value of the csg. Onshore it can happen but you can seldom get it all out.

DUH (not thinking oil patch $$$$$$$$$$$$$...) :-)

If anyone wants to take a course in Oil 101 get Morgan Downey's book of that name. Comprehensive, to say the least; Morgan was blogging and contributing here for a while as well but he's been MIA for a few months now - hope all's well with him.

I understand that continual mud monitoring is required. It seems to me that it's the most important test. I don't understand the pressure testing. Am I incorrect in believing that the pressure tests are carried out with mud in the casing and DP? If pressure testing is done with mud in the well, how can one tell if the cement work can withstand the formation pressure? Seems to me that the real pressure test only occurs as the well bore is unloaded.

If the well kicked via the casing annulus, and assuming the cement plug inside the foot of the casing held, mud in the casing must have served to weigh it down to seal the top of the production casing at the wellhead. I'm guessing that the production case annulus would have been full of mud at some point. If that mud was not circulating could oil/gas percolate up through it to the top seal? Once it started to leak wouldn't it have put gas directly into the riser. In which case the mud returning would have been the mud in the riser, not the well. Seems to me that would have been near impossible to stop.

And just 1 more thing that looks anomalous. Why have 4 sets of blind rams which seems like excessive redundancy. Isn't it more likely that some kind of tool is down hole when the need to close the BOP arises?

In which case blind rams are useless aren't they?

Multiple shear rams seems like a safer way to go and I don't think that's just hindsight given that 10% of the DP is joints

The testimony I listened to over the weekend suggested the kick came up through the annulus - first water, then mud, then gas (boom!), more gas(BOOM!!), then oil and gas.

The issue of the mud returns came up repeatedly and everyone I heard testify said 1) the returns were going to the pits and were being monitored; 2) there was no way to send the returns directly to the boat - that had to be a separate operation. Either some funny business was going on and those who testified were ignorant of what had been going on or lying (both possible I suppose), or we didn't get the full story. Those with the most pertinent information are dead.

I was surprised also that the cement curing time was not a point of discussion.

IP -- the witnesses are going to have to pick there poison: either they weren’t monitoring the mud returns or they saw the well coming in and just sat back and watched it blow out. IMHO they can characterize themselves as either incompetent or insane…their choice. The well could not have blown out unless it unloaded most of the mud out of the well…many hundreds of bbls. They either measured the mud gain and didn’t shut the well in (SOP) or they didn’t measure it. There’s no in between.

Wait, I thought they were replacing the mud with seawater?

DBNS -- They were pushing the mud out of he well by pumping salt water into the bottom of the well. That's why they took the kick: taking the back pressure off the reservoir with a bad cmt job allowed the oil/NG to flow to the surface.

RM, the story circulating here was that the returns were being sent directly to the boat (not the pits of the rig) and not being monitored. The OIM and a couple of workers testified, when asked about this, that it was impossible to set up the returns in that fashion - it had to go to the pits first. I would think the boat captain might know something about this. So either the mud was going to the pits or the OIM was lying - a rather high-risk lie IMO. That said, just because it was going to the pits (if it was) doesn't mean they were keeping proper track of it. Perhaps it was being pumped to the boat from the pits and not being monitored...

How quickly could the well start to flow? Is it possible for something to fail catastrophically - be ok and then minutes later start geysering water and mud all over the rig?

IP -- As soon as the bottom hole pressure from the mud/salt water column was less than the resevoir pressure the flow potential was established. The unknow is how quickly the cmt failed as a result: 2 minutes....40 minutes. Will probably never know if the didn't get an accurate record of the pit volume changes. But it's real simple: if 100 bbls of oil flows up the well then they gain an extra hundred bbls of mud. They either see the gain or they don't. this isn't rocket science.

And yes, eventually someone will either recant their testimony or be charged with perjury IMHO.

RockMan

A gas influx is different from oil as I'm sure you know. A very small, high pressure gas influx can migrate up the annulus through the cement and mud with very little gain at surface as the pressure/volume relationship is exponential. Over the last few hundred feet the expansion is tremendous as a few barrels becomes thousands. I'm not saying they didn't make big mistakes in monitoring flow back, I'm simply saying that a migrating gas kick in the annulus can "explode" in volume at the very top of the hole if left unchecked. I think on top of everything else this very likely occured.

I would agree with you Dog. I try to keep it simple and didn't want to address gas slippage up the mud column to the general TOD audience until we start seeing some detailed testimonies. I've been kicked in the butt by more than one gas bubble in my career. Sounds like you have too.

IP,

Closer study of the BP preliminary report is still confusing.

From the report:

Data: Mud transfer to boat begins at 13:28.

Interpretation: The approach to transferring mud may have impaired pit monitoring over next 4 hours.

Data: Mud offload to Bankston ends at 17:17

Interpretation: Mudloggers not informed that offloading had ceased.

There is no further mention of mud or Mudloggers after this.

Hard to know exactly the meaning of this. Were they simultaneously displacing the well mud into the mud pits and pumping from the mud pits into the Bankston? Not sure if that is possible, but they say monitoring may have been impaired at this time. Might make sense if you have mud coming in and mud going out. I do think that my original reading that they were pumping directly to the boat, bypassing the mud pits, was incorrect.

Also not sure how the Mudloggers would not know the offloading had ceased. Do Mudloggers only work the mud coming into the mud pits? The fact that it is noted in the report seems to indicate it is significant.

This has been posted elsewhere. Released by Waxman and co at the House Energy hearings http://energycommerce.house.gov/documents/20100525/Memo.BP.Internal.Inve...

So they got it coming and going. I don't see how they could have been monitoring mud flows accurately, but then what do I know?

Rockman: Third option: Take the 5th.

EL: One all ready took the 5th. That's when I decided to not be so fair and balanced. Now I let my personal prejudice on how to drill safely guide my comments. You might have noticed that I'm not too inclined to cut anyone involved much slack now.

X -- watching mud return volumes is not typically the duty of the mud logger. They monitor the mud for signs of hydrocarbons as well as other parameters. There's a fair possibility that the mud logging unit was already shut down at the time and they were packing up to head home. Those details will become clear in the formnal investigation.

Nit – Not required but is “best practice” IMHO. And it’s THE definitive cmt test as far as I’m concerned. Yes…drilling mud used when testing. Let’s say I want the cmt to hold the equivalent of 17 ppg mud weight. I have 16 ppg mud I the hole. I increase the mud pump pressure so that the ECD (effective circulating density) at the bottom of the hole is 17 ppg. I hold it there for some predetermined period and record the pressure. If it holds I’m good. If the cmt leaks and I can’t get the ECD to the required level I know I have an unsatisfactory cmt job. A negative test is just the opposite: I lower the ECD to a value less then the reservoir pressure. I chart the pressure and if I see it increasing then I know the cmt is leaking.

The objective of the cmt is to isolate the reservoir from the rest of the well…both above and below the zone. I’ll let the BIOP pros handle the rest of your questions.

RockMan

Small point on ECD. It's not a direct function of pump pressure. It's a function of annular pressure losses. The easiest way to increase ECD is to take returns through the choke and "pinch" the returns. This will of course increase pump pressure but that is the result of increased pressure losses on the annulus. Once the plug "bumps" holding pump pressure has no effect on ECD. At that point you need to hold pressure on the annulus through the choke line if want to keep the BHP at an increased level.

Good point Dog. I'll let you offer details for the more tech minded folks at TOD...there are inquiring minds that want to know. But I'll stick with simple stories however incomplete they are. I especially like working with all the newbies showing up these days...makes me feel all the smarter. Hey...Rockman has ego too. Rockman go back cave for more coffee now.

Negative Pressure Test

Typically, you would run a packer on drill pipe to a predetermined depth above the point you want to test. You then pump a volume of seawater down the drill pipe sufficient to displace the mud out of the drill pipe down to the packer and set the packer. At that point you the negative pressure is equal to the difference between the mud weight displaced out of the drill pipe and the seawater down to the depth of the packer. You then observe the drill pipe for flow. If there is no flow back, a succesful test. As you say, it's not rocket science. For example at 5,000', displacing 14.4 ppg mud with 8.6 ppg seawater: PSI = (14.4 - 8.6)(0.052)(5,000) = 1508 psi. This is the reduction in pressure observed at the packer. If you want to put a more severe negative test you need to displace the drill pipe with a lighter fluid, say nitrogen but that's the general idea. The only confusion could be questions as to if the packer is sealing or leaking as the u tube pressue is 1508 psi. If the packer leaks then you will observe a flow at the surface due to the unbalanced u tube and not an influx.

the guys at BP handle the decision making, not the actual doing. BP isnt doing this work you see via camera. as far as im concerned the skill of these operators has absolutely nothing to do with BP

I'm not seeing much of that around here. Just some complaining about BP while everyone keeps driving as much as they always have. The assumption is that other oil companies are drilling safely (so far), and that's so much more comforting than having to adjust your lifestyle.

actually its certainly made me more mindful on the impact of using oil, even on an individual level. it really makes me glad i have a fuel efficient car, not just because it saves me money, but because it uses less gas. i know thats a small step, but its a start.

Everyone probably figured out, but I should clarify. By "around here" I don't mean on TOD, but between family, friends, neighbors, etc.

One can admire the skill of the engineers and technicians and still look for BP to face appropriate consequences for this incredibly destructive blowout.

Evnow speaks the truth regarding time of membership ... at least in this threadlet.

No, you do not ROCK. Sorry, I am sure they work hard and master a lot of skills but people who deserve our admiration work for change and the future, in my opinion and RISK things like their livelihood and reputation when they stand up to power and demand that corners not get cut. I think when we learn more it may be possible that there were some, like possibly men from Schulumberger who tried to make a stand but in the end it was "the BP way or the highway" and they wisely choppered off the DWH after objecting to the lack of testing that was going on as BP rushed to complete the well.

Jimmy Harrell of transocean objected in a meeting to the bad drilling practice but ultimately bowed to pressure. Had he not, I am sure he felt he would have been replaced anyway. This is the current culture at which the oil and gas industry works, and it is a bad culture. It led directly to this disaster, and the supposed live cam you are impressed with is showing to me proof that things are rotten down there and topsides, too. We know already from sworn testimony that plenty of people screwed up bigtime. I won't get into it here, but you need to realize that MAJOR mistakes were made and they were human error and BAD drilling practice. It's been written about elsewhere.

Yes, the ROV people have skills. Too bad they are not applying them for science, instead of mitigating man made disasters of biblical proportions caused by greed and stupidity.

As for reputations, one BP company man has already pled the fifth and the other called in sick when asked to testify by the coast guard. If I had to characterize thier reputation I would have to use words you can't print in a newspaper, and end with the words incompetent and cowardly. I could list their names, they are a matter of public record but it is their bosses that are ultimately culpable. Criminal charges can and should be filed here and these people and their bosses (especially their bosses) deserve a day in court to defend themselves but also deserve justice in the form of lengthy prison terms if it is proven that they did the things they are already admitting to, more or less.

Don't get me started on the culture of the regulatory side of the industry either, it is almost suppertime and I might get sick.

Please explain further what is unfair about BP's reputation being ruined. I don't see it. A fish rots from the head.

wilis_newton I went through the aggravation of registering to tell you you hit the nail on the head. BP SUX nuff said.

Man, I read your post twice, and can't find anything I disagree with.

Well said.

My haven't we entered the shill zone. They have't accomplished anything yet, other than keeping everyone occupied - and what they are trying to accomplish is to fix their own major mistake.

Please ... perhaps resist going over the top - we are seeing what people who are good at arcade games can do. No need to over-sell the event. Sure it's fairly clever - but if they were really clever ... um ... we wouldn't be in the mess we are in.

Let's be honest, two shuttles blew up/disintegrated and one caught fire and burned to the ground on NASA's watch and an unmannedprobe crashed into MARS all under NASA's watch.

I don't care how dumb or smart someone is, all it takes is one bad decision. The people working on this are capable and know their jobs just like the NASA engineers are capable and knew their jobs. Mistakes don't necessarily mean the who organization/industry is incompetent.

NASA's mistakes did not impact a large ecosystem, only the people directly involved. I think the whole NASA comparison is a silly red herring, just another way to say "really cool high tech".

However, that is not how I see this. What I see is an industry that tried to re-purpose equipment and techniques for use in DW, and that is now demonstrating that these are woefully inadequate. They had no plan do deal with a fairly obvious eventuality, did not even do basic research into what they might encounter - which is why they're making it up as they go along, getting surprised by everything, and so far have failed.

The BOP is a good example - the operation and control systems are way complicated and vulnerable, and the main devices are not assured of shearing materials that are likely to be inside. What conscientious engineer would accept such a thing as a fail-safe emergency cut-off? It might have worked, but there were way too many failure modes to be relied on.

The ROVs strike me as extremely limited in capability for the tasks required of them.

So what I see is desperate people working hard to overcome inadequate tools and techniques, and a lack of planning and preparation. It's not one bad decision or one bad apple, it's systemic incompetence and a long way from impressive.

Exactly ... they're not dumb, but they're certainly not rocket scientists either - they are just oil-patch jockeys and tech-heads, working against the odds. Nothing wrong with that, but keeping it in perspective would be nice.

I wonder why they wanted that coupon? Whatever the reason, I have to marvel at the skill of the ROV folks...that has to be max stress situation.

I think I get it. To guarantee minimal dead load on the saw blade when they make the cuts just above the flange. They know what they're doing.

Hi guys: