The BP Deepwater Oil Spill - Why Top Kill May Have Failed and Tonight's Open Thread

Posted by Heading Out on May 30, 2010 - 4:45pm

New Thread--redirect to http://theoildrum.com/node/6551

The Top Kill attempts have failed, and the Government has given its response.

He (President Obama) said US Energy Secretary Steven Chu was leading a team of "the world's top scientists, engineers and experts" in devising a contingency plan should the "top kill" attempt fail.

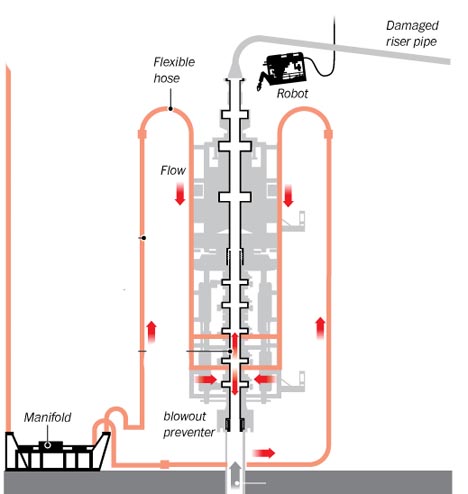

But while waiting for that, and for the Lower Marine Riser Package (LMRP), I thought I would spend a few paragraphs discussing why Top Kill may have failed as a substitute for my tech talk tonight; you can find that under the fold by clicking "there's more."

(The last post has a very technical discussion of LMRP, check that out there and in the comments.)

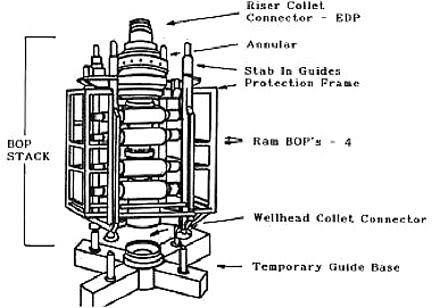

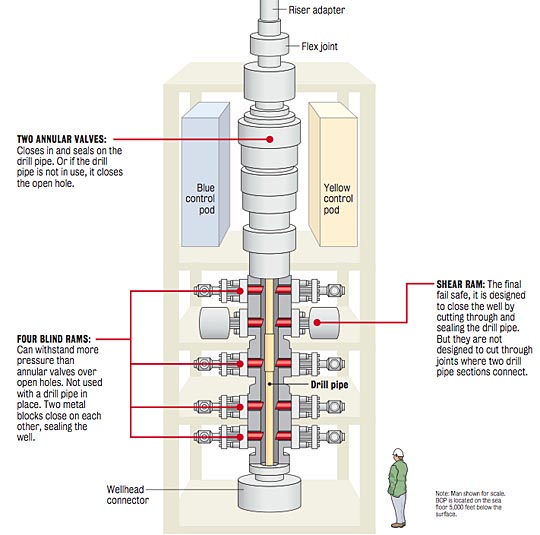

In a couple of earlier posts I wrote about how it was necessary to fill the gaps that ran through the Blow-Out Preventer (BOP) either with spheres and triangles or with wire (string would act similarly). To refresh your memory, in the initial simpler analysis, I had put up a simple sketch of the BOP and well, to show how the blocking particles were injected.

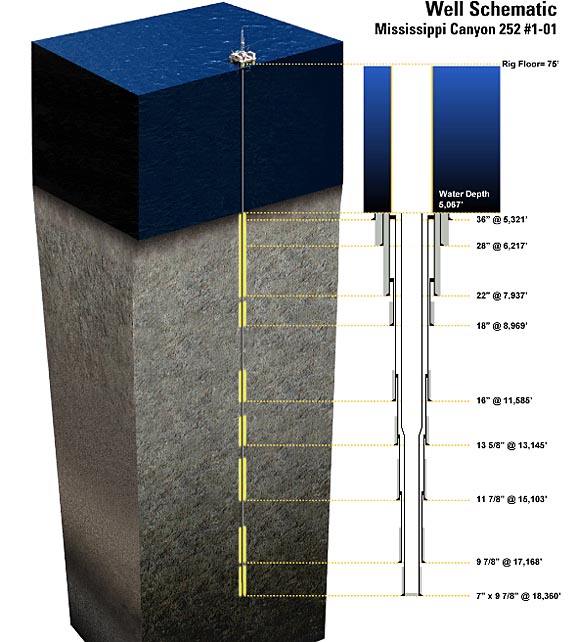

Now, unfortunately that diagram left a significant part out, and that is that there are three sets of pipes leading down into the well. These are the well outer casing, which, surrounded by a layer of cement, holds the BOP in place. Then there is the production casing, which had just been set to the full depth of the well. And then there is the drill pipe that, at the time of the incident, extended down 8,367 ft from the platform, or roughly 3,367 ft below the BOP. That drill pipe (DP) had previously been used to locate the production casing at the bottom of the well, and itself now rode inside that production casing. In most normal operations it is closed at the bottom by a drill bit, but (and I’ll come back to this later), it had just finished the cementing of the production casing into position, and once it detached from that and was being pulled from the well, it was an open pipe all the way up to the rig floor. And in that condition, it could be used for other things. By pulling mud out of the DP and transferring it to the mud pits (or standoff vessel), the level in the riser would fall and be replaced by seawater flowing in at the top. Unfortunately this also lowered the weight of mud in the well, and that is what caused the oil and gas to flow into the well.

Outside of the DP is the casing and cement segments that make up the outer lining of the well. The diagram presented in Congressional testimony, shows these various pipes, except for the central drill pipe.

BP do not know, but believe that the oil is getting into the well through the cement wall at the bottom of the well, and probably rising up the well through the empty space (annulus) between the production casing and the outer lining of the well. However the oil and gas may have broken through the bottom of the cement plug and be rising up within the production casing, in which it is also rising through the DP once the oil reaches its lower end. It could also reach the bottom of the DP by flowing up the annulus then go down the production casing to the bottom of the DP and then back up into the BOP.

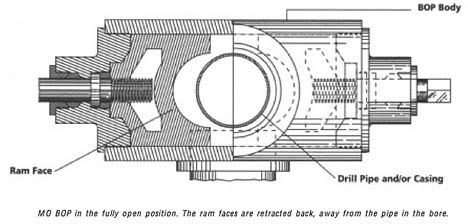

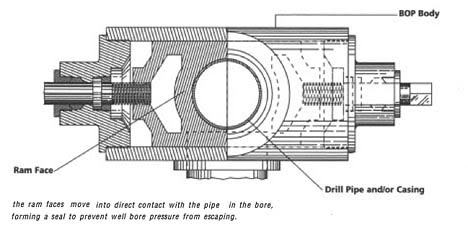

Most normal blowouts occur when the well is being drilled, and mud is flowing down, through the drill bit, and then back up the space (the annulus) between the DP and the rock wall. Thus, when there is a blowout, the oil and gas that flow into the well normally flow up this outer passage to the rig, and give the spectacular fountain of oil. The BOP was invented (by Harry Cameron and Jim Abercrombie) to stop that flow and to protect the crew at the surface. Because the flow is normally up the outside of the drill pipe, the initial BOP designs were rams that pushed seals across the flow path through the BOP, and sealed against the side of the DP.

A BOP could have two of these mounted so that one sealed to the production casing in the well, and one to the drill pipe, but if underwater then the production casing is tied back to the Wellhead Collet Connector, and then the only tube running through the BOP will be the DP, to which they will seal.

The problem that this leaves, in the current situation, is that the pipe that runs through these two seals is open at the bottom to the oil flow. So how can the flow through this be stopped?

The answer is to mount a top ram set that has a set of shear cutting blades on it, that will cut through the pipe and seal the full face of the well.

The DP should shear, but would be held in place by the grip of the annular sealing rams below.

In this case it seems to be recognized that for some reason this shear event did not totally succeed. Thus the pipe was not totally severed and the two shear plates did not fully move over one another to complete the seal.

Now this is where the problem arises, because, in part, that pipe is still open at its lower end. If the leak is around the outside of the pipe, through a gap that has generated between the pipe and the annular seals, then the use of the junk shot to fill the cracks and gaps could conventionally have worked. But the configuration of the rams on the Deepwater Horizon had changed from the initial simpler configuration to add seals for occasions where the drill pipe was not in place.

And the "junk" is being injected at the bottom of this stack.

If the leak is coming up through the remnants of the drill pipe then life is complicated. It can’t all be coming up through an undamaged pipe alone, since it was the far open end of that which was successfully closed at the beginning of the remedial steps, but if it is coming through the pipe and leaking out at the shear rams into the annulus that feeds into the riser, and out to the sea, then putting sealing particles into the bottom of the BOP to seal the cracks could have sealed some of the leakage around the DP trapped in the shears, but not that flowing through the shears in the remaining pipe section.

The reason that it can’t is that the access to that flow is occurring 3,367 ft below the riser, and there is no easy way to get the sealing particles down that far. If they are mixed with mud and pushed down the well to that level and then released they have a different problem. The hope when they were released into the well was that the flow of the current would be enough to carry them up to the cracks that they could seal. But if they have to be carried down to the zone where the oil remains, then their density may be sufficiently high that they get into the flow without enough speed to lift them up into the BOP, instead it will cause them to sink to the bottom of the well.

The materials that BP tried included materials that might float on the surface, and might not be dense enough.

Those materials, including fibrous pieces of rope and chunks of rubber, were supposed to force more of the mud down the wellbore, but ultimately it did not work.

Rubber has a specific gravity of 0.91 and rope varies from 0.9 to 1.4. But remember that at that depth any buoyancy from air entrainment would be lost.

In other circumstances it might have worked, If they could have dropped the DP out of the shears perhaps, but they couldn’t and it didn’t. So on to the LMRP.

UPDATE: Thinking about this a little more, I had two more thoughts. The first is that once the LMRP preparation cuts off the riser and the bent drill pipe, then the full weight of the pipe below the shears may come onto the section in the shear jaws at the moment, pulling them further out of alignment and increasing the flows. It could also cause the pipe to drop out of the jaws, pulled out by the underlying weight, and hopefully not distorting them too much so that in the best of worlds they could then be cranked shut.

One could also, once the bent riser and pipe had been cut, go in down the pipe bit that extends up, go down past the annular seals with an abrasive jet lance (most of the flow is around the DP as we have established above) and cut it off, right above the shears. Then partially open the shears, drop the pipe out, and close them again. If they move all the way closed, without the obstruction, then the well may be sealed.

To begin, a sincere thank you to all who have donated thus far. It will help with the increased costs (see point 3 below).

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome, 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of threads today. They are really good--but when we get to 400 comments, it's really unmanageable. Lots of good stuff in there though.

Prof. Goose That is the best explanation I have seen anywhere. I hope POTUS asks you to come to DC and brief his staff on what is really going on in GOM

Thanks for working the W/E. Wish our POLs were doing the same.

Help please re MIRC. I cannot make it work. The app has only a 30 day trial period. Is there any free alternative?

with all due respect

Jim...

You can get to IRC via a browser at

http://webchat.freenode.net/

Just enter your nickname and #theoildrum in the boxes.

Or XChat.

Or XChat.

Chatzilla is a good free IRC plugin for FireFox

Chatzilla

https://addons.mozilla.org/en-US/firefox/addon/16/

FireFox Browser

http://www.mozilla.com/

If you use Firefox you can install the ChatZilla extension. If I remember correctly from the other day, it will launch itself the first time upon restarting Firefox, but then after that you can launch it by going to Tools > ChatZilla in Firefox to use it.I have no idea why I didn't see the comment above mine.

video - what are we seeing - this the top of the BOP that we were watching during topkill?

Live now are the clearest images I've seen yet of the top of the BOP and its connection to the riser. Could someone knowledgeable please take a look and render an opinion of the feasibility of fitting the LMRP to the top of the BOP after the riser's been cut off? It looks pretty twisted.

Thanks; amazing site.

Guys, check out the chat room--they're talking about this in real time. (see point 5 above)

Rainyday - thnaks for the question - re the cannibalised BOP and links / citations - it is all on the BP website. I am really quite surprised (or maybe not) that there are so many wild guesses and conspiracy accusations (not from you) when info is readily available in the most obvious places. Perhaps it is easier to type than read.

So looking at the second diagram in BP's Response in detail:Containment Contingency Option

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

the device above the LMRP cap looks similar to the top half of the BOP. I don't see any text in the detailed response suggesting that that has come from the RW BOP. Referring to header of the previous thread, I wonder what portion of the LMRP package has already been placed on the sea floor. I had thought that referred to the already assembled top hat device, which has been on the bottom for quite a while, just appearing under a more technical name.

I appreciate your highlighting the info on BP's site, and, while I agree that it seems to be easier for some to type than to read, I don't agree that it is "all on the BP website." If it were, we wouldn't all - newbies like me as well as grizzled TOD veterans - have so many questions.

The RW BOP was said to be sitting at ready close by the wellhead should the LMRP fail. By my understanding, it was not to be part of the LMRP attempt, which is why it is not in the rendering - I think. If LMRP fails, the 2nd BOP a Lula would be next up.

You know if you're juggler vain is cut, and you're just gushing blood all over the place, about to die; you don't ask folks to go around the room and clean up your bloody mess everywhere while you bleed to death. First of all you've got to stop the bleeding. Then focus on the mess. I don't understand why they can't just fly over, or send ferries and start dumping tons and tons of gravel over this thing until it's completely covered in a mountain of gravel on the bottom of the ocean. I don't know how long it will take for the rocks to fall all the way to the bottom, but that would stop the bleeding at least. Then we could focus on cleaning up the mess.

Building a mountain down there may be impossible as I believe the mud's pretty deep and soft. So much so that the Horizon-wreck simply sank into it (seen any pictures of it?).

But what the heck would I know.

Regards, Matt B

PS. I like your jugular vein analogy

It's ok, but carotid artery would be a better analogy.

If your base is wide enough, your slope gentle enough, there is no reason you could not build a "mountain" on soft soil. Remember, you are not concerned about how much that mud compresses over time. You're not building a nice structure that cannot tolerate large differential settlement on top of this thing, so as long as you don't have slope stability problems you're golden. And you avoid slope stability problems by having shallow slopes.

Technically, it's feasible. Financially, that's another story, and we are not event talking about the time frame involved. That thing would be HUGE. Artificial islands have been build in shallow waters for good reason. And even then they are among the most massive undertakings ever done. Don't forget that you would have to pile up a mountain taller than the depth of water available to match the pressure of the reservoir... which means that you are talking about a colossal undertaking.

Simply put, that solution might take (very, very very much) longer than building a relief well, it would be immensely costly and most like even if carried out it would prove fruitless. As I understand, there is something like 3 kilometers of rock (I may be wrong here) drilled through the bottom of the sea to reach the reservoir. The pressure of the reservoir is normally at least that much if there were no leaks. This is compatible with the 13000 psi pressure reported. Now, if you want your "montain" to resist that pressure, it must be of comparable height to offer the same pressure. If you cannot balance that pressure, than you cannot hope to stop the flow, right?

The goal of the top kill, is basically to refill the same height of rock removed by drilling with a material of similar density (the drilling fluid) so that by the time we reach the bottom, we are balancing the pressure in the reservoir. So it is the same 3 km (1.8 miles), but with a limited volume, (idealized as a cylinder to make it simple). In reality it is a truncated cone, varying from 46 cm (18 inches ) in diameter to 18 cm (7 inches) from the drawings higher up in the post. Assuming a mean diameter of 32 cm, and 3 km depth of "cylinder" you get a few hundred cubic meters of material (couple of thousands of barrels in volume).

Now, if you pile stuff on top of your gusher, to build a "mountain", you are using an unconfined volume. All materials you will use for this will have an internal angle of repose, equivalent to their friction angle. If you pile up sand, you cannot make it stand as a cylinder. It has an inherent friction, and will end up making a nice little hill. The side slopes may vary depending ont its surface properties (mineral composition, particle size distribution, density), but will be generally in the viccinity of 30 degrees. So to make a mountain of sand of 3 km it will need to be 5 km in radius, that is 10 km in diameter. I don't think we need to go through the details of the calculations to start seeing how big this needs to be. Even if we assume we are using rockfill with a higher friction angle (say 45 degrees, , so 1:1 slopes) we would need 6 km of diameter, and a lot more material. Also, if you notice, there is only 1.5 km of water above the seabed, so we need to start building our mountain up once it surfaces. It starts getting big. The volume of the cone is 1/3 π R2 H, and now you are talking something in the order of 30 KILOMETERS cubed of material. That material must be mined somewhere, transported, dumped, placed, etc. etc. etc. You're likely talking years of work. And what then?

Well you ahve the same problem they had with the leaky riser... you have pores within your material. To avoid leaks, what you need to do is to dump a good mix of soil (of all sizes, from clay to silt and sand) and not just rock to plug the holes (like they tried to do with the junk shot). But if you just dump it in the water all your fine material will get washed away, leaving you with mostly only the coarser stuff, full of leaks in between... so you are left with... exactly the same situation, after years of effort immense cost (both monetary and environmental if you have mined the rocks nearby... you've compounded your problems). And you've done exactly nothing.

What's more, because you need kilometers of space on the sides of your well, you now have essentially kissed goodbye to your relief wells (you can't start drilling them until you have completed your mountain, and then through the slopes of the mountain, or so far away that it would take forefer to reach your well, and you would risk problems due to the construction of the "mountain"). Those relief wells are ultimately the best bet of getting this thing under control, you can't just sacrifice them like that.

Finally let's not forget that we would have to place this rockfill and soil on top of a gusher, with a lot of pressure behind it. That may not be easy to do at all. When you drill a hole, you start putting the drilling mud as you go down so that by the time you get to any given depth, you have the full depth of the drill hole above you providing pressure. When they tried the top kill, they had to fight the pressure by attempting to pressurize the mud in the BOP. If you just dump your rock/soil into the sea, you may find a nich hollow place all around your gusher, as the material will settle around it rather than on top of it. Even the heavier bits.

This situation is one example where "doing anything" is just not good enough, and most likely harmful. It is very tempting, in a panic, to just do "anything" for the sake of feeling better, feeling like we are doing something. But more often than not, the gut reaction may turn out to make things worse. Given the potential harm that this thing can cause, I think we need to rush, but rush in a well thought out manner.

Simply put, that solution might take (very, very very much) longer than building a relief well, it would be immensely costly and most like even if carried out it would prove fruitless

wow. very long post and meaningless.. May be this show why we may need to split the newbie post with the more experience folks. Basically it is a ranting because of lack of understanding of the technology. All the industrial expert is saying that relieve well is the answer and it may take multiple time but ultimately it will shutdown the well. So what exactly is this ranting added into the discussion. Any proof that show why it is "fruitless"? Nothing and it just waste everyone time. But I read into about 1/3 of the post before I figure out that it is completely off topic. And if you multiple the time I wasted by the total number of readers in this site, we just manage to waste a lot of valuable time..

SomOfZilch:

The seawater pressure at the well-head is about 2400lbs per square inch. The pressure of the oil leak is about 10,000 or 13,000 lbs per square inch. As one of the experts around here commented several days ago, even if you could drop a huge monolith over the site, the oil would just tunnel out though the mud to the edge of whatever you dumped. This is not a simple problem.

The experts are tired of responding to naive suggestions like yours, and the best reply you'll probably get is from a non-expert like me.

What part of 13,000 psi at the wellhead did you not understand? Pour rock on a volcano. Hum, gee pour rock on it, the smartest people in the oil industry and no one has ever poured rock on it? What about item 6. in my book a moutain of fast setting post cement? A giant moutain 5,000 ft. deep in the GOM? Would you put the battle ship on top or on the bottom? Before or after the nuclear weapon? Pour giant screws until one of them sticks in the hole? Oil uould never find it's way through rock would it? Labra tar pits? Maybe you could do a manvour called the reverse Jed Clampett? You could fire your shotgun until the well fills with lead, unlike the lead fishing weights item 7 in the book??

Have we explored harmonic vibrations from a giant crystal pyramid?

That preamble to this new thread was the most lucid explanation of all the various parts involved in this puzzle that I have ever seen.

Really really good. It took me a while to digest it, but it was worth every moment spent.

Excellent. Many many thanks.

I'm reaching for my wallet right this minute.

Hundreds of miles? No. How far inland the oil moves in depends on the storm surge, which is in turn affected by shape of the shoreline, elevation, etc.

More here:

http://www.noaanews.noaa.gov/stories2010/PDFs/hurricanes_oil_factsheet.pdf

I wonder how much of this toxic brew can evaporate and then rain back down?

I have seen this happen when a shrimp boat dumped it's fuel after sinking halfway. The fuel went out on an outgoing tide (they avoided the Coast Guard fine) then I noticed all this fuel back in fresh water ponds that weren't connected to the ocean.

Either way, I think what is bad for this region is bad for everyone.

I've never heard of hydrocarbon rain on this planet. I seriously doubt that you are going to be able to saturate the Earth's atmosphere (even locally) with hydrocarbon vapor, and if you did it would make a god awful bang when the first spark came by.

With heavy rains maybe it just seeps right through the soil? A lot of people reported their well water tasted like fuel after that fuel dump. And what about the rest of the toxic brew? This stuff is probably going to end all over the place and in the drinking water.

In every place I can think of in South Louisiana (south of Lake Pontchartrain), drinking water is taken from rivers. Fresh supply daily.

Alan

It's nice to know the GOM is safe and sound. No need for additional testing of ground water after heavy use of dispersants in the region for the worst enviromental disaster in the history of the US.

FOR ALL

Previously it was asked why the POTUS doesn't fill the GOM with supertankers and just suck up all that oil. I'm not too expert in such matters but here's a simple answer

It’s difficult for folks to envision what’s going on out in GOM. First, there are no pools or plumes of oil out there. They are dealing with an oil/water emulsion. The oil/water mixture won’t separate easily. This is not an uncommon problem with some producing wells. The emulsion has to be broken and that takes chemicals and, more importantly, time. If they pump the emulsion into a tanker much, if not the majority, of that volume will be water. If they don’t separate the water from the oil most of the storage space will be wasted.

Another big problem: the emulsion is not concentrated in big pools. That’s the purpose of the skimming ops. The goal in skimming is to concentrate the emulsion to limit the amount of water sucked up with it. If there’s a 6” layer of emulsion floating on the water and they drop a suction hose into it they’ll likely draw up 90% + water with it. So yes, such a process would recover some oil but it would be horribly inefficient and have a minimal effect IMHO.

I'll take a shot at this. In the Arabian sea case where they did this successfully they used booms/skimmers to corral the oil, then pumped the mixture into the tanker -- that's the purpose of booms to direct the oil. I've seen the claim of 85% cleaning was made--though obviously it couldn't have been that good, or anywhere near. Today, the big problem could be the dispersant use--but that's just hiding the problem anyway. Today, we also may have these centrifuges to separate the mix--I don't know how well they work, but now is the time to find out if there ever is.

I don't think it'll be all that successful, but the Gulf and loop current is pretty closed. I think it would definitely help, with zero downside to anybody but BP.

John Hofmeister president of Shell Oil from 2005/2008 is on tour promoting his book Why We Hate the Oil Companies. I heard a radio interview with him in which he described how they sucked the oil up into tankers in the Arabian Sea. He said Shell has been trying to persuade BP to try that in the Gulf with no success. He was extremely critical of BP saying their reasons for not doing it are bogus. I know nothing of the technology involved but it seems BP is either extremely negligent in not doing this or has a reason they haven't as yet shared.

Yes, I heard his book tour on Canadian public radio too, and it was quite repulsive.

He was willfully ignorant of the difference between a shallow "unreported" (now, who can argue with facts against some claim that is stated as "unreported 'spill' ") and the physics of a a deepwater and "dispersed" emulsion.

Fact I see is, there seems to be a gigantic PR machine at work, even reaching Canadian public broadcasting, even these hallowed forums at the TOD.

[my background is political - I helped establish the Green Party in my home town in '82 and got voted into city council, for I believed it was an idea whose time had come. I had read "Global 2000". But, I'm a Realpolitiker, not an Idealist. I try to see the forces at work, and strive for the realistically possible]

That said, bearing my soul, - we can in innuendo repeat the same arguments of reason to the great unwashed why gravel/concrete/uranium/mercury/airplane-carriers/Mr. Spock/hydrogen bombs drops onto the well won't do shiona. But, I am afraid, in somebodies grand plan, this is a wanted behaviour, to drain our combined energies.

What is needed, I think, is a simple and decisive technocratic argument that needs to be repeated and hammered home, over and over again, to cut through the noise machine.

I am poor, and have problems to donate 20 bucks to keep my beloved TOD online, but I would gladly give 100$ for a thinktank of Goose, Gail, Rockman, Shelburn, Alan NOLA (and whoever they'd like to add, no offence meant) to put out a strong, unified message that we can get behind to counteract this ridiculous PR empire that is "dissolving" public opinion.

I do hope, that this is an idea, that various people from different political backgrounds could rally behind.

(this is a cognitive response to a Rockman comment a while back, that he would not believe anybody would like to hear him speak in public - If you think you don't make good interviewees at single, insist on group interviews! Don't follow patterns, lead!!!)

This is rather interesting that Shell doesn't seem to have more influence with BP since I think I read somewhere that both Shell and Exxon had been investment partners with BP in this project.

i agree its not the most efifcient process....

but these tankers can process 1-2 million gal/day .....and i doubt on the surface the 6" layer of emuslion is 90% water......te top surface has to be upwards of 25% oil ....yes maybe down the water column its 90% water not on the surface.......

throw 5 tankers skimming in there processing lets say 1.0 mil gal/day ....thats 5 mill a day

assuming you are correct and the emulsion layer at the surface is 90 cut water ....thats still 500,000 gal of oil recovered daily

assuming I am correct and its 75 cut water at the surface ...thats 1250000 gal of oil recovered a day

the oil collected can help offset the cost of running these tankers which i am sure will be enormous...

i know I am over-simplfying what will be a tough shop to run since there is no big oil spill here but lots of medium sized ones by now ....if it will work or not i dunno but the numbers sound like it would be time well spent for someone to sit down for an hour and work this over...and it has a better chance of success than top kill on a flowing well.....

ali - when yu say the tankers can process so much per day what do you mean process? Tankers are tankers...process ships are process ships. Also, I didn't say the emulsion was 90% water but that when you tried to suck up just that thin layer of emulsion you would also suck up much additional water with it. How much would depend on the suction rate. A low pressure draw down would decrease the water cut but also slow the recover up. Also, tankers can't skim oil...skimmers do that. You can have 100 tankers out there but you acn't fill them any faster than you can skim and process the emulsion.

Again, not a area I'm too familiar with. Was hoping some environmental type with recover experience would jump in with details. But I do have experience with seperating oil emulsions from water in onshore producing wells. It is no small effort to just seperate a few hundreds bbls PER DAY. The biggest problem is the retention time it takes to do the process. No matter how you scale the effort up you can't make the clock change as you would like. The problem seemed to be highlighted earlier today when I saw folks using paper napkins to pick up emulsion along the marsh.

I guess the short answer would be that if this approach could really make a difference than the POTUS and the Coast Guard must prefer to see the GOM filled with oil. Not a bet I would be willing to make.

Rockman ...man i dunno myself if it can work or not ..although I do know for certain Shell had a technical group working on such things in netherlands when I was there early last year....but then i'm sure if they did get something going those ppl are already state side helping out

although a low pressure draw will help ....maybe have 10 straws sticking out a tanker so something at minimal del P..

by process i mean the ability to take in X volume of emulsion and seperate it ......

i'm just a drill and completions guy....got no experience with emulsion seperation ..all i'm saying is if the arabs can hire Americans ..give them a free hand with the cash and do something about it ....we oughta be able to do something to help ourselves ...maybe station the tanker near the bayous and do what you can ..

these dog and pony tricks with top kills and LMRP caps make me cringe... time relief well is sunk and bottom kill attempted it will be august (i personally think it will be around early sept before bottom kill can practically be attempted...and dog leg severity restrictions on the RW approach I am sure will cause a big mess in the ops, come time) and by that time the bayous are going to be a black cess pool....

one thing that's for sure....the poor ROV guys over at Oceaneering are earning their keep these days

ignorance is bliss...someone said it right....

Your time frame for when BP expects to complete a relief well may be accurate. On the news tonight someone from BP said "end of August" for when they expect that. I clearly hear him say "end of" and then August. (It was either CBS or ABC - not sure which.)

What's the latest word on the plausibility of the Kevin Costner centrifuge system working in this arena?

I think the Kevin Costner centrifuges will need just the right skimmers; skim to deep and you get too much water, which lowers efficiency. Skim to shallow, and you get too much oil. Too much oil and you get oil in the discharge water, which also lowers efficiency.

Maybe the centrifuges can discharge the oil or oil/water into to a tanker, and the water will sink which can then be pumped back into the gulf, leaving just oil behind.

It seems as though there are three "avatars" of the contents of the reservoir that are involved, each with its own behaviors and properties and each demanding unique identification/capture/control techniques. I'll provide the links on which I base this observation below, and one is Dr. JOYE'S blog. There was also information posted recently on the web that the oil [droplets] in the "plumes" behave like water. Sorry I can't find that link, but if there are any hydrologists on board, maybe they can provide it.

1. "Plumes" as a natural substance remaining underwater and detectable only with special instrumentation

http://gulfblog.uga.edu/

"...CDOM signature and invisible – to the eye at least – oil"

"...plumes like these most likely form through natural processes. At the temperature and pressure of the reservoir, methane is dissolved in the oil. When the fluid is expelled at the seafloor, the methane comes out of solution in a fairly violent manner. This gas expulsion likely fractionates the oil and it is this fractionation that generates the diffuse oil in the plumes."

2. Crude from the reservoir + Corexit, synthesized substance: visible

http://www.nalco.com/applications/corexit-technology.htm

"...When the COREXIT dispersants are deployed on the spilled oil, the oil is broken up into tiny bio-degradable droplets that immediately sink below the surface where they continue to disperse and bio-degrade."

3. Crude from the reservoir reaching surface intact, natural substance: visible

http://discovery.kcpc.usyd.edu.au/9.2.1/9.2.1_CrudeOil.html and

http://www.bp.com/extendedsectiongenericarticle.do?categoryId=16002782&c... which offers a spreadsheet

Still can't find the Macondo assay so I lifted Thunderhorse. I hope that wasn't too far off base with that.

(Mods, server running slow, if this is dup post, please delete!)

Rockman the Reasonable. Thank-you. And thanks to Heading Out and Professor Goose who continue to demonstrate how well ad hoc can be done.

There will be two mitigation efforts. Make work and nature's efforts. I'm all in favour of make work, though not at the expense of people's health, for two reasons. Something has to be done to help people deal with their sense of powerlessness. Might as well put money into the region.

But my faith rests with nature's ability to recover.

I hope Obama has at least one more team focussed on the Gulf. An economic team, evaluating the possible ways to mitigate the economic hardship the BP Big Bop is causing and will cause until nature has done with the oil.

RM

Is the oil emulsified as it leaves the broken riser and mixes with water or is it being emulsified by the dispersant? Once they cut off the riser and there's only one point source for the leaking oil, would it make any sense to stop dispersing, see if the oil rises up in more or less one sort of localized spot then burn, skim, supertanker that "spot" maybe use some solid boom with extra-deep skirt? I realize that might be problematic with the traffic jam over the well but if it was concentrated they could rearrange the fleet?

The info at the top is excellent and informative. Would a FAQ section help hold down the posts from new surfers regarding the Bruce Willis type options?

Moose – I suspect it emulsifies rater quickly when it hits the seawater. But I have no idea how the dispersant interacts with the emulsion. Just agues but I don’t think removing the riser will change what's happening in the water column.

As soon as the oil hits water it is going to start forming an oil/water interface. Energy minimization means that interface will be spherical. Since there is a lot more water than oil it means oil drops.

Basically what happens next is the droplet size is influenced by how much energy is available to form surface (surface tension x area = force x distance = energy). The dispersant adsorbs on the oil/water interface and lowers the surface tension which means you can make more surface for the same amount of energy, which means smaller drops. The dispersant also provides electrostatic charge and stearic hinderance on the droplet surface making it less likely that two colliding drops will coalesce.

Over long enough time and storage in a quiescent environment energy minimization will win out and the oil will coalesce.

As far as plumes and water column go that appears to be dissolved methane. If so these plumes have nothing to do with the use of dispersant.

One of the technical names for this is a surfactant.

FYI, I have another treatise posted, this time on dispersion.

http://mobjectivist.blogspot.com/2010/05/word-on-dispersion.html

Anyone who wants a technical workout is invited to read it.

Surfactant is not really a technical term. It's simply a portmanteau of "surface active agent" that was originally invented by a marketing guy.

Not really. I have published in surface science journals and we used the term surfactant 20 years ago to describe weird crap going on during single crystal growth with the introduction of impurities.

BTW, Weird Crap is also a technical term.

Per Wikipedia:

The term surfactant was coined by Antara products in 1950.

I think I first became aware of the term in the early '60s.

I have worked on making asphalt & coal tar emulsions. The concept of minimizing emulsification is pretty good, I think. What is needed is to slow down the velocity with which the oil impinges into the sea water, and eliminate the dispersant (which reduces surface tension, thus reducing particle size. Something as simple as a piece of pipe or hose big enough so that the energy of the pressure drop from the inside of the riser to local sea water pressure would be dissipated via turbulence within the oil/gas phase (prior to mixing with sea water) would reduce emulsification greatly. The less violent the mixing, the less the emulsification. The rising plume could be contained in a flexible tube (made of fabric-reinforced elastomer; one example: http://www.spinpro-us.com/?gclid=CNXvxo6d-6ECFUlB5god6VvPGA not the best reference, but I could not find that quickly)

Excellent idea Roger to reduce emulsification. Please recommend to BP/Deepwater Horizon Response.

One thing potus did right was having Mr. Chu in charge of the scientists. This makes me feel a little bit better about the overall health of the damaged BOP. Without him down at the hive expressing his concerns BP probably would have been dumping mud for an extra 24 hours.

Since we may be looking at August for a complete stoppage. I would like the experts/s opinions on using Tankers with the cleanup effort. What are the main issues on why these are not working in/around the gulf now> I already know BP's explanation around the broken well itself, far too much surface activity. I just think we need at least two-three of them circling the gulf so that the boom vessels can herd the surface oil towards them. The plumes are really another issue in itself, armed with centrifuges separating the oil from seawater a Tanker can literally park dead center over these and start vacuuming the oil up.

I don't really have much confidence in Chu. In a recent interview he didn't even know that oil was under his purview. And he has been Energy Sec for 16 months.

Oil comes under many depts -- MMS, for instance, is not in Chu's, but Interior. Transportation is also involved - so it would depend upon which link of the chain from source to final destination downstram you would be taking about. And Chu may quite correctly have stated that he was uncertain whether a particular link belonged under his purview.

Not sure who posted this last thread...but a good .ppt to scan for any geos/engineers. From BP's reconstruction of timeline...

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

PS - can somebody pls. explain what the casing hanger lock-down is for? Does it prevent casing from being being pushed up the hole in the scenario of a blowout? Or something else?

tt, thanks for posting that link. I had not seen that and it fills in a lot of the missing links. After studying that document, one can only guess what was going through the minds of the supervisors on board as the warning flags started flying.

Items from the latest BP email:

The 20 percent number (10-20%) has been quoted by BP for at least 10 days.

So, if they collect all the oil do you reduce the value by 20%? And, how do you know, given the variations of current flow estimate? I can hear it now : "Total flow captured is now 12000 BOPD. Obviously the flow did not increase." Let's hear from all those who have claimed the flow will shoot up by a great amount and who claim it is already at least 50000 BOPD.

I'll chip in for any nominations for HO to get some kind of prize for reporting/analyzing/explaining this whole thing!!

Jeff Masters at Weather Underground has a post on how the Loop Current works. There's a link there to a (large gif) 1-year animation. Looks like blowing huge watery smoke rings...

Masters has some pretty pictures, but I like Roffer's overlays of oil extent on top of currents mo' better. Roffer's analysis also shows more experience in predicting current flows:

http://www.roffs.com/DeepwaterHorizon/ROFFSOil29May10.pdf

IMHO, the Loop Current/Loop Current Eddy has been holding the oil in the northern Gulf for weeks, confining it in smaller counter-rotating eddies along the northern bounds of the Big Eddy. As the Loop Eddy detaches and moves west there will be a breakdown of the oil-carrying eddies and an accelerated flow east and south along the Florida coast toward the new Loop Current path. As well, some southerly flow from the western spill area could run clockwise around the northeastern quadrant of the Loop Eddy and directly into the new Loop Current. If this seems like wild speculation, see this and related current charts from the July 2009 Loop Current Eddy separation:

http://www7320.nrlssc.navy.mil/GLBhycom1-12/navo/glfmexspdcur/nowcast/sp...

For clarification, if the spill had been popping up in the middle of the Loop Current, the Eddy migration would be good news for Florida and points east. But the spill has been outside the Loop, basically walled off from the rest of the Gulf. That is now changing and the chance of greater spread of the oil has gone way up.

James

I am not technical, so have nothing to contribute on that score. I too appreciate this site; and have done so for several years now.

There is another thread on the FTW blog about BP and their behaviour. Summing up, it seems that this well could have been "killed" with explosives, maybe even nukes, several weeks ago, but that BP, for commercial reasons (because the well cost hundreds of millions and they may never be allowed back to the field again) is trying to save the well.

Could that be true? If so it stretches credulity beyond imagination and Obama has made a catastrophic error of judgement, or failed to take charge as he continuously promises.

yr reading inaccurate undocumented date, jus the facts m'am

Dog - you might dig thru some old post. The blow out well will never, ever produce. The GOM is being killed by the flow of oil into as a result of the well BLOWING UP. Blowing it up again won't reverse physical laws.

You would be surprised how many posts I have seen here and other websites that seem to be absolutely convinced that the government is just holding out, by not nuking this thing.

I guess I shouldn't be shocked by that, when I see people these days who don't even seem to know who the first president of the U.S. was. Having watched a few of those Jay Walking videos on TV and see comments on the internet. Makes one wonder just what are they teaching in school these days? Anything?

SailDog:

IMO, there is exactly Zero probability of the United States Government ever considering using a nuclear explosive device to close this, or any, well.

Absolutely Zero Point Zero Probability.

I personally have 100% confidence in my assertion.

Perhaps Professor Goose can add this statement to hi fine BP DWH Blowout thread Preamble posts.

I offer no citations to back this statement up, nor a CV.

Believe my assertion, or else continue to engage in harmless but useless speculation about the use of nuclear explosive devices for this situation.

The submission of brainstorming ideas to TOD, the USG, and BP is wonderful and by all means keep the efforts going, but focus your finite time to use your problem-solving skills by forgetting about this non-starter idea.

For reason's sake, the Russian's wouldn't even consider this as an option if they had a similar situation.

Inbound biosphere-killing asteroid detected with at least several years warning time....maybe, particularly as other actors would have the option to go that alone, so the World would likely pull together if that option was seen as the best or maybe only shot at deflection.

Not for this though.

I certainly hope you're right the the USG is not considering a nuclear detonation to deal with this...because the only consequence of such an action, would be that then we could all be horribly bent out of shape about the RADIOACTIVE oil that is spewing up from the (completely forever uncontrollable) hole that USED to have a casing that could be intercepted by a kill well, back before we blew it all to Hell and gone...

I'm sure that Bobby Jindal and the MSM would then switch back to excoriating Obama about how his fascist/socialist/communist Administration had overstepped the bounds of limited government with the nuclear bomb, and that all they want is to be left alone to solve the problem themselves...

PeterHug,

You can sleep soundly, at least wrt this particular concern.

Using a nuclear device to seal this, or any, well is utterly off the table.

The idea was never on the table.

This idea was never let inside the room with that table.

There is a much greater chance of someone running a prototype commercial nuclear fusion reactor by the end of this year.

I am no fan of BP, but, no, they are not trying to save the well. The Well is already toast. They are trying to stop the leak. It is in their best interest to do so, quickly. Whether they are competent or whether they are being pushed hard enough may be another story. I will leave it to you to read through old threads like a responsible newbie to see why nukes or other explosives is a really bad idea.

I'm not in BP's fan club either, and enjoy a plausible conspiracy theory as much as anyone, but the notion that there is some agenda to let this well continue spilling so as to try saving money just beggars belief.

Sure, the upper echelons at BP are bigtime worriers about PR and the legal department has a lot of clout too, but the hardhats working on the problem are serious people, and they want to kill it.

I don't see that as even debatable.

It's true they are fenced in to working on low probability solutions right now, but that's sure as heck not their fault.

And what is it with some people that when they can't figure out a solution to a problem the first idea they turn to involves high explosives? I mean, really? I know they've worked to put out fires on land-based rigs and the like, but now all of a sudden we're suggesting nukes because the Russians say they did it ?

Please.

How does it go? "Just drop a nuke down the well and collapse the whole thing" ???

Aaaargh!

There is an old Army saying:

"There is no problem that cannot be solved with a sufficient quantity of high explosives."

However - I think that this leak is the exception to this rule.

When does this kind of nonsense stop?

1) No, BP will never, ever, ever, ever produce from this well, nor the relief well(s).

2) No amount of explosives nuclear or otherwise could or can seal this well. Presumably a well would have to be drilled in order to place the charge which is the same thing as a relief well. Only you blow the crap out of the ocean floor and make the leak 1000 times worse. Nuclear bombs only fix things in Bruce Willis movies, not in the real world.

Besides, you see, the Russians used low yield nuclear blasts in the 1960-70s to shut off blow outs and were successful 4 of 5 times. Therefore, it is technological nonsense for anyone to even SUGGEST that an American engineer might think about doing the same thing. Also, you see, the Soviets were COMMUNISTS!!! and therefore morally incapable of being real engineers.

After seeing the condition of Russian oil fields and development I saw in late 80's early 90's I can see why they would set off a nuke.

Given the sediments and the nearby wells I am sure the results here would be interesting...as would the political ramifications.

The Russians did this because it is/(was?) WAY beyond their technical capability to drill a relief well that could intercept a blowout. So what they did instead is drill a relief well in parallel to the blowout and then pack it with a nuke.

Given that some kind of relief well is needed I'd go with the non-nuke kind first. It probably isn't going to be any faster to drill the nuke kind.

Speaker,

Your last sentence in your post is a serious understatement!

Sleep easy, the nuke idea ain't..gonna...happen...

If I was a betting man, I would take all bets from those who would bet on any non-zero probability of employing a nuclear explosive device to seal this, or any, well.

Depending how much money everyone wanted to stake, I could retire in style!

Honestly, it would be swell if everyone stopped posting this nuke idea, like as in yesterday. It is a complete waste of time, a distraction from ideas that have a non-zero probability of being tried, and these posts are likely diminishing the reputation of TOD.

There is no evidence that the Soviets used nuclear weapons to shut down oil wells that had gone out of control. The story appeared as an unsigned column in Komsomoloskaya Pravda which did not provide any source data for its claims, and this was picked up by an American blog. It wouldn’t surprise me if the editor of Komsomoloskaya Pravda had seen Borat and thought he too could make westerners look like idiots by peddling a daft story about the Soviet Union that would be swallowed whole.

Tim -

if you follow this thread:

http://www.theoildrum.com/node/6467#comment-624079

You get to a Christian Science Monitor article:

http://www.csmonitor.com/Science/2010/0513/Why-don-t-we-just-drop-a-nucl...

searching around finds this:

http://www.businessinsider.com/how-a-nuke-could-plug-the-oil-well-2010-5

This is behind a pay wall, but the abstract notes "...closure of runaway gas wells..."

http://www.informaworld.com/smpp/content~content=a788806050&db=all

continued searching finds...

The wiki mentions the Soviet "plowshare" program:

http://en.wikipedia.org/wiki/Nuclear_Explosions_for_the_National_Economy

Ah, and therein is the link to the ("free") DOE pdf report:

The Soviet Program for Peaceful Uses of Nuclear Explosions:

http://www.llnl.gov/tid/lof/documents/pdf/238468.pdf

starting on pg 34

fascinating....

It does depend on having the right clay/salt/etc. formation above the producing zone.

n.b. that should be section B.3 in appendix B.

n.b. you are technically correct, they never shut down an oil well, only gas wells. ;-)

I stand corrected, and yes I agree it is fascinating stuff. I had been unable to find the report on the DoE website so I dismissed it.

Although I think letting one of these things off in the GoM would be insane. That the Soviets did something is not usually a reliable indicator as to whether it was a good idea or not.

Or really make westerners look like idiots by seriously discussing it as an option. The idea of a nuclear option looks to me like agitprop by the successor to the KGB (whose name escapes me).

The World has changed wrt nuclear weapons and the original five club, since the 1960s and 1970s.

If the Russians did such things then, that ship has sailed since about 20 years ago.

That time is over.

We used such devices for peaceful experiments as well back in the day...

http://en.wikipedia.org/wiki/Gasbuggy

That time is over.

It IS nonsense to suggest that a nuclear device would be employed in a desperate attempt to seal this, or any, well.

By us, the Russians, the Chines, the Brits, or the French.

Everyone mooting this idea has absolutely NO idea of the moral, legal, and the many, many, many technical and safety considerations which would have to be dealt with or waived away.

I seldom use any ALL CAPS or repeated modifiers to make a point, but the point I am making is absolute and unequivocal, IMO.

One would think that someone called Heisenberg would throw a little uncertainty into their spiel, on principle alone.

Yes, the Ukrainians were successful running 4 out of 5 nuclear plants... do you feel lucky today?

The incomplete relief wells (only one will be completed) can be repurposed into production wells "later" and much of their cost retained as value.

Alam

The incomplete relief wells (only one will be completed) can be repurposed into production wells "later" and much of their cost retained as value.

This.

After all is said and done and properly killed, one of the two relief wells will end up sidetracked out and drilled down to the reservoir for technical purposes, and then suspended for possible completion later on.

Alan -

I'm hoping that, as a knowledable local observer, you can explain for me an apparent contradiction in common assumptions. It is this:

the seabed at the site is described as being so soft that pouring concrete as a base for a containment option would be futile as it would sink into "thousands of feet of silt and mud" -

Yet -

not only is a 21" pipe supporting a 450 tonne BOP, plans are afoot to perch another one on top of it. In addition to which the 21" pipe gives way to smaller diameters relatively soon, and there are also significant side thrusts on the BOP from pipe loads and material flows.

Personally I'd not care to trust even a 200ft 21" diameter pipe to carry a 90 tonne load without solid side support, let alone 450 tonnes, let alone 900 tonnes.

So could you say whether I'm missing something, or whether the softness of the seabed has been greatly overstated ?

Regards,

Backstop

That pipe was pile driven into the muck and mud for several hundred feet. Much as piles are driven into the ground under tall buildings & bridges in New Orleans.

Friction on the sides of the pipe hold it in place and for the pipe to tilt, many cubic yards of muck will have to move too, and the only way to displace a cubic yard 150' down is to move muck above it.

One can build on muck, but the techniques used have to adapt.

Hopes that helps,

Alan

Alan -

many thanks. It does indeed help.

As far as I can count, making a solid base for a double-skinned containment dome -

with an outflow pipe and stopcock for very slow closure

(after filling between the skins with concrete, and its partial burial under more ballast) -

would use about 40 barge-loads of 5,000Ts of ballast to provide a foundation-mound of around 400ft x 100ft deep -

Feasible, but certainly beyond the competence of BP to arrange promptly. Thus I guess this would necessarily be a US navy operation.

My interest in this is the same as yours in urging at least 4 relief wells -

such are the stakes that all viable non-conflicting options should be prepared for reliable sole operation, with the earliest successful option closing the well.

I wonder if we may also share an objection to further BOP-connection options - that without knowing its internal condition, nor that of the 21" carrier pipe supporting it, it is deeply imprudent to assume that these will stand whatever additional pressures halting the outflow generates.

Regards,

Backstop

You cannot rock-dump in a mile of water.

If you did, you'd waste a large fraction as it spead out on its way down.

The efficient approach is to deliver ballast to the seabed via wide MMF chutes.

Regards,

Backstop

Here is a good description of the process:

An Introduction to Drilling Offshore Oil Wells

http://www.treesfullofmoney.com/?p=1610

I'm sure we'll have wingnuts from both ends telling us things from their own personal reality for quite a long time now. Friday, one of my co-workers repeated the talk-radio notion that this was all the fault of "environmentalists" demanding that BP drill too far out in the Gulf.

Now we have the tinfoil brigade making up still more silly stuff...

I keep coming back to this site for the few remaining scraps of reality-based information to be found anywhere any more.

You got that right, buddy!

Even some of the other science based sites I frequent seem to have been suddenly flooded with batshit craziness. I think that the very tenuous hold on reality that we as a collective society were barely holding on to, has finally been completely lost... OMG!

It seems that every insecticide soaked, mentally deficient cockroach, has jumped out from under the kitchen sink and is flipped over on its back racing its hairy little legs in the air, or just running around, in little death throe, circles of insanity!

Houston, we've got a lot of problems!

Part of what you are seeing is a crisis of faith in technological fixes.

People simply can't bring themselves to believe that you can't just plug the hole, you can't just drop something big and heavy on it, you can't just send in the military, you can't just nuke it. There must be some simple solution, or an iPad app, or lasers, or something that will just fix it.

It must be a conspiracy (quick! check for commies under the bed!) of evil people with evil intent, because there simply aren't any technological obstacles, anything in the real world can just be fixed. The real challenges are getting a dozen old white guys to agree to an obscure change in a 3000 page law, of course that takes a year and is a huge accomplishment. This? "Plug the damned hole!".

++++++++++ !!!!!!

What a great post. People can't wrap their mind around a problem that can't be solved quickly and easily and in real time video.

Great post GM. I am amazed (and disappointed) that so many people think what happens in movies/games can be replicated in real life.

Spot on. I would only add that this culture of technological silver bullets is fed by the film and TV industries, who are terribly fond of deus ex machina plot devices to wrap everything up in the last reel (and the enemy who keeps paying to watch that slop is us - well, some of us, anyway...)

Reality of the physical nature of things is harder for some to wrap their head around, if they have never seen it, experienced it first hand or worked around it.

Reality bites

As someone on here suggested earlier, it would be great if the press/media could go to well control school for a few days and then maybe they could ask questions that make sense. Then possibly they could write the reports for the uninformed public to read that would make sense. I am not going to hold my breath for that one.

I only partly agree with that statement, I think many people are also suffering from the cognitive dissonance caused by being anti-science and technology while at the same time demanding that science and technology provide the fix to all our problems.

http://arstechnica.com/science/news/2010/05/when-science-clashes-with-be...

We as a society have some really tough nuts in urgent need of cracking...

An interesting insight into how Sarah Palin came to be. And why she is so attractive.

Alan

...really?! Who, when, how...?

i was talking about this today with a friend, and we decided that the very, very, very, very thin silver lining to all of this is that America's getting a crash course on the real cost of oil drilling. It seems spills in Angola, Mexico, etc. haven't entered our consciousness the same way, when it's bad environmentally-speaking no matter where it's leaking/spilled.

Can anyone out there address what laws are in place in the Gulf states as to where drilling's allowed?

I really appreciate seeing informed ideas and infromation about what's going on. Thank you all.

Re: formation of icy hydrates. The current capping idea seems to be counterint this by trying to heat the gas as it escapes.

Seems to me this phenomenon could possibly be used to separate (dangerous & expansive) gas from less expansive oil at or around the well head. I see the same priciples at play as used in refrigeration.

Gas rather than oil seems to be the problem in diverting well output to the surface and controlling it.

I'm not clear on oil/gas temp from BOP, but it seems like it could be 180 degress or more flowing into 42 degree water.

It also seem there is a significant pressure drop (and phase change) that is also likely to lower temps and induce or increase freezing.

There might be a way to use these differentials to separate ond concentrate oil so it can be collected. There might also be a way to use them to create pressure to counter/reduce all flow up the casing.

I'd like to see someone who knew post some ideas.

The LMRP is outfit for ethanol lines for warming.

I've been thinking about that too. If there was a cross-flow of water where the gas/oil contacts the sea, the oil (which is less buoyant) should be carried further with this flow than the gas. A much simpler scenario might be to have a horizontal piece of pipe to accept the outflow, with valves along the top to vent the gas. a relatively pure oil stream would come out the far end of the pipe at the bottom. Perhaps something approaching this could be accomplished by drilling holes in the riser to vent gas between the kink and the end of the riser?

dang, watching the ROV's manouver brings home how difficult that's gotta be w/ no sense of human touch.

No sense of touch. The occasional passing underwater current, right when you think your ready to grab something. The problems with depth perception, when trying to grab something. The problem of not being able to move your eye's over your work for alignment etc(everything is at arms length). I'm a carpenter, watching the operator try and run the saw yesterday, was almost as painful for me, as it was the tech operating the ROV. The further you extend the arms, the more pronounced(exaggerated)the motions become.

That brings up something that's been bugging me for a while - the tool handling capabilities of these ROVs seem to be stuck in the 70s. If they routinely handle stuff like saws and screwdrivers, not to mention metal machining stuff - why haven't the designers taken advantage of the work done to allow CNC machining centers to change out tools?

I really don't think that I should be watching video, where I am breathlessly anticipating that a bloody screwdriver can be used successfully. That sort of thing was solved in the manufacturing world 10 years ago, and the solutions would be 100% transferable. Seriously.

I wonder if the RealD 3D technology could also be adapted to the ROVs to provide depth perception. I'd imagine by now they have some sort of force feedback - then again, they might need that too.

They look awkward and clumsy, but you know I'd just love to sit at the console and drive one of 'em for an afternoon..

Agreed. It was disappointing to see the ROV struggling to use an open-ended wrench 5,000 feet below the water. While the ROV grippers may be designed to mimic the human hand, there should be other arms or hand options with a common interface and a tool storage/changing component on the ROV.

That would save BP from going to the hardware store to buy more wrenches to send to the inky depths.

I am a CNC machinist for a living and I can tell you that an automatic tool changer is a good idea for the ROVs. I was wondering if they just carried a big bag of tools down with them and hoped they could manage to toss em all back in before surfacing.

As far as the 70s style movement...I think its just how it has to be...they could use software/hardware controls to offer movement acceleration and deceleration to smooth it out, but for every bit of smoothing you add to a system that determines the endpoint of motion dynamically you will lose accuracy. This is unlike a CNC where start/endpoints are clearly defined and the machine can predict the cut accel/decel by using fairly straightforward math. Perhaps attaching a longer stick to the control would be a quick way to allow more precision while operating the ROV arm by increasing the amount of motion in the control (experience from another of my past careers running heavy equipment.)

I am amazed by the patience the ROV ops are demonstrating. I could not deal with some of the challenges they have had.

Yeah, it looks like trying to pick your nose with gloves on.

Thanks to the editors for making sure to associate the BP name in article titles and references as in "Deep Water BP oil spill".

BP clearly would like the media to use an alternate descriptor e.g. Macondo spill, Gulf Spill, Deep Water Horizon etc. not for today but should they survive as a company they would not want their corporate identity associated with one of the greatest environmental disasters in a generation. Make no mistake this is something they are consciously trying to manage and avoid.

And exactly what good would it do anybody to name it the 'BP oil spill?'

The only thing you are going by this sort of thing is forcing BP into a position where they are on the defensive. If you want to increase the flow of information from BP - you are going to have to convince tham that you are not looking for additional ammunition to use against them.

Sometimes I get the impression that people like yourself think that 11 people decided to be irresponsible and get themselves incinerated.

BP may be the cause of the disaster - but they are also likely to become its biggest victim.

Activated05b asks:

"And exactly what good would it do anybody to name it the 'BP oil spill?"

Activated05b answers their own question with their comment:

"BP may be the cause of the disaster - but they are also likely to become its biggest victim."

I think this is bordering on behaviour that I've talked about in previous posts: there's certainly some justice in remembering it's something that may have happened due to BP/Transocean/anyone else? ignoring safety concerns that were raised, but by the same token you make focus much of the anger at the company BP rather than oil drilling safety issues, and the anger has only a finite time before dissipating. (Does anyone still feel ashamed of Union Carbide, or of Exxon, etc?) Unless you believe BP is systematically worse (rather than just the most recent company where "luck" hasn't counteracted ignoring safety concerns) than the rest of the oil industry, you really want to focus energies on things that will affect the oil industry as a whole.

According to several CNN reports BP has nearly 100 times more "serious" safety violations as the next company on the list (894 to 12 for Citgo). "Serious" defined has "having potential for catastrophic consequences". Sounds like more than just "bad luck" to me. this includes refinery violations, not just or only drilling.

Trying to understand sequence of events.

Set bore hole, attach BOP, then riser. Where/when do they attach the risers, underwater?

BP’s live stream today showed riser is bent down to flange area of BOP. Not being concentric, I don’t see the possibility of getting a good seal after the cut.

Cut and unbolt what’s left of the riser and install new shutoff.

Great posts HO & thank you for all the massive amounts of work you are putting into this.

Could someone tell us what percentage of drilled wells blow out?

And what percentage of these blowouts are stopped by the BOP? (by default what percentage of blowouts are are a result of a BOP failure).

Like is this a 1 in a million accident or a fairly common 1 in a thousand event?

Thanks. I am sure this may have been discussed but there are so many threads now it is difficult to keep up with them all.

I believe the previous answer is that the risk is very low. How low should the risk be?

Some people are calling for the dismiasal of BP in favour a consortium of other companies taking over the operation. I think there is every reason to believe that BP is already tapped into the best people the industry can provide.

I'm more concerned that most of the effort that Exxon etc is making as a result of this disaster is directed to minimizing the regulatory costs that might result from legislative changes made in response to the systemic failures that led to this mess.

"I'm more concerned that most of the effort that Exxon etc is making as a result of this disaster is directed to minimizing the regulatory costs that might result from legislative changes made in response to the systemic failures that led to this mess."

and rightfully so. This catastrophe will affect everyone in the future and those that had their technical expertise, regulatory compliance, risk taking, Management of Change, and well control ducks in a row will suffer from it. Sad.

I'm unsure what you mean by "ducks in a row". If you mean "had all the forms appropriately signed, didn't have any dissenting opinions making it into the record, etc" then I'm having a hard time feeling sorry for them if new legislation aiming to make it less of a form filling exercise and more focused on making sure safety concerns get resolved by investigation costs them money. If you're asserting that other companies actually inherently care more about saftey concerns than BP, then assuming you're right then that may be a lamentable effect. But you'd have to convince me that was true, rather than just "luck" on their part so far.

97% of the "egregious willful" safety violations in the USA were at BP refineries.

The remaining 3% were spread over everyone else's refineries.

I see a difference in how safety is valued.

Alan

That's a reasonably compelling statistic :-)

I don't understand the oil business but do understand management and despite the all the skill, expertise and conscientiousness of crews "on the ground" these decisions come from the top down - How about the "BP - Tony Hayward Oil Spill"

Wot – I don’t think I ever seen anyone offer that stat. More importantly I doubt anyone has been trying to maintain such a database. I would guess the number would be a small fraction of 1% given the hundreds of thousands of wells drilled. But the number that would alarm most folks is the number of “near misses”. Have an unplanned flow of oil/NG (”taking a kick”) is not an uncommon event. Take the BP incident: had they noted the mud flowing back when they turned the mud pumps off they could have turned off all the return valves (“shut the well in”), went in to the bottom of the hole with drill pipe and pumped down heavy drill mud until they stopped the flow. They could have then pumped more cement down behind the csg and gotten a proper seal. Then they could have temporarily abandoned the hole, come back years later and produced a few $billions of oil.

And virtually no one in the public and even very few of us in the oil patch would have never known just how close we came to seeing what’s happening in the GOM today. And such incidents happen daily around the globe. It’s such a common possibility that there are schools that companies send their hands to for training in such “kill procedures”. BP took the backpressure off the well by displacing the riser/csg with salt water. And when the cmt failed that action allowed them to take a big kick. The kick those actions caused was not a Black Swan. It obeyed an undeniable physical law: HIGH PRESSURES FLOW TO LOW PRESSURES. If you were to ask any engineer what would happen if the cmt failed in this circumstance they would all, without exception, give the same answer: the well will kick. And every one of them would tell you the first sign that this was happening: the mud would rush out of the well even when the mud pumps were off. A well kick can very from a very minor incident where you just let the small amount of oil/NG vent out the well as use raise the mud weight. The other extreme is when the control valves can’t contain the flow and it’s sent to a flare line to burn off the oil/NG. About 30 years ago I had a well expel every bbl of mud in it and we had a 100’ flare shooting out over the cornfield roaring like a jet engine. We were able to pump a kill pill and get control back. What would we have done if we started to lose control of the flare? That’s when we would have hit the BOP…THE LAST LINE OF DEFENSE.

Rockman. Thanks.

The underwater blowout of the Montara well off the NW coast of West Australia occurred August 21 last year. It was not stopped until November 1 when relief wells intercepted the blowout well.

http://www.watoday.com.au/photogallery/wa-news/the-west-atlas-oil-spill

Two major underwater blowouts in 8 months. Both needing weeks of relief well drilling to cap.

As you noted this is definately NOT a Black Swan event.

With increases in Arctic and other offshore deep water drilling we are definately entering a very scary environmental future.

wot -- I'll also toss out a number I can't verify with regard to near misses. In the last 5 years there have been 50 (an educated guess but still a guess) well kicks in the GOM that required shuting in the well. These kicks were killed using standard procedures. Had they not been able to shut such a well in they would have had a blow out that would have necessitated activating the BOP. So does that scare you that we might have had that many near missies or do you take comfort that we are that good at handling well kicks? Like I said above: if BP had seen the well coming in they could have shut in and killed it. And no one on TOD, including me, would ever known how close it came to being a world class disaster.

Rockman & Dasher (below) Thank you.

Those numbers are scary, that's 10 wells a year that needed to be shut in because they are blowing back up at you. And that's just in the GOM. Nearly one a month.

Multiply that around the world. WOW

So yes you guys do a great job stopping the blowouts but sooner or later the numbers will win.

Wonder where and when the next one will be?

One more like this anywhere off the coast of the mainland or Alaska will be the end of offshore drilling stateside for a long long time.

Somehow that figure comes as no surprise.

To reprise the analogue that was made with the space programme a while back. Back in the Apollo era, the question arose about what was an acceptable risk. How many missions could you realistically and acceptable lose. One in ten? Clearly that was not going to be acceptable to anyone. One in a thousand? Probably not enough money on the planet to fund a program that safe. One in a hundred? Seemed about right. Fast forward to the shuttle era. In reality, the odds turned out to be about one in fifty. (Which is sobering, especially when you consider those astronauts that flew multiple missions - they had a 1 on 50 chance of dying each flight.)

And to reprise Richard Feymann's observations about perceived risk. Engineers at the workface were pretty clear that the risks of losing a mission were probably about the one in a hundred mark, and yet senior management, and assurances given to government, were more like one in a hundred thousand.