Deepwater Oil Spill - the Congressional Illustrations - and Friday Early AM Thread

Posted by Heading Out on June 4, 2010 - 2:46am

Please transfer discussion to http://www.theoildrum.com/node/6572.

10:06 PM Heading Out's comment: They have the cap on but it has not gone down far enough to generate the seal, and so there is a lot of oil still coming out from under the cap.

We are now reading that BP says there will be a 12 to 24 hour wait before the new cap is installed. So in this post, I will go back background material I put together earlier, based on material presented in the Congressional Hearings.

I am sure you are still interested in current events as well, so before going to the background material, these are a few news items. According to the New York Times:

A technician involved in the effort said that because the shear cut left the riser with a slight bend, a different cap would be used than the one originally planned. This cap would fit over the flange that attaches the riser to the blowout preventer stack, the large assembly of equipment atop the well that was supposed to seal the well in an emergency but failed to do so.

The technician, who spoke on condition of anonymity because he was not authorized to comment on the work, said that robotic submersibles had to "dress up" the cut end of the pipe before the cap could be lowered. "Everything just takes time," he said.

If the cap succeeds in capturing most of the leaking oil, BP will try a couple of other measures to minimize the amount of oil still leaking into the sea, Mr. Hayward said.

To combat hydrate problems this time around, BP is running methanol, which will act as a kind of antifreeze, and heated water through a hose down into the containment cap.

The Christian Science Monitor reports:

Embattled oil giant BP made headway in containing the gushing Macondo well Thursday morning, severing a piece of riser pipe to make way for a "top cap" device with a garden-hose-type seal designed to siphon leaking oil to surface tankers. . .

Currently, the well is emptying at a pressure of 9,000 pounds per square inch (psi). The pressure of the water at 5,000 feet is counteracting that pressure and bringing the flow pressure at the wellhead to 3,500 psi. For comparison, a crocodile's bite is measured at 5,000 psi.

"The question is, will the pressure of oil going up into the much smaller pipe mean that [it will create] enough pressure to force the oil up and around the oil seals," says Allen. "We won't know until the cap is seated and we can see how the seals are doing their job."

According to the Oil and Gas Journal:

The cut on the riser pipe is irregular, and the top of the riser is leaning about 10º, Allen said. Crews will place a containment cap with a rubber seal on top of the riser. BP has caps available with different widths and sealing mechanisms so that it can use the cap that best fits the cut riser.

“Once the cap is on, there is some chance that some oil could escape,” Allen said. “It could be close to none, it could be some,” leaking out, he said, adding this only can be determined after the cap is placed.

The reservoir pressure is 9,000 psi, and the pressure of oil coming through the BOP is 3,500 psi, he said. The collected oil and gas will go into a smaller pipe, which could increase back pressure and cause oil to leak out around the seal.

Before the riser was cut, federal scientists estimated the flow rate of the spill could increase 20% between the time of the cut and the time that the cap was placed. A team of scientists had released preliminary findings showing the estimated flow rate is 12,000-19,000 b/d although it possibly could be 25,000 b/d (OGJ Online, May 27, 2010).

BP's spill camera is now offering 12 live feeds from ROVs. This is the link I have, but it is not clear how one gets to the 12 feeds.

(These updates are by Gail. The background material below is by Heading Out.)

Congressional Testimony Illustrations

One of the considerable problems that arise in writing about the Deepwater Horizon oil spill in the Gulf of Mexico comes in determining what information that is given is actually accurate. I’m going to assume, however, that when a company provides information to Congress that it is, to the best of their knowledge, correct. Since the illustrations that accompanied the testimony of BP officials is now available, albeit in draft form, I am going to summarize some of this so that, as discussion and later posts require, it can serve as a useful point to find reference material.

This information was presented the Energy and Commerce Committee of the House, on May 24th. (Note that the illustrations have been condensed to fit on the page. Clicking on the image should lead to a larger view on a separate page.)

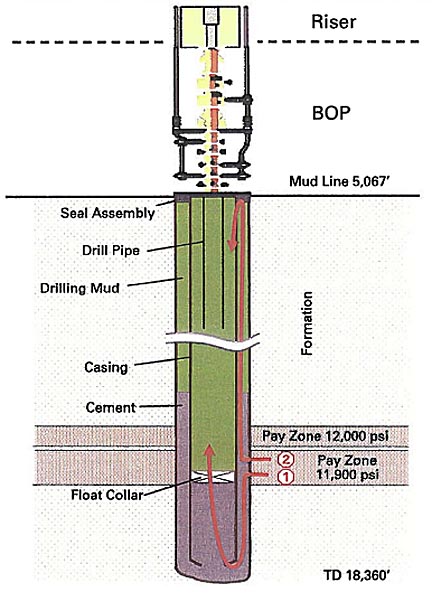

There are several points that I want to highlight, and so I will be taking selected parts of the BP slides to record separate pieces of information. The first of these is where the actual pay zones of oil and gas are, relative to the total depth of the well, and what the pressures are within them. Notice that the pressure at the bottom of the well is about a thousand psi lower than I had been using in earlier posts.

There are several different parts of the overall structure for which more information is available in these slides (and my many thanks to several folk who have pointed me to their existence).

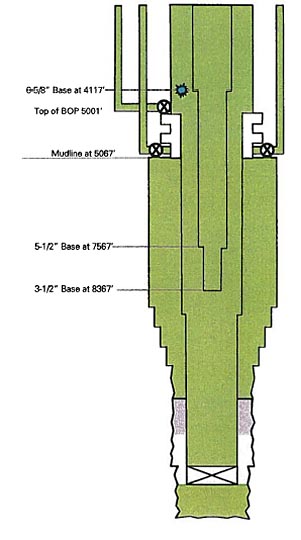

Consider first the Blow-Out Preventer, on which I have focused recently. The exact nature of the different rams is not the same as that illustrated by the paper from which I took the illustration.

The various components of the BOP, from the top are:

UAP – Upper Annular Preventer, used in normal drilling operations for well shut-in, rated at 10,000 psi

LAP – Lower Annular Preventer - down rated to lower wellbore retaining pressure to 5,000 psi.

BSR – Blind Shear Rams – cuts through the pipe and seals the well. 2 rams, one on either side of the drill pipe (DP).

CSR – Casing Shear Rams – non sealing, cut drill pipe and casing, but not designed to seal the well.

The three variable bore rams (VBO) would normally be the following with the functions designated:

UPR – Upper Pipe Rams – Ram packers can close on a range of drill pipe, from 3.5” OD to 6 5/8” OD and seal at 15,000 psi well bore pressure.

MPR – Middle Pipe Rams - Ram packers can close on a range of drill pipe, from 3.5” OD to 6 5/8” OD and seal at 15,000 psi well bore pressure., can also be used to hand-off drill pipe to a maximum weight of 600,000 lb.

LPR – Lower Pipe Rams – A Test Ram that can hold up to 15,000 psi.

The lowest ram did not function, I believe, and there was evidence of hydraulic leakage which has raised questions as to whether, or which, of the other rams functioned. However, as a part of the protocol for the positive pressure test, the drill pipe is lifted out of the BOP, and the BSR is closed to seal the well, while fluid is pumped into the well through the kill line, to raise the pressure and ensure that the cement job had held pressure. That test was successfully completed.

Following the positive pressure test the drill pipe is lowered back into the hole. Note that it is in three sizes, as it goes down the well, with the upper segment at a diameter of 6 5/8” , and the lowest at a diameter of 3.5” extending down to 8,367 ft below the rig.

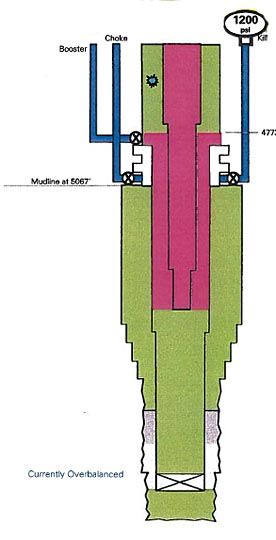

To separate the seawater that is then going to be pumped into the riser a special, heavy mud known as the Lost Circulation Material (LCM) which has a weight of 16 pounds per gallon (ppg) is injected into the well, through the DP, and it circulates from the bottom of the DP back up to the BOP. The choke and kill lines had been filled with seawater, and the kill line pressure gage was still reading 1200 psi. (This takes the time to 16:28 on the 20th April. The green color is 14 ppg mud, the pink the 454 barrels of 16 ppg LCM, and the blue is seawater at 8.6 ppg.

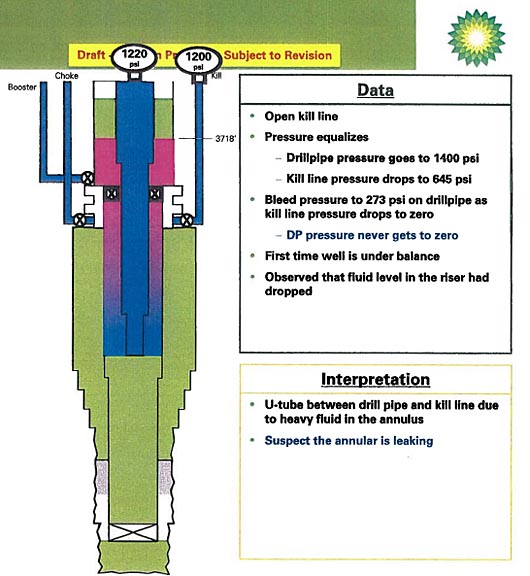

The sea water is pumped into the well and circulated behind the spacing LCM, material. Once it has filled the drill pipe, and started to rise back up the production casing, the pressure rating of the water in the DP is at 2325 psi, and that in the kill line is 1200 psi. The annular seal is closed around the DP, and the pump is switched off. The pressure in the DP (on the rig floor I imagine) is reduced to 1200 psi, to equate with that of the kill line. Once the two are at the same pressure the kill valve at the BOP is opened, but this is where, at around 5 pm the first signs of a problem appear. The fluid in the well, for the first time, exerts less pressure on the fluid in the rock, than the value of that pressure.

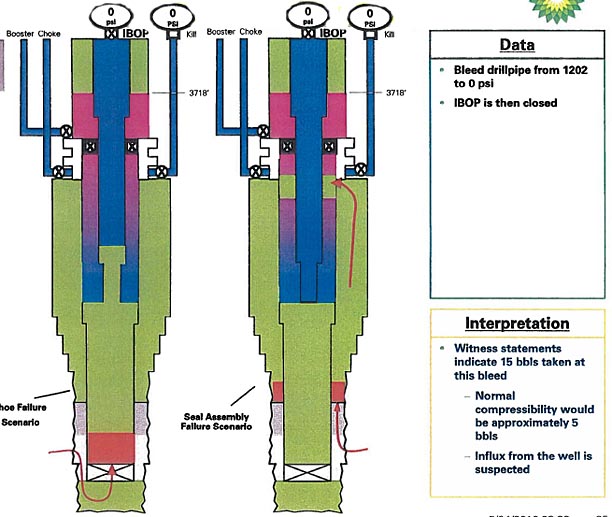

The annular that is leaking is, presumably, the annular seal at the top of the BOP. The term “U-tube” I believe refers to the fact that there is not a pressure balance at the point it is measured. At this point there are two separate scenarios as to how fluid starts to migrate into the well, as the pressure in the DP is bled back to zero. It is now 17:52. Note that the oil/gas flow is shown as an orange arrow and in either case has a path to the bottom of the DP.

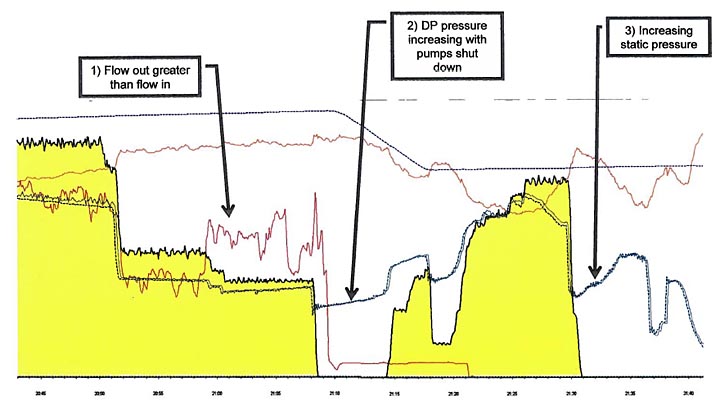

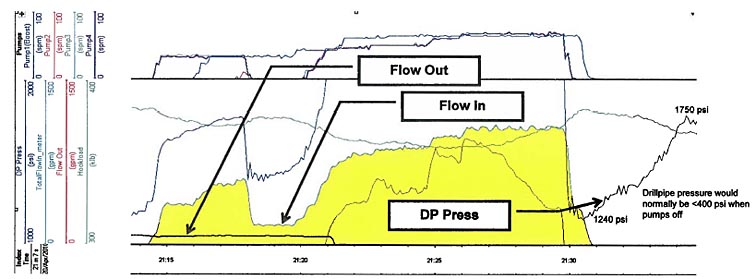

Pressure in the well now starts to rise, fluid is flowing from the kill line (about 3 – 15 bbls, the kill line was closed. Pressure in the DP was monitored and held steady at 1,400 psi, This was the negative pressure test, at 19:55 the decision to continue pumping seawater was implemented, at 20:58 it was noted that the flow out was greater than the flow in. The flow meter indicates that the well is flowing. Pressure in the DP continues to build, even after the pumps are shut down.

The first indications of this flow was 51 minutes before the explosion occurred. Seawater displacement restarted, at 21:14 and at 21:56 the Emergency Disconnect System (EDS) was activated, which should have led the shear rams to activate, and released the riser from the well. It did not work. The gage results leading up to the explosion were provided.

The activation time for the EDS should be 46 seconds. In this time, after the EDS button is pushed, the blind shear rams close, cutting the drill pipe and sealing the well.

The choke and kill line valves are closed and the lines unlatched.

The LMRP is unlatched and disconnects.

The sequence is complete and the rig can move away from the well.

There is no evidence that the EDS fully activated. Even if hydraulic power to the BOP had been lost there was a second procedure, the AMF, that should have sensed the loss in power, communications and hydraulics and closed the blind shear rams. But it required all three to have been lost to activate. It should take 37 seconds. There is no evidence that it fully activated.

The subsequent use of ultrasonics and gamma ray examination suggests that the blind shear and VBRs may have functioned, and could have reached the locked (closed?) position.

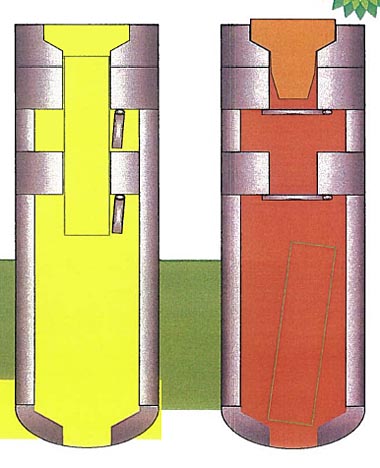

The testimony also showed a simplified version of how the shoe at the bottom of the casing should act to stop re-entry of fluids into the bottom of the production casing. The flappers stay open as first mud, and then cement is pumped down the well. Once the plug reaches the well, and all the cement has been ejected, then the flappers swing back horizontal, sealing the well. (The testimony pictures has the flapper in the wrong place in the middle figure so I deleted it from this copy.)

A continued sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

Here is the page with all of BP's submersibles and their live feeds:

http://www.bp.com/genericarticle.do?categoryId=9033572&contentId=7062605

Seems as of the moment of my comment that the leak is as bad as ever....

Rovers of Enterprise 1 and 2 and especially Skandi 1 are impressive.

The leak seems to be stronger than at any time I saw it.

It appears BP is currently dispensing *twice* as much Corexit dispersant.

Only 1 ROV (Skandi-ROV1) has been used to do so, until now. Beginning approximately 4 hours ago, B.P. began using two ROV's for this (Skandi-ROV1 and Skandi ROV2).

Does ANYONE know why they are now pumping twice as much dispersant???

Is this temporary? Has something changed? Did BP just make a unilateral decision?

Any insight would be greatly appreciated.

Enjoyable chat on the IRC this evening as well. Take care, everyone.

It's late, I'm tired, but why do they keep calling it a "siphon line" on the TeeVee?

Doesn't it just suck?

And isn't the whole problem to be solved exactly how hard to suck?

And how to get a hot bottom so the suck doesn't freeze up?

Clathrate. Sounds like someone choking on a ... booger.

Well, you said on-topic humor was OK!

In theory, once the oil reaches the top of the tube and starts to flow, it will indeed create a suction. The pressure of the *moving* fluid in the tube will be lower than the pressure from the surrounding ocean.

anybody know of any current/recent aerial/space pictures/video?

I'm trying to download and learn google earth to see what they have at:

http://www.google.com/crisisresponse/oilspill/

but WTF is a KML file and why can't they just use Java?

Often find good, up-to-date shots at NASA/MODIS: http://modis.gsfc.nasa.gov/

KML is "Keyhole Markup Language"—an XML dialect specialized for geographic annotation. Not that hard, really. Very much like HTML. Tutorial here:

http://www.google.com/url?q=http://code.google.com/apis/kml/documentatio...

Careful. If you have techie-geekish tendencies (and would you be here if you didn't?), you may encounter strong, attractive forces... ;^)

Edit typo. Getting late even in PDT.

http://www.skytruth.org

[Edit - delete duplicate links, etc. Pardon my dust ]

Hat #3 doesn't look likely to be anymore more effective than hat #4. I will say that moving on so quickly isn't how they've been doing things, so that's sort of an improvement, no? I figured if this didn't work, we wouldn't see them doing anything different till about this time tomorrow.

---

It occurs to me to ask, how do they know #4 isn't working? If they haven't begun to collect and therefore draw the oil up to the surface, how do they know it won't work? I'm asking because #3 with it's skinny looking pipe doesn't look like it will be much different. Seems anything you plonk down on this thing is going to spew in every direction till the oil is collected up top. For once, maybe they're giving up too soon, if I even understand what they're trying to do.

Man,

You go away for an hour and come back and all kinds of stuff is happening. Instead of 2 or 3 active feeds there are now at least 8 active feeds each with some sort of activity. I guess BP was waiting for Andy Cooper to go bed so they could get to work without him wondering what was going on.

Re: BP's spill camera is now offering 12 live feeds from ROVs. This is the link I have, but it is not clear how one gets to the 12 feeds.

Here they are:

http://www.bp.com/genericarticle.do?categoryId=9033572&contentId=7062605

http://www.sanaracreations.fi/rov-feeds/index.html

Tons of sites, that's the one I'm playing ground control on.

As has been said before,

http://mxl.fi/bpfeeds/

will give 9 feeds at once. I use firefox and it will crash if you push things too hard. Internet Explorer reportedly doesn't handle multiple feeds very well/at all.

Internet Explorer is handling 12 feeds just fine for me. I just wish I could figure out how to get it running with Google Chrome.

I have the composite view running in Windows Media Player 12 via Chrome 5.0.375.70 beta and FF 3.6.3, no problems other than both need to be refreshed every so often. Win 7, 2.4 GHz Dual Core, 4GB RAM.

"...it is not clear how one gets to the 12 feeds..."

Here is the link to show all 12 feeds on one page:

http://mxl.fi/bpfeeds/

HTH

That one looks really well done, but for some reason the feeds aren't stable for me, at least in Firefox on my Mac. This composite is much less... umm... spastic on my machine:

http://www.spasticsquirrel.com/oil/

Here's another link showing all 12 feeds on one page:

http://www.americaswatching.com

There are links to info for each platform and the ROVs that it carries under each video.

The surface the flange offers an enticing target for a seal.

Instead of attempting to get a seal around the distorted neck of the flange with the LMRP the following could offer a containment AND A KILL SOLUTION.

1. Install HYDRIL annual preventer on drill pipe/tubing or sections of riser.

2. Have a by pass above the Hydril run in the open position.

3. Install Hydril over the stack in a position to seal against the top flange.

4. Close Hydril.

5. Close by-pass

6. Initially allow well to flow at surface, progressively bean down the well whilst pumping kill weight mud through kill line.

7. With mud at surface shut choke, bullhead the well to TD.

8. Bull head 1500 foot cement plug.

My only doubt is whether the Hydril is big enough to go over the flange.

This would be the fastest way to kill the well before the huricane season.

Ken B

Before the put the cap on I could see a flange under where they cut the riser. Could they remove that by unbolting the flange and put a new piece on with a new flange etc and a open connector then connect the riser and suck? Could the robots perform that maneuver?

Probably not as it sounds too easy but if I was looking at fixing a pipe with an uncontrollable flow and had that to work with I'd try it. I couldn't get such a good look at the flange though maybe its an unconventional piece that is more complicated than I am aware.

I don't think they have the ability to unbolt those big bolts/nuts with ROVs.

I don't think there's any need to unbolt the bolts. They must know the size and shape of the flange face and all the bolts holding it. Why cant they manufacture a seal to fit over that?

I suppose if they made a gasket of some sort and had some clamps that would grab underneath that flange and pull the cap into place and hold it like a clasp but it doesn't sound as though they have the muscle to do anything mechanical like that. Certainly if they can't unbolt the flange they never pull this off either.

Is it working? It would be nice to know if they have it in some sort of balance or if it is frozen up.

I saw it commented in the last thread that Enterprise knew they would be working without a BOP in the riser assy above the cap. Unless something has changed, I'm pretty sure this is incorrect. The plans offered by BP definitely showed a BOP in the LMRP above the cap/seal assy. Not for the purpose of shutting in the well but for the purpose of protecting Enterprise.

Yes, but a BOP in a system without a hard seal at the wellhead, with no DP in the well, is essentially any old valve that will stop the flow below the drillship (and, as things stand now, blow it out at the junction of cap/cut-off riser).

Also, if you *had* a secure seal to the old BOP, activating a new one above it might (and I'm pretty sure BP thinks it might) result in an even more catastrophic failure.

Edit: Should really say "attachment" rather than "seal" in second point Not the same thing, I know.

What happened to the sunken rig? Could the oil emerging a mile or two away (if that is what is happening) be from that structure?

unless they install a pump near the bop i dont think they have any chance of sealing that top hat to collect the oil and enable it to flow up that mile lone narrow pipe. The whole top hat idea seems mickey mouse and doomed. Are they are references to anything showing it can work? most of the way thru that narrow pipe you will have expanding gases acting to push the oil out top and bottom - how can it ever work??

Now that the top of the BOP is acessable, could one stab coiled tubing in it, run to TD and kill this thing with mud?

Earlier reports are saying the BOP is compromised or the oil route to the reservoir is compromised so that pressurising the BOP is not going to work and only pressure from below will prevent the BOP or the sea bed from being damaged.

comment deleted

A bunch of people are in the IRC channel.

I think the Top Hat option is doomed, no matter which type of fitting they manage to fabricate it won't seal. Valid options left are 1) let it flow, add dispersant and wait for the relief well 2) Off with the LMRP and on with a second BOP.

It doesn't look good right now, certainly. It's not that hard to envision a "capping" solution that *could* work. It's a lot harder to envision one that is likely to do so, given that it must be conceived, designed fabricated, tested (?) and installed under prevailing conditions, with everyone trying to keep multiple options running simultaneously and not able to fully develop any one of them.

Mangled riser, bad seal, narrow pipe with serious turbulence and separating gas, apparently erratic flows from the well. Hard to be optimistic.

(1) What's current status? Looks like one of the top hat configurations,#3(?), is directly above and or close to riser stub (partially seated)? Also appears that two ROVs are spraying dispersant. Overall, flows look very gassy and, in general, worse than last night. (2) Tried to get on IRC. Server = freenode, channel = #theoildrum. No luck connecting, tho'. (3) Comments?

Could they make a rubber annulus much like the one they use within the BOP that can be 'inflated' hydraulically around the O/D of the now exposed flange and within the cap? During assembly it would be deflated to a larger diameter to ease that assembly - quickly dropped on with a spacer to snub against something of known distance from the flange so it lined up. Then immediately inflated to a pressure beyond gas/oil pressure.

Incidentally, I think they are frightened of pressurizing the BOP to circa 8000 psi to fully reverse oil/gas flow. That is why they are not considering a stop valve because, as others have pointed out (sherburn?), the strength of the upper casing and the connection to the BOP are probably compromised; if not before, then certainly with the collapse of the riser and drill pipe once the rig sank. I also think they prematurely ended top kill (with junk) attempts as they realized, if it had worked, in the sense of being able to fully backpressure the BOP above the casing, then it would not have taken that pressure without something else letting go. If they limited the backpressure to the point where mud was entering the bottom of the drill pipe then it would always be a combination of oil gas and mud coming up the drill pipe. The statement that it had a 70% chance of success was just PR. On an engineering bases it might have been that if the goal was to somewhat reduce the leak, but they did not say that.

Been reading for the last few days. Hard to keep up. Two idle observations in response to various upstreams. Superpiper. Re what engineers are any good. I heard this from someone I became friendly with. It happened before I joined the company. The plant had an inspection visit from a multi star Marine Corp General. On the way out, the General and the VP Engineering were walking briskly with an entourage of lackies in their wake, including my friend. The General says, 'BTW, how many engineers work here?'. Without a pause the VP responds, 'About 10%.' The entourage shit a brick. Now I for one understood what he meant. That was how many were real engineers. The rest just happened to get engineering degrees. On that basis I think 10% rather harsh. I'd go along with 20 or 25%, particularly for that organization as it was one of the better I ever worked for.

My other comment in response to valverx relates to not being able to fully test the equipment until out in the field environment. At another time I worked with large powerplants where, at the factory, we could only do no load testing. When we had a new frame size or a performance upgrade I'd enjoy going out in the field with a trailer full of instrumentation and read out equipment to do the first load tests. It was then that all the sins were revealed so that, whenever Murphy's law struck, whatever the event, the engineers would confuse wives and girlfriends by just saying, 'Well, we made RPM'.

Really enjoy this site. Much upset by pictures of oil covered seabirds seen on TV last night. Rachel Maddows program covering no development of booming technologies since the 70's, despite being the most profitable industry, devastating. BP have a great corporate logo (very clever, it's 'green' credential in marked contrast to the emerging reality and past reputation, at least in the Mass Media and Congresses eyes.) Expect to see someone photoshop an oil covered seabird alongside it. Right or wrong, in the public eye, that will be what they must live with in future.

This is from a George Stephanopoulos Tweet:

BP COO Doug Suttles just told me on GMA that top cap working. Hope to capture most of oil flow by day's end. Let's hope good news holds

This true?

BP need to show some progress all this operation will be nationalised. Looking at the top hat now it seems total BS that they will have this solved by tonight but here hoping i am the moron

Just goes to show how gullible those with no technical training (including the untrained Stephanopoulos) can be. He if anyone, should know how spin doctors work.

I'm kind of getting tired on everyone dumping on the engineers who are trying to fix the mess caused by the operations team.

After getting a better look at those flanges, it appears there’re about 8 – 10 bolts which would make this a non standard flange. I’m assuming the flange is the same size as the riser-21 inches. A 21 inch 5000 lb standard flange has 24 – 2 inch bolts. Valves are all cast to a standard drilling meaning same bolt holes and bolt circle for a given nominal size and rating. There is not a valve on earth that will fit that flange on top of the BOP. I would think Cameron would build everything to standard so that if anything like this happened pieces could be found that would mate. IMHO of course.

Idontno About a metre under the top hat is another flange which looks like you describe - i thought about 20 bolts. The rovs were anchoring themselves to a rusty human access platform just by it and the bolts are covered with a rubber mat. Next problem would be that the multiple pipes inside the pipe to be removed may prevent that top part coming off easily.

I was thinking that BP could take those flange drawings to Cameron and have them machine a mating flange. Then weld this flange to a stub and weld another standard flange to the other end and mount a valve there. Slowly close the valve.

I thought the idea was to abandon trying to stop the flow because it would just cause it to emerge somewhere even less accessible down under the seabed.

looks like Viking Poseiden ROV1 maybe getting another cap ready....

looking at the current top hat leaking you have to wonder what aspect of 4000psi these people do not understand.

they knew the first LMRP might not seal properly because the shear surface wasn't as smooth as might have been w/ the diamond wire saw. the engineers apparently prepared a variety of diff'ly configured tops, and looks like they are readying another w/ a diff config. i do rather suspect they know very very well the pressures involved, but there are other issues too.

please read the previous threads to get the whole story - this has been explained many times

Viking Poseiden ROV1 cam had been showing a top hat device (in a basket) being lowered to seafloor, but then -- switcharoo -- it suddenly reversed direction and headed to the surface(?). Meanwhile, the current seal between the cap (top hat #3?) and the BOP riser flange is obviously abyssmal: perhaps some oil is reaching the topside tanker, but a tremendous volume (~2/3rds gas?) is still blowing out the bottom of the cap due to lousy fit/seal.

Here is a link to a picture of the leaking riser and the flange it is attached to:

http://www.reuters.com/news/pictures/slideshow?articleId=USTRE6520422010...

That flange is all they need to make an almost watertight connection to the pipe coming down from the ship. The basic design is a clamshell (hinged) sleeve to put over the flange in the picture and secure top and bottom. (think of short piece of pipe which has been cut in half vertically and then hinged on one side so it can be opened and closed by bolts attached to the side opposite the hinge. Welded to the inner and outer sides of the pipe are encircling lips (like inner and outer washers but thicker - which will fit above and below the flange to which the riser in the picture is attached) Or you could have the inside of the pipe milled and put in tight fitting pipes inside which would provide an overhang for the inside lips. Or you could weld in chunks of metal to the inside of the hinged sleeve pipe - the important thing is that whatever is used gains a purchase on the lower lip of the flange holding the riser from which the oil is spouting.

They will have an exact replica of the flange to work with in a brightly lit BP room somewhere - to design a clamshell sleeve to take advantage of the lower side of the bottom flange for purchase. Cut out slots in the inner lips of our sleeve to fit around the bolts and other protrusions sticking out top and bottom - you only need an inch or so and it doesn't have to fit perfectly. (add an outer flange top and bottom to the sleeve with bolt holes if you like, but it shouldn't be necessary) A hinge on one side and half a dozen bolts on the other to loosen the sleeve enough to slip it over the flange that is down there then tighten it when it is in place. The vertical surface (outer edge) of the flange in the picture is almost perfect for a seal so that part of the sleeve should be lined with rubber. Open the bolts of the clamshell sleeve to their widest so the device will slip over the flange in the picture (and allow quite a bit of the pressure to escape while that is happening) , lower it down and tighten the hinge bolts. The rubber lining of our sleeve is now crushed against the vertical edge of the flange the riser is attached to - providing a tight seal against the leaking oil. The lower lip of our sleeve has been pushed tight against the bottom of the flange holding the riser - pushed there by the pressure of the oil in the cap above before we got our sleeve completely tight. The upper lip may not be necessary but it would provide additional stability.

Sorry if I've been long-winded but could it work?

yes, and if the clamped down top clogs, much more at risk. this has been discussed many times - please read the previous threads

i think if they understood the pressures involved they would not be attempting to get a seal by using a losely fitting light weight cap with additional weight only from a flexible pipe one mile long and probably we woúld not be looking at what seems like a fiasco.

... as 19 minute member you haven't read all the abundant info here

I don't know why you need this clam shell. Position the open heavy valve-appox 10000 lb- over the flow. Then slowly close the valve.

It needs to be a through conduit ball valve.

I have been coming to the oil drum site for the past week because there is a dearth of real time information elsewhere. Also, I am not an engineer...but I did just read on twitter that Suttles says that the valves on the top hat are all open and will be slowly closed throughout the course of the day. That said, I now cannot find where I just read that information.

One of those you can get pig though it.