BP's Deepwater Oil Spill - Capping the Riser - Part 1 (Cap on, but leaks) - and Open Thread 2

Posted by Heading Out on June 4, 2010 - 7:01am

Please transfer discussion to http://www.theoildrum.com/node/6572.

Update: It is still too soon to know how successful the new cap will be. Spillage of oil was apparently expected by design, initially. As the system is adjusted so that more oil can come from the top, less spillage is expected. Updates on the amount of oil being collected will be provided only every 24 hours. The first estimate is expected tomorrow morning. The ship doing the processing is set up to handle 15,000 barrels of oil a day, so that is the upper limit on the amount the system is set up to handle. - Notes by Gail, based on this afternoon's press conference.

This post describes what leads up to Heading Out's statement at 10:06 PM that they have the cap on but it has not gone down far enough to generate the seal, and so there is a lot of oil still coming out from under the cap.

The vertical section of the riser was cut, using a Shear, at 9 am Thursday morning.

The oil and gas are rising vertically, from the top of the riser, the drill pipe (DP) and the saw cut in the side of the riser (just down from the top of the shear)

At 8:30 pm, the ROVs maneuvered the latest version of the “top hat”, variation 7, of the LMRP over the top of the LRA. As the new cap was lowered into place, it was surrounded by clouds of oil and gas, making the actual progress of the event somewhat difficult to follow. The new variation had been finished yesterday, to accommodate the changing upper surface of the remnants of the well.

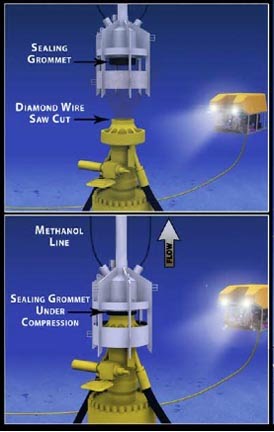

The Lower Marine Riser Package (LMRP) was first connected to the riser, and to a methanol feed that would help, between them, to inhibit the formation of methane hydrides when the gas came into contact with the surrounding cold seawater. It was then slowly lowered to the site, and across into the fountain of oil and gas, and down over the top of the riser.

The initial attempt halted after a while, and by 9 pm the situation was, for while static. The cap was sitting apparently on the rubber seal that had been designed to fit between the LMRP and the flange, but the amount of oil that was leaking out of the bottom of the LMRP was still a considerable amount, even though some of the flow was also being bypassed through ports on the LMRP that could later be closed.

The question now arises as to whether the LMRP could be lowered sufficiently that it could seal to the flange surface, since it was no longer possible to get the seal needed on the upper surface of the riser, given that it had been distorted by the Shear which had cut the bent riser away.

There was a pause, while the engineers had a bit think for over an hour. Looking at the cloud of oil coming out, it does contain small white specs that could be either methane hydrates or drops of the dispersant. And now, at 10:30 pm, there is a little more action.

For those who may not remember, this was the initial plan as it was proposed.

So far it is not quite as simple as the sketch would suggest. But I will put this up, and then update, as changes appear.

At 11:12 PM Central Time, we received an e-mailed press release with a statement from National Incident Commander Admiral Thad Allen that the cap was in place.

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

3 quick things:

1. B.P. has doubled the number of ROVs dispersing Corexit (chemical dispersant in use) underwater as of approximately 2:00 am EST. Can't tell the flow rate for sure, but identical equipment and what appears to be identical flow rates. This begs a few questions:

- Why are they now pumping twice as much dispersant underwater?

- What purpose does doing this serve if the newly placed LMRP is working as planned?

- Has something changed near the well head?

2. The idea of capturing the oil using large underwater "balloons" seems to be popping up more frequently in various areas and media outlets. Do these things even exist/operate at that pressure or is this more "nuke the well" talk?

3. The WSJ has an article today, "BP Cites Broken Disk in 'Top Kill' Failure" (available at: http://online.wsj.com/article/SB1000142405274870487560457528013357716426...)

Once again, this goes to show just how far ahead of the curve theoildrum.com is. I'm surely not the only one who read about this likelihood here days ago. This group deserves our support/contributions whenever possible.

Take care, everyone!

1 - I think they are using 2 dispersant wands because they have all the flow in one spot, before they were using two, one at the kink and one and the end of the riser. I don't think it indicates anything about the success or failure of the top hat, that information is on the deck of the ship and not yet available to us lurkers.

2. Unfortunately the balloon ideas are as far off target as the nuke options, but with less potential side effects.

3. Above my pay grade.

Maybe they are using more because the Federal Panel convened by NOAA to examine the issue has recommended continued use of dispersants.

http://calamities.gaeatimes.com/2010/06/04/apnewsbreak-expert-panel-oks-...

Regarding the rupture disc in the casing...does anyone have access to a casing tally that would show at what depth any of these rupture discs are positioned and in what string? I'm glad to see BP mentioned failure of this disc as a possible cause of failure of the top kill. It gives me some comfort that their response team is looking at all the possibilities. The burst disc was pretty high on my list of possible casing failure points early on.

Also, it seems BP is no longer updating the graphic on the relief wells. Does anyone have a link to any data on current depth of the relief wells?

Thanks.

ExDrllgMgr

Do you have any links or info on these rupture disc. I have not heard of them and would like to know more.

Who supples them, weatherford, Haliburton or Drilquip.

Look forward to your update

OK. I made my donation and registered. Thanks for so much useful information. I'm learning and will post my messages at appropriate places. I'm a graduate Ceramic Engineer with an MBA. (No, I never made toilets nor ashtrays)

any proppant for frac'ed wells? LOL

Hi. I have done a fair bit of deep water robotics, surface robotics, and studied fluid flow for many years at MIT. I think I have a solution. The BOP, with its partially closed shears, and junk shot garbage is the problem. I say, get rid of it and start with a clean hole which is spewing oil and gas. Next start forcing steel shafting with a clearance of about 5-10mm (so that it can freely move) down the hole. One could do this either from the surface via a riser, or a frame mounted over the spewing well. Once one has about 200 meters of shafting into the well, the flow should be choked enough to attach a riser and force drilling mud down the hole on top of the shafting. The clearance of the shafting should be such that it will not get stuck in a bend.

The first step of stopping a flow is to choke it. The BOP needs to be removed to get access to the well so that it can be properly choked. Preferably, it could be removed with a flange still on the well casing, but even if it were to be blown off, the steel shafting could be forced down the hole to staunch this flow.

I would appreciate any comments on this idea. If there are no obvious problems, then I will write a report and send it to BP next week. These folks seem to need all the good ideas they can get.

I'm a lawyer, not an engineer, but I am game. Like you, I believe this leak needs to be stopped long before a kill bore. I would first try a good seal on the riser flange with a pipe and clamp system connected to a valve and slowly shut off the flow. On the last thread, I outlined how I think that could be done.

But if that didn't work because the internals of the BOP fail and begin to leak, then I think this is a great back-up. The question I would have is whether the BOP can be removed by these robots or whether the wellhead would have to be sheared. As I understand it, the wellhead was a 36 inch pipe so it might be difficult to take the BOP off the wellhead either robotically or with shears.

The integrity of the upper casings are questionable, at this time. The last casing run has probably been displaced by the blowout, up into the BOP stack. Or possibly a few joints of it

It is probably wise of them not to press their luck by trying to shut anything in and risk having something worse than there already is now.

The BOP's probably could still handle the pressure.

All of these things will be analyzed once the well is dead and they are in a position to do the final P&A on the top. Then there will be more things made clear to them of what happened when the well came in.

The BOP is designed to be unlatched from the wellhead, pulled up to the rig and re-used (it is a rather expensive bit of hardware). Its is actually in two parts - the lower part with the rams, and the upper part with the control pods, annulars, etc - the LMRP. These can be retrieved separately. Now it has a drill pipe sticking through it, has internal damage, and oil flowing through it - who is to say if the latching mechanisms are functional and what would come with it if removed. That said, the wisdom of removing it....

Gee wiz, sounds odd to me!

Remove the BOP? Jonniesmokes WHAT?

Remove the BOP? Jonniesmokes WHAT?

We used to make jokes about stuff like that, bad rope? bad weed perhaps?

The risk is blowing the casing out deep in the mud from pressure spiking as you quench the flow. I had a similar thought that if you lost the BOP you could push a thin drill-pipe down the hole and pump a LOT of heavy mud, but with no BOP the flow will be tremendous, and likely too high to easily kill.

Another option would be to hot-tap below the BOP and feed in either (a) long heavy rods, like depleted uranium, which would "fall" through the oil faster than the flow moves up (make them long enough to be heavy enough to fall). Put in enough and the flow will slow, or (b) a small-diameter pipe that would go alongside the drill-pipe to the bottom, and then pump mud, or (c) both.

I can't help but wonder what fraction of the oil is coming from the drill pipe (which is high-pressure ready) and whether it is intact through the BOP. If so, you could capture, control, and then just use it to pump mud like God intended -- but I doubt it is.

long heavy rods, like depleted uranium

My scheme was to use gold. Perhaps hexagonal (to allow packing) 8 mm across flats. 16 mm long with a cone on one end and an indent for a cone above to fit in. It should self stabilize "pointy end down" and fall down the bore till it hits as obstruction or makes it to the bottom.

Easily fabricated, no environmental issues, malleable if 24 K is used. LOTS of it available with appropriate payments.

Best Hopes for BP chequeing account,

Alan

"My scheme was to use gold. Perhaps hexagonal (to allow packing) 8 mm across flats. 16 mm long. . ."

I'm pretty sure we could shoot these down the bore with low-yield nuclear flare guns.

Alan, you funny guy you got me ha! This really is a solid gold well though.

I do have to ask you if you think our blood lust for oil will at all be tamed by this global disaster? I don't believe it will for very long. Drill deeper baby, along with two or more relief wells drilled at the same time? Hey what an extra 100 mill among friends?

What's odd, is that it is actually a valid engineering approach.

Inject, say, 500 tons of these gold what ever you call them with the mud during top kill and there is a reasonable chance of diminishing the flow. Depends on the flow path.

And, as I said no environmental issues and easy to fabricate (just tight security !).

Alan

PS: Seeing Tony's face when this would be seriously proposed would be priceless !

Alan, damn your good! Stilling laughing at the BP GOM solid gold well! 500 tons I think that's all the gold the IMF has left? Kill two birds with 500 tons of gold ha! Thanks for making this a better place my friend. People should have listened to you weeks ago. Four relief wells even if they don't get to target is a absolute must! Hey is that why gold is sky high? Did you leak (no pun, oh ok yes pun intended) your plan using most of the worlds gold down the BP rat hole?

I like gold being thrown down rat holes; I keep a hard hat on standby, just in case.

Your plan has one insurmountable obstacle: "All the gold in California...." And Tony don't live in Beverly Hills.

if you think our blood lust for oil will at all be tamed by this global disaster?

Did the bus boycott in Montgomery end segregation ?

Did "Uncle Tom's Cabin" end slavery ?

etc. etc.

No, not directly. But a small minority of people will be affected and start thinking new thoughts.

Perhaps Obama can use this as a teaching moment. Far less than half of Americans will learn anything (see Jimmy Carter), but seeds will be planted.

And in a very few years, post-Peak Oil will create a panic. Any seeds planted now will be useful then.

Best Hopes for a Productive Response to Disaster and Panic,

Alan

For those that have not wondered off the BP spill discussion, I would recommend reading

http://www.theoildrum.com/node/6544

The Oil Drum is *FAR* more than "all BP, all the time".

One of my better comments there.

I have to agree, your best post ever! The thought that runs through my mind is the last 10% is worth far far more than the first 90% and we just hit the wall at that point. We really are so fortunate most oil exporting countries are goofs. Why on earth would you sell the most productive, highest btu content energy per volume for next to nothing? We are so lucky they are not smart enough to understand the economics of VALUE ADDED ( I didn't say that). If I were any of them we would not see a drop of crude ever! Gasoline, Diesel, propane, ethane right down to tar! Do you think they will spring it on us when we least expect it? If you want oil build your factories here? What then? The GIANT (love that word) hissing sounds of trickle down economics (by the way don't ask what that was trickling)sending jobs and technology overseas yet again? Please, please god of physics save us with that all powerful endless yet seemingly unreachable goal of FUSION! Give just a a lot more than a micro second of success please!

At first I found this idea intriguing.

Ok, we get some chunks of gold or DU to fall through the stream.

They start to block the flow.

Wooo hooo!

But this issue niggled at me:

Q What happens when they assemble into a clog that is actually resisting x000 psi of force?

A: They get shot upward as from a cannon

Well not so fast. As a cannon.

The pellets form a packed bed. Assuming that the pellets have a terminal velocity greater than the fluid velocity AND the pressure drop across the packed bed is greater than the weight of the bed what you get is a fluidized bed the depth of which depends on the velocity of the fluid.

The equation for pressure drop across a packed bed is the Ergun equation.

http://en.wikipedia.org/wiki/Sabri_Ergun

Attn jonniesmokes, David

Please don't rebuild anything. There is a subsurface blowout with gas and fluid leaking into a shallow formation, migrating across a salt weld or fault plane. If you shut this well in, it will vent uncontrollably.

The only cure is to kill the reservoir ("relief wells").

That's just fine and f'ing dandy.

Where do you suppose it is?

200 feet below the seafloor?

500, 5,000, 10,000?

Ding, ding, ding, school is open! Return to school please. The well is 13,000 feet deep? So you are going to re-bar the entire well? You don't think 13-14k psi will want to eject your re-bar idea like most people with an understanding of this well? So you want to release 50 million barrels a day while your 1% plan fails? This goes in my book with the battle ship, giant screw, 100k tons of quick setting post cement. The battle ship still gets the cover sorry.

Damn! I thought my expanding foam idea would win it.

Some of these ideas are fun to read. In the "remove propellershaft while at sea to repair it" category.

I like the battleship one. Why a battleship, one wonders? Is it to go down with guns blazing, torpedo-tubes firing? Or is it because a battleship sounds more serious?

And then there's "fill it with gravel." OK, so we're smashing a gravel filled battleship into the BOP. Doing what, exactly?

But removing the BOP entirely seems quaintly attractive - you'd have a solid stream jet of oil and gas spewing - so powerful you wouldn't be certain where the pipe ended and the jet began.

Try pushing rods into that.

Here's a sampler:

http://www.youtube.com/watch?v=5EHqb9wU_NY&feature=related

Thanks, I needed the extra chuckles ha! I know some times you think wow am I the only one that thinks this is so anti-physics ha!

The battle ship has two claims of ownership. One person from a brilliant comment on Huffington post and the other a claimed admiral. Of course the spawned firing cannons with GIANT propeller SCREWS are additions from TOD fans.

Gotta love a country that can defeat the mighty science of Newton ha!

Well, Neils Bohr really screwed up Newton (and Einstein, for that matter) at some level. Perhaps, there's a quantum battleship solution to the spill that needs exploring, you know. Just put in a call to your friends at the LHC and shout "Three quarks for Muster Mark!" at them. ;)

EL, did I tell you I worked at the LHC for 3 months last year? Fun place and great people that are driven. Really did I tell you that?

landrew: And you weren't sucked into The Black Hole? I have a new level of respect for you, Mon. Flash of genius! I just realized that the answer to the Great BP Blow Out is creating a black hole.

Not "fans"

Me, if you please.

And don't forget the J-B Weld.

Otherwise the torque on the battleship's keel will strip the slot in the giant screw.

I had this solved weeks ago.

Couldda dun the fabrication in my basement.

Well, maybe not the battleship part.

You are the best! I think this is so tragic a spot of humor is needed now and then. Thanks for the laugh.

The other day I heard someone seriously suggest ramming a submarine down the well. Aye aye, cap'n.

Subs :)

Johnnie etal,

BP has been a Dril-Quip shop for a long time so I suspect they ran the Big Bore SS-15 subsea wellhed system with a Vetco HD-H4 profile. The wellhead with top flange should have been run on the top of the 22" casing. It appears the 22" x 18" adapter was run to facillitate landing the 18" casing. Subsequent strings would have been hung in the profiles located in the subsea wellhead housing. A ring groove is located on the face of the wellhead flange (looking up) which accepts a VX ring gasket. There may be a newer model but I am uncertain it has been about 9 years since I ran one. There is also a ring groove on the internal face of the connector.

Located on the very bottom of the BOP stack is the wellhead connector which can mate with the HD-H4. Within the connector are a series of "latching dogs". These things are about 6" long and located inside and around the circumference of the connector. The connector is stabbed over the HD-H4 profile and landed. Hydraulic pressure is applied to the connector to push up the "dogs" to latch the wellhead. Slight tension is applied to the riser to pick up the stack weight to ensure the connector is locked. The connector can then be tested against the VX ring the seal. A failry simple, albeit time consuming, operation. This is a 15,000psi WP system as the stack was a 18-3/4" 15K WP.

This connector remains locked until opening pressure is applied. Here is the rub, if you have an inclination >6degrees the dogs bind up and you can not get it to unlatch. Last time I saw the bullseye on the LMRP the stack inclination was well north of 6 degrees.

Point being, given the current setup, I don't think the could unlatch the stack if they wanted to.

The connector between the LMRP and top of the BOP is typically a Cameron HC collet. It is far more forgiving but not as robust.

On a side note, I am profoundly happy that the wellhead system performed as designed in terms of bending moments and torsional shear. When the rig sank a huge bending moment was applied to the wellhead system and it help up. Had that failed everything else would have been a moot point.

I hope this helps and forgive me for any errors as I am running this from memory and I have slept since the last time I ran this system.

This just keeps unfolding and unfolding. What a drama. Things are looking better now but my gut feeling tells me its not going to work this time either...at least not completely. In the meantime we have pictures of oil soaked birds and a riling president - which doesnt help matters. Maybe BP should start using more outside help?

For all those who have no, and I mean no, deep drilling knowledge, this site is still one of the best experiences one can have, I'm old enough to remember listening on the radio with my father to the Philadelphia Eagles beat the Chicago Cardinals 7-0 for the NFL championship and marveling with him at modern technology that sent us that game live. (For those of you who don't remember the game, try the Google.) And now I'm here. "What a long, strange trip it's been." And I have had great thread discussions with Landrew, TheraP, Diverdan (did I just write that?), Alan and many others. This site is more than about oil; it is about where the world is heading... written by people who care. I attended some pretty fancy universities and have had some pretty fancy continuing education classes. theoildrum beats them all. Thank you one and all. DONATE. DONATE. DONATE. [Is that clear?]

"The Oil Drum is a pretty special place."

I agree, Prof. Goose.

But it's also a boring place at times, a place for the like-minded to preach to the choir via censorship of dissenting views.

I for one would like to see more dissention, Prof. Goose. But, hey, it's your website so do as you please.

So the concern seems to be that a 6" pipe isn't big enough to capture much of the flow.

What about taking a series of Tyvek rolls (like they use on houses) and glueing/sewing/heatsealing/whatever them together to create a mile long, 20 foot diameter tube for the oil to flow up to the surface in a small enough area for a ship to suck it up?

Would the gas be totally out of control at that point? What diameter would this have to be for it to be more like an open garden hose and not a pressure jet?

How do we control the Tyvek curtain in the currents?

I've been thinking about this. The no pressure/gentle guidance design appeals to me.

I see it including the following

A framework consisting of

• Heavy hoop on ocean floor connected by cables to flotation/enclosure on the surface.

• Intermediate steel hoops or ribs connected to the cables

The fabric should be a strong geotextile or something like shrimp netting

Passage needs to be wide enough that there is no threat of clogging by hydrates

The mouth should be wide enough and there should be enough water mixing that gas at the surface doesn't present a huge problem (after all it doesn't at the moment, in the open ocean)

Anyway, fun to think about. Having a few such things on hand to immediately drop over leaks might not be a bad thing.

I find it appealing also as it sidesteps a lot of the technical challenges involving pressure gradients, it greatly reduces the amount of oil on shore or in currents, it allows for the oil to be concentrated in a large collection pool, and it would make the dispersants unnecessary. The only drawback I see is a large flammable area of oil and gas around a bunch of ships. I don't know enough to comment on those dangers.

As for anchoring against currents, I think you would need the large hoops and I would think you could anchor the first few hundred feet against the sea floor if you could pile drive some supports into the muck. The top few hundred feet could be anchored to ships. Maybe a few ROVs could be employed to gently push the middle sections against currents. Again, I don't know enough about this stuff to ascertain if it is at all feasible to maintain such a large curtain against the current.

So this would be a giant (love that word in my book) shower curtain like Lucy used in her TV series? The 5000 foot shower curtain? Wow, that is so fun, like a GIANT water weenie? Why don't they just drill all wells like that? GIANT shower tubes. You could print fish and whales on the shower curtains and have glass bottom boats to show the tourists how environmental the shower tube is?

But it can't be a vinyl shower curtain. Those are bad for the environment. ;)

I wish I knew more about this but it seems to me the buoyancy difference would take care of that.

can someone tell me why this won't work? please

Another for the book ha! Better idea wrap yourself in the Tyvek to keep you safe from ( I was going to go mean but not). Tyvek, never ever did I think I would hear that ha! The worlds supply of Tyvek blowing about the ocean killing all things it smothers in it's wake ha! Really, almost tops the battle ship!

Maybe if you experiment with 13,000 psi in your house first? Really?

Wow, the longer I think about this it starts to dethrone the battle ship?

Readers would be so upset with the loss of the battle ship cover.

landrew,

You are a guest here, please act accordingly. Humor that insults, is not funny.

Thank you.

Really, I guess you have never been to Vegas? Watched a tv show, read a magazine? Read many of the posts here in the past? Anti science is fun to a point but really a giant Tyvek shower tube 5000 feet long is too toooooooooo weird even for here. Yes, I wear a Tyvek suit in a class 1 clean room. If they used all the Tyvek in the world, how would I be able to suit up for science?

Ever teach a class on science were the cartoon with Wiley Coyote runs off the cliff and half the class doesn't understand why he can't just hang there?

We wonder why censorship is so popular here?

Have you ever worn Tyvek to protect yourself from chemicals? I have. It's very strong stuff and I'd guess very oil and saltwater resistant. Given they wrap houses in the stuff I'd think manufacturing a few hundred thousand square feet of the stuff in very long sheets (it can be joined using a branched polyethylene and heat with high joint strength) wouldn't take very long, and it could be rolled up and transported in rolls before being deployed.

As for 13,000 psi (isn't that the pressure down in the reservoir?), I can't imagine what you're talking about, but if you're intimating that something within 30 or 40 feet of the oil flow is doomed to instant destruction, the ROV video seems to indicate quite clearly that once released into the ocean, there's not enough oil pressure to actually cut anything.

Perhaps you should have gone mean, at least that might have elicited a laugh...

Did I say I didn't like the GIANT Tyvek shower curtain? Love that idea of a 5000 foot shower curtain in the ocean that is calm as a glass of water. Love that idea using a GIANT sewing machine to create a 5000 ft. shower curtain. Do you think that could finish that before the relief wells? Could they finish that before the sinking battle ship? Really a 5000 ft. Tyvek tube is a great idea really. I just wrote six pages on that idea for the book. Fun stuff this anti-science stuff. Yes, I wear Tyvek almost everyday in a class 1 clean room that has < 1 .5 micron particle per day contaminant. Bringing you real science:)

tell us why i won't work science guy

"Tell me why it won't work, science guy!"

1.9 knot currents?

Do the math.

thanks,

at least someone gave me a number

Since there seem to be no good answers, maybe you should write a book about why we should never drill offshore again.

Your other book is garbage.

Drilling relief wells to stop Gulf oil leak poses challenges:

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/challenges_inv...

Looks like August might be one of the more optimistic estimates for killing this well, in which case BP will have plenty of time to fiddle with the LMRP.

Cheers,

Jerry

Considering the stakes, one wonders whether two relief wells is the optimum number.

It's probably hard to assign absolute probabilities, but I'd be interested in hearing from industry experts on why two relief wells is "enough".

I'm in contact with a number of people discussing policy and response, and would appreciate input.

best

Last month AlanFromBigEasy concluded that 4 relief wells should be drilled.

Rockman or HeadingOut wrote that he would recommend 3.

Four relief wells makes sense if the probability of success of each well is 50%.

Two relief wells makes sense if the probability of success of each well is 75%.

Basically, when the probability of success is above 90%, no more relief wells need to be drilled.

thanks for the comment.

Anyone agree/disagree with that?

Be that as it may, I think it could be rather an open question what the actual probability turns out to be in this real-world case. If, say, a million human lives depended on killing the well ASAP, what would be the ideal number of relief wells? Hypothetically?

Disagree.

Is the damage that would result from failure less than 10x the cost of an additional well? If so just in a cold-blooded "money is all that matters" sense 90% is too low.

And if the damage is to be born by innocent parties shouldn't the guilty party be responsible for something closer to 100% protection?

It's impossible to characterize simply. We have just proved there is about a 1:30000 chance that the rig will blow-out and collapse, making the problem twice as bad. What if a hurricane dumped a ship on top of one BOP? What if one blows a casing and the other sticks a bit or something?

I'd say it's a probability curve something like this: 0% in 60 days, 50% in 90 days, 90% chance in 4 months or so, 99% in 6, and a small but finite chance it will be leaking the same or worse this time next year.

Two wells makes the same assumption this first well did -- most of the time things go along in a more or less typical manner.

yeah, I do.

Risk management is based on impact and probability. this covers probability, but not impact. When your impact is really high -- you want better than 90%.

you can't look at relief wells in a vacuum, unfortunately -- its a corrective control against the impact of a seriously damaging spill. However, there are other controls -- preventative and detective, for example, that also contribute to probability, and can contribute to impact.

I would first attack probability -- with the right use of detective controls -- procedures, and other corrective controls -- better monitoring and testing and such. The domain experts have covered some really good suggestions in this area.

So calling the number of relief well is tricky, since each additional relief well can add its own level of risk.

Sorry for the non answer, but I guess what I'm trying to get at is that in a risk management landscape, the number of relief wells depends on the other controls at play.

Good answer.

Of course, the risk management landscape is somewhat opaque to those of us outside the situation looking in. The administration will be under pressure to "do something" additionally; I was glad to see the "nuke it" option rejected by the white house. Clearly the second relief well was mandated for what were considered good reasons. If those reasons were correct, it raises the question whether three might not be better, considering the scale of possible consequence.

I'm hoping that TOD will spearhead a call for at least one, if not two, more relief wells. I'd like to see them do this via a post or two which in describes, in layman's terms, all the reasons extra relief wells would be helpful in terms of solving this leak ASAP. Then all of us who can write blogs or disseminate that info (including lobbying congress and the White House) gear up and move this into the MSM. Maybe, hopefully, before we need to do that the Obama administration will insist on it.

I agree...

and please click on my user name and drop me an email. We should talk.

Please do.

Alan

Done, Alan!

It would be great to offer recommendations based on root cause analysis or a fault tree. Something a little more pithy than "people want oil" would be helpful.

BP would be showing a lot of credit if they were to share that RCA (Root Cause Analysis) in the sense that the larger industry can become safer.

I think if the proper posting were done here, with all of the right reasons stated, a Facebook group could also be started and people could link to it. Don't underestimate the power of social networking these days. It's a good way to get people that care, but aren't going to take the time to write letters let their opinion be known.

Two relief wells are one too many.

I tried looking at this from the perspective of a BP bean counter, and one or two relief wells doesn't seem like enough. If a relief well costs $100 million and BP is fined $4,500 per barrel of spilled oil (plus MMS royalties), then they should drill an additional well if it prevents the spilling of 22,000 barrels of oil. We don't know the exact flow rate, but that's a couple/few days worth?

See brief report on Montara, incl sat pic. The slick visible here is about 150 miles long:

Points:

1. The multiple relief well attemps were side-tracks from the one well, not multiple wells. Basically you directionally drill passed the target well line, run a magnetometer to spot its steel casing, then plug back and drill a side-track in that direction. Repeat till you hit it.

2. The inquiry report is still not out, but the eventual ignition of the blowout appears to have occurred during the kill ops. Probably the target well kicked and displaced something on the abandoned rig, causing a spark.

3. The "bottom kill" target will usually be above the reservoir, so a repeat blowout, while possible, is less likely than on a well that penetrates the reservoir.

G.

Hrm, I wish I had inside data that the BP engineers are looking at. However, just from our layman's perspective don't you all think the cap needs to be larger (and the tubing above it a lot bigger in diameter). It looks like whats happening is that the Oil/NG is trying to fit through this tiny tube/hole and it's just too darn small for all of it to go through, so they go where there's least resistance, the opening around the grommet.

Further, anyone have pics/information on the NEW LMRP (7 was it?) that BP is thinking about replacing this one? And when they are replacing the current one?

No.

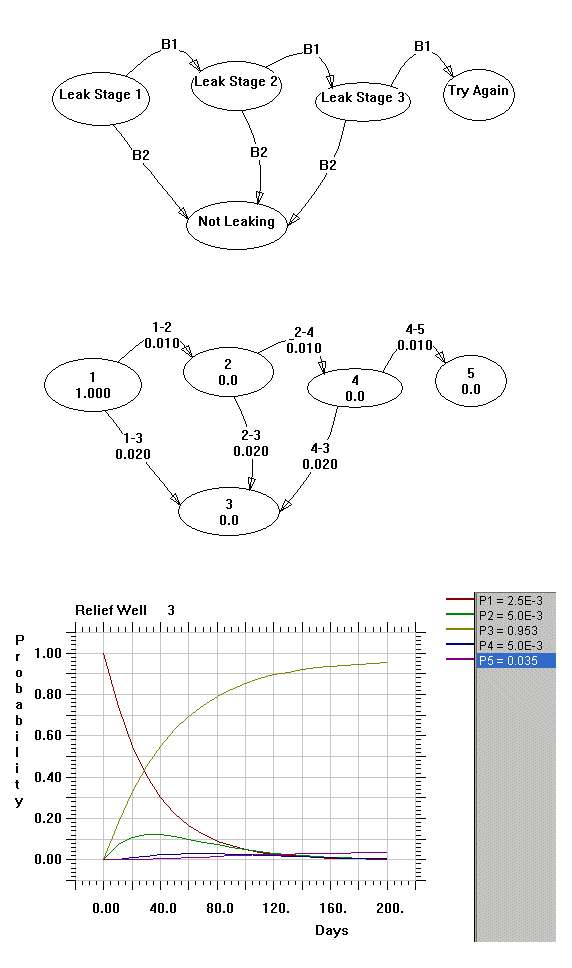

some idle thoughts on what happens when the RW misses the target on the first try...(IMHO which it most likely will) ....

1- if a RW misses....it will not start over...instead they will back out a little ...set a plug , run a whipstock, time drill and do a sidetrack...essentially making a little offshoot of the RW and try to approach the leaking well (LW) again .....so every time the RW misses ...you add around 7-10 days before another attempt can be made....

2- now there are 2 RW being drilled spaced out by around 10 days.....both RW's are optimally spaced out....first RW misses the target and back off to run a sidetrack ....while the second RW can make an attempt in the mean time.....and second RW misses and back off for the sidetrack ...again while the second RW is side tracking the first RW is ready to make an attempt.....so really 2 RW`s working in tandem will give plenty of shots at interception within a very small time ...relatively speaking ...(see engineers at BP are thinking two steps ahead also....stop trashing the poor engineers at BP like the dont know what they are doing)......

3- IMHO i have said its more likely to be early septmeber ....i am guessing around 3 or 4 attempts before success.....that is taking into account above mentioned things...

4- the csg on the LW is brand spanking new which means (interms of target acquisition) that it will have excellent magnetic response characteristics ....this is good news for RGR (radial gradient ranging) and PMR (passive magnetic ranging) which are the processes likely to be employed in tandem for the last 100 ft or so ...

5- wellbore surveying is a process where small errors add up .....the presence of above average iron in the Mississippi delta will further skew the survey measurements...but then again every time the RW misses....the next attempt will be a more informed one and the driller will have just the much more information...

other than that you just gotta back your rig crew.....not something BP has done considering they were out pointing fingers at the field people week 1 .... even before there was a memorial service for the 11 top hands was held...I personally owe a couple of fingers or maybe more to such a top hand back when i was a roustabout in west texas to put myself through college and couldn't believe I was hearing such stupidity coming out of such senior management at BP....how do you repay 11 men who willingly run towards a bomb out of sense of duty ....and out of the 120 odd people on the rig these 11 top hands knew they were running towards a bomb better than anyone else on the rig.... one guy died lowering a vessel so others could get away ....why because it was his duty to lower the boat...drilling DW is a risky business ...everyone involved understands this and accepts the risks.....but the 11 or at least their families deserve better than this....just my 2 cents of this

aliilaali: "gotta back your rig crew." Those five words should be tattooed across Tony the Twits chest with a dull needle and high acid ink. And I'm being kind. Then he can go fox hunting with Lord Browne.

Just remember Haywood came up through the ranks starting as a well site geologist. He is not a lawyer, a Harvard MBA, and obviously did not come our of the PR department. I think he knows what working on a rig is all about.(Does not mean that someone did not screw up). Comparisons with Browne are off the mark.

Diverdan: You can be present and not learn much. Earlier Rockman, a site geologist, said he was so upset he couldn't post for several days because it was "blame the guys on the rig first." But what does Rockman know? Bye the bye, I didn't compare Hayward to Browne. I just said that they can share the pleasures of retirement in disgrace together as ex-CEOs of BP.

El: I too worked on rigs and managed companies. Safety and environment was a big deal as was prudent cost control. Let's see what actually plays out. May not be quite so clear cut. As I remember Hayward cited the BOP but did not blame a rig guy directly. Remember though that pilot error does happen and does not always mean the CEO is evil. Could just be wrong place at wrong time.

There is a natural tendency of worker bees to question management and visa versa. Having been on both sides I prefer to take the middle ground until I get all the info and to see it in context. As a society we are hell bent on finding blame....and for many playing the role of victim. Ninety percent of what is written is speculative and biased. Even with politicians I do not like (which is most of them), I hesitate to say they are evil.

Diverdan: I agree with you. But. I have heard first hand Hayward frequently say some pretty stupid things, and I have read quotes that have not been refuted where he has said pretty stupid things. It seems to be a pattern with him. If his mouth is connected to his brain, then I am concerned that he is way over his head in his ability to manage as complex an operation as BP. Perfectly decent people rise to a position where, because of incompetency, they become dangerous to others. If Hayward is publicly humiliated and does not deserve it, that is painful to me. But, I would bet you any sum that his humiliation leads all managers at whatever level in all oil related companies to have public and company safety at the very tippy, tippy top of their agendas. We all now know how risky deep water drilling. Minimize the risk. Bye the bye, I have never said Hayward is evil. He just looks to me careless or incompetent because of his very public performance. And, therefore, he deserves public ridicule for his public performance.

Any experienced working oilpatch crew-man I ever

met I learned respect for (on the job that is.((-;)

When chips were down, any one of them would walk

back into the fire and sometimes did.

It's the ONLY way a well can operate successfully.

'Greenhands' learn quick to follow that, else they

soon go home. Nobody want's somebody on a well that

they can't count on 100% in an emergency.

As there are no excuses & no accounting,

when somebody is hurt or dead Then they are hurt or

dead, period!

It's no 'Willis' movie, no quick rewind,

& everybody working on a rig anywhere for real

gets to know that darn fast.

It's dirty dangerous and damn hard work.

I will bet Monsieur Tony never worked a DAY on a rig,

(let alone ever actually worked anywhere.)

If he was running an actual rig, I'd be swimming home

as fast as I possibly could, that's a fact.

Hayward has offshore rig experience.

Then go update his resume for him

he's gonna need it.

How 'bout goin' back to HuffPo or the Daily Kos where you REALLY belong?

"2 RW`s working in tandem will give plenty of shots at interception within a very small time ...relatively speaking ...(see engineers at BP are thinking two steps ahead also....stop trashing the poor engineers at BP like the dont know what they are doing)....."

You make some great points above, but you are ignoring the fact that the whitehouse forced BP to drill a 2nd RW.

IMHO 2 RW`s would have been sunk WH or no WH ....rmbr this is not east timor or some other timbuktoo country where O&G producers can run rough-shod with the environment .....the fact the 2 were not sunk of east Timor was a financial decision weighted with potential penalties for not doing so ...also east timor was in high seas where HC`s were being displaced all over in rough seas.....not like the GOM which is protected by land and provides HC accumulation potential ...

not disputing what you`re saying....if the WH cracked the whip ...good work WH. But all that arguing is for later...there`s 2 RW headed south and we are better off for that

me I would say put one more rig on this job.....3 to me would be a good balance all things considered

I agree. After your and Alan's remarks (regarding need for more relief wells) If I were in charge I'd sleep lots better with 3 RW's going in rather than 2.

Other than the cost, what's the down side? Seriously.

The risk of another accident. Loss of life. Drilling wells is dangerous.

How common is it for more than one relief well to be started?

Deep Horizon accident happened on 4-20. MMS and BP began discussing two RWs on 4-23. On 4-24 MMS reported they expecting applications for 2 RWs. Testified equipment for both rigs on way. On 4-26 they reportedly got the application for one. There it gets murky. They soon had two applications - the MMS testimony indicates same day.

Sounds like it could have been a call from the White House.

Development Driller III was spud in on 05/02. Development Driller II was spud in on 05/10, and its drilling was temporarily suspended to supply a BOP for the BOP on BOP solution.

Indeed.

I phrased the question a bit flippantly to draw out just such responses. Anyone else care to expand on that theme? There are obviously risks either way. I'm now leaning toward thinking that 3-4 relief wells might be optimum, and taking steps to see if that can happen. I greatly respect this forum, and if there's good reason not to advocate this, I'm listening...

thanks.

What's the difference between one in a million event and a three in a million event?

Two RW blow outs.

They could spud one or two more and stop and wait, but at the rate this is going there will be more DW RWs in the Gulf of Mexico than before the moratorium suspended the DW wells that were active before the accident.

Just remember CEO probability analysis: if 999,999 things in a row go wrong, the next up is certain to go right. BP has to be close.

So you think the odds of a relief well blowout are high?

I know you've got a bit of humor mixed in here. But it would seem that the odds of a relief well blowout are significantly lower than the odds of the existing blowout causing more damage. Disagree?

I'm unqualified to know. aliilaali seems okay with two, describes a try and retry scenario where they are coordinating attempts, so that must mean he does not think it crazy to think they'll both make it. He knows. ROCKMAN says three. He knows. I doubt he's freaking that the effort is doomed with only two.

I'd say any well drilled carries a risk of a blowout happening. Increasing the number of wells increases the odds of success, but also the risk of another blowout. It's a game of balance.

Just money greenie. There's room for 4 or 5 wells that wouldn't interfer with each other.

Thanks. That has been my impression.

I'd go with more than two relief wells, at least until two of them had casing set below salt. To me the odds of losing a well entering or exiting salt are pretty high, and you need to avoid a second 6-8 week process of getting back through salt. Other than the salt interfaces, the fact that they have logs from a few thousand feet away really reduces the unknowns and risks this second time around.

aliilaali:

Thanks for answering--especially Question 1 above.

I was wondering if they would have to start over completely if not success.

Very helpful information for me and anyone else who is totally non-technical.

Tears -- There's such a wide range of possibilities that I can't give much of an answer. First, wells never finish sooner than planned. It can take 90 days to drill a 60 day well even when there are no major problems. Worse case you can lose a deep well shallow and have to start from scratch. There is one good bit of news: they have the drilling history of the blow out well. When you drill a well in a new area you can only guestimate the pressure profile you'll encounter. A while back I was a pore pressure analyst working on DW GOM wells. I would work with the drillers to make changes of the estimate as we drilled. They have that data on the blow out well in the can now. The RW are so close that the profile should be very similar if not exactly the same. This should give them the best shot at getting the RW down as fast as possible.

Rockman:

Thanks for the explanation

As the summmer proceeds, we will all, both professional and non-techies, be eagle eyeing those RWs.

It might be worth looking at the Montara spill in 2009 for comparison (600 feet of water and 8,500 feet depth). It took five attempts to intersect the drill pipe, five separate sidewells, and the original rig (which was still intact) caught fire when they intersected the pipe. We're just at the beginning of this thing, not the end.

http://blogs.ft.com/energy-source/2010/06/01/how-difficult-are-relief-we...

After the first relief well was drilled on the Ixtoc I spill (160 feet drilled to a depth of 10,000 feet) ... the oil continued to flow for the next three months (until a second relief well was drilled). BP should be making it's seismic data available for the Macondo prospect so that engineers and scientists can be working on all the contingencies associated with the drilling of these relief wells.

From the linked Ft article:

How likely is this? Wouldn't the wellbore be intercepted significantly above the target reservoir? I'd like to see a little discussion on the risk/benefit of relief well drilling... thanks.

Sounds to me like a whole thread on this topic is in order soon.

(I saw your message, greenish, and sent you an email.)

Relief wells are the tried and tested solution for the problem. The relief wells will intercept the leaking well near the bottom where the hole pressures will be nearly equal - standard procedure. All drilling is risky, but the short and sweet answer is this solution will work - even if they have some difficulties. The drilling crew will be especially careful, given the accident that occurred, however they also have all the information about the geology, formation pressures, etc. that was obtained when the first well was drilled.

If you searched the older threads you would find a lot of discussion on this topic - and perhaps Rockman and aliaali will repost some of that if they are in the mood.

Green -- this is a load from bloomberg

there is no question of the RW drilling into the reservoir...if they did that then it would be a production well not a RW by default....

what they are going to be doing is .....based on geological and seismic data and all that good stuff ...try to get near the reservoir and tap in the leaking well....they will not tap the reservoir in any stage ....

although this time around they will be going slow to be careful and to position wellbore in a way as to make a good approach to hit the leaking well....

a blowout is a risk on any well that has ever been drilled...drilling is a reactive business since you can never predict what lurks miles below the surface.....

thanks aliiaali... this is what I had understood, I just wanted confirmation that the quoted article wasn't correct about drilling into the reservoir. Seemed incorrect on its face, but since I'm thinking about advocating an additional relief well, I'm triple-checking. I tend to think that 3 relief wells would be a pretty good idea. If you'd like to see that happen, (or talk me out of it), might want to drop me an email by clicking my user name.

Thanks again

They probably want to intersect the #1 well near the producing depth - the shallower you hit it, the more likely your mud will just blow on out with the oil rather than accumulating enough column in the blowout well to kill it (essentially the same problem they had with the Top Kill.)

The biggest risk I see is that as the RW intersects the #1 well, that well will act like the world's biggest 'lost circulation zone', at least until/unless the mud going in is enough to kill it. And you MUST keep your RW full of mud, or it too will blow out. When they get close they'd better have big mudpits, full, with work boats lined up to refill them fast.

Yes, this is how I understand it, thanks. Here's a more naive question: are there ever wells which might require a higher flow rate of mud/cement than you could get down one relief well? I reckon the answer is no, but I haven't seen it discussed.

greenie -- The rate at which they pump the kill pill down isn't that critical. It's the pressure that's critical. The good news (if I read correctly) is that they drilled the reservoir with 14.5 #/gallon mud. That's really not that high a mud weight for a deep well. Just a guess but the kill pill probably won't be greater than 16.5 ppg. Too high a mud weight and they could fracture the rocks and lose the RW. The good news: as a soon as they start pupming the kill pill the oil/NG flow will help push the mud up the csg. The bad news: a lot of the kill pill could be pumped out of the well at the BOP. But any amount of KP in the csg will put some additional backpressure on the flow. And that will cut the oil/NG flow some. And that will help keep more of the KP in the well bore. A very helpful feed back loop.

"BP should be making it's seismic data available.."

http://blog.skytruth.org/2010/06/possible-leak-from-platform-23051.html?... "...platform is located at 28.938022 degrees North latitude, 88.970963 degrees West longitude..."

http://blog.skytruth.org/2010/06/gulf-of-mexico-time-to-get-serious.html... "...We've observed the slick on Envisat MERIS and ASAR images taken on April 25 and 26, and May 12, 18 and 31; on RADARSAT images taken May 8 and 11; and on COSMO-SkyMed images taken May 11, 14 and 15..."

I'll ask before it gets crowded. If an event occurred March 12, 2010 at Macondo, then the explosion on April 20, 2010 could this be related? Someone mentioned the link last night on the IRC. I remember that a number of geophysicists identified themselves as TOD members on one of the earlier links. As someone commented in a thread of a couple of days ago, if the mud was going into geological formations, so was the oil.

I wish they would release their sesmic data. Why doesn't the government just nationalize all available data related to the Mississippi Canyon as a matter of national security? Since BP and MMS collaborated in so many studies related to this particular issue, I think that the US can be justified as an equal shareholder.

Just out of curiosity, what would be the purpose of obtaining the seismic data?

Shelburn: it would be submitted to TOD for an objective third party expert analysis.

I still don't understand what we can learn from the seismic data that applies to the blowout.

The people drill the RW might be interested but I'm sure they have all the data - primarily logs - that BP can provide.

We do this professionally. At least a month to give you maps and attribute analysis, minimum fee $100,000. And perfectly useless in the present context unless we have BP well logs and good narrative of stuck tool and directional bypass.

And I still don't think it would tell you much unless somebody is really looking for shallow hydrates or something...

Or a big whopping bright spot.

And then I STILL don't think it would tell you much (again, in this context).

(not that I think you disagree...)

Assuming we had all the data, I could identify the weld or fault plane that's leaking gas and light fluids 5 miles away, develop an intervention scenario.

So not to particularly dispute what you're saying....but I think that a) that would depend on what 'all' the data meant, b) that the leaking fluids actually had an identifiable signature relative to surrounding sediment, c)that there ARE leaking fluids. And it seems it would be kind of a major assumption on where in the well the underground blowout was happening....

I've seen some attribute studies done on the basis of a single well for control that were kinda off target. Unless 'all' of the data means all of the offset wells in the area (Rock mentioned that there are producing leases adjacent to this one).

And does anybody know where the original person who talked about this got the idea of shallow salt? The guys who have been posting that know the geology in the area say that this area is inbetween salt. E.g. none around.

ETA: Well, duh! Just realized nobody would even have seismic that had any leaking fluids on it. Given how faulted up the GOM is, I have no doubt that you could find any number of small faults that reached surface. However, getting from there to 'this is where fluids are leaking' would be a major stretch unless somebody has a satellite fix on a leak thats 5000 feet down. The Skytruth article I saw indicated that fluids were leaking from a nearby platform - it wasn't attempting to say it was this one.

To clarify, not shallow salt, but a salt weld or fault. I don't have access to BP proprietary dip data or seismic, but generally slumping MC tertiary sediments evacuated or displaced salt randomly. In BP's 29977 Drilling Plan, they stated there were no faults in the prospect, which must have been necessarily false.

http://www.searchanddiscovery.net/documents/2007/07083chowdhury/images/c...

http://www.olemiss.edu/depts/mmri/programs/LowEtal2.pdf

http://www.gomr.mms.gov/homepg/offshore/gulfocs/subsalt/ss_map.html

http://www.searchanddiscovery.net/documents/2009/10215chowdhury/images/c...

http://www.onepetro.org/mslib/servlet/onepetropreview?id=OTC-11863-MS&so...

avon -- I get your point now. And IMHO there is a little merit to your idea. But 5 miles is a long way for the type of event you're imagining. Maybe but I would be very surprised. But Mother has surprised me more than once. OTOH the feds have all this data. And if they wanted to contract someone to do the study you envision the gov't is free to do just that.

But before I would burn up work station working time on seis analysis I would make a survey to prove there's oil leaking from the sea floor in that area. Maybe I've missed it but I've seen no evidence of it...just folks speculating it's happening.

granted the engineers know what they are doing... but... heard on cnn tonight... white house leaned very heavily on BP to run a 2nd RW in the first place...

unrelated to what i blockquoted... now there's stories that the coast guard's efforts at putting out the fire may be what caused the rig to sink... too much water... they quoted a couple of industry veterans... there goes BP's liability... it'll get to john robert's Supreme Court for Corporations circa 2022... and the U.S. Govt will reimburse BP stockholders for the govt's mishandling of the fire rescue...

and though i've retorted your comment... you are spot on to focus on the human loss... hayward may of "come up the ranks"... but he got out a long time ago... now he wants his life back... seems he had complete control of his life before the mess...

once WE stop being pigheaded energy users... and maybe start making ALL CEO's sign a personal liabilty document for the actions of their corporations... we might not see rampant ongoing trashing of the environment...

let's not foget... the niger delat region's normal lifespan is about 40-something... after decades of no-so-dramatic-as-this spills... but who cares about 'dem dare dark skinnned folks oh so far away... we get a heck of lot of oil from other places too... just when it hits home that we all get up in arms...

no to worry... van der sloot just gave the cable shows... MONTHS of new material... i can hear oreilly and greta and what's that other dingbat lawyer become talk show host???? oh well... glad i gave up ALL tv in 2002...

Looks like there will be plenty of disperants dispersed.

More at Panel of experts ...

and it looks as if we will be seeing less of Tony H.

BP hives off 'toxic' Gulf spill operation to dilute anti-British feeling in US

I wonder if this is the beginning of an emergency disconnect of their US operations.

Oilfield opinions on Mr. Dudley? Is this likely to change anything of importance?

Also, "riserless mud recovery" (RMR) came up in another thread.

http://drillingcontractor.org/new-deepwater-riserless-mud-recovery-syste...

Looks like a complex operation with only ROV access to some critical components. Upsides? Downsides?

He apparently knows how to hide...

Read more: http://www.dailymail.co.uk/money/article-1284087/BP-oil-spill-Bob-Dudley...

This just shows adaptation to Russian 'politics' - deal with confrontation head on and don't back down (find a bigger stick if you can), but in the end if you don't find the right friends to back you up you have to take cover or you will be eliminated...

Yes, I was being flippant.. Russia sounds like a very tough place to do business.

Judging from his bio on BP.com, Dudley has worked his way up the oil industry via the negotiation and strategy side rather than the technical or operational side.

I know a cell tower installer who had worked in Russia. He got out when his boss was killed by the Russian Mafia.

With an X-Acto knife.

Riserless drilling has been used for a number of decades for very deep water holes drilled for scientific purposes. In this context drilling mud is often not used. When it is they use the system diagrammed in the article. But the important thing about these holes is that they do not expect to encounter hydrocarbons. If they do its a bit of a disaster.

Sorry... but somebody has to say it:

http://en.wikipedia.org/wiki/Dudley_Do-Right

Well Hayward is a British Aristocrat and he wasn't handling the colonists properly with all those inept statements he kept making so no surprise with this decision.

I seriously think BP is trying everything they can to cap this well, they run a huge risk of a hostile takeover.

A few days ago I asked about employment on the clean-up crews for PAY. However after watching the news last night and looking at the dregs of society they have working on them now it's not even a remote option for me. These people if you can call them that are literally smearing feces on the walls of store owners restrooms, not really working, 20 minutes work 40 minutes rest?????? WTF????? No wonder @ 10 dollars an hour what can you expect. Once BP announced a mandatory drug test would happen half the crew went back on the bus!!!!! This is ridiculous, if you want a job done right HIRE good people. BP isn't focusing on the clean-up effort. Right now they don't care since the well is still gushing.

I'm afraid Louisiana is doomed especially the wetlands, can you imagine the damage inflicted on them if the current stock of BP clean-up personnel are used??? Hazmat training for these people???? Heck the only thing most of them care about is loading a rock in a crack pipe!

YOU GET WHAT YOU PAY FOR!

Better not find out what they pay TSA employees and their training. You would never fly.

I really try not to fly, or drive if possible. Since i'm collecting unemployment AGAIN my car sits in the driveway. Since it's a 99 GM this is a good thing since if it's not being driven it can't break down LOL

Seriously though the scum that BP is hiring is beyond belief!!I feel sorry for the store owners who have to deal with this trash. The good news is I noticed ZERO of them have 1/2 mask respirators so they'll probably die in 10 years. The flip side is with national health-care we the taxpayers will have to fork out some heavy duty cash treating all the petrol related ailments they're bound to contract.

NO WINNERS IN THIS DISASTER.

well except for the mfg. of booms, corexit, drilling mud, scientists, and politicians, *cough couch* except for Obama and his crew!

No kidding! President Bush could have stopped this with his bare hands! He would clamp the leak with one hand and wave a "Mission Accomplished" banner with the other!

No way this happens with St. George the Infallible.

I've always found that looks are deceptive. If you really want to know how much feces someone has between their ears, read what they write.

Maybe you can keep the smell down with a little vaseline-soaked cotton in your ears.

I hope that's grammar related, i'm a naturalized American citizen and german is my primary.

A company is only as good as the employees they hire and the crud BP is placing on the clean-up crews in contempt-able to say the least.

Tchuss!

You watched TV and judged people whom you've never met. A previous generation of Germans were cursed to have too many in their ranks who thought like you.

My father also emigrated from Germany, in 1928. But he came to this continent with a spirit of openess and kindness. You have a lot to learn.

those "dregs of humanity" are my family. In fact you are a relative. I am german also. It doesnt matter. Your lack of compassion and arrogance are showing.

I know a little about British corporate law. This move sounds like the beginning of a special purpose vehicle to "ring fence" looming damages from the rest of the corporation's assets. In Indonesia, the mud flow disaster damages have been off loaded to a "special purpose" and separate company isolating damages away from the original corporation's assests. I don't know the details but I'll bet that legal research on "off loading the damages" is being given an equal priority with stopping the blow out.

Sounds like a pretty safe bet. And a good reason for the US to consider freezing assets within its jurisdiction, lest they be transferred elsewhere, leaving the "special purpose vehicle" with only liabilities.

Here in the UK this disaster is getting very little media coverage, and the coverage it gets almost invariably has some financial expert talking about BP being this super-important company in the *markets*, that 12% of all pension fund dividends here in the UK come from BP, that the share price is going up and down with each bit of news about the success or otherwise of the latest attempt to cap the well.

I listen to all this and feel ashamed. Then I come to TOD and get a reality check; I remember that people died in this disaster; I see people losing their livelihoods as an ecological catastrophe unfolds; I listen to the experts talking about the guys, the ROV operators et al who are working their hearts out to try and stop the leak; I follow the analysis of the experts on TOD; I watch the videos of oiled birds lying on their backs dying in the surf.

My personal opinion (I work in many different industries so am making a generalisation) is that profits have been put before safety, that safety has been too much of a paper exercise designed to indemnify management if things go wrong, that there's a culture of Risk Assessment in which permits are issued and signed off without enough scrutiny and supervision of what actually happens once the guy walks away with a permit in his pocket. This is just my personal opinion. We do actually have a Corporate Manslaughter Act here in the UK. The guidance states:-

"The offence is concerned with corporate liability and does not apply to directors or other individuals who have a senior role in the company or organisation. However, existing health and safety offences and gross negligence manslaughter will continue to apply to individuals. Prosecutions against individuals will continue to be taken where there is sufficient evidence and it is in the public interest to do so."

Lovely. "Nice retirement plan you have there, shame if something happened to it."

I have little doubt this move is to protect the larger company assets and interests (circle the wagons). Right around now the "significance" of this event is beginning to get the attention of the big fish at the top of the pond. People are starting to do the math on a "worst case scenario." I wonder what the thinking is in Congress and the WH about one of the US biggest taxpayers taking a loss for quite some time? I am not sure if it is a good idea to force the issue at the moment. If there is even a hint of the bean counters driving this response on either side of the pond, the political fallout will be enormous. I hope the leaders keep stemming the flow the highest priority.

Yes, I thought the same and know nothing of British law!

landrew: But. BP might want to keep the damage threat in house because it's a poison pill in any hostile takeover attempt. And as I said in an earlier post the most blood thirsty piranhas in the financial ocean are circling BP like a sick guppy. Risk assessment in different waters.

Excellent thought! Do I smell merger? EXXON Valdez BP GOM SPILL? What would you call that company? To Big To Fail Oil Company of The World stock symbol

SPILL ha!

It's not anti-British feeling, it's anti-moron feeling. If the American makes the same sort of insensitive, idiotic and false comments that Hayward is making, we will hate him too.

I have to concur. I feel nothing negative against the British because of this spill. It could have as easily been any international megacorp that chucked up. There is a cultural difference though in interpreting Tony's remarks and attitude in the states. As Toyoda recently learned too, marketing and PR in the states is extremely sophisticated and different than in other nations. This is because the USA is (probably) the largest market for products such as petrol and cars and we have a lot of experience being that economic powerhouse.

I don't quite know that I can put my finger on it, but I will try.

The US expects to see extreme emotion, and even crocodile tears from those responsible. But we also want to see that things are being handled and under control. This must be done temporally. First, one must show outrage and sadness, then followup with "it is under control." For the same person to play those two different roles is difficult. Also there is an expectation that ownership of this issue is taken by those in charge that I often find lacking. Americans do not like externalization of problems "The well has had a blowout" versus "Our Well has blown out". We want Donald Trump when you are winning,

We don't want to accept that Tony's attention is on anything but this situation, we want a hero to focus on it 24 hours a day and the "buck stops here" attitude that we expect means you don't appoint someone else to do it. I read in TOD that Tony is appointing an American for the cleanup, the better PR move (from a US perspective, and maybe not the better market move) is for Tony to appoint a Briton (or anyone) to run the rest of the dang company and Tony be seen to be focusing on only this until it is solved.

It may make complete sense from a international megacorporate perspective. But they are really screwing the PR here in the states.

"The US expects to see extreme emotion, and even crocodile tears from those responsible... This must be done temporally. First, one must show outrage and sadness..."

With all due respect, pbnj, I read this and wondered if it could possibly be true because I immediately thought of Duncan's comment in Shakespeare's Macbeth:-

There's no art to find the mind's construction in the face.

Below the dashed lines, I quote a comment posted on the previous thread from Oil Drum member 'shelburn'.

I just thought it shouldn't get lost in the shuffle as it answers a variety of questions being posed here.

Thanks shelburn, for the patient, cogent explanation.

Peter B.

----------------------------------------

"It is obvious that most people do not understand the basics of how the top hat is supposed to operate. And BP, per usual, has not thought it necessary to explain anything.

The Top Hat Seal

For a number of reasons the top hat seal is NOT a pressure seal. It is designed to try to keep seawater out, not to keep oil in.

Let me repeat - The top hat seal is NOT a pressure seal. It is designed to try to keep seawater out, not to keep oil in.

Any water that can get in at the bottom of the top hat will form methane hydrates and probably block up the pipe. If that happens as they are beginning to start a slow flow it just means another setback.

But it is much more likely to happen when there is substantial flow going up the line and they are starting to “pull suction”. At that point there is a high flow rate and the “water hammer” effect of suddenly stopping a mile long slug of oil and gas could easily start tearing the equipment apart, probably at the top hat or onboard the ship so it becomes a safety issue not just another failure.

The top hat is not designed to take any significant pressure, certainly not the pressure that could result from sealing to the BOP so that pressure must be able to escape - through the seal area. Even 1,000 psi would blow the top hat apart and there is potentially about 9,000 to 13,000 psi at the BOP

And at this point I think they are scared enough of the integrity of the well head and BOP connection that they don’t want to have any pressure build up which would happen if you sealed the top hat to the flange.

There are other safety issues that are solved by not having a solid seal.

1. The rig must be able to shut off the flow on deck at any time and the resultant flow has to go somewhere - which is out the top hat seal

2. The rig must be able to pull away from the well at any time in an emergency and just raising the top hat off the BOP solves this problem.

Flow to the Surface

The flow to the surface is through a drill pipe from the top of the top hat. The drill pipe should be able to flow between 20,000 to 30,000 bpd or more if it was 100% oil – NO PUMPS NEEDED. With gas in the flow the amount of potential flow is even greater. In any case the processing system on the ship cannot handle as much as the pipe can transport.

The oil is about 0.85 specific gravity. If the drill pipe was filled just with oil the buoyancy of the oil will raise the pressure at the surface to close to 400 psi. If filled with gas the pressure would be about 2,000 psi.

The problem won’t be to get the oil to flow but to keep it from flowing too fast. They will throttle (choke) the flow back to get the volume they are comfortable with and then pipe the oil and gas, still under some pressure, into a separator vessel where the pressure will be reduced and the gas will go to the flare to be burned and the oil will go into a storage tank.

The product flowing from the bottom will be a mixture of oil (with dissolved gas), NGLs and super-critical methane gas. Hopefully there will be no water as that can really mess things up. During its journey to the surface, and through the processing system there will be a number of changes as gas dissolves out of the oil, the methane goes from super-critical to gas, some of the NGL will turn to gas and all the gas will eventually expands about 150 times before it hits the flare.

The optimum flow at any time will have to be determined by trial and error on the rig. If they were to open it up quickly they might get lucky and obtain a stable flow quickly. The downside of trying to do it quickly is that you could suck in water setting back the whole process for hours or days or worst case end up with an uncontrolled flow on the ship resulting explosion and fire with fatalities and another disaster.

So the fact that it could take a period of days to reach maximum flow is no surprise.

The oil gas ratio in the flow from the well will probably keep varying all the time and coupled with the phase changes and gas expansion will be a continuing problem for the processing crew on the rig. I expect that is the reason we saw daily changes in the amount of oil recovered by the RITT."

-----