Next Generation Biofuels: Five Challenges and Five Positive Notes

Posted by Robert Rapier on July 2, 2010 - 10:14am

The U.S. Department of Agriculture (USDA) has just issued a report detailing the outlook and challenges of next generation biofuels. I provided some input during the drafting of the report, which hopefully was of some use. Here I select five pessimistic projections and five optimistic projections from the report.

The report is: Next-Generation Biofuels: Near-Term Challenges and Implications for Agriculture

Here are five findings from the report that promise to strongly influence the country’s direction on next generation fuels.

1. Production and Capital Costs

“Estimated production and capital costs for next-generation biofuel production are significantly higher than for first-generation biofuels.” The report quotes costs for a 100 million gallon biochemical conversion plant (e.g., cellulosic ethanol) at $320 million, and the costs for a 100 million gallon thermochemical conversion plant (e.g., gasification and conversion to liquid fuels) at $340 million. The report states that this is “more than three or four times those for corn ethanol plants.”

2. Biomass Feedstock Costs

The report suggests that the presumed costs for purpose grown biomass have likely been underestimated. It cites POET, for instance, as assuming a $40 to $60 per ton price for corn cobs. But the report states

the range of prices may underestimate the cost of increasing biomass yields on marginal lands and the incentives required for harvesting, gathering, and delivering bulky material to the biorefinery

and

dedicated energy crops would need to compete with the lowest value crop such as hay which has had a price exceeding $100 per ton since 2007.

In a previous essay I identified this as one of the bad assumptions many biofuel producers today are making: That biomass costs will be low or even negative in the future as demand ramps up.

3. Algae Conversion Costs

The report repeats the mantra that you have heard from me many times:

Production cost estimates (net of capital costs) for growing and converting algae to fuel are significantly higher than for first- and next-generation biofuels, ranging from $9 per gallon to $35 per gallon.

As I have noted before, I think people confuse the ease of growing algae with the ease of growing it commercially and turning it into fuel.

4. Support for Cellulosic Ethanol May Be Short-Lived

The report suggests that support for cellulosic ethanol may be short-lived:

Given the limited market for ethanol as a gasoline additive (due to the E10 “blend wall”) and as a gasoline substitute (because of slow development of the E85 market), developers and investors may turn away from cellulosic ethanol in favor of production of another class of next-generation biofuels, petroleum substitute fuels. These so-called ‘drop in’ fuels can be used as gasoline or diesel substitutes in current vehicles without limit and distributed seamlessly in the existing transportation fuel infrastructure.

The report further states

There may be a shift in favored technologies underway. Several companies planning to be operational with some of the larger plants in the next several years plan to use thermochemical approaches or other processes that produce biobased petroleum-equivalent.

My position on this is clear: I believe that thermochemical approaches are more scalable and less energy intensive than most biochemical approaches.

5. Scale

Fiberight is forecast to be the leading cellulosic ethanol producer for 2010 – with a production capacity of 130 barrels per day. To put that into perspective, the very small oil refinery I used to work at in Billings, Montana had a capacity of 60,000 barrels per day.

The bits I extracted are all themes that I have addressed here many times. In a nutshell, they relate to the fact that many would-be next generation fuel producers are making unrealistic assumptions about things like feedstock costs. Thus, where they project falling costs based on their optimistic projections, the USDA report forecasts that their biomass costs will be much higher than expected.

Here are five positive notes from the report:

1. Renewable Diesel Plant Capacity

“Next-generation U.S. biofuel capacity should reach about 88 million gallons in 2010…” This is primarily a result of the expected start-up of a next-generation renewable diesel plant. I have reported on this technology before, as well as the efforts of first-generation biodiesel producers to slow it down and protect their own interests. My guess is that unlike the ConocoPhillips project that was killed after Congress voted to deny them the full tax credit, this project will receive the same tax credit as a conventional biodiesel producer. On a level playing field, I believe the hydrocracking approach is superior to first generation biodiesel, but our political leaders will need to stop playing games with the tax credits in order for next generation diesel to realize its potential. (For a complete explanation of the different kinds of renewable diesel, see my Renewable Diesel Primer).

2. Competitive Race

Companies are taking a number of different approaches to coming up with next-generation solutions, increasing the chances that a dark horse will arise as a contender: “There are about 30 next-generation companies in the United States developing biochemical, thermochemical, and other approaches, and experimenting with a variety of feedstocks, some of which are directly linked to agriculture..”

3. Open for Business

The first next-generation plants are expected to come online in 2010: “Range Fuels and Dynamic Fuels are expected to complete the first commercial next-generation biofuel plants in 2010.” I have certainly given Range Fuels a hard time over their public statements – especially in light of recent reports which this USDA report also flagged: “According to the EPA, however, the plant’s initial capacity has been reduced from 10 million to 4 million gallons per year and initial output will be methanol.” However, readers should not mistake my position as hoping that they fail. To the contrary, I hope they succeed, because we are going to need a lot of successes. I am just skeptical that they will achieve commercial (unsubsidized) success, and unhappy that they sucked up a lot of taxpayer funds based on their initial promises that clearly did not materialize.

I would further note, however, that Range Fuels and Dynamic Fuels may be the first U.S. plants that could be classified as next-generation commercial plants (although as I have pointed out, we had commercial cellulosic ethanol plants in the U.S. by 1920), but such plants do already exist overseas. Neste Oil, in fact, has built several plants based on the same sort of technology that Dynamic Fuels is employing. There are also other overseas companies doing gasification (the Range approach) that are further along than Range is.

4. Algae Research

Just as there are many different approaches to next-generation fuels, there are many companies taking many different approaches to producing fuel from algae: “More than 30 U.S. companies currently are experimenting with different approaches to producing algae-based fuels.” Some of these approaches are unconventional: “Although the majority of algae-to-biofuel companies are focusing on producing algae oil for traditional biodiesel production, some companies are using algae to produce ethanol (Algenol), or petroleum-equivalent fuels (UOP and Sapphire).” The challenge of course will be to drastically reduce production costs, but the potential is too great to ignore.

5. Production Costs Decrease

Both production and capital costs for cellulosic ethanol are falling. The report noted “POET recently reported it had lowered production costs for cellulosic ethanol, including capital expenses, from $4.13 to $2.35 per gallon in a year as of November 2009 at its South Dakota pilot plant.” The report further notes that estimates for a 100 million gallon cellulosic ethanol facility have fallen from the $650 million to $900 million range (2004 estimate) to $320 million (2009 estimate). However, the report notes that these estimates should still be considered speculative, since “there are no actual cost data for commercial operations since none are yet operational.”

As a body of work, I highly recommend you read the USDA report if you are interested in the status of next generation biofuel facilities. It is a sober, objective assessment of the challenges and opportunities that lie ahead as next generation fuel technologies continue to develop.

Thanks, Robert, for some interesting information!

When I look at the five challenges, they seem to be close to overwhelming, (except possibly for "thermochemical approaches" that you refer to above). The positive notes don't seem all that positive.

Do you see any of the next-generation biofuels succeeding? With subsidies? Without subsidies?

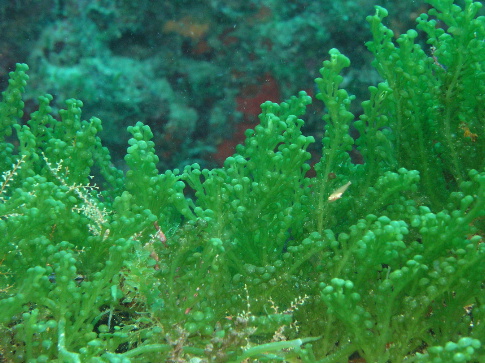

Yes, thanks Robert for laying it out in a very accessible manner. I'm keeping my eye on algal biodiesel/ethanol/other (see pic below) and the ongoing efforts there to reduce the costs of harvesting, dewatering, and bio-cracking. Since DoE is handling algal fuels, I wonder if the Ag Dept is downplaying its competition...

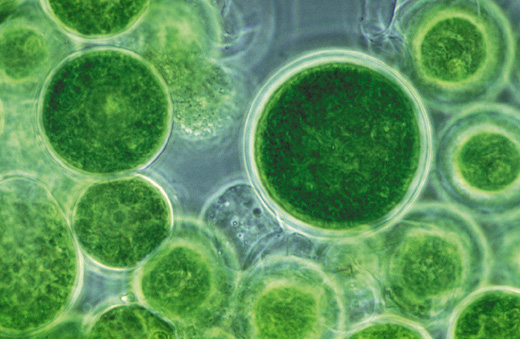

There are two major limiting factor to all biomass-based fuel concepts. The first is the limits of primary production - the amount of biomass fixation from photosynthesis is ultimately limited to the ~1% efficiency of the process combined with the dilute nature of sunlight (as well as its intermittency and seasonality of active growth). These boundary conditions will dictate how much surface area is needed to meet some level of demand. Certainly at current transportation demand this would likely take up most of the arable land in the country (or world). Note, BTW, that no amount of genetic engineering of algae is going to substantially increase either the photosynthesis efficiency or the proportion of biomass fixation going to convertible molecules (oils and carbohydrates).

The second limit is EROI. As we saw with corn ethanol the energy inputs to converting any kind of biomass to usable fuels is considerable. All oil/nat. gas inputs need to be factored in as well. I would really like to see good studies (independently performed) on the overall EROI of all of these biofuels. Such studies should include opportunity costs associated with other food production that gets lost or marginalized.

A third factor has to do with the long-term sustainability of a biomass to fuels approaches and that is will the energy gain (if any) from these methods supply not only the energy demands of transportation (and farming) but also provide energy re-investment for building and maintaining their own capital installations? This is the same question that is faced by all alternative energy sources. We know that fossil fuels are not sustainable because of their finite nature. But aggravating that is the fact that the consequences of the Best First principle are causing the EROI of these fuels to diminish at an accelerating pace. To be renewable requires long-term sustainability and self (or mutual with other alternative mixes) replication of capital equipment.

The first and second laws of thermodynamics will always rule these schemes. Why don't we start with those and work our way back to what is really feasible?

Question Everything

George

To me, the high current cost of production pretty much equates to low EROI. Subsidizing the cost can temporarily hide the low EROI problem, but cannot fix the long term viability, if that is ultimately the problem.

The fact that costs are so much higher is a major concern. Admittedly, as Will Stewart has shown, there are different approaches, but if the limiting factor is physics, that is something we should figure out before trying to spend a huge amount of money researching areas which are sure to prove futile.

While cost may correlate with EROI at times, I do not believe it to be a reliable EROI indicator. Volume production of tested/piloted processes has the potential to drop production costs tremendously (it has in every other situation where a product is currently on the market). I don't have any current EROI on the various algal fuels (and these change almost weekly now), hence would prefer not to speculate.

I have to admit to a very jaundiced view of this whole issue of biofuels. It is (not to make a pun) grasping at straws. (OK maybe I meant to make a pun).

d

Yes, what George said. That's all one needs to say. Start top down and decide if we're just looking for things to burn up in our panic.

I hear Bill Gates is finally starting to get a clue. Way to go, Bill. Are you out there listening? Why don't you put some of your greed-gotten-gains behind something that can REALLY make a difference?

The "National Algal Biofuels Technology Roadmap" gives a oil production figure of from 1000 to 6500 gallons per acre per year.

To supply 100 billion gallons of oil per year would thus require between 100 million and 15.4 million acres or between 156,250 and 24,038 square miles.

By way of comparison, Montana is 147,165 sq mi, while West Virginia is 24,230 sq mi.

Could you provide a link?

Meanwhile this is what I am looking at: http://www.scientificamerican.com/article.cfm?id=algae-biofuel-growth-en...

Comparing square areas of states is cute but not applicable. Growing algae will require a considerable infrastructure (roads, pipes, you name it) because there won't be one huge algae pond. The logistics and impacts are non-trivial. And I still stick to my original point about photosynthesis and biomass production. Taking some lab bench production and multiplying it by some large scaling factor isn't the same as actually raising the algae, harvesting them, and producing product. I know a few researchers who are working on the genetic engineering problem. For them it is just interesting science. That they sell their grant proposals because there is some "plausible" link to energy is just a strategy for doing more science, not for solving the energy crisis.

National Algal Biofuels Technology Roadmap

Thanks. Downloading now.

Took a look and read the relevant parts re: algae physiology and biochemistry etc. As expected there were a huge number of typical science-speak caveats, "might be possible", "need more research", etc. What might be possible is a hell of a lot different from what is likely.

Don't bet the farm (another pun intended) on scientific "mights".

Well, it wouldn't be "research" if we knew the answer.

The Environmental Life Cycle Comparison of Algae to Other Bioenergy Feedstocks paper by Andres Clarens, et al, is behind a pay wall. Apparently they assume that a fossil fuel is burned to provide the CO2 input for algae growth and that the nitrogen and other mineral inputs can't be recycled. But without access to the paper, one only can read press summaries and opinions of varying credibility. The press appears to have missed "the use of source-separated urine was found to make algae more environmentally beneficial than the terrestrial crops".

I wasn't suggesting that we flood Montana or West Virginia with algae ponds. The pilot plant are likely to be small affairs until a better understanding of scaleability is gained. There are some in conjunction with coal-fired generation plants. Perhaps it would be possible to find a nice flat desert with lots of sun near a beach, so that solar power could be used to pump seawater into algae ponds and it could also be used to power separation and recycling.

Merril,

My point, and then I will stop harping, is that we already know the limit answers! We already know what the boundary conditions are for biomass primary productivity. These mechanical/operational issues are moot because we already know that the combination of photosynthetic efficiency and carbon partitioning to usable products are so limited that no more research is needed. It is mind boggling to me that we keep pursuing these minutia when we actually can compute the boundary conditions quite well. How do we justify pumping more money (and esp. energy) into research where we actually can easily determine the outcome from what is actually feasible. This is the madness of King George (no namesake relation I hope). This is what William Catton calls the Cargoist mentality.

My $0.02

George (not the king)

George, provide a research link from a regarded institution that specifically lays out the photosynthesis efficiency boundaries for algae (i.e., not land based plants).

Will, this is an incredibly laughable request. Open any good botany book and check out photosynthesis. Admittedly the range of photosynthesis efficiencies is all over the place with a high up to 5, maybe 6% for some land based plants. But it also ranges as low as .1% (big variation) so typically 1% is the quoted figure. If you hadn't read this then you have some educatn' to do.

Even at a top range of 6%, given the low intensity of sun light you still have a huge problem. As for references, here have fun: http://www.washington.edu/research/energy/researcher/rose-ann-cattolico

I'll be meeting later next week with a genomic scientist to talk about this issue some more. Good luck with wishful thinking.

Numbers and your point please?

The patent application does not provide numbers -- I'd think that numbers would be proprietary.

Professor Cattolico's web page say that they use non-GMO algae, which would be lower in photosynthetic efficiency than GMO organisms.

George, I asked politely for numbers from you on algal photosynthesis limits, and you could provide none. Please don't descend into mockery and deflection, this is just a simple request to have you support your assertion "photosynthesis is ultimately limited to the ~1% efficiency".

"given the low intensity of sun light you still have a huge problem."

Most of my home's heat and electricity comes from sunlight. Obviously, I'm not talking about BAU demand. Let's keep this a civil, reasoned discourse.

Civility ends when someone asks me to provide an education for them. All you need do is look up photosynthesis on Wikipedia if you want to go the lazy route. The information you requested is widely available in many forms. YOU need to take responsibility for your own knowledge acquisition Will. Besides, I took your request as more of a challenge than a request. When I offer an "opinion" or original research that isn't something widely known, then I will meet any such challenges as best I can. But when I state a fact that is widely known I take offense at those kinds of requests. Sorry if this seems a hair trigger.

I will add that if you didn't know these facts already you would be well advised not to dabble in this field.

I most certainly did not know algae was limited to ~1% photosynthesis efficiency, which is why I asked for a reference. If you do not have a reference, one can only assume you are talking off the top of your head.

You've since widened your 'limits' by 600%, which is closer to what I had assumed (I still don't know, but am not afraid to say so), so I will no longer seek a reference from you. You would be well advised to be able to back up claims (like the "~1% limit") before you state them with the 'authority' you did.

Sorry Will, but George is almost certainly right.

Granted, theoretically photosynthesis can be fairly efficient, but any biological system is going to consume the majority of that energy for basic metabolic processes such as reproduction, movement, active transport, etc. For larger organisms in the food chain we learn that this ratio is ~10:1, although for simpler organisms it could not be quite so bad, which is where that 6% maximum comes from... fairly unusual and optimistic.

Even if you can use UV, which doubles your available light energy, you're talking about perhaps 12% efficiency in an *extremely* optimistic calculation, and without discussing the efficiency of the overall process from sunlight to fuel. Subtract from that the energy required to extract the algae, dry it, crack it, etc and it doesn't look nearly as good as I wish it did.

This is not even to mention how expensive it is to grow in the first place. Regardless of how good it looks on paper, even a raceway pond is extremely expensive to operate due to the water requirements, cooling requirements, the need to co-locate with a high-quality CO2 source, the need to have trained engineers on staff to operate the plant... it's depressing to actually do the cost analysis (which I have).

A far more realistic solution is terrestrial crops, if for no other reason than that the crops are well understood, and farmers with no training in formal biology are already equipped both in terms of knowledge and physical tools to utilize those crops. They may not actually be physically able to meet our current transportation needs, but at least they are economically feasible.

And if it gets a hundred thousand people to move from cities back to the country to become farmers, all the better for our (again optimistic) transition back to a less petrochemical intensive agriculture system.

That said, I am going to continue to work to find ways to make algae a practical feedstock for biofuels, but take it from an actual researcher in the field -- it's not going to be easy. Think of it like fusion. Sure, it might solve lots of problems... but there's this little problem of it being 20 years out for 100 years.

Neltnerb, thanks for joining the discussion. Do you have any (formal or informal) photosynthesis efficiency rates for;

- Schizochytrium sp.

- Nannochloropsis sp.

- Botryococcus braunii

- Neochloris oleoabundans

I certainly understand the concern about EROI. Another researcher in the field, Dr. Patrick Hatcher, director of the Virginia Coastal Energy Research Consortium, estimates achieving at least 3000 gallons per acre per year in Virginia, though has not established any EROI estimates (or had not as of 7 months ago). He also estimated $1.40 to $4.40/gallon.

http://www.vbgov.com/file_source/dept/planning/HatcherPresentation.pdf

Here's a nice one:

http://www.theoildrum.com/node/2531

According to it, the maximum theoretical output can be 0,89GJ/m2/year while the energy content of biodiesel is 0,133GJ/gallon. So a square meter can provide 6,7 gallons of biodiesel at maximum. If you assume a pond of 1000m2 you get 6700 gallons/year. Or about the yearly consumption of 10 vehicles. The US has around 255 million vehicles registered. So you need 25 million x 1000 m2.

Okay ... let's divide this conversation in half. One half is the predictable (and realistic) output from either algal or terrestrial biocrops. This part of the discussion is pretty thoroughly examined. There is marketplace performance that can be used as a reference point.

The other half of the conversation isn't as well examined, the assumption is a kind of 'fuel X' that is easily fungible in the ordinary fuel stream, either as a gasoline additive or some form of diesel fuel. Why is this necessary? The extra refining steps to produce a gasoline analog or diesel fuel increases the energy investment.

What would be the best and highest use of biocrops as these would likely be competitors for food crops or crowd out other necessary services such as land for pasture, forest, watershed recovery or simply fallow land? Any operation that would make a difference against the background of our current consumption would have a massive footprint.

That the industry does not address this footprint issue directly makes the entire approach suspect, that the industry has something to hide, that the entire biofuel speculation is another fraud, a form of underwater Florida real estate.

One background discussion from previous TOD articles (including a discussion between Gail and myself) was the whether biofuel could support agriculture operations. Before widespread farm mechanization a third of cultivated acreage was set aside to provide fodder/pasture for draft animals. Could a fourth of cultivatable land produce enough biofuel to support tractors, cultivators, harvestors, irrigation pumps, etc., needed to cultivate the other 3/4ths.? Would another fuel formulation such as 100% ethanol be a better way to support agriculture use rather than creating incentives for auto consumption by adding to the motor fuel supply?

Or perhaps another chemistry approach altogether such as alcohol/peroxide combos?

There is precedence for this approach as ag diesel is not to be used as road diesel and is not taxed the same way. An ag- only fuel would perhaps be more systemically efficient and the footprint upper- boundary would be more clearly defined.

Interesting approach Steve. I think it's pretty clear that if agriculture cannot produce enough biofuel to power itself, then biofuels are not worth pursuing.

I have long argued (on RR's blog) that the ethanol industry ought to be powering itself first, before selling fuel to anyone else.

In answer to your good question about the fuel type - my vote is with methanol. It can be made from any carbonaceous feedstock, from coal to ag/wood waste, sewage sludge municipal waste and methane. It can be mixed with gasoline, or better still, used by itself as a fuel, where it delivers greater thermal efficiency in ICE's than either gasoline or diesel! (see my comments and links downthread). Both gasoline and diesel engines can be adapated for pure methanol operation, with diesel based engines giving much higher efficiency than gasoline.

An advantage of using biofuel instead of draft animals, is the the tractors need no fuel when they are sitting idle, but the animals do. Animals can, of course, replace themselves, but cannot achieve the economies of scale of tractors.

There is no doubt in my mind that agriculture could power itself, it;s jjust a question of how much land (and water etc) or produce (e.g. corn) needs to be diverted for this purpose. Corn to ethanol only uses half the calorific value of corn, the remainder is in the distillers grains, so if we are using corn ethanol, I would attribute 50% of the land for fuel. However, this will produce much more fuel than is need to produce the corn.

My guess is that it would be around 10% of the land. If the fuel is methanol this is an advantage as it can be made from anything that grows, so marginal land can be used for low yield tree farming to supply fuel. By making use of a lot of currently unproductive land, the national set aside may not be that much at all.

Already the subject of a story, and yes, engines are more efficient—so efficient they should be able to make do with crop wastes for many crops, no need to dedicate acreage to fuel.

Hello Will,

You may want to take a look at Gates, D.M., 1980, Biophysical Ecology. New York: Springer-Verlag. The book contains detailed calculations on the energy flows from the sun to plants across the globe. It is the most detailed work that I know of on solar energy calculations and photosynthesis. It does not cover specific biofuels though but does lay out the exact boundaries of solar radiation/photosynthesis on earth.

Rembrandt

My operating assumption for some time now has been that long-term, biofuels are just going to be used for aircraft, shipping, heavy equipment, farm equipment, emergency and public service vehicles, and some local delivery vehicles. We probably could produce enough biomass to fuel just those things, and do so without starving ourselves, especially if we severely limit the amount of flying that is being done. Most long-distance overland freight will have to be by electrified rail, and most local and long-distance hauling of people (masses or individuals) will have to be by electrified rail or other electic vehicles.

Of course, we have to get from here to there. I don't see biofuels as a silver bullet, but they could be very useful in a transitional strategy.

Whatever the demand you still need to match the energy fixing capacity of photosynthesis and metabolism with feasible output from production. Plants can't make more energy than falls on them and they can convert into usable biomass. That is what we have to grasp.

Meanwhile if we spend the resources (esp. energy) to build out a whole infrastructure on the basis of BELIEVING that biomass-to-fuels will somehow fill a gap, we are wasting resources that might have been better spent on something more productive. That is my beef with this whole business.

Do you see any of the next-generation biofuels succeeding? With subsidies? Without subsidies?

I think some will succeed when oil prices get high enough, but those will obviously be the ones that aren't heavily reliant on fossil fuels. But success will have to be kept in perspective. None of them are capable of replacing oil; the scales will be much smaller.

A relatively small scale(compared to oil) biofuels industry capable of supplying critical needs such as farm production, food distribution,and so forth would be a good thing.We are going to need some fire trucks and some bulldozers for the forseeable future, and the odds of running them on batteries are slim to say the least.

The thing that disturbs me the most about biofuels is the possibility that they might actually get to be cheap enough to keep us hooked on personal automobiles.

If that were to happen, the pressure to produce such fuels in vast quantities would be totally overwhelming .

It won't just be the automobile manufacturers, thier workers, andd the paving companies.It will be the entire travel/tourism industry, the banking industry, the educational establishment,everybody on medicare and social security whose checks depend on the continuation of bau, all the farmers and landowners wanting to cash in, or out, the owners of restaurants and convenience stores, thier employees

In short , just about everybody.

The end result would be environmental destruction and hardship for the poor on a scale hard to imagine.

While I really enjoy ethanol in a cool refreshing drink, I think that it is poorly suited as a scalable transportation fuel. The problems with ethanol are fundamental to its chemical properties, and exist whether it comes from corn, cellulose, algae or fermented BP executives (which are really just a lower species of algae).

Ethanol is hygroscopic which means that is absorbs water. This is a problem in refining since much energy is necessary to remove the water in production. And, it's a problem in storage and transport. Ethanol must be transported by truck rather than the more efficient pipelines for gasoline and diesel.

But the agribusiness industry is very good at attracting subsidies so ethanol production will continue. The industry is quite adept at diverting focus on the fundamental issue by focusing on what the optimal feedstock should be.

Here's my idea to solve this fundamental problem. Congress should pass a law that makes ethanol hydrophobic rather than hygroscopic. But sadly, there will be severe consequences to this law. Most significantly ethanol will no longer be useful in refreshing drinks which will disrupt my weekends and decimate the effectiveness of lobbyists. The citizens must decide: do we want ethanol as a transportation fuel, or a drink? Let's replace the tea party with the cocktail party and let the citizens decide!

[note to literalists: I'm joking about congress passing a law to change chemical properties.]

Converting biomass to electricity may be a better option anyway. This paper, Greater Transportation Energy and GHG Offsets from Bioelectricity Than Ethanol says that

If one goes to using "straight ethanol", that is 180 proof as it comes from the still, then the 10% water is not a problem and could be put through a pipeline.

Cars could easily be designed to run on "straight ethanol" but I doubt the petroleum industry will let that happen for a while yet.

But there is nothing stopping individuals from switching to "straight ethanol". (Except for availability?) And it does have an advantage. Gasoline, especially today's gasoline with 10% anhydrous ethanol, degrades fairly rapidly. But you can leave "straight ethanol" in you fuel tank for multiple years and it will not degrade, nor will it leave gummy deposits in the fuel system.

For those of us that drive rusted out junkers in the winter on Midwest salted streets and a nice vehicle in the summer, the 6 month storage of a tank of current gasoline causes many problems with carburetors and fuel injection systems. Older tractors on the farm that still run on gasoline (what I can afford) work all summer and sit all winter, again causing fuel system problems from degraded gasoline.

"If one goes to using "straight ethanol", that is 180 proof as it comes from the still, then the 10% water is not a problem and could be put through a pipeline."

If you design the engine properly, the 180 or 190 proof ethanol (and 5 -10% water) will act as an in-place water injection system. The engine will run very well, and cleanly. And you can boost the compression way up. If memory serves, VW built a pure ethanol (190 proof) engine with a 14:1 compression ratio that worked very well. It was a technology demonstrator back in the '70's. But then oil got cheap again, OPEC fell apart, and everyone lost interest.

100% ethanol's RVP is too low to work effectively in internal combustion engines. As I understand it, moderate ethanol blends of 30% are ideal in terms of octane content for hgh combustion efficiency.

Retsel

Actually Retsel, PVguy is right here. 100% alcohol (be it methanol or ethanol) will work much better than gasoline, in a properly set up engine.

See my comments downthread on this.

Here is a link to a paper where they compared the performance of methanol blends from M100 down to M50 and of E100 down to E10

http://www.methanol.org/pdf/ISAF-XV-EPA.pdf

The M100 and E100 gave better efficiency, over a wider operating range, than any of the lesser blends. The authors conclusion;

Decreasing the fuel alcohol content generally gives lower brake thermal efficiency and somewhat decreased load range.

The RVP is really only an issue for cold starting, and this can easily be handled by an electric pre heat for the fuel.

Keep in mind that Indycars have run on (pure) methanol for decades, and then switched to E85 a few years ago (under pressure from the corn ethanol lobby). Their engines get less power on E85, but they still run fine, and produce much more power than the same engine could on gasoline (as it could not run such high compression)

The 30% blends are optimum for engines that need to be able to run on straight gasoline, i.e that have normal (10:1) compression ratios. If you lose the gasoline and go to straight alcohol you can run compression of 20:1 and get much better efficiency. The same engine can run on M or E or diesel or natural gas - anything but gasoline - with high efficiency. It has been know for almost two centuries (since Carnot in 1824) that higher compression leads to higher efficiency, and you just can;t get that with gasoline.

By making an engine backwards compatible with gasoline, you give up the efficiency benefits of the alcohol fuels. And by blending said alcohols with gasoline, they must be anhydrous, so they are more expensive to make, for less benefit received!

The sooner we ditch gasoline completely, the better.

Not so much of a problem with biodiesel, and as RR's post mentions, apparently the problem with bacteria is being solved. Most of the transportation applications that are LEAST amenable to electrification (shipping, air, heavy equipment) all happen to presently use diesel or slightly heavier (bunker oil) or lighter (kerosene/jet fuel) fractions. This suggests that biodiesel (or next generation equivalents) could be a promising transition path.

Can be solved by fermenting to butanol or amylic alcohol. Much less miscible with water and it stinks something repugnant.

Are the zippy graphics part of the report or part of the post?

I checked. It doesn't look like the graphics are in the original report.

Are the zippy graphics part of the report or part of the post?

Steve, that idea was Sam Avro's, editor of Consumer Energy Report where my blog is now hosted. He is more social media savvy than me, and thought it would make the post more visually appealing. I think he was right about that.

They look very nice, and do indeed make the post eyecatching.

(Particularly after a couple of months of looking at leaking underwater blow out preventer stacks ...)

A National Algal Biofuels Technology Roadmap - May 2010 was also recently released from DOE. It appears that corn and cellulosic biomass programs are in the purview of Agriculture while the algal program is in Energy. This will perhaps spur some useful competition.

R^2 skeptical of cellulosic ethanol?

What a shock!

How many green gasoline plants are listed? Clear Fuels?

No bio-oilers? UOP?

Algae?

That single animal fat plant/biodiesel Dynamic Fuels is 60% of the petroleum substitute market operations.

Will this one go the way of the allegedly smelly Missouri turkey guts plant?

I count Coskata as thermo and I don't see how Range can make ethanol out of syn-gas without Coskata's bugs.

Rentech is doing BTL for PR only, they really want to do CTL.

If you have a choice between ethanol and methanol, it would seem that higher energy density ethanol would be better.

POET is way out in front IMO, tackling real problems of biomass collection alone. They deserve to win.

The problem is finding a market for cellulosic ethanol. One way would be to force all the ethanol plants to convert to cellulosic running on corncobs.

This would make the food-for-fuel people slightly less unhappy.

The other is to mandate all new cars to be E85 compatible and pass the couple hundred bucks for the technology on to consumers.

I have little patience for car companies whining about engine damage from E15 when they mass produce defective cars every day and regularly recall millions of them.

There is no industry as brain-dead as the US auto industry.

Corn ethanol at $1.65 per gallon for E10 right now is cheaper than refinery gasoline RBOB which is ~$1.94 per gallon at $75 per barrel world crude prices.

Going to E15 would decrease energy density only 7% less than straight gas.

Only the most paranoid drivers would notice.

http://online.wsj.com/article/BT-CO-20100701-711867.html

If gas prices remain go above $122 per barrel, cellulosic ethanol at $2.65 per gallon(2007) will be the cheaper fuel for mixing; $122/42 x 1.1 =$2.65.

If oil prices go up, won't ethanol prices go up as well?

The price of corn based ethanol will go up, but cellulosic ethanol would go up less.

Corn ethanol is largely a conversion of oil and natural gas to ethanol. There has been some debate over whether the EROI is greater than 1 or not.

It is mainly subsidy backed by farm state politicians to keep corn surpluses down and prices up. If export demand for corn rises and eliminates the surpluses, corn ethanol will disappear.

R^2 skeptical of cellulosic ethanol?

My skepticism has been warranted. Don't you recall a 94% reduction in the cellulosic ethanol mandate for 2010? How long have I have saying that there was no way they would meet it? That is skepticism that has been validated by developments. And don't forget, I have actually worked on this before. I can assure you I know more about the technical challenges than you do - and I understand when things are being hyped out of control.

I don't see how Range can make ethanol out of syn-gas without Coskata's bugs.

They aren't using bugs. They are using a catalytic approach, but what that means is they actually produce mixed alcohols. It isn't economical to take those and purify to ethanol. They have figured that out, and now plan to market methanol as a first product (again, something I said all along would be the case).

There is no industry as brain-dead as the US auto industry.

Of course one solution to the E15 problem would be for the ethanol industry - which stands to benefit greatly from an expanded mandate - to step forward and assume all liability from any issues arising from the higher blends.

@majorian

If the process were profitable and cheap - then this would cease to be a problem. There is no market because it is more expensive then its competitors. simple economics.

Wake up, Dave.

People buy ethanol make E10 to put in their car as fuel. Ethanol producers have been knocking up against E10 limit now which is why they want E15. Right now there aren't a lot of things to be done with ethanol except as a fuel.

Some people are trying to make biodegradable flexible packaging from corn.

http://www.smithsonianmag.com/science-nature/plastic.html

Oh brother, Stupid...economist

@ majorian

So let me get this right - you want the government to construct an even more complex incentive/subsidy system to bolster even more ethanol production? Lets remember that it was not a free market from which the ethanol industry emerged, it was a market created by government mandates and subsidies.

Don't be a silly goose, DaveM.

You're arguing about nothing.

The government started adding ethanol because burning straight gas with tetraethyl lead causes severe air pollution.

Lead was replaced with either 10% MTBE from natural gas or ethanol mixed to E10.

MTBE ended up poisoning groundwater so we are left with ethanol mixed to E10.

That is why we subsidize ethanol.

The proposal is to raise it to E15.

Higher future oil prices from Peak Oil will make ethanol competitive even without subsidies.

The free market doesn't care about air pollution.

No, ethanol and MTBE were not used to replace tetraethyl lead. They were used to supply oxygen to reduce emissions in older cars during cold-starts. The cars which benefitted from this are long gone and California has asked for the mandate to be repealed because ethanol increases other emissions, but Washington refuses to allow it. Now Californians (and everyone else) are paying ag subsidies to increase their air pollution. Thanks, Iowa!

Litigation issues hound everybody including Big Oil.

Florida Power and Light have a big IGCC plant in Tampa ready for carbon capture and sequestration, except the state of Florida won't idemnify the plant in case CO2 manages to leak out of a 2500 foot deep saline aquifer.

The only folks who seem to get idemnified nowadays are nuke utilities.

This is actually a very important topic not really discussed at TOD.

"An old Chinese said he had heard that when

empires were doomed they had many laws."

Friedrich Nietzsche, The Will to Power, 1901, 745

Why cellulosic ethanol from ag waste? Why not just combust the ag-waste to offset the 2/3rds of the energy input to corn ethanol which is made up of plant process heat and electricity? Voila, EROI triples for corn ethanol.

In the absence of petrochemical fertilizers, there won't be very much corn if we turn all the cornstalks into alcohol.

There is no such thing as "ag waste" in any agricultural practice that aims for a high level of sustainability. Everything that isn't harvested for food or fiber needs to go back into the soil to maintain nutrient levels, along with any available animal wastes.

We can't have our biofuel 'cake' and eat it too.

Listen to Lee , folks.

Why stop at E85? Why not mandate they be designed to run on straight gasoline (E0) to straight ethanol (E100 - 180 proof [90% ethanol + 10% water])

Eliminate the expensive step of using a molecular sieve to remove that last 10% of water that a still can not remove. This would further reduce the retail price of E100.

People with their own stills (with the appropriate Government free license) have been using E100 for over 40 years (search Mother Earth News site for references)

How about eliminating the State and Federal fuel taxes on E100 for 5 or 10 years and see how fast that builds interest in producing and using them on the local/consumer level?

When fuel cells get perfected I believe we will see E100 with 5% water thrown in. But we still have lots of oil to make up that 15% of gasoline.

Or we could use green gasoline.

Energy density is only one consideration. But what if you can use methanol more efficiently than ethanol? I.e. get more mechanical work out of the same btu's of M than from E?

And, you can make M more easily than E, and from many more materials. With the fermentation route, you can only make E out of the celulose and hemicellulose part of wood. but with thermochemical conversion (gasification and catalytic production) you can make methanol out of the lignin also, and also from municipal waste, and and organic material, not just those with carbohydrate structure.

This paper (http://www.methanol.org/pdfFrame.cfm?pdf=2002-01-2743.pdf) gives the results of fuel testing of a VW diesel engine (20;1 compression) converted to run with port injected methanol and/or ethanol.

Peak thermal efficiency on diesel is 41%, on E100 is 41%, over a slightly larger operating range, and on methanol is almost 43%, and over a much wider operating range (i.e. lower rpm and lower load levels). They couldn't test the engine on gasoline as compression is too high, but the best gasoline engines (like the Prius) get about 33%.

So if methanol fuel allows greater thermal efficiency over a greater proportion of the real world operating range than ethanol, which is the better fuel? The energy density of the fuel is really only an issue for aircraft, for a car having to carry around an extra 20-30lb of fuel is no big deal.

of course, you can run such an engine on mixed alcohol, which is what the gasification processes produce, for about the same results as methanol. But given that you don;t need to refine the fuel to a single component (i.e. M or E) and don;t need to dehydrate to 0% moisture (alcohol fuel can have up to 20% moisture for no penalty, and actual improvements in high load/hot weather situations), then methanol starts to look much better.

We can use more feedstocks (renewable and fossil) to make methanol than ethanol, it is a superior fuel, in engines optimised for alcohol, and it can be made cheaper - what's not to like.

And methanol does not preclude using ethanol either, you can mix them both in any ratio, the key thing is to get the gasoline out of the fuel, and then we can use efficient, high compression engines, without the NOx problems of diesels

Compared to all that, the lower energy density is only an issue for the size of the fuel tank.

And just to add more pro-methanol thoughts, it also works in fuel cells, and it's much easier to store and transport than hydrogen. And it's a great chemical feedstock.

And for those who are about to scream "but it's toxic" its about the same as gasoline. "Don't drink the motor fuel" is always good advice. Even with 180 proof ethanol. You will get into serious medical trouble a lot quicker than you think you will.

Once you have methanol, you can build ethanol or butanol, or lots of other chemicals.

http://en.wikipedia.org/wiki/Gas_to_liquids

(if you have methanol, skip the first step and start in the middle.)

But methanol is half oxygen which has no energy value. Thus, half your distribution costs are for nada. Another problem with methanol is its compatibility with water. Finally, it is not cheap to convert methanol to ethanol.

Retsel

Yes, it is half oxygen which is part of what gives it it's great properties. I would not say half the distribution costs are wasted. If the pure methanol engine gets uses 3/4 the fuel for the same mileage, (40% eff v 30%) then you are only transporting and carrying 33% more, is not such a big deal.

Methanol is very compatible with water, and that is just fine. It means you do not need to make it anhydrous to start with, and condensation in fuels tanks etc is not a problem. In fact, it you want to clean out a gasoline tank/pipeline, you run methanol through it! You can actually run an engine with methanol (or ethanol) that is up to 30% water, if you set up for it.

The alcohol fuels burn very cleanly and completely, and a catalytic converter is not needed.

As for converting M to E, why bother? That is my whole point. Once you have converted the biomass to methanol (by gasification) you have a liquid fuel that is ready to use. why go to the expense to process further to ethanol (or gasoline, which can also be done), when you actually have a better fuel already?

the read-pdf-in-a-frame didn't work for me.

direct link to

High Efficiency and Low Emission Engine from Port-Injected Engine with Neat Alcohol Fuels:

http://www.methanol.org/pdf/2002-01-2743.pdf

Ummm - doesn't seem like a VW diesel engine.

(PFI == Port Fuel Injected)

Interesting reading on this type of engine and how it works well with alcohol fuels.

Well, you're somewhat correct:

thanks for the pointer anyway.

BTW

ummm - anhydrous MeOH is easy enough to make, but anhydrous EtOH is a bear.

Sunnv, Glad you read the link, it is the best presented comparison of efficiency of diesel, methanol and ethanol I have seen. As I said above, if the engine is optimised for these fuels, the engine is very efficient. A diesel block plus port fuel injection is far cheaper than the high pressure common rail diesel injection systems. That seems like a fairly simple modification to make, and then emissions are so low you can dispense with the catalytic converter!

Also from the same authors, this paper has some graphs showing efficiencies on M100, M90, M80, down to M50.

http://www.methanol.org/pdf/ISAF-XV-EPA.pdf

Their conclusion;

Decreasing the fuel alcohol content generally gives lower brake thermal efficiency and somewhat decreased load range.

The same engine running M100 gets 43% eff on M100, but on M50 this drops to 38%, and they don;t go lower, but M0 (gasoline) is around 33%, so it looks like an almost linear relationship.

Anhydrous EtOH is what almost every commercial ethanol operation produces today. Taking it from 95%EtOh to 100% requires the molecular sieve method, and MUST be done so the ethanol can be blended with gasoline. So, in order to mix with gasoline, where you get inferior performance, you need anhydrous ethanol which is more expensive. Go to M/E100 with no gasoline, and you get a better fuel that is cheaper to make!

"Next generation" is a code-language in the nascent biofuels industry for processes and/or organisms that will somehow bend the natural world to our industrial will. The term has come to be assumed, but is rarely defined and almost never questioned.

"Next generation" ethanol depends on unknown enzymes produced by unknown organisms to convert fibrous stringy cellulose into simple sweet starches and sugars available for fermentation. Much rides on low energy costs/high eroei process that are better than conventional mechanical or caloric hydrolyzation. These biological systems don't exist, yet the industry blithely assume geneticists at Bayer, ADM, Monsanto etc. will deliver the creatures. Why? I have no idea.

"Next generation" lipid refers to heretofore unknown algae strains that both breed and produce lipids in commercial qualities. When the NREL project folded in 1998 it had become quite clear that no algae strain existed that would both produce lipids in sufficient quantity (through diets restricted in selenium and silica) and also breed in profusion, or resist yeast/bacteria/virus infections in a production environment. We may build skyscraper-sized test tubes or open ponds the size of entire counties and states. There is little evidence that they will be inhabited by anything useful.

So the ExxonMobil Algae Biofuels Research and Development Program is a public relations and marketing stunt or a misguided use of R&D dollars, sort of like the General Motors hydrogen fuel cell effort?

Or will they really spend $600 million in partnership with Synthetic Genomics, Inc. (Craig Venter et al.)?

Note that nothing is likely to be published from privately funded R&D until lines of research are thoroughly explored and patent applications filed.

Yep, Merill, these are all dead ends. The science we're talking about here that values these processes has been around for 40 years. During the post peak oil period for the US, we have experimented with all of these possibilities, and the system has sorted them out. What you see now in the energy mix of renewables and nonrenewables reflects 40 years of selection, barring the process of politics and subsidies. Bio fuels is a combination of Hail Mary pass and human arrogance, to think we're can do it better than Mother. You have to ask yourself why we're thrashing oil shale again when we went down that cul de sac 35 years ago. Only this time, we're not just thrashing it, we're fracking it, with the inevitable deadly consequences. Mother Nature doesn't just get mad, she gets even.

We actually have done better than Mother Nature. All of the food plants and animals are highly modified forms of their natural ancestors. If we had to go back to eating their wild forebearers, most of us would starve to death because the wild varieties have tiny seeds, rudimentary roots, small fruits, and skinny muscles. New plant innovations, such as potatoes, cabbages, beets, turnips and others made possible various historical expansions of populations by providing more carbohydrates and proteins per cultivated acre.

Now we have the tools to describe the biochemistry of organisms in detail, and to selectively modify metabolic pathways. This enables the design of better organisms more efficiently than tradition methods of cross breeding and selection.

We haven't done better than Mom. We've used natural processes of selection to nudge evolution along a track that gives us certain traits, mostly already existing within the genomes, that make the food better for us. Darwin recognized this. Learning to work with Mom instead of against her (or arrogantly thinking we are beating her) has always been a winning strategy.

The traits were not generally pre-existing. Farmers identified newly occuring mutant phenotypes and then selectively propagated the naturally occuring mutants.

In the last century, mutations were induced randomly by ionizing radiation or by mutagenic chemicals. This sped up the process, since one did not have to wait for cosmic rays, naturally occuring radioactive nuclides or naturally occuring chemicals to do the job.

Exactly. Mom did the mutating!

Please provide a reference where this technique (not denying that it was used) actually produced better crops.

In any case you are still faced with the fact that humans only used natural processes after all. We didn't invent a specific mutagenic chemical for the express purpose of causing a specific mutation that would produce a favorable phenotype. We humans are a part of nature after all. To be sure a clever part (your reference to speeding things up is certainly valid). But nevertheless, we haven't invented anything from scratch that has contributed to agriculture. Ventner's artificial genome may be the first real instance of true genetic engineering.

All I'm saying is be careful of hubris. It is what gets us in trouble every time.

Mutation Breeding: Theory and Practical Applications, A. M. van Harten.

Amazon seems to be having server problems tonight. The title actually doesn't sound inspiring though. Have to look carefully at the "practical" applications. A link to a current research article would have been more appreciated. Have you read this book? Could you provide a synopsis?

When I was doing biology we exposed bacteria to various radiation and chemical treatments to induce mutations for fun. Interesting results, but here is the bottom line. It was still hit and miss, trial and error. We still relied on Mom to do the actual work and all we could do was sort through the results looking for the rose amid the thorns. You'll find it hard to treat agriculture as if it were engineering.

[Edit: except, of course, for direct genetic engineering by inserting genes for Roundup tolerance or some such. Very limited at present. And it isn't even clear that it works all that well!]

The book is partly available on Google Books. Page 47, in particular, describes the first commercial mutant induced by radiation as being a variety of cigar wrapper tobacco. The work was done in 1938 in Indonesia. The table of contents shows Section 2 as "History of Mutation Breeding", and subsections of 6 and 7 dealing with commercial exploitation of mutants of seed and vegetatively propagated plants.

I thought the book might be in your university's library.

The $600 million is contingent on conditions that have not been met. But then claims for genetically modified crops are legion. Who can forget flounderized strawberries that don't freeze, or square tomatoes which ripen on supermarket schedules, etc. Yet only two--BT and herbicide-resistant products--are commercially used. And there is little scientific evidence that either really works i.e. produces more food on a given land at lower costs with less pollution.

Though the commercial potential is dim, the holy grail of laboratory life is very seductive.

The $600 million is contingent on conditions that have not been met.

A point I recently made to a reporter. This is often overlooked. XOM is unlikely to spend that kind of money, but it bought them a lot of good publicity.

THE CURRENT SITUATION OF BIOFUEL: ECONOMICS, POLICY, TECHNOLOGY, AND RESEARCH

Faculty Club, UC Berkeley, June 24 &25, 2010

http://www.berkeleybioeconomy.com/program

From the presentations at the Berkeley Conference, I get the impression that no serious questions are being asked about the feasibility of getting costs down to a reasonable level.

Currently most of the fuel I use in my ute/pickup is conventional biodiesel made from vegie oil. However I can see that is a dead end on a larger scale. My view is that the hydrocarbon fuel of the future is a combination of natural and unnatural gas. If necessary the large amounts of natural gas used in stationary electrical generation should be diverted to transport. Thus I disagree with the MIT report suggesting most electricity will be generated by natural gas in 2050. That is the job for nuclear power since large numbers of cars should be running on compressed natural gas.

I suspect that PHEVs like the Volt won't get that many buyers. Such vehicles might be good for running around town but they won't suit long distance commuters or builders. Nor will larger trucks won't suit the plug-in approach. Liquid biofuels at say $3 per litre will be too expensive. For equivalent energy CNG should be priced at no more than half of that depending on fuel taxes.

Now the 'bio' part comes in after several decades when NG is running low, remembering that nukes not gas plants are making the electricity. To stretch the dwindling natgas we blend it with biogas and synthetic (Sabatier) methane made with biocarbon and nuclear hydrogen. I'd guess by then most vehicles will still run on internal combustion engines since the cheap methane burning fuel cell vehicle seems some way off.

In short forget liquid biofuels and conserve natural gas as a transport fuel by phasing it out of electrical generation.

Boof said "I suspect that PHEVs like the Volt won't get that many buyers."

You have to keep in mind that this car is intended for the US market, where a ridiculous amount of miles are done just "running around town", or even worse, fuel is burned while crawling along a congested freeway. The Volt does reduce fuel usage on both counts. Once they get it right (probably 2nd gen model) there will be plenty of buyers. For a long distance commuter, they are still cheaper per mile travelled than and equal size conventional car.

The real answer, of course, is to have small, efficient cars, but like I said, this is the US..,

Builders and other commercial users, are a different story, and these vehicles are not aimed at them.

But given the number of pickups used for commuting in the States, if we cant get drivers to give them up, then making them hybrid/PHEv is the next best thing, and more likely.

"The real answer, of course, is to have small, efficient cars"

The real answer, of course, is to have no cars

The economy will not support electric cars for the common folks

Maybe electric rail if we don't wait too long.

"The economy will not support electric cars for the common folks"

This is a very interesting point of view. I wish I could be as certain, one way or another. I think the current analysis does normally brush off the potential impact of distributed generation. This is mostly a function of the US federal government policies. There are tremendous disincentives for self generation of electricity. This is because it would be *messy*. People throwing up solar panels everywhere creates an annoying glare at Tee Time. And battery raw materials would be a limiting factor.

I raise this because the current analysis also shows the near impossibility of increasing Elec. total output *and* building the grid to support it.

But, distributed generation has a funny side effect of reducing energy use greatly. If you have to ride your bike, you're not going to make as many trips.

Off-grid homes, and by extension electric vehicles, are absolutely practical now, with one major exception: heating and cooling in unfriendly climates. I *think* that problem could be solved with architecture.

I am still dreaming I can keep a personal vehicle. The Volt is a sleeper. The concept of primarily battery plus small backup energy system is the obviously preferred strategy. Living off the grid normally works with a primary system and a backup system. It's amazingly efficient. It's about the low hanging fruit or something. We need an acronym for this.

PBPSBES

PBSB for short. Or PBs. Yeah it will take a generation or two of cars. And it's understood it's still a niche.

I suspect that PHEVs like the Volt won't get that many buyers.

I love my Hymotion modifed Prius.

Even if it only gets 20 - 25 miles (32-40 km) of electric assist around town,

that is still enough to get me 60-70 mpg in winter, 90-100+ in spring/fall, and even 80 mpg in summer with AC.

Not bad for a "hack" with only 5 kw-hr of (more) battery.

(for you "ute" drivers: 60 mile per gallon == 3.92 liters/100 km, 100 mpg == 2.35 l/100km)

Given the US fleet average around 20 mpg, PHEVs can have a huge impact on alleviating peak oil's impact in the short/mid term (now -> 20 years). (and climate change too).

Cutting US oil as gasoline usage by 75 to 80 % means biofuels can have a meaningful impact. Without the extreme efficiency of PHEVs (due to hybrid AND the electric fuel), biofuels are a fools errand).

When PHEVs come out with multifuel engines, so much the better.

A natural gas turbine or diesel seems easy enough.

I do agree we should save the natural gas for mobile applications (either as CNG or GTL) and for climate change, but renewables -> electricity will take a while to get to scale.

Alt-E LLC seems to have made it work. Doubling the economy of a full-size pickup after the 52-mile AER isn't half bad either. Going up in size you have things like the Smith Edison delivery van (all-electric) all the way to electric drayage trucks being used to haul container cargo in Los Angeles.

About the only thing which doesn't electrify well is long-distance road freight, and that competes with rail (electric or otherwise).

Biofuel meant for combustion inside an iron-block (ICE) is a dead end road. This knowledge should be clear by now to anybody who wanna see..

As George mentions, that 1% photosynthesis conversion rate has come to stay.

The energy balance on bio-fuels sucks. In addition, ethanol production uses 3-6 gallons of water for every gallon of fuel produced, another limiting factor. The environmentalists will kill ethanol eventually. The more land that is cleared to grow the plants, the more fertilizer used, the more water used, the more likely they will pressure politicians to end subsidies. Without subsidies there is no business case to continue.

Hey, Robert.

What do you know about a company named MME?

Retsel

I hope there are no BP executives in my tipple.

Hi Robert - I am a new member of TOD, and previously worked for a major oil company in refining R&D, engineering, design, operations and safety for many years.

I am interested in some of the project economics that lead off this article. It says that the capital cost for a 100M gallon plant is 320M or 340M$ depending on what technology is employed. Can I assume that the basis for 100 million gallons is one year? If so, that equates to about 6500 bpcd, and the capital cost per barrel of production is about $49,000. Do others on this blog agree with my math, or did I make an error?

I searched your blog for capital cost per bbl to get a perspective on what a next gen bio-fuel plant costs compared to competing technologies. From your renewable diesel primer article...

"According to the Energy Information Administration’s Annual Energy Outlook 2006, capital costs per daily barrel of production are $15,000-20,000 for a petroleum refinery, $20,000-$30,000 for an ethanol plant, $30,000 for GTL, $60,000 for CTL, and $120,000-$140,000 for BTL (EIA 2006)."

This suggests that the the latest USDA capital cost estimate is about 60% cheaper than what EIA put forth in 2006 (e.g. 120,000-ish $/bpd vs 49,000 here). From my oil company days I recall that GTL was around $25,000/bpd - close to the EIA figure above (esp. after adjusting for inflation from a mid-90's perspective)

I also agree with skepticism around scale-up. I worked on several scale-up projects that involved pilot plants of various sizes, demo plants located in refineries, and commercial implementation. It would take a plant size of say 5,000 bpd bio-fuel production to convince me that it is truly viable and practical.