BP's Deepwater Oil Spill - Adding Mud to the Well - and Open Thread

Posted by Heading Out on July 9, 2010 - 10:20am

This thread is being closed. Please comment on http://www.theoildrum.com/node/6711.

Admiral Allen held another briefing yesterday in which he elaborated a little more about the procedures to be followed when the two wells, the relief (RW) and the original (WW) are joined. He also promised that in a briefing tomorrow, he will bring together the different numbers that have been used for well positioning - the measured depth and the true vertical depth – so that everyone can start talking from the same page.

However, in discussing the connection between the two wells he broke down the process into four parts, and to illustrate these I am going back to the figure that I used yesterday, and making a couple of modifications to it so that the process might be better understood. I am also going to revisit my gripe about the “band of brilliant minds” which Secretary Chu put together, but who seem unable, in a timely fashion, to decide whether to allow BP to change the cap on the well, or not.

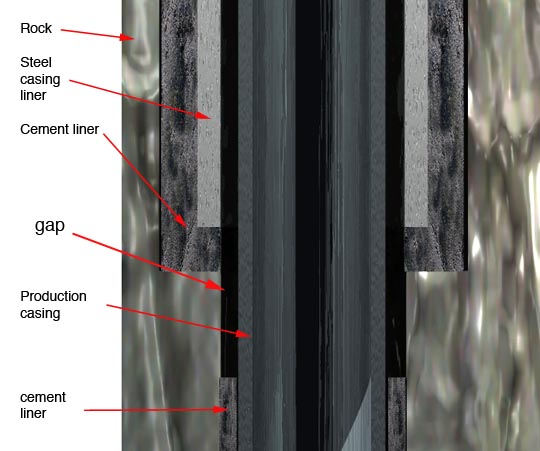

So to begin with let me start with the illustration from yesterday showing the possible configuration at the bottom of the lined section of the Deepwater Horizon well.

As I noted earlier, we don’t actually know how long the gap is in the cement around the production casing. It depends on how far up the annulus the cement was able to penetrate after it was injected from the bottom of the production casing. The bottom of the lined section is at 17,163 ft, and the bottom of the well is at 18,360 ft (according to Congressional testimony ). And, for reference, in his briefing today Admiral Allen said

Development Driller III, which is the lead drilling rig for the relief wells is now at 17,780 feet measured depth, within a couple hundred feet of the proposed penetration point of the wellbore.

Well it was at 17,700 ft on Monday, so the progress has been 80 ft over three days, but with 200 ft to go from the beginning, we should perhaps be about 120 ft above the intersection.

For those who want to do the math, Haliburton, if my memory serves, injected 55 barrels of cement into the well at the bottom of the production casing, and the casing has a 7-inch outer diameter. I believe the last section of the well was drilled at 8.5 inch diameter from this bit of the Congressional information.

Operations Procedure for Cementing Production Casing

1. Ensure BOP has been tested (per compliance with approved APO).

2. Ensure 16" liner and blind shear rams have been tested (per APO requirements). Record pressure with volume pumped.

3. Pick-up and run-in-hole with 8-1/2" clean-out drilling assembly (same as drilling assembly)

• Dril-Quip Wear Sleeve Running/Retrieval Tool should be run in the 6-5/S" DP4. RIH to bottom and wipe/work any tight spots (document)

5. At TD circulate per WSL recommendation / hole conditions

• If a short trip is not required, circulate per step 7.6. If tight spots were seen, make a short trip to the casing shoe to ensure any tight areas have been properly cleaned up and mud weight is correct.

7. Once at TD again, pump a 100 bbl weighted / viscous sweep and circulate hole clean with a minimum of 1-1/2 capacity.

• Plan to set the 7" x 9-7/8" long string 50-60' off bottom

• Circulate and condition, as required, to clean hole and lower yield point for running liner (lower YP to ~15 or as hole conditions dictate and keep gels flat).

• Do not need to set 16.5 ppg mud in rat hole as volume is only ~4 bbls and a large volume may cause issues with the cement job or breaking down the formation.8. POOH and retrieve the wear sleeve.

• Do not rotate once the wear bushing has been pulled.

(That is an interesting document to read, in regard, inter alia, to the discussion on centralizers it notes:)

Centralizer details: Weatherford Bow Spring subs (6) / Weatherford Slip-on (15)

I may revisit those procedures in a later post, since they contain several bits of information that has been debated after some earlier posts.

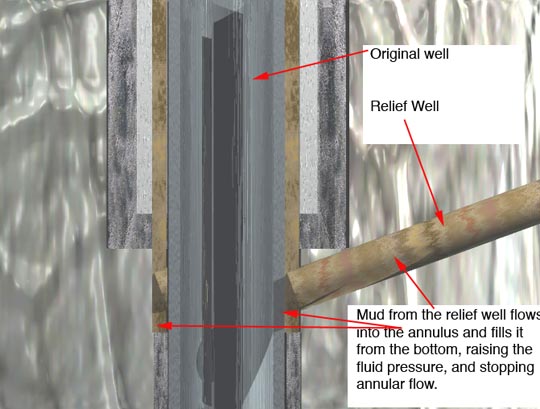

To return to the discussion of the kill process, the RW will drill over so that it intersects the WW in the gap zone below the last lined section. This means that the drill will enter the gap between the production casing and the well. At the point that the drill enters this space, the mud in the RW will flow into the WW, and be carried by any oil and gas flow up the well. At this time the mud pumps on the ships will kick into gear, and keep pumping in mud at a relatively high rate, so that the mud concentration in the column now flowing up to the surface through the WW annulus is as heavy (mud containing) as possible. The relief well is not cased but is, at this stage an open hole connection (i.e. just lined by the rock drilled through).

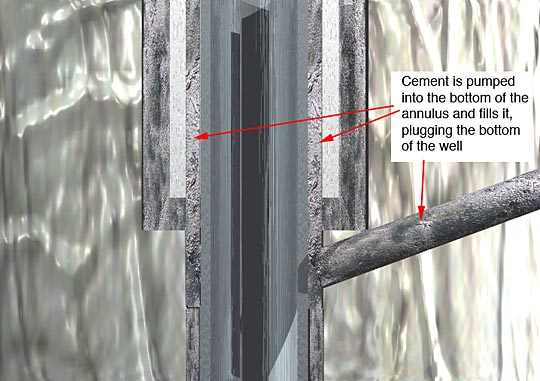

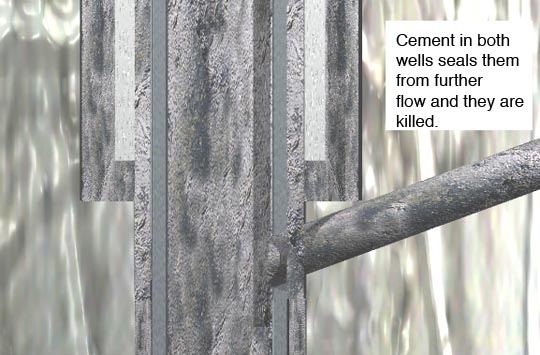

Once the mud reaches the surface, and the concentration, over time, increases to the point that flow up the annulus is halted (because the mud column weight exceeds the reservoir pressure) then – if flow is only through the annulus, the well has been killed. To seal it, the mud is displaced at the bottom of the well, by injecting a cement plug into the well that fills the bottom of the relief well and the annulus.

If the flow of oil has only been up through the annulus, there should, at this point, be no more oil flow out of the well, and the top of the well can be sealed with an additional cement plug, (as will the relief well) and the site can be closed down.

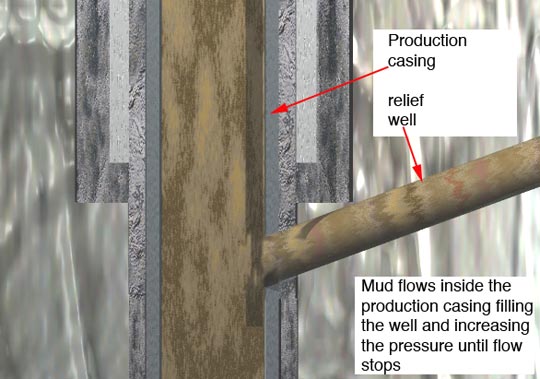

However if the oil flow continues, then it means that the oil is flowing up the inside of the production casing, At this point the drill is replaced on the end of the drilling string in the RW and the drill drills the cement plug out of the well, and continues drilling forward until it has penetrated the production casing. (It will use PDC cutters to do this). As before the mud in the RW will flow into the open channel, and with the mud pumps engaged, mud will flow into the central bore of the well filling it with a heavier and heavier mud concentration, until, again, the pressure exceeds that in the rock, and the oil and mud flow stop. The well is now killed.

Once the well is stable, then, as in the earlier step, the mud is replaced with a cement to create a plug at the bottom of the WW and the RW and the wells are sealed. Additional caps at the top of the wells, and they can be closed down.

Admiral Allen described the process thus

What will have to happen is when the relief well is adjacent to the well bore and close enough to be able to turn to make the penetration, then we'll first penetrate the area outside the well pipe.

And we will see if there is oil there or not. At that point mud will be pumped into the wellbore to see if that contains the well. If that does not, the mud and a (inaudible) plug will be inserted and then we will drill again into the inner pipe.

That will be the second attempt to plug the well if oil is coming up through the pipe with mud and cement. These two procedures will take us into August. There're things that could happen that could shorten that but right now into August is what the official estimate is.

And he then reinforced the point

Number one, if you take into account that you’re going to exhaust every possibility, if you go someplace and there’s not oil and you have to go find it in other place in that wellbore and you have to first seal what they call the annulus, the area outside the pipe, with mud and then cement that and go back in and re-bore into the pipe itself because you’re going to slowly remove any source of oil the closer you get inside the wellbore.

If you have to do all of that, it will take you well into August. If you get in there and you find the oil, you can see the oil in the annulus of the well bore the first time around, then it could be shorter. So it could happen, but I’m not going to assume that. I’ve been around you folks long enough to know that we need to under-promise and over-deliver.

He also mentioned that the decision on the cap had not yet been made.

I am asking BP to give me a detailed timeline in 24 hours on how they would accomplish the hookup of the units producer to the free standing riser pipe and then how they would move the current containment cap off, putting a containment cap on that would effectively seal the top of that well and go to the new containment structure, which does a couple of things, it gets us to a production capacity and a redundancy in the system of 60 to 80,000 barrels of day.

It also gives us quick hookup and quick disconnect and it will give us heavy weather or a hurricane. So not only do we have number one we have a weather window, number two we're going to get the weather to be able to hookup the Helix Producer.

I have asked BP to give me within the next 24 hours a detailed timeline that we can look at and then approve that will allow them to move forward. If we can take advantage of this weather window we will certainly do that.

The bottleneck here is the “brains trust” that Secretaries Chu and Salazar have assembled, and who will vet the idea. Here is my gripe. They have known about the design and the plans for weeks now. They have a short window of opportunity before the next storm rolls in and stops the effort, and they are only now getting the paperwork that they have to approve. It does not seem unreasonable to ask why this wasn’t done over a week ago, so that approval was in hand the moment that the weather allowed the procedure to begin. If the weather closes in again before the approval is given and the process completed, whose fault is this?

If the new cap is on, then when mud flows up the well it will go through the BOP and the sealed cap and up to the surface so that there is an additional pressure on the bottom of the well. If it is not, then the mud column weight above the BOP is lost. But the Federal Government is in charge, and processes and procedures must be followed, as they are repeatedly now informing folk. Sigh! So if the opportunity is lost, why that is just the way things go!

The current data on oil and gas production from the site:

For the first 12 hours on July 8 (midnight to noon), approximately 8,565 barrels of oil were collected and approximately 3,940 barrels of oil and 28.3 million cubic feet of natural gas were flared.

• On July 7, total oil recovered was approx. 24,575 barrels:

• approx. 16,655 barrels of oil were collected,

• approx. 7,920 barrels of oil were flared,

• and approx. 57.6 million cubic feet of natural gas were flared.

Prof. Goose's comment:

New stuff in this introductory comment, 1 JUL 10.

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we brought online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read all the other previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all the comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. If you would like to catch up with what's been going on in the last few days, our IRC channel has been maintaining a FAQ, which is an open source log full of information, links, and such. Check it out: http://docs.google.com/View?id=dff7zmqz_7c6rdwsc9

6. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

7. Don't be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

8. Yes, HO and others have put up many counterarguments to the "DougR" comment. There are many many links, but the first one was here: http://www.theoildrum.com/node/6609. If you ask in the thread nicely, they will also point you to others.

Deleted-wrong thread.

"But the Federal Government is in charge, and processes and procedures must be followed"

This reminds me of the offers of help from outside the US.

http://www.zerohedge.com/article/oil-spill-belgians-shouldnt-feel-too-ba...

Reminds me of far too many times when a Government Agency took so long to make up it's mind on an obvious situation that the window of opportunity closed or was closing and the actions taken (when finally approved) were done quickly and not very well such that the schedule could be kept AFTER all the delays. The Challenger accident comes to mind.

Let's hope this time the delay from the "decision making" doesn't cause any problems.

and here's another article, Skimmers and sand barriers

http://www.financialpost.com/Avertible+catastrophe/3203808/story.html#ix...

Anyway most of the Netherlands is now focusing on the football finals against Spain.

tonyw, the claim that foreign skimmers could have averted a catastrophe had we "accepted their offer of aid" (i.e. had BP purchased the equipment earlier) is false and has been repeatedly debunked here. It is very misleading to compare the claimed capacity of the Dutch skimmers with the actual performance of US skimmers. BP's cleanup contractors had dozens of large-capacity skimmers stationed in the Gulf. Their claimed skimming capacity was 500,000 bbl/day. But skimming an unconfined slick is ineffective regardless of the equipment. Three ships carrying the Dutch skimmer arms have been at work in the Gulf for 3 weeks, and there's still plenty of oil out there.

I've been reading TOD since day 1 (and before that too) and I've not seen a "total debunking" from EXPERTS in the area on this topic. Please post what you consider as that evidence.

It's just common sense that more skimmers regardless of their origin can cover more area, which is exactly what you need when things are unconsolidated. You can send skimmers chasing about different parts of the slick and play the divide and conquer approach. Maybe it would work but maybe not but why not TRY?? Even if the foreign skimmers were only as effective as what was available every thing helps. As I recall BP was accepting ALL offers but foreign skimmers had to be cleared via the MMS and other agencies due to legal issues such as the Jones Act and others. As several legal minds here mentioned there was more to the legalities than only the Jones Act. Anytime you get into legal issues involving the Gov't things slow to a crawl.

NASA, if you've read all the skimming subthreads and are unconvinced, I don't know what else to tell you. The skimming fleet has averaged around 1000 bbl/day over the life of the spill, and to me it seems preposterous to claim that a few foreign skimmers arriving on say May 7 would have kept the slick from making landfall. Here is a map from that time:

http://www.deepwaterhorizonresponse.com/posted/2931/forecast_20100508_06...

The slick covered around 5,000 square miles on May 8. One Dutch-armed skimmer ship can cover about one square mile per day. Yes, every little bit helps, but every little bit doesn't "avert catastrophe" as tonyw's link claims.

Once the flow has been stopped, skimmers will help reduce the slick, but not nearly as much as in situ burning, evaporation, and bacterial action. Under good conditions today, the fleet could capture 2000-3000 bbl compared to perhaps 15,000 bbl that will be spilled in 24 hours.

Gobbet: I still have not seen them post the actually oil skimmed number. Also the skimming is highly variable and really weather dependent. During the early days in a press conference the skimmer oil/water mix was 50%. But as you say the overall results do not approach expectations. A breakdown of results by sea state, location, and skimmer type would be interesting and a good future planning tool.

No Diverdan, they have not posted the amount of oil skimmed, so we have to estimate. In a press briefing (June 11 IIRC), Allen said "We usually get a 10-15% return on that," that is, the percentage of oil in the oil-water mix. I haven't seen the 50% figure you mention. But 12% x total mix collected yields roughly 1000 bbl/day of oil. At 12% they were getting 1,500 bbl/day of oil in the good weather before Alex. If the Dutch skimmers are vastly more efficient than the rest of the fleet, they might get 500 bbl/day each, which is why I guesstimated a possible 3000 bbl/day for today's fleet.

The Dutch skimmers can cover roughly 1 sq. mi. in a 12-hour day. Oil near the center of an unconfined slick can be about 0.1 mm thick (perhaps less for light crude on warm water). At 100% efficiency and running through thickest oil every minute of the day, the maximum it could collect would be 1,600 bbl/day, unless I've misplaced a decimal. This would also be roughly the limit for A Whale unless it is widened by booms.

Thank you for making my point. I did NOT say the extra skimmers would have prevented landfall, I said every little bit helps. 1600 bbls per day is not a huge amount but it's more than we would have had without them. Plus BP was paying the bills. Just plain stupid.

NASA, my posts in this subthread have been addressed to the claims in tonyw's links that fumbling by the government prevented the miraculous Belgian and Dutch skimmers from containing the spill near the wellhead. Anyone who looks at the May 8 map I linked should understand that this is a preposterous notion. I agree that every little bit helps, but realistically, skimmers don't seem to make much difference in a massive, open-sea spill.

I posted total barrels skimmed (67,143 bbl) allegedly from BP on July 6th. This is from article written by Kimberly Kindy of Washington Post.

http://www.theoildrum.com/node/6696#comment-669931

Gobbet, I am one of many arguing with you about skimmers. You obfuscate the points I make so much you are either a lawyer, politician or both. Here's the salient quote from the previously mentioned FP article

Emphasis mine.

Now we've had this discussion BEFORE and you ignored it then as you ignore it now. The EPA regs that don't allow "tainted" water to be returned to the gulf is asinine, stupid and moronic on ANY planet but planet Washington D.C. So instead of having let's say 80% clean water, we have substantially more 100% dirty water hitting our shores because of bureaucrats. Now once the press makes a big enough stink about this (ala the Jones Act stink) the bureaucrats in charge will PRETEND they weren't being obstructive, but the facts are facts. Meanwhile, because the ships have to go back to port constantly to unload their mostly water cargo, they are indeed falling under the 3 mile limit as well as the Jones Act requirements. IF and it is a big IF this government ever is called to task for their response to this spill, heads should roll. But I won't be surprised to see a whitewash investigation, just like we saw with Climategate and Penngate and Sunday Bloody Sunday (maybe they'll admit something 40 yrs from now).

widelyred, I agree with you about the EPA rule and have said so here more than once. The EPA has ruled that skimmers with a water-return system--including A Whale and the Dutch skimmers--may operate by returning the polluted water upstream of the collection device, and they are doing that as we speak. However, it is still a stupid rule for any large unconfined spill. I can't imagine why it has not been suspended unless it is based in a directive law. It surely has had the effect of inhibiting the development of more efficient skimmer technology in the US. However, it has not prevented the deployment of European skimmers. We don't know whether it played a role in BP's initial decision not to buy the Koseq arms, or whether BP in April just thought they wouldn't be needed.

There are tank barges positioned out in the water for the skimmers to offload their oil-water mix, so they don't have to return to port (normally; I'm sure there are exceptions). This is primarily for efficiency rather than to satisfy the Jones Act.

Gobbet, the Dutch skimmers aren't configured that way, and the Dutch clearly think the US gov't has its collective head up its you know where (and they're not far off IMHO). I really recommend you read the whole article I linked to, not just the part I quoted. Bottom line, the skimmers in Europe (offered already to the US, offer refused) are substantially superior to ANY American vessel, but unfortunately don't have overpaid, under-worked American union employees on board (who just happen to vote 99% for a certain political party and contribute 100% to that party). My flight instructor flew those booms from Holland, so I know when they arrived and how. I further know they went on ships that weren't designed to hold them, and crews had to be trained, then refused to go out in anything approaching rough seas. AFAIK, the only ship that gets to spill contaminated water in front of the skimmer is the A Whale, which is experimental at best. It is obvious you haven't captained any boat larger than a speedboat, or you wouldn't so blithely talk about offloading (what is now by EPA rules considered HAZARDOUS WASTE) ship to ship in potentially rough seas (even minor swells make this problematic at best).

Here's how an INTELLIGENT COMPETENT administration would have handled this problem:

First accept ALL help immediately.

Second, suspend ALL stupid laws that don't contribute to the cleanup

Third, starting at the SOURCE, use any and all booming equipment to contain the spill, skim there

Fourth, spend tax dollars and use federal resources as necessary, sending ALL bills to BP for reimbursement, if they complain too bad.

Fifth, move QUICKLY, quit dragging your feet

Sixth, Fire that moron Allen and put a true military admiral in charge

Hear! Hear!

If you're referring to the Jones Act preventing skimming ships from other countries operating in the Gulf then you're simply regurgitating right-wing lies and anti-union propaganda. The Jones Act only applies to ships carrying cargoes from one American port to another and it specifically exempts oil and pollution control operations from requiring American built, owned and operated ships to carry out this trade. The Jones Act has not prevented any foreign-registered ships from being brought in to perform oil recovery in the Gulf and such vessels have been on station from shortly after the Deepwater Horizon sank. Basically rich right-wing interests are using this disaster to carry out a union-bashing propaganda operation in the hopes of eventually offshoring a lot of the coastal cargo trade in the US to foreign-registered ships crewed with cheap labour and theyu are finding lots of folks like yourself who swallow their lies and regurgitate them on demand.

As a matter of interest what would a "true military admiral" do in this situation, once the Coast Guard has been taken out of the picture? Bring in a couple of aircraft carriers and launch an alpha strike on the wellhead? Send in a submarine or two to torpedo the BOP? I know, order Navy SEALs down 5000 feet to attach demolition charges and blow the thing up!

Nojay is correct wrt assigning command to the US Navy.

The USN excels at blowing stuff up...other surface ships, hostile subs, ground targets, airplanes, and even ballistic missiles and the occasional falling satellite!

Round peg, square hole...please stow the 'U.S. military is the answer to all problems' jive...

//A recently retired U.S. military member//

I've got a military related question, I'm from the UK and rather clueless on the subject.

As I understand it the oil slicks are spread out in strings and hard to see from the skimmers. They are using spotter planes to direct skimmers to the slicks.

Why not point a spy satellite at the GOM, get analysts provide real time locations of the oil, then have an awax in the air directing all the skimmers? Oil slick data could be supplemented with drones, rather than actual planes. My limited understanding is the US has the capability. So why not use it?

Spy satellites are located where there are military requirements and their wavelengths tuned for that purpose so I doubt they would be of much help. NOAA/NASA has a fleet of earth observation satellites that are up to the job and I would expect that the coastguard has full access to whatever they require. I doubt AWACS would be up to the job of directing skimmers, its primary role is in control of airspace not ocean. It may not even be capable of handling the comms the skimmers are using but I can't say for certain. Drones are mostly tied up in the middle east/stans so not a not available plus FAA issues about using them in US airspace. Coastguard probably has the best capability for directing the operation anyway. Biggest issue I see is that the skimmers are just totally overwhelmed by the scale of the job. HTH

NAOM

http://www.winnipegfreepress.com/local/witnesses-tenacity-along-with-cat...

Canadian Govt aircraft are doing radar mapping of the oil spill for cleanup by skimmers.

tabbycat,

Google KH-11 and/or KH-12 . Look for hits in Wikipedia on these code names. They designate a couple of the more modern US spy satelites.

I don't think they would be much help. The Coast Guard already has airplanes and pilots specifically for searching the open ocean. I think the problem is actually skimming the oil that has already been found. Vessels with really tall masts, and a crows nest would probably be better suited to the task. I dread to think about the national security issues that would have to be addressed. Especially when Coast Guard is already doing a better job with equipment designed for the task --- searching for stuff in open ocean.

A fleet of drones that could be assigned one drone to one skimmer and operated from the skimmer crew might be nice to have. US or BP have the money to pay for such, but it would take years to design, build, and deploy. Should be put on the list of things to do before the next blowout.

The spy satellites are interesting to read about, so have at it!

Nojay, right on and well said. However, there is one union I hope we can bust up real soon: Rightus Wingnutus.

Agreed, The Jones act is a bit of a non-issue, but if you have exemptions for stupid laws then it removes all fear, uncertainty and doubt about the issue. The issue becomes a non-issue, one less thing to even bother to think about, more time can be spent focused on solving problems quickly.

Recall that when Katrina happened a certain blue ocean admiral was brought in and coordinated everything immediately and did an excellent job. The negative military comments are uncalled for and unjustified. What any true student of history knows is that the military excels NOT just at blowing things up, but at something called logistics. Allen has shown himself inept at reading the cue cards, let alone logistics, replace him with someone who understands the job, I don't care if he's a quartermaster, he'd do a better job.

The Jones Act apologists do not sway me. I don't watch Fox News, but do read voraciously hence my nom de guerre. I've read the Jones Act, I've read the appeals in Congress to temporarily appeal it, and I've read Allen's apologetics about it, without admitting the salient fact, which is that ONLY the Sec of Defense can ask for a waiver, so until they hear Gates ask for the waiver they can pretend all day, every day, that no one has asked. Left wingers trying to bury this under legalese won't fool me, it IS an ongoing issue, enough that foreign flagged vessels worry about it. Now some of the left wing lawyers (and I often wonder if there are any other kind) on this site will argue about the nuances of the law, but ask yourself how familiar YOU are with for instance French law and ask yourself if you'd feel comfortable playing the nuance game in the country where the word came from.

My list still stands.

"Now some of the left wing lawyers (and I often wonder if there are any other kind) on this site will argue about the nuances of the law..."

Widelyread, i thought yoo were widely read. If yoo think all lawyers are left wing, yoo can't be. Either that, or you are letting your politics color reality.

Your lawyer friend, left on some things, right on others, mainly what works.

Again with the 'Military can solve anything' meme: Stow that bilge!

The military can certainly conduct Command, Control, Communications, and Intelligence (C3I), as well as Intelligence, Surveillance, and Reconnaissance (ISR) operations, and can do these ops well in many circumstances.

However, the military can do what it has been trained and equipped for, and does not necessarily have the ability to step into any situation which is out of its realm of experience and then excel. Dealing with civilian authorities and private firms which it does not have a standing relationship with is not the military's forte. For a recent example, witness how well the military and the other parts of the USG have cooperated in Afghanistan. Then take an objective look at how the military has not only cozied up to, but out-sourced major parts of their mission to contractors such as Blackwater, now known as Xe, and their little Rambo-style shooting sprees. Don't forget KBR and the electrocution showers for our troops.

Don't blithely assert that if you put your favorite admiral in the mix to 'command' this GOM fiasco that much would be better. The military does not know the oil business, including the clean-up response mission.

I have 20+ years in uniform (not counting four years of military training) and am still associated with the community. I make my comments based on actual experience and not by being widely read in Tom Clancy novels.

Widelyred, you quote approvingly from a financialpost.com article. You shouldn't.

This is complete crap.

Why don't you go to http://www.koseq.com/ and see for yourself.

First, Koseq themselves don't give any numbers on their website. There are only pictures and a brief explanation of how the skimmer arms work. So you have to make your own estimate.

Max possible volume of oil recovered per day is Area Swept x Depth of Oil.

Depth of Oil is somewhere from 1 µm to 50 µm (a human hair is 100 µm) in the slick.

Area swept is Speed x Width. 24 hrs x 3 km/hr x 25 m = not much. Use your own numbers, these are just a guess. It's always going to be insignificant compared to the scale of the current slick.

And the booms don't "extract" the oil. They are v-shaped and guide the slick to the point of the 'v' where a pump about the size of my swimming pool pump sucks the oily water into tanks on the boat, where the oil settles out.

It's just common sense that more skimmers regardless of their origin can cover more area, which is exactly what you need when things are unconsolidated

No, it doesn't. Adm Allen covered this yesterday. You can't coordinate the skimmer operation without air support. i.e. you can have skimmer in an area but they have to spend time to find the oil.. It is the failure of the initial respond plan where they thing all the oil sheen will be in the same general area. And they can just cover the area like a grid search.. But right now the oil has been spreading out to a very big area and you need eyes in the sky to direct the skimmers to the right place. Right now we are paying for the "inadequate" emergency response plan.. But the next one will be much better.

Like the USAF and Army, Civil Air Patrol and Oil company planes/choppers couldn't have been out there in a grid search pattern calling in the co-ordinates? I don't know of any pilot who wouldn't want seat time paid for!!! In the early days the slick was small and pretty much within a few tens of miles from the well, that would have been pretty easy to co-ordinate. Now with it spread all over it's much harder.

They have to think quit thinking so rigid when all the rules that normally work don't apply. Cut it with the Analysis Paralysis.. Bring in ALL the resources you can get, don't worry about credit/blame just get the bleeping job done. This applies to BP and the Government both. Don't do anything wild-ass crazy to make things worse but venture out of the box.

The Dutch company Van Oord was ready to help with both skimming and dredging capability two days after the Macondo tragedy. In fact, BP had a signed contingent contract on April 23rd, only three days after the disaster. If deployed earlier, the slick would have been more confined.

That coupled with the tardiness of several federal agencies goes to the heart of determining responsibility and to what extent. At the end of the day, their will be significant concurrent responsibility for the disaster, something that the federal government is now leaning towards.

Meanwhile, every true deep water expert is waiting with baited breath for the BOP to come to the surface to be analyzed. So am I.

Your concerns and Heading Out's are totally valid and serious. That said, it would be probably unfair to paint Dr Chu as a clueless bureaucrat who would slavishly follow bureaucratic process to the exclusion of all else. He is new to government and many of the scientists on this team are not in government, but academia. Could it be, that YOU may not know all of what needs to be considered (I know, a shock), or that as knowledgeable as you and HO and many others are here, you may not have all the facts and key dependencies in this situation?

I have no problem with justified criticism...and I recognize even without being an expert in this area, that the time window that HO and you point out is extremely important. However, you have to assume, and there is no evidence of it, that the scientists are either completely clueless, or stupid to adhere to bureacratic process in the face of such an important issue.

Too many knowledgeable people at TOM fall into easy bias in their commentary about the behavior or decisions of those in government. Unless you are mind readers, it would be nice to state your bias upfront or some other caveats about your ability to read minds and know all in a given situation to which you are not formally privy.

You also have a very simplified interpretation of what happened in the Challenger accident and the complex organizational environment that added to the delays. NASA and its contractors have a very tight, interdependent relationship and culture that could not be just easily characterized as purely "government". Also the nature of the activity (space flight) was inherently filled with uncertainty in materials and behavior of key components as well as budget and other accountabilities.

Please. Just make an attempt at even handedness. The assumption that underlies your bias is insulting and incorrect: that people who work in government have no desire to perform well and do the right thing -- that they are all nincompoops who could care less about performance and outcome. That people of Dr Chu's stature, would allow themselves to be part of an entity that has no goal but to be fools and foot draggers.

What you are thinking is distorted by your bias.

Amen, Elie. Steve Chu, according to all I've read and observed of him, is about as far from "fool" or "foot-dragger" as a human being can get. When the smoke clears, I'm willing to bet everyone who's working on this with him will attest to that and his good humor too. He didn't dump all those characteristics at the "gummint" door.

Having jointly won the Noble Prize in Physics for his work in "developing of methods to cool and trap atoms with laser light", Dr. Chu is obviously a brilliant man and not a foot dragger.

Dr. Chu is also aware of BP's $500 million grant which helped establish Lawrence Berkeley National Lab's Bioenergy Research Center. As such, he will probably not be as preconditioned against BP as many in Washington. Most scientists at his level tend to be driven more by facts than by politics.

I have skimmed through this thread a few times and I don't think anyone has addressed HO's point of expressed frustration/exasperation with the sudden need of the government to see details from BP in regards to acceptance of the plan to replace the cap. The flip side of BP's negligence is the Fed's with their need to see everything through a magnifying glass in detail with reams of boilerplate. One more flip is the aire of complacency which attributed to the disaster in the fiirst place. There is no real accountability if things go wrong and no incentive to really get it right.

The decision mentioned should have been decided when the welders started on the project. How long has it been since we saw the 10" thick overshot containment device in progress. I agree with NASA on the "NO" fear factor. Standing on the outside looking in it is a rather sad site to behold. Heads down, walking in circles or from cubicle to cubicle making sure someone will guarantee to the last gallon how much crude will be spilled while the cap replacement occurs. If someone murmurs a tangled cable...ooops back to the drawing boards. The mere mention of the unfinished detail states how inefficient government bureauracy is. I have served in the military under military direction and control; in the military under the direction of civil service (ultimately military control) and employed in a civil service capacity under government contract and I agree with NASA on the points he is making. In doing so it isn't necessary to take away from Dr. Chu and crew or Adm. Allen but their field of expertise is not DW well blowouts.

I am reasonably sure any of the shrimp boat captains skimming the GoM could organize an armada to keep the coast clear and clean if given the resoures to do so. The difference (I may hurt feelings here)in how they would proceed is based on their incentive. They have lots of incentive that's been stymied or more appropriately killed, by bureauracy.

I don't think everything in government is as I expressed but I think I can safely say it's a comfortable fit for about 90%. Whoever was responsible in the chain of command between Dr. Chu and Adm. Allen for missing the sign-off on the procedure for cap replacement deserves to be B*&^H Slapped.

Elie, For who you are, Thank you.

Landrew, I'm sure it's probably Freudian; you meant 2016.

I wonder if the delay has not been the government but the lack of sufficient detail provided by BP. When government bodies want a plan they want a PLAN. Admiral Thad's request seemed to have a tone of frustration with emphasis on 'detailed'.

NAOM

We really don't know what Thad Allen wanted in a plan, so it is problematic whether or not BP complied.

I seriously question the notion that when government bodies want a plan, they want a PLAN, as there are so many notions of what a plan involves. As an example, take the recent national Health Care Initiative. It is still in the 'early' development stages even though Congress and the President signed the bill into law without having seen a completed plan or even read the bill.

Elie: Despite my feelings about government inefficiencies, I all along have felt that Chu is probably what we needed and the most professional. He is one of the few who has not joined in the the political grandstanding we have seen from other agency heads and government officials. My guess is that behind the scenes he and his experts have worked quite collaboratively with BP and industry partners to objectively look at ways to solve the problem.(I think CG and BP are working pretty well together too). Unfortunately, many people are keen on making one or the other out to be evil and incompetent while in reality, despite the imperfections and time it is taking, this is probably a better example of working together than many would ever admit. I would guess that amongst those there in Houston there is probably a mutual respect and pretty good working relationship.

Thank you, Diverdan.

While I support government more than many on this site, I definitely will criticize it when warranted -- and unfortunately, it is warranted often. That said, there are many occasions when the private and government sectors has worked together sufficiently well to achieve something important. Let us hope and pray that this is one of those instances. In any case, I am sure that Dr Chu and his associates on this mission are working hard with all the important players from industry and academia to get this done. After all, everyone wants to look good as well as have a good result...Everyone.

Yep, a lot of the good work gets lost in the cloud of politics, bias, and agendas.

Somewhere recently I saw an article that described Sec. Chu's role in a long meeting as one in which he repeatedly asked "Yes, and imagine if that doesn't work.. what then?" in attempts to get the participants to continue thinking beyond proposed solutions. Seemed like a more sustained version of the the reported government requirement to start a second RW ... "what if the first RW fails?"

I thought TOD banned ad-hominen posts?? Oh well, I'll answer anyway. Shouldn't feed the trolls, but I can't resist.

Umm NO it is NOT. Go read the report. It clearly faults indecision at the higher levels of NASA as to go or no-go based on the conditions. The longer they delayed the longer the "cold soak" which made the O-rings worse. Then they decided to blow off the engineers who said it might be a problem and they should just scrub. No one wanted to make a "NO" decision as they thought it might look bad that they lost the cost of the fuel that had to be drained from the External Tank.

I was also a member of the Columbia Accident Investigation Board, and the NASA Mission Assurance and Safety Group. I validated the Safety and Performance of several NASA Missons such as HST. I've shut down missions and launches due to serious quality and safety issues. I have awards and honors out the a** from NASA and DoD. I've worked for the Army, Airforce, Navy, DHS, Treasury, Federal Reserve, FAA, DOT and others. I'm not basing my opinion on just one person or one agency. I've yet to see ONE manager (exception is Military) that could make a decision without consulting several levels up and playing CYA to make sure if they made the wrong call they didn't get hit with the splash!! That attitude of not accepting responsibility is just the culture.

What you call "bias" is the scars of years of experience. Note that I'm NOT talking about Engineers and Technical people, just Managers.

Why don't you disclose what jobs you've done? I bet you've got some "bias" too!!! I'm suspecting you work for a Gov't agency.

nasa: Wow! Great insights. You have had some amazing experiences.Thanks.

Nasa --

I don't think that I attacked you on a personal basis -- did not call you names or such -- just referred to your bias, to which you attest to based on your "scars".

I am definitely not minimizing your scars or experience -- who am I to do that? That said, your extensive experience with the complexities of government and private sector organizations in very complex collaborative relationships still gives you a fairly black and white, good/bad sense of that experience rather than a more complex and nuanced respect for their differences and respective responsibilities. Different roles may see the world slightly differently. Doesnt mean one side is BAD and the other is GOOD. A senior manager may have a great deal more to weigh in a given decision that a technical expert working on one specific project has to deal with. Its easy but totally false to say that only the technical expert has the only TRUTH worth respecting. Is that what you are saying?

I am not an "expert" in your field of engineering. Am I therefore unable to make any judgements on anything about the process of organizational decisionmaking and priority setting? Or on analytical decision making versus sweeping generalizations? Note, I have not nor have I ever disrespected private sector, industry or other organizations. I only challenge the ongoing unbalanced criticism of ALL government, which I hear from your statements particularly.

I am a nurse and manager. Historically I have worked in government and provider organizations as well as data organizations. I spend a lot of time evaluating and making decisions, weighting options using a variety of information sources. I hear it when I make mistakes, so I had better come through with the goods.

I believe in the ability of all types of organizations to do good work and to be accountable. That always starts with integrity to honest analysis of information and challenging bias -- made up minds before the information supports one's conclusions. You apparently believe in the role of bias and support retaining it rather than having an open mind. Your choice. But don't give me push back on MY credibility, Mr fact based engineering, if YOU don't wait for eviddence to form your opinions.

Elie,

First, thank you! We do care about what we do! Many of us could make far more in industry but, we pursue science with a love not the love of a dollar.

Chu, one of the smartest people in the country now. I confess, I work for him but wish he could stay long after BO is gone in 2012. In fact I would like to see Chu as president. We need a problem solver and he may very well be our best.

Yesterday, in a previous thread, I wrote:

I received several requests for stills from this video, since apparently Pee Cees can't read Quicktime movies.

I put up some stills at

http://homepage.mac.com/james_r_white/tei_share/OilSpillMovies/pix.html which are basically screen grabs off of the movie. There are several stills from different angles of both ends of the cut-off riser.

Hope this helps.

Mine does. All I had to do was download 100MB of iSoftware that's constantly nagging me to upgrade and be willing to put up with the iStore popping up every time I brush by something it thinks it can sell me.

Anyway, thanks. Interesting but still mystifying stuff.

Deleted - reposted in correct place.

I can't play it either, even though my system says the QT codec is working and I can play other .mov files. I even tried to reencode it but it crashes Handbrake, and avidemux says it doesn't have a video stream.

Can someone elaborate on what is in the gap(void) between the DEEP WATER steel casing liner and the production liner AND between the rock and the steel casing line (before the mud is in place)?

I recall reading somewhere that there was not enough production casing to reach TD so a liner was used instead. If so, how would the casing and liner connect; in other words, are they compatible?

Z - This link (http://www.energy.gov/open/documents/3.1_Item_2_Macondo_Well_07_Jun_1900...) will get you to a schematic of the well. That will make it easier to follow the chat. The profile shows that the annulus (gap) between the prodcution csg and the various shallow liners is empty except for where there was cmt pumped at the base of the prod csg. This cmt seal is what has apparently failed. The prod liner was run to TD and hung off the bottom of the well head. There was discussion that running a liner from the previous liner instead of running the prod csg would have been a safer approach and probably could have prevented the blow. Perhaps you're misreading some of those comments. The prod csg and any liner don't really connect per se. Liners are connected: the deep liner is attached to the shallower line by (drum roll please) the "liner hanger".

I don't think we can say it was really empty. Somebody from outside the industry may think it was just an empty cavity full of air. The best way to put it, I think is that this space had the mud used to pre-flush the annulus ahead of the cement job. Since the well is new, that mud should have been fairly fresh. Later, during the blow out phase, because the cement job failed (probably because hydrocarbons chanelled into it), then the subsequent flow probably blew out pieces of cement, some of the mud, and quite a bit of adjoining rock formation, to form an erosion channel.

We call them wormholes when they're made in viscous oil reservoirs, where they can grow very fast and reach hundreds of feet in length, so I'll use the term wormhole here because that's the closest I know to what's likely to be going on, an eroded channel cut on one side of the casing running to a point where the casing failed.

Good point fd...coffee hadn't kicked in yet. Z -- listen to FD.

Hope the guys out on the rig have your knowledge and understanding. If what you say it true they could be pumping mud a LONG time before they get any flow in the annular area stopped as the mud would have to fill those wormholes before starting to stem the flow. They better have a LOT of mud on the site.

When they lost control of the well they were swapping out heavy drill mud for lighter sea water - inside the production casing, IIUC. The mud ahead of the cement in the annulus would still be heavy, and not replaced - at least up to the riser, right? So the total pressure on the formation on the annulus side should have been considerably higher than up the inside of the production casing, and the blowout occurred while that pressure difference was getting larger. Wouldn't that make shoe failure and flow up the inside more likely than flow up the annulus?

Isn't this scenario just what the doomsdayers were talking about? Luckily casing broke and let the flow inside and at least all these caps devices have a chance to work?

Rockman-

Start right there with the DOE well configuration and you can see how Chu et al clearly DO NOT have any working familiarity with the engineering. I offer into evidence the three 16" rupture/burst disks shown in the 9-7/8" section of the production casing. I sell rupture discs (Continental & LaMot) and have sold BS&B and have looked at Fike, and I can assure one and all that none of those manufacturers has a 16 inch disc that will fit inside a 9-7/8" pipe. I did my civic duty and sent Sec Chu an e-mail to point this out and yet it is still uncorrected (more dithering and indecision!).

Heading Out

I agree that dithering, not decisionmaking, is the hallmark of the government overseers. On another thread, I discussed the difficulties of getting the mud weight right to stop the flow when the WW is open to the sea at the BOP while the RW goes all the way to the surface. Installing the new cap to rectify that problem is a no brainer.

I would offer a solution to controlling the WW from the top without a RW, a modified top kill procedure I'll call "All the Marbles". Run a hose or tubing (about 3/4" OD) from the surface to the kill line on the BOP with valves at either end. Fill it with 1/2" diameter glass marbles, then fill the space with oil. Close the upper valve and open the lower one allowing oil form the WW to flow into the hose equalizing the pressure, at which point the marbles will start to fall out into the flowing oil at a measured pace which is limited by the reverse flow of oil needed to backfill the space vacated by the departing marbles. Repeat as needed.

This drops the marbles into the oil stream where they will fall downhole per Stoke's Law. Assuming the acceleration of gravity is 32.2 ft/sec^2, the marble diameter is 0.5 inches, its density (SG) is 2 gram/cm^3, the oil density is 0.9 gram/cm^3, and the viscosity is 0.3 centipoise cP (0.3 gram/meter-sec) you can calculate the terminal velocity of the marbles here http://www.ajdesigner.com/phpstokeslaw/stokes_law_terminal_velocity.php

If the terminal velocity is greater than the upward flow rate, the marbles will fall to the bottom of the well. The maximum upward flow velocity based on a 60,000 barrel per day flow can be calculated thus.

A 42 gallon barrel is 5.61 cubic feet x 60,000 barrels = 336,6000 cubic feet per day. Divide by 24 hrs/day by 60 mins/hr by 60 secs/min to arrive at 3.9 cubic feet per second. The worst case for this well would be all the flow going up the annulus (i.e. between the ID of the 9-7/8" liner and the OD of the 7" production casing).

The ID of the liner is about 8-5/8", that area is 58.4 square inches, the 7" OD casing's area is 38.5 square inches, so the Minimum Net Flow Area (MNFA in ASME Code-speak)is 19.9 square inches. Dividing by 144 sq inch/ sq ft and you get an MNFA of 0.138 sq ft.

3.9 cu ft/sec divided by 0.138 sq ft gives us an upward flow rate of 28.3 ft/sec. So the Stoke's calculator proves the marbles' terminal velocity is greater than the upward velocity of the oil and the marbles will fall to the bottom. As they do, they will introduce a flow restriction (e.g a "choke") to the WW further reducing the leak rate. Choke it enough and you can go to progressively smaller "marbles" until you get to the point where you can pack the all intersticial spaces in the marbles and kill the well, FROM THE TOP!

NO MUSS, NO FUSS JUST A SLOW MOTION TOP KILL. It might take a couple of days to inject all the decreasing sized marbles, but it would be a lot faster than this project has been.

That would be a pretty good trick. It is just another example of the misinformation that is availible to the public that makes hard for them to understand what is happening. Another is Admiral Allen often uses the incorrect terms. You would you would take at least a very short course in drilling if he is going to hold press conferences about it.

I guess accuracy does't matter anymore.

Thanks for the stills. The end with one pipe appears to be a pipe within a pipe. At first I thought it might be casing and a collar, but the in last picture the outer pipe appears to long to be a collar. Do you know which end of the piece of riser was closest to the BOP?

The end showing two (or one deformed) pipes was closest to the BOP. IIRC, the shear crushed from the side with the more squished pipe.

Also the end with two pipes it appears that you can see threads within one of them. To me they looked pretty course like a drill pipe tool joint, but I could be wrong.

2 pipes at one end closest to the BOP. Pipe on left has threads. Pipe on right has cement in it. One pipe at end of section furthest from BOP also has what looks like cement in it.

Any idea how cement could still be in there?

Not sure I see cement but a possibility is that the cement was not fully set when the blow out occurred then the DP caught it on they way up. There are reports of cement falling on the support ship.

NAOM

The only pipe in the hole that should have had cement in it, or on the outside except for the liners and I believe the pipe shown is smaller than any of them, is the bottom of production string (7 inch casing), but wierd things can happen to pipe during a blow out.

If the pipe on the left is a female drill pipe tool joint as it kind of resembles, it is upside down too what is normal. Again see my comment above. It could also be the threads of a casing collar which could have detached either way so it could be right side up or upside down.

I sure would like to know what is in the rest of the riser laying on the sea floor.

This is totally wild speculation, but what I see appears like the production string was torn in pieces and parts including the 7 inch at the bottom came up into the riser.

Side note, if that is the case it would effect the magnetic rangeing by the RW after they get below the last liner, but there could still be steel in the bottom of the hole to range off of, like the drill pipe may have dropped to bottom.

This is the first time I have taken a close look at the piece of riser, so the possiblities are still cooking in my mind.

Good observation. Would there have been enough room in the BOP for a piece to get turned around? There is only one pipe in the other end so that may well be it. On the other hand the bits have a male screw on them so that end of the pipe would need to be female. Wonder why that should be all the way up there. Seems very coincidental that it should have ended up at the exact point of the snip. Any thoughts?

The riser was reported to have been brought to the surface. It is about time we had some hard information on what was found. I was surprised it was not recovered during the cut off operation as they already had a sling and hoist attached to it.

NAOM

EDIT: If that was the casing and there was nowt down there then they wouldn't be doing those ranging runs?

Normally the bit is screwed into the bottom drill collar (very thick wall heavy pipe to add weight to the drill string for drilling purposes) which is female on both ends.

For the operations they were conducting I think it is unlikely that they had any drill collars in the hole. Drill collars are a bit harder to deal with so if thay are not required you just run drill pipe into the hole.

But, they could have a short sub (short pipe for adapting different threads) for the purpose of running the casing down to the well head. One of these could have flipped over somewhre in the hole or even been female on the bottom end to start with.

We just need more info on the drill pipe and any other tools attached to it.

The liners would still be in the hole, but below the last liner who knows. The drill pipe may be there to range off of.

I was speaking to a retired drilling engineer friend of mine today and he told me that on the first job he was sent out to do, they were doing some kind of workover and had been shut down overnite and when he arrived on location in the morning the entire 6000 ft string of 5 1/2 was laying on the ground. Guess they were lucky that it happened at night while no one was there. That would have been quite a phone call back to the boss on your first day.

I couldn't play this movie with either Apple Quicktime or VLC (which pretty much plays everything). Could you check your encoding. It appears to require the WMV3 codec which is bizarre for an Apple encoded movie.

WMV3 = Windows Media Video 9 not an Apple format. Unfortunately there are proprietary formats that companies don't want to be allowed to be used by other companies so they have a monopoly on their use. There are formats such as Vorbis that can be freely used.

NAOM

Oh, 2 pipes. LHS with female thread, break at collar? Maybe 1st BOP shear attempt landed on a collar and broke the joint and loose pipe was displaced?

NAOM

Oh, 2 pipes. LHS with female thread, break at collar?

When I saw the still those threads just jumped out at me.

That may be why the BOP was compromised. IIRC the shear rams usually can't slice or crush the joints.

In a blowout you take what you can get though.

I'm more concerned with the other pipe as some have speculated that it may be casing. and BP's docs sent to congress indicate the casing may be compromised at 1000ft or so. below the BOP/well head.

I don't have enough info to even guess.

See my exchange, above, with RioHondoHank.

NAOM

The family and I were waiting for the main course in a restaurant last night - Outback if you must know - so I got to playing with the cylinder-shaped loaf of bread. Sure enough, as AlanfromBigEasy indicated quite some time ago (think it was him but others too) you can take a cylinder and squish it into a figure 8 shape cross section.

Not saying it's one or two pipes in the pics just saying if you want all the table bread to yourself then just squish it into a figure eight shape.

Pete

If you download the high resolution image of the riser mock-up you can clearly see there are two pipes. It seems that BP would not have used two pipes in the mock-up if there weren't two pipes in the cut off riser.

Link to that?

The high resolution image is at:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

As seen on

http://www.bp.com/genericarticle.do?categoryId=9033571&contentId=7061902

Thanks.

Anyone want to take on the question? As I see it, the question is "WTF?"

I'm willing to bet you're somebody's little brother, ptoemmes, because in my family that was one of the best little-brother tricks.

See there? I knew it was worth it to donate to TOD, just for that piece of info right there!!! Thanks! I've wondered all my life how to solve that conundrum! Heh! Heh!

But, Pete, wouldn't the two parts of the "figure-8" be about half the size of the original cylinder-shaped loaf of bread?

Something like O=oo vs. O=OO??

I don't have a loaf to play with, but . . .

James, do you happen to have ROV videos from 5th June 2010, late afternoon?

The screen capture at the following link

http://www.flickr.com/photos/51953657@N08/4776922637/

shows the far end of the broken riser at 16:27:07 on 5/Jun/10, a few days after the other end was sheared from the top of the BOP stack by Jaws. For visual reference, the screen capture at

http://www.flickr.com/photos/51953657@N08/4777555820/

shows the same end of the riser several days earlier, when it was still spewing oil and gas.

The later image appears to show two concentric pipes within the riser, and from their sizes the larger one looks more like casing than drill pipe. However, I know how easy it is to see what you expect to see, and I could easily be convinced that what I'm looking at is just remnants from the siphon assembly that was inserted in the riser for a while to capture some of the oil. The image at

http://www.flickr.com/photos/51953657@N08/4776922717/in/set-721576244572...

is the end of the riser on the following day, and I can't really tell what I'm looking at in it.

Anyway, if you have higher resolution videos or still images of the same area they might be interesting.

Again, I refer anyone who doubts there are two pipes to the high resolution image of the Cameron mock-up of the riser.

Here is just a small piece of the image clearly showing the two pipes in the mock-up.

I don't believe the mock-up would have be built with two pipes if there weren't two pipes in the piece of cut-off riser.

You can download the entire image from:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

I think (based on some of the pictures of the riser itself) that there are probably two pipes. But over and over again I hear the argument "they wouldn't have built the mock-up with two pipes if there weren't two pipes in the riser".

That's not evidence, it's conjecture. Maybe they thought there were two pipes; maybe they were exploring alternatives and one of them was that there were two pipes in the riser.

In any case, I don't think anyone has disputed there being two pipes in that mock-up. But it's not proof and there's no point in posting and re-posting pictures of a dang mock-up.

Edit: caption to the pic at BP page (emphasis mine):

Is this the only mockup they did, or the only one they published a photo of? Nobody knows.

I don't believe the mock-up would have be built with two pipes if there weren't two pipes in the piece of cut-off riser.

Thad Allen in this morning's briefing, describing what will happen over the weekend:

Mainstream media just reporting that BP admits second pipe in BOP.

*BREAKING* Coast Guard and BP admit “MYSTERIOUS second pipe” stuck in BOP; Experts say indicates casing “dislodged”

http://www.floridaoilspilllaw.com/coast-guard-and-bp-now-admit-mysteriou...

Discovery of second pipe in Deepwater Horizon riser stirs debate among experts, New Orleans Times Picayune, July 9, 2010:

For the first time Friday, the Coast Guard and BP acknowledged that a mysterious second pipe, wedged next to the drill pipe in what remains of the Deepwater Horizon’s riser, is fouling up the works where the well is spewing hundreds of millions of gallons of crude oil into the Gulf of Mexico.

Second Pipe (nola.com)

“We used a diamond saw and we got inside. We found there was actually two sets of drill pipe there,” said retired Adm. Thad Allen, the top U.S. Coast Guard official overseeing the response to America’s worst-ever oil spill.

It “presumably fell down beside it as a result of the explosion and the riser pipe being bent over,” Allen said. He noted that the second pipe does not have oil shooting from it.

BP officials said late Friday that they believe the second pipe is drill pipe. Pictures show it is similar in diameter to the known drill pipe.

While Allen said he believes the second pipe fell from above, some experts have advanced another explanation. They believe poorly cemented casings — tubes that are supposed to form solid walls down thousands of feet of the well bore — may have been dislodged by the blast of natural gas that shot up out of the well and above the sea floor.

If that’s what happened, the piece of pipe would have gone into the blowout preventer, the 450-ton tower of valves and pistons that sits on top of the well head and is supposed to shut off the well in an emergency. The Deepwater Horizon’s blowout preventer failed to cut through the pipe that ran through it, and subsequent efforts to shut the so-called shear rams using remote-control submarine robots also failed. …

The idea that a loose pipe shot up from deeper in the well and prevented the shear ram from closing has been espoused by such experts as oil industry investment banker Matt Simmons and Bob Bea, a University of California at Berkeley engineer leading a scientific investigation into the blowout. But others have wondered if the mystery pipe isn’t just a section of the same drill pipe that came loose, or even a pipe that fell down the riser from the rig 5,000 feet above.

The Coast Guard’s acknowledgement [sic] of the two metal tubes Friday — and a subsequent reference by BP to its plans to tie the two pipes together as the company installs a new oil collection system over the shaved-off riser — actually comes more than a month after the Department of Energy noted the existence of two pipes using special imaging technology. At the time, BP dismissed the Energy findings as “impossible” because only one pipe in sections was used for drilling, a Tribune News Service story reported last month.

Video images of the riser when it was cut in early June clearly showed the two pipes, raising speculation on blogs. Allen said the second pipe also led to a jagged cut on the larger riser pipe, forcing the response team to use the loose cap with a rubber seal. And now, the two pieces are forcing the team to spend several days tying them together and clearing the way for a new, hopefully more solid connection.

Oil industry expert Matt Simmons says the second pipe is lodged in the BOP after “tremendous pressures” from the blast ruptured the well casing. This ejected part of the casing through 50 feet of steel inside the BOP.

A better read, IMHO, is the original story at

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/07/post_19.html

Looks like somebody from nola.com reads the oil drum.

It is interesting that after the pipe was cut, the stuff coming out of the stub at the top of the BOP was different color on one side than the other. I presume the lighter-colored stuff had drilling mud and/or sand . . . one flow might have been from the one of the drill pipes, the other from the annulus?

I will post some video stills of what I am talking about when I get a chance.

It will be interesting to see the BOP once it has been retrieved, if they share the info.

This well and surroundings should be treated like a crime scene. 11 people died due to probably criminal negligence. Odd that they allow the folks that are responsible to clean up the crime scene.

Yesterday, I wrote:

OK, OK, there is lots of folks who have crippled non-Mac 'puters that can't view .mov files for some reason, so I put it on Youtube. Youtube said:

There isn't any audio . . .

I tried loading it into iMovie, but iMovie wouldn't recognize it either.

I uploaded it twice to Youtube . . . got the same thing both times, and when I try the links at

http://www.youtube.com/watch?v=yLm5-tyZGoc

or

http://www.youtube.com/watch?v=XZLpYMTs7QM

Youtube says

So I am out of luck. If any of you guys can fix it, have at it, but I just don't have the time. I gotta run to the store for some BlueBell . . .

Mainstream media just reporting that BP admits second pipe in BOP.

*BREAKING* Coast Guard and BP admit “MYSTERIOUS second pipe” stuck in BOP; Experts say indicates casing “dislodged”

http://www.floridaoilspilllaw.com/coast-guard-and-bp-now-admit-mysteriou...

Discovery of second pipe in Deepwater Horizon riser stirs debate among experts, New Orleans Times Picayune, July 9, 2010:

For the first time Friday, the Coast Guard and BP acknowledged that a mysterious second pipe, wedged next to the drill pipe in what remains of the Deepwater Horizon’s riser, is fouling up the works where the well is spewing hundreds of millions of gallons of crude oil into the Gulf of Mexico.

Second Pipe (nola.com)

“We used a diamond saw and we got inside. We found there was actually two sets of drill pipe there,” said retired Adm. Thad Allen, the top U.S. Coast Guard official overseeing the response to America’s worst-ever oil spill.

It “presumably fell down beside it as a result of the explosion and the riser pipe being bent over,” Allen said. He noted that the second pipe does not have oil shooting from it.

BP officials said late Friday that they believe the second pipe is drill pipe. Pictures show it is similar in diameter to the known drill pipe.

While Allen said he believes the second pipe fell from above, some experts have advanced another explanation. They believe poorly cemented casings — tubes that are supposed to form solid walls down thousands of feet of the well bore — may have been dislodged by the blast of natural gas that shot up out of the well and above the sea floor.

If that’s what happened, the piece of pipe would have gone into the blowout preventer, the 450-ton tower of valves and pistons that sits on top of the well head and is supposed to shut off the well in an emergency. The Deepwater Horizon’s blowout preventer failed to cut through the pipe that ran through it, and subsequent efforts to shut the so-called shear rams using remote-control submarine robots also failed. …

The idea that a loose pipe shot up from deeper in the well and prevented the shear ram from closing has been espoused by such experts as oil industry investment banker Matt Simmons and Bob Bea, a University of California at Berkeley engineer leading a scientific investigation into the blowout. But others have wondered if the mystery pipe isn’t just a section of the same drill pipe that came loose, or even a pipe that fell down the riser from the rig 5,000 feet above.

The Coast Guard’s acknowledgement [sic] of the two metal tubes Friday — and a subsequent reference by BP to its plans to tie the two pipes together as the company installs a new oil collection system over the shaved-off riser — actually comes more than a month after the Department of Energy noted the existence of two pipes using special imaging technology. At the time, BP dismissed the Energy findings as “impossible” because only one pipe in sections was used for drilling, a Tribune News Service story reported last month.

Video images of the riser when it was cut in early June clearly showed the two pipes, raising speculation on blogs. Allen said the second pipe also led to a jagged cut on the larger riser pipe, forcing the response team to use the loose cap with a rubber seal. And now, the two pieces are forcing the team to spend several days tying them together and clearing the way for a new, hopefully more solid connection.

Oil industry expert Matt Simmons says the second pipe is lodged in the BOP after “tremendous pressures” from the blast ruptured the well casing. This ejected part of the casing through 50 feet of steel inside the BOP.

I put up a new batch of movies and stills at my website

The movies at

http://tinyurl.com/23ztdwr

http://tinyurl.com/27yk9lx

http://tinyurl.com/2eu42rd

show the cut stub of a riser at the top of the BOP a day following the cut but without the LMRP cap or dispersants being injected into the plume. It looks to me that:

(*) the color of the stuff coming out of one side of the riser is different than the color of the stuff coming out of the other side of the riser.

(*) the darker fluid has gas bubbles, the lighter stuff does not.

From that I conclude that at the top of the riser, we have fluid coming out at two different locations from within the well. Perhaps one of them has a oil/gas mixture, the other having seawater and drilling mud (or water and sand from some other part of the formation).

Mind you, this is a day *AFTER* the riser was cut.

My guess is that one of these flow streams is coming from inside the one of the drill pipes inside the riser, the other is coming from the annular region around the drill pipe, but which is which, I don't know.

I wish I could put all I have on the 'net, but I have a *LOT* of stuff saved . . . and there is a *LOT* of interesting stuff there - 170 GB of stuff (or about 25 DVDs full of stuff) .

I just wish somebody at BP or the Government would tell us what they know. Surely somebody pulled a sample of this stuff. I guess if I were under investigation for a felony, I would probably keep my cards close to my chest too . . . .

At the DoE website, there are even better video clips than the ones I posted which shows the multicolored nature of the stuff coming out of the sawed-off riser - in high def even. They may be seen at

http://www.youtube.com/watch?v=IPpKZx854VQ

and

http://www.youtube.com/watch?v=f4i_mN_AWvU

Thanks for all this clarity, HO. Just one quick question:

8. POOH and retrieve the wear sleeve.

POOH it? I take it this isn't the "Oh pooh" we hear from wives whose husbands are jumping up and down squeaking, "I Am your lord and master! I AM your lord and master"? So what does it mean in the Patch?

POOH-Pull out of hole. I remember as young guy learning to decipher the daily drilling reports that were faxed and telexed in from wells. Someone gave me a little black book published by petroleum club of Midland, Tx Women's Auxiliary or similar group. I may have it buried somewhere.

Might still have a mock comic telex that was circulated using the abbreviations and terms like perforating etc.....you get he idea.

Rockman may remember it too.

Thanks so much, Diverdan.

i think you mean desk and derrick.

elwood:That's it! Thanks. It has been probably 30+ years since I looked at it!

dan -- Yep...still have a list of such oil patch abbreviations that, should I ever get drunk enough to post, would lead to my life time ban on TOD. Thank goodness I don't drink like that anymore.

Rock: I remember having to get up in front of a company pres when we were drilling and getting ready to test the J. Hyman well ....

NOT WITH A 10' POLE DAN.

I'd love to see that list!! Being in a business with lots of slang and acronyms I enjoy seeing what others use and if I can decipher them. Kinda like code breaking. Would a couple gallons of Blue Bell grease the skids? Or a donation to the charity of your choice?

NASA: There are others on the Web but this will work.

http://en.wikipedia.org/wiki/List_of_oil_field_acronyms