BP's Deepwater Oil Spill - Starting to Change the Cap - and Open Thread

Posted by Heading Out on July 11, 2010 - 10:00am

This thread is being closed. Please comment on http://www.theoildrum.com/node/6717.

This weekend, BP is carrying out two steps that will move the process of reducing the oil flow, and killing the well further forward. In fact, should the new sealing cap be placed over the well by Monday, then, with the new connections that are then to be made, there may well be no more oil flowing into the Gulf from shortly after that new collection system becomes fully effective.

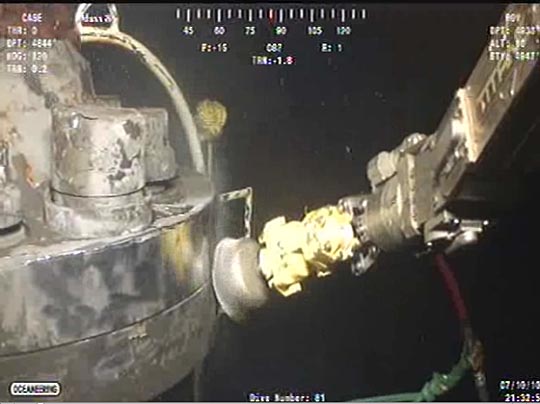

There are two parts to the process. The more immediate part, that would have been in place, except for the bad weather, is the connecting of the flow from the kill ports on the blowout preventer (BOP) to the floating riser and the Helix Producer. At the same time the old riser section is being removed from the top of the well. At the moment (9:15 pm Saturday evening) the ROVs from the Ocean Intervention are working on continuing to loosen the bolts on the riser flange. The box to the left has just been brought to the riser by Ocean Intervention ROV2, and this view is from ROV1. (Skandi ROV1 also appears to be monitoring the operation).

UPDATE: 1. The broken riser and flange were removed at about 3:00 am, and thanks to sunnv , the video can be found on Youtube.

UPDATE 2. At 1 pm (Eastern) Sunday the transition spool is being lowered into position, I am watching through BOA ROV 1 .

UPDATE 3. At 3 pm the transition spool was set into place, and at present (7:30 pm Eastern) the bolts attaching it to the underlying flange appear to be still being tightened. The next step, I believe, is to lower the Lower Capping stack into place, and lock it into place. It will be lowered on a rigid riser from a drillship.

The view from ROV1 also shows, intermittently, one of the two pipe segments inside the riser.

Kent Wells has described the process that is being carried out, noting that as the testing of the new cap proceeds, once it is installed, it might be possible to shut the well in.

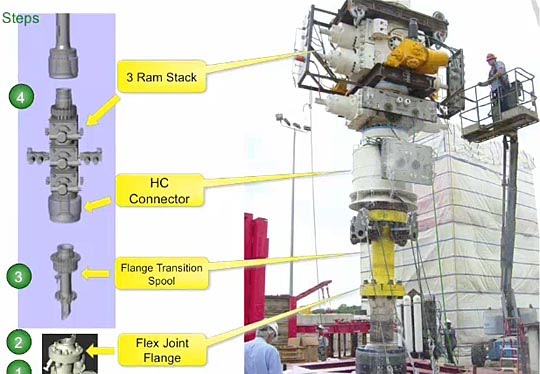

The flex joint has been straightened and blocked into place, and is aligned with the BOP. And the cap itself is a much more complex structure than had originally been discussed. It will also be installed in a number of stages, and I will use Kent Wells' illustrations and comments to walk through this.

The first step, in the installation process was the alignment of the flex joint and the removal of the old cap. The second (currently ongoing) is the unbolting of the old flange. There are 6 bolts to be removed, shown in this illustration as well as above:

There are a couple of tools that have been developed to split the two halves of the flange after the bolts have been removed – the initial one will be fielded from the Inspiration drillship, and will fit around the flange, so that the top segment can be just lifted off.

This will expose the two segments of drill pipe that are sticking out of the BOP, and so these will then be strapped together, so that they will fit within the transition spool. A guide shoe and positioning pins will be used to help lower this in place, and then the ROVs will bolt the 12 ft flange transition spool (the yellow segment) to the top of the old BOP.

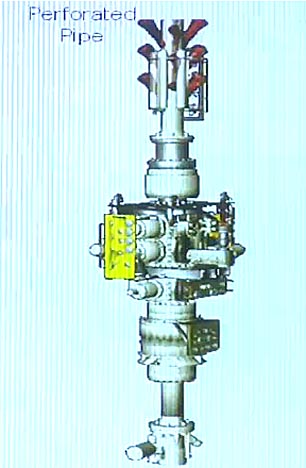

The 18-ft Lower Capping stack will now be lowered, on drill pipe, to fit on top of the transition spool. It sits on the HC connector, and is fitted with rams to control or stop the flow, and connectors that will allow feed of the oil to the different risers that will carry it from the well to the surface vessels.

The capping stack has a perforated pipe at the top, and initially oil and gas will issue from that pipe, once the stack is locked in place.

At the moment there is some doubt as to whether the fixtures on the top of the well, and the well itself, can hold pressure. In other words if they seal off the well, will the internal pressure rupture one of the casings or the BOP. With the capping stack, with its control rams in place, the well can be gradually shut-in, while pressure and strains in the system are monitored. The flows can possibly be reduced, diverted to the surface vessels, or even, if the results are favorable, even completely shut down.

There is an animation of the process, that was put together to allow the teams who will be doing this, to be trained in the assembly of the system. BP currently projects that it is going to take 4 – 7 days.

And at the moment, the Ocean Intervention ROV2 is cleaning off the side of the flange, so that the joint can be seen. (The wire brush is rotating so you can’t see the strands).

And at this stage, it looks as though they have the bolts loosened - vide the one above the brush, and these below, which appear partly backed out and thus we may already be waiting for the separation tool to come down and remove the old riser. Then the transition spool (under the BOA ROV control) will be moved into place.

We will wait and see how this unfolds as the day progresses.

Prof. Goose's comment:

New stuff in this introductory comment, 1 JUL 10.

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we brought online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read all the other previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all the comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. If you would like to catch up with what's been going on in the last few days, our IRC channel has been maintaining a FAQ, which is an open source log full of information, links, and such. Check it out: http://docs.google.com/View?id=dff7zmqz_7c6rdwsc9

6. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

7. Don't be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

8. Yes, HO and others have put up many counterarguments to the "DougR" comment. There are many many links, but the first one was here: http://www.theoildrum.com/node/6609. If you ask in the thread nicely, they will also point you to others.

I would have thought that the crimping would add enough pressure to dislodge the flange. Good thing is that they have two contingency plans so that will not be a factor. Or is the off center pressure binding the pins? They are tooled up so it will be OK no doubt.

How ugly could the flow become if the flange removal releases the stuck drill pipe? Would that increase the flow?

We really appreciate your excellent coverage of the Gulf oil spill.

In the lessons learned column, undergraduate fluid mechanics (taught it for the past 50 years) emphasizes the fact that changing the direction of the flow where the riser pipe crimped just above the BOP caused a reaction force opposite to the flow momentum change in addition to throttling the flow rate. (Attempts to saw off the full diameter riser just above the BOP were bound to fail.)

Why did BP not consider shearing off the riser just beyond the bend and then fitting a cap on this restricted flow riser? If the first capping attempt failed, the reduced flow in the crimped riser would have greatly reduced the flow rate issuing from the BOP while another attempt was made. I'm curious why I never found this discussed in my frequent reads of this excellent blog.

The bend was leaking hugely and getting worse with erosion.

The bend was still acting like a nozzle partially open. So you would rather not leak at 5000 bpd in an erosion situation but open it up to 50k bpd? If it is true that all the pressure drop was through the BOP, why is it gushing at a much higher flow rate now?

50 years. Long time to teach undergraduate fluid mechanics.

I think they already knew the throttle point was in the BOP and there was minimal pressure drop around the bend.

Apologies if this has already been covered ... but why are there TWO segments of drill pipe expected across the BOP?

Some say that bop sheer was engaged twice, some say that the blow-out caused it. I vote for #2. Rockman would have the definitive reply.

sharkey - I definitively don't have any proof. OTOH I've had drill pipe part a number of times just during normal ops let alone during such a violent kick. And ended up with two joints side by side in the csg string. Somethimes the simple answer is the best.

I believe it has been said that a piece from the riser had fallen down into the BOP when the rig fell over.

Lots of speculation, but nobody knows why there are two pipes, but thre they are. Two have been seen, both within the BOP via gamma-ray, and in the section of riser that was cut off the top of the LMRP some time ago and subsequently lifted from the seafloor and taken to New Orleans.

I hope someone has confirmed that those two sections of drill pipe are held securely in position. It would be a shame for one of them to come loose, rise up, and jam the new BOP stack.

The direct answer to why they are EXPECTED, is because some people from a government funded research laboratory SAW them using a gamma/xray camera. No one yet knows for sure HOW they got there. But they are expected because they have been detected using gamma radiation. It may still turn out to be that they are not there after all. But don't hold your breath waiting for a different result.

They could have done this with in days after the accident, and anyone who believe differently is a fool.

The robots have preformed much more difficult tasks, and that pipe flange has been there from the start.

The worst of this disaster could have been avoided, if they had just bolted a new riser to that flange months ago.

Please explain how they could have done this days after the accident if they have spent the last couple of months building it. Please specify the more difficult tasks that ROVs have performed. Please explain how how oil and gas would not have blasted straight up a new riser and blown up the ship/rig installing it.

NAOM

They could have just burned the oil at the top, and continued doing that until sufficient production capacity was available. A controlled burn would not require special flares or anything other than a valve and normal pipe fittings. See the previous thread for discussion of the objections to this solution.

They've been more collection limited, than cap limited, and that large stack of equipment shown above, was not 'just sitting at the docks'.

barnbilt - I agree 100%

I have yet to hear why a new riser was not bolted on. They have performed more complex operations than that in the past. They have the equipment to run a new riser to the bop.

They have everything they need to remove the bent/broken riser, bolt on a section of wide open valve, then gradually close that valve. Come on!!!!!!!!!

Not rocket surgery.

I'm sure this will be dismissed off hand by the techies here as over simplified...."you just don't understand...bla bla bla" I'm certain it is difficult but no one has explained why they didn't do the MOST obvious thing and bolt on a wide open valve, then close that valve.

Unless the well is critically compromised.

What does the BOP do? Close off the flow. You have slice valves, or gate valve, ball valve... come on!!!!!!

Why don;t they just say that they can not close off the flow because ...............???????

It's like they are standing by the door and coming up with a barrage of reasons why they can't close it...none of which makes any sense. How effing stupid are we?

There are a half dozen ways of cutting off the collapsed riser, (which they finally did after a month or so), there a half dozen ways of unbolting the connection, (which they are doing months later), theres a half dozen off the shelf valves that could be bolted on to shut off the flow or connect to a new riser,(which they are now doing months later) but noooooo.

Instead of swinging the door shut first we are going to try and rotate the house 45 degrees on the axis of the hinges.

But we are not supposed to ask why the obvious is not done...we are only supposed to be awed with the technology of deep sea wells.

eeyore and barnbilt,

The simple answer to your question is: Yes, they could have, IF they had planned ahead, which they obviously did not.

Now we're finally getting the "worst-case scenario" equipment on site, that was never designed or manufactured beforehand, b/c it would appear that the BP bean-counters, in their arrogance (or ignorance), may have decided to play it fast and loose, while attempting to save money. JMO

I think barnbilt has on of those Deloren cars like in Back to the Future, so he can go back in time and start engineering and construction on something we learned we needed in the present.:)

It has been explained repeatedly.

It is an obvious solution and they had it underway early.

The valve (a second BOP) was loaded on the drill ship in addition to its own BO

P that was to drill the second relief well. That ship started its well then moved off station in preparation for bolting on the second BOP.

Then top kill failed and they came out of the experience fearing that the casing was compromised sub-surface. A In which case closing the valve could have created a worse blowout- one outside the pipe.

The idea was abandoned and the drill ship returned to drilling the relief well..

So, I must understand that we are very lucky that the first BOP dit not work?

BOP is Blow Out Preventer with the emphasis on prevent. Once the blow out had taken place the game was changed. The longer it ran the worse the likely situation. If the BOP had been operated successfully before the blow out finally happened then there may have been less damage and not the potential issues we have now. So maybe we would not have needed that luck.

NAOM

Winners make their own luck; losers curse theirs.

Yes, they could have captured all the oil within days, and it would not have required unbolting the flange. They could have moved a new riser pipe close to the leaking end of the old riser, then slowly tightened a sleeve around the two ends.

Looks to me that they were completely surprised by the methane hydrate problem, or they would have had some gates on top of the original cap to let the hydrates out. Slowly closing the gates would have the same effect as slowly tightening a sleeve. The hydrates can't form if there is no water in the coupling to the new riser.

Everything since then has been one bad design after another. It's as if the politicos who run BP are coming up with these designs, then ordering the engineers to make their ideas work, instead of letting the engineers plan it from the start.

Uh NOT.

In the first days most of the leakage was coming from a crimp in the riser where it bent when the DH sank. There was no end to fit a sleeve over. That came much later when the "claw" was used to slice the riser. Cutting the riser was a very controversial move because it reduces the restrictions in flow resulting in more oil coming out of the pipe.

Everything looks simple in hindsight. During the first few days of this accident the priority was to try to activate the BOP which unfortunately didn't work out. Go back and look at the history of the various attempts to contain the spill.

Criticisms that BP was not prepared are justifiable. Criticisms of the post accident response are not justifiable - the talent assembled and resources made available are first rate, and they are doing as much as possible with limited information in unprecedented circumstances with the world looking over their shoulder.

What I saw in those first videos was a lot of oil coming out the torn end of the riser pipe. But in any case, they should have been ready when they did decide to cut the riser.

I understand that things look simpler in hindsight. We can each have our own opinion as to whether these simple solutions are "hindsight only", or something any engineer with common sense would figure out.

I believe you are right as to the level of talent and resources BP is focusing on this task. That makes me hesitate to say they are screwing up. It makes me listen carefully to what you and other experts are saying. It does not make me abandon my common sense.

I am encouraged that others on this forum share some of my common sense.

If you recall, they were ready with several different cap designs when the riser was cut.

You said you were an engineer. You must then appreciate that without a detailed knowledge of the situation it is possible to come up with all sorts of simple ideas that look like they would work well but in fact would be a disaster. It may look like some if these ideas are common sense. In reality they are false hopes because they are based on incomplete understanding of the constraints on the system.

Understood. I'm still listening for any plausible reasons why the oil couldn't be burned at the surface. Until then, I am 90% confident I am right.

BP could eliminate all this uncertainty by answering a few questions.

So you would burn at the surface while collecting oil from the process ship? You don't think a controlled flare is dangerous enough? Really? Maybe you should ask who in their right mind would work in a burn like that? Any of you would like to work that ship in a burning pool of oil? I guess the sight of the horizon burning didn't bother you?

put some subsea pipeing in, do a freestanding riser/hose up to a spar buoy like flare pipe, away from the rest of the activity, and torch it off.

maybe the spar buoy has multiple pipes to keep the flow velocity up, so the gas will entrain the oil.

Also, a simple pelton wheel in the side will power a generator to keep sparks going during a hurricane and a pump to spray water on the thing to keep it from melting too soon.

Have a couple of these, with quick-change fittings so they can be swapped out and re-paired during intervals between storms/too much melting.

They were burning oil at the surface. Didn't you read about the Coast Guard doing controlled burns?

Of course you have to do it a safe distance from the various ships and drilling platforms involved in the effort, which does restrict where you can burn, and weather conditions need to be favorable, but this was part of the process from the beginning.

Are you confusing common sense with selective reasoning? It seems you really are ignoring most of the physics involved with this problem. You should head down there and tell them your common sense is far more accurate then engineering principle and physics. Cheryl, we need you!

See Wikipedia for a sketch of the proposed sleeve. There is a collection of other ideas there also. Anyone who would like to join me in writing an article for Wikipedia, please follow that link.

Yes, they could have captured all the oil within days, and it would not have required unbolting the flange. They could have moved a new riser pipe close to the leaking end of the old riser, then slowly tightened a sleeve around the two ends.

No, they cannot.. If you just bolt a new riser to the bop and try to produce the oil/ng, there is no control on the flow of oil/NG going up the riser..i.e. if it exceed the capacity of the drill ship processing the oil/NG mix, you are going to bring down another drill ship.. In the LMRP, they have vent that open to release the oil/ng. And if you remember they were never able to close all the vents. And that is because the production capability on the surface is not enough. In this iteration, they have valves that can direct the flow of oil to different drill ships (and I am sure they have emergency valve that will release oil/NG if it exceed some critical pressure).

And this would have accomplished exactly what?

The previous system was capturing all the oil they were able to process.

They didn't even have enough processing capacity to enable them to close the vents on that cap.

I think this guy forgot NO ONE knew the condition of the BOP or casings below sea floor. So quickly people like to re-write history! Without that kill attempt they had no idea what that BOP would handle pressure wise.

Agreed. Cutting the riser was a risky move. Still, they should have been ready to collect all the oil when the did decide to cut it. This would not even require unbolting the flange.

Wow, you really should read the time line of what happened. That is what the top hat was, it collected all the oil they could up until yesterday.

WRB, see the discussion in the previous thread re burning the oil until sufficient production capacity is in place.

There has been no indication that the previous cap wasn't capable of capturing effectively all the oil.

The most likely reason for the switch it to be able to use top pressure as part of the kill.

It took them weeks to set up the Q4000 to flare. Turns out they badly underestimated the capacity needed. So they then set to work to hook up a third ship, which is now ready.

You think they've been purposely delaying despite the billions in fines for which they are liable as a result of the delay?

The one possible alternative I can see is simply abandoning work at the well, pulling the ships off, and lighting a giant torch at the surface. How far away the relief well drill ships would have had to have been for safety and what delay might have resulted would then be a question.

What about all of the oil spilling out under the cap? Is there evidence that it was a negligible amount?

It was spilling out because they had it throttled bak at the top because they had no more flaring/processing capacity

OK that makes sense. We had different definitions of "capable".

I guess nobody is reading our previous discussion on burning the oil, so here is a summary. I suggested that they run a pipe to carry the excess oil to a barge 500 feet away from the ship where it is currently being processed, and it could be safely burned. There were several objections:

1) The fire is too hot. It will melt the metal.

2) The parts to build another flare aren't readily available.

3) It would not be safe to burn without a properly-designed flare. I assume this includes heat, risk of explosion, and smoke inhalation.

4) There would be objections from environmentalists concerned about air pollution.

My responses:

1) The fire isn't hot enough to melt metal. It will weaken steel, but not melt it. If necessary, line the edge of the barge with cement.

2) We have an emergency situation here. Use ordinary, readily available pipe and connectors.

3) The heat would be no worse than what is currently coming off the flare attached to the processing ship. 500 feet extra distance should be quite enough. The smoke will go straight up most of the time. If wind conditions are bad, shut off the flow to the barge, and move it downwind. As for the pipe exploding, don't let air get into it. Submerge the outlet whenever the flow is shut off.

4) Let the governors of the gulf states make the choice - oil on your beaches, or air pollution 50 miles offshore.

That is what they are doing. The Q400 is the "barge they hooked up. It took some weeks to build the flaring equipment and connect and run the pipe.

It proved to have inadequate capacity. So they built another connection and brought in the Helix producer. You aren't suggesting anything that isn't being done.

In retrospect maybe it would have been better to pull everyone out and flare the whole thing at the surface. But without benifit of hindsight no one knew that top kill would fail or that BP would repeatedly underestimate the flow and bring in inadequate flaring/processing economy.

The Q400 is not a barge. What I mean is a low, flat floating platform with sides sufficient to contain a few inches of oil. It has no engine, and no personnel on board. It's sole purpose is to contain and burn off whatever oil cannot be properly processed by other ships. Yes, I know, there would have to be some way to tether it to other ships. Use your imagination.

Let's keep in mind the objective. We need a way to temporarily get rid of excess oil, while all the proper processing facilities are being built. Just letting it gush out at the bottom of the ocean is not a good choice.

regardless of the technical issues involved, I have to agree that the current procedure is suboptimal, no offense to the smart, talented people working on this. Appreciate folks like you for coming up with ideas, and pointing out the obvious flaws with the existing process.

Not an awful idea as long as it was far enough away and their was no possibility of setting the sea afire.. Maybe some miles. I can see the reasonableness of being resistant to trying something untested that involves fire in the midst What would make attaching and rigging this barge any faster than than attaching the Helix Producer, which already has connectors and plumbing in place?

If their was a shortage of processing ships it might be a different. But there isn't. There has been a failure to recognize the size of the spill and plan for it. The Helix Producer was offered in the first weeks after the spill started. BP didn't think they needed the capacity.

Again, this is a solution to the wrong problem

I do understand that the main problem here is not technology, but human factors. Still, I believe engineers have a responsibility to do more than provide systems that will work if everyone does their job. If we want to drill a thousand wells with less than one in a thousand chance of disaster over a period of thirty years, we need to anticipate human failures, and do what we can to compensate for those failures in our designs.

Or maybe some of us have read and participated in the earlier discussion, think your ideas are nuts, but realize that you're going to continue to think you know the answer and if only people had listened to you we'd all be happy now.

It's pretty clear that your own estimation of your own engineering skills and physical intuition is so much different than (for example) my estimate of those skills that there's really no point in arguing. And since your continued posting will only hurt or benefit you it seems best to stay out of it.

Except for this post of course :).

can't just light it off at the surface,

the release is too deep, so the oil is too dispersed,

and much of the gas is dissolved in the water.

They needed to go with floating/freestanding risers ASAP.

They should have hot-tapped the old riser:

1st, where it was easy - near the end, away from the wellhead so other ships can look at the BOP, but up a slight elevation so they could cement in the broken riser end.

2nd, between the kink and the top of the BOP, once they figured out that the BOP was broken. This would have taken a custom machined saddle to deal with the deformed pipe, but do-able. This relieves pressure on the kink.

Then, with enough taps below the kink, one can CNC machine a saddle/patch for the kink to reinforce the kink.

Then clamp that down, and there - riser is sealed.

Want more? Afraid of the torque on the BOP from the riser?

then wedge some customer machined wedges into the kink from a port in the hot taps using remote endoscopic manipulators, inject some sealant, and then CRAW the riser above the kink.

I claim all of the above would have taken less time than what they've done, particularly sealing things up with hot-taps and a kink saddle/patch.

Good ideas, sunnnv. There must be many ways to skin the cat. I wish BP execs could think like this, or trust the people who do.

As someone who has done a fair bit of cat-skinning on an old 46-A D-8, I can tell you there are lots of ways to skin a Cat! I was told early on to think and not move the dirt twice, if you can help it. Sometimes a feller just can't. Sure glad most of you folks around here are learned. I can't offer engineering solutions as far as this collection effort goes. Or the relief wells. Wouldn't want to. It just seems, looking back over the years, it was sometimes hard to actually build what the engineers designed. Heck, dont forget us peons are the ones that gotta get it built or installed. Big gap there sometimes. What do I know..... this aint some engineering football game we are watching here. Havin beers and .....well, you know.

The most likely reason for the switch it to be able to use top pressure as part of the kill.

No, it is not.. Please check with Adm Allen previous briefing.. He mentioned quite a few times why BP change the cap.. It may help the kill process but the primary reason is that they want to be able to process all the oil without any leaking to the sea. And they also want the redundency (if one of the processing ship is in trouble) and ability to grow the capacity (up to 80Kbbl a day)...

Yeah, hindsight is wonderful. But, they did not have benefit of hindsight, so... Here's how things went...

1. Rig catches fire, crashes to the ocean floor a day or two later.

2. Undersea examination begins in earnest.

3. Attempts to close the various valves and determine if the BOP was fully functional take quite some time.

4. Pulled in crews and additional ROV's begin the process of trying to determine how much oil is leaking, and what is damaged.

5. Eventually, it is determined that the BOP cannot be further activated or closed.

6. ROV's attempt to unbolt sections of the riser. Fail.

++++ Top kill fails ++++

7. The big nipper comes down and eventually, they cut off the riser.

8. Wire saw to cut off the remainder of the riser is tried, fails.

9. Big nipper eventually is used to chop off the remainder of the riser.

10. Big collection hood failed, it clogged.

11. Several small collection caps are designed, one eventually installed.

12. ROV brings down improvised tool and finally is able to turn a bolt on the riser flanges.

13. Period of time passes while flow apparently increases slowly and ever increasing efforts to capture flow continue to be deployed. More ships brought in, conversion to processing is undergone, flares installed, etc.

14. Flow is more accurately determined, along with pressures, gives reasonably good confidence in well's composition and flow capacity, along with downhole pressures.

15. collection hood is removed, chopped flange is removed, and new valve package - probably started back around event 12 - is readied to bolt on, special one-off design to enable installation on producing wellhead under deep water conditions, and now appears to be underway.

AT no point before #12 was it determined to be assured possible to put a new riser on top of the one down there now.

So, please, let's not get all short sighted and start shouting stuff that's NOT true and NOT accurate.

With regards to #12 -- loosening the bolts -- has it been determined that no tool existed till recently that could have removed the bolts? It's hard to believe that the need to do so wasn't foreseen well before this disaster -- or that a tool couldn't have been quickly developed.

Well, early on in this endeavor they tried various tools and approaches for around three days before they could finally get a single bolt removed. They came back later with improved tools. That is one reason that a number of posters here said earlier that they doubted the riser stub flange could be removed.

I remember watching those attempts. I was astonished at the difficulty they had. In the overall scheme of things, that doesn't seem like it should be the hard part.

I don't see much shouting, but I do see a lot of ad-hominem attacks. I don't mind blunt language, as that often leads to a better understanding of an issue. The best thing to do with ad-hominem posts is ignore them. If the poster has a valid point, it can be re-stated in a separate post.

So all of the studs are now removed, and it seems that Cameron have not designed a bevel on the flanges to enable the flange splitters wedge to easily locate and drive the flanges apart?

Good point, why not have a universal interface(Flange) for fault situations? It boggles my mind as I think they now have them for submarines and have had them since some other deep water accidents,

How can we improve things if everything needs to be universally backward compatible?

You raise a good point about Universal interfaces, what about the stub the BOP connects to, are they Universal fittings, can BOP be replace with a BOP from a different manufacturer.

Of course my point about flanges is FOS because they do have a standard and are using it now with the new cap. But perhaps the standard should be easier to latch onto then the a 6 bolt flange.

Maybe this new connection they are installing might become that mechanism.

NAOM

It won't get any easier than 6 screws.

A tapered interface with an locking mechanism for the outer circumference instead of bolts? 30 seconds of thought comes up with a solution that is better then a flange with 6 bolts.

What makes you think this is better? Locking mechanisms are subject to accidental release and mechanical failure. Six bolts is a hell of a lot safer in normal operations which is what you have 99.99999% of the time.

Be sure your cures aren't worse than the disease.

Hindsight is a wonderful thing. I'm sure the designers will have learned from this and bevelled edges will in future be used on flanges, as well as dome-headed nuts to allow wrenches to be more easily located.

As an engineer, I can tell you ease of use is far down the list of determining factors in fastener and connector selection. Dome nuts and beveled flanges are on a different page in the guides. They might change these things, but I assure you, good engineers have already thought about it.

In the previous article now closed people were asking about Queen Bess Island and what it is like now. Earlier in the DWH saga it was pretty messed up by oil. Here is a picture of Queen Bess after the oil incedent. Plenty of green and plenty of birds.

I have video of thousands of birds flying above it as LDWF scare them up as they evaluate the situation.

Thank you, this is very good news. I'm the one who raised this question. What is the date of the picture? I can't really see anything; could you post a larger version? Would you consider putting your video on youtube?

It looks like the pressure is not as high as it was the last time the cap was removed. Anyone else noticing this?

They are taking more oil out from the choke/killlines.

NAOM

Drop the bolt! We have GPS and can recover it later! At 100,000 barrels a day , we can pick it up later!

It will sink into the mud at the bottom of the GOM. Good luck finding it there.

yes, perhaps that second collection stream is already pumping ? (from the kill lines IIRC ?) Supposed to be right about now ?

Anyone seen numbers on that new flow-path yet ?

The top hat is now lying, on its side, on the bottom. Wonder what that does for the contingency plan of putting it back on the BOP?

NAOM

Per the latest from Wells today, either during the briefing or in one of the videos, they won't use the old cap again. If there is a problem with the new sealing cap, they have another new LMRP cap that they would use instead. He didn't say whether it would bolt directly to or balance on the BOP as the old one did.

Various 7/10 Kent Wells updates

The old LMRP cap is probably the most famous piece of metal in the world right now, having been watched by millions all over the world for hours at a time. Now it lies discarded.

If BP were smart they'd clean it up and exhibit it. But when it comes to PR, BP never miss an opportunity to miss an opportunity (as someone said about someone else).

Are you sure about that? I would think the numbers watching the cap for the last month might approach - at best - 1% of those watching the World Cup, and its much more valuable metal prize.

Okay, I give you that.

"The most famous piece of scrap iron..."

The old LMRP cap is probably the most famous piece of metal in the world right now, having been watched by millions all over the world for hours at a time. Now it lies discarded.

If BP were smart they'd clean it up and exhibit it.

Should go in the Smithsonian, gloriously becrudded as it is, if they can prevail upon BP to salvage it. Surround it wih a frame of monitors showing tape loops of the gushing oil and narrated loops of the attachment and removal operations.

It belongs in the Corporate Hall of Shame.

Newbie here, go easy on me :) Someone (SDW?) on the previous thread asked what the verticsl pipe was that was being cut with a diamond saw, shown by Enterprise ROV1. I was watching as the saw completed the cut. The lower section fell away to the seabed and the upper part remained where it was. The ROV then maneuvered to look up at the cut end of the upper part. I was surprised to see it was very thick-walled with only a narrow bore (had been expecting it to be thin-walled.) Would this have been a drill pipe? I supposed it would need to have high torsional strength, and the narrow bore would allow mud to be pumped down to the drill bit?

My previous post indicated that that might be the riser pipe from the old cap. That or another riser pipe to collect the oil. I think it was dumping the old cap which is attached to pipe.

Moved by author.

Mike, the pipe that was cut was the riser connected to the top hat cap that was lifted off the LMRP earlier today. That's the path the flow of oil and gas have been taking up to the Discoverer Enterprise - no drill pipe inside it.

For newbies who might not have noticed, there is a IRC channel where the ROV activities are being discussed and debated in real time. Directions on how to access it are in point #6. in the Prof. Goose comment that has been appearing regularly as the first comment in Open Threads.

Notes on #theoildrum channel are at #theoildrum Channel Resources.

Wish I could but can't from work.

Good reminder. I just checked out the irc page today and it's a far better way to see what's going on than the web site.

FYI, for anyone keeping score: the posted plan allows about 3/4 day (18 hours?) for "Stop containment - Discovery moves off station" to "Unbolt flange & remove bolts". They pulled the cap at 10:42 PDT and were done by 21:43 PDT. This despite the numerous cries of panic every time a ROV had to change tools.

Has Ocean Intervention III - ROV2 Video Feed now finally gone belly up ?

It was showing signs of stuttering before, with moved images, and I thought I saw droplets (?!) appear on the image left - not a good sign, if it is behind a thick glass pressure protector....

Ummmm, pretty sure that about 30-40 mins ago, OI ROV2 http://mfile.akamai.com/97892/live/reflector:44838.asx?bkup=45135 was showing a feed from the ship deck - there were occasional gimpses of the booted lower legs in the shot, as the operators worked around it. Then the feed went dead.

So I'd say it's up for maintenance / toolset change, rather than a subsea failure

Regards Chris

Was there any clue before this week that the "tighter fitting cap" would be a device this big and complex? I do recall a technical briefing by Kent Wells several weeks ago where he alluded to an interim device following the Top Hat, but he kind of glossed over that.

I know that the idea of unbolting the remaining stub of the damaged riser has been discussed on TOD. I wondered why that hasn't been done. It was encouraging to hear Adm. Allen mention "bolting" something on in the update on Friday -- though it seemed odd that they were going down that path immediately after BP said they might have the well killed in another two weeks or so.

After searching for info on what this new cap would be, I was shocked to see something much more massive and refined than I expected.

fdoleza in the closed section http://www.theoildrum.com/node/6711#comment-672597 said this:

Sorry fdoleza, but I gotta comment. In fact I laughed out loud because I proposed the SAME THING! I even sent drawings and explained how they could use thermite to ignite the fuel (fire needs 3 things, fuel, heat and oxygen, thermite provides all three). Once lit, they wouldn't need to keep feeding thermite, but could use iron oxide to provide the oxygen component, the natural gas and oil provide the fuel obviously and the sustained combustion provides adequate heat. Worst case they just keep feeding it thermite. That would have solved almost ALL their problems especially saving the Gulf, but of course might have made a mess of the BOP. I suggested it could just slag in, which would help hold it together until the relief wells kicked in. So stupid idea or what?

Interesting thing is they sent me the dear john email, then followed up with 2 emails saying MY idea was something they were ALREADY CONSIDERING! Now I know why, they were also considering YOUR idea! ROTFLMAO :-)

Oh well, I guess we'll join the Rube Goldberg Flare Hall of Fame. At least this is sophisticated. The first flare I built was a pit dug with a dozer, a line made up of drill pipe with sacks of cement sitting on it, and a bucket full of diesel sitting next to the pipe outlet. The device we used to light it was a lit sack carried by a native, dropped in the bucket just before we opened the well up.

did you calculate how much iron oxide is needed?

going back a while, I calc'd the air to burn 5000 bpd.

http://www.theoildrum.com/node/6467#comment-623757

A lot of compressor(s)/energy.

N.B. that calc did NOT include the air to burn the natural gas.

no multiply all by 10x for 50,000 bpd (more likely spillage).

Just hook up floating risers, let the oil/gas rise of its own accord, and torch things at the surface, where convection will supply fast quantities of oxygen "for free".

Didn't calc the Fe304 I'd need, but is different than your method because we wouldn't be using compressed atmosphere, and the ratio isn't 21% oxygen. In fact there are better things than iron oxide (with more O's), but the solution would be similar. No compressor to push the rust down, it will sink quite naturally. Would have been fun to watch actually, I was visualizing an underwater volcano like this:

http://www.youtube.com/watch?v=hmMlspNoZMs

Seems bad, but look how similar it looks to the current oil volcano, and realize that the waste product would largely be CO2 and H20. To protect the BOP, they could have used a chimney on top of the LMRP. Irrelevant now unless EVERYTHING fails, must be why they sent me the "we're already working on our own idea, which happens to be similar to your idea" emails. :)

The flange (aka "Phalange") is OFF.

Looks like more oil/gas, and it is flowing from BOTH the inside the cutoff DP and outside of DP.

It was hard to see, quickly became obscured in oil, but could make out only one DP, not two.

for those that missed it, "nuala" on chat recorded it:

http://www.youtube.com/watch?v=TNv4tfyyvxA

The overshot flange removal tool did the trick,

no need for the flange spitter.

see 08:00 in:

http://bp.concerts.com/gom/sealingcapinstallationoverviewwithkentwells07...

"Overview with Kent Wells 9 July 2010"

I saw it live and it was awesome!

Did notice that the DP appears to be spewing a lighter, yellower flow that the rest of the BOP orifice.

Hope folks in the know can comment on the implications of this.

Well, they are doing what I have been clamoring for, for about a month and a half.

I am glad the opinions that the bolts could not have been untorqued/cut/removed turned out to be too pessimistic.

Good to see the ugly flange gone. Happy to see the leaky cap gone.

Hope that the next phases go well.

What are they doing now? It looks like they're trying to pull out those nipples on top of the flange. They don't want to budge.

Their sketch did not seem to include a space for them, so these got to go.

I did not realize these would stay with the base, once the flange was gone.

The ROV should hold on to the BOP with his left arm and use his more powerful right arm to pull the nipples out.

They're trying a tool that fits over the stub.

Boa #2 is now (4:27 CST) rotating a T handle on top, must be to tighten it to the stub.

(the stubs are for the choke/kill/hydraulic lines outside the riser).

The tool has a cable sling on it, so they can exert some upward force (from a surface wire line or multiple ROVs?)

So you knew before they did what the condition of the BOP was like below the mud-line? Re-writing history are we? Without the kill attempt they had no idea what pressure the BOP could handle. These people have done what some thought was impossible. It's not over, the easy part was removing the old LMR flange. That they could not do without the gamma ray image of the interior of the BOP. This plan has been very logical. What if they had applied torque blindly to the BOP and fractured a broken casing below mud-line? 50K BPD into the GOM, you would have called for heads?

Dimitry, count me among those pessimistic about their odds of pulling out those bolts. On the other hand, it might be that they've taken this month and a half to figure out EXACTLY how to do it right. Maybe upgrading some hydraulics on the ROV's for starters, that kind of thing. We're still not "out of the water" yet on this thing, and who knows, maybe they took more than just a cursory glance at YOUR drawings!

Why don't they just create a collar for the flanges? A hinged collar could be snapped into place in short order; locked and sealed, providing a connection for whatever they would want to attach to the mount.

.

Instead they choose to undo the flange that's there, and reattach a new one, while it's gushing. This will take a loooong time ... before they begin collecting any oil again.

Here's the principle - snap a collar around the flange, with the upper section of the collar having the mount you require for your containment unit. You can get a perfect seal, and you can create various venting options to be used while attaching the containment pipe.

But no - we have to unscrew the top half of the flange, a mile below.

I thought about something like that, but dismissed it because of

* not strong enough in tension

* With the bolts in place, there was very little 'freeboard' to grip

You would need some lead-in taper, but have no room for it.

I think they may need some back-pressure ability from the cap, to help the kill, hence the 'brick outhouse' approach we see now ;)

Trail -- I would bet lunch that any number of new latching arraignments have already been design for the next gen of BOP's. Why don't we have that capability today? My reply to another TODer late last night has a very sad answer:

That's why I have to point a dirty finger at my own industry. BP et al have said they had considered the "worse case scenario". First, a simple fact: BOP fail about half the time. Period...that's the record. Second, wells blow out. Not that often but it does happen. Third, anyone ever develop a plan to deal with a failed BOP in 5,000' of water? No one has jumped up yet saying they did. So what's the obvious WCS: a failed BOP on a blow out in 5,000' of water. Obviously every DW operator knows what the WCS is now. So how many can stand in front of camera today and say they are ready to deal with the WCS? They may do everything human possible to reduce the risk of a blow out. But if it does happen at such a water depth they will be just as screwed as BP. Can’t argue differently.

The operators have no choice but to develop a new system to deal with what is now not an unimaginable event.

Rockman said:

Yup. When drilling offshore, you gotta do everything you can do to avoid a blowout. Gotta cut the odds per well to 1/1000 or so via better training, quality assurance in operations, redundancy of warnings, automatic BOP actuation under certain circumstances, etc., etc. Then you gotta have BOPs that fail less that 1/1000 times they are called upon to act in a blowout situation. That would cut the odds of a blowout and major spill to 1/1,000,000 per well. That oughta be good enough in my book.

Now, how to a failure rate of BOPS from 1/2 to 1/1000? Rudundancy . . . multiple rams . . . multiple BOPS . . . multiple ways of activating the rams . . . inspections . . . certifications . . . testing . . . quality assurance during all phases of construction, installation, and operation.

The industry must do better, or it won't be allowed to operate in the GOM without a real good story as to how it is very unlikely that something like this will never happen again.

There was an interesting segment on NPR this morning about possible implications of the impending development of DW drilling off the coast of Cuba, some of it within 50 miles of the Florida Keys.

Cuba's new deepwater oil well uncomfortably close.

US oil industry folks will be meeting with Cubans to discuss safe drilling practices, but, at the moment, can't bid on any of the work, either the drilling or potential cleanup activity due to the 50 yo embargo against Cuba. Perhaps some of those agitating about the Jones Act will add the eliminating the ineffective embargo to their efforts.

rainy -- If the Cubans can't use US drillers maybe they can get this Russian drill ship I was on a few years ago off the coast of Africa. They pulled the BOP to the surface during my last hitch. They thought they had a bad control pod. Turns out it didn't really matter if the pod was bad. When the pulled the cover off the main control valve guess what? It was empty. No valve...no functioning BOP.

That said, do you support the 6 mo.deepwater hiatus ?

GW -- An arbitrary time frame doesn't work for me. First, what I would like to see didn't have chance of happening. But in my fantasy world I would have dispatched MMS inspectors/consultants to every DW rig within a few days of the blowout. An immediate shutdown and shake down. At the same time a complete review and modification of required safe drilling standards. That wouldn't take more than a week by a select crew of consultants. Most operators already have such outlines in the can (whether they follow them or not). And to make sure there is full compliance station inspectors on the rigs full time. And the operators would pay for this relatively minor expense compared to the cost of a typical DW well. This wouldn't solve the apparent lack of adequate BOP design. But it would hopefully provide an acceptable low level of risk while the next generation of BOP's were designed and deployed...18 months or so.

IMHO such a plan could provide an acceptable risk to drilling the DW while at the same time not adding addition financial suffering to the folks in S. La. In the end that's going to be the choice of the gov't and American people: accept whatever minimum risk by drilling that is perceived or shut down all offshore drilling. As I've stated before I don't consider offshore drilling as right or wrong. It's decision tp be made and I see no value on putting an arbiter timeline on the process. Decide if the process is acceptable with something like the modifications I've suggested or shut it down indefinitely. IMHO not making such a choice right now is just the same as carrying on BAU as it's been done for decades. I also conside taking 3 months after the blow out for the investigation to have their FIRST meeting to be just another obscene waste of time in addressing the situation. There are not hundreds of witnesses to question nor thousands of documents to review. If we have an accurate picture of what went wrong it would not have taking a group of qualified investigators to come up with the clearest answer possible with a few weeks IMHO.

I really think Rockman, that one of the most critical "investigations" after this whole thing is not about what happened in relation to the accident, but what were/are the core capabilities and personnel capacity of the MMS to inspect anything. Who are/were there key operations staff, their backgrounds and core responsibilities. What role if any did these personnel have in permitting not only the BP well but all wells in the last two years?

I think that they must have such a low level of performance expectation about this in the Obama administration, that they may not have wanted to open that can of worms right now since fixing is going to be a full time job and the likelihood of getting these folks out to do a creditable job may be slim and none. Would you want these folks out there doing reviews when they do not have your basic trust? I am not going to give one of my nurses more of a load if she or he has demonstrated a failure to care for these same types of patients before and there have been significant consequences.. Naw, I want to have time to look at all of their performance very critically and perhaps bring in back ups during a period of assessing them and the patients in our charge. They have already blown it, so to speak. Yeah, you can bring in back ups, but selecting them and getting them ready to not only do the certification work but pick up past errors takes some planning. The government has already sustained a major black eye and broken nose. Does it want to have its teeth nocked out as well?

We always want to move fast to correct stuff -- and that is understandable. But when your whole system is suspect, as in the case of the MMS, you have as bad a situation as a failing hospital -- some units and personnel worse than others, but sorting through who goes and stays and where the cuts should be made is very difficult. Do you want to put these people on the units and increase their responsibility or do you want to limit new admissions and just carefully monitor your current initiatives. Having these folks back out "certifying" their own handiwork, just doesnt seem like what I would want to do.

In all seriousness, I am sure prep for housecleaning is happening right now...but below the radar. Poop is going to hit the fan once this well is capped for sure, and I am sure that there will be a lot of both expected and unexpected fall out.

Rockman persuaded me that the 6 month moratorium was wrong. He lays out the issue honestly. The bottom line is we are not prepared to shut down all off-shore, and an arbitrary time line will do nothing to lower risk. Lowering risk is the real goal. On the ohter hand, the more wqe delay, the more economic harm we cause people to suffer, worse than what was caused by the spill for some.

The only problem is that it may take 6 mos to implement Rockamn's alternative. But we should be able to do better than that, and i think Salazar will try to. He is in trouble IMO. In fact, i have been very disappointed in him. He gave an interview in Dec. 2008 before Obama took office, but after Salazar was appointed. Reformiung MMS was supposed to be at the top of the list. He took some preliminary steps, and then just dropped it.

He has done a poor job of taking charge. He botched the moratorium. He botched the clean-up. I think he should be asked to go.

My big question no one has answered directly and no one has asked directly is this:

Of the 34 rigs operating in deepwater, what percentage likely conducted business in a similar manner as BP before the bow-out? Was BP's SOP as reflected in the DWH drilling this well substantially the same as the otehr operators, or was BP a rogue operator?

syn -- Difficult to guess how many other accidents were (are) waiting to happen on the other DW rigs. I mentioned being on a DW rig some years ago when the operator took a chance that was a full magnitude of stupidity worse than what BP did. But they got away with it by shear blind luck. So BP certainly isn't alone in poor SOP's. Having a moratorium of any length seems pointless unless there is a serious effort to radically improve the system. And by improve I don't mean just change. Banning drilling for 6 months is a huge change but zero improvement. Certainly no chance of any spills for sure. But also a 100% chance of the lose of billions in salaries along with 10's of thousands of jobs, loss of billions in federal income and an eventual increase in our balance of trade from the eventual decreased production. OTOH continuing on with BAU isn't a logical move either.

I know my solution might sound overly simplistic. But remember I've done this for 35 years. I've had such greedy idiots put my safety at risk more than once. I know what the bad habits and pressure points are. And we all now know the industry had made no preparation for dealing with a failed BOP in 5,000' of water. Safe drilling protocols are very well known. They don’t need to be improved at all IMHO. They just need to be mandated and enforced. And I have no doubt that, in time, the engineers will greatly improve BOP functionality. I just don't think it should take a couple of years to get there. That's the time frame I anticipate. I have no confidence the political system will allow progress to move much faster.

Rock, I agree with your position on the moratorium. It is solid IMO, more so that the 6 month blanket moratorium. Clearly Judge Feldman and 2 of the 3 judges from the 5th cir. agree with you too, as do the govenors of the affected states.

(That's a position that many liberals would blast me for taking, BTW, WidelyRead.)

On the other hand, I suspect BP wasn't the only one playing loose with best practices and cutting corners, ignoring the regs, etc., out in the deepwater. And you seem to confirm that. So, shutting down all DW for some period made absolutely perfect sense under the circumstances. We do indeed have to do something and given the sorry state of current affairs, there is a lot we can do and do quickly. Lets do it, then, asap, so we don't cause more harm than what we are trying to prevent.

BTW, i came up with a better formulation for answering your question for the poor TO guy on the stand. BP is responsible for all risks originating in the well, TO is responsible for all risks inherent in operating the rig. And where the two intersect, BP has primary responsibility since it has far greater ability to assess how any one decision will affect overall risk given its possession of superior information about all prior decisions and the risk load of each of them.

I suspect the contract spells that out in similar terms. A contract typically will set a standard of care or assignment of risk responsibility more precisely than negligence common law would, and sometimes even contrary to what the common law would assign.

syncro, our lawyer-phobic companions notwithstanding, your presence here enriches my experience of TOD immeasurably. Just wanted you to know.

Respect.

ditto what lotus said, syncro.

I wouldn't say I'm lawyer-phobic, tho personal experience has taught me not to leave my fate entirely to lawyers, as long as I have the power to do something. Abraham Lincoln was supposedly called up to the judge one afternoon for arguing the opposite side of an argument on a different case than one he'd argued earlier that day. I think E L once mentioned here, that he could have argued for both sides on a point of law.

There's a lot of training that goes into being a lawyer in legal reasoning, and that's something I respect, and like to learn from, so thanks to all of the lawyers who share their thoughts here.

I apologize if I have an apparent distrust of lawyers. It comes from the experience of having a judge tell me "you shouldn't be pleading guilty" to a plea bargain, looking at the lawyer I couldn't afford standing next to me, and being satisfied that I got the charge reduced to where I was able to continue with a career. The court appointed lawyer, (who I still had to pay), had told me to plead guilty. It was an expensive, and emotional affair. And a hell of an education on what the system can do to you, if you don't fight back.

Cheers.

motownmutt, don't get me wrong, there are lots and lots of imperfections and injustices in the legal system. It is an imperfest system for sure. And there are some terrible lawyers and judges out there, believe me i know, just like there are some terrible doctors, cops, you name it.

But there is a lot of good in the system to, and it is a system that evolved over thousands of years, literally, and people fought and died for some of the principles embodied in our system of justice. Don't throw the good out with the bad, like everything else. And recognize that no system is going to be prefect.

That's not what I said. I said that, in a very close case, I could write a reasonably argued opinion justifying a decision either way. Knowing a judge's leanings is very important in predicting out how he/she might decide a close case. Judges to some degree are umpires, but, if you know baseball. you know that different umpires have different strike zones. It's that kind of misinterpretation of what I have said, along with the outright ignorant lawyer bashing here, that has cause me to quit commenting except to correct the record when some one misstates what I wrote.

"Do not try to teach a pig to dance. It wastes you time and greatly annoys the pig." —Robert Anson Heinlein

Apologies for mis-quoting you, E L, certainly didn't mean to. And thanks for the clarification, I guess I didn't appreciate the distinction.

I realise that lawyer-bashing typically takes on a more insulting tone than say, geologist-bashing. If more people in all walks of life had to deal with geologists under unpleasant circumstances, (one would think that just dealin' with a geologist might be unpleasant enough in itself, let's just say), maybe that'd be different.

In any case, look at how many TV shows are about lawyers, and courts, and you realise, that the general public finds the profession fascinating.

So, once again, thanks for pointing out my mistake, and the clarification, and hope to see your contributions again.

Best regards.

Thank you.

Hey, cutie, good to see you EL. ;~)

Well thank you very kindly, Lotus. That's mighty nice of you. But of course i am here for selfish reasons. I get tremendous satisfaction from reading and participating in this forum. (And my apologies to those i may irritate.) While i may like the law, even love it sometimes, I like the technical side and working with my hands just as much if not more. The interesction of these two gives both the abstract and the technical to work with. Throw in the political and social issues involved, and it's all pretty darn fascinating.

Syncro, Lotus, et al, I'm not lawyer phobic, just don't trust the 99% who give the rest a bad name. I look at law and say, "There but for the grace of God go I". I was a champion debater in high school and had my choice of freed ride scholarships to famous colleges that happened to be associated with large law schools afterward. You know the ones, they've got that green leafy substance growing on the brick outside. Everyone was shocked when I went a different route, but I thank God I did, at least for me. Virtually 100% of my old team are partners with prestigious firms, and most of them are on their 2nd or 3rd trophy wife by now and no, I would not trade places with any of them, ever. But I'm glad you can work with your hands, in my book that means you're redeemable. We might become friends after all. ;)

BTW, one of my best friends is a lawyer, I tell him he's a One Percenter. Of course he has a Harley... ;)

Hey, WidelyRed, don't forget, i worked in the oil patch for college money just like you. And although the law school i went to is covered in ivy, before i got there, i spent lots of time covered in drilling mud, concrete, grease and fish slime.

P.S.: And of course it is the special expertise and experiences of the other commentors that make TOD so fascinating to read.

I still think the government did about the crappiest job imaginable in trying to argue for their moratorium (whether in the original Feldman stay proceeding or subsequently in district or the 5th circuit). Just horrid; to the point where I suspect it was intentional. That said, I still thought there was a chance the 5th would take Feldman to task over how he applied the standard of review. They did not, as you seemed to predict, my hat is off to you there. Of course, it was all made easier by the utter failure of the government to distinguish the State Farm case, among other errors, but still it is what it is.

bmaz, i basically agree with you. Except I don't think the govt. tried to kill the moratorium by doing it badly on purpose. It all started with how Salazar handled the report, long before the court challenge. That gave Feldman the opening to exercise some discretion, legitimately so.

And then the govt. compounded the error. Instead of cleaning up their act, they doubled down on the fancy footwork BS. They did an emergency appeal of the denial of the stay, but did not seek an emergency expedited hearing on the appeal. What does that tell you? (The judges on the 5th were so impressed they sua sponte expedited the hearing on the appeal during the hearing on the stay motion). The govt. saw political and tactical advanage in stringing the appeal out. The court did not like that at all. And the govt. alsl let out that they would issue another moratorium if the 5th denied their motion. More sneaky fancy footwork trying to game the system. Not the way to go before a court sitting in equity and when you are claiming the need to act quickly due to an emergency.

The 5th cir. judges were as put off by that conduct as was judge feldman over the reprot. And they did not believe the govt. So they exercised their discretion against the govt. too. But don't forget they were ruling on the stay, not the merits, so they did not have to get to Feldman's substantive runing, and never did. They just found that the gov. failed to show irreparable harm if the injunction was not lifted.

The initial mistake was in not foreseeing that they would have to defend the moratorium in a hostile forum most likely, so don't dare give the judge any room to exercise any discretion by doing a sloppy job, and don't piss off the (already hostile) appellate court if you do run into trouble with the trial judge.

edit: removed junk sentence and edited last sent.

It seems to me, that improvements come about by doing, or at least trying, things. We didn't determine that the containment hoods, or top kill, wouldn't work by theorizing about them, we found out by trying. To me that's a big problem with a blanket moratorium, it means people aren't doing or trying anything that will lead to better practices and understanding.

just 2¢

Rockman - If I were prez I'd ask you to take over MMS for 12 months. You name the salary.

Unfortunately, it's gummint and you have too much real knowledge and common sense to be effective in a bureaucratic setting.

Even as an enviro-lib-former semi-hippie I agree that the 6 month thing is not logical. But, the gummint folks don't want to make any more mistakes so - they do nothing on the theory that, if you do nothing you can't make a mistake. Therefore, do nothing as it's a lot harder to prove later that doing nothing was also a mistake.

SEE, 6 months and no accidents! Ain't we the smart guys? !!

I'm a retired engineer and have worked at all levels of gov't as well as a brief stint at attempting to make a living in the "real world". It is positively (and mind meltingly) true that the "do nothing" choice is the first choice of top bureuacrats. That's why I never lasted more than 2-4 years in all but my last incarnation.

Keep up the posts RM, your knowledge, common sense and sense of humor make it easier to put up with the huge amount of "non-sense" that is nbeing generated by this event.

Keep on truckin'

Thanks moose. But I wouldn't need 12 months. Would only take a couple of weeks to draft the new rules for OCS operators. The new rules (along with rigorous enforcement) would scare the hell out of them so bad you would see the safest ops human possible within a week. Heck, most of them are pretty close to being there already. The companies won’t publicize it because it makes them look like they weren’t taking care of business. But I’ve heard what’s going on: they’ve been beating safe drilling ops into all their hands like their lives depend on it. And it does. I know I make it sound simplistic but we all know how to drill as safely as possible. And we all know the dumb moves you can make to screw things up big time. And that’s because most of us have done stupid things and were lucky enough to get away with it. We don’t have to write one new safe drilling procedure. It’s all written down somewhere right now.

I can appreciate the govt feeling like a deer caught in the headlights. But the govt sitting back and doing nothing quick isn't a whole lot difference than how BP got themselves into the current situation: sitting back and doing nothing like retesting the cmt and redoing it. In fact, I hadn't thought of it this way, but the vast majority of screw ups I've seen n the oil patch the last 35 ears didn't come from hands doing the wrong thing but sitting there and not responding as the situation requires. Typical human reaction I suppose: I'm not sure I know what’s going on so I'm not sure what to do...so I don't do anything.

Yes, I see that human reaction often. It has nothing to do with oil exploration and I question if there is a management solution either.

I was in a meeting where I said there was a problem with our software generating a larger than normal number of errors when moving data between systems. Two fellow designers and two testing analysts and my manager gave me the deer eyes look. Finally, my manager said our clients have tested the software and no one is "screaming" to fix anything. We released the software and I started getting 35+ additional text alerts per week because of this problem. After many hours I found the problem. This version of software changed the source folder for data to be encrypted and the OS was mucking up the transfer of file during automatic decryption. Merely by adding one line of code to programmatically decrypt file before transferring, the problem was fixed.

And I have time to write more TOD comments since I get less text pages.

Interesting story brit...thanks. I've always found there was a solution to that non-responsive attitude: accountability. And I don't mean "Opps...sorry messed up there..won't do it again". I mean "Do something stupid and I'll nail your balls to my office door. And then I'll fire you". I've found that this approach works very well with my hands. And my owner finds it works really well with me, too.

One of the main factors that convinces me that a temporary drilling moratorium is necessary is that nearly all personnel and equipment which might be needed to respond to another major spill are now in use responding to BP's disaster. If there were another big spill now, where would they get more boom, or more vessels and personnel to deploy it?

This situation should give the federal government the legal authority to temporarily halt drilling: each driller is required to have a Facility Response Plan, which must (among other things), "identify and ensure availability of resources to remove, to the maximum extent practicable, a worst-case discharge." http://www.epa.gov/oem/content/frps/frpelems.htm

It's just not possible for anyone to ensure availability of resources to respond to another spill until this spill is under control. Each driller in the gulf (and maybe beyond?) should be notified that its Facility Response Plan is, under present circumstances, inadequate, and that they cannot continue operations until they can assure that the resources which they would need to clean up a worst-case spill would actually be available. In other words, once the industry is done helping BP clean up its little mess, we'll let them start drilling again.

That would be the worlds largest vacuum clamp. You didn't show the beveled flanges for the o-ring. These are flat flanges.

Ok. You leave the flanges in place. Then you put a collar over them. This gains you exactly what? You now have a stub sticking out of a flange with a collar around it. Still no place to make a good connection.

Use your imagination. The photo just shows the principle of the locking flange - you can design a longer "neck" with a taper that encapsulates the remains of the cut riser, and that ends in a perfectly sealing receptacle for docking your new containment riser.

As Rockman states above - the industry hasn't thought this through, going with "will never happen and hoping for the best" as their plan B.

This is just one possibility, but I'm amazed I didn't see something like that being snapped into place once they sheared the riser, instead of wasting days with the diamond chain saw that went nowhere. The whole point of using the diamond chain was to "get as even a seal as possible." But that's one-dimensional thinking - they could get a perfect seal with a hinged neck collar as described here.

The mechanical engineers I used to work with would say they have no way to model the stresses under bending loads or tension of such a thing, while standard ISO flange connections are well specified for all conditions. Without that model information and industry experience they can't sign off on the design, especially when failure is likely to put the environment or lives at risk.

You just don't throw away a design paradigm that has been in use for over a hundred years in favor of an off-the cuff idea.

Is simulation software used as an acceptable method to verify designs that are difficult to test with real world conditions?

I understand there are many reasons why simulation software may be impractical or provide a false sense of security so please don't interpret my question to mean I'm an advocate.

Yes, your right they are all stupid. So how exactly is your magic clamp better then what has been done?

Up until yesterday they have been processing all the oil they could. I think of these people as heros, not in the least bit (pun intended) stupid. Amazing you think your worlds largest vacuum clamp is better than a LMRP, really ........................ really.

Good work Trailman. I was thinking of something similar, but didn't know where to look. I would add one improvement - the collar should have a carefully designed breaking force, so if an attached riser is falling, it will break loose at a controlled point, and not endanger the BOP. These collars should be used in all new designs, on all flanges that might need an emergency disconnect.

Does anyone know how the flange puller gripped the flange? They lowered it over the flange, then gave it a good tug, and the upper flange came away. Was it some sort of suction device? I have looked at the Kent Wells pdf and they don't explain. They show a flange splitting tool which was never used.

Video of flange being removed: http://www.youtube.com/watch?v=TNv4tfyyvxA