BP's Deepwater Oil Spill - Windows Can be Short, a Delay, and a Digression - and Open Thread

Posted by Heading Out on July 31, 2010 - 10:45am

This thread is being closed. Please comment on http://www.theoildrum.com/node/6800.

The windows that allow significant work on the oil spill in the Gulf are likely to become rarer and more valuable opportunities as the hurricane season, forecast to be stronger than average, moves towards its mid-point. While the starting signals for a hurricane don’t begin by looking that ominous, and those initial signals don’t always grow into a significant threat, as Bonnie just demonstrated, the last thing that can be afforded in this disaster is complacency. And so, as plans are laid out for a methodical approach to sealing the Deepwater well, so we see two more possible threats appear on the horizon.

There is now a delay in both the relief well and the static kill because of some settlement in the relief well when work was temporarily halted for Bonnie. The Oil & Gas Journal write up says:

BP PLC is cleaning some debris from the bottom of the first relief well being drilled to intercept the Macondo well, and the “static kill” probably will be delayed until Aug. 3, National Incident Commander and retired US Coast Guard Adm. Thad Allen said.

The static kill initially was planned for Aug. 2 although Allen had suggested it possibly could happen sooner than that depending upon how fast the Development Driller III semisubmersible could run its final casing. On July 30, Allen said cleaning out the debris would delay the static kill for 24-36 hr.

“Some of the sediment around the side walls just settled in on itself,” Allen said. “It’s not a huge problem, but it has to be removed before we put the casing down.”

There is now some curiosity on where all the supposedly spilled oil went (some of which might be explained by the ramp up in flow as the BOP eroded so that in the earlier stages of the disaster there might have been significantly less oil escaping into the Gulf than the flow levels seen at the time of the capping), but there is not a lot of new information. And so, with your indulgence, a little digression.

One of the reasons that I write is to help explain why things are being done the way that they are, and how technical processes now being used to produce fossil fuels came to happen. Early in my experience of doing this I discovered that you can really help ease a descriptive explanation by using the right illustration. As a result my classroom type lectures are now made up with many more illustrations than they are with word-intensive Power Point slides. Yet, to be honest, that knowledge came, in part, from the memories of my childhood, and my still fond recollections of reading historical fiction where, if I was lucky, the story would be illustrated with four or five illustrations of the action. (And it was the presence of those illustrations that often drove the selection of the books that I borrowed from the local library).

Many of these early stories were illustrated by N.C. Wyeth and it was his teacher, Howard Pyle, who noted that “Pictures are highly important for children, well worth a thousand words, especially if they don’t understand 800 of them. First graders know 6,000 words, adults 30,000 or more.” This remains true with older audiences where the technologies being discussed are a little arcane, where the artisans of this new era use words that are not in the common lexicon.

And so, having the chance at the end of the family vacation, today we dropped by the Brandywine River Museum, where for the second time in the last month we spent almost from opening to closing time, wandering around the galleries. (The other was the Peabody Essex in Salem, a more conventional museum and thus a totally different experience).

The Wyeths are a legend in American art, with the major focus being on Andrew and Jamie, and indeed the tour we lucked into joining and given by Andrew’s grand-daughter Victoria focused very much on those two with wonderful, and unique insights. (We went out to the Kuerner Farm that Andrew painted, and also up to the House and Studio that N.C. built; both of which were well worthwhile, and seeing the “backset” with some of the props held a fascination that could have used a lot more time than we had available).

Having stayed across the street in the Brandywine River Hotel, and eaten dinners at the two immediately local restaurants, we have had a really enjoyable break, and one that I would really recommend.

The art of illustration has, to a large extent, been lost over the last half-century even though there are programs such as Poser, Bryce and Vue; tools that folks such as I (who needs two rulers, a computer and a drawing table to create a straight line) can use to make our less mechanical ideas visual. (I use Strata for my mine models.)

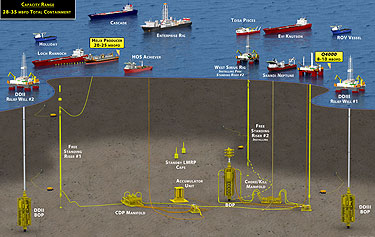

It is no less critical now than it was in Howard Pyle and N.C.’s days that folk understand what the words are trying to say. Witness that Kent Wells uses illustrations and animations to help explain the complexities of the processes being planned at the Gulf.

Our family argue about ranking the members of the Wyeth family and their work, but the legacy of illustration that Howard Pyle and his students grew, and which N.C. Wyeth came to be a master of, brought his work and the pleasure of viewing it to more folk than I suspect have been influenced by his later family. Wyeth and the critics of his time downplayed the role of the illustrator, but it is an honorable and indeed vital need that we, who communicate information, have and make use of.

Sadly I don’t think that nearly enough technical teams across the board of technical application take the trouble to phrase their talks with illustrations, so that those outside of the “select few” that are masters of the technical terms can follow the discussion. And yet I should admit, on the other side there are also those who can present, with a suitably generated illustration a promise of a technical future that is not really born out by the technical details of the technology that is being sold.

But illustration can be a great help to imagination, and so I take my hat off to the masters who made it so, and if you’re in the neighborhood . . . . .

Prof. Goose's comment:

Welcome--modified 21 JUL 2010

Thanks for your donations; they have been helpful--be assured that every penny of that will go toward Institute for the Study of Energy and Our Future/The Oil Drum costs, especially towards the servers, etc.

1. The Oil Drum is a special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity is more than welcome.) We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes. Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address. It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up. Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries. That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much. You can find the donate button in the top left hand corner of the main page.

4. If you would like to catch up with what's been going on in the last few days, our IRC channel has been maintaining a FAQ, which is an open source log full of information, links, and such. Check it out: http://docs.google.com/View?id=dff7zmqz_7c6rdwsc9 . Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum (google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum) or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

5. Don't be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. That will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable.

Nungesser calls Bob Dudley and Thad Allen liars:

http://www.youtube.com/watch?v=Fxbz-4FrhKM&feature=player_embedded

I guess Nungesser wants guys with Hazmat suits walking around looking for oil to clean up.

I think Tony Hayward's replacement also said something about scaling back clean up operations and Hazmat suits on the beaches, of course Nungesser's issue seems to be more about the wetlands ...

In the past 24 hours, Alabama lifted its swimming advisory, Mississippi opened MS Sound to commercial and recreational fishing. At the same time Jindal and Nungesser are Mau-Mauing the massive oil threat, the state of Louisiana opened waters east of the river to fishing and oystering.

Jindal and Nungesser are insufferable, I much prefer Dudley's nothing to see here move along approach, plays much better with a southern accent than Tony's upper crust dialect. Great news about the oystering too, one wonders if the media, Jindal, the administration and federal agencies over reacted by closing those three areas to begin with:

Escambia County (Pensacola area) Gulf waters were also opened for fishing today.

http://www.pnj.com/article/20100731/NEWS01/100731001/Oil-spill-Saltwater...

The water hear has been intensely clear here for a while, no rip currents etc., and tons of fish, crab, rays, dolphins while I was snorkeling today. These are from today, and I am going to get an camera to use underwater for those photos

And your toes are in there!!!!!!!!!!!

plus a banana.

Nice pics, wish our beaches were so clear. You have to go out to the islands for that, the town beaches are between rivers so the water looks terrible along the edge but as you go out it is really clear.

NAOM

LOL~The crabs don't bother me in the least, just happy for a calm day so I could snorkel and see how much marine life was there today (more than my toes were in there, I snorkeled for 2 hrs). I'm going to get the bananas when I get the camera........promise!

Our water sans those few days when we had tons of tar balls and sea grass, algea is always like that, looks moer like a pool........and we are on an Island so maybe thats one reason it's so clean, the sound is not to bay and clearer than the bay.

Nearly full beach today. I made my pictures clickable.

Can't tell you how much I appreciate this post, HO, how much I envy the day y'all had with the Wyeths, and how loud an AMEN I'm hollering. ExCELSior!

Just the other day, I was whining for Kent Wells' animator to go rescue an NYT story on the GoM's salt substructures (really, to rescue me from ignorant confusion).

Anyhow, the verbal/visual cross-fertilization available here is one of my favorite features of TOD, so thanks to you and everyone else who contributes to it. (I'd drop a deep curtsy 'cept that it might mean missing the next 10 minutes while I'm on the flo').

FOR ALL

At the end of the previous thread: Relief well collapses. The well bore did not collapse. Even in the captioned video they don’t say that. There was “debris” in the bottom 40’ of the hole. Debris is a very loaded word. It was sand and mud. When you POOH there is always a certain amount of “sloughing“ or as we call it “fill up“. It’s often caused by pulling the drill pipe out of the hole: it scrapes the sides and knocks some of the rock loose. The standard procedure when going back to bottom is to “ream” the last 100’ or so to clean out the fill. It wouldn't take the estimated 24 hours to just clean out the fill either. It’s also standard procedure to circulate the mud around a number of times to make sure it’s uniform and all the fill has been removed. The round trip time for mud at this depth would be around 6-8 hours.

A side educational note since we talking mud cleaning: As the mud gets back to the surface it passes thru the “shakers”: large vibrating horizontal screen panels that separate the cuttings from the mud. Typically one of the loudest spots on a rig. I’ve spent thousands of hours at the shaker watching returns. Double ear protection is highly recommended.

Thanks for confirming what I figured, Rockman. Isn't that rock near the reservoir apt to be pretty honeycomb-like, so not hard to jostle into sand with the DP's vibrations and whatnot?

lotus -- The sandstone reservoirs might have a tendency to "wash out". But if they have the mud chemistry right the shales will be pretty stable. But if the mud wizards do their magic right even the sands will stay put. I’ve drilled completely unconsolidated sands at 2.000’ with almost no wash out. The trick is to keep the "water loss” down. WL is the tendency for the water in the mud to separate from the clay particles. Just takes the right chemicals. With a low WL there’s very little wetting action of the sand. Imagine a pile of sand on a plate with a nice 36 degree slope...nice and stable. Now slowly lower into a fish tank…woosh…no more sand pile.

The RW depth should be in tight shale section, not sand.

Shale is usually pretty "tight". It has low permeability. But there's a good chance they have little tiny silts and sand layered into the "shale section". Shale has a tendency to swell and fall out. I've seen a lot more washed out hole in shale and silty shale than in sand, that's for sure. No matter how soft the sand is, or high a perm, the shale caves in a lot more. If they run a caliper log, I'll bet one BP ADR the washouts will be in the shale. And because the intercept is going to be above the pay, I bet they're drilling shale right now.

When I saw that post I (1) got nervous, (2) thought about it, and (3) decided it was a normal part of the process.

Thanks for the confirmation. A random thought: wouldn't it be nice to have "shakers" to separate doom'n'gloom from information? A second thought: guess that's what TOD is for.

"shakers" to separate doom'n'gloom from information ... guess that's what TOD is for

Bingo (and we glad to have it)!

You got to blame Allen for this gloom and doom. " we had about 40 feet where it just settled in on it's self..........."

http://www.youtube.com/watch?v=HZPC_QtKXOc&feature=player_embedded

i guess he sounds the way I would sound if I were trying to play at being admiral for a couple of months. "Enemy craft downwind, pull out of hole and fill those suckers with mud, boys!"

>>"shakers" to separate doom'n'gloom from information<<

I would have thought it would be better to have "shakers" to seperate facts from fiction. It seems to me that just because a particular situation is gloomy doesn't mean it's not a fact. History is full of bad things happening, in fact.

I'm not saying that we should buy into all the doom and gloom associated with this oil spill. I am merely pointing out that just because some of the information isn't all sunshine and lollipops that doesn't make it invalid.

IMO Thanks.

Most folks around here are predicting two years of economic gloom, intertwined with a bureaucratic nightmare of a compensation plan. All is not doom however, we are predicting a record Shrimp Festival in October. Perhaps a by product of pre-spill efforts by the media to highlight the fact that most of the seafood served at the festival was from overseas. Go figure, the media was trying to make the vendors look bad and instead the media may have saved them.

In addition to economic trends, here's another measure of community resilience/corrosion (highlighted in Riki Ott's two books on the Exxon Valdez oil spill).

Keep a running list (with dates) of lawsuits filed, then distinguish those against primary vs. secondary parties. I noticed one of the latter in gulf coast papers last week.

I'm not arguing that lawsuits are inherently bad. Actually I think having recourse to settle serious differences is fundamentally good. But when a citizen sues the local gov't or one interest group sues another (in this case, over oil spill dynamics) that shows that there are serious differences and that a link in community trust has broken. If new lawsuits tail off pretty quickly, that would be good news.

And on a related subject-- Feinberg: ‘There’s gotta be a better way’ than litigation

http://www.sunherald.com/2010/07/30/2371672/feinberg-theres-gotta-be-a-b...

Well the fact that most of the seafood is from overseas would keep me from every going there and spending any money on seafood.

Why would anyone travel to a seafood festival where the food was some imported crap?

My wife was making crawfish stuffing for Thanksgiving dinner a few years back and I told her to make sure it wasn't imported crawfish (processed tails). She got back from the grocery with two 1 pound bags of crawfish tails sold under the name "Boudreaux's". Fine print on the back of the package said "product of China". She took them back to the store and raised hell about it.

She is Canadian and saw the name "Boudreaux's" and figured "Cajun".

Always watch the fine print.

Point re: facts/fiction taken, and agreed with. Doom and gloom rolled off my fingertips primarily because I have a lot of folks around me who are specialists in that particular kind of fiction, and it does tend to wear.

And yes, I surely would make a distinction between difficult realities and "doom & gloom", but I still was on my first cup of coffee and not into distinctions yet. ;)

Part (1) is completely normal. What's sad is how many people seem to be unable to do parts (2) and (3) and let go of their fears.

Wells clarified Allen's comments yesterday afternoon during his own briefing. (Wells almost always schedules his briefings later than Allen's, even if it means changing his time slot if Allen moves his - gives Wells a chance to answer any questions raised by something Allen said.)

Rockman, did you ever see chucks of rubber sifted out by the shaker, as reported by one of the survivor witnesses?

I think it was Mike Williams who was present when an M.I. Swako (sp?) "mud inspector" brought two hands full of these little apparently rubber chunks to some Transocean manager (could have been Mark Hay?), a day or so prior to the blowout, and he was told, "Don't worry about it." To my knowledge, no one else but Mike Williams has told the "rubber chunks" story. I have watched MOST of the Marine Board testimony, but have not, perhaps, seen it all.

Later: The story as I remember it from the hearings:

When the first negative test was unsuccessful, somebody increased the pressure on the annular from its normal 1500 psi up to 1900 psi. Then they did the test again, and this subsequent negative test resulted in no mud return and was deemed successful. (Some professorial "expert" on data examination has said there were actually four negative tests, but I think that might be a difference in his and the crew's terminology.) Anyway, as Chris Pleasant (sub-sea guy} left the drill floor for the last time, which was after the "successful" negative test, he noticed the annular pressure was still set at 1900psi, and he RETURNED the pressure setting to its normal 1500psi. (You can see, when he says that, that he considered it to be a very normal, logical, and right thing to do.) He went to his office to do some paperwork or computer entries. Not so long after that, SWOOSH...BOOM, BAM, and subsequent Hell, fire, and maybe even some brimstone (or the liquid equivalent thereof)!

I seem to be the only person who has wondered upon this little chain of events and have, therefore (with an abundance of ignorance and a little bit of knowledge), tried hard to assume it is meaningless.

Is it?

You must be claravoiant. At least now I am not alone in my thinking.

One question remains for me. Would reducing the pressure on a compromised annular by 400psi allow enough supersaturated fluid to move up the riser to cause the blowout?

[edit to correct term]

Era - See all kinds of stuff come across the shakers: rubber, cmt, wood, lots of pieces of steel worn of the csg, an occasional pebbles, big chunks of clay we call “gumbo”. When the cuttings come off of the shaker they fall into a trap so you can see hours worth before you empty the traps. Mud engineer and the derrick had usually log unusual stuff the pull out of the trap.

To be very blunt I don’t tend to believe any numbers someone else cooks with any absolute faith: the equipment could be recording wrong, the hand might not know how to do the measurement correctly, he might know what he’s doing but is prejudiced in his interpretation/methodology for any number of reasons. As a rule I like two or three independent bits of info to base a decision. And then I’ll doubt my own conclusion and keep a close eye on any indications that I could be wrong. Sometimes you get it wrong and there’s not a big price to pay. But sometimes you don’t and someone will pay with a finger, a leg or a life. Arrogance causes more problems than high pressured reservoirs.

BTW: In 35 years I've seen very little data on a drill rig I would call meaningless. Especially the lies.

Rockman is as usual in my small opionion exactly right.

Everything has meaning, its how you interpret it that counts.

When you consider the size of a 15k psi annular preventer, losing some rubber is normal. That's why we do BOP tests. OTOH, if we don't test the BOPs properly, we have a huge problem.

Many of the BOP tests I have been involved with over the years were cut to 2 mins or so per test, rather than the 10 mins mandated. Frankly I have never seen any difference. If the pressure holds perfectly flat for 2 mins, you have a good test. If you can't get a perfectly flat reading over x minutes, you tweak it a bit, and eventually call it a bad test.

This is one of the reasons I have a bit of sympathy over the interpretation of the faulty negative (inflow) test. But I have no sympathy for the really crappy reading of the final result. That killed people. We don't do that.

JTF

I wondered about Pleasants admission as well, and like you, I discounted it, because surely, if it is important, it would be a common topic of discussion on the net and in the papers.

If it turns out to be important, I give up on the internet as a source of news. It's easier to get bad information from the tube.

Someone said that gum was still made from tree sap. I saw synthetics being used on TV.

The exact composition of gum bases is usually a trade secret, but generally consists of ingredients from the following categories:

* Elastomers: provide the elasticity or bounce, and can be natural latexes (eg. couma macrocarpa (also called leche caspi or sorva), loquat (also called nispero), tunu, jelutong, or chicle which is still commercially produced), or synthetic rubbers (eg. styrene-butadiene rubber, butyl rubber, polyisobutylene).

* Resins: provide a cohesive body or strength, and are most often glycerol esters of gum, terpene resins, and/or polyvinyl acetate.

* Waxes: act as softening agents and are most usually paraffin or microcrystalline wax.

* Fats: behave as plasticizers and mainly come from hydrogenated vegetable oils.

* Emulsifiers: help to hydrate, the most common being lecithin or glycerol monostearate.

* Fillers: impart texture and the most commonly used are calcium carbonate or talc.

* Antioxidants: protect from oxidation and extend shelf-life; the most common type is BHT.

Old gum bases were based on either natural elastomers such as latexes, vegetable gums like chicle, spruce gum, and mastic gum, or alternatively on waxes, eg. paraffin wax and beeswax, but today synthetic rubbers are preferred.

Glee gum, available at my local food co-op, is still all natural chicle-based gum.

Now, someone please find me some ice cream WITHOUT gum additives, please, besides stratospherically-priced Haagen-Das (Even Blue Bell is chock full of gum additives, sorry to say).

Here you go - Strauss ice cream. I had some of their yummy vanilla bean ice cream on top of a slice of marionberry pie last night.

But I don't think it is available outside of California.

(I gave up on Haagen-Das when they switched to too sweet HFCS.)

Synthetic rubbers in gum = styrene-butadiene rubber. You can chew on that for a good long time. Not my favorite thing to put in my mouth.

As for gum in ice cream that's usually a vegetable material, typically guar gum with is a polysaccharide extracted from the endosperm of the seeds of the guar plant. Guar is a legume annual grown mostly for cattle feed in India and Pakistan.

It's used in ice cream mostly to promote smaller ice crystal size making the ice cream taste smoother.

It's actually probably better for you than the super high fat levels needed to get the same effect without guar gum.

I like guar gum in ice cream...especially Blue Bell. Without it the ice cream also seems to melt much quicker. Real home-made ice cream is nice, but you can't eat much before it melts. oth, maybe a good thing.

Blue Bell holds the status of an addictive drug in our house.

Here on the left coast the Korean restaurants drop a stick of Melon flavored gum on the bill tray. We call it WiFi Gum because if you start chewing it at the door, the flavor is all gone by the time you've walked out of WiFi range.

Liggi Moi's? Not sure about the Hangul spelling

http://www.bonanzle.com/booths/OneOfAKind/items/Red_Li_Hing_Mui_Plum_Haw...

Rice paper

Hard candies

Korean gum does suck. A Korean kid wants Hubba Bubba or Double Bubble.

Candy is for children in Korea. Most poor and/or rural adults have bad teeth. The adults prefer dried cuttlefish, rice cakes, ho-ho buns, snails, dried minnows, some chemical orange Play-Doh consistency Pixy Stick candy that I have only seen in Korea (sometimes they have grape), sweet goat milk (awesome), and Fido on a stick (no, I tsk now too but when in Seoul).

TFHG:

Reading this post and recalling the mix of posts you have made before, on a wide variety of subjects, I could not help asking myself, "with how many subjects is this guy conversant?"

It occurred to me, however, that it might be easier to list the number of subjects with which you are not conversant.

That immediately set me off on issues of possible obsessive compulsive disorder, insomnia, hyperthyroidism, efficacy of tinfoil hats (I'm pretty sure it's not just the "guy" part), some secret diet (I presume you're not drinking GOM water or eating GOM food), time travel, some method of slowing down time to increase productivity, etc., etc., and/or some combination of those.

I don't expect you to reveal what are probably trade secrets, but give us a break guy! Give us a chance to at least catch our breath, even if we can't keep up with you!

If you go to my blog http://gcn01.com you would see that TinFoilHatGuy is 'based on a real person' but is also a composite of folks I know that sometimes contribute with advice and stories, but leave the posting to me. I fully disclose that any stories can be fictional or based upon others and I miss stuff all the time. Just post and call me out. Click the links I provide and keep me honest. But yes, it does seem have I had an inordinate amount of weird crap happen in my life, even by my family's standard. As for the Korean part, I was born I Seoul, native US by way of Jus Sanguinis. I moved here when I was ten, so post away on the old time Korea questions.

And, just for grins:

Asphaltum, a black gooey substance that is common to wash up on Texas beaches, had a number of uses. Aside from use as a liner for pottery, the black tar served as body paint and a form of chaw. Karankawa people were said to frequently sit cross-legged on grass mats and chew balls of asphaltum...

Who knew?

http://www.fishgame.com/print/print.aspx?ArticleID=4276

Big blocks have been collected from the Dead Sea since Biblical times. It was quite valuable then. Used for caulking ships and lots of other stuff. That came from an oil spill there that happened before any people were around. Must have been quite a mess!

Here is what made me nervous yesterday.

Allen says this....." we had about 40 feet where it just settled in on it's self...........

Then he goes on to say............

Thad Allen: Let me go to the risk associated with this and how we’re mitigating the risk. This procedure is going to take place in three parts. We are very near the Maconda well with the relief well in fact, the end of the relief well bore right now is approximately four and a half from Maconda well and about 100 feet above where we intend to intercept it.

Read more: http://www.miamiherald.com/2010/07/30/1754347_p4/transcript-of-adm-thad-...

4 and a half feet is really close to have walls settling in.

I am glad we have Rockman to explain it and I think Allen and Wells both could have described this a little better and pointed out they had 2k feet of uncased hole they were dealing with when it came to the 40 foot of debris.

Quantum, they should be drilling that hole using an 8 1/2 inch bit, or something close to it. When we drill that size hole, and we run a caliper log, we seldom see anything bigger than say 12 inches diameter. In this type of situation, the walls will cave in a bit, and the well will end up with sections which are wider than the hole by a few inches. To wash out 4 feet of hole wall it takes some pretty exotic work. I have heard of wells with very large washouts, so large they lost the original hole and started drilling a new one below the washed out section. But that's pretty rare. It usually happens when a rookie mud engineer doesn't know how to mix the stuff.

Found a very simplified video of a bottom kill of a flowing well. I say again very simplified but interesting.

http://www.youtube.com/watch?v=UHnWefOI0aw&feature=related

edit: spelling

Thanks, Doug. Helpful and cute too -- "Hi Mom!"

Nice job - bet they had fun putting that together, even including the little white top hat.

Another example of the value of visual presentations.

Thanks for posting the link LA Doug. (It's taken me a while to switch from automatically thinking LA = Los Angeles.)

Not to mention Lower Alabama.

Wow, that video is absolutely brilliant !

Well done those LSU students.

Keep it simple, stupid. Have to say what they have produced seems in the spirit of Heading Out's OP.

What with Bob Dudley in town yesterday, the Sun Herald has all manner of spill coverage from various angles: scroll down and see what interests you.

Broken Link?

Sure looks like a broken link to me.

Sun Herald

Ratz, some garbage code sneaked in there. Sorry, folks, and thanks for the fix, rainy.

Let's see how this one works: Feinberg wins friends in Orange Beach.

My former employer, the largest restaurateur in the area, practices Judaism. Feinberg is going to get a fair chance to do a good job. Folks in this area sort of respond to the stereotypical Jewish work ethic around here. There is a noticeable Jewish condo owner population down here too. Again, folks around here tend to respect them as investors in our community. He had friends before he showed up.

This brings up an interesting question. Are positive stereotypes a bad thing? Say I had to pick 3 guys from the NBA to play pickup for me. If I only knew skin color, would I be wrong to pick the dark skin folks like me? It is a very hypothetical situation, but if done with respect and in deference to tradition, is it wrong to prefer a Swiss watchmaker? Where is the line? I am a minority and I am scared that I will say or write the wrong thing whenever I think about or discuss such things. If you saw me you would pretty much know I cannot really claim full membership to any group. Can any of us?

TinFoil

Edit: Here on the street he is already being called 'the Jewish 9/11 compensation guy'. It is said as a very high compliment because folks around here remember 9/11. NYPD & FDNY 9/11 also get the same love.

Edit again: The importance of family is the same too. Call me bigoted, but to me a very positive.

Well, TF, you're there and I'm not, but seems to me that folks respond to him as they do because he's quickly recognizable as a Good Guy, never mind his religion. (I know some 9/11 survivors disagreed, but they were apparently a small minority. Nobody pleases everybody.)

TFHG, I was going to answer with a *Yawn* but that would have been disrespectful and that is genuinely the last thing I would want to do (so why did I say it? Stream of Consciousness, or something).

I've followed your posts for a long while and have genuine, full-on respect for the things you are doing and saying here, but I have to tell you with all due respect that this post is a bit below par.

The obvious answer is Yes, you would be wrong to pick the dark skin folks like you. And yes, it is wrong to prefer a Swiss watchmaker.

Specialisation is a result of the Capitalist system's need to break down the industrial and hence the global workforce into units-of-specialisation. The Swiss watchmaker is a benign example. The extreme of the phenomenon was slavery, and in the opinion of many people (my own included) the world is still full of slaves who specialise in mineral extraction or plumbing or accountancy or whatever you will.

We are all PEOPLE. We are all born the same. We are all capable of being good at the things we're good at.

The great John Ruskin (19th Century English polymath) said it all when he said:-

It may be proved with much certainty, that God intends no man to live in this world without working: but it seems to me no less evident that He intends every man to be happy in his work. It is written, "in the sweat of they brow," but it was never written, "in the breaking of thine heart" thou shalt eat bread.

Perhaps I should have said Swiss watch? Does then the move from the personal to the inanimate change things. A Jewish made Desert Eagle can be preferred, just do not call it a Jewish gun but an Israeli gun? Actually that sounds reasonable. So preferring things is OK, preferring folks is not if you use race, color, creed... Fair enough, but is even calling it an Israeli gun fair? Who would you drink a Coke after out of the same glass. Your wife? Your kids? The old church lady? What about fondue? I bring out for discussion and it is tough not to offend others. I think I have offended five people in the last 2 days and those are the ones I know about. The local blogs mention race at least 20% of the time. There is more positive mentioned than negative, still is that a good thing?

Example: http://blog.al.com/wire/2010/07/protesters_target_selma_counci.html

#3 Blog item on al.com today

TFHG, all of them. I'm a bit lost. You haven't offended me in any way whatsoever. I wasn't talking about race, I was talking about Capitalism and its insidious mantra of Specialisation, which I think is an evil construct. No space left for self development. No space left to take a chisel and help build a cathedral.

I'm definitely on your side, sorry if I'm not making myself clear.

Specialization - Money, preservation of food, farming, Mesopotamia (3000 B.C.)

Capitalism - Industrialization, colonization, expansionism, Disraeli, Marx, Engels [helped coin the term and studied it, but promoted communism](19th century AD)

Some of the founding works on capitalism - "A later use of the term capitalism to describe the production system was by the German economist Werner Sombart, in his 1902 book The Jews and Modern Capitalism (Die Juden und das Wirtschaftsleben). Sombart's close friend and colleague, Max Weber, also used capitalism in his 1904 book The Protestant Ethic and the Spirit of Capitalism (Die protestantische Ethik und der Geist des Kapitalismus)."

From: http://en.wikipedia.org/wiki/Capitalism

Told you it wasn't just me.

Edit : Ok logical trap time. Would you drink the Coke after Steve Nash? Rasheed Wallace? Why or why not?

Logical trap? Yup, I'm trapped. Never heard of Steve Nash or Rasheed Wallace (I'm in UK) but I Googled them and found them to be basketball players (not even sure what basketball is). You have completely baffled me with referenes to Werner Sombart, Max Weber, et al.

I was inspecting an absorption chiller today, uses hydrogen and ammonia, apparently. Not sure how it works, but it has something to do with the Spirit of Capitalism. Can you help? (Only joking.)

Best Wishes, PT.

I may be bigoted again, but if it was the offseason, no way I would drink 'Sheed's Coke because:

1. It may have something in it that would occupy me for two days.

2. He might get mad and kill me. I really think Sheed is as angry and conflicted IRL as he is on the basketball court and how he is portrayed in the media. Nash is a Canadian gentleman. I would drink after Nash.

Interesting. Rasheed Wallace and Ray Lewis just intimidate folks yet have a soft side too. I still would not want to make either mad at me. You have Graeme Souness.

Thanks. Got my dawg looking for him now. Got my shotgun handy, just in case. There's nothing more viscious than a cornered code.

R

Hee! Good dawg. Catahoula Cur?

Having read all the recent discussion on how the kill(s) may go, I'm still not clear on quite how the mud is supposed to flow. Can someone clarify this for me?

I get that we don't know the exact flow path, because we don't know the exact relationship between the annulus, the production string, possible casing or joint compromises at various depths. But I think my question is more basic.

Let's take the top-kill first: Ok, you pump in some relatively heavy mud. Assuming the well is capped, something necessarily has to move down the bore (or something else has to give -- let's hope not).

1: Ideally, the heavy mud stays at the top, and pushes the oil back down. If you could just keep doing that, you end up with a bore full of mud, and you've got a kill. Great. This is what I imagine "bullheading" means.

But the mud is heavier; so several posts have suggested that it will sink through the oil to the bottom. I picture this as a fairly slow diffusion process, but I have no idea *how* slow. If there's gas at the top, I imagine the gas or gas/oil mix is less viscous than straight oil, and perhaps the mud would sink faster? Is this sinking through the oil, slow enough that bullheading works pretty much as if the mud stayed completely on top?

Several posts have suggested that the mud will sink to "the bottom" and as you add more and more mud, you'll get the kill "bottom up". But that makes no sense to me -- the bottom of the bore (TD) is not "magic". Oil flows into it from the reservoir, so the mud would similarly flow out and sink to the bottom on the *reservoir*, where it's useless. Right?

So is what's really going on, that the flow of mud through oil is slow enough that you can finish the kill and have time to cement, even though if you just let it sit for long enough without cementing, the mud would eventually ooze into the reservoir and restore the original problem? That would make sense to me.

Or am I completely missing something fundamental here?

Switching to thinking about the bottom kill, it seems like the problem is similar: as you force mud in, why should it move up and displace the oil, rather than down and into the reservoir? Now if you pump mud into the annulus, and the only communication from the annulus to the production string is up high, and the only communication to the reservoir itself is the end of the production string, then I get the dynamics; but how likely are all of those things to be true?

It would seem much simpler if for the bottom kill, you vent oil from the wellhead at about the same rate you're adding mud at the bottom. Is that sometimes done, and if so what's it called, and there a reason that wouldn't be done here?

I have this feeling I'm missing something basic, but I still don't see it. Can somebody relieve my ignorance?

I can't relieve you, but I would like to second your plea.

I have made several stabs at trying to clarify these issues, but, apparently, the way I pose the questions misses the mark. I thought I had the answer in the "kill pill" concept which floated around here for quite a while (then seemed to disappear) without ever being defined (that I could discover) then I thought I had it solved when I discovered the concept of spacers, but that seemed to get shot down, so i'm just as puzzled as you are.

Like you, in situations like this I'm usually where I am because I'm missing something simple, but in this case the key has continued to elude me.

So thanks for asking it more coherently than I appear to have done.

David, this is my opinion only.

Forget kill pills, forget spacers, forget 'lubricate then bleed'.

Sounds like they are going to do an injection test first to establish frac gradient. No idea what fluid they are going to use for the injection pressure test, could be water, could be oil, could be mud. I would use water in the absence of any other information to guide that decision.

I doubt they are going to use any sophisticated spacers to separate the oil in the well from the kill fluid. Too much potential damage once that kill fluid hits the formation at the bottom of the hole. We do NOT want to cause more damage to the formation we are injecting to than absolutely necessary.

My estimate (better than a guess, but not by much) is that they will go straight to kill mud with no spacer. Pump until the well is dead, or you run out of mud, all the while comparing actual results to forecast results.

Then if we have a stable well that is holding the column of mud with no problems with lost circulation, consider whether you would like to pump maybe three hundred bbls of cement behind the mud to kill the well sufficiently to R&R the old BOP stack for a new one. Then go clean out the well to near TD and Plug and Abandon as normal.

As I say, this is an opinion. We will see what transpires.

JTF

Thanks JTF:

Unfortunately, I still seem to be missing something. I'll try to explain my dilemma.

If I inject a gallon of kill fluid, regardless of what it is, as long as it's more dense than what is already in the well, that volume has to be displaced in the well. My understanding is that there might be a leak somewhere, so the displacement might go there, but they appear to think that's unlikely, they expect the displacement will be into the reservoir, thus, because of the displacement, increasing the pressure in the reservoir, but at the same time reducing the pressure at the injection point in the BOP because the heavier kill fluid somehow relieves it (although I'm not clear on how).

I could imagine that, if you were pumping the kill mud fast enough (as they appeared to be doing in the previous top kill method, the nature of fluid dynamics would carry the existing fluid along with the kill mud in some definable way. But that does not appear to be the plan in this case. Apparently the plan is to inject the mud in a fairly slow manner.

In any case, that kill fluid, according to one scenario, gradually settles through the fluid in the well, leaving the existing fluid behind. The expectation that i would have, however, is that either the pressure remains the same, or possibly, after the kill fluid hits the pores in the reservoir it clogs them up enough so that no more fluid in the well can reenter to reservoir, thus any new injection of the fluid after that point of necessity increases the pressure at the BOP, with the amount of pressure increase dependent upon the compressibility of the fluids in the column, since we're in effect trying to cram more and more fluid into the same volume.

Now, when I heard about the kill pill, my understanding was that it would act as an interface between the kill fluid and the existing fluid in the well which was designed to prevent the two fluids from intermixing. Thus, it would have the same effect as inserting a piston into the well which would push the existing fluid ahead of it, forcing it back into the reservoir until the volume introduced emptied the well of it present contents.

Again, it was my understanding that the key to that approach was the spacers, and that by using a relatively small amount off a heavier than usual kill mud above the spacer, they would be able to harness gravity to more quickly force the contents back into the reservoir. Again, because of the yet undetermined (at least to me) nature of the spacer it is able to keep the two fluids separate (it appears that normally there are two spacers, one each above and below the relatively small volume of kill mud, but I could imagine that in this situation they might just use one spacer, and only one density of kill mud).

As I said, I still don't understand the composition of the spacer, but I would imagine that it would be a pump-able fluid with a viscosity or other property which ensures its immiscibility with other fluids. I would still like to know the composition of such spacers, but, in any case I don't see how this operation is possible without them.

It occurs to me, of course, that injecting a less dense fluid would also force the existing fluid down into the reservoir, but that would increase the pressure at the BOP which they appear to believe would have the risk of damaging the integrity of the well.

In summary (and my apologies if this was all I had to say in order to make it possible for someone to clarify this for me) Kent Wells has apparently said that they were going to "bullhead" the well by forcing the existing fluid down ahead of the kill mud. I don't see how that might be possible without employing at least one spacer, short of pumping kill mud at a higher rate than they appear to be intending.

David, seriously, forget the spacers, forget the kill pill and let your mind go blank. :)

What are we trying to achieve here?

Getting a column of mud in the hole (for values of hole) that will balance the remaining pressure generated by a (partially) depleted reservoir.

Everything else is paper engineering on an Internet forum.

So we need to establish the pressure required to pump fluid back down the well into a formation that is either the reservoir, or near enough to it to have the same effect.

We gradually start pumping, and once we see a certain pressure (x), we see a sudden breakdown (leveling out of the pressure increase) that allows us to continue pumping with no further pressure rise. This is establishes the 'frac gradient' as opposed to our theoretical calculation. Compare reality to theory then proceed if not to disparate.

At this point, we know exactly the pressure required to inject fluid into the formation (which may or may not be the reservoir).

Now all we have to do is get the whole fluid column (note I didn't call it the casing annulus or well bore, because we don't know) filled with kill mud to bring the well to a static condition. No flow, no losses. Static.

To back up a bit, we are very interested in what happens when we stop pumping. Does the well try to flow, or does it start to take fluid.

If the latter, we have to be prepared to deal with lost circulation. This is generally not a biggie. It can be done. If the former, increase your mud weight a bit to compensate.

If you would like to spend a few minutes going over the issues, I would be happy to supply a phone number.

JTF

Thanks for the try.

I'm with you right through paragraph 7: "At this point, we know exactly the pressure required to inject fluid into the formation (which may or may not be the reservoir)."

Where I get a disconnect is in the next paragraph: "Now all we have to do is get the whole fluid column (note I didn't call it the casing annulus or well bore, because we don't know) filled with kill mud to bring the well to a static condition."

That word "all" implies that filling the column with kill mud is an easy condition to fulfill, but it's a bit (for me) like putting me at the base of Mt. Everest and telling me that "all" I have to do to get to the top is climb the mountain.

I know I switched majors in engineer college at the end of my sophomore year, but by then I had already taken course in both statics and dynamics, among others, as well as in physical networks which integrated all networks available at the time (1963), physical, electrical, mechanical, gravitational, fluid, etc. (we didn't have the internet yet), so I think that I have an understanding of most of the fundamental concepts (although I know full well (no pun intended) that I may, therefore, only have enough knowledge to be dangerous.

It's not the static condition of the well that is the critical point. It's in a static condition now, there is no flow in the well, but that's only because there is a pressure cap. The intent is to substitute the mud for the pressure cap, by virtue of its weight, but that only works if the present fluid in the well cannot percolate up though the column of mud.

That's why the spacers make sense to me. It's my understanding that they are designed to prevent the penetration and intermixture, let alone percolation, of the oil/gas mixture up through the mud, a condition which is inevitable if the mud is heavier than the oil/gas mixture (which it has to be in order to work) and has a low enough viscosity to allow the penetration.

If I can get around that problem I'm fine (except a few details about penetrating the annulus and any other passages that might allow leakage), and since I know the technique works, I know that either a step has been left out or I'm not understanding something. So I'm inviting someone to be gracious enough to help an old, but still curious, man to understand what his feeble brain has not yet absorbed.

David, we're there. You are on the edge of being able to say 'JTF is an idjit and should be stood against a wall and shot', or we are going to be very close to being on the same page, or at least where we are arguing about details rather than the broad scope of the solution.

Consider this.

We are basically trying to drive a 'wave front' down the well. We have no real idea what path its going to take, but we know we need to fill the entire fluid path with kill-weight mud. In order to get the correct hydrostatic against the formation to make the well static. At a guess, that path could vary from 2 sq inches to 20 sq inches, and we simply don't know which is which.

The wave front we are talking about is going to be contaminated between the kill fluid and the fluids already in the well. Could easily be 50 bbls of cross-contaminated fluid by the time we get to 3.5 miles down to the formation that will accept the kill fluid.

So assume that it takes 1500 bbls of clean kill fluid to kill the well. Above and beyond that, we have to pump an additional 50 bbls to account for the 'wave front' that has been gradually cross-contaminated in its journey down the well into the formation too.

Could we have made the 'wave front' volume smaller?

Sure, by using a sophisticated spacer. But what would be the impact on getting the formation to revert to close to its normal frac gradient by pumping in a denser, more viscous spacer that make keep the fracture open more effectively? In a well where we all are just guessing? I don't think so, but I am merely JTF rather than the almighty.

Best regards

JTF

JTF & Rockman:

Thank you very much for indulging me way above and beyond the pale!

I am prepared to call me cured, at least with regard to this issue (Now i can begin to address the other 4,532, but don't worry, you both have already more than fulfilled the quota that you didn't have anyway - I have a familial obligation to honor "Brownie" points).

Apparently I had seriously underestimated the viscosity of the mud, and the amount of "friction" (for the lack of what is a better term for the effect one fluid has on another) between the oil/gas mixture and the kill mud.

In any case, I may still not understand it, but I think I do, and it's perception, not reality, that counts.

In any case I'm out of questions for at least 10 seconds.

Again my profound thanks for you patience and indulgence.

Dave

David -- I’m not sure exactly what they are planning to do but I’ll offer some generic answers to your questions. First think of the scale of the csg: 13,000’ long and less than 1’ diameter. This is little bit from my knowledge base but I doubt there’s much potential for the mud to flow under the oil/NG. If they are indicating they’ll be going with slow injection rate it may be due to the need to max pump pressure. With mud pumps you have two extremes: high rate or high pressure. The mud column in the kill lines with exert a pressure based upon the mud weight. But the pump pressure will add an equivalent mud weight (ECD) above that due to the mud weight alone. Crank the pumps high enough and you can add 2 to 3 ppg to the ECD. This is how we test csg shoes: a 14 ppg mud can be made to act like a 17.5 ppg against the csg shoe as long as the pumps are running. Start to leak thru the csg shoe and you shut the pumps off and the leak stops. Called a LOT: leak off test. If they crank the mud pumps high enough when they begin the top kill it could instantly stop the flow potential of the wild well. If they see a LOT showing lower pressure than what would be necessary to push the oil/NG back into the reservoir it would tell them they have a shallow leak: ruptured csg and broken csg shoe. They can then quickly shut the pumps off and stop any more potential damage. If the LOT shows what they are expecting for reservoir pressure they can just keep pumping with the high ECD. Once they’re pushed to mud/oil interface to the bottom of the csg then the static (non-pumping) mud weight should kill the flow.

Static kills like this are done all the time. Every year many OCS wells take a kick and are shut in before they blow out. Then a static kill is done just as I described. Once they kill the flow they raise the mud weight to control the situation. And no one, including the vast majority in the oil patch, ever knows a static kill was performed. No blow out = no headlines.

Once the well is killed I'm not sure what they plan. Trying to bull head cmt down like they did with the mud would not be a good option IMHO. There's a critical time factor with cmt. They'll add a retardant to the cmt so it will set up at a certain time. Too much retardant and it might not set properly or where you want it. Too little and it could set up too shallow and prevent cmt being pumped as deep as they need. I won't be shocked if the use the RW to pump cmt from the bottom up. That’s a much more predictable/controllable approach IMHO.

Again, not my area but I don't see a reason for a spacer.

This is little bit from my knowledge base but I doubt there’s much potential for the mud to flow under the oil/NG.

And is this because of the higher viscosity of the mud? Is that what keeps it from sinking below the O&G even though it is heavier? The mud remains on top, not in a hurry to get anywhere lower?

rainy -- Viscosity helps but my gut (a dangerouse source of conclusions) tells me it just more geometry than anything else: it's has just to small a diameter more much linear flow IMHO.

Hmm, ok ... I'm beginning to understand why there is a whole field of study of the behaviour of fluids.

Wanders off to kitchen to gather water, oil, honey and various diameter tubes...

Well done. Visualizing what happens from kitchen fluids gets you 95% of the way there. The rest is engineering, and 'engineers and O-rings' screwed up the oilfield. :)

JTF

FressDir, you are absolutely bang on the money.

Partly because of the undetermined fluid path, partly because of the geometry of the well bore, a "lubricate then bleed" is not likely to happen. IMO only, but we'll see how it all ends up.

Instead, you are going to see a gentle bullhead. At least from what we've heard so far.

The issue here is "fracture gradient", which is the pressure that it takes to pump fluid into the formation.

In very basic terms (I am not a reservoir guy, but have done this lots of times), you have to reach a certain pressure before **any** significant leakoff into the formation occurs. Once you get past that pressure, your additional pump pressure is a function of the friction generated by how fast you are pumping.

There are also going to be variances in pressure depending on what kind of "stuff" you are trying to pump into the formation. Water, or water with viscosity reducing agents is generally the easiest to pump. There are other solutions, generally higher viscosity, that are deliberately harder to pump, but generate bigger fractures and carry "proppant" (think sand or a similar granular material) much better and much deeper into the fracture in order to keep it open to aid production. We are trying to do the opposite here and let the fracture close as soon as we stop pumping.

In this case, we want to be subtle, so we create a fracture but don't get aggressive or try to prop it open at all. What we want is for the fracture to close as soon as we stop pumping. Then we get no additional 'leakage' into the formation and the well is stable.

In reality, we may have done enough damage creating the fracture that it may not want to close or 'heal' on its own. In that case, we need to add some kind of 'lost circulation material' to our kill fluid (or cement) to help plug the fracture and stop leakage off to the formation.

There are a couple of 'tells' in this conversation. Be wary of those that speak in 1 psi increments. They may be great on theory but light on practice. Measured pressures while pumping one of these jobs are unlikely to be spot on within 50psi either side. Be very wary of anyone telling how the fluid is actually going to flow, and presenting an 'elegant' model. We don't know where the fluid is going, how big the path is the fluid is traveling along (remember the discussion about 'channeling', you can't assume the whole well bore or annulus is available as a fluid path), so we don't know the exact volumes involved.

There is a tremendous amount of guesswork here, but I am hugely encouraged that the overall plan seems to be generic and robust enough to tolerate various assumptions while achieving the goal of killing the well.

If things do start to go wrong, hopefully the powers that be have the gonads to pull the plug on the operation and backtrack to another plan...

JTF

JTF, what a lot of us noobs can't get is what keeps all the mud from dropping uselessly out of the well into the reservoir? Can you (and others) have a run at that for us, please?

Lotus, thanks for the difficult one!! :)

Rockman can express this far better than I can. I do fixes to intractable problems involving bad things happening in wells, but at a mechanical level rather than a formation level. I do have considerable experience with cementing, acidizing, special tools, fishing, custom tool design, nitrogen operations and other similar things, but none of those really gets into a lot of detail about what is going on inside the formation.

That said. All formations have a certain intrinsic pressure. If you don't pressure up your well over the pressure required to generate a crack in the formation, the formation effectively stays 'closed' and doesn't absorb much fluid from the well bore.

If you do go over that pressure, then fluid from your well bore will 'leak' into the formation.

It isn't anywhere near that simple in reality, which is why you have 'mud engineers' to keep the chemistry of the mud from causing you problems with the formations you are drilling through.

Given that your mud chemistry is correct, we come back to pressures. If you go over the 'fracture gradient', then you can pump fluid into the formation easily via a crack you created in the formation rock However, you can also come back to a pressure below the 'fracture gradient' where the crack in that rock (fracture) you created closes by itself once the pressure is reduced.

As mentioned, this is a horrendous over-simplification, but the principle is sound for most formations you are likely to be pumping fluid into.

Does this help at all?

JTF

It does, JTF, if for no other reasons than that I finally get that what you've been calling "formation," I've been calling "reservoir." (Before, I thought you were talking about the natural walls of the annulus as the "formation," not the structure down at the bottom.) Sometimes I'm as thick as rock, ya see.

Thank you!

Lotus, you are most welcome. Glad I could help a bit.

Consider that the term 'formations' is used to describe any one of the many kinds of rock we may be drilling through at the time. Could be mudstone, could be sandstone, could be limestone, could be shale. All of those formations have much more granular descriptors of exactly what they are.

A reservoir on the other hand, is generally used to describe something with oil or gas in it that we can produce in commercial quantities.

So the reservoir in this case is a number of layers of sandstone that has oil and gas in the pores between the grains of sand in the sandstone. If I understand it correctly, and I an not a reservoir guy!!

JTF

Yah, we were seeing "reservoir" in the same way, but I was thinking of "formation" as whatever rocky stuff was above that, up to where the mud starts. Better to think of (a) as part of (b) though, huh.

Lotus, I'm making a series of unjustified assumptions here.

Assuming we are going to pump fluid down the outside of the 'long string' of casing that was last run in the hole, and this is a dangerous assumption.

There is quite a big gap below the last casing that was run and the theoretical top of the cement in the 'long string'.

In addition, we may have a bad cement job so the theoretical 'top of cement' on the long string may not mean too much, and all the various rock formations all the way down to the bottom of the 'long string' may be exposed to pressure.

I am guessing that we could pump kill fluid into any of those formations between the upper casing shoe, and maybe for formations right down to the bottom of the 'long string'.

The big question is "what is the weakest formation we can pump fluid into?".

Not sure myself. Could be the reservoir, if its pressure has been reduced enough by the last 100 days of producing oil/gas, or could be a lost circulation zone somewhere above the reservoir, but below the bottom of the casing above the 'long string'.

A somewhat confusing conversation. Probably a lot easier in person with a whiteboard to draw on!! :)

JTF

See if this helps:-

http://en.wikipedia.org/wiki/Formation_%28stratigraphy%29

Take a look at the Grand Canyon illustration.

NAOM

Another "thank you" from me, too, Fish. I also had been thinking in terms of fracturing some of the formation along the annulus - undesirable - rather than fracturing the reservoir formation - desirable in this case.

That helped a lot.

ETA: I see your later comment that the area being fractured might not wind up being the reservoir, but instead some formation above that - but, if I understand correctly, that would still desirable in that the formation would accept the oil&gas in the well (whether in the casing or the annulus), ideally allowing the heavier injected mud to displace enough of the O&G in the well to balance the pressure from below.

fish -- You may have seen it already but BP posted a pore pressure plot showing the frac gradient to be around 16.2 ppg in the area of the reservoir. The plot seemed reasonable. You probably already know the MDT showed a 12.6 ppg or 11,900 psi reservoir pressure. Seems like they have enough of a window to avoid pumping into anything but the reservoir. Unless they got something broken up shallow of course.

ROCKMAN - you have my greatest respect on anything to do with the formation, not to mention your wonderful communication skills here. I have been kind of cruising around 14.2 and leaving the rest to you experts.

I can deliver as much hydraulic horsepower to the zone that you need, plus 50%. Biggest I have ever done was on land in Iran, 28k horsepower, every spare bit of cement and frac iron in the Middle East...

If you need a casing string recovered, and suggest 1M lbs of capacity would be nice, I am perfectly happy to design the tool string to deliver 2.5M lbs. I like brutal and redundant and would much rather any failure was not in my tool string.

But I don't mess with the reservoir guys, because I am clueless in that area.

JTF

"You probably already know the MDT showed a 12.6 ppg or 11,900 psi reservoir pressure."

And I keep asking What am I missing? Why not drill in to the WW from the RW with 12.8 or even 13ppg mud and the WW will be dead. Then start "reversing" so to speak the fluid in the WW no longernow the OR or original well out by bradenheading(if necessary) down the drill pipe on theRW and up the other leg of the U tube now established on the two wells. I am a retired Back Off Hand Backed off soms DCs in Roger Mills County Okla below 25000' Also did pioneer work with running conductor lines under pressure. Worked with what as far as I know was the first grease seal lubricator for conductor lines. Back in the Mid fifties

Company I roughnecked for drilled what was then the deepest well in the world. in 1954-55 22570' made a well around 21800 Close to Sulphur plant behind Pt Sulphur La. Steam drill barge

If it's screwed together and toolie can tie on to it I can back it off

I have collected, dried and filled many a core sample bag. Also saw shavings from cyprus log come over the shakers while drilling surface hole on a well out of Pt a La Hache

Pass - Last I heard they were going to go with 13.2 ppg in the RW kill pill. But that may have changed. Try this: imagine a fire hose (A) flowing full force. Now picture a valve at the base of it near the fire hydrant that you can connect another fire hose (B) to. Now connect B to another hydrant that is at the same pressure as the first. Connect B to the base of A. Open the hydrant feeding B. A won’t flow up B because it at the same pressure. B won’t flow into A for the same reason: no pressure differential = no flow. But A keeps pumping water out the end of it because that pressure is so much lower.

The high mud weight in the RW keeps the oil/NG from flowing up it but has no affect on the wild well. The only way for the mud in the RW to flow into the WW is for its bottom hole pressure to be greater than the current reservoir pressure. Raise the RW BHP higher and the mud will flow up the WW. The big problem with the bottom kill is that the mud will be diluted by the oil/NG mixing with it. It’s the bottom hole pressure in the fluid column in the WW that will stop the flow. The $64,000 question is how much mud will they have to pump for the mixed fluid column reaches a sufficient weight to develop enough BHP to kill the flow.

I still don't understand the process of getting a column of heavy mud into the WW when it is not flowing. And how do you get cement into bottom of the staticly (sic?) killed WW?

Donner - If you’re talking about the top kill: It will be a rather standard process if the BIG IF is true: there’s no failed csg or csg shoes in the shallow portion of the well. It’s actually done numerous times in the GOM every year: they’re drilling and the well takes a kick - oil/NG starts pushing the mud out of the hole. So they shut the well in: close all the return lines from the well bore. This is what the hands were trying to do when the rig exploded. So now they mixed a heavier mud and cranked the pressure up on the mud pumps so it exceeds the pressure in the well bore. This pushes the oil/NG back down the hole and into the reservoir. When the now heavier mud fills the hole the flow stops. It’s not difficult to push oil/NG/water into any formation: just need the horsepower.

But your perception about trying to bull head cmt all the way to the bottom of the WW is correct IMHO. I’ll skip the tech reasons but it’s often difficult to pump cmt much more than several thousand feet. And that's from the bottom up. Just a guess on my part but that’s why I suspect if they stop the flow with the top kill they’ll use the RW to pump cmt in from the bottom. The best way to cmt and P&A the well would be to enter it from the top with drill pipe, go to bottom and then spot a number of cmt plugs on the way back up.

If I understand it correctly, there's 3000 ft of broken drill pipe in the well, presumably at the bottom but could be stuck anywhere. To circulate bottoms up, they'd have to attach a riser from a drillship and go fishing, right?

avon - yep...probably no practical way to get back on bottom. The best way isn't always available unfortunately.

Thank you Rockman.

After 9 weeks of reading every thread on this subject and researching other references I am beginning to understand. I have learned just enough to know that I didn't understand what I thought I knew. Thanks to all who post here my education begins.

Donner

I tried that but it doesn't seem to work for me.

Lets assume both hoses are connected to separate mains (100 psi) and at the connection point for hose 'B' you put a pressure gauge. If you have nozzle of hose 'A' closed, gauge will read 100 psi, but the minute you open the nozzle on hose 'A' gauge reading will drop to (say) 60 psi.

Hose 'B' also has a pressure gauge, likewise if hose 'B' has no Flow (Closed) it will also show 100 psi, so when you open up connection from 'B' to 'A' you have 100 psi facing 60 psi - So hose 'B' will flow into hose 'A' until such time as pressure drops equalize across both hoses, 'A' and 'B' hoses are both showing (say) 80 psi.

And this is where I have problems with Mud weights, Sure, with a heavier mud in 18000 ft vertical system of the relief well it has a calculated pressure greater than the Frac Point of the formation, But that Calculated pressure is only there while the relief well is in a No Flow situation.(closed in.) The minute it is connected to the WW it will flow into the WW until both RW and WW pressures equalize.

So the way I see things, you cant reach Frac Pressure in formation until the WW Column weight is also brought up to the Frac Pressure, and by my way of thinking well is dead before that staged is reached.

I may be wrong, when you get down to the finer details I tend to get lost. So most of my thinking just boils down to the basic physics. - But then again, that's all self taught, I was thrown out of school real early, Had my drivers License and was working at 14 yrs old.

sticks -- I think you're thinking right. But remember that Hose B flow will go in the direction of lowest pressure which is up Hose A due to the pressure draw down you state. Hose B is 100 psi, Fire hydrant A is 100 psi. Hose A is 80 psi. Hose B flows towards the 80 psi and not into the 100 psi hydrant.

Of course, we don't know exactly what the pressures will be down there. But the key is that the reservoir will follow the path of least resistance. As long as the bottom hole pressure in the WW is less than the reservoir pressure the flow will continue.

It'll be interesting to see whether/how Feinberg, Witt, and Mabus might coordinate their efforts instead of reinventing the same wheel three different ways. If the independent, corporate, and federal shops pull together, that could really be something. But how to do it, especially with state and local sticking their oars in too? Seems that Mabus and Witt, in particular, may have about the same assignment and could get in each other's way pretty easily. I hope POTUS doesn't end up repeatedly having to sort them out.

A new NYT article/blog post by Andrew Revkin on the future of the Gulf ecosystem, with reflections various scientists and others, including a new song by 91-year-old Pete Seeger.

http://dotearth.blogs.nytimes.com/2010/07/31/tracking-gulfs-fate-as-slic...

Good stuff, Gobbet. I sure hope Sylvia Earle's subjects stay healthy. The last video of her I saw, 2-3 weeks ago, really had/has me worried for the whale sharks. Wonderful to see a big pod still in good shape.

Yeah, you gotta love those big guys/gals. I actually found this article by Googling for whale shark news, which I compulsively do every few days.

Question for Rockman or maybe somebody else.

How do you actually start drilling in the mud bottom? Is a casing sunk through the mud before drilling starts? I'm have a hard time figuring that out....

Lady -- Even when drilling onshore you don't start "turning to the right" at ground level. You set a "conductor pipe". Offshore they normally drive it into the mud with a hydraulic "hammer" or use water jets to open the mud up to let the conductor or "drive pipe" get deep enough... typically a few hundred feet at a minimum. Then they drill down thru the conductor but just a little ways..maybe a few thousand feet. Then they'll set what is often called "surface csg". At that point drilling ahead is fairly routine.

Unless my brain has blown a fuse, I thought that I posted an Open Thread style comment earlier on ... but it has disappeared ... moderated I assume.

So what CAN be posted as an Open Thread item? (Clearly discussions about ice cream are valid!)

You too? That happened to me a couple of days ago. Didn't have time to ask about it at the time, and then forgot to, but I'm kinda relieved to know it wasn't just me.

Ice cream, chewing gum, Hooter girls, alligator soup.

Ice cream from Texas, it was turtle soup, Hooter's girl from Gulf Shores back to 66% employment, chewing gum now made from oil, and now this.

Fishermen arrested in Bayou La Batre after blockade protesting little oil cleanup work

Thanks for your patience

TinFoil

Mrs. R2 and I drove through Bayou La Batre a day earlier on the way back from Gulf Shores on our

tarball finding missionvacation. Quiet little place.We had just come across the ferry to Dauphin Island. While waiting for the ferry, we met a guy who went on and on about the fishing boats whose captains are raking in the dollars doing very little. He mentioned that with fishing, you might make a good wage for a day's work, but with this oil work, there's practically no downtime. There's a good bit of jealousy out there. In short, for these fishing boat types who are "employed" by BP, this will be their best year financially in memory.

Boat owners did make quite a bit of money. Deck hands made $200-$300 daily in Bayou La Batre which is about what they make when they are shrimping, oystering, fishing. I live in Bayou La Batre so first hand knowledge on that one, but don't ask me what these several fishermen were doing. It seems to me that they are a bit behind the curve.

TinFoil, I've never had occasion to reply before. Let's be candid. You get top marks for popularity, photo journalism, personal remarks and pedigree. I'm not interested in Nawlins, Gulf Coast employment, oil cleanup or fishing. My thing is exploration. I don't know much about drilling. I'd like to learn more.

Fair enough, is current drilling status in the GOM of interest because I have some posting I could do on that. Also we could talk about the Alberta Oil Sands project. If not, post a more specific issue and though I may not answer, someone will.

Now I'm curious what you posted. Try reposting it, or add it to your posted comment as an edit.

I wish bp would reinstate the feeds of the BOP and well head monitoring. They have brought Skandi Neptune back on line but the video feed is sorely lacking.

Until 3 days ago we were able to witness all BOP and wellhead leaks and now we can see not one.

Why?

Quick summaries of leaks/rov:

Leaking wellhead in Bayou St. Denis could be closed Sunday

Interior secretary tours rigs this week, keeps drill ban for now

I count 6 live feeds, 1 snow, 1 bars, 4 black screens and 3 green screens

Enbridge -- July 30 Evening Update

We can confirm that in the past 24 hours there has been no forward movement of the oil in Talmadge Creek or the Kalamazoo River. We have recovered and removed and transported 5,000 to 6,000 barrels of oil from the waterways. There is a significant reduction in the amount of heavy oil being observed on the water. To date, there has been no oil observed on Morrow Lake.

path: Public ~> Gulf Oil Disaster

originally posted: 2010-07-31 15:09:28

Engridge -- July 31 Afternoon Update

As we continue cleaning up Talmadge Creek and the Kalamazoo River, our top priorities remain the efficient cleanup of the site and the safety of the people living and working in the area. As with yesterday, we note that the oil from both the creek and the river has remained stable, and has not progressed to Morrow Lake.