Electrifying the Railroads - Alan Drake's manual

Posted by Heading Out on October 29, 2010 - 10:23am

While I was away Alan Drake sent me his “An American Citizen’s Guide to an Oil-Free Economy -A How-To Manual for Ending Oil Dependency.” It is only now that I am able to review it. His objective is sound

We can transfer our economy, bit by bit, to the new, more efficient and oil-free replacement as our present system becomes increasingly more fragile and eventually unsustainable. These plans all rely on mature, proven and economically viable technologies and not the current “Hunt for Miracles” that Secretary of Energy Chu has so aptly described his department’s Advanced Projects Research.

As new technologies develop, as they will, and are debugged and scaled up, our plans can be adjusted to incorporate these new solutions. Yet we can make a viable, workable plan with what we have “on the shelf”, ready to go today. We need not gamble our future on “Just-in-Time Technology” appearing at just the right time and with just the right technology. No miracles are required, simply foresight, persistence and hard work.

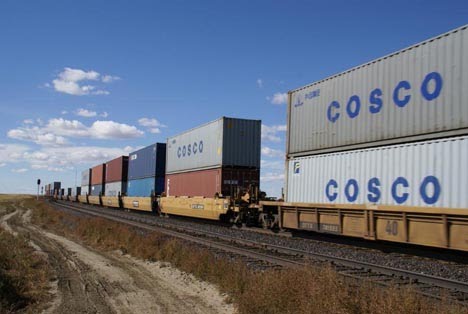

Alan is a great believer in the energy savings that can be achieved with a transfer to electrically powered railways. I largely agree with that underlying premise, and in Europe particularly, generally travel by train, where I have a choice. In his manual Alan points out some of the considerable savings that can be achieved if the country were to switch to an enhanced electrically-powered railroad system, relative to the oil-based transportation that we currently enjoy.

There are two factors that are required to achieve, in the long run, considerable energy savings, as well as a move toward energy independence, rather than our continued, and growing dependence on importing oil. The first is the transition itself, from diesel locomotives to electrically powered engines. It is a change that has already occurred in many parts of the world. He points out that the current system, which relies heavily on diesel-powered truck transport, could reduce energy costs comparatively, from 20 Btu’s of diesel power, to 1 Btu of electrical power, if long-distance haulage was carried out using Double Stacked Trains. In Europe, without the stacking, the trade-off is still 2.5 to 3.0 Btus of refined diesel converted to 1 Btu of electricity, with a slight reduction (circa 10%) in transit times. He cites Switzerland, China and France among those making the change. Roughly 30% of the 10,000 miles of track in the UK is electrified and the system is one of the busiest in Europe. (And on a personal note I have seen the density of passengers increase over the years as I ride the trains from London to Carlisle and beyond. And, in Austria, an off-peak trip from Vienna to Graz last week was made in a train that was close to full.)

He notes the lower maintenance costs of train over road transport, and given the delays that have been encountered around the country this summer as more highways were repaired under the Stimulus program, that is not a small consideration. I am reminded of a British Rail ad from some years ago, showing a commuter looking at his watch aboard a train running past a highway blocked and stalled with cars, and complaining that the train was running 5 minutes late again. (On the road into St Louis this summer delays of more than half-an-hour have not been uncommon as the highway has been widened near Pacific.) Rail is also a safer method of transport (he conjectures the savings in life would be from 4,000 to 5,000 individuals a year).

However the second step that must be made is to increase the capacity of the existing rail system. Even as far back as 1998 Brennan was writing for the USDA of concerns that the existing system was reaching capacity.

Employment in the industry fell from 532,000 in 1980 to 256,000 in 1996. Similarly, rail mileage fell from 179,000 miles of road in 1980 to 147,210 in 1996. Over the same time period, the number of freight cars fell from 1.7 million to 1.2 million and the number of locomotives dropped from 28,094 to 19,269 units.

Even though their miles of track and number of employees, cars, and locomotives decreased after deregulation, railroad output has increased. Measured by carloads originated, output increased from 22.2 million carloads in 1980 to 24.2 million in 1996. In addition, shipments of intermodal containers and trailers increased from 3.1 million to 8.2 million over the same time period. Measured in terms of revenue ton-miles, the growth has been even more impressive. In 1980, railroads handled 919 billion ton-miles of traffic. By 1996, that number had increased to 1,356 billion ton-miles of traffic. U.S. railroads have been able to move this increased volume of freight by handling larger shipments over a longer distance at a much greater velocity. . . . . . However, the recent rail congestion problems suggest that U.S. railroads may have reached the practical limit of their possible productivity increases without major expansion in the capacity of their basic infrastructure. Increasing the volume of freight movements on a fixed network by handling larger shipments over a longer distance at greater velocities cannot be continued indefinitely. Indeed, one of the lessons of the western railroad crisis is the sensitivity of current railroad operations and the productivity of major sections of the U.S. rail system to even a slight downturn in the velocity of the system.

To overcome this more of the track will have to be converted from single to double tracking. However, as Alan points out, most of the infrastructure is already in place, and the right-of-way established, so that it will not incur the high costs of a totally new development.

Good cost estimation is difficult given the variety of issues with the existing infrastructure. However, rail investments can provide superb value for money. An excellent investment example is BNSF double tracked and improved 2,217 miles (Los Angeles to Chicago) for slightly over $2 billion recently. BNSF more than doubled track capacity and now offers 70 mph express container freight service.

A $2 billion investment made BNSF’s Transcon line the world’s busiest container rail line (the Trans-Siberian is #2). By comparison, $2 billion spent on highway expansion projects would have no national and limited local impact. For example, $2.3 billion is proposed to just rebuild the Milwaukee Zoo interchange and $1.2 billion to add two lanes to the Huey Long Bridge outside New Orleans.

The arguments that he makes are strong and should be persuasive, after all – as he points out -

Warren Buffett (BNSF Railroad is his largest single investment) and Bill Gates (30% of his non-Microsoft stock portfolio is in CN Railroad) are hardly charity cases.

Smart though they may be in foreseeing the benefits of investment, the money is not yet being fully invested to make the transitions that Alan feels are needed.

The following are reasonable cost estimates for what is being proposed, given the available information, in 2010 dollars.

• Electrify 36,000 miles of double track railroads - $100 billion.

• Double track 15,000 miles of single track, new rail over rail bridges, better signals, improved curves and grades – $75 to $150 billion.

• Grade Separation (a cost that should be borne by highway budgets) could easily absorb $50 to $100 billion.

• Semi-High Speed “3rd track” on existing ROW - 7,000 to 14,000 miles - $140 to $280 billion.

• Strategic Railcar Reserve – perhaps a couple of billion dollars for mothballed used equipment. New equipment, when used is not available, should be an order of magnitude more expensive.

• Improved Intermodal Centers – a very rough estimate to supplant 85% of existing truck traffic would be $50 billion or so.

Given the investors, it will be interesting to see how this catches on.

Thanks for putting this up here, HO.

I did look at it at your blog the other day as well.

Could you or Alan clarify a number for me?

"In Europe, without the stacking, the trade-off is still 2.5 to 3.0 Btus of refined diesel converted to 1 Btu of electricity.."

..Compared to the 20:1 ratio that Alan has offered, if I got it straight, for 'Diesel Truck:Electric Rail-Freight(Double-Stack)' .. are we still talking about the Truck to Rail improvement of Electric Drive, or just the conversion in Europe from Diesel Trains to Electric Trains?

I'm sure the comparisons have numerous other factors to weed out, but the difference is a little startling.

Bob

Clarity is needed on this point.

If one transfers freight from trucks to electrified double stack trains, the "trade" is 20 BTUs of diesel for 1 BTU of electricity.

If one electrifies an existing diesel train, the "trade" is 2.5 to 3 BTUs of diesel for 1 BTU of electricity. Basically 2.5 : 1 in flat, rural land. 3 : 1 in mountains or urban areas (lots of braking). The delta is regenerative braking.

Many diesel-electric locomotives also use regenerative braking, they just dissipate the generated electricity in resistor grids.

Best Hopes for Clarity,

Alan

Thanks Alan, that helps. (A lot)

HO was also making a point about double-stacked US trains in the same sentence, so I wasn't clear how that factored into this efficiency for the single-stacked European Trains.

Do you have a figure for single-stacked US trains, or some other way to keep apples/apples? Maybe a comparison with Euro Truck-freight vs Euro E-Rail?

Thx,

Bob

Much of the advantage of double stack vs. single is aerodynamic. The savings there are highly speed dependent (square of speed from memory).

Higher payload as a % of total weight in double stack. Double axle loadings just about doubles frictional losses AFAIK so no real savings there with fewer wheels.

In addition, trucks typically travel fewer miles/km (less circuity) to get from A to B (say 3% to 5%) BUT they go up and down more than trains (more losses there).

My SWAG is that single stack would take about a 10% to 15% hit on fuel efficiency vs. double stack. However, the density that a rail line can carry is doubled when they go to double stack (two months ago Norfolk-Southern finished double stack clearance from Chicago to Norfolk, VA and saw an immediate jump in traffic).

Hope that helps,

Alan

Alan, any information on how wear, on tracks, and rail cars scales with weight. I've no doubt that double stack saves nearterm cost and energy. But we know from the trucks/versus roads case that road damage scales as a pretty high power of axle weight. I would think something like that also applies to railcar axles and track.

The axle loading issue is with coal, gravel, etc. trains, not container trains. Stuff that has to move by train and does so today.

The US railroads run exceptional high axle loadings, past the cold deformation of steel limit at the extreme. And mile plus long trains, one after another in Wyoming, etc.

They have found that the savings from heavy weight/axle loadings more than pay for the additional maintenance. Steel suffers abuse better than concrete and asphalt roads do.

Best Hopes for durable railroads,

Alan

PS: The Swiss plan to make their tracks last 100 years in the 58 km long Gotthard Base Tunnel. 300 trains/day, pax + freight, but lighter axle loadings gives VERY long life even with a VERY busy line.

US railroads run very high axle loads on coal cars, but the axle loads on double-stacked container cars are unexceptional. The maximum weight of a truck on the Interstate Highways is 40 tons. Two 40-ton trucks are 80 tons, and the standard US rail car capacity is 100 tons. It's much more than the capacity of two highway trucks.

If you need more weight capacity than that, you can always buy higher-strength alloy rails. Maybe not from US steel mills, but you can buy them.

Single-stacked containers weigh less than half the axle load that a rail car can handle. Double-stacked containers are closer to the maximum loading capacity, and so the additional capacity comes more or less "for free". Twice as many containers, same number of locomotives and cars. This makes the economics of double-stacking containers somewhat overwhelming for railroads.

Another factor that shippers like is that, when you put a container into the lower level of a container well car, you can't open the doors without taking the container out of the car. And you need a ladder to get to the doors of the upper level containers. This reduces their pilferage rate dramatically. Thieves don't like to be standing at the top of a ladder leaning against a two story high railway car when the police come along and say, "Hey! What are you doing?"

PS: Ratios of 27 : 1 to 17.5 : 1 or even 15 : 1 can be rationally calculated . I chose a round and defensible ratio of 20 : 1.

Alan

Truck to diesel rail: 3 to 1?

diesel rail to electric rail: 3 to 1.

single stack rail to double stack: 2 to 1.

Total ratio: 3x3x2 = 18 to 1.

I should think that the largest benefit from double stacking would be the 50% reduction of labor and overhead cost per container.

Gil Carmichael, former head of the FRA (Federal Railroad Administration) has used a 9 to 1 savings for for diesel truck to diesel double stack container trains repeatedly.

One example: Today, a doublestack train leaving a coastal port can replace 280 trucks, run at speeds up to 90 miles an hour on the western railroads, and afford as much as nine times the fuel efficiency of container transport by highway.

http://www.sehsr.org/news/GilCarmichael.html

I had this article reviewed by a number of experts and professionals, and I modified a number of claims.

One pointed out that no one knows the transit time savings for electrifying US style freight trains. Big, long, heavy. I can make % claims for EU trains, but he advised that I just hand wave for US trains. Which I did.

Others believed that that I over-estimated costs. My response was that doing things in a hurry adds cost.

The energy savings were not controversial with the reviewers. Or the claim that the more rail is used, the cheaper it is.

The basic physics of rolling resistance and aerodynamics support a large delta as well.

Alan

Alan, here's one reference for rail CdA improvements from TOD's Fuel Economy Factors - Part 1: The Role of Aerodynamic Drag article, if you want to get into that level of detail;

Lai, Barkan, Onal, Optimizing the aerodynamic efficiency of intermodal freight trains, Transportation Research, 2008

Overall recommendations (the article details expand on these);

1. Use an aerodynamic loading assignment model (ALAM) for for intermodal train loading

2. Better matching of loads with railcars

3. Optimize loading for more than a single train simultaneously

4. Uncouple empty railcars at the end of IM trains

? were you assuming the containers are always-paired, so are loaded/unloaded as doubles ?

I would add other factors, like absolute train length limits, allowing ~twice the container count in the same limit, and for a single labour cost.

The tonnage of containers, I'd think would be relatively low, so it's a volumetric issue.

Ports and hubs tend to be very land constrained, so they can dictate train length.

? were you assuming the containers are always-paired, so are loaded/unloaded as doubles ?

I'm suspecting that the labor costs of running the trains (engineers, etc) are a much bigger % of overall labor costs than the labor costs of loading/unloading.

That's a weird assumption.

First of all...

Running a train takes two people. Loading/unloading takes two people per crane (more than one crane is usually used), plus a switch crew, plus crews to stage container chassis. All these guys probably work fewer hours per train, but there are more of them, so man hours are probably similar.

Secondly...

Some stack trains are short enough that if the containers weren't double-stacked, they'd just be longer, but not require extra train crews.

Thirdly...

Labor for running trains probably costs less than fuel consumption in most cases, so it's doubtful that anything to do with labor would be the 'largest benefit' involved.

How is electrified freight made compatible with container operations?

The cranes used to handle containers would seem to be incompatible with catenaries. And I doubt that one would want third rails in a container terminal.

There must also be a similar requirement for overhead clearance for loading hopper cars and tank cars.

Perhaps diesel electric switching engines must always be used for these operations?

Loading facilities simply don't need catenary above them. Electric locomotives can spot cars from the ends of the loading facility tracks. Some facilities may need track modifications to make operations of this type practical, but that's a small cost compared to electrifying mainlines. And yes, in the meantime, diesels can be used for switching loading facilities.

Battery locos with pantographs (run off wire when you can) are another solution used.

Some, such as the Swiss, just do not want to deal with diesel fuel tanks, refueling, etc. Or even the smell of diesel in their nice clean rail yards.

Alan

Well, if a train takes 24 hours to travel, 2 hours to load, and 2 staff during travel, then 12 staff for unloading would cost 50% as much as the onboard staff. I don't know what these numbers should be - it would be interesting to get good data.

I looked at a financial statement for BNSF( http://www.stb.dot.gov/econdata.nsf/f039526076cc0f8e8525660b006870c9/4e5f07db852df4e78525770300603a5c/$FILE/BNSF%20Railway%20Company%202009%20R-1.pdf table 750).

The fuel cost is $1.2B. Wikipedia says their revenue is $38B, so that would mean fuel is only 3% of their revenue. Does anyone have good data for this?

Just from watching container operations in Oakland, I'd guess 4 hours each for loading and unloading long trains. Of course loading times vary with train length, and travel times vary with the destinations. I think your guestimate goes to show that the man hours for running the train and (un)loading would be in the same general overlapping range, keeping in mind that both would be highly variable. Pay rates for different tasks may not be the same either.

Amtrak's 2009 annual report shows $272,801,000 for "Fuel, power, and utilities". This is a small part of the total expenses of $3,507,238,000 or their net loss of $1,264,355,000.

Amtrak's largest expense item is "Salaries, wages, and benefits" of $1,699,101,000.

They probably have way too many stations and people spread out across the country on poor revenue routes. Amtrak's energy costs for the trains could go to zero and it wouldn't make them profitable.

Not that that has anything to do with container trains. Comparing the labor expenses of passenger and freight operations is no doubt apples and oranges.

There was a time when passenger trains were profitable, before cars and planes took over. Those circumstances may re-emerge at some point.

It looks like an Acela train would have about the same size crew and carry about the same number of passengers as a medium sized airliner, e.g. one of the larger model 737s.

However, the crew probably works about 4 times as long for the DC to Boston journey. So for longer distances, the train has a definite handicap in terms of operating labor expense that has to be made up by lower expenses in other categories.

It thought you were underestimating the train capacity. Quick googling:

Acela: 304-321

largest 737: 215 when all coach

largest 747: 467

TGV duplex: 545

Labor cost isn't going to be the determining factor. Passenger trains were profitable before commercial jetliners existed, and if liquid fuel scarcity in the future makes jetliners prohibitively expensive for ordinary folks, then passenger trains running on electricity might be profitable again.

Air transport is the most difficult area in which to eliminate fossil fuels, but

1) 3x greater efficiency is possible, and synthetic FF-free fuel is unlikely to be more than 3x as expensive per gallon, and

3)We're going to have fossil fuels for many decades, should we want them, albeit at lower levels than today - we have time to find the cheapest and most convenient way to replace aviation FF consumption.

No. Since they started running with 2-person crews, labor costs have not been that bad. Remember, you can move 200-250 containers on a double-stacked freight train with 2 people, whereas on the highway it would require 200-250 truck drivers.

In Europe they often get by with 1-person crews on the trains, but then they usually run only single-stacked trains.

The new EPA standard(2017) for big rig truck tractor-trailers configurations(+8500#) will be 6.3-11.4 gallons of diesel per 1000 ton-miles, which works out to 850-1570 BTU per ton-mile. Right now there are no efficiency standards and tractor trailer trucks average 5-6 mpg.

In the broad scheme of things trucks(55% of ton miles) use 10% of transportation energy frieght trains (45% of ton-miles)use 1.4%.

http://www.epa.gov/oms/climate/regulations/420f10901.htm

http://www.truckinginfo.com/news/news-detail.asp?news_id=72016

Diesel electric trains get ~457 BTU per ton mile.

Since the difference between a diesel electric and electric is the regenerative braking(17% savings) and the efficiency of grid power at 37% nationally) versus the efficiency of diesel engines (30%) x fuel production(80%); overall 20% efficiency. So electric frieght trains would get about

247 BTU per ton mile.

http://en.wikipedia.org/wiki/Regenerative_brake

Newer truck technology(hybrids,advanced diesel) will substantially close the gap between electric trains and tractor-trailers.

So an electric train with regenerative braking sends juice back to the grid?

Yes, or to another train, in the vast majority of cases.

One example in British Columbia where they were too cheap to. Some issues with old DC electrification and so forth.

Alan

Discussion Continues after TOD closes here

http://www.steelinterstate.org/topic/sneak-preview-alan-drakes-american-...

Best Hopes for More,

Alan

The full 21 pages are available at three sites:

ASPO-USA

http://www.aspousa.org/index.php/2010/10/a-citizens-guide-to-an-oil-free...

Energy Bulletin

http://www.energybulletin.net/stories/2010-10-27/book-excerpt-american-c...

Steel Interstate

http://www.steelinterstate.org/topic/sneak-preview-alan-drakes-american-...

The last one has a discussion forum that is being set up for long term use.

In addition, another review at Energy Smart (Adam Siegel)

http://getenergysmartnow.com/2010/10/27/energy-smart-invest-in-electrifi...

Best Hopes for Creating a Meme,

Alan

One of the objections to Alan's plans for what is in many ways a return to electrified rail, especially on the local level, is that our low density auto centric suburban lifestyle is not conducive to mass transit, which is largely true, but I would question the underlying premise of this objection--that the low density auto centric suburban way of life is sustainable.

In my opinion, we need to start thinking seriously about a triage operation, about how we are going to start abandoning (or in some cases continue abandoning) outlying suburban areas--as part of Alan's plan to build, or in many cases rebuild, an electrified rail system. The great post-war tragedy was that so many electrified rail systems were torn up and paved over, starting in the late Forties. Here in the Dallas/Fort Worth area, at one time we had about 350 miles of electrified streetcar lines, plus an electric Interurban system.

Maine had a number of interurban and trolley rail companies running in the first third of the century, which made sense before cheap oil undercut the market.

They'll be back.

http://www.american-rails.com/maine-interurbans.html

Alan asks a brilliantly simple question, to-wit, how did we arrange for transportation before the widespread use of automobiles and trucks? Rather than waiting on a "Mr. Fusion" device, why not go back to what we know worked (and is working), and which can be powered by non-fossil fuel sources of energy?

It seems to me that there are really two ways of doing this:

1. Going back to what we did before what we have now.

2. Adopting the latest technology.

If Alan had said, we are working on a plan that can be done with robust, older technologies, and with local materials that can be easily repaired 50 years from now, and entirely uses a US work force, I would be more enthusiastic about the idea. I would like to hear that the windows will open, and the doors will have simple mechanical controls. I would like to hear that current trains in India are being studied, for robustness and cost effectiveness. I would like to hear that cars will not have to be taken off line for months, because some replacement part from an exotic part of the world is not available.

A couple of days ago, I was driving in Atlanta on a sunny day, and had to go through several major intersections where the electric traffic lights were out. It was no fun! Alan has great hope for electricity. Maybe we can keep a robust international system indefinitely, but I am less hopeful. Is there a way to have duel-fuel (or multiple fuel) trains?

The overwhelming bulk of the railroad infrastructure and rolling stock is made in the USA or Canada. All reachable by rail. Some specific types of switches are made in Europe, but US production of these long lived switches should not be a problem. We have repair shops here for these switches.

I can think of nothing else that is dependent on non-NAFTA imports. Anyone else ?

Indian Railways are 29% electrified today and they are lobbying fiercely for more.

Electric locos last much longer, and require less maintenance, than diesel-electrics.

In dealing with high value, perishable cargo, I would suggest using, say, two electric locos and one hybrid (electric & diesel) to get over a bad spot.

The Trans-Siberian RR was electrified in 2002. And to the Arctic port of Murmansk in 2005.

This thin link is an INCREDIBLY strategic railroad#. Without it, Russia could not maintain control over Siberia. The weather and distances to outposts of civilization are quite daunting in Siberia.

If electrification was fragile and vulnerable, the Russians would not have electrified the Trans-Siberian, regardless of economics. Or to their primary northern port.

Alan

# The last major project of the Soviet Union was to construct BAM, a single track rail line parallel and north of the Trans-Siberian (double track), from mid-Siberia to the Pacific. A $14 billion strategic insurance policy.

http://en.wikipedia.org/wiki/Baikal_Amur_Mainline

Cars "built" in this country probably use castings from Brazil and imported steel plate. The Huck bolts that fasten it are made in Mexico.

Considering the education level in India, any "lobbying" is probably being done by Siemens and Alstom.

Amtrak has just ordered 70 locomotives from Siemens, replacing some as little as 8 years old.

The trans Siberian is electrified not from nonexistant savings, but because it is an environment where crankcase oil becomes too thick to pump, fuel gells with wax crystals, and cooling systems could freeze even with the engine running.

There is a Made in the USA requirement for Amtrak purchases that extends to the nuts & bolts and steel plate.

The trans Siberian is electrified not from nonexistant savings ...

You have no proof of that claim. Just made up. I have read proof to the contrary.

The Russians, and then the Soviets and then the Russians managed to keep the Trans-Siberian running for a century before electrification was completed. And many more temperate lines have been electrified as well, all over the world.

So you appear to be grasping for straws to support your prejudices.

Alan

Considering the education level in India, any "lobbying" is probably being done by Siemens and Alstom.

It's best not to underestimate the educational capabilities of countries like India. India graduates about 350,000 engineering students per year, versus 70,000 in the US. Meanwhile China graduates 600,000 engineers per year.

They are quite capable of building high-tech railway equipment, and they can do it quite cheaply given their low labor costs.

Gail,

"Is there a way to have duel-fuel (or multiple fuel) trains?"

I think that is an important transition consideration. It is difficult to get congress to agree on any one thing even on a sunny day, but something that allows multiple choice may have a better go of it.

One nice thing about trains is that there can be multiple "engines", meaning multiple types of engines as well. Heck, even on the same train.

So, we know that methanol can be converted to run in diesel engines that already exist, but without the pollution. Methanol can be created, among other ways, from grabbing the CO2 on the stacks of coal fired power plants then converting it into methanol.

In the transition context, a mix of fuels and electricity could be a smart strategy too it seems, depending on the type of grid technology used to get the electricity to the train's electric engine.

During the transition from fossils fuels to others, we could try all of the above then see which one pans out as the best in any given area.

The "allie samie" or one size fits all approach we adopted with petroleum / coal / gas is not likely to be as effective in the long run as diversity is.

I should think that a well run electric railroad would have as part of its equipment, locomotives that are held for rescue operations in the event an accident interrupts the electric system, or in case the electric system must be turn off for safety during a rescue. The cost of promising to Congress that there will be locomotives using alternative fuels seems to me trivial and well worth the extra expense of ink on the sales brochures.

It may, however, be difficult to convince any serious locomotive manufacturer to pay the development costs of an alternative fuel design locomotive, since it would almost certainly be more expensive than preferred fuel, whatever that is at various times in the future.

About diversity and competition: I think Alan assumes that the electrified rail system will be managed as a unitary enterprise, or at worst an oligopoly of regional enterprises. The hard part of selling this might be convincing market fundamentalist that there are not cost saving in chopping it up into independently managed competing chunks.

"An oligopoly of regional enterprises" is a very apt description of the railroad network as it already exists. Only seven Class I carriers in the US and Canada, with numerous run-through and trackage rights agreements.

jaggedben,

The article Gail referred to says this:

Like the Beatles said, we don't want a destructive revolution, but since there is no choice we have to have a constructive revolution or peak oil reality will provide the destructive revolution for us.

I don't think I was the one who referred to that article.

Dredd, I don't understand how your comment is a response to mine.

geek7,

"locomotives that are held for rescue operations"

That is what an electric train system is ... a rescue of civilization that is coming down unless we deal with peak oil and climate change by using non-fossil locomotives ... you know getting rid of the LOCO MOTIVE if you know what I mean.

"an alternative fuel design locomotive, since it would almost certainly be more expensive than preferred fuel"

There is no alternative ... the best fuel is the one that saves civilization ... biofuels and methanol already run in diesels with minor, not major, modifications to filters and the like.

They are already running in diesels ... they are already running in diesels ... they are already running in diesels ...

Did I mention that they are already running in diesels?

dredd,

My comment was intended to add support to Gail's comment that pushing a variety of fuels might make the proposal more palitable to Congress. I see that it doesn't make a lot of sense when read outside of that context.

I think the extra cost of pushing variety is trivial cost of extra ink for extra words on sales brochures. And the reality is that under competent management, which Congress might not allow, but assuming it happens anyway --- under competent management there will be one optimum fuel and one plausible backup fuel during any decade in the future.

I really feel that there is already a cadre of competent operational managers of railroads, such that discussions here do little to advance the state of the art of railroad management. I don't know anything about current academic programs in railroad management. Are there schools that offer an MBA specialty in railroads?

A big part of the appeal of railroads for me is that there is a strong tradition of having them operate under a unitary management without the hodge-podge of 'stake holders' with conflicting agendas that compete for attention on issues of public highways.

With what energy?

This is one of the least-practical schemes I've ever seen touted.

Yes, it's incredibly easy to simply couple both a diesel locomotive and an electric one on the front of a train. You can even add a coal-fired steam locomotive, too, if you want.

As do I !

Unfortunately I've missed out on most of this discussion today because I was on site installing another low voltage off grid solar powered LED lighting system. There is absolutely no reason those traffic lights shouldn't be powered by Solar with battery backup so they keep working when the grid goes down. Of course if you were on an electric train you wouldn't have to worry about traffic lights at all.

The problem is the current system, we just need to change how we do things.

No, no, please NO. The only time we get free running traffic, without hold ups is when there is a power cut and the traffic lights are out.

NAOM

Sooooo, you're the guy blowing thru the intersection and causing havoc!!

Basic traffic laws that the killers in their SUV's continue to ignore.

WHEN THE LIGHT IS OUT....IT'S A FOUR WAY STOP!

Just can't fix stupid.

LEDs are where the traffic light market is going. Much more efficient. Much longer life means lower maintenance costs and Total Cost of Operations.

Only disadvantage: little excess heat to melt snow and ice in northern climates.

This transition has already happened. I can't remember the last time I saw non-LED traffic light. I have in my house a front glass from an old pedestrian "Walk/Don't Walk" sign that the city of San Francisco was dumping because in the new ones the symbols are made up of LEDs.

Ah. Well, it's still happening right now in some places - I just had a highway engineer from a large county telling me about it last week.

Well, we don't get a snow problem here :) The biggest advantage I have seen for LED traffic lights is the visibility in strong sunlight. When traditional lights cannot be seen the LED lights still stand out.

NAOM

Sure. Incandescents have to be filtered to get a color, which knocks out most the light.

It's not clear exactly what you were meaning by dual, but an obvious transitional step, is to run diesel-electric, simply designed to derive Electric from overhead, where available.

With local energy storage (natural for regen braking) the diesel size (thus weight) shrinks drastically, as it needs provide averages only.

That slashes diesel consumption, but also means you avoid having to electrify ALL rail.

So it's a very simple, and clean way to handle your electrification upgrades, and it avoids any bottlenecks.

I had taken him to mean, can use other non oil derived liquid fuels in a pinch. But I think that presumes that oil will be completely unavailable. If we did as you suggest, we would only need relatively small amounts of diesel to overcome local or temporary unavailability of electricty. We could also make electric trains with diesel backup run on interruptable power, which gives the grid an extra dollop of swing load, which will be needed in the future to balance out variable renewable sources.

Hi folks

Dual mode electro-diesel has already been done in the UK ages ago. The Class 73 is still active in some places in Southern England, and can either use a (relatively small 1420HP) diesel engine or pick up current from the 750V third rail available in most places in that part of the world. It was originally used for pick-up freight so that it could work temporarily off the third-rail system in non-electrified yards.

http://en.wikipedia.org/wiki/British_Rail_Class_73

Obviously this locomotive would not pass muster for today's traffic, but the principle is there.

sf

The US has had them for ages too - NYC at least banned anything non electric from the centre and electro-diesels were part of the solution. More importantly the US and Canada are both getting modern ones.

Almost all the large rail systems in the world (outside NA) are dual fuel, electric + diesel. They may have a few hybrids running around, but that is *NOT* the common solution.

Everybody else gets by with electric locos and diesel locos and that is it.

*WHY* do Americans think that this is some new unique problem that has not been dealt with, efficiently, for a century elsewhere (MANY elsewheres, from Chile to Germany, China to South Africa) and no new inventions are required.

This is MATURE technology !

Alan

Alan,

One puzzle for me is:

If it is a mature technology and it actually works, how come it hasn't been invaded and raped by Wall Street, and totally trashed? ;0)

They are too busy strangling it to protect their investment in oil.

NAOM

Yair...from Gail's post "2. Adopting the latest technology."

Seeing as here in Australia our electricity will most always be sourced from coal powered generators I have often wondered if some modern thinking could be applied to developing a locomotive using a reciprocating steam engine and "state of the art" boiler technology.

It seems it would be more efficient in this country to go back to burning coal direct in locos and avoid transmission losses and the huge expense of overhead electric catenerys.

That is to say:- Australia is a similar landmass to the U.S. and we have a very low population.

Reciprocating stem engines have so many mechanical and practical disadvantages that there is zero likelihood of ever using them again. Many double expansion locomotives were converted back to single expansion because of mechanical problems. A steam turbine is only about one tenth the size of a reciprocating engine and would be preferable, but still not a good choice. A high pressure boiler is not something you want to subject to the stresses of bouncing along on rails. You’d have to inspect it constantly and repair all the stress cracks. Then there is the problem of loosing the condensate. The make up water has to be de-mineralized to keep it from fouling the boiler and from causing cracks in tubes and drums.

It would be more efficient and practical to use coal for synfuel diesel. Electricity is still the most efficient way to use coal for locomotive power.

It's much more efficient to burn coal in a power plant than in a locomotive and you can also afford to put on much more sophisticated pollution control equipment. If greenhouse gases are a problem, you can capture the CO2 from a coal-burning plant and inject it into deep underground formations. You can't do that with a coal-burning locomotive.

Steam engine locos are HORRIBLY inefficient. It is MUCH (at least x2, x3) more efficient to burn it in a good coal fired plant (you Aussies need to buy a couple of efficient ones from the Chinese) and run it in an electric loco.

Alan

Alan, the risk of Australia buying Chinese power stations is the same risk that buying any cheap Chinese cr@p incurs. We (Australia) have been buying Chinese locos, bulk wagons and passenger carriages and it has been a case of breakdowns, failed welds, delayed delivery from China and almost certainly a short life for the rail cars (years instead of decades). DON'T go for the cheap option.

Yair...I thought we were discussing here as to how to continue with life after oil becomes unavailable or too expensive to use for transportation?

Traditional style steam locos MAY be HORRIBLY inefficient...but a bloody sight MORE EFFICIENT than stringing thousands of miles of copper overheads to run a dozen trains a day.

I don't think you blokes grasp the implications of a huge country with a tiny population and an existing rail network that used to work well with steam.

We still have a couple of mainline steamers here and they let them loose occasionaly. It occurred to me while we were topping up the water with the local contractors water truck that the only oil the loco was using was in the drivers oiling can.

So, here we have an ancient technology that can move five hundred tons of freight into any part of the country using a few litres of vegetable oil or melted whales and you dismiss it out of hand.

My original post was a polite enquiry as to whether anything could be done to IMPROVE on old and proven technology that works.

Electric trains don't normally use copper wired overhead. Aluminum is cheaper.

At any given point on a two-track line you will normally see several dozen trains going each direction per day, and each will be carrying up to 10,000 tons of freight (the equivalent of 200-250 highway trucks per train, or several thousand trucks per track). At high levels of freight they are very efficient.

Some years ago, I read of a enthusiast's proposal for a modern steam locomotive. I did not pay much attention to it. It seemed a modest improvement.

I Googled and found this.

http://www.internationalsteam.co.uk/trains/newsteam/modern12.htm

There are little used spur lines, but they are on the order of a dozen miles long. A battery loco would seem more appropriate, or a bio-diesel loco, for such.

Your googling may find more.

Thanks,

Alan

Aside from the copper vs. aluminum misconception...

You might want to do some math on the embodied energy of catenary before making assumptions. I'll hazard a guess that in energy terms catenary saves well more than enough coal (or other sources of energy) in operations to justify itself.

re:Aside from the copper vs. aluminum misconception...

http://www.isodraht.de/Default.aspx?pageid=3540

He's right. About 99% copper

Scrub Puller: Steam engines are inefficient, so I am told, and I can agree, but I do take your point about not having any oil at all to burn. I would think you may have some wind down under there in the Southern roaring 40's and 50's, which can be converted to Compressed Air. Using a dual water and compressed air pipe line, laid down near your rails, possibly as a mono-rail track, or rail bed, your new modern steam locomotive may be more feasible. Moving large amounts of water, from wind power, into arid areas may work, especially using greenhouses and other water conservation techniques. I wonder how the Compressed air and coal combination would work. I know it's being used with Natural Gas and CAES (compressed air energy storage). I don't discount steam engines as never ever being a possibility, which of course is how the future of Compressed Air Hybrids may start. If you have coal and only coal, and you have plenty of wind .... use both. The synergy my work.

Modern cars may use a frame of tube tanks for CA. This CA may be able to be loaded on the fly, and from a track side pipe, or conveyance of some sort. Just brainstorming here.

Wishing you all down under greasy luck. Steve www.environmentalfisherman.com

If you think the losses in electric distribution are bad, don't even try calculating the pressure drops in a compressed-air pipeline system. You'll be mourning your illusions and wondering how you could slay them so brutally.

Ditto if you think that compressed-air tanks have anything on batteries, even lead-acid batteries.

I don't think that's true. With line drop the electricity is lost, period: ... GONE. With compressed air systems there are defined lag times for pressures to equalize. Pressure drops are not pressure losses, right? You are comparing apples to oranges. And, yes I do think the losses in electric distribution are bad. I of course have to grant the possibility of leaks, and friction, but friction is a factor of time to distance, and volume, and this will not be an issue that will be insurmountable. Fundamentally the pressure you put into a pipe, (or hundreds of charged incoming pipes), is the pressure you get out on the other end, just like a water system, an equilibrium is achieved, even over thousands of miles. The key is the size of the line, and multiple lines, and the very high pressures. These are the factors that will allow an interconnected compressed air system( and so much more ) to be reliable, and to provide much very needed and usable horse power. A scuba tank uses 2-3000 psi. Track pipes should be able to carry up to 8000 psi.

My systems designs for offshore air compression entail dragging air to depth, using non piston systems, which may be your hang up on the past compressed air generation inefficiency problems. My systems do not use up any FF to compress the air, of course if you don't count the construction factor. Try going to the SustainX web page for some interesting reading regarding you illusions and ignorance about compressed air systems. Please go to that site, and other sites before any more un-needed embarrassment. Google up CAES. I too, probably like you, have used lots of compressed air in construction work, or to start a diesel, but these are not where my head is at, these are different applications, with different parameters.

Compressed air vehicles are silly looking now, and I don't like that. But they are working, and being manufactured and sold. That technology is on the move, and we need it. But I think if "air" were everywhere taken from a connected matrix of rail, and mono-rail based utility lines, the feasibility of running autos on wind, wave, solar, geothermal generated CA ... the possibilities seem good to me, good enough not to be discouraged. The important thing is to have a system that is able to create a commodity market for the green fuels of CA, ORCA (oxygen rich compressed air), and Hydrogen. The need now is for these green fuels, and the technology, which we have never yet needed, because we had oil. The main problem with sustainable energy sources is not in the creation of power, but in it's transmission and storage. Are you aware of this problem? If you become more aware of the problems inherent in sustainable energy storage and shipment, you may be more open to ideas in the future. Currently we are making the mistake of framing the questions wrong, and looking in the wrong places. IE: Problem: storage and shipment v Problem: energy mfg.

Do you understand that the analogy of pumped hydro power is very similar to compressed air, in that this is reserve power, and not like electricity at all? The use of CA is in the conversions. Any FF or nuke plant that produces steam can be boosted by Compressed Air, and you want to discard these possibilities, this technology? We can produce massive massive massive quantities of CA offshore, and we can ship that power. So the analogy to pumped hydro ends there. The Compressed air wins hands down, because it is easily transported in pipelines, just like natural gas. Please go ahead and take off your gloves, Engineer-Poet, and teach me what you know, I'm a fisherman, so not too sensitive.

The key is to produce CA and the green fuels with the brute force of offshore wind and wave, and other sources. If there is another way to ship offshore power inshore and to use it locally, nation wide, I haven't heard of it. I'm not saying our grid is a dinosaur, but what I am saying is that it can be greatly augmented with sustainable energy, BUT, ONLY, only if there is a transmission and storage network, that is practical, to do so. The track pipes are storage and delivery systems for power. It's just a machine design that needs to be developed beyond rough concept to model. If it is feasible and sensible, we're on our way to getting off of the CO2 problems and peak oil problems. What have you got for CO2 and peak oil? I have a system proposal to develop, please give it a shot, one way or the other. Crank BS the hell out of it if you like, but what's it worth? Thanks Steve

Sorry to tell you, but the two are very comparable. Zero flow electricity (like a socket with nothing in it) has good voltage (like pressure). Start flowing electricity to the limits of the conductor (pipe) and you get some voltage drop.

Supersize the conductor (pipe) and losses drop to close to zero.

Water (incompressible) flow in pipes is a near exact analog to electricity and is used in freshman classes to help students understand. Compressible air adds some complexity, but same general result.

Zero flow, no pressure loss. The larger the flow, the greater the loss. Solution, super sized pipe. But that costs $$.

I know you are invested in this, and I appreciate your willingness to "fight the good fight", but from an engineering POV, there is a reason no one else is pushing this.

Best Hopes for Other Good Ideas,

Alan

Thanks for the good teaching Alan. The problem with the assertion you make is that there is no practical way to supersize the conductor with electricity, so we are realistically plagued with line drop. So, while I recognize the theory, in practice the comparison between CA and electricity, where losses are concerned, especially over mega long distance, such as with track pipe: The CA stands out as a winner there. But of course I love electricity. I still maintain the factors with CA being volume, time, pressure, so we are able to overcome "the drag" factors, due to many many multiples of large diameter pipes. Like water systems, which are generally short range, the needed water is usually there due to this equilibrium, of course a good fire will tax the system. But just an analogy. As far as costs go with large diameter pipes, I think they are over blown, only because of the multi cash flows of things like broad band, natural gas, transportation infrastructure, other utilities such as waste water, bring costs down to very reasonable, if we amortize over decades.

I am only invested to the extent that I think it's practical, trying to be cold and analytical. Offering thanks for the learning.

If it's more a cost objection, and less engineering, then fine, I like that. Today I spent more time learning on the Energycentral.com web site, and I look forward to reading about 10,000 psi hydrogen. "If wishes were horses Beggars would ride" (Mother Goose) I'm with you on that one, and don't expect a pass. But the draw is strong for me to find a way to ship my offshore energy, via CA, Hydrogen, . Thanks.

Technically they don't ever equalize, the difference just becomes asymptotically close to zero.

Wrong. Drops ARE losses. You have viscous drag of the fluid against the pipe, converting work to heat. That work is GONE, you cannot get it back.

The people who've been near the recent gas-pipeline ruptures, and the family of those who were too close to survive, may have something worthwhile to say about high-pressure gas distribution systems.

If you admit you're weak on the science, you are not in a position to call others on their illusions and ignorance. You are in an especially poor position if you have not even bothered to search for the compressed-air pressure drop calculator and see what its results indicate for the practicality of your ideas.

Maybe you should Google what I've written about CAES.

The compressed air is like shipping coal in trains pulled by coal-fired steam locomotives, only with much greater per-mile losses. The losses in HVDC lines are on the order of 3% per 1000 km. The vast superiority of electric transmission is why Google wants to build an offshore HVDC network, not a compressed-air pipeline network. They have done their homework.

I'm not against compressed air, but I've taken the thermodynamics course used to introduce mechanical engineers to things like steam powerplants and refrigeration systems and I can show you with numbers just how much energy is lost in compression (if you have to cool to ambient) and the energy density of your tank volume. I get the distinct feeling that you haven't, and probably can't. I'd be happy to educate you at some reasonable rate for tutor's services.

OK I have my home work in front of me. Thanks. Reasonable rate? I thought I was frustrating you free of charge. Thanks Steve

It seems to me that you have mentioned compressed air and offshore production together before. Why would it be cheaper off shore?

The offshore equipment to compress air is different, and it's cheaper than inshore standard methods by orders of magnitude. With conveyors, air can be drug down to deep depths. Compressed air pipeline networks will range in all oceans, coming up from the South Seas.

As in the SustainX technology, there is no heat loss due to the slow nature of the compression. Hydraulics or straight mechanical force can do this, from windmills and wave mills. There is no better place to tap waves than our own gulf stream, South and East of Nantucket, because during a Nor'Easter the phenomenon of wind against water, over a long fetch, the waves chop, or steepen, meaning their peaks and troughs are closer. This is money. Waves are a tremendous force, driven by the sun to the wind to the water. These tremendous waves which if tapped using flywheels and hydraulics, offer stunning potential to produce usable power. The machines to drag the air to depth are simple, I think, but we've never needed such. We think we need electricity, but it's a red herring.

I have three generations of wind mills. The first I call the Georges Bank Mega Mill, which I've been working on for about 6 years. These are tied together, for strength, like a forest, and the sticks raise and lower in a female receptacle that I call a base. These GB mills have wave generators, which use the flywheels. The files I have, I believe, represent the new state of the art, as I have seen what the U-Mass offers, and it's not too good. I know with these machines we can produce compressed air in tremendous quantities. The land side experts think of compressed air in terms of its inefficient production, of normal turbines, or compressors, all driven by fossil fuels. So I don't expect others to believe that the sea can produce compressed air, just because I say so.

My second generation of mills are Venturi mills, which are cowling related. The third generation mills are square rig mills which are the future, following a low pressure area, sending air to the bottom. Also the creme' de la creme' of systems I have is a square rig mill with an under sea ring of pipes around the Antarctic. Of these systems for air compression and for the generation of hydrogen, and oxygen rich compressed air I have thousands of detail drawings. The track pipe came later, and I've been working hard on that, but I'm on a learning curve with rail systems and with fundamentals of standard compressed air thinking. Steve the idiot.

So what are these "conveyors"? What compresses the air? Is the conveyor in a pipe?

tdmidget: Thank you for the interest. Think of the simple water wheel. Or, think of the Archimedes Screw. These work. But air compresses, so the volume needs to be added to as the container goes down. For this I prefer a simple sand style conveyor belt, that you could rent. It has a motor, in this case hydraulic, powered by wind and wave flywheels, or powered by the Gulf Stream currents, or some combination of all three. Some days the wind blows hard, and so this would be a "wind mill day" as I call it, and the systems will be very pressed and productive. Calm days not so much, but the compressed air and other "fuels" have the ability to sit in the bottle and wait till we use them or transport them. Pushed air, or compressed air, can produce electricity, with or without natural gas, but better with. For higher compressions of air, the conveyor style systems can work in reverse, letting air up to the surface, in return for higher compression, but lower volume. Or you can just use the hydraulics as you see fit, either to use conventional compression or to pipe the air to remote deeper locations, then using that air to move more air down to depth. As I have admitted, my science is weak, and my physics is non-existant. This frustrates the educated, I'm sure here at the oil drum, and I have no good excuse. The seawater depth compresses the air, as it's transported, and this apparatus could be put in a pipe, or variously configured. I may have forty or fifty different conveyors, I forget, because my designs are pencil and paper, and bounce around enormously in concept base.

Ah, you are proposing effectively isothermal air compression by thermally coupling the air to seawater.

It might surprise you to learn that this has been done, using flowing water to carry air bubbles to depth (e.g. in a mine) and compress them along the way. Expansion could similarly propel a column of water upwards by buoyancy of the air. But if you want cheap storage of that air, you need high pressures to get reasonably small volumes; this means great depths, which you don't get until you are beyond the continental shelves.

You also need reasonably small bubbles, or the thermal conductivity between air and water gets too low. You'll have some losses due to dissolving gas in the water.

I like to work out ideas like this too. Every time I tackle something new, I wind up with a new area of study. Often I have to shelve an idea because I can't find a way to analyze it properly given what I know and the methods I can find in my searches. Good luck to you. The odds are against you (and me; I keep finding that my "great new idea" was published somewhere between my teens and the 19th century), but you just might hit the jackpot. Also, study, study, study; serendipity favors the prepared mind.

Thanks for hanging on Engineer-Poet. I think you may be right from what I read in the SustainX site, where they use slow hydraulics to compress air. Think of the tidal possibilities to all the weight of two tides a day bearing down on some hydraulic to compressed air machines! Wow! I never heard of the bubbles pumped down, but that makes sense. Most any home aquarium does use bubbles and a tube to get flows going, and we used this in our shellfish hatchery on Nantucket to flow water. If the air is being dissolved it will need to be isolated in bags, or bottles.

I have a vow of poverty, formally, after a vehicular homicide, in 1975. So money isn't my goal. As far as success goes I find it equally rewarding to smash one of my many ideas, upon discovering it isn't so great. I can remember thinking I had invented the horizontal axis wind mill, and I had paid some money for a patent search, I think I was about 20.

thanks. Steve

There's a saying about things like that: "With a few months in the laboratory, you can save yourself a few hours in the library."

You can substitute "some money to patent attorneys" for the part about the lab.

My thanks to you all. Alan, you are a gift. Your work is excellent, and I hope the idea gets a full consideration. Steve

I don't think you appreciate the efficiency gains from electrification. Coal-steam locos are perhaps 5% efficient, PCC steam turbines about 33-35%, IGCC about 40% (and immensely cleaner).

Current US railroads achieve about 400+ ton-miles of freight per gallon of fuel. A gallon of diesel is about 38 kWH (call it 11 ton-miles per kWH); at the 3:1 efficiency the electric loco will get 33 ton-miles per kWh.

The steam loco would get about 1/20 of that, or 1.6 ton-miles per kWh of coal. At 25 million BTU per short ton, a kWh of coal is about 0.27 pounds. Moving a ton of freight 1000 miles using coal-steam takes about 170 pounds of coal; using coal-fired electric takes about 24 pounds. Seen another way, every 14,000 miles the electric system saves the cargo's weight in coal.

A modern steam loco could likely do a bit better - maybe 12% or so open cycle or 15% with condensing, I can't see why you would bother though as simply using a coal to oil plant would be better for where traffic density doesn't justify electrification and distances/loads are too great for batteries and just use the diesel locos already available. There might be a continuing niche for biomass fired steam (still just holding on in the sugar industry) but not much else.

Your last comment is a reason for abandoning steam often forgotten - moving the locomotive coal (and sometimes water too) was a massive overhead eating into the useful capacity of many rail systems where the coalfields were a long way from the point of use.

Steam engine locos are HORRIBLY inefficient. It is MUCH (at least x2, x3) more efficient to burn it in a good coal fired plant

I think this statement makes more sense if you write it as "steam engine locos from the 1930's are horribly inefficient" But then, so were diesel engines from the 1930's.

They used steam because they worked on cheap solid fuel, they were more cost efficient than anything else, then.

And, those same locos would still be more cost efficient than diesel ones today, if running on PRB coal.

That said, if we used modern steam engines, it is a different story.

Like this sort of engine;

http://www.spilling.de/english/produkte.php

A modern steam engine, with oiless steam for simple condensing and recirculating. You would need a large condenser area, but that can be arranged using the sides and top of the engine + tender.

It would be particularly good for passeneger rail - where the engine is always couple to the same cars (or types of cars), and where the steam can be used for cabin heating/and/or cooling. Passenger rail typically has much lower HP per train than freight (except high speed rail)

It comes down to the frequency of service for the line length, and Australia has plenty of long lines with infrequent service - you would never recover the cost of the electrification - unless it becomes a conduit for input and transmission of solar power or the like.

Also, diesel technology was still being developed. Practically speaking, the steam engine was centuries old and the ICE decades old at that point.

I have always stalled on Alan's proposal and it just became clear as to why. It the jobs/ and economic activity that is auto centered and auto dependent. From filling stations to auto parts, car stereo to tires. McDonalds. Highway departments to accident attorneys and insurance.

Wrap your head around the enormous change that will be needed. This is huge.

Massive job changes and unemployment. Manufacturing would have to move back, as well as agriculture and food processing.

I do see some evidence of this 'retrenchment'. I'm noticing how many chain stores that have smaller sq. footage stores are starting to look "homogenized". Wall Greens, Bi-Mart, High School Pharmacy, etc. etc. all are starting to carry food items, and other common items. Like the old mom and pop without the mom and pop.

The local Fred Meyer's can contain the following smaller shops -jeweler, pharmacy, optician, hair salon, banking. A small 'town' in one building.

Take away the employment revolving around the automobile center then the only work option has to be manufacturing of needed items like clothes, shoes, etc. producing and processing food.

This is a hug shift with a lot of needed re-investment and rebuilding of factories and canneries. There is a huge wasted capital investment in the auto centered society -- but we already know that...

We are not just talking electrified rail this is much, much bigger than that. we are talking about a restructuring of our current society. In a lot of ways going backward with the possibility of higher technology being incorporated.

The USA today consumes much and invests little (see Aesop's Grasshopper at the end of the Foreword).

A shift in economic activity is needed from consumption to investing in long lived energy efficient and energy producing infrastructure.

A corollary is that Americans can see increased wealth coupled with reduced income.

-----------

On a personal level, let me try to explain. Income is what you make for any given year. Wealth is the net of assets - liabilities.

Let us suppose that Mr. U. Sam saw his hours cut and his hourly wage cut as well in 2010.

In 2008, Mr. Sam lived well. Made a lot, spent a lot and saved almost nothing. All he has to show for the good times of 2008 in 2010 are some photos from Las Vegas.

In 2010, he has paid down a good percentage of his credit card debt (see LV) and decided to add R-30 insulation to his attic, paid for with reduced consumption. The on-line calculator suggests a two year payback ($400 invested, $200/yr savings on utilities. When he needs a new a/c he can buy a 3.5 ton unit instead of a 4 ton unit (a few hundred saved there as well some time in the future). Next year, replacement windows and an insulated door perhaps in 2011.

At the end of 2010, Mr. Sam will have had a bad year for income, but he will owe less and his house will be significantly more valuable (NPV of annuity of $200/year, larger if utilities go up). He will be wealthier.

I see this strategy, en masse, as the best policy option for the USA post-Peak Oil. Reduce consumption and invest wisely in long lived productive assets. We may make less, but still enjoy a good quality of life and be wealthier.

Alan

You might want to think in terms of "net income", or disposable income.

If you reduce your expenses faster than your income, then disposable income rises.

Investment is also a form of consumption as far as measures like GDP is concerned. The investment dollars also func employment. But, it is hard to be earning less and simultaneously saving/investing more, that implies a big drop in consumption of non investment stuff.

The problem with trying to use something like net present value for a project such as additional insulation is that the market price of the house probably won't reflect the (invisable) efficiency gains. So if the residence is going to be sold withing a few years, the owner may not be able to recoup the cost of his investment. [That happened to me twice with energy star refrigerators, had to move, and just got a generic refrigerator price upon sale of the residence. Even owners have agency problems realizing conservation savings.

Just because we had Railways before we had an interstate road system, doesn't really mean we'd be 'heading backwards' in an absolute sense. It's more like we're 'Backing Out of a Dead End' and continuing on a path that we ought to have stayed on in the first place.

As far as 'This is huge' .. Yes, you're right. Hence, 'The Oil Drum', etc..

Meantime, there is a LOT of work to do, no? Install residential Insulation and Solar Water heaters, Set up Train Car Factories and lay a lot of track, move people closer to their jobs, start farming on appropriate scales again, build bikes, train a new generation of architects and vehicle engineers..

The transition is huge, but there's hardly a shortage of work to do, even for laid-off truckers.. it's a matter of managing this horizontal leap, on all these fronts.. but there ARE at least places to jump TO.

Bob

Backing out of a dead end sounds more accurate. I agree.

I agree with what Allen has to say and understand it is the best of the "makes sense" options we have going forward.

This is more than that. Fiscally unsustainable consumerism provides a lot of the jobs in the US. Selling stuff we don't make to each other will have to reduce and manufacturing will have to increase.

True dat.

Thus the need for transition (a notion of the average of baby steps + giant steps).

We can't, can't, can't (did I mention can't) go from night to day forthwith.

We must think in terms of twilight ... the transition ... the time between night and day.

Thus the discussion of transitional consumption, transitional fuels of various sorts, and transitional thinking.

One (average of giant + baby) good step forward at a time, remembering that the giants must take the giant steps, because the babies can only take the baby steps.

I agree!

Now that I'm living in small Midwestern city within walking distance of the biggest employer in the area, my concern is to make sure that the employer needs my services more than my neighbor's services (literally). To this end, I've signed up for classes that should lead to advanced degree and doing my best to pay down debt. Hopefully I'll be able to pay off my mortgage before the real squeeze starts, but that remains t be seen.

If I can get rid of debt, if I have no real transportation expenses, and if I'm unusually employable, then I ought to be able to afford super-expensive food and energy in order to keep my family fed and warm.

EDIT: I sure like my neighbors, though, so I really hope we can all stay employed...

To the mechanically inclined I think there will always be the need for a plant maintenance kind of person. Be it in railroads, canneries, or out on the farm. Someone on site who can fix everything and keep it running, baring the more heavy industrial types of repairs- lathe, milling machine kind of work.

I look back to the horse powered days and I cannot see us returning completely to that. It will be a local or individual decision based on local resources and personal finances. I think machines will be in our future, to some degree.

Taking the position of trying to be as energy self reliant as possible. Feeding and caring for a horse for those times you need it is expensive it terms of space, time, and possibly resources. You feed a machine only when you use it. Is it better to gasify hay for use in a tractor?

In a word, yes, though you're probably better off using straw or wood chips (less fixed nitrogen lost in the gas).

Anything that improves productivity puts people out of work. Productivity is why we make $22/hour on average compared to less than $0.50 in 1800, measured in today's dollars. Periods of economic depression coincided with the fastest growth in productivity, as is in the 1870s-1880s and 1930s. , the exception being the late 1940s-1960s when we entered the age of consumerism, or at lest there were other thing to spend money on beside food, clothing and shelter.

What we did in the past was lower the work week, form 70 hours in the early 19th century, to 50 hours by 1900 and to 40 hours in 1933(National Industrial Recovery Act).

We would be lucky to be able to reduce truck ransport by half. The savings would be nothing like that of going from wagon to rail in the 1800s. Wagon freight cost 24.5 cents per ton-mile versus .875 cents by rail.

It the jobs/ and economic activity that is auto centered and auto dependent. From filling stations to auto parts, car stereo to tires. McDonalds. Highway departments to accident attorneys and insurance.

Wrap your head around the enormous change that will be needed. This is huge.

The same can be said for things like shutting down the Military Industrial Congressional Complex or the Flat Tax-shut down the IRS movements.

Change is going to come. You'll know the car/roads are almost a dead issue when you hear "think of the police/safety" as an answer to why we can not stop funding the roads.

Southern California once had the largest interurban electric rail system in the world, and Los Angeles once had subways. All the interurbans were abandoned, and the subways converted into sewers. The process is alluded to in the movie, "Who Framed Roger Rabbit". I admired the clever ways it circumvented the libel laws and avoided the producers being sued.

General Motors, Standard oil of California, Mack Trucks, and Firestone Tires were not mentioned by name in the movie. However they were convicted in court of conspiracy, so I feel free to mention them as indicted and convicted co-conspirators in the plot to eliminate American streetcars.

You can look up General Motors Streetcar Conspiracy on Wikipedia or Google if you want to know the details. I don't want to get into it because it will turn into one of those, "When did you stop beating your wife?" sort of arguments.

The fact is, however, that many parts of the US once had very extensive electric rail transit systems, and almost all of them were abandoned. The same is not true of many other parts of the world.

Ed Tennyson, who I have mentioned before, is the last living member of the team that prosecuted GM. He was technical support, not a lawyer.

They won. GM was fined $5,000.

Best Hopes for Justice,

Alan

Ed also told me after WW II, when the transition from steam was starting, GM let it be known that any railroad that added electrification rather than going to diesel would be blackballed from GM shipments.

AlanfromBigEasy & RockyMtnGuy,

So many people do not understand the reality of the conspiracy, like you pointed out, even though in many ways it has been proven beyond a reasonable doubt.

That was then, but now is now.

It is a criminal conspiracy now, not a benign conspiracy.

The consequences back then may not have been foreseeable, but they are entirely foreseeable now (to all but those who suffer the dementia of denial).

Thus, we are discussing the issue in The Age of Criminal Insanity, not your normal mom & pop competitive enterprise context.

That was then, now is now.

GM did kill off what remained of the street railway system, but it had been in long term decline, beginning around 1914 with Ford's mass production of the Model T. Jitneys (5 cent taxi's) followed by motor busses and personal cars took away ridership.

This is covered in General Motors and the Decline of Streetcars: http://www.lava.net/cslater/TQOrigin.pdf

Actually, the decline of the US railway system did not begin until after WWII. The numbers of people US streetcars and railroads carried during WWII were just astronomical. The people who say, "you can't carry that many people on on rail systems" should look at the numbers. They're mind-boggling.

In the US the decline of rail systems began after WWII with the construction of the Interstate Highway system and the urban freeway construction frenzy. In Europe, they continued using rail systems because they couldn't afford to build the freeways and highways for many years after the war.

Today, the Europeans have all kinds of sophisticated high-speed long-distance trains and urban light rail systems that the Americans can only dream of. It's really because after the war they couldn't afford to build freeways and interstate highways. They just took the existing systems and put some modern technology into them. Nowadays they can afford to build freeways and expensive highways, but they don't think it's a good idea.

The data in the report whose link I posted shows a peak of 14 billion ridership in 1920, falling to a little over 6 billion at the start of WW2, rising to almost 10 billion during the war. Bus ridership during the war was 20 billion.

This data is in consistent with other data on electric interurbans in The Electric Interurban Railways in Amreica that shows the track abandoned druing the period.

I personally like railways and used the system in Atlanta (heavy rail) whenever I could; however, the Atlanta route was too limited for everyday use. In the days of streetcars cities were much more compact and some streetcar systems had good area coverage.

Southern California once had the largest interurban electric rail system in the world, and Los Angeles once had subways. All the interurbans were abandoned, and the subways converted into sewers....General Motors, Standard oil of California, Mack Trucks, and Firestone Tires were not mentioned by name in the movie. However they were convicted in court of conspiracy

Conspiracy? Naw, it can't be true. Sounds more like a theory....

The Washington Monthly has a good article that explains that the housing market has already started to turn away from low density suburban patterns. The points illustrated in the below article mesh well with Alan's proposal.

http://www.washingtonmonthly.com/features/2010/1011.doherty-leinberger.html

Even more so with Chapters 2A - Urban Rail, 2B - Transit Orientated Development and 3 - Bicycling.

*IF* I can find the time and energy to do this well, this is the book I want to write.

Chapter 1 - Electrified Railroads

Chapter 2A - Urban Rail

Chapter 2B - Transit Orientated Development

Chapter 3 - Bicycling

Chapter 4 - Electric Cars and Trucks

Chapter 5 - Home Heating

Chapter 6 - Using Oil More Efficiently (Aviation, Hybrids, Recycling)

Chapter 7 - Secondary Technologies - Electric Trolley Buses, Segways, Monorails, PRT

Chapter 8 - Bioplastics and Chemicals

Chapter 9 - New Technologies

Bonus Chapter - An 88% to 90% Carbon Free Electrical Grid in 35 years

Any suggestions are welcome.

Best Hopes for no writer's block,

Alan

A desire named streetcars:

http://www.energybulletin.net/node/47021