Energy costs are becoming more critical

Posted by Heading Out on November 5, 2006 - 10:52pm

That now is changing, and energy costs are already having an impact that goes outside the more obvious ones of driving less, or turning down the thermostat. Anecdotally one hears that the National Glass Center in Sunderland is closing four of its furnaces, because of the rising price of natural gas. That's one way to cope with the increase in cost, simply stop doing what you were, or at least at the same level. But as the entire economy becomes a victim, long-term that is not going to help.

The oil crisis is not a vexing "cost crunch"; it is an unfolding catastrophe that could set back efforts to reduce poverty and promote economic development for years. . . . . Here in the capital of Senegal, gasoline costs $5.62 a gallon. . . . . in a country where per capita income is $849 a year. Senegal's electrical utility has been forced to turn off the lights throughout the nation for long periods every day, a crippling problem that could be eased if energy cost less.

Unfortunately the Cornucopian point-of-view that we will soon be swimming in oil and gas again, doesn't help encourage any thought of change in the way that energy is used. There is an implied thought that if we can just stick it out, soon we will be back in the land of plenty. For example the EIA data shows, the U.S. demand for gas is continuing to grow, despite the price.

.

As a result efforts to find new ways to operate with less energy are not given much attention, or support, since (learning from the lessons of the 80's) that investment will be found to have been thrown away when the tap re-opens. And this is a pity, since the last of the generation that worked on these problems the last time they came around, are now retiring. Further, since a lot of the work was done before the Internet was around, there is little of it that can easily be recovered through Search Engines, and thus it will likely be lost.

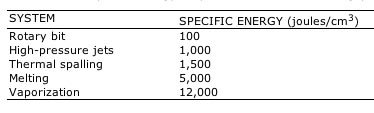

I was thinking of some of this as I watched the lasers at the Fabtech show. In cutting applications they work by either melting, or more often vaporizing the target material. This is inherently a less efficient method of cutting than, at the other extreme, a guy with a pair of steel shears, in terms of what we call specific energy - i.e. the amount of energy required to remove a unit volume of material. Laser cutting is much more energy intensive, though it gives a precision and speed, that is often hard to match if you were doing it, with less energy cost, by hand.

And if you were thinking of using it to drill an oilwell, then Bill Maurer, has some sad news for you.

You have the same level of cutting energies when you use the same sorts of tools for cutting steel. So it is that we are now using one of the more energy-expensive techniques for cutting. It is possible, by narrowing the beam, to remove only sufficient material to allow separation, and the process can, in that way be more efficient. But there is only a certain amount of change one can make in a system like this before one reaches a limit. Vaporizing material just costs a lot of energy, period. Which suggests, as energy costs become a greater part of the industrial process, that we should see more research to try to find new and better ways to get things done with less energy.

I was thinking about vaporization on the plane back from Altanta, and was reading in the latest Wired that the brain allows alcohol molecules in, while keeping others out (something they are trying to overcome) and did suggest to my students that perhaps if we put a tap in their ear, and allowed them to drink to excess we might find a new way of concentrating the alcohol from cellulosic production - but this obviously was not the humorous aside I thought it might be.

My point, however, was that we are in need of finding different approaches to saving energy in most of the things we do. In many cases the older ways did not use as much energy, but were slower and required some skill that has, in large measure, been lost. The values for energy cost that are assumed in many of these cases are not absolute values, but are reflective of the current way in which we carry out the work. A man with a pick can mine coal at around 4 joules/cc, which is a mere fraction of that needed by a laser. But he (there were no female miners in the UK in those days) did it by breaking the coal out in large pieces, using the leverage of his pick to extend existing cracks. If a laser is used, then the existing crack system is not taken advantage of, and the energy cost is much higher. (And to anticipate the comment - if you use a pico-second laser the coal will not ignite as it is vaporized). There is thus a lot of potential in reconsidering how we use energy beyond just the improvements that can be made in transportation efficiency.

But, sadly I do not think that we are looking for these alternate approaches that intensely. It was legitimate and timely for Matt Simmons to point out the lack of investigators (at 24:30 on) and that there are very few break through ideas on the drawing board for the fossil fuel industry. Though he spoke specifically to the crude oil problems. He also pointed out that the majors aren't funding research in these topics, and that the relevant departments at the universities have shrunk and lost their budgets, so that the technology pipeline is nearly empty.

I have bemoaned this problem before, but the steps that I see coming from the government seem more tied to single, large center funding, rather than encouraging a multiplicity of studies to find answers. Which is not to say that they are not there, but if folk aren't looking that hard for them, (because of both a lack of interested faculty and students, and a lack of funding) then it will take that much longer to find answers when it will no longer be needed as a prudent step but rather as a vital one.

And in the meantime, it is back to working with that fuel that warms me twice. The first time when I split it (as in now) and then, later, when I burn it.

Of course, the "solution" the free market provides might be to move operations overseas, where natural gas is cheaper, and where the people who took your job now have the money to buy their products...

Like you I have been laying up the wood this weekend and come to the same conclusions you have. Some things are done faster with modern equipment, but not as energy efficiently. Specifically, splitting wood with and ax requires skill to split with the grain at weak spots in the wood. Mechanical splitters just brute force the problem, often cutting through knots rather than splitting around them.

If speed is the only criteria than Paul Bunyon can't keep up with the steam splitter! But when energy is scarce it should be treated with respect and not be wasted. We need to trade speed of accomplishment for efficient use of energy whenever we can. But it is now a habit for people to trade speed for quality in just about everything. A craftsmen using power tools is a wonder to behold. The same tools in the hands of most people just makes a mess quickly. Most houses built in the last 20 years show this. There is no real thought going into when high energy applications make sense vs using a less energy intensive method.

A steel liner is more affordable.

I have thought a lot about the loss of basic skills as being discussed here. I am "skilled" in many ways--carpenter, good at lots of things--but my "skills" are largely mute absent the grid.

It's "moot".

http://www.thefreedictionary.com/moot

Sorry. I couldn't help it.

Jack

But a solar oven is more efficient yet and doesn't use any electric. But it takes a long time (hours) to cook a meal in a solar oven which makes it a non starter for most people.

The key is to use the most appropriate tool in each situation instead of always relying on the most energy intensive, which is also usually the fastest. The modern world is obsessed with speed.

They are really portable. I know people who take these on camping trips.

We do it that way if we're going to be out all day.

Another option is the Sierra twig stove, by ZZ manufacturing. A single, rechargable AA battery powers a fan, which burns a few handfulls of twigs very hot, cooking our food or boiling our water very fast. We've phased out our propane and only use the twig stove and the solar ovens.

Are you using the Solar oven like a CrockPot, too? I've been chewing on getting a Solar CrockPot Design to work this way. Shouldn't be too hard.. and the great thing with crock pots is, as you said, you do all the setup in the morning, and when you get home, a hot dinner is waiting for you. Soups, stews, potroasts!!

Bob Fiske

And our "vendors" have gotten so efficient at selling us stuff that is made by those marvelous machines that no one notices the poor quality of what that stuff or the even worse quality of the service provided.

Co-generation is one of the really major areas of conservation/efficiency, and yes, it also works real well at the micro level too.

It may not scale that well to a city dweller, but the real problem is that such solutions, where workable, provide no incentive in an economic sense. That is, no one is making money off your physical fitness, your reduction of carbon emission, or your reduction in electrical/burning use - so such solutions remain in the realm of personal virtue, not social benefit - remember, more profit is the goal, not more efficiency or a better life for the individual.

This is where I split from the idea of catabolic collapse, compared to entropic collapse - that is, societies set priorities, and then ignore reality while attempting to maintain those priorities in the face of any and all challenges, since any change represents a self-defined failure. Successful societies over time change their priorities, and unsuccessful ones die off trying to maintain their visions in the face of uncaring reality. And yes, this should sound like a reference to a certain society which seems utterly incapable of changing itself.

I keep toying with the idea that the society which currently exists in North America will at some point in the near historical (not in my lifetime, but not thousands of years either) future become something like the Mayans - that is, a group of people who still belong to an identifiable culture, but who no longer have anything to do with their past, having become a footnote, so to speak, even if their past accomplishments remain part of the world around them.

Of course, if you have bulldozered the fields and woods to make McMansions, then you would have to wait a good generation or two before the first wood becomes available as fuel - and you would need to tear down all the McMansions to build good housing in terms of energy requirements and comfort.

Obviously, the time to have started such planning was the 1970s.

We live in the mountains of AZ, in a 250 square foot paper adobe house which has high insulation and high thermal mass, with a lot of south facing windows. Luckily the sun shines a lot, so the walls, floor and roof heat up and stay warm, but it can get down to 8 degrees in the winter. We have a modern, but tiny Danish Morso stove, and last winter only used it once or twice a month.

I've had friends who homesteaded in the north east, in large drafty, uninsulated houses, and they chopped a lot of wood, and tended to huddle in one room. But without thermal mass, the room tends to heat up then get cold. With a tight, high thermal mass room, it is harder to heat up, but once warm it stays warm. In a conventional house, there is not thermal mass; only insulation. The only thermal mass is the air, adn the mass of the stove.

I once lived in a well insulated shack in the north woods, and any fire in the stove would make the place sweaty in minutes, and I'd have to open the windows. Once the fire went out, it got cold immediately. Needless to say, that winter was not terribly comfortable.

The idea of a Kackelofen (tile stove) hinges on the idea of mass - it is normally a quite large and heavy part of the house, built to retain and then relase the warmth of the fire built in it.

I may add, most German wood stoves (and oil and coal, for that matter) are designed to be efficient heating units - people pay for fuel, not for effects. Here, people want the steak, not the sizzle, so to speak.

Expat... I have wondered about external insulation since living in a very cold English detatched house in the 1970s... never read of any commercial product though.

Do you know any details of this... layers/surface finish etc. How is the structure allowed to "breathe"?

How does extra 10" allow for window setback etc...

Is it only for new structure design or can it be retro-fitted?

Any web links?? (German or otherwise?)

The examples I have seen of external insulation is often more like 5-10 cm then 25 cm. You get diminishing returns with thick insulation, it is indeed harder to make the windows nice and you probably dont want to extend the roof. And its no use to super insulate unless you have a ventilation systems that recovers heat energy and good windows.

The window setback is less of a problem, since southern Germans have what is called Rolladen - these are vertical 'shutters' which completely cover the window from the outside. Very efficient at cutting down on noise, light, and heat loss (northern Germans that I know living around here tend to find Rolladen insane, and a sign of how southern Germans have some real problems). In other words, windows here are already set back, and adding a few inches more is not really a problem.

As noted, the variables are huge, and also hinge on how the house is built. German houses around here tend to not use wood at all in their wall construction, and have overhanging roofs. The styrofoam is normally attached in a very water tight fashion, both underneath, between, and on top - the Rhine Valley where I live is a good place for redwoods to grow, if that gives a picture.

If North American society switched to a diet that included half as much meat, we could turn croplands to forests that would be ready in by 2012.

I'm hedging my bets and planting the steepest parts of my property to mostly poplar, some spruce, and a smattering of maple, just in case. Even if the cornucopian's are right, it will still protect those areas from erosion and provide shelter for my sheep. The mule and white-tail deer that go along with a poplar grove are welcome too.

My experience is with tulip poplars in Virginia, which are really fast growing - though loblolly/Viriginia pine is also comparably fast, and the poplars in Germany are also fast growing - where I live now is roughly as north as you, so that may be a better comparison.

Nobody here would waste their time cutting and burning such wood after less than maybe 15-20 years. Much of the red oak I am currently burning (mostly cut and split by hand - I don't use chainsaws) is 20-30 years old.

Here's a link you might find interesting (Google for "hybrid poplar culture" for more of the same):

http://a-c-s.confex.com/crops/2006am/techprogram/P25753.HTM

In any case, I'm sawing a load of firewood from a six year-old planting of hybrid poplar this weekend. The logs are about 4 1/2 to 5 inches in diameter for the first 8 feet or so. Since I prefer sawing to splitting, this is perfect for me and I feel safer cutting down smaller trees. This is a managed planting that was irrigated regularly for the first year and when necessary for the second. I believe it was fertilized once with liquid cow manure. The owner plants in 200' rows (the length of his drip irrigation lines and one row planted per year) spaced at 4' and wants me to cut every second tree so he can let the rest grow to a larger diameter. I never cut maple for firewood but occasionally cut one down and saw the trunk into planks for woodworking and the rest into firewood for the owner of the tree.

The 50% for wood stoves is terrible. Half the extractable energy is lost because of poor combustion.

In Denmark the efficiency must be at least >70%

This one ( randomly chosen) gets >80% efficiency.http://www.fokus-pejseovne.dk/dokumenter/Fokus2.pdf

The Nordic swan label for wood stoves ask for more than >73% efficiency.

http://www.svanen.nu/DocEng/078e.pdf

Citation:

The efficiency of slow heat release fireplaces, ©¯k, must be at least 78%. The efficiency of sauna stoves, ©¯k, must be at least 60%. The efficiency of wood stoves and inset appliances, ©¯k, must be at least 73 %. The efficiency of pellet stoves, ©¯k, must be at least 75 %.

From test institutes I have seen results above 85% efficiency.

regards And1.

If it is from your local woodlot next to your house, not too much bother. If it is further, then you have serious energy usage issues.

Here in London, wood is technically illegal (the Smoke Orders, arising from the winter of 1952 when thousands of people died due to smog) but is burnt. But I doubt it has any positive CO2 consequences (we use open hearth fireplaces as well).

In Aspen, Colorado, I believe, new wood burning sources are illegal, due to smog arising from temperature inversions.

1)cutting and stacking- we still have need to run an economy, and there will be businesses who you can pay to bring you cut firewood, or pellets, etc. Money doesn't go away with the 'Easy Oil'..

Huh? Microwave ovens are a lot older than that, and they weren't invented by someone looking for a more efficient way to cook--it was yet another of those things someone stumbled over (a guy working on a radar project accidentally melted a candy bar in his pocket). The first commercial one hit the market in 1947:

http://www.gallawa.com/microtech/history.html

Bob Fiske

Which pocket?

cfm in Gray, ME

The New Atlantis: Shop Class as Soulcraft

Here's an article along that theme.

I found the work to be challenging to both my mind and my body. When I was done I had a very sharp saw that was tuned to perform it's job well. I had a sense of true accomplishment and pride, something sorely lacking in many aspects of my paid work as a middle manager.

The dreamer in me hopes the current state of economic affairs can't last so that I can get out of my 9-5, windowless cubicle grind and into the work of a skilled crafstman. Presumably these skills will be in short supply and people will pay (or trade) well to employ my skills.

So many aspects of our technological advancements leave much to be desired in regards to a quality of living, especially when it comes to finding work that is fulfilling. I read the "New Atlantis" article last week and I can very well relate to the message.

Tom A-B

My main concern now is that the infrastructure we have built over the last hundred years will crumble post peak oil.

I mean buildings roads rail factories etc.

Especially in countries like the US that did not build to last. This means we will quickly be facing a situation where we will have to rebuild significant amounts of our infrastructure with very expensive post peak energy sources and material and worse it will no longer be cost effective to build cheap requiring additional cost to build long lasting structures.

We tend to be focused on what I call transient fuel use such as heating fuel for cars etc but I'm beginning to think the real problems will be caused not by high fuel costs but the increasingly exorbitant expenses of maintaining our current infrastructure much less growing it.

In addition of course esp in America the infrastructure is not peak oil friendly with sprawling cities etc so a lot of it may not even make sense to rebuild instead the focus will probably be on newer saner infrastructure. One one hand this is a good thing but on the other we will be writing off a lot of the structural wealth created from cheap oil.

Considering the EROI of fuels such as ethanol if you add in the "infrastructure" tax which has not been done I think you will see that not only are they negative they probably are quite negative. By infrasture tax I mean for example the direct EROI of ethanol for example is slightly positive. To maintain the roads buildings etc used by the ethanol fuel vessels turns the EROI negative. Rebuilding to lessen the use of ethanol does not help.

This problem applies to any move away from cheap plentiful liquid fuels CTL Ethanol what ever.

If you think about it its quite simple once we move to renewable energy sources we simply don't have the energy on a year by year basis to build or maintain a infrastructure that degrades significantly over a period of decades.

No expensive fuel solution will prevent the failing of our current infrastructure so we should focus on using the remaining cheap energy to build as much post peak friendly long lasting infrastructure as possible. Waiting till well after the peak could easily result in projects that could be done today delayed for centuries because of the reduced energy budget.

I think in part this may explain the care Romans took when building roads and bridges. They were a significant investment of the resources available and high energy maintenance was not possible. I fully expect our society to move back to building for hundreds of years.

Buildings are depreciated on a 5 year basis on corporate balance sheets. Therefore, financially, there is no tax benefit for a building to last longer than five years.If the building last longer, it is considered icing on the cake. Even so, most buildings today are expected to last for around 15-20 years, as that is the maximum length of the warranties for big ticket items such as the roof.

Also, when a cost analysis is done on a building for financing purposes, the analysis stops at completion of construction. It is difficult to convince the financial whizzes that provide the building capital to pony up additional funds to put in more efficient HVAC systems or lighting systems, or any other energy saving device. They do not care about operating costs, they are solely concerned with the construction costs.This stems from most accounting practices having the construction funds and the operating funds in different budgets managed by different departments.

Building to last hundreds of years requires a significantly higher outlay of funds as compared to your industry normal today. For one thing, it requires a much higher level of craftsmanship, which means higher labor costs. And since labor costs are the largest percentage of the construction budget, the money whizzes want the labor cost to drop, not increase, regardless of the increase in quality.

This has been going on for so long, that the knowledge of how to build for longevity is no longer available within the construction industry due to retirement or death. For instance, in non-unionized areas (unions do a better job of retaining skills within the workforce, but you pay for the expertise), it is hard to find masons today that know how to construct a brick arch properly.

The problem roofs face is not structural, but relates to sun and weather exposure. There are roofing treatments which are used today which will last multiple decades without 'reskinning'.

Yes, builders (usually) build to codes, but the codes are only the minimum requirements. Yet the key problem arises when the client is not willing to pay for quality. Sadly, this describes the majority of the clients building at the moment.

As for the roofing types, I will relate what the state of Mississippi project manager told our firm when we suggested a green roof on an existing concrete university building that would require no improvements to support the weight. "I will not be the first to approve a green roof in the state system. The roof approved will be the cheapest typical one available and installed by the lowest bidder, even though it will need replacing again in 15 years. By then, I will be retired."

Until those holding the purse strings change their ways or are replaced, no progress will be made.

Cool thanks for the response.

I would say that underlying these decisions is cheap energy.

So your correct that this is the current financial structure but it works because energy has been cheap thus building/material costs are low relative to labor. In a expensive energy world this no longer holds not that labor is necessarily cheaper but materials are no-longer cheap.

My view is that these decisions to build cheap replaceable structures will add a tremendous burden on the post peak economy. Now we will be in the situation of trying to maintain these crappy structures in a expensive energy/expensive labor world.

I'd be interested in hearing your view of this situation.

I actually think it may be the biggest problem we face post peak.

Its interesting you brought up the political/tax structure that in effect subsidizes this wasteful "growth" economy.

Since this is the basic problem that moving to renewable buildings, efficient structures face. We are not going to move away from our cheap energy world until we quit subsidizing wasteful building practices.

Of course supporting creating lasting renewable energy sources and efficient long lasting infrastructure is important but we face a huge hurdle just removing the hidden subsidies behind the current approach.

Next of course its obvious that this means a lot of the "wealth" that's been created in structures that need constant maintenance or rebuilding will have to be written off. This wealth is controlled by people that don't want to see this happen so it will be interesting to say the least. Anything that has a large negative impact on a lot of wealthy people will not be supported.

Again the reason I keep bringing this up is the debate over ethanol or other energy sources post peak oil I think really hides the underlying issue of "hardening" our infrastructure so it can work in a expensive energy environment.

Once you focus on the real issue of building a infrastructure that works in a expensive energy environment it becomes clear we need to skip the ethanol powered SUV stage and pour our energy into using the remaining oil to build out electric rail/trolleys denser cities etc while we have the chance.

The Roman Empire crumbled because the road and other infrastructure finally decayed.

http://killeenroos.com/1/Romefall.htm

I think its fascinating we are facing the same problem and seem to be more concerned about how to power our SUV's and Air Conditioners. I figure each decade from now on out that we waste our energy will probably cost us 50-100 years post peak to simply recover our current level of infrastructure.

Whats interesting in our era is we have in our favor cheap communication systems which we should be able to keep and bioengineering/ medicine which should keep the population pretty healthy where the infrastructure remains intact. But this is a world of technical islands in a sea of misery.

Those that manage to retain a modicum of wealth will put the needy to work for a pittance, in effect creating a peasant class.

At first, these people will be put to work doing manual maintenance of the infrastructure, but as things continue to deteriorate, they will begin cannibalizing existing structures and infrastructure in the poor sections of the nation to maintain that in the rich enclaves.

Sadly, it will only be those that are debt free that will be able to avoid such a fate. Considering the amount of personal debt the average American has, there won't be many.

In a best case scenario, we will force our elected officials to get their collective heads out of their asses and make the regulatory changes necessary to begin a rapid energy descent.

Reality will fall somewhere in between, but the longer the nation's leaders stay in public denial, the more likely it is to trend closer to the worst case scenario. Of course, to those in power, that scenario may not be all that bad.

People will survive a long time on the detritus of the excesses of this detritvore society.

An important point here, infrastructure requires maintenance. The economic and political system which maintained the Roman roads crumbled before the roads. Over the last century, the tribes of "barbarians" found the roads quite convenient to sacking various parts of the empire.

The page you link to asks if the US is on the same decline road as the Roman Empire, but in the immediate future what's more relevant analogy is the American republic and the Roman Republic, which met its end four hundred years before the fall of the Empire -- Caesar, Brutus et al. Though the American republic and its incipient empire might fall simultaneousily, history never repeats in exactly the same way.

Alexander Cockburn has nice related piece concerning tomorrow's election:

Brutus

It isn't hard to build to last and there really aren't special skills needed, only the kind of experience that a seasoned builder has plus some understanding of the behaviors of various materials and techniques.

Good point!

As someone in the infrastructure business...I think you are exactly right. I suspect most people have no clue just how much time, energy and resources it takes to design, build, and maintain infrastructure.

Look at a suburb which is now 40 years old: most have some very tired infrastructure, new social problems (aging parents with nowhere local to move to that is still close to their old haunts-- the housing is rigorously single family detached; poor people living in basements; etc.) and rising tax bills.

Infrastructure was never intended to be run, maintenance free, for 40 or 50 years. It degrades rapidly.*

*doubling the axle load on a vehicle increases road surface damage by a factor of 8. 40 years ago, even big trucks were smaller than they are now, and no one dreamed of an SUV.

TABOR, the "Taxpayer's Bill of Rights", is on the ballot here in Maine.

Essentially, it caps what is spent on government infrastructure, whether in salaries, health care or roads. The part of Maine where I live has at least doubled in population in the last couple of decades. And now we are burning out of state trash, paying to clean up our water, and unable to afford health care. All of those additional costs - making a mess, cleaning up the mess, increasing the rate and scale at which we make the mess - that's all infrastructure. [TABOR only addresses the government sector - industry is way bigger.] What makes my head explode is hearing the consensus trance politicians and their Brookings Institute flacks talk about the solution - more growth.

By cutting down on infrastructure, TABOR advocates aim to increase growth. The opposition aims to increase growth by cutting taxes for big businesses and retirees. Me, I'm all for raising taxes to cut growth, but that option is not on the ballot. [YMMV - not *all* types of growth are bad.]

cfm in Gray, ME

I think the Germans actually build them for longer (how Germanic ;-).

However it is much lower if there is sub zero temperature (freezing and thawing), and the amount of traffic the road has to take-- surface damage varies as to the cube of the axle weighting.

The thing which tends to go first is bridges, again due to the freezing/cracking problem.

The trend now is to privatization, and I expect that will continue. That was how roads and bridges were built in the past.

There's an old bridge in my area that is still in use. It costs $1 to cross, and many cross every day, going to work or school. But the old-timers remember when the bridge toll was so expensive it might as well have been the Berlin Wall. Ordinary folk rarely crossed it. If they had to go over the river, they'd wait until winter, when the river froze, and drive the car over the ice.

http://www.asce.org/reportcard/2005/index.cfm

Pretty bad. Even with all the energy we have now, we can't begin to keep up with the maintenance.

Unfortunately, all the solar vehicle designs I see have very low clearances, and they are designed for very well built roads. Our electric scooter has 80 psi tires! They don't take bad roads very well.

I'm not sure I agree. A book can last centuries. Electronic storage of text and other data tends not to be available for very long.

I encountered this problem working in museums, including a monthlong internship at the Smithsonian. The rage is to get rid of paper based filing systems and go to computer based systems. THe problem is that standards and formats constantly change, and all data soon becomes legacy. We had piles of computer printouts of various laboriously input collections records, printed out before the system changed and the data became legacy.

The problems for museums is opposite that of business, which developed data storage. In business, data loses value over time, until after 7 years (or some other magic number) it has no value whatsoever. In museums, in contrast, you want your collections data to last forever. And to the best of my knowledge, only paper does that (no, let me take that back; velum is better, carved stone or noble metals is best.)

I have a book I wrote, and backed up on floppies, and every single floppy has degraded over the past five years to where they will take extensive work to be made readable. If I didn't have a laser printed copy, it would no longer exist. As for ink jet printed materials, perhaps the inks have improved, but I've had older print outs fade away.

Can we really expect data on the net to last decades or centuries?

You want it to stick around? OCR it and release it to the world ebook library or project gutenberg.

in fact most books published after about 1880 will be dust in 100 or so years. The problem is there was a change in paper making technology, which led to high acid paper.

Nicolson Baker also wrote quite a good book about the modern library, the trend in which is to dump paper storage (aka books) as quickly as possible in favour of electronic media.

When I am reminded that the 1972 Landsat photos proved to be unreadable (we didn't have a machine that could read them, still, it had to be rebuilt from scratch when we wanted to see what had happened to the surface of the earth since 1972) this sends a chill down my spine.

Permanent electronic media are anything but permanent.

Anyway, nothing is permanent (as the Buddhists point out). Old gravestones carved in stone are often unreadable after a couple centuries out in the elements. Carved stone works best in Iraq and Egypt, where it rarely rains or freezes.

As we carefully pulled it from the shelf, and blew off the dust, we saw the matching holes on either side volume as the book had, through the years since it had last been moved, been burrowed through by the local wild life.

It was still a treat to see it, but, alas it was not undamaged.

HO

Could it be the fuel that warms you five times?

Once when you plant it. Again while you watch it grow and are warmed with pride. Thrice when you chop it down. Four times when it heats your home. And climate change makes 5.

Instead, as soon as prices drop a bit, SUV and pick-up truck sales take off again.

Especially, in North America, where energy is wasted like water, it shouldn't be impossible to reduce energy consumption by 30 -50% using current technology. Getting a vehicle fleet that meets a CAFE standard of 40 mpg is possible now with today's technology. All that would be required to do it is the will.

Research on new technologies is necessary, but there is no reason to wait for a magic bullet. The research results will likely provide incremental results in any case.

What is really expensive is replacing a house, powerplant, industrial building, car etc. before it would economically be replaced.

A car lasts something like 14 years on average. Half the housing in the UK is more than 50 years old (ie effectively pre 1939 as nothing was built 1939-1949).

Which if there was a sudden increase in fuel prices (or a panic on CO2 emissions) is what we would have to do-- scrap and replace.

Most models of the economy in the 1970s capture that effect: the USA switched towards energy conservation, and in the process other economic activity suffered (a lot).

It's better to take the Japanese or Swedish approach, and engineer it in from the beginning.

Scrap and replace housing? Maybe, if there is money and materials for its replacement. More likely people will make do, and get used to dealing with being cold or hot, like they used to do.

My mother grew up on the Kansas prairies in the Depression, and she says they left their bedroom windows open even in the winter! (hard to believe, since she never opens her windows now, and the temperature rarely strays very far from 70 degrees, but there you have it...)

Lots of what we can put up with is a matter of perspective.

And real dumb things have been done from time to time. One major concrete bridge, the 6 km Ölandsbron, were built in 1972 using salty water as a very minor cost saving measure. This has lead to repairs and strenghtenings costing more then the bridge cost to build, notice the sheats cast on the pillars to strenghten them:

http://sv.wikipedia.org/wiki/Bild:%C3%96landsbron.jpg

Its fairly common to see 30-40 year old road bridges having their surfaces and sides jackhammared or water cut exposing rusted rebar to get new surfaces and sides. The knowledge of how to make them last well seems to have been accumulated slowly and there is a hump of maintainance work that needs to be done. Two years ago I thumbed thru a standard steal catalogue from an company selling all kind of beams and rebar and they had gotten themselves a chapter for stainless steel rebar recommended for concrete exposed to salt water or salted roadways or exposed places with thin covering concrete. A pity that was not used back then, I hope its used today.

I donbt think there will be an end to this process, there is allways a better way to build things.

What is the determining factor for wear & tear in reinforced concrete structures... hi-rise buildings/bridges etc. Is it rusting of the rebar or chemical breakdown of the concrete itself??

Are there are "better" non-degradable materials for reinforcing concrete than rebar...(price notwithstanding)?

This means that you MUST repair a concrete structure when it begins to deteriorate since it gets far worse with time and if you wait too long you will loose it.

I know concrete can be reinforced with ordinary steel, galvanized steel, stainless steel, steel fibers ordinary or stainless, glass fibers (cheap and convinient for small pours) and glass fiber rods. But I am not knowledged in the field and there is probably a lot more to it.

I shall check with my resident concrete-pouring expert (who is 80, but knows a few things) when I next speak to him.

The joints in bridge decks, concrete roadways, etc., are especially problematic. They are necessary, or the concrete will crack due to thermal expansion, but they are weak spot where water will eventually leak through.

Sadly this was just about the time that Volvos lost their legendary reliability record. They used to be this car that was sexy because it was not sexy, that you could own and drive forever, even in a Canadian winter (rust due to salted roads was always a problem, as with all cars).

My brother (Ottawa) has a Volvo estate ('station wagon') because it is one of the few non-SUV class family sized vehicles they still sellover there. However at 8 years, it is beginning to have mechanical problems.

His first car in the early 80s was a Volvo 240-- very used. We installed a stereo, and I still remember the day it burst into smoke as we were driving down the road-- flooding the whole car with smoke ;-). It was a great car. It looked like the below:

http://volvo240.free.fr/images/bonan3.jpg

http://en.wikipedia.org/wiki/Volvo_200_series

Saabs were never particularly reliable, but were lovely cars-- idiosyncratic in all the right ways.

At least you still make great trucks ;-).

I think Swedish practicality (comfort + efficiency) has tended to prevail, whereas in North America we go for 'least cost' (the UK is worse, believe me).

However it's usually a sign of an overstretched system when they start cutting corners on roads and bridge construction.

Inspector Kurt Wallander (Dogs of Riga, etc.)-- author Henning Mankell- is a revelation to us over here because of the focus on the decadent underside of Swedish life. Not the image of your country (clean, safe, modern) at all.

Anyway, as he lived in a hollow with no roads the biggest obstacle to getting wood ( he cut by hand) was getting it to the house. This got worse as time went.Sustainability!

Of course, it is not the "same" economy. Alot of energy intensive manufacturing has been transferred abroad (primarily to benefit from ultra cheap labor rates and benefits) and the products are being imported back into the US. Up to a point there are also real energy savings from this arrangement, because such manufacturing is taking place in a "lower energy intensity" environment (think of the living standards of a chinese factory worker vs. an american one).

However...the flip side of this situation is a tremendous explosion in the trade deficit, the emasculation of a well-paid middle class and the resulting astonishing rise in debt (if you can't "earn it" you go on living as before by "borrowing it"). The combined debt of the US (government, corporate and household) is now up to 323% of GDP, up from 150% in 1970. Add to that the negative personal savings rate (i.e. americans are now spending their savings in order to consume, something that last happened during the Great Depression).

In my opinion we are barking up the wrong tree. Peak oil is not a cause, but a phenomenon of an economy gone awry: the current or future onset of peak oil consumption-production is due to massive consumer spending based on debt. And that debt has been allowed to literally explode by inflating, hypothecating and trading "assets" (houses, securities, derivatives), instead of expanding real incomes. It is a rather unsophisticated example, but the minimum wage has been stuck at the same level since 1997, having lost over 30% of its purchasing power by now. The highest real purchasing power of the minimum wage was back in 1968 ($9.10 in 2005 dollars).

No one really knows for how much longer this "assetization" of the economy can go on - probably until the assets themselves start to go down in value. For this, the recent housing bubble pop may be a serious warning sign. If it deepens into a real, prolonged decline then I bet we will see a rapid decrease in consumer spending and thus a drop in oil consumption/production that will have nothing to do with geological reasons - valid as they may be.

Correct me if I'm wrong, but I thought that running the grid on NG was the exception rather than the norm?

(ex transport uses).

Peak Oil will accelerate global warming, possibly disastrously.

It is easy to forget that these machines are the spear point of a massive mobilisation of technical human and machine labour which is in itself highly energy intensive (all those engineers driving to and from work everyday). They are capable of and often do massively overproduce parts that sit in large warehouses for extended periods of time and far too often carry defects that are not discovered until later (making such lots into scrap material).

This work in progress is called "muda" over at Toyota. It is the height of inefficiency and is becoming increasingly recognized as just that by manufacturing firms around the world - in no small part due to Toyota's insane success.

What I've been reading about the Toyota Production System or lean manufacturing seems to be conscious of Headin Out's concerns. It champions human involvement in manufacturing, treating machines as tools to ASSIST value added work rather than entirely replace it. Why? Because a machine can't think. When a vital production segment can't think, problems that arise can't be solved and quality goes down, waste goes way up and no one is happy.

Part of this thinking is that we should only produce what we need at the rate we need it. Productivity is not a simple measure of dollars per hours worked or units per hours of operation. It is a measure of input:output and production:demand where each should be as close to 1:1 as possible. Imbalance implies inefficiency. This almost entirely eliminates the need for non thinking, fully automated machinery producing parts at rates well above what is required to deliver the final product to customers at the rate they purchase it.

It sounds nice and is being adopted in parts by a lot of companies worldwide. What doesn't seem to jive with a lot of current business practices is taht the obvious implication of optimisint the flow of material and work through a production process is the engagement and dependance on INVOLVED manufacturing labour. Instead of babysitting large machines pumping out parts, workers have to be multiskilled, tool using, skilled trades. The historical perception in Western management of such people is that they are expensive, unionised and difficult to control.

I live in Germany and I'm sometimes inclined to agree with this perception. There's a strike on my street by some union or other every other weekend. They all complain about offshoring and then demand higher salaries, more benefits - even when they know that their employers are getting shit from the shareholders.

These shareholders are concerned about the value of their stock tommorrow and in today's instant market, companies are compelled to maximised "precieved" value rather than real value. We historically percieve high technology automated factories as efficient - even if they have huge work in progress inventories, massive overproduction, extremely expensive machines and HUGE energy related operating costs. It is an psychological artifact of the advent of mass production. More to the point, the alternative of relying on labour for production is seen as a major liability, explaining the phenomenon of completely subcontracting manufacturing to third parties (Nike). So long as these archaic and outmoded perceptions dominate, global manufacturing will continue to veer towards speed, high volume energy intensive methods.

When the shit hits the fan, incrementally over the next twenty years in terms of energy (we already see it moving up towards the spinning blades with heating/generating gas and transport fuels) these large machines will be mothballed in favour of demand rate pegged production methods of far lower energy and dependant on far more human labour.

No links because you need to see what is going in a number of countries.

But yes, the big aluminium smelters strike sweetheart deals with the power providers-- in the US Northwest that is the hydro producers (the likes of Bonneville). In the Middle East, where gas is cheap, it is with gas producers.

it's actually a very small employer (a smelter doesn't employ that many people) but the arguments are 1). exports/balance of trade and 2). the associated processing industries which spring up around.

Put a CO2 price on everything we do, and the economic organisation of the world will change (by a lot), which is politically the reason why it is so fiercely resisted.

The bottom line is that processes like electro-winning, solvent extraction (pulverize it, leach it with sulphuric acid, and use powerful electrodes, around which the copper collects) use massive amounts of cheap energy.

As long as there is plenty of cheap energy, we will pulverize ever larger pieces of the earth's crust to extract it's minerals. Once cheap energy is a thing of the past, copper mining won't work anymore, and we'll be recycling, and digging through waste dumps for all the metal goods we buried there.

France maybe (how would one know, the question of the cost of French nuclear power is buried in the murky accounts of EDF, and of the French ministry of industry).

But generally, no. Nuclear power was an ongoing economic disaster for the utilities that engaged in it, despite heavy government subsidies to the industry to get it off the ground, and ongoing subsidies re R&D and waste disposal.

Now that real interest rates have come down, there is a greater interest in nuclear power (the length of time to commission a nuclear station means interest costs are a big fraction of the final cost).

But there aren't, I don't think, good reasons to believe that nuclear power will be cheap, merely reasons to believe that when you put a price on carbon emissions, it looks competitive.

http://www.uic.com.au/nip08.htm

http://news.bbc.co.uk/2/hi/business/4457210.stm

http://www.nucleartourist.com/basics/costs.htm

There was also one in Fort William (Scottish Highlands), again near a hydro power station. It's closed now.

Canada has big Alcan smelters in Quebec, also Reynolds had a big smelter there. And there are smelters in British Columbia: during the California power crisis I think they shut them down and sold the power to California instead, causing a brief worldwide shortage in aluminium.

Niagara Mohawk had a power deal with a smelter in ?Tonawanda? ie somewhere near Buffalo. Not sure if that one is still around.

Of course the Russians have lots of aluminium smelters east of the Urals in Siberia. And Western Australia (from memory).

An aluminium smelter, once shut down, cannot just be restarted, I think you have to reline it (this from memory) as the cooling aluminium sticks to the sides. it is a continuous process.

The French had one in Dunkerque, to tap the cheap nuclear power that was on offer. The suspicion was that there were big subsidies in terms of cheap power.

Expect to see future aluminium capacity put in where gas or coal is cheap-- better to take the mountain (alumina) to Mohammed and export the other than vice versa. So the Middle East in general.

The hydro plant you're thinking of is Dinorwic, which isn't on the island, but is in north-west Wales.

The uncertanities in scheduling and the need too batch transportation via electrifield rail instead of frequent just in time trucks will lead to larger inventories.

We will probably need to accumulate more capital in manufacturing equipment and warehousing in an energy poor future.

It is really impressive how little thought people put into their arguments. Energy storage is easy, on any scale. I can tell you about any number of methods which are workable. Since we are not used to apply them because with our current infrastructure they are unnecessary, they simply seem exotic and unusual. To conclude that what one does not know does not exist, is a rather poor logical choice, though.

Let me know when you need to store your excess wind energy someplace. I will be there to help.

See you in 20-25 years!

You seldom get a complete product in such a work cell but its not unreasonable to in the future have a lot of almost staffless production cutting metal and welding during nights with cheap power. And you can melt metal during nighttime and cast during daytime.

But I agree... IF one could have machines run without supervision, it would be a whole different game. But I have my doubts we will see that being mainstream before peak oil sets in.

If you melt metal during nighttime, you pay twice the wages in many European countries and three times if it is on the weekend. That is a killer for a lot of industries. The problem is less in the US, so here it is a killer for a lot of families... :-(

Heading Out,

Very interesting, thoughtful and broad ranging post, full of interesting jumping off places, thanks :-)

Of course, it opens up little places to part company on some opinions and views, but why do that when they are relatively minor given the things I was glad to agree with! The first:

"Unfortunately the Cornucopian point-of-view that we will soon be swimming in oil and gas again, doesn't help encourage any thought of change in the way that energy is used. There is an implied thought that if we can just stick it out, soon we will be back in the land of plenty. For example the EIA data shows, the U.S. demand for gas is continuing to grow, despite the price."

Of course, this seems to follow as surely as night follows day in America, doesn't it? This is why those concerned about energy should hope for the "sweet spot" which really is about $70 to $75 per gallon of crude. Sorry to have to say that, but $70 seems to be something of a mental milestone that seems to wake folks up, but not so high as to cripple the economies of most developed nations, and it spurs forward alternatives and at least some effort at conservation. It keeps energy and fuel prices on the radar screen of the buyer, so to speak. Any price below that is so nominal in most people's lives it is not even noticed. And the truth is, if we proceed even a year or two forward, it will take $85 to $90 per barrel to do the same job. The normal inflation in costs of everything is now so taken for granted that the increasing cost of energy will be swallowed up in the massive expenditure on luxury goods, medical needs, housing, college costs, etc., unless it is truly noticable. What this means is, that despite all of the howling and screaming you have heard, the cost of energy is still very far below actually hurting most Americans very badly. Connecting things like the "housing bubble burst" etc., to the recent rise in energy prices seems to be a stretch, reaching at straws to prove a point. Many "bubbles" have burst, and will burst, with little or no connection to energy prices. Think of it this way: one switch in vehcles as the prime commuter car would swallow up in savings the run up of the higher gasoline prices since 2000, and this is a consumer base that will switch cars every 3 to 5 years.

"My point, however, was that we are in need of finding different approaches to saving energy in most of the things we do."

Exactly. What you said sounds like a simple sentence, but it says more than it looks like it does:

We will NOT stop using energy, but "find different approaches to saving energy." Sometimes it seems like I come to TOD, and greatly enjoy the information exchanged, the discussion, the conjecture and ideas, but spend at least half of my time trying to dodge around the rhetorical pylons finding my way back to the main track of reality. NO, we are not going to stop using energy, not even oil and gas. NO, we are not going to "run out" of oil or gas, it just ain't gonna happen. For the most part, thank heaven, TOD is better than many of the "dieoff and wilderness" sites, in that one does not often get recommendations on how to learn to eat grasshoppers and farm with draft animals such as oxen. But there are going to be changes, big ones. I have to state my view here, honestly though: Most of the people directly involved in "peak concern" and "peak awareness" seem to have virtually no idea in what ways these changes will affect them and their children, and in what direction they or we should be moving to prepare, if you take out the "run for the hills!" option, which in fact is no option at all.

You pointed out Simmons remarks about "lack of investigators". There is a real reason for that, it is not something that just "happened". After 1982, when the oil price collapsed, companies in the oil and gas industry engaged a bitter, hard fought 20 year battle for survival. Any talanted young engineer, technician, manager, or even middle level "functionary" could find better paying, more rewarding, promising work than in the energy industry. Notice the way I phrased that: The ENERGY INDUSTRY, because it was not just oil and gas that were in a massive multi decade depression, but alternative energy all but died post 1982. This brings us to the above point of "preparing" for the changing energy environment. I suggest that we all be VERY WARY of projections and predictions.

In 1977, when I graduated high school, the view was that energy WOULD NEVER get cheaper. People invested (or failed to) and planned (or mis-planned) on this basis. Those of us with long memories are now being to cast our lot based on projections and predictions again. Frankly, we are now too old to get it wrong a second time, or we will spend out our days on Earth in poverty and possible homelessness, having missed all the opportunities to invest, and even enjoy a bit, that those who avoided being "single sourced" on information enjoyed. The time for EXTREME caution is at hand.

This brings us to:

"But the steps that I see coming from the government seem more tied to single, large center funding, rather than encouraging a multiplicity of studies to find answers. Which is not to say that they are not there, but if folk aren't looking that hard for them, (because of both a lack of interested faculty and students, and a lack of funding) then it will take that much longer to find answers when it will no longer be needed as a prudent step but rather as a vital one."

I cannot stress this one stongly enough: The "answers" WILL NOT come from the government. At it's heart, a "government" does just that, govern. Think of that word in the mechanical sense: A device to restrain, hold back, control. It is NOT nor will it ever be the government's job nor it's strong suit to inspire answers, nor to find them. IT WILL NOT HAPPEN. It shouldn't.

The government simply has to remove roadblocks to the birth and use of new ideas. It simply has to "govern" the predatory competitors to keep them from descending on the newer ideas. Other than that, it has no role in creating or inspiring "answers". The people will have to do that. The firms, the bankers, the managers will have to be "woke up" to what is available, and what is needed. Sometimes, it can come from shocking places.

Robots, for example: I will never forget an automotive manufacturing engineer I heard, speaking on a public TV show, even though I didn't bother to note his name. He was speaking of the first fully robotic car welding assembly plant he had seen, welding up the chassis/bodies of new cars (Mazda's, in this case). They opened the door to the welding floor, and there were no lights, only the flashes as the welding tips hit the metal fo the chassis. There was no heat! The interior of the building was at about 40 degrees, the same as outdoor Japanese temp for that time of year! He said the Japanese technician told him the robots actually ran best in winter, with synthetic oils in the gearboxes, they could keep working at below freezing tempetures all winter. The Japanese engineer told the American that the welding plant used a fraction of the energy of an older manual labor plant. Yes, the robots took electricity, and a fair amount of it, but not nearly what the building took in lights, heat, etc. when it housed a large labor work force.

It was a revealation. This is happening in industry after industry, and will happen based on two premises:

- The price of energy stays high enough to make it "pay".

- The young generation is developed to enjoy the friuts of the changes, and enjoy a satisfaction that prior generations enjoyed, that being to engage in meaningful work.

Right now, the price of energy is still high enough to retain interest. Will it remain so? We will have to wait and see. WE JUST DON'T KNOW. We, by which those of us, and I count myself amoung them, having long been a fascinated student (since the aforementioned 1970's, my junior high school years) of the human energy situation, "we" have been very wrong before.If deep offshore oil, undeveloped fields that have been so easily dismissed in the Persian Gulf, offshore Persian Gulf oil, hit us with a "last flood" of cheap fossil fuel, it will destroy the science and development of alternative energy for a generation. Oh, I know, THIS TIME it's different, this time it CAN'T HAPPEN. Can you prove that?

Then, at about the time the now small children of the world reach adulthood some 2 decades from now, we will have given them no road forward, and no tools to work with. By then, the climate change from the human races "last luxury carbon bath" will be far past any hope of regaining control of.

Another poster mentioned the possibility of "losing" much of what had been learned by the alternative energy researchers of the 1970's and earlier.

This is already happening. So many ideas that were tried and either showed promise, or collapsed miserably in the 1970's are back as "new ideas" today, and it is obvious that most bankers, technicians, and govermnent offiicials have never seen them before.

One example: Coal to Liquid. When I was growing up in the 1970's, a coal to liquid plant was planned in central Kentucky. Our county library still has the 30 something volume set of the environmental impact study, and it was imcomplete even at that. The water consumption would have been fantistic, but we had the Ohio River. The amount of "tailings", dust and debris, water pollution would have almost incalcuable per gallon of liquid fuel. No one calculated greenhouse gas in those days, but you wouldn't want to know.

Equipment and facilities were complicated to the point of easily surpassing the complications of a normal nuclear plant. When gas prices collapsed in the 1980's, the whole idea completely collapsed, because it would have never been profitable even at higher energy prices.

Now, coal to liquid is being reborn as a new invention. Likewise, alcohol fuels. Likewise, nuclear.

Of course, some very sensible ideas are being reborn too: Bermed housing. It sounds so simple, to berm the north side of a home with earth, and reduce infiltration and heat loss. But it was forgotten. Hydraulic hybrid drivetrains. These have been around before, and only make sense....a hydraulic pump captures the deceleration and braking energy to be returned on acceleration.

Passive solar, ground coupled heat pumps, on and on, are all being passed off now as new developments, and we are now spending years relearning the technology, trying to re-acquint the public with them. More wasted time that education could have assisted us with, had education been provided.

Such is life. We do not have worry lately about technology getting too far ahead. We have to invent the same damm thing every ten years.

Yes, change is coming. But it will catch most Americans completely and totally by surprise.

Roger Conner known to you as ThatsItImout

However, I think we've had time to study the energy question since the 1980s.

- There are no replacements for oil on the horizon, despite the rapidly rising price. We've been working on fusion energy since the 1950s and we're nowhere close enough to economical production. Every other technology I've seen is marginal at best.

- We must now consider the environmental cost of fossil fuels which will no doubt factor in to the price of oil in the near future (see proposition 87 in California). Alternative technologies are either inefficient on a large scale (solar/wind) or have an even worse impact on the environment than oil/coal (i.e. methane hydrates.)

- The world population continues to grow. The middle classes in India and China are growing. Where are we going to get the energy at $20/bbl to sustain these populations?

Demand destruction is likely the only way we'll see prices drop, and I admit that may be a likely scenario. Still, in the long term, barring any magical technology breakthrough, energy ain't gonna be cheaper.- we've made some truly amazing strides in energy efficiency (that compact fluorescent being an example). Germans have a home design and hundreds of examples of it that doesn't require external heating.

- wind is now economic in scale. I mean really big scale-- 10% of world electricity consumption is almost certain to happen, 20% is possible. Wind has entered the realm of big power (the field has moved so fast that people haven't updated their opinion of it-- those 1000MW wind farms aren't being built by Green Party members). It will be particularly important in supplying power in emerging markets, where the alternatives themselves are very high cost-- for this reason, India is the world's 4th largest installed base of wind power.

- solar isn't there yet, but all the signs suggest it is on the same learning curve as other technologies, and since solar is fundamentally a materials technology, it could show the same price curves downward that silicon technology has in microelectronics. The solar revolution has barely begun.

If there is a hole in our energy suite, it is in energy storage. Fuel cells and battery systems are going to be very important in the next century.- there's always coal. Which could drown us in our own CO2, but there is still a lot of coal out there. Carbon Capture and Storage isn't there yet, but conversely most of the bits of the technology (IGCC etc.) exist (Enhanced Oil Recovery is nothing more than CO2 injection into long term geologic storage).

I don't disagree we have big problems. First and foremost the rise in atmospheric CO2, which seems inexorable due to political, economic and institutional constraints.

Second that our only feasible transport fuel at the moment is oil based, and shifting to alternatives will be the work of a generation.

The biggest problem is the political and economic system aren't recognising the reality of global warming, and responding to it fast enough.

If atmospheric CO2 is a bathtub, that bathtub is overflowing, and we are doing little or nothing to restrain the steady drip of water into the top.

The overflow could ruin the whole house.

- we've made some truly amazing strides in energy efficiency (that compact fluorescent being an example). Germans have a home design and hundreds of examples of it that doesn't require external heating.

- wind is now economic in scale. I mean really big scale-- 10% of world electricity consumption is almost certain to happen, 20% is possible. Wind has entered the realm of big power (the field has moved so fast that people haven't updated their opinion of it-- those 1000MW wind farms aren't being built by Green Party members). It will be particularly important in supplying power in emerging markets, where the alternatives themselves are very high cost-- for this reason, India is the world's 4th largest installed base of wind power.

- solar isn't there yet, but all the signs suggest it is on the same learning curve as other technologies, and since solar is fundamentally a materials technology, it could show the same price curves downward that silicon technology has in microelectronics. The solar revolution has barely begun.

If there is a hole in our energy suite, it is in energy storage. Fuel cells and battery systems are going to be very important in the next century.- there's always coal. Which could drown us in our own CO2, but there is still a lot of coal out there. Carbon Capture and Storage isn't there yet, but conversely most of the bits of the technology (IGCC etc.) exist (Enhanced Oil Recovery is nothing more than CO2 injection into long term geologic storage).

I don't disagree we have big problems. First and foremost the rise in atmospheric CO2, which seems inexorable due to political, economic and institutional constraints.

Second that our only feasible transport fuel at the moment is oil based, and shifting to alternatives will be the work of a generation.

The biggest problem is the political and economic system aren't recognising the reality of global warming, and responding to it fast enough.

If atmospheric CO2 is a bathtub, that bathtub is overflowing, and we are doing little or nothing to restrain the steady drip of water into the top.

The overflow could ruin the whole house.

I just swept my first chimney yesterday! It was great! For some reason, I just love being up on the roof.. maybe I just love putting the climbing harness back on and pretending this is my 'extreme sport'.. anyway, we have a nice bucket full of creosote scrapings, and since it apparently burns so well, I'm reluctant to throw it away! Of course, I don't think I'll go and create a mini 'Creosote furnace' to use once every fall, (unless I become a chimneysweep and have a guaranteed supply of the stuff. The Sweeps around Portland, ME are cranking out some 15 houses a day, 7 days a week right now, which is why my mother got me to do hers, since she couldn't get a booking until Christmas week.

So, instead of burning the scrapings, my answer for a better use of our combustible timber and scrapped pallettes (which is what mom burned all last winter.. this year, the piles of spare pallettes are WAY down, apparently) ..is Masonry Stoves, which combine a small firebox with a larger 'post-combustion' chamber which allows many of the gasses to continue burning, much hotter than the wood mass, and then winds the smoke through channels in the great mass of stone or brickwork involved in the stove before exiting to the chimney. This produces very little creosote and provides a more even heat source for hours and even days, than does a typical Franklin Stove.. and forget fireplaces! My Mom had two of these built in earlier homes, and with a 2hour burn, the stonemass would stay quite warm for a day or two, depending on the severity of the season.

They are also called Finnish or Russian stoves, 'TuliKivis' are a version of this system, as are 'JetStoves', I believe.. and the 'Gasification' furnaces seem to be working the same idea again!

Does this solution count as shouting 'Fire' in a crowded theater?

Bob Fiske

I have seen plenty of 5.8L V8s with 280-360hp roam the streets. I have yet in my life to see a laser cutting machine. I would venture to guess, being the physicist I am, that a 5.8l V8 running down the highway at 75mph consumes about the same amount of energy as a 6kW industrial laser.

Now, friends, please let me know who of you believes that the energy budget of the US is driven by industrial lasers and not by SUVs?

Anyone?

In most countries the labor cost for the operator of a machine overwhelms the cost of the machine itself, by far. That is why China is so succesful. If anybody thinks otherwise, they are most likely not a small business owner or CEO.

However, if you are a succesful small business owner or CEO, you will know that laser cutting has its applications and that conventional milling and cutting have their applications and that they are mostly non-overlapping. Any good sheetmetal shop therefor has both: a laser and plenty of mechanical cutting tools. They will suggest to use whichever technique gives the best results to the customer. If they don't, they usually go out of business within rather short time. When that happens it all has to do with poor business sense and technical understanding and nothing with the cost to power the laser.

I largely agree.

Also, I would like to point out that the metal forming sector of industry probably uses but a fraction of the energy expended by the primary metals sector, i.e.,that involving the extraction of metals from ores and the initial forming of large high-volume metal objects, such as automobile engine blocks.

American industry has traditionally favored a posture of minimizing capital investment and treating energy consumption as just another operating expense. This made sense when coal and coke were dirt cheap. But as energy became a larger and larger fraction of operating expenses, many US industries that failed to modernize found themselves at a serious disadvantage in relation to freshly built German and Japanese operations that were far more energy-efficient.

Described below is what I think is a very good example of where this mindset has led.

During the 1970s I was involved in some environmental work for a huge iron foundry complex owned and operated by one of the Big Three automakers. It made engine blocks, brake drums, and other cast iron auto components.

The iron ore was melted in giant cylinders called cupolas, in much the same way that steel is smelted in a blast furnace. In this case the odd thing was that the cupolas were made of plain carbon steel plate, the outside of which was cooled by a continuous wall of water which was cycled through a large cooling pond. If the cooling water were shut off, the walls of the cupola would melt in a matter of minutes, as the inside temperature at the wall was probably well over 2,000 degrees F.

If one knows anything about basic heat transfer, one can easily appreciate that the energy losses in such a system much have been enormous ( a almost 2,000-degree temperature differential across a 3/4-inch steel plate can move one hell of a lot of heat).

When I inquired about this rather odd system, I was informed that it enabled better operational control and that they could start up and shut down quicker than if the cupola were made of refractory brick, as in the much larger blast furnaces used in the steel industry. Energy consumption never entered into the picture, but production rates were paramount.

Up until fairly recently, there were thousands of other examples of very wasteful US industrial energy usage. And most of this was driven by the perceived need to minimize capital investment and maximize daily production rates.

I would also have to agree with a previous poster that much of reason why this was so had to do with the biases in the US tax code, particularly those provisions having to do with the manner in which depreciation is handled.

I also have to agree that 25-40 year write-off schedules are not helping.

It depends how far back you want to go to include in "those days". A parliamentary report in 1842 found that in Yorkshire, women, some as young as 12 were actually hewing coal. The use of women and children to haul the coal to the surface was common throughout Britain. As a result of this report, women were banned from underground although it seems that it was the danger to their morals working naked or partly naked with men that alarmed parliament rather than the risk to their health.

The use of women in heavy surface work continued for some time after that as this picture from the Rhondda valley in Wales in about 1880 shows.

There are yet some areas of the world not fully explored for oil also. There were new oil discoveries in offshore Cambodia. Vietnam will reverse out of its decline with significant new discoveries. Kikeh in Malaysia might reverse declines there in 2007. England will temporarily reverse declines with the Buzzard Field in 2007. Sudan might soon produce 500,000 barrels of oil per day with official reserves of 500 million barrels of oil, but probable reserves of 5 billion barrels and most of the country not yet fully explored. Iraq and Nigeria might expand capacity from 2.5 mbod to 4 mbod within a few years. There is so much oil in the world, OPEC needed to cut back production to keep the prices above $50. Saudi Arabia mothballed numerous fields and did not develop others in order to prevent a world oil price collapse. In 2006 China reported some satellite fields in the Daqing oil province totalling 2.8 billion barrels; they have continued to expand production and are expected to expand until 2010 and perhaps beyond. It was hard for ASPO to get data about Russia, they surpassed Saudi Arabia as the #1 oil producer. One Russian stated they could someday produce 16 mbod, another more recent statement was that they might not be able to export by 2016. See, the Russians like to drive Porsches and have been increasing internal consumption. The lower tertiary in the GOM might contain in excess of 10 billion barrels, the US might actually reverse out of a decline for a while with at least a million barrels a day possible or probable from this new area. Mexico has signed contracts to develop a slightly developed heavy oil field of several billion barrels of oil NE of Mexico City to try to offset the expected draining of Canterrel. Canada might soon grow from 3 to 4 million barrels a day in production with heavy oil seams only partly explored and open in all directions. The Caspian Sea oil was recently beginning to come on line and should more than offset declines in the North Sea. In the North Sea more satellite fields have been found this year and EOR recompletions and pressurizations have extended the production of others. The Caspian Sea is not yet fully explored. Earlier this year Russia discovered a 600 million barrel discovery there and numerous structures have not been drilled. Parts of Asia and Africa are wild cards as there has been little E&P activity there.

Estonia and Brazil have been doing commercial production of energy from oil shale for years. Efficiency ratios of PV cells were increased and rooftop water heaters were economical in many parts of the world with current energy prices. The Israelis have installed rooftop water heating units nationwide in order to reduce dependence on foreign energy sources.

It's a pity the new 'Borat' comic film took on Kazakhstan as a target. Turkmenistan is a lot softer target: some of the things that go on there really do remind one of comedy (of the blackest kind: they torture people).

Read this report.

Buzzard at 200,000bpd is unlikely to do more than slow the overall UK decline of about 250,000bpd per year

Also most of the oil in the UK continental shelf is a lot nearer Scotland than England.