Of earthquakes, coal bursts and retreat mining

Posted by Heading Out on August 9, 2007 - 10:15am

Those of you that have been following the reports of the trapped miners at the Crandall Canyon Mine in Utah may have read that there is some debate as to whether the incident was caused by the mining itself, or whether it was a naturally induced earthquake. Also you may not understand what the mine is describing as “retreat mining.” And so I thought to write a short description that explains both, without dealing specifically with the details of what is happening in Utah, for which I do not have specific information. There is, however, a basic mine map at the NYT site that I am going to use as a reference.

The latest information from the MSHA website reports

Friday, August 10, 7 a.m. EDT

The small vertical drill bit punched through to the mine on Thursday night at 11:57 pm EDT. The large rotary drill has reached a depth of 1,016 feet. A microphone was lowered into the cavity through the drill stem, and no human noise was detected.

UPDATE: One of the questions that arises in this type of situation is to see what caused the blockage of the passageways to where the miners were working. If you look at the first picture in the Reuters series shown on Friday it would appear that the rubble pile is caused by the floor lifting. This is the equivalent of the pillars punching through the floor, which they could do if they were loaded up, since the floor can be the weakest of the three components (roof, coal and floor rock). If this is the case, it is not clear how extensive that blockage is. But you can see that the roof rock appears intact. They may well have run the drill down through the cavity to see how much room there is in the area where the men are expected to be.

First of all I am going to explain how “bumps”, which is what the MSHA site is calling this, can occur, in the general sense of what are more generally known as rock bursts. I am going to relate this to the seismic signals that they can generate, and then I will describe retreat mining in general.

To begin as you drive tunnels deeper into the ground, so the weight of the overlying rock or cover increases. As a very simple rule of thumb we calcuate that it increases by about 1 pound per square inch (psi) for every foot that you go deeper. So that, at a depth of 1,500 ft, the pressure of the cover on the rock is, at background, 1,500 psi.

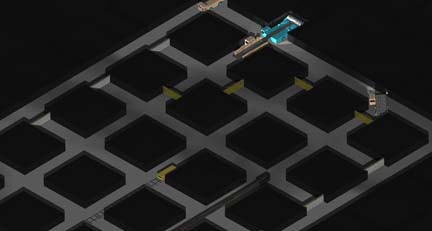

Now when we drive a series of tunnels or entries, into the coal, we leave pillars to hold up the roof. Taking illustrations from the earlier post on Room and Pillar Mining we have simplistically this picture.

Overview of a room and pillar mining operation - the blue machine is a continous miner, which mines the coal and loads it into one of the two tan vehicles, which are shuttle cars. These carry the coal to the conveyor belt in the lower part of the picture. The yellow lines are temporary curtains to control the air flow around the mining.

Now if, for the sake of illustration, the pillars are 60 ft on each side, and the entries and cross-cuts (the tunnels that run between the entries) are 20 ft wide, then the pillars have to carry the weight of the cover that used to be carried by the mined coal. This increases the load on that coal, so that that the 3600 sq ft pillar is carrying 6400 sq ft of overlying rock. Thus the pressure on the coal pillar goes from 1,500 psi to (1500 x 6400/3600) 2,670 psi. (And for those who are knowledgeable about this I know that I am being very simplistic, but I think this will serve the purpose).

As mining progresses, for various reasons, (some of which I will discuss later) this base load on the pillar can increase to the point that the coal fails. As a general rule this is not unexpected and is designed for in the mining plan. The coal crushes, but in just the same way as you can put your hand on a pile of soil and push and the soil will hold your weight (because it is held in place by the soil around it) so the crushed coal can still carry the weight of overlying rock.

It is, however, in this failure that we can sometimes run into a problem. Normally as you apply increasing levels of load to a rock it will start to develop internal cracks as the load gets over around 60% of the ultimate load at which it will fail. These cracks grow bigger as the load gets up to failure load, and can be detected locally with the right instruments. The growth of these cracks in the rock as the load increases means that failure becomes more of a gradual process, and the energy of failure is released over time without any violent result, and the coal or rock, once failed generally stays in about the same place (unless it is falling out of the roof).

Occasionally however you have a stronger, or more brittle rock that is part of the pillar or immediate roof or floor, rather than the softer, more crushable, normal rock. This does not follow the more general path but builds up energy as the load increases, without much intermediate cracking, and then we may get what we know as a rock burst –“ that phenomenon which occurs when a volume of rock is strained beyond the elastic limit, and the accompanying failure is of such a nature that the accumulated energy is released instantaneously.”

Generally these rock bursts are more common in very deep mines, with very strong rock, such as, for example, in the gold mines in India, or South Africa. To the extent that it is a sequence of events where the energy is stored in the rock, and then suddenly released when the rock fails, it is very like an earthquake, and can generate seismic signals of considerable size. For example in the potash mines around Merkers in Germany the stress concentrates in one of the rocks (carnallite), while the salt around it failed, and so when this stronger rock failed, in March 1989 it generated a seismic signal equivalent to a 5.7 earthquake. Earlier events in that area had been strong enough to be registered in Constantinople, some 1200 miles away. Rockburst energy in South Africa has been measured as being the equivalent to the detonation of 2,000 tons of TNT. Most events are much smaller, however, and those mines might see, over six months, only 7 or 8 events that measure over 50,000 ft-lbs of energy (i.e. 25 lbs of dynamite) with about 90 being measured seismically.

Normally coal will undergo the more gentle crushing, without storing the large volumes of energy that create a burst, or bump. But as coal quality improves, and also if there is some gas present in the coal, energy can be stored in sufficient quantity that when the coal fails, it is a more sudden collapse with a greater energy release rate that can cause both a strong seismic event, but also throw debris from the failure a considerable distance. Failures at this level can also create a very strong air shock in the mine, as well as the physical projection of rock, and this can, itself, do considerable damage. One of the ways in which you can tell if the rock is likely to be under a high enough stress to fail, yet not crushing is that, when you drill holes into it, the rock around the hole breaks into it from the sides, during the drilling operation. However, at the same time, if there was a nearby natural earthquake that suddenly threw an additional load onto the pillar, then this sharp increase in load can occur faster than the normal cracking can dissipate the stored energy, and again the failure may be a more sudden release of the contained energy, giving a mine burst.

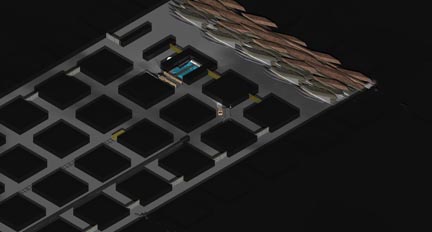

So what is retreat mining? Well after the mining has reached as far as it can in the seam (such as reaching the boundary of the leased land for example), the removal of coal between the pillars has still left 57% of the coal still in place, using the sizes discussed above. If we can safely mine some of the coal from the pillars as the mine retreats back from the edge of the property, then even if the roof collapses behind the operation, we can increase the total amount recovered. This is an operation that is fairly tightly regulated, since it is pulling away the supports from the roof, as the mining goes on. One of the simplest ways of doing this is to run the mining machine (the continuous miner) up the middle of the coal pillar, mining out the center, but leaving the two wings in place.

Simplified view of retreat mining. In the picture the continuous miner has split the pillar to the left, and is now splitting the second pillar in the row. The previous row of pillars have collapsed, and the overlying rock has fallen on top of the remains. As the broken rock falls and breaks it bulks up so that, over time and as the area grows, it will carry the weight of rock higher above the seam, reducing the weight that must be carried by the remaining pillars.

There are a number of different ways the immediate roof can be held up while this is taking place. One is to build wooden cribs that give support, another is to install small concrete columns, and a third is to use moveable hydraulic roof supports of the same type that hold the immediate roof up behind a longwall face .

The ones that are used in retreat mining are a little taller and thinner, but hopefully you can understand that they can be placed in the area around the working area, to hold up the roof, as the coal is removed from the body of the pillar.

Because the roof rock, in the area that has been mined out, collapses into the space left, and breaks into pieces that fill the void, the overlying rock that the supports carry may not be required to hold all the rock going up to the surface, but only that bit until the overlying beams come down onto the broken rock in the abandoned area. This is normally only a few seam sections high, and thus, the supports don't have to be that large for the temporary support of the roof, around the mining machine (which is usually operated remotely).

Hopefully this gives a little more meaning to some of the terms that are being used. For the present our thoughts and prayers remain with those trapped, in the hopes that they will be rescued soon and safe.

Here's a reddit link, if you are so inclined:

http://science.reddit.com/info/2dq5k/comments

And here's a link to the slashdot firehose:

http://slashdot.org/firehose

(search for the title).

The authors really do appreciate your willingness to spread their work around. Thanks. :)

Thanks for telling us a little more about these operations.

With the difficulties of underground mining, I would think that folks would use surface mining as much as possible.

What are the constraints on surface mining? I would suppose you need to own quite a bit of land around the strip, to put the overlying rock that has been dug out. Are there also some limits on how far you can down you can dig? I would suppose that the Utah mines are far too deep to be strip mined.

Gail:

Generally, though it depends on how thick the coal is, you aren't going to strip much above a hundred feet of overlying rock, or that order of magnitude. In the Utah case they are mining in under a mountain, so while the cover starts out very shallow it increases as the mine gets further under the hill that is developing from the valley where the coal came to the surface. The reports are stating that the drill is located over where the miners are thought to be, and at this point, some 3.4 miles into the mine, the ground is some 1,500 ft above the seam.

When strip mining you generally have enough land to contain all the mining, but the rock immediately over the operating strip is moved into the strip that has just had the coal removed. This leaves it in the piles that are the usual picture of strip mining, but after a few more strips have been taken, these piles are graded out back to the original contour, and the topsoil, which has been saved in a separate pile, is then replaced, together with other features that were agreed when the reclamation plan was originally submitted. (Note that they don't go back to original contour with mountain-top removal which is a special case, but still have to fit to a pre-approved plan).

North Antelope coal mine views.

Fascinating stuff. I'm originally from Derbyshire and that has a long mining history.

I've read the term 'in situ Coal-To-Gas' -is this what it sounds like?

Nick.

Nick:

generally in-situ coal to gas will likely refer to in-situ coal gasification, which is where you burn the coal in place, but control the flow of oxygen so that the gas that comes out of the second, recovery hole is a combination of hydrogen and carbon monoxide that can then be burned at the surface to generate power or provide other useful heat. (It is called producer gas).

A team from the Berkeley Seismological Lab (plus a summer intern at LLNL) have completed a review of the first motion data for the event and have derived a mechanism which differs significantly from the automated solution derived shortly after the quake. Importantly, they calculated a solution which allows for volume change at the energy source, which the automated solvers disallow.

They've concluded that the observed waveforms are most consistent with an "anti-crack", which is to say the reduction of a long, thin gap.

The most relevant figure from their work:

Figure 6. Source type plot based on Bowers and Hudson (1999). In this plot earthquake, explosion and collapse data from Ford et al. (2007) is compared to the August 6th event (red star). The August 6th event plots in the general moment tensor space that defines an closing crack, or collapse. The event is located well outside the region occupied by tectonic earthquakes.

Link to the full report (omitted from my comment above):

Seismic Moment Tensor Report for the 06 Aug 2007, M3.9 Seismic event in central Utah

Prepared by: Sean Ford, Douglas Dreger, Peggy Hellweg and Bob Uhrhammer

They additionally model the energy released at 1.92*10^22 dyne*cm (about 2*10^15 joules for the SI world) which is roughly ~500kilotons of TNT. That corresponds to a moment magnitude of 4.2. The magnitude of 3.9 that has been widely reported is the assigned Local Magnitude, which I assume the USGS has been reporting due to the initial difficulties in calculating the mechanism and the associated uncertainty in the moment...

It should also be noted that although the conclusion that this was a collapse-type event is fairly robust, not too much detail about the exact motion or the exact mechanism of stress release can be developed with this sort of analysis.

We can't, for example, say where in a modeled cavity the collapse initiated and in what direction it propagated. Given engineering data from the mine and a detailed model of the propagation paths to the stations which recorded the events, a priori models of the collapse could be evaluated against the observed waveforms.

None of these exercises can provide much information of use to the rescuers, unfortunately :( Here's hoping there's promising news from the drill team soon...

I heard on TV the epicenter of the quake was about 1000 feet below surface and near the back end of the mine. A natural earthquake epicenter was usually from a much deeper level. It seems the roof caved in on top of the miners. They are drilling to determine if there is some airpocket or intact chamber down there.

Some of this information suggests that one of the overlying beds, that may not have dropped earlier, suddenly broke and dropped down onto the underlying rock pile. That hanging up, and then failing to drop over a large area is what might happen if there were a thick sandstone layer in the roof, but if the cavity transferred upwards I would have thought that it might have been detected in the drilling activity, since intersection with a cavity would lead to lost circulation in the drilling fluid. (Though I don't know what type of drill they are using).

If the 'value' of human life were factored in, EROEI for Coal would be much LESS than presently assumed.

Coal would thus, be neither energetically, nor economically feasible as an energy resource, (if mine owners had to make working conditions "safe").

However, since human life is so cheap (and getting rapidly cheaper), coal extraction will become MORE labor intensive, more dangerous - and thus, cheaper, and used more.

Perry