Comments on Some Recent Oil Spill News Items, Including the Dome

Posted by Heading Out on May 4, 2010 - 11:25am

Today, I have just a few comments on recent oil spill news items.

The steel and concrete containment dome that is the first of the three systems that BP hope will be able to cap the leaking riser has been built and will be shipped out today. There are three points at which the riser is leaking oil. The main leak is some 600 ft from the well head apparently. Part of the concern as to how well it will work, even if it does get put in place by the end of the week, lies with the relatively soft seabed at the point where the cap will be placed.

Nate Hagens has a good description of what is intended, showing the plan for capping each leak:

How it works

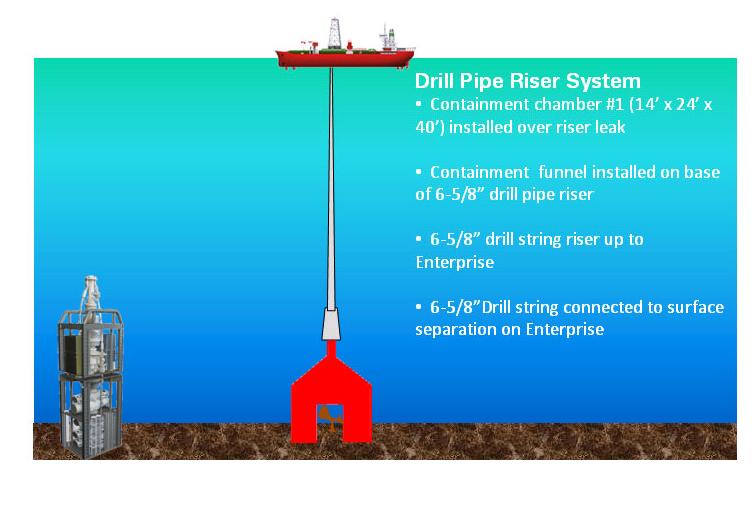

• The system is made up of a 125-ton, 14’ x 24’ x 40’ structure that will be set on top of the largest leak source. This leak is located at the end of the riser, about 600 feet from the wellhead.

• Equipment at the top of the system is connected to a 5,000 foot riser that will convey the hydrocarbons to the surface ship, the Deepwater Enterprise.

• Once in place, oil will flow up into the containment system’s dome to the surface ship.

• Once on the surface ship, the hydrocarbons will be processed and oil will be separated from water and gas. The oil will then be temporarily stored before being offloaded and shipped to a designated oil terminal onshore.

• The Deepwater Enterprise is capable of processing 15,000 barrels of oil per day and storing 139,000 barrels.

• A support barge will also be deployed with a capacity to store 137,000 barrels of oil.

• This system could collect as much as 85% of oil rising from the seafloor.

There is also a picture of the cap itself, from the same source.

While the impact of the spill has not stopped other companies who are drilling in the Gulf. It has caused the Governor of California to shelve plans for off-shore drilling in California, for the present.

The report from a fisherman who was fishing near the rig at the time of the explosion states that the rig first vented water, and then natural gas, and that after the lights on the rig went out. The explosion came possibly as the emergency power generator kicked in.

There has been some significant attention paid as to whether the rig should have been fitted with an acoustic remote control system for the BOPs – though in one discussion I heard there was some confusion as to what this would have changed on the rig, since there were BOPs in place. The acoustic system has the following benefit:

The ACS system is a redundant receiver/transmitter for communication with the rig through acoustics. It is interfaced to the BOP control pod so that different sets of emergency functions can be executed to shut down the well and avoid a pollution. If the regular umbilical is broken and normal communication with the BOP is not possible, the ACS is the last and only means to shut down the well. If a function is executed from the ACS, signal goes to a solenoid that activates a big valve on the BOP; the valve is then energized by air pressure bottles on the BOP.

In this case that doesn’t seem to be likely to have helped, since there was, apparently, a signal on the rig floor that the BOP had activated, though obviously it had not worked the way it was intended. The reason(s) for the BOP failing to work as anticipated is still a matter of conjecture.

FWIW....found this last nite.....

http://www.northeastshooters.com/vbulletin/showthread.php/99645-Deepwate...

Deepwater Horizon Info

This is from a friend....

> Terry xxxxxxx, who works for ADTI, had a son who was one of the BP Company

> reps on the Horizon when the incident occurred. Here's what he sent me.

>

> TALKED TO MY SON, HE IS AT HOME NOW, AND IN GOOD SHAPE, WHAT I WAS TOLD WAS

> THEY HAD SET A 9-5/8 TAPERED PRODUCTION LINER, DID THEIR CEMENT JOB, HAD

> POSITIVE TESTED, AND ALSO NEGITIVE TESTED, THEY WERE GOING TO SET A BALANCED

> PLUG AROUND 3000' BELOW THE WELL HEAD WHICH WOULD BE AT ABOUT 8000', THE

> SENIOR COMPANY MAN WANTED TO SET THE BALANCED PLUG IN MUD, BUT THE ENGINEERS

> WANTED TO DISPLACE WITH WATER PRIOR TO SETTING BALANCED PLUG, SO THEY

> DISPLACED FROM 3000' BELOW MUD LINE, AND WERE GETTING READY TO SET PLUG. THE

> DERRICKMAN CALLED THE DRILLER AND SAID HE NEEDED HELP, HE HAD MUD GOING

> EVERYWHERE, AND ABOUT THIS TIME THE DRILL FLOOR DISAPEARED, THEN THERE WAS

> AN EXPLOSION, THEN A SECOND EXPLOSION.

>

> THE FLAMES ARE NOW GOING STRAIGHT UP ALLOWING EVACUATION OF MEN, THEN YOU

> KNOW THE REST.

>

> THE HANDS THAT ARE MISSING ARE THE ONES THAT WERE ON THE DRILL FLOOR AND

> PUMP ROOM. YOU KNOW THE RESULTS OF THAT. THIS ALL TOOK PLACE IN LESS THAN A

> MINUTE.

>

> RIG WAS EVACUATED IN ABOUT 25 MINUTES.

>

> IT IS BELIVED THAT THE SEAL ASSEMBLY AT THE WELL HEAD GAVE UP. IF THAT IS

> THE CASE AND THEY WOULD HAVE SET THE BALANCED PLUG IN MUD THEN DISPLACED THE

> RISER, IT WOULD ONLY HAVE DELAYED WHAT HAPPENED BY A COUPLE OF HOURS.

>

> GAS MUST HAVE CHANNELLED THROUGH THE CEMENT JOB AND UP THE BACK SIDE OF THE

> 9-5/8 PRODUCTION CASING.

>

> THIS IS ALL I KNOW AT PRESENT.

Thanks. Excellent information.

How can gas at any pressure channel through 10,000 feet of concrete, however poorly filled, once it is hard? Wouldn't the gas have had to be channeling as the cement was poured, leaving a clear channel?

Or does it back-channel just around the plug, then blow through the liner?

Seems more likely that plug or shoe failed to seal well to me, but I have no experience to calibrate my intuition.

Once the gas started leaking and the water displacement was underway, the result would have been escalating mud ejection velocity as the pressure dropped and the gas expanded. Perhaps that's why mud went everywhere before water did, as some of the low-pressure mud-dump plumbing failed?

Paleo -- the productive formation might have been only a few hundred feet about the bottom of the casing. So I suspect you are correct to guess the casing shoe failed and the oil/NG only had a few hundred feet to u-tube back up the casing.

If I understand this correctly, the cement was too light and allowed formation liquids to flow with the cement outside the casing as it was being pumped in. This degraded the cement job and exposed the seal at the top of the hole to more pressure than for which it was rated. The BOP failure is a separate issue.

Is this correct? Can the cementers pump against the cement outside the liner to defeat this possibility? LOL, differential pumping?

Sky -- Done all the time to fix a bad cmt job. Called doing a "squeeze" job.

Saw this yesterday morning in the London Telegraph comments on this story.

Accuracy unknown but it seems imformed so I will pass it on.

"I work as a drilling engineer for an oil major. I heard that they were cementing with foam cement, which is cement with nitrogen injected into it to achieve a given density. When that gas-laden cement is pumped downhole to secure the steel casing to the borehole walls the effects heat and pressure on the nitrogen cannot easily be predicted. If they got their calcs wrong and the hydrostatic head was less than the formation pressure then an influx would occur. Even when this happens the BOP is supposed to close in the well. But the BOP obviously failed. Low frequency, high consequence hazards are almost impossible to rule out completely and since we all reap the benefits of energy and petroleum products we all have to accept the risks and consequences."

It looks like the engineers knew they were in a bit of a bind with this well and only outside of the box thinking would fix it. That is the only reason I see they would consider nitrogen foam cement that is usually only used in top hole where you get very weak formations and relatively low hydrostatic pressures.

The main problems you have with cement jobs that pass through producing formations, are leak paths. Passages in the cement where oil and gas can trickle through. It would seem that by using Nitrogen foam you are reliant on the strength of a foam instead of a solid and leaving yourself open the foam breaking down.

If the foam does break down apart from the nitrogen causing leak paths, it would leave the rest of the cement heavier than planned thus leading to formation breakdown and loss circulation.

To control this type of cement given the 15,000psi bottom pressure with the temperature of the cement at surface where the density is measure going from ambient to near freezing at 5000ft, up to something very hot in the reservoir and to maintain its physical properties must be a mind blowing calculation.

toller - that story goes a long well to supporting some of my unspoken suspicions. There is always going to be a debate about when to displace the mud with sea water. Leaving mud in the casing can be a small nightmare when you come back to complete a year or two later. That's why one engineer wanted to clean the casing of mud before trapping it below the top casing plug. A couple of months ago I spent 2 weeks and $500,000 to do just that on a well in S La. It might cost $5 million or more to do the same on a Deep Water well. OTHO, the heavy mud inside the casing is one safeguard preventing the well coming in. You can displace but obviously need to be very sure your cement job/bottom plugs are holding.

The derrick hand's alert matches the story re: the captain reporting excess amounts of mud delivered to his boat. All this can be done safely IF you make sure you've isolated the formation at the bottom of the casing string. Obviously that engineer thought it was safe. The investigation will ultimately show whether he had sufficient info to make such a judgement. Why the BOP didn't funtion properly will be another point of investigation but it appears right now that the problem was initiated with that one bad call on displacement. This entire nightmare from what might seem a rather simple decision. But often such problems result from such seeming simple choices.

So if the shoe (or something at/near bottom) failed - would the mud have contained the pressure? Or would the thing have blown later when there wasn't a rig attached to it?

toll -- Obviously the mud controlled the pressure in the formation initially. And was doing so as the cement cured. Guessing what actually happened but as the back pressure from the heavy mud was reduced as it was displaced with sea water, the formation pressure starting pushing uncured cement back into the casing. What amplifies the problems is that when the NG starts to enter the mud column ("gas cut mud") it effectively lowers the back pressure by reducing the mud weight. And that allows more NG to flow into the casing. And the feedback repeats. When your drilling a well you monitor the returning mud for gas cut. This is one of the first signs of a well kick. A second significant indicator is "pit gain" = mud is continuing to flow from the well to the mud tank even though you've shut off the mud pumps.

We'll have to wait for the investigation but this is what MIGHT have happened when they started displacing. The subcontractor (the mud logging company) tasked with monitoring the mud returns for gas cut might have been shut down at this point. Almost all services charge by the day. There's always a push to get them off the clock as fast as possible. Additionally, all such equipment needs to be shipped back to the shore as the rig prepares to depart. If the engineers thought the well was secure they could have shut down the mud loggers. If so it will come out in the investigation. The mud loggers survived and will testify as to exactly what they were or were not doing at the time of the accident.

Is anyone from TOD, or ASPO scheduled to attend or in the loop even for the hearings that will be taking place?

Craig

Might be wrong zap but hard to imagine the hearings won't be covered live on CNN 24/7.

Rockman, I think the query was phrased incorrectly. While undoubtedly there will be hearings on CNN, the people testifying will basically be PR people, politicians, lawyers...explaining why this was an act of God... What the query probably wanted to know was in terms of whether any TOD regulars will be participating in/have access to any serious technical investigations as to what went wrong.

pt - I can promise you the investigation (and hopefully the public hearings/trials) will include the testimonies of all the eye witness accounts of every survivor. I've sat through such investigations and every fact known by every individual will become part of the court record. Probably 95% of the personnel on board were not BP employees. And, other than to protect their own butts, no one is going to lie to protect anyone.

Been there....done that. And as recently as 3 weeks ago.

Not sure why you guys are worried about a little oil spill - there was a car bomb in NYC! Terrorists! Sorry - I had to spend time in a waiting room in front of the propaganda device, and you can guess what was on. 100% terrorism, not a peep about oil or anything else. I guess I think that the masses can be reliably distracted and really won't care that much.

Funny you mention that, I've begun to wonder if that whole terrorist story isn't just a bit too fishy and one heck of a timing coincidence to possibly be a deliberate distraction set in motion by TPTB. Wouldn't want too many people paying closer attention to the mess in the Gulf now would we? Then again I wouldn't really know since I stopped watching propaganda devices quite a few years ago. Though I might make an exception to watch the World Soccer Cup...

It's not fishy, in the sense you suggest - it's just the way we H. sapiens think - or, rather, the way our media like to report - the potential for one dead human makes better news than watching a few crying fishermen or an oil-soaked pelican being washed.

And you what that means - they will cover the political and business spin, and the moment anyone starts to talk about anything remotely technical (that is, facts of interest to readers of TOD) they will cut to a commercial, and when they get back Wolf Blitzer will breathlessly repeat the political talking points until the interesting bits are over. Then they will interview Justin Bieber and Micheal Jackson's doctor for their points of view on the clean up.

Let's hope any hearings are on C-SPAN's http://www.capitolhearings.org/

Former mud logger checking in here: we never actually measured mud density, we just listened for the pit hand to call that out and recorded it. We did have sensors on the mud flow line (to see if the well was putting out more mud than the pumps were sending in) pit level probes (to watch for pit gain) and a gas detector in one of the possum bellies to see if the the mud contained any dissolved gas.

You are absolutley correct about the push to get us off the clock ASAP; in about two dozen or so wells I worked I never once stayed to the plugging of a well. While my memory has been surprisingly accurate (judged by following this story) I must admit to learning a lot of new stuff about the completion end of this business.

I received the same info. Today I got a slightly different version but very similar which I've attached:

I continue getting calls asking what happened on this problem so here’s a response from a friend in the oil business with possible inside info on the blowout. Please keep in mind this is an “UNOFFICIAL” report so this may or may not be factual. However, the scenario as written makes reasonable sense as far as I am concerned. The focus needs to be on well control now and not speculation as to what may or may not have happened. BP, the MMS and most likely a third party will certainly provide a very in-depth investigation which will be the official report. Having said that I would certainly not look forward to a copy of that report as it will be furnished only to those in need due to the possible liabilities of the findings.

Details as conveyed to me:

This well had been giving some problems all the way down and was a big discovery. Big pressure, 16ppg+ mud weight. They ran a long string of 7" production casing - not a liner, the confusion arising from the fact that all casing strings on a floating rig are run on drill pipe and hung off on the wellhead on the sea floor, like a "liner". They cemented this casing with lightweight cement containing nitrogen because they were having lost circulation in between the well kicking all the way down.

The calculations and the execution of this kind of a cement job are complex, in order that you neither let the well flow from too little hydrostatic pressure nor break it down and lose the fluid and cement from too much hydrostatic. But you gotta believe BP had 8 or 10 of their best double and triple checking everything.

On the outside of the top joint of casing is a seal assembly - "packoff" - that sets inside the subsea wellhead and seals. This was set and tested to 10,000 psi, OK. Remember they are doing all this from the surface 5,000 feet away. The technology is fascinating, like going to the moon or fishing out the Russian sub, or killing all the fires in Kuwait in 14 months instead of 5 years. We never have had an accident like this before so hubris, the folie d'grandeur, sort of takes over. BP were the leaders in all this stretching the envelope all over the world in deep water.

This was the end of the well until testing was to begin at a later time, so a temporary "bridge plug" was run in on drill pipe to set somewhere near the top of the well below 5,000 ft. This is the second barrier, you always have to have 2, and the casing was the first one. It is not know if this was actually set or not. At the same time they took the 16+ ppg mud out of the riser and replaced it with sea water so that they could pull the riser, lay it down, and move off.

When they did this, they of course took away all the hydrostatic on the well. But this was OK, normal, since the well was plugged both on the inside with the casing and on the outside with the tested packoff. But something turned loose all of a sudden, and the conventional wisdom would be the packoff on the outside of the casing.

Gas and oil rushed up the riser; there was little wind, and a gas cloud got all over the rig. When the main inductions of the engines got a whiff, they ran away and exploded. Blew them right off the rig. This set everything on fire. A similar explosion in the mud pit / mud pump room blew the mud pumps overboard. Another in the mud sack storage room, sited most unfortunately right next to the living quarters, took out all the interior walls where everyone was hanging out having - I am not making this up - a party to celebrate 7 years of accident free work on this rig. 7 BP bigwigs were there visiting from town.

In this sense they were lucky that the only ones lost were the 9 rig crew on the rig floor and 2 mud engineers down on the pits. The furniture and walls trapped some and broke some bones but they all managed to get in the lifeboats with assistance from the others.

The safety shut ins on the BOP were tripped but it is not clear why they did not work. This system has 4 way redundancy; 2 separate hydraulic systems and 2 separate electric systems should be able to operate any of the functions on the stack. They are tested every 14 days, all of them. (there is also a stab on the stack so that an ROV can plug in and operate it, but now it is too late because things are damaged).

The well is flowing through the BOP stack, probably around the outside of the 7" casing. As reported elsewhere, none of the "rams", those being the valves that are suppose to close around the drill pipe and / or shear it right in two and seal on the open hole, are sealing. Up the riser and out some holes in it where it is kinked. A little is coming out of the drill pipe too which is sticking out of the top of the riser and laid out on the ocean floor. The volumes as reported by the media are not correct but who knows exactly how much is coming?

2 relief wells will be drilled but it will take at least 60 days to kill it that way. There is a "deep sea intervention vessel" on the way, I don't know if that means a submarine or not, one would think this is too deep for subs, and it will have special cutting tools to try to cut off the very bottom of the riser on top of the BOP. The area is remarkably free from debris. The rig "Enterprise" is standing by with another BOP stack and a special connector to set down on top of the original one and then close. You saw this sort of thing in Red Adair movies and in Kuwait, a new stack dangling from a crane is just dropped down on the well after all the junk is removed. But that is not 5,000 ft underwater.

One unknown is if they get a new stack on it and close it, will the bitch broach around the outside of all the casing??

In order for a disaster of this magnitude to happen, more than one thing has to go wrong, or fail. First, a shitty cement job. The wellhead packoff / seal assembly, while designed to hold the pressure, is just a backup. And finally, the ability to close the well in with the BOP somehow went away.

A bad deal for the industry, for sure. Forget about California and Florida. Normal operations in the Gulf will be overregulated like the N. Sea. And so on.

Oustanding Dog. Sounds like you've gotten the details down pat. Fits all the bits and pieces that have surfaced. Why the BOP didn't function remains to be determined but as far as how the blowout initiated I think you have it tied down as good as possibble short of the official hearing.

The only big question for me remaining is the decision to displace. Did they have proof of the bottom plug/csg shoe holding as per BP policy/Fed regs? As I suspect you know it often isn't a black and white interpretation. Always some gray areas.

Additional info on the foam cement job. Evidently there were no returns during the entire cement job. This calls into question the actual cement placement, it might never have even covered the pay zone.

That's when having a "fail-safe" becomes a curse and not a blessing.

Mad Dog,

BP will know where the cement is, it is just a matter of calculating where the top of the cement was when they lost returns. BP also knows where the producing formations are from there logs. The call to continue with the TA would have come from town. That is not a call to be made on the rig in a split second.

I am not sure why BP is trying to put so much blame on Transocean, as all fingers seem to point to BP. Unless of course it is just all lawyers bluff.

Toolpush,

I agree that the decision to continue would come from town. I also agree that the approvals of the cement test and proecdure would also come from town ultimately. The top of the cement is a bit more complicated. If they were having lost circulation problems while drilling with mud then that zone could be anywhere. I don't know what the weight of the foam cement was or when losses occured, maybe even before the cement entered the open hole, who knows. However, this calls into question the decision to continue as you rightly point out.

I believe that the ultimate responsiblity for the incident will rest with BP. I haven't seen the particular contracts but based on my years in the business the operator always bears ultimate responsibility, save gross negligence (which is nearly impossible to prove). Tony Hayward is flailing away, blaming Transocean but I think this is a desperate move. I wonder who will replace him.

Hi ROCKMAN. Excellent thread. Question to you and Mad Dog and Toolpush about the relief well.

Bob Fryar BP senior executive vice president is on video http://bp.concerts.com/gom/bob_fryar.htm as saying that the relief well will be drilled at 18000ft and intercept the well then CUT A HOLE in the pipe. Enter the well, take control and stop the flow of oil.

My question is this. The well was not perforated. I therefore think the blowout is up the annular. Why the need to enter the seven inch casing. Do they think it might have collapsed?

This is the final method of keeping the well from blowing out, and as the 2004 MMS study indicated, many shear rams on deepwater rigs are probably not robust enough to handle the high strength drill pipe being used in these deep wells. Apparently no action was taken by the MMS in response to this report (see Russell Gold's article in Monday's WSJ).

And to return to my personal soapbox, I see no reason why the MMS could not implement--tomorrow morning--the apparent "Brazil Rule," which reportedly requires the drilling company to demonstrate that they can seal the well with the shear rams, by actually cutting through a length of drill pipe at depth, prior to spudding the well. I guess we could call it the "Missouri Rule," i.e., "Show Me."

From Monday's WSJ:

http://online.wsj.com/article/SB1000142405274870396920457522063063839762...

Safety Device Questioned in '04

Jeffrey-

I wonder what reasonable drilling supt, toolpusher, assistant toolpusher, driller, and deepwater crew that has heard about this accident hasn't done this already-- if their was a question.

You guys know the situation-- you know it works when you lose circulation during the cement job--- you know you have a fail safe. But what if it doesn't work then.

You guys also know what the well would be like 20 hours after the cement job, especially a well from hell. Especially after successful pressure tests. Nobody would be on their tiptoes at this point.

FF

Better yet, let's see that ram cut though the worst case collar section, then hold seal with drill depth PSI +margin applied -- at depth.

(And for paranoia's sake, the drill string length should be sized so that the bit assembly or other hard to cut down hole gear should be above or below the rams when adding or removing joints. - That's probably going too far.)

If I understand what was going on from various comments, the whole drill string / pipe was kicked up from below to a height of a few hundred feet - so maybe the BOP was attepting to close onto a moving-upwards pipe -

this might have caused the ram to jam in it's tracks as it touched the moving pipe and got shoved hard into the roof of it's travel tube, ... maybe ..

Already shifting into high gear here are you? Misregulated is more of a concern. If the regulation is redundant but follows a discenably functional path an extra layer of redundancy or two adds how much to the cost of a barrel of oil? The industry's internal risk assessment will move a little to conservative side for a while on its own but enough barrels pumped without a mishap and the cost cutting will bring it right back to where it was two weeks ago. Too bad so much turf protection always emerges in the regulatory beauracracy. Misregulation seems inevitable--just hope the functional regulatory core will somehow be strengthened within the whole morass that follows this.

Yeah, those damn socialists with their safe rigs and clean beaches.

Government regulation is fallible, therefore, no regulation is the best bet.

American LOLbertarianism at its finest. Anything else is COMMUNISM!

Did everyone here see the AP report this morning that there is a $75 limit on non-cleanup costs for oil spills? This law was apparently passed after the Exxon Valdez spill. Now "our representatives" in congress are talking about raising it to $10 billion. It sounds to me like a law written by Exxon.

This is in the same catagory as the Price-Anderson bill limiting liability for nuclear power accidents.

It seems to me we could have a real "free market" energy policy by removing these liability limitations and letting industry pay all of the costs for these accidents and, assuming that some accidents are going to happen, require posting bonds as the profits are made to avoid what has happened in the mining industry where the corporations are long gone when the liabilities begin to add up.

Remind me of what is a typical mud weight for older drilling practice. I think 16 ppg is heavier than I have seen before in any of HeadingOut's posts. Is it a special high value in your opinion?

geek -- No "typical" mud weight per se in older or newer practices. But the deeper drilling we've been seeing the last 10 years has led us to bottom hole pressures much higher than had been common. What makes the Deep Water wells especially difficult is the narrow range we need to keep the MW. At 17.5 lbs/gallon you might fracture thr rocks and lose the hole. At 17.2 lbs/gal you might not be able to keep the oil/NG from flowing into the wellbore. There are also a variety of other mud parameters that come into play besides MW. Despite a seemingly simple name as "mud" it is actually a rather complex fluid.

Mad Dod,

This version is realy spreading fast across the oilfield, it dots nearly all the eyes and most of the Tees. The lost circulation they were having drillng the hole will be the answer to where the cement went to. The fact they were attempting to use nitrogen injected cement on a well with 15000psi (calculated from the mud wt) shows a sign of desperation, as nitrogen injection is normally used in surface casing in the slop and muck that is normally called seabed. As Mr Boyle points out in his law the gas bubbles at 15000psi will be very small. I know I am just a time served roughneck, but that does not make the bubbles any bigger when engineer does the calculations. The idea of the nitrogen, it is suppose go into the loss zones and seal them off. That is the theory at shallow depth anyway.

There were some comments at "Drilling Ahead" that it took numerous attempts to set the packer, and the fact this story points to the seal assembly / packer, looks to me as thoughit was damaged somehow, but after spending some time they managed to get a test, ie a straight line for the required time, possibly 30 min. This is done by having pipe in the hole, closing a ram around the pipe and pumping down the ckoke or kill line on the riser. This would pressure up the casing and be a large volume and that is why you need a realtive long test time.

This is the traditionial and accepted method of testing barriers, but it does not test in the direction of flow. This is done by an in flow test, where you expose the casing to light fluid in a controled condition and measure the flow. This would then see if anything leaked out, rather than seeing if you could push anything in.

I feel once they went past this step their fate was sealed. If it was the seal assembly that failed, it did not matter if they had bridge plugs, cement plugs or any other plugs in the hole, as this would all be inside the casing, where as the cement and the seal assembly seals the outside of the casing. As soon as they displaced the 16ppg mud to 8.6ppg sea water, and they would only do this with a "safe" well, the result would be the same.

As I have said before, you must have two barriers, on the outside of the casing the 2 barriers are the cement and the seal assembly. Contry to what most people will think, the cement does not go all the way to the sea bed, for several reasons, 1/It would be too heavy and break down the formation 2/The last thing you want is cement in the BOP. Therefore it is only designd to come up to the previous casing string, all with a margins of error thrown in to account for losses and over size hole. Where ever the cement went, it did not go high enough to create a seal across the producing formation.

Now why didn't the rams shut. By this story it would have been straight pipe across the BOP. Any deep water driller worth his salt would know where his tools joints were inside the BOP and would ensure he could shear incase of a drive off, (GPS gone crazy)and these were experenced hands. Well here goes some wild a$$ spectulation. I suspect the casing has jacked itself out of the hole, either by stretch, pumped out by the flow, or it parted, who knows, but it would explain why none of the pipe rams sealed, they were not all on a connection. The fact BP announced they had closed the annular, but not the rams fits this sceanario.

Don't think BP have many places to hide on this one.

I wonder when that Operations Manager will volunteer to go out on a rig again!

Toolpusher - Thanks for your comments. The casing having been displaced upward is what I had speculated, but at my level of sophistication, I have never heard of N2 foam cement. The little old onshore stuff is sometimes to complicated for me anyway.

For the benefit of readers, you might explain what a Toolpusher does. My understanding is that the chain of command is as follows:

(1) God

(2) President of the United States

(3) Toolpushers

Correct order, but at least the toolpushers know what they are doing. Also used to have a wad of checks in their pocket - if a hand got hurt due to someone's negligence, they were off the rig and had to go get their check, and often more, from the toolpusher. Not everyone wanted the extra, so they never got their checks either.

Westexas,

When I was roughnecking, it sure seemed that way. Now I am there it just seems differant. I believe the main differance is modern communications. In the "good" olds what happened on the rig stayed on the rig. These days the office even a camera on the rig floor they can watch if they get bore with their daily soaps.

Thanks for all your previous posts, I have learnt a lot over the past few years. The last few projects I have worked on are both struggling to meet name plate capacity and fits well with everything that been said on this site.

In that Superior Energy cartoon above, that thing would cone water so bad I don't know how it would work. You've got 2,300 psi infinite water source at the "door" and gaseous oil stream going up the riser. Pure gaseous oil stream may create a 800 psi drawdown.

I would think the real device will have to be driven into the mudline. I don't understand why the "door" is exposed above the mud "wings". But I been out of college a long time.

FF

Gas content of the oil reducing the static head, maybe? With the door essentially being an inverted weir?

Perhaps they expect the oil to collect at the top, and water and gas to shoot out the bottom?

Craig

A couple of thoughts, somewhat repeating comments made below.

a) bear in mind that the oil is being displaced from the rock in the producing formation by the pressure difference between that in the rock formation and that at the end of the riser where the oil emerges into, simplistically a 2,500 psi subsea environment. That pressure difference may well be enough to drive the liquids all the way to the surface. (That is what it would do if this was a producing well).

b) The hole at the top of the cone will allow the oil and gas to be drawn off to the surface, as described in the post, there is no need to try and accelerate the flow by pumping, the flow can likely be controlled by putting some sort of choke on the new riser, if that is necessary. If they can drive the edges of the box into the soft seabed so that you have only a small gap around the riser as it feeds into the box, then they should be able to contain, capture and entrain the flow from that particular point. Then they have to go after the other two, but if this is the worst (and I am assuming it is since they are going for it first) then there should be an immediate drop in flow into the sea, and some small degree of confidence that this can be fixed might be generated.

I'm not an oil guy, but I would agree that the differential between the density of the oil/gas/water mixture going up the riser and the density of seawater outside should drive the oil/gas/water to the surface. The open window area on the side is probably for pressure relief. Any kind of pressure accumulation in the device and it would be pushed up off the seabed. Therefore it will catch whatever it can, but may still have to release some of the flow. The area of the window above the mud flaps looks plenty large to vent 5000 barrels per day or even significantly more.

The exposed portion of it above the mud flaps needs to weigh at least 38 tons or risk lifting off if the pipe fills with gas, so good to see that it weighs 125 tons. Actually, the weight of the pipe would also count, so maybe this is not a concern.

If the whole dome fills with gas down to the level of the opening, that could be a problem. Guessing that the opening is 15 feet below the top, 15*12*24*62.4 lbs/ft3 gives 300,000 lbs flotation = 150 tons. Oops! Since they have used these on shallow wells, maybe they have built in some answer for that. Also, the calcs ignore the density of gas, which could be pretty high at those depths.

If it doesn't float or tip over, it should work, at least partially.

Those windows are for the whole thing to be set over the pipe and not crush it. The structure cannot set directly on the pipe without the risk of further leak and damage. My question is more how they will assure themselves that it remaims stable at the required depth, but it is out of curiosity. I would think that they will need support like is used with the drilling vessles to compensate for all that. I do have faith in the field guys to make it work at least in the short run. The sheer determination of those guys when faced with a challenge is almost incomprehensible.

And an awfully lot is possible when you say "money is no object" and you really mean it.

Funny, it strangely resembles putting on a condom the day after.

My Granddaddy, once a dairy farmer, used to talk about shutting the barn door after the cows had already gotten out. Why weren't preparations made for this sort of thing beforehand? It is not like you need to be a genius to figure out it is going to happen. AND, it will happen again, and again, as long as we keep doing this.

Craig

A key point. The processing ship can only handle 15,000 barrels/day. They state "oil" but I suspect "liquids", i.e. a seawater and oil emulsion.

The force up to the ship is the density differential between sea water and a seawater/oil mixture. This seems unlikely to be able to force 15,000 b/day of liquids up a 6 5/8" mile long riser.

IMVHO, a band-aid for a gaping wound. Better than nothing, but not likely much better (IF IT WORKS).

Alan

Why not use a surface pump plumbed to the floor to drive "jet pump" fittings along the string, to boost the upward flow? Or bubble gas up in the string to further reduce density? If you could harness the well pressure in that manner you'd get a boost for free at the bottom.

Seems like it will come down to the size of the tube when calculating flow based on some differential.

As I note above, they may be intending to use some of the driving pressure from the formation to help move the fluid up the new riser to the collecting vessel.

From the photos I have seen, the flow from the end of the pipe is more horizontal than vertical. Inertia is pointing the wrong way for the pipe at the top. In any case, inertia transfer into unconstrained water is rapid.

If the inside of "coffer dam" maintains a significant pressure differential with the open sea, the mud will VERY quickly erode away (bearing strength of pudding we have been told).

I see almost no hope of any of the formation pressure (beyond, say 2 or 5 psi) going into the 6 5/8" pipe at the top.

The one unknown for me (slender hope) is the evolved gas. Despite not noting separation from undersea photos, I know that it will quickly separate. And head straight to the top.

I could see a complex situation where partially evolved natural gas entrains oil and forces a mixture up the pipe.

Any thoughts on this ?

Best Hopes for gas drive to the Explorer,

Alan

In terms of "heading straight to the top", how long does it take for the oil and gas to reach the surface - just in the open, without the dome? What average speed would it travel at?

On my rough calculation (and using 16.5mm pipe diameter), the volume in the whole pipe is 34,500 litres, and to move 5,000 barrels of fluid per day (800,000 litres) would require ~24 "pipe volumes" per day, which means each one has to rise to the ship in about 60 minutes.

Given the depth is ~1600 metres, then that would mean a speed to the surface of 26 metres per minute. To capture 15,000 barrels would require a speed up the pipe three times that, of course. To capture 5,000-15,000 barrels of actual oil, speed would need to increase in proportion to the percentage of water in the pipe volumes.

Does it travel much faster than that, given that presumably the pipe will contain a mix of oil, water, and gas? I also assume that there is no additional pressure gain via using the dome (it is just a funnel) - so the oil travels to the surface via the pipe at the same speed as it currently does unconstrained (or perhaps somewhat faster, because it stays vertical - and is not subject to any dispersal or currents).

My apologies if this seems terribly simplistic.

I am confused. If the leak they start with is 600 ft. from the wellhead, and they drop the thing on the riser that is leaking at that distance, wouldn't it cut off the riser, beginning a new leak at that point? And if the are talking about the riser going straight up 600 ft., then if the containment thingie (box/dome) is less than 600 high, it crushes the riser as it drops. Wouldn' it be better to drop it right down on the wellhead, even if that would happen? I mean, crush it into the wellhead! Or would that tip it over?

Also, I am still unclear on what sort of pressure we are talking about, and for how long it would be a 'gusher' before pressures equalized and it became just a slow leak - annoying but much easier to deal with.

This is all crazy anyhow. We all know this will happen again, over and over, until we stop mucking around down there! As great as the technology is, it is not perfect. Anytime you are trying to drill a mile or more beneath the surface of the oceans, using vessels whose stability is controlled by computers and mechanical devices, you are guaranteed an eventual failure! I am reminded of the question about the space program during NASA's early days... "How safe is a device that is made up of more than 25,000 parts, each manufactured by the lowest bidder?

So, what were we thinking? Didn't anyone read or prepare?

http://www.offshore-environment.com/oilpollution.html

What happens when a rig in the Mediterranian fails? At least two companies are already set up for drilling:

http://selfinvestors.com/tradingstocks/oil/investing-in-offshore-oil-dri...

Barking mad!

Craig

Sorry for the rant; this whole thing is disturbing, and the attitude of the PTB is very nonchalant, IMO. Finger pointing, promises made, attempts made and failures again! The economic consequences are staggering; the ecological and environmental unimaginable.

In theory, if the riser is the same diameter as the well, it could accomodate all of the output of the well. In reality, as the liquids leave the well, they expand. You then have a large volume of liquid, with a fraction of the pressure, trying to escape. The well is about 7" in diameter, with about 600 psi; the dome is 12'x14', or 48,384 inches (wellhead is 21.9905"). That is .0454%, so that the pressure forcing the oil/water mix upwards is .2727 psi. It won't do the trick! It is like trying to combine traffic streams from 8 separate lanes of traffic into 2... the traffic backs up!

One of you engineer, mathy/charty types can figure this out better that I did, and do a nice illustration? I know there is a law of physics that deals with such.

Craig

I don't see where you are getting the 600 psi from? The driving pressure is actually somewhat hard to predict since it depends in part on the friction in the flow path that the oil is taking from the original rock to the open end of the riser, and I am doubtful that, at this time, anyone knows, with any degree of certainty, what that is.

Not sure what the viscosity of the water/oil/gas mixture will be, but a back-of-the-envelope calculation gives a bit under 5 ft per second velocity for a 15000 bpd flow and a friction loss of 100 to 200 psi plus or minus. The driving force for 100% light crude would be around 2300 psi*(1-0.87), or about 300 psi. So numbers are in the ballpark - if everything goes according to plan......

The crude density will be less due to the dissolved gas. You are using the API gravity which is after it has settled in a sales tank and the gas has broke out. I estimated about 800 psi versus your 300 psi. You also have to factor out the breakout of gas constantly up that mile as the pressure is reduced. You will likely have to operate the surface pressure below the bubble point of the oil in order to have any driving force at all.

Flowing gradient for this mix probably closer to .65.

I can tell your a helluva hand though.

FF

I for one don't mind admitting that I AM HAVING TROUBLE TRYING TO FOLLOW THIS DISCUSSION IN RESPECT TO THE TECHNICALITIES OF THE WELL PLUMBING SYSTEMS.

I do believe if someone who is knowledgeable about this stuff coiuld condense it all into a single post,with simplified drawings, it would be very helpful to the vast majority of us who have not had the time to go thru Heading Out's very fine posts one at a time, text book style.

Given my current garbled understanding of the well plumbing systems, I have refrained from even asking questions until now, in respect to the actual repair /capping process-other than speculating about using a nuke as the last resort.

But I do agree that expecting a rather high volume flow thru a six inch pipe a mile long due to only the pressure differential created by the different densities of oil and water seems unreasonable.

It does seem that a pump of some sort is almost a necessity-unless of course the cap can be cemented into the sea floor tight enough for the well itself to pressurize the riser pipe.If the seal is not pretty good, the oil will emerge under the edge of the cap rather than go up the pipe.

Driving a pump large enough to take care of the large flow from so deep a location obviuosly requires a large motor, probably up into the high hundreds of horsepower, possibly much more, I have no real idea..keep in mind that the flow might steadily increase if the piping system erodes as some here have deemed likely and becomes a larger diameter pipe for practical purposes.

Could such a pump be deployed quickly and powered by electrical cables dropped down from a ship on the surface?

Might it have to be custom built, with a long lead time?

Do pumps designed to run on air and fuel such as ng or diesel sent down a supply pipe capable of doing this kind of job even exist?

there are people here with more technical know how than me, but I would assume the pump would have to be at the surface. It takes a huge amount of power to pump liquids. Perhaps the plan is to allow a door for the pressure to escape until the pump at the surface can start moving some liquid substance. I may be completely off base but I would be surprised if the primary pump is at the bottom.

I would guess that a submersible pump (Reda) would be required, but doubt the capability of anything except a mud pump could handle the flow. Probably would not work using a mud pump since they usually do not have the suction which would be required, although I am guessing here - they do suck, but not from depth. If the flow had some pressure to it, it might help the flow but would not truly be pumping the full stream.

I don't know anything about oil wells, but you can't SUCK liquids up from a great depth using a vacuum created by the pump at the surface.The pump will have to be either on or very near the sea floor , if one is used, or else it will have to use some sort of arrangement like the foot valve on a domestic water well pump.

A physics teacher will explain this as "there is no such thing as suction; there is such a thing as unbalanced pressures in fluids;similary, there is no such thing as cold, but there is such a thing as a difference in temperature between different objects or places.

Such an arrangement requires two pipes,the "up" pipe carries more liquid to the surface than the "down" pipe reinjects.When the pipes are full, and the pump is not running, the pressures outside and inside are equalized.when the pump starts, the "SUCTION" is effectively relocated to the foot valve, and the somewhat greater pressure outside the pipes causes water to flow in thru a venturi located in the valve.In a water well, this pressure difference is limited to a little less than the local atmospheric absolute pressure. A suction pump as a practical matter will lift water a little over twenty five feet iirc. Atmospheric pressure will not push a water column much higher than that. A foot valve pump will work at any depth up to the limits of the plumbing materials.

The only reason the oil would enter the pipe is that the pressure outside it is greater than the pressure inside it; and as the hieght of the column of oil inside the pipe increases, there will be less and less pressure differential to supply the push.Of course SOME OIL will travel up the pipe because oil is lighter than water, and the oil column will reach all the way to the surface and still be less heavy or dense than the surrounding water.

But my WA guess is that the pressure created by this difference in density would not be adequate to push the oil thru the mile long pipe FAST ENOUGH.

Hence the need for a pump, unless the dome can be sealed to the well head, in which case the well itself will presssurize the riser pipe.

I grabbed a physics book from the shelf and did some quick calculations on this.

I use the following estimates:

Density of water 1000 kg/m³

Density of oil (ρ) 800 kg/m³

A depth of 1600 m gives a seafloor pressure of 160 bar or 1.6e7 Pa.

Static pressure in the oil filled riser is 128 bar or 1.28e7 Pa.

Pressure diff is 32 bar or 3.2e6 Pa.

I assume a flow of 5000 bpd, this is about 10 l/s or 0.01 m³/s.

A diameter of the riser of 6-5/8 gives a cross-section of 0.02 m².

Flow velocity needed is 0.5 m/s.

For laminar flow in a pipe, I found this formula:

v=Δp*r²/(8ηl)

where

v velocity

Δp pressure diff 3.2e6 Pa

r radius of pipe 0.084 m

l length of pipe 1600 m

η viscosity of fluid

Here it gets difficult. Lacking better numbers, I use as worst case the lower limit for heavy oil (at reservoir temp), which I found given as 0.1 Ns/m². This is the same as olive oil at 20°C.

This results in a velocity of 17.6 m/s, much more than 0.5 m/s.

The Reinolds number

Re=ρvr/η

at v=0.5m/s is ~320, so the flow is indeed laminar.

A lower viscosity would result in turbulent flow (switch is at Re=1000-2000), but in lower flow resistance as well.

So the static pressure difference between a column of water and a column of oil would be more than enough to drive the needed flow. They probably will have to choke the flow in order to avoid too much water being sucked in at the box.

This might result in more liquid than they can handle. And in washing out of the mud around the box.

Any gas separating from the oil would improve things.

IF they are able to place the box nicely over the leak, and IF they can keep it there upright, this might well work.

Rainer

When they first set the box over the leak will the pipe be connected or is that done later? The latter would seem to make more sense as they could settle the box into the mud and weight the platforms around it while the gas and oil flowed out the top, but at some point they have to hook up a pipe will a mile tall column of water in it. That will put a heck of cap on the hole in the top of the box and would seem the time the flow might find it easier to escape around the bottom of the box than to push up the column of water in the pipe. If the doors at the bottom can accomadate the flow while water in the new pipe the the surface is siphoned up by a topside pump a with the some of escaping oil column following the siphoned they might be able to keep the box settled through this critical period. If they get the oil to come out the top of the pipe they can probably pile enough stuff around the box keep it down and close the escape doors at the bottom. Well I guess typing it out worked out my problem wonder if its anything like what they are actually intending to do?

Very well done.

Yes water coning- sealing the door and not sucking mud and bridging off- will be the problem.

FF

Looking at the top of the box, it seems like they have more than one pipe coming in on top. If the put a pipe from the top to halfway down or so, they could draw water from different points and prevent suction at the door. Perhaps even pump water in to equalize the pressure?

It might take a while for it to start working -- maybe some gas will help "prime the pump"?

Once flowing, the water mix may be nicely self regulating. As flow goes up, the mix moves increasingly toward the water fraction, which reduces the density-gradient drive. As flow then slows, the water mix declines, and drive increases. Hopefully the resulting feedback loop is nicely damped by friction so there are no oscillations (surges) in the flow.

Perhaps the "separator" Alan mentioned is actually a "mixer", to regulate the influx of water such that the box isn't much in suction.

Dug out my old 41CV and checked the math, and it looks right. Didn't verify the flow equation, but found an on-line tool that indicated a little bigger than 1" pipe would be adequate at 30 bar. 5,000bpd just isn't that much if you keep it corralled I guess.

Looks like the dome is overkill, or they are worried that flow may increase significantly.

Well I'm confused. I thought the riser/collection system is the same system they'd use to bring oil to the surface and collect it under normal conditions. The new riser is the same diameter as the old one, and I think it's being hooked up to the new rig in the same way as the old one. The riser, the rig, it's all been built for this exact job - to collect the oil from deep under water and process it. I'm laboring under the assumption that the "new" way of getting oil from the bottom to the surface is as similar as possible to the way they normally collect oil, meaning that the riser and the rig are not different from before.

I think the question to focus on is whether this containment unit can provide a seal that is ultimately as good/stable as interlocking pipes.

I think the question to focus on is whether this containment unit can provide a seal that is ultimately as good/stable as interlocking pipes.

Absolutely and Positively NOT !

The bottom of the "seal" is made of pudding like sediment and it is open to the sea (square corners over a round pipe).

Not quite the equivalent of steel threads.

Alan

Hey, OFM, this is how we get an education. (I share your difficulty in understanding.)

The density differential is the reason the oil is sitting on top of the gulf right now. The "funnel" merely redirects the oil headed to the surface into the rig, instead of spraying it all over. They don't need pumps/suction/etc to get it from the riser to the top. You just have to re-orient yourself with the notion that in this environment, oil wants to move upward.

6 5/8" pipe vs. dozens or hundreds of square miles to rise in.

Collecting 85% in the pipe seems to be a stretch.

Alan

Isn't this the same pipe that was once and normally would be connecting the rig to the well? My impression is that everything from the pipe upward (the pipe itself, the rig, the processing) is just the normal oil-collecting technique. The only difference is, instead of a clean connection from the end-of-pipe to the wellhead, they're using a funnel to push it into the pipe.

The 85% reflects that this leak (which is the end of the old 'straw') is responsible for 85% of the flow. There are two smaller leaks (think 'holes in the straw') that are doing the other 15%. If this works, they will repeat the process on the other leaks and collect all of it.

I agree with Alan. This is unlikely to work.

The effect of density differences between oil and water only plays a role when the two liquids are in the same column: the water sinks and the oil rises. If the oil and water are in a narrow column this process is slow because the two fluids are moving in opposite directions (in order to minimize the potential energy of the system-the inside of the pipe).

Once the pipe fills with oil there is no density driven flow and any flow of oil needs to be driven by pressure from the bottom. The pressure needed to move significant amounts of oil such a large distance is quite large. The pressure is presumably available from reservoir drive, but once this pressure accumulates in the box, the oil will force its way under the box through the sediment.

If the amount of oil leaking is small and displaces only a small amount of water from the pipe it should work, but "small" is probably only a few gallons/min.

Nevertheless, I'm sure BP feels the need to do this since they need to be seen as trying every possible solution, even ones they know will not work.

This is what has been bothering me about this concept too. Clearly the dome cannot hold any pressure at the bottom. If you imagine the pipe to the surface 100% filled with oil, then what causes the oil to move? You'd need some kind of pressure differential to drive it.

Read the math elsewhere in this post -- the density gradient should be sufficient to propel that volume of oil up that size pipe for that distance (assuming the math is right, the volume is right, etc.).

The flow has to be slow enough and low enough in volume for this to work. If the flow goes up, there is risk in the box floating or the pipe jetting out or pushing the box off.

Really this will work nicely if the passive, density-driven flow is sufficient. I certainly hope it is, because simple is robust, and you can't get much simpler than "oil floats on water". If it works on a shallow well, it should work on a deep well, if you properly size the pipe so as to match the head requirements.

I have moved from "somewhat doubtful" to "rather optimistic" that the basic mechanism will work, as long as the flow stays relatively low.

deleted.

I think that this is a good alternative to catching the oil and eagerly would give it a try if I was on the scene. Remember that this oil is pressurized and contains dissolved gas that will break out as the oil moves up the riser towards the surface. As the hydostatic pressure decreases, the oil will resemble a vigorously shaken Pepsi that has been opened quickly. The result will be to drastically increase the pressure differential between the sea water and the oil column. It will definitely not be laminar flow.

5/5/2010

Western Australia's battle for offshore oil

Crude Oil dropped by 27% in 2009

http://www.crudeoilpeak.com/?p=1425

It seems we have reached environmental, technical, maybe even financial limits in offshore production

Seeing that picture with four construction workers standing around a some pump that appears to be broken is discourging.

Is it impossible to place an open valve around the pipe that would allow oil to flow through, then close it off?

That oil is going to take a path of least resistance.

I hope it works but they need to shut that thing off.

From what has been said already, I believe they first must cut the pipe below the BOP; then they put a new valve on the pipe, weld in place and close it off. All robotically, at 5,000 feet below the surface. It is possible, but difficult.

One problem is that, when the BOP is cut off, it may open the well and create an even stronger stream of oil/gas/water (as in about 10 x the present stream). This would make placement of the valve muich more difficult. We can hope not impossible.

Of course, the Rush Limbaugh technique is leave it alone and let nature take care of it. Not acceptable, IMO. But maybe that is what will wind up happening by default. In time, the pressure will equalize and the leak will wind down to where it can be capped. At which time, of course, recovery of oil from the well becomes even more expensive. I think that, counting the remediation costs, lost jobs, etc., the oil would have to be priced at a few thousand dollars per barrel to be profitable. But, hey! Drill, baby, drill!

Craig

I only see three guys and the caged equipment is the right shape to be a diesel welder generator, one of many in the picture. Nobody in sight doing any welding, though it looks all those steel wings are welded in place wih a few upper 45 degree braces still needing to be installed on the wing (platform) facing us and a manlift standing by.

I just picked up my local newspaper and the same contracption is on the front page and is a little easier to make out. It is very difficult to tell if the upper braces are box beams or 6x6 timber (which would make them temporary construction braces). Possibly those shelf like wings will be balasted with a whole lot of weight somewhere in the process. Those shelves could also function as external stiffeners on the concrete walls. All guess work and much more pleasant to think about than what is coming out of that hole and where it is getting to. We can only wish them luck at this point.

I was really hoping they were going to deploy some state of the art robotics to shut flow off at the BOP.

Big hero would be some R2D2 lookalike posed with a team of MIT dweebs.

Instead, the preferred solution looks like something from the 10th century.

A photo from a 1920 National Geographic, "...early pilgrims would stop at the shrine of crap-i-hope-this-thing-works and say prayers..."

What is the purpose of the "door"? or is it a slot to go over a horizontal riser feed-pipe?

Two of those will need to be able to stradle the pipe, so there is probably one on each side, and they probably hope to set it down over the pipe, let it sink to the depth of the platform(s) on the side and maybe have some room for it to vent. I hope they can keep it upright and have plenty of tethers to adjust and/or remove it if this does not work.

Looks like the sort of thing which would be constructed by oilfield welders, though. They can send it out to engineers and marketing people to get something which looks nice, and then manufacture in quantity for the next uncontrollable blowout.

I do have a question, however. If the BOP was designed for drill pipe and they were setting casing, I am going to guess that the dimensions of the two types of pipes would be different. Also, if they had the casing float shoe, with probably at least one float collar, to hold the cement job and be sure it did not re-enter the casing, this might be enough to give the casing enough bouyanacy to allow it to move up into the BOP, possibly along with the drill pipe, depending on the size of the two strings, and further impede the closing of the BOP, expecially the shear rams. Has enough info been presented to rule this out? With what appears to be a bad cement job, it would seem to me that this could be the complicating factor.

Paleocon -

That huge 'box' is very heavy, so I would think the purpose of the 'door' (which looks more to me like just a slot) is to allow the lower edges of the box to fit around the horizontally lying riser pipe and sink into the mud instead of possibly further damaging the pipe if it were to rest directly on top of it.

Picture putting a heavy upside-down bathtub over a garden hose. If you don't want the edge of the tub to damage the hose, then you would cut a slot in the tub so it wouldn't rest directly on the hose.

Just a guess on my part.

very heavy for a garden hose, with what's blowing out of that hole, it could as well be cardboard to my untrained eye (steel and concrete I know, about the force of the stream of gas, oil and water just above and around the hole I'm clueless). If that thing was designed to be a coffer dam in shallow water, it would seem there would be whole steel brace and internal sleeve wall structure inside the hull we see to make it suitable for depth and to help it function as a funnel. It really looks like on hell of a long shot. Maybe just something to focus on for a while as the relief wells are working toward the real fix, but maybe it will work--if they can get oil up a mile of new pipe that has water in it to start with without having the oil flow excavate a hole under the box that tips it over.

What are the chances the uncontrolled stream wears away some casing and rips in the rock enought to plug itself? Any educated guesses out there?

I guess it's easy to second guess, and I know very little about oil drilling or the industry; but why wouldn't someone like BP have maybe five or ten of these caps prefabricated and ready to go just in case of a situation like this? Maybe of different shapes and sizes to fit different scenarios should they arise?

Why did we have to wait a week or more for this thing to be constructed if it was what everyone imagined would be a first line of defense against an oil leak on the sea bed? Did everyone just figure the BOP would work and there would be no need for this kind of thing?

I'm all about risk management and am always looking at what can go wrong ahead of time. I don't know if I'm paranoid or what, but this seems like something that could easily have been imagined and prepared ahead of time.

I mean, I guess if it doesn't work, the point is moot.

Just a guess 292 but maybe it's because they never saw much possibility of such a method working. I hope I'm very wrong but I don't expect much relief from this approach.

Huh. That's not an answer I was expecting :-) Yes, I hope it works too.

A quick engineering question about the dome:

Where did the huge Transocean Horizon rig sink to the bottom? Did it land on the bottom near the well head? Is it covering the oil volcano? How can they put a simple concrete and steel dome over it - if it is covered with mangled metal?

Looking at

http://www.drillingahead.com/video/video

rp -- I believe they found the rig lying on the bottom 1,500' north of the well. But there may be other debris in the way.

It is so simple that I have some doubts.

At what depth is the liner hanger head?

During the cementing job did they had big losses or partial losses or nothing?

If a channeling occurred (quite common but difficult to appreciate in this kind of well) and a liner head pressure test was not perfect before having set the liner head seal, then a big mess has been done. The liner head seal is another barrier by passed… Second big mess is off course displacing the well with water (probably to save some very expensive mud...) especially if the mud was heavy (not known but probable). The drill pipes are big ones 5 7/8 or better 6 7/8 with very strong tool joint connections……impossible to shear if by accident the tool joint was in front of the shear rams……when it was activated in emergency!

The drillers world is very sad and sincerely affected by what happened, I encourage everybody to share this feeling and have thoughts for the missing workers.

I don't know how they expect this thingie to stay over the leak. If the well is an 8" hole, delivering a 600 psi stream of oil/gas/water, that means there is 7.5 tons of upwards pressure. Granted the device is 15 tons, unless it is perfectly centered, and allowing for displacement of water, etc., and for additional upward pressure from the gas as it expands, there is absolutely no way it stays on the bottom!

Craig

Greetings. I saw this site linked elsewhere ( LATOC) and have found it to be fascinating the last few days. Many thanks to those of you taking the time to help us laymen understand this gulf situation.

I do have one question which I hope is not too far off subject. Last night I saw Arnie on TV talking about how he is going to stop all offshore drilling plans for CA now.

This is a map of tectonic plates:

http://www.google.com/imgres?imgurl=http://media.maps.com/magellan/Image...

....and as you can see, CA lies right along a fault zone while the GOM does not. I have to admit I was shocked to find out that anybody was even thinking of drilling near tectonic plate boundaries such as off CA. The gulf I can understand, but not CA.

My immediate reaction was to be happy( instead of totally horrified) that this spill has occurred, if it prevents future wells all along CA. I was assuming that an earthquake there could rip apart pipes all along the coast.

So, I guess I am wondering....was the CA idea idiotic in the first place and it took this to wake up Arnie? Or is CA just as safe as the GOM in theory (the wells can flex or whatever)?

Thanks for any imput.

lynnie - IMHO much safer to drill offshore Ca than DW GOM. But never ever will it be risk free. Just impossible to eliminate that human element.

I have very serous doubts as well for the dome. Perhaps, a valve that could have a compression fitting that would be tightened by wenches pulling two cables that are wound around the valve in different directions creating enough torque to tighten the compression fitting. Then close off the valve once it is attached. I guess such a valve doesn't exist come on, make one! Install it on the pipe by bolting it on then if it is successfully attached cut the pipe and close it off.

I don't know if that is possible at 5000 feet but they should start planning because the sand will eat away the pipe anyway.

zaphod42 -

I think what you need to keep in mind is that this box is not intended to plug the leak per se, but rather only to allow a means of collecting the oil/gas being blown out of the well. It is open on the top, where it is to be connected to a pipe string going all the way of to the surface. As such, the interior of the box isn't seeing all that much pressure, as a good part of the pressure at the well exit is converted to velocity as the fluid moves up through the box and into the pipe.

The rough analogy would be a garden hose pointed upward. If I place an inverted bowl over the hose, I will experience almost the full force of the water jet slamming into the bowl, whereas if I cut a hole in the bowl and attach a hose to it, I will no longer experience the full force of the water jet, as a good part of it would now be escaping upward and out the hole and hose.

It would seem to me that, without a pump dragging the oil mixture out, it would only leave at a fraction of one percent of the volume it is coming in. And, only that much pressure would be relieved, hence abut 7.5 Tons of pressure on the vessel. If the vessel is pumping actively at 600 psi through the 6 5/8" pipe, that will relieve most of the pressure, but then the sand and stuff would be eroding the new pipe and the pump... problem postponed, not fixed.

I am not at all sanguine that anyone has thought this thing through all the way. We will see, and we can hope. I am rooting for the box/dome thingie. Cap, baby, cap!

Craig

The problem with your suggestion is that one can not "drag" or "pull" with a fluid. The fluid must be pushed. There's going to be a pressure differential between the oil/gas/water mix at the bottom and the top of the pipe, since the column of sea water outside will produce a higher pressure at the bottom pipe than that of the column of fluid inside the pipe. The result would be a flow thru the pipe if it were open at the surface. How much would flow would depend on the size of the pipe and the pressure differential. Of course, a pump at the bottom of the pipe would speed the flow as it could be used to increase the pressure differential from the bottom to the top...

E. Swanson

Okay, so we need the pump at the bottom. Isn't that somewhat more problematic than one at the top?

Also, I recall from basic physics that ordinary pumps, whcih work by vacuum reduction, won't work past a certain depth; you need, as you said, to push the material rather than pull it. How do these deep wells usually operate? Is it, work with natural pressure and get out, or are pumps routinely placed at the bottom of the riser?

Craig

I wonder if this operates similar to the "pumping" action in a coffee maker. Essentially those work by creating a gas bubble (steam) in a cavity connected to a riser tube. The bubble enters the tube and expands as it rises, carrying a slug of water above it. The effect has a natural pulsing cycle: alternating bubbles and water "slugs" in the tube.

If they introduce pressurised air into the cavity, it will collect at the top and start to enter the tube. With even a slight amount of encouragement at the top of the water column from the suction of a surface pump, a bubble could be induced into the riser. Once this is intiated, there would be a bubble, fluid pulse established. The work is done by the expansion of the air.

This phenomena is dependent on surface tension to maintain the bubble integrity across the bore of the tube. That may be why the exit tube diameter is so small.

This is like a compressed air suction dredge as used in small scale alluvial gold mining.

It probably would not require a compressed air feed to be more than a few hundred feet down the riser to initiate a strong flow that would then be maintained by the lower density of the oil/gas/water mix in the capture chamber. Just my WAG.

Okay go outside and hang a bowl with a hole on top of it on a string and try and manuever it over the full force of the garden hose. You can use the afforsaid numbers for getting the bowls weight to the hose force proportion right. That getting the box over the hole (a mile down) does look to be just a bit tricky. Then getting a pipe hooked up--or will it be hooked to the surface all along--either way it would seem a mile of water will be capping the bowl when the stream starts pushing up through the pipe (assuming it can all be placed). Am I missing something? That mile of water in the pipe seems the trickiest part.

Luke,

15000 barrels per day is a bit under 500 gallons per minute. The energy from this would be dispersed pretty fast, so there won't be much force on the dome. Kind of like a kitchen bowl over a squirt gun. However, guiding this thing precisely at a mile down will be tricky, no doubt.

Thanks, I guess I could have calculated that, a good flow but not a river. Still I see getting the oil to push the water out of the new riser at the outset without excavating a nasty one sided hole under the collecting box in the soft mud as quite the mile down challenge. Five hundred gallons a minute can dig quite a hole when constricted. Quite the pressure balancing act as they hook it all up and then of course they have to be ready for whatever comes out up at the rig. Those openning moments might be very tense. If they get it going it would seem there would be a tendency for a suction pull out the top of the box into the riser to want to drag ocean floor along with it unless some circulation pattern in the lower part of the box could cylcone the sediment back to the bottom. Well the guys working it have probably run all kinds of simulations. Best hopes for a good, stable fit and a controlled flow.

Unlike some here I've no problem not seeing some R2D2 contraption holding it all together. A nice mass of steel and concrete half buried in the mud is something I understand.

Not to mention you're doing it in pitch black holding a penlight in your teeth...

Dow is off 230+ so far today. Oil is dropping fast as well. I have read theories that say that systemic collapse would impact everything; does anyone know what is going on other than this? How would the spill impact oil price in a negative way? Did someone announce that the 'recovery' is a lie, or what?

Craig

The sovereign debt issue is on investors minds.

Simple equation: The markets go down. The price of oil goes down. Cash is being shuffled from one pot to another. The money changers are scrambling for safe havens.

Then again, what I know about economics you could write on a match book cover. I've been hanging around TOD and the Automatic Earth blog sites too long. It's affecting my thinking.

Seems to be concern re: potential economic meltdown in Greece....and then having that spread to Europe.

Craig: Even though we have a hell-of-a-mess in GOM. The dollar is very strong this morning due to weakness in the Euro/PIIGS situation thus oil is down (and gold too dollar wise). It is too early to call the economy in the toilet. The major indexes are down because most everyone in the markets know it is simply an illusion. Of course it will go in the toilet because accounting tricks are not part of the real world i.e. mark to model rather than mark to market. And a vast number of other financial problems have everyone scared. A world of de-leveraging (read ressession) still has to be done and then all the peak resourses kick in to keep it down.

Here is Reno, the city and the county are ending employment of a lot of people who will be in the market for jobs of any kind in 99 weeks. Move over Jose, I want to pick that asparagas.

With world oil production flat since about 2005, there is a squeeze on economies (felt as higher oil prices /debt defaults) that keeps economic growth down. All of this is affecting credit markets.

As we go forward, financial problem seem more and more likely. See There is plenty of oil but . . . or Delusions of Finance.

And, I have now seen that Spain is reported to be in trouble. Can the Euro Market bail out two countries? Who's next?

Craig

Despite plan, not a single fire boom on hand on Gulf Coast at time of oil spill