Tech Talk: Progress on the Gulf oil leak and comments on cementing pipes and well completion

Posted by Heading Out on May 3, 2010 - 11:05am

BP held a press conference a couple of days ago in which they reported on progress in trying to stop the oil leak in the Gulf of Mexico, following the blow-out and sinking of the Deepwater Horizon. The well was in the final stages of being closed down, after having been completed, so that the initial drilling rig could leave the site. This meant that the pipe that would ultimately carry the oil and gas to the surface, the production casing string, had been put into place. To hold that pipe in place, and to make sure that it is sealed so that no fluid can flow into the gaps between this tube and the rock walls left by the initial drilling of the hole, the casing had been cemented in place. I am going to repeat part of the post where I talked about that, to explain what this involves. I begin as the hole is still being drilled.

Casing a Well - (Excerpt from previous tech talk)

As the bit goes deeper we add additional lengths of drilling pipe to form the drill string, and the bit penetrates through rocks that are of different types and some of these will have fluid in them. Water, whether fresh, which might be the supply for a local community, or salt, is quite common. The hole cannot be left open any longer, because the water flowing from the surrounding rock into the well will dilute the mud, so that it no longer works as it was supposed to, plus, we might start losing some of the drilling fluid into the surrounding rock. Plus different layers of non-drinkable water can work back up the well into the drinking water aquifer.

To stop this from happening we have to stop drilling and seal off the rock on the sides of the well from the well itself. This is known as casing the well, and running casing will hopefully (but not always) be only needed once before we get to the bottom of the well.

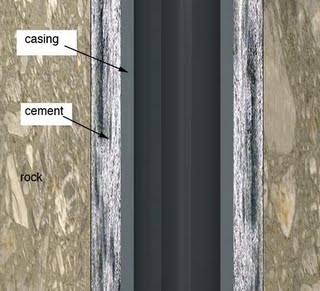

So we pull all the drill string out of the hole, remove the drill and lower steel pipe into the well to encase the well, from the bottom of the conductor pipe down to where the bit has found (and hopefully drilled through) the rock that is giving us the problem. (Hence the name casing). Having this continuous length of casing in the hole will likely stop, say water, from getting in and diluting the drilling mud, but if this was all that we did, then it would still leave a problem, since the steel pipe does not completely fit up against the rock wall created by the drilling bit. In other words there will be a gap between the casing and the rock wall, that will allow fluids to travel up or down. This gap has to be filled, and the filler is normally a special form of cement.

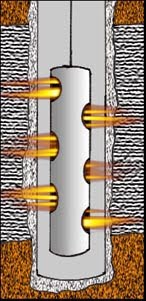

The way that the cement is placed is simple in principle, but a fair bit more difficult to do properly and effectively. Think of the long thin tube of casing, filled with a cement that acts something like toothpaste. This cement has to be pushed down the tube so that it squeezes out of the bottom and then flows back up between the casing and the rock wall, filling all the gaps as it is pushed back up to the top or surface. (Hence the name surface casing). Particularly when this casing is run, it is important that the gap is fully filled. This is because this is the casing that seals the well from local groundwater, used for domestic and industrial supply. Since the cement will move more easily thorough a larger passage, than a very narrow one, this gap has to be above a certain minimum size. Small centralizers will be attached at points down the steel casing to keep it in the middle of the hole, rather than pressing up against one of the walls (since this might leave an open channel up through the cement). There are also “scratchers” which are put on the casing so that when it is rotated in place it will scratch the walls of the borehole and remove any mud cake that might have formed, so as to give a better bond between the cement and the rock wall.

A small plastic plug (the bottom plug) is put into the casing ahead of the cement. This separates it from the mud that is already in the hole. It is fitted with wipers, that clean mud from the walls of the casing, and it is pushed down to the bottom of the casing by the cement that is pumped into the well behind it. There are some pictures of some of the tools and descriptions of the process here, here and here.

Once the bottom plug gets to the end of the casing, there are ports it passes that allow the cement to flow out of the casing and back up the outside. Once the cement has been pumped into the casing a second, top plug, also fitted with wipers, is put into the casing and this is then pushed down by the conventional drilling mud. As it is pumped down it forces the plug down, and the cement out and back up to the surface. Because of possible variations in hole size and other possible problems, perhaps about 50% more cement might be pumped into the well than the calculations might suggest. When the top plug hits the bottom plug, then there is a pressure spike at the pumping station, telling the operator that it is finished. The rig then waits on cement (WOC) until the cement is hardened. The drill pipe can then be put back in the hole and drilling can restart.

But whoops, the bit won't fit in the hole any longer! For the sake of discussion lets say we ran half-inch thick casing. And that we had an inch of cement behind it all around the casing. Then the hole we have available to get the drill through down to the bottom is now only 6-7/8th inches in diameter. So we now might use a 6-5/8th inch diameter bit to continue drilling (since we don't want it rubbing against the casing wall).

If we run into another layer of problem rock as we drill down to the bottom of the hole, then we are going to have to run another set of casing. This is known as intermediate casing, and the process is the same, and it leaves us with an even smaller hole through which to get a drill bit through.

Completing and Perforating a Well (Excerpt from previous tech talk)

That describes a little of the process of how a casing is cemented in position. The well that the Deepwater Horizon had drilled had reached the zone where the oil was, and in preparation for leaving the site had, as I mentioned above, run in the production casing. Let me add the post on well completion to explain this a little more.

There are a number of different steps that we have yet to go through before we can finish what is commonly called, the completion, of the well.

And one of the first things that we do is to flush out the drilling fluid, and then clean the walls of the well – firstly by washing the remaining mud from the well down in the production zone. That means that the rock wall is exposed, just as it was drilled. There are several issues that can come about as a result of this. The first is that the rock we have drilled into can be fairly weak. This is one of the peculiarities of geology. To a degree the richer in oil the rock is, the weaker the rock will be. (And that also holds true for oil shale - of which more at a later date). Why is that?

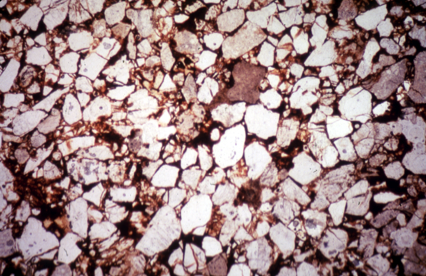

Well let's talk a little about the rock structure, particularly in this post the porosity that it has. (I’ll talk about permeability next time). There are, simplistically, two types of rock, that oil is usually found in and for now, to make a simple generalization, I am going to call them sandstone and carbonate (as I said holding shale until a later time). Sandstone rock is made up of relatively large grains that are glued together at the edges with various different types of natural cement. The grains do not fit that well together (think apples filling up a room, and connected where they touch). We call the gaps between the grains, the pore space of the rock, and it is these gaps that the oil fills up to form the reservoir. And so we can calculate the "free volume", as it were, of the rock as the (relative amount of free space in the rock, you can get this by subtracting the weight of the rock from the weight of the same sized piece cut from solid quartz and it will tell you how much empty space there is in the rock, and thus, how much oil there could be in that volume.

Section of sand with oil in the pores-–this is actually an oil sand, so the grains aren’t that well cemented together. (Syncrude)

So say we had a core that weighed 144 lb/cu ft and the weight of solid quartz (flint) is 220 lb/cu ft. Then only 65% of the rock (144/220) is solid rock and the remainder is what is known as pore space. Now these holes can be connected or totally separated, with each pore surrounded by a solid piece of rock. Normally the percentage given is reversed, i.e porosity = proportion of void space to total volume, or in this case 35% of the total volume is not rock. (Another picture showing porosity of a sandstone can be found here. Now in the reservoir rock this space is going to be filled with a fluid, either gas, oil or water. For now let us assume that it is filled with oil.

What I have described so far is known as primary porosity,i.e. that which is created by this initial structure of the rock. With carbonates more than sandstone there is a secondary porosity, and this is the porosity induced by rock movement and the dissolving of channels and holes in the rock by the movement of fluid over the rock through the millennia. Again put simply the oil found in a sandstone will occur between the grains of the rock. In the case of the carbonates, which normally have a much smaller individual particle size, the oil is more often usefully found in the cracks and joints formed were the rock bedding planes were created (and which can be seen in exposed rock in a lot of road cuts along the highway).

The voids and spaces in the rock are also formed from the spaces from what might have been old coral reefs, or where water dissolved holes through the rock. But sometimes the two methods of formation mix, and I would like to quote from Kenneth Deffeyes book "Hubbert's Peak" (my favorite text as an explanation of the geological case).

Fine grained calcium carbonate mud usually gets consolidated into massive limestones, usually with little or no porosity. . . . . . . .About 10 percent of ancient limestones do have porosity. . . . . . .Most massive and nonporous limestones contain textures made by invertebrate animals that ingest sediment and turn out fecal pellets. Usually the pellets get squished into the mud. Rarely do the fecal pellets themselves form a porous sedimentary rock. . . .I twisted Aramco's collective arm for samples from the supergiant Ghawar field. . . . .Examining the reservoir rock of the world's biggest oil field . . .a small part of the reservoir was dolomite, but most of it turned out to be fecal pellet limestone. I had to go home that evening and explain to my family that the reservoir rock in the world's biggest oil field was made of shit.

So there you have it. And the reason for the quote is that the rock at the bottom of our well can be very weak, and may be left in poor shape by the oil drilling bit that just passed it by. Now remember it is this wall around the hole that is the barrier through which all the oil in that rock must pass to get into the well. So before we leave it we have to ensure that it is in as good a condition to allow that flow as possible. (Hence the reason for the removal of the mud and the cleaning of the wall). We also have to isolate the production zone from the rest of the well, and we do this with what is known as a completion or production packer.

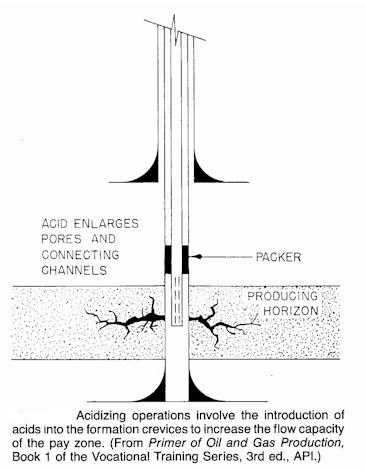

One of the problems is that the drill bit may have overly crushed the rock, so that fine carbonate particles are pushed into the cracks and pores of the rock, right around the bore. These can block the passages that will allow the oil to enter the well. And so, in order to get rid of these particles, a strong acid can be poured into the bottom of the well. This acidizing dissolves these fine particles and opens up the cracks leading out into the surrounding rock, so that the oil can flow into the well bore more easily.

Another problem is that the rock may be very weak, since a lot of its strength comes from the oil that fills the holes within it. This oil only provides strength as long as the rock is totally confined on all sides, but when the pressure is removed on one side (think of popping a champagne cork) then the oil can flow away, taking the support for the surrounding rock with it. If the rock bridges that are left are weak then they can crush. This will cause the crushed rock (sand) to mix with the oil, which will require a de-sanding process at the surface, but it will also close some of the passages through which the oil is flowing to the well. A well operator that speeds the flow of oil out from the rock around the well, can reduce the support that the oil gives to the surrounding rock to the point that it crushes, and permanently reduces oil flow into the well. We can put in a screen that will hold the rock in place, but allow the oil to seep through slots in the screen wall.

Or, to stop that rock crushing from happening and to reinforce the rock, we can pump a layer of concrete into the bottom of the well, cementing a steel liner into the rock, just as we cased the well higher up the well. The steel liner, or production casing, has, however, one problem. Once it is cemented into place, there is this hollow tube all the way to the surface, but there is no way that the oil can get through the cement and the steel into that passage.

And this is where Her Majesty's Explosive comes in. Small, specially designed, explosive charges, known as shaped charges are now put together into specifically designed charge packages, and lowered down into the well into the completion zone.

Here they are detonated, sending small jets of metal against the wall of the casing and perforating the steel and concrete into the surrounding rock. There is an animation that shows the jet being produced (see also information here) .

Update for Deepwater Horizon

At the time that the explosion occurred on the oil rig, it appears that they had cemented the production casing in place, and were cleaning the mud from the well, prior to putting a temporary cement cap at the top of the well. This would allow them to leave the site (abandon the well), with the well ready to be connected to the pipes that would more permanently carry the oil and gas from the well.

Thus this rig would not carry out the perforation of the well that I have just described, and the production casing should have been surrounded by a cement jacket, that would help seal, temporarily, the bottom of the well. It is the condition of this cement that is, I gather, why Haliburton, who were responsible for that part of the operation, are now in the picture.

The latest report from Upstream, suggests that there have been a number of attempts to get the current BOPs on the well to work, and that they may be providing some restriction to the flow, or this may be coming from the kinks in the riser above the BOP. However they have cut off the riser to give a better target, and they will do this again before lowering a new BOP arrangement that will “stab” onto the initial structure, and allow them to possibly seal the well with that (depending on how good a seal they can achieve with the stabbing operation – these are normally fairly tight).

They will still have to drill the relief wells, and are apparently already drilling the first well, while a second rig is completing another well in the Gulf, and then will come over and provide a back-up to the first in drilling a second relief well.

Any new word on the cap (or caps) that BP is reportedly going to drop over the ruptures?

The explanation is greatly appreciated.

What I can't really get my mind around is the scale of this operation. Suppose all attempts to seal the well fail. How much oil can come out of a single well before the pressures are naturally equilibrated and the pores are filled with limestone and sand and seawater and the well stops leaking? Surely the whole GOM can't leak through one well?

Left alone for years till depletion (~100 million barrels), this spill would seriously pollute not only the GoM but the North Atlantic Ocean as well, with a few tar balls showing up on Mediterranean beaches.

Alan

http://slatest.slate.com/id/2252681/?wpisrc=newsletter

Words fail me.

Craig

http://www.msnbc.msn.com/id/36917022/ns/technology_and_science-science/

"These oceanographers are carefully watching the Gulf Loop Current, a clockwise swirl of warm water that sets up in the Gulf of Mexico each spring and summer. If the spill meets the loop —the disaster becomes a runaway."

Expected tomorrow.

Alan

Alan - do you have any links about that handy?

The Exxon Valdez spill in Prince William Sound of Alaska has a number of similarities to GoM spill. Prince Wm. Sound has current patterns similar to the GoM in that they circulate seawater through the sound and then back into ocean. The 11 million gal. EV spill was circulated within the northern end of the sound and then swept out into the open sea. At this point the prevailing coastal currents took over and carried the spill northward and then westward impacting coastal lands along the lower Kenai Peninsula and then along the entire length of the Alaska Peninsula all the way to the beginning of the Aleutian Chain, well over a thousand miles. The spill now taking place in the GoM seems destined to follow a similar course as it is carried into the Atlantic and then circulated along the U.S. east coast possibly impacting lands as far north as Nova Scotia in Canada. Ultimately, it could be carried eastward on the gulf current eventually reaching northern Europe.

I expect tar balls on the coast of Italy.

Alan

Sadly LNG this well could leak huge amounts of oil until the relief well is successfully drilled. If it had blown out while drilling the hole often collapses on itself. But in this case the hole was cased and cemented. That’s how we set a well up to produce for years. Maybe the casing will collapse but the system is designed to prevent just that possibility.

Rockman, how long will it take to get the relief well drilled approx?

Hard to guess right now Earnie. The producing zone is down around 18,000'. To offer a guess to timing we need to find out how deep the plan to intersect the original hole. If above 10,000' it could happen in a few weeks. But if the situation requires them to hit it deep it could take 3 months or more and that's if there are no problems.

The announced plan is to go down to the pay zone, 18,000'.

I meant to ask you what factors would drive that decision. Obviously, more months of leaks.

Alan

Thanks Alan. I suspect the decision to go that deep was a function of the original casing plan and the fracture gradient. When drilling you need to keep the mud weight below the fracture pressure of the rock but high enough to prevent flow. They might have to set 3 or more strings of casing to reach this balance point before cutting into the old well. Unfortunately such multiple casing sets take that much more time. They should have a pretty good estimate of that timing as it should twin what was done in the original well. I'll guess about 60 to 90 days right now but someone with BP should be offering a hard timeline.

A forward on political action...

There is no verbal hyperbole sufficient to express the magnitude of

the environmental catastrophe now known as Deepwater Horizon. It is

nothing short of an Armageddon of Oil. Assuming we even survive this

one, we must immediately mobilize a crash program for truly renewable

alternative energy resources.

Action Page: http://www.peaceteam.net/action/pnum1043.php

Despite the gusher of lies we've heard trying to minimize the

planetary scale disaster now in progress in the Gulf, the terrifying

truth is available for those who will hear it. First they told us the

"leak" was only 1,000 barrels a day, when in fact it is at least 5

times that much. Of course it's hard to pretend an oil slick the size

of New Jersey isn't there. And it could easily blow out to 50,000

barrels a day (2,000,000 gallons) in a heartbeat, according to a "not

for public" NOAA emergency report.

This is not just a leak, it's a monster underwater oil geyser, under

upwards of 100,000 pounds per square inch of pressure, enough force

to lift 50 tons with your thumb. And unless it is somehow stopped, it

may spell the end of all marine life on the planet. We are not

talking about just one Exxon Valdez size tanker spill, we are talking

about one of largest oil fields ever discovered completely venting

its entire contents into the ocean, thousands and thousands of

tankers. It's THAT cataclysmic.

But assuming we miraculously dodge the literal end of the world this

one time, we need to finally do what should have been done 20 years

ago, and throw everything we've got into a crash program for

alternative renewable energy, and stop burning fossil fuels before

they kill us all.

Action Page: http://www.peaceteam.net/action/pnum1043.php

And after you submit the action page, please consider picking up one

of the timely "350 ppm or catastrophe" caps from the return page,

emphasizing the urgency of immediately reducing worldwide carbon

dioxide emissions. It is not as if we have not had every warning

already. Or you can get one directly from this page.

350 PPM Or Catastrophe Caps:

http://www.peaceteam.net/message_items.php

It should have been done twenty years ago. Stop all new oil

exploration. Forget about insanely expensive nuclear plants. End

immediately the lunatic military occupations that have cost us

trillions. And put everything we've got into an all out push to

develop and bring on line truly renewable alternative energy sources.

The burning of fossil fuels was already slowly killing the planet,

causing inexorable rises in greenhouse gas levels that have done

nothing but accelerate, despite the rampant disinformation campaign

waged by oil industry toadies pretending to be real scientists. Now

unless we find some way to stop the venting of the entire contents of

a gigantic oil field in the Gulf, under 100,000 pounds per square

inch of pressure, we may be looking at the end of all marine life on

this planet. We have literally punched a hole into hell.

Please add whatever personal comments of your own you like, and

emphasize it is time for our politicians to stop serving only oil

company and nuclear lobbyists paying the off to continue to pursue

bad energy policy, but to start doing something to save our country

and our world instead.

And here is the Facebook link for the Crash Alternative Energy action

page further above.

[Facebook] Action Page:

http://apps.facebook.com/fb_voices/action.php?qnum=pnum1043

http://blog.al.com/live/2010/04/deepwater_horizon_secret_memo.html

'The following is not public' document states!

[See link for more information and pics]

"The following is not public," reads the National Oceanic and Atmospheric Administration's Emergency Response document dated April 28. "Two additional release points were found today in the tangled riser. If the riser pipe deteriorates further, the flow could become unchecked resulting in a release volume an order of magnitude higher than previously thought."

Asked Friday to comment on the document, NOAA spokesman Scott Smullen said that the additional leaks described were reported to the public late Wednesday night. Regarding the possibility of the spill becoming an order of magnitude larger, Smullen said, "I'm letting the document you have speak for itself."

In scientific circles, an order of magnitude means something is 10 times larger. In this case, an order of magnitude higher would mean the volume of oil coming from the well could be 10 times higher than the 5,000 barrels a day coming out now. That would mean 50,000 barrels a day, or 2.1 million gallons a day. It appears the new leaks mentioned in the Wednesday release are the leaks reported to the public late Wednesday night.

"There is no official change in the volume released but the USCG is no longer stating that the release rate is 1,000 barrels a day," continues the document, referred to as report No. 12. "Instead they are saying that they are preparing for a worst-case release and bringing all assets to bear."

The emergency document also states that the spill has grown in size so quickly that only 1 to 2 percent of it has been sprayed with dispersants.

The Press-Register obtained the emergency report from a government official. The White House, NOAA, the Coast Guard and BP Plc did not immediately return calls for comment made early this morning.

The worst-case scenario for the broken and leaking well pouring oil into the Gulf of Mexico would be the loss of the wellhead and kinked piping currently restricting the flow to 5,000 barrels -- or 210,000 gallons -- per day.

* LATER REPORT: Video shows federal officials knew quickly of potential for massive oil flow in Gulf spill

If the wellhead is lost, oil could leave the well at a much greater rate.

"Typically, a very good well in the Gulf can produce 30,000 barrels a day, but that's under control. I have no idea what an uncontrolled release could be," said Stephen Sears, chairman of the petroleum engineering department at Louisiana State University.

On Thursday, federal officials said they were preparing for the worst-case scenario but didn't elaborate.

Kinks in the piping created as the rig sank to the seafloor may be all that is preventing the Deepwater Horizon well from releasing its maximum flow. BP is now drilling a relief well as the ultimate fix. The company said Thursday that process would take up to 3 months.

View from above

To keep track of the Gulf of Mexico oil slick, visit www.skytruth.org or follow its Twitter feed.

To see updated projection maps related to the oil spill in the Gulf, visit the Deepwater Horizon Response Web site established by government officials.

How to help: Volunteers eager to help cope with the spill and lessen its impact on the Gulf Coast environment and economy.

"I'm not sure what's happening down there right now. I have heard there is a kink in what's called the riser. The riser is a long pipe that connects the wellhead to the rig. I really don't know if that kink is a big restriction. Is that really a big restriction? There could be another restriction further down," said LSU's Sears.

"An analogy would be if you have a kink in a garden hose. You suspect that kink is restricting the flow, but there could be another restriction or kink somewhere else closer to the faucet.

BP Plc executive Doug Suttles said Thursday the company was worried about "erosion" of the pipe at the wellhead.

Sand is an integral part of the formations that hold oil under the Gulf. That sand, carried in the oil as it shoots through the piping, is blamed for the ongoing erosion described by BP.

"The pipe could disintegrate. You've got sand getting into the pipe, it's eroding the pipe all the time, like a sandblaster," said Ron Gouget, a former oil spill response coordinator for the National Oceanic and Atmospheric Administration.

oilinhand.jpgView full size(AP Photo/Patrick Semansky)Oil scooped up from the Gulf of Mexico 17 miles southeast of the South Pass of the Mississippi River is seen on the hand of deck hand Jordan Ellis on the Louisiana coast Friday, April 30, 2010. The oil originated from a leaking pipeline after last week's explosion and collapse of the Deepwater Horizon."When the oil is removed normally, it comes out at a controlled rate. You can still have abrasive particles in that. Well, now, at this well, its coming out at fairly high velocity," Gouget continued. "Any erosive grains are abrading the inside of the pipe and all the steel that comes in contact with the liquid. It's essentially sanding away the pipe."

Gouget said the loss of a wellhead is totally unprecedented.

"How bad it could get from that, you will have a tremendous volume of oil that is going to be offgassing on the coast. Depending on how much wind is there, and how those gases build up, that's a significant health concern," he said.

The formation that was being drilled by Deepwater Horizon when it exploded and sank last week is reported to have tens of millions of barrels of oil. A barrel contains 42 gallons.

Smullen described the NOAA document as a regular daily briefing. "Your report makes it sound pretty dire. It's a scenario," he said, "It's a regular daily briefing sheet that considered different scenarios much like any first responder would."

http://pesn.com/2010/05/02/9501643_Mother_of_all_gushers_could_kill_Eart...

Mother of all gushers could kill Earth's oceans

Imagine a pipe 5 feet wide spewing crude oil like a fire hose from what could be the planets' largest, high-pressure oil and gas reserve. With the best technology available to man, the Deepwater Horizon rig popped a hole into that reserve and was overwhelmed. If this isn't contained, it could poison all the oceans of the world.

"Well if you say the fire hose has a 70,000 psi pump on the other end yes! No comparison here. The volume out rises geometrically with pressure. Its a squares function. Two times the pressure is 4 times the push. The Alaska pipeline is 4 feet in diameter and pushes with a lot less pressure. This situation in the Gulf of Mexico is stunning dangerous." -- Paul Noel (May 2, 2010)

[snip]

If we can't cap that hole that oil is going to destroy the oceans of the world. It only takes one quart of motor oil to make 250,000 gallons of ocean water toxic to wildlife. Are you starting to get the magnitude of this?

[snip]

While this is a very serious topic, I would be grateful if some of the more exaggerated stories could be avoided. The hole in the ocean floor is not huge, the oil is coming out of a pipe of much smaller size, and if you look at the picture that I started with yesterday, it is not coming out under very great pressure.

While it may very well have eroded a passage through the BOP so that it has increased the flow to 5,000 bbl per day this is at present a guess, and the volume is likely nowhere near as great as some of these wilder stories are suggesting. BP have a riser down that is now injecting a dispersant into the oil as it is coming out of the riser, and is preparing some equipment to try and trap the flow sometime this week, so yes it is a very serious problem, but please don't let's get hysterical.

Yes, 5000 is a guess, but most of the sources I see call this a very low ball guess, with 20,000 to 25,000 more likely, and 50,000 to 100,000 + not figures that can be ruled out.

fraudonomic.blogspot.com

When level heads like rockman's sound deeply worried and pessimistic, you can't be surprised that some of the rest of us are starting to freak out.

My view is that the 1,000 & 5,000 barrel/day "estimates" are border-line public relations lies. The lowest numbers that had any rational defense.

Based upon the surface results, an average of 20,000 to 50,000 b/day seems defensible.

Even very high pressure jets dissipate very quickly in uncontained water. The inertial transfer is quite rapid.

Alan

to put this into perspective, 1000 bpd is not that impressive. a garden hose might deliver something on the order of 5 gallons per minute (try it sometime). this converts to 170 bpd or 6 garden hoses per 1000 bpd.

If crude oil were coming out of your garden hose, I think your neighbourhood might have something to say about that.

yeah, what would that be: "elwood is richer than old jed clampit" ?

"This is not just a leak, it's a monster underwater oil geyser, under upwards of 100,000 pounds per square inch of pressure,"

This situation is bad enough without folks posting this alarmist dribble.

Stiv, do you have any clue how over-the-top 100,000 psi is?

I was re-posting something that seemed relevant. I am not trying to be alarmist, but the dominant tendency has been for BP to start off underestimating the problem. First, they say 1000 barrels/day, then 5000, now we're getting reliable sources saying THAT could be off by an order of one magnitude. 50,000 barrels/day is possible. We simply don't know yet but why not prepare for worst-case scenarios? Why not consider them? If you can prove that 50,000 bpd is impossible, go for it.

It is hard to imagine 70k psi. I don't know where the figure of 100k psi came from, but that's certainly wrong. Sorry for reposting that info! I think these exaggerated PSI figures came from Paul Noel's theoretical discussion here: http://pesn.com/2010/05/02/9501643_Mother_of_all_gushers_could_kill_Eart...

However, From

http://blog.al.com/live/2010/04/deepwater_horizon_secret_memo.html

I don't think there is any disputing this:

"Typically, a very good well in the Gulf can produce 30,000 barrels a day, but that's under control. I have no idea what an uncontrolled release could be," said Stephen Sears, chairman of the petroleum engineering department at Louisiana State University.

On Thursday, federal officials said they were preparing for the worst-case scenario but didn't elaborate.

Kinks in the piping created as the rig sank to the seafloor may be all that is preventing the Deepwater Horizon well from releasing its maximum flow. BP is now drilling a relief well as the ultimate fix. The company said Thursday that process would take up to 3 months.

I wasted a perfectly good napkin yesterday on this, for what it's worth.

If the well is flowing 28k bbl/day that's 20 bbl/minute or 840 gallons. A fire hydrant running full throttle is 750 gallons per minute. It's not a huge geyser, it's a 6" pipe with some oil coming out of it.

If it's leaking 28k bbl/day that's about a million gallons. An acre foot is about a third of a million gallons. This well's flow rate could fill a football field waist deep every day.

There are about 300,000 microns in a foot and the oil sheen on the water is a micron thick. Three acre feet of oil times a 300,000 spread factor means the slick could expand by 1,600 square miles a day at most, assuming perfect dispersion.

So ... it's a gruesome mess, but it isn't the apocalypse cow, come to eat all our lawns down to bare dirt.

Gouget said the loss of a wellhead is totally unprecedented.

And, in 60 days that is 120 million gallons, or enough to fill a football field to aboaut 200 ft. in a year it is 365 million gallons... I have heard that if not capped, it could go for more than a year.

Does anyone, Rockman perhaps, know how much pressure, volume of the reservoir, and can those figures be used to compute how long it could run before the pressures equalize?

I serously doubt the entire 100 MB could leak out. The questions are, how fast, for how long, what can be done to stop it, and what can be done to remediate the damage? Also, BTW, who gets stuck with the bill?

I nominate BP and Halliburton. I predict the US Taxpayers, and maybe Mexico, Europe and, what, Canada? You know the drilling company is out of it in any event.

So... drill, baby, drill. The lawsuits from this disaster will keep the legal industry alive for decades!

Craig

The lawsuits from this disaster will keep the legal industry alive for decades!

A couple of lawyer ads are already running. Low production values, so I know that they were done quickly.

Alan

ZAP -- If it’s a water drive reservoir the pressure will never drop. Just keep flowing till it depletes. Pressure depletion drive and only BP could make a guess but it would be years probably. The only way for this flow to stop anytime this year is to kill itself or have the relief well kill it.

BP pays 100% less any money they win suing a guilty third party

Any good crisis needs multiple causes, and multiple guilty parties.

This will likely be like Pearl Harbor -- plenty of warning from system specifically intended to provide warning, plus plenty more from anecdotal sources. Yet when the information became actionable knowledge, it's a bit late, and the repercussions are extreme.

Complexity is fragile. Ignorance is a liquid. Stupidity is a gas. They get into all sorts of things you would think they shouldn't.

pesn.com is a wacko site for "Free Energy" (aka Perpetual Motion). Those people think they can get free energy from magnets... not a reliable source of info.

Ouch! Sorry. I don't believe in 'free energy.' Paul Noel's article seemed reasonable enough. I'll be more careful. I was multitasking today in a rather tragic and inefficient way.

stiv, posting something that has clearly-inflated numbers is not necessarily helpful.

One needn't claim that 100 million people were killed in the german death camps to make the point; the truth is quite sufficient.

In this case, you've done a favor for those who might wish to trivialize this abominable situation, by publishing a piece which contains unsupportable numbers and statements.

I share your deep sadness, rage and revulsion at what's being destroyed. But over-the-top claims provide shelter for those who think the loss of species and habitat is well worth the price.

It's quite possible to make the same points in a scientifically-supportable way. Maybe you can consider this a "first draft", and edit it with information you can find here.

As bad as this is, it's of a piece with what our species is doing to the entire planet. This focus of the world's attention should not be wasted.

Don't offer easy rebuttal arguments to those who will say this is OK.

Great STIV, let's save the world. I'm all for it.

But your posts remind me of a conversation I had a few years back with an old coot from up the valley who in complete sincerity told me that climate change was real and that it could be traced to the puncture holes caused by rockets blasting their way into outer space.

Two pieces of advice: get your facts right, set out reasonable goals.

Well, like I said, the 70k psi number came from an abstract discussion by Paul Noel, and I believe it was his statement that was turned into 100k by someone else. But those 'facts' I apologized for 'spreading' (not creating), however, the more disturbing 'facts' that are still theoretical have to do with the amount of oil spilling daily that is quite possibly being underestimated AGAIN. They won't be able to hide that for long. Is it 5000 bpd? Or 30,000? Place your bets. I'm not so sure. I don't trust BP, nor the US government, to tell us the truth. We'll find out soon enough.

I guess I'm kind of glad you were alarmist. The way the news and spokespeople (notably BP) have been underplaying this is shocking, considering it's nearly two weeks after the initial explosion. People are only now just waking up. The lack of real news--truth--on this accident staggers.

Yawn..........self centered alarmist.....yawn

Yawn: "The view from space indicates that the oil may be leaking at a rate of 25,000 barrels a day, dwarfing the figure of 5,000 barrels that US officials and the British oil giant BP have used in recent days." Source

Q: What's worse than a 'self-centered alarmist'?

A: Yawn... an apathetic, self-centered apologist for the oil industry... yawn.

Please explain what you mean by "stab". Why the quotation marks? Is there some special meaning for the word? What or who is the stabber? What or who is the stabbee? (Is stabbee a word?)

Geek -- Sounds silly but the best way to describe a stabbing op: Assume you have a big tub full of water and a hole in the side. You can’t screw a plug in because there are no threads. You can’t weld a plate over due to the water flowing out. So you cut a wood plug a little smaller than the hole and stab it into the hole. Just like stabbing you knife into a watermelon. The plug doesn’t stop all the water but slows it enough to let you work on a permanent fix. No real official definition of “stabbing” but I think you get the idea. Just like the little Dutch boy and the dike.

Back when Flowdril was working with Grace on ultra-high pressure drilling (running a 30,000 psi waterjet around the outside of the hole to cut a groove at the edge, stress relieving the core so that the tri-cone could drill about twice as fast as usual) they could not use conventional tubulars to make the connections that carried a mud flow as well as the high pressure water down to the bit. So they developed high pressure fittings that could be be just slid into one another, with a bit of force to make sure that it made the seal (which it did - the tools drilled several thousand feet). These "stab" fittings could hold a 30 ksi seal, and so might be planned for the same this time.

I hear that they have cut the top of the riser, so that it could make such a seal, if they develop the mating female part of the joint with the appropriate surfaces (and not having the measurements I couldn't tell you what they would need).

Since this well is cased and cemented, all the log data should be completed and tell the thickness of the production Zone, and formation name, the permeability of the rock and porosity. So has any one made this data available yet? This should shine some light on max flow possible.

I've got gardening to do be back later.

And in this case it's slightly easier than the stick of wood plug because (I guess) you're effectively sticking an open tap over the flow - then once you've fastened it good and solid you try to turn the tap off.

Good luck...

Thanks for this terrific clarifying post, HO. In light of the current direction of inquiry and from statements from Toolpush about mud loss and possible slurry loss, I wonder if you, or one of our other pros here would help us understand more about how operators determine during the cementing operation how they know the annulus has been filled.

When I think about cementing into this formation with it's heat, pressure and porosity...does displaced fluid flow from upper controls? Other than the upper plug contacting the landing, and later pressure testing, does the cementer (don't know the term obviously) have any other indication the operation is done right?

There are tests (I do not know the details) and if a large void is found, additional concrete is added in that area.

Alan

Cement Integrity Logs are explained some on this page, from which I grabbed the following example:

EXAMPLE 8: At Zone A, amplitude shows good bond, but VDL shows low amplitude formation signal. This indicates poor bond to formation. Travel time curve reads very high compared to baseline, indicating cycle skipping on casing arrivals – but casing bond is still good. Travel time less than base line value would indicate fast formation. If you can detect fast formations, bond is still good, regardless of high early arrival amplitude.

Several methods X. First, a caliper log is run to determine just how much hole volume you have to fill up. Just because you drill an 8” hole doesn’t mean it is 8” all the way down. Holes normally wash out at different spots so it could be 12” in diameter along different intervals. Subtract the volume that the casing fills and you get the amount of cement you need to pump. There are specific regs as to where cement needs to be placed. So one calculates the amount needed to achieve those requirements. Once the cement is pumped it has to set up…12 to 24 hours. Once the cement hardens there are regs that require a specific testing procedure. Essentially pressure up to X psi for Y minutes. The pressures while holding static are charted. You check the chart to make sure the pressure isn’t falling off which would indicate the cement was failing. If you don’t get a valid AND CERTIFIED TEST there is a second procedure required: called a “squeeze job”. You shoot holes in the casing and pump more cement in. You might also try to pump cement up from the bottom of the casing as was done initiallyYou might first run a CBL (cement bond log) log that MIGHT indicate where you have bad cement. That’s where you do your squeeze job. And then retest until you meet specs.

Thanks Rockman between this, your other comment below and what others are bringing in I can't see getting too far from theoildrum today.

You're welcome X. I'm able tgo hang around longer than normal: I'm sitting in the middle of a Texas cow pasture logging a shallow well. Lots of "hurry and and wait" moments with nothing else to do. Thank goodness for my air card.

I'd like to see you on a rig sailing out to the leak. You, I'd trust to get it right! Meanwhile, thanks for the many very informative comments. You and Alan, esepcially, have been great. I've learned more about off shore drilling and engineering in the last 2 weeks than I had in the past 4 years! Sad way to acquire knowledge!

Craig

zap - I'm only good at trying to keep them out of trouble while drilling. After the fact I'm really not much use.

Yes indeed...one of saddest experiences being one of the smartest guys in the room. It actually has been a bit of a struggle to run updates on TOD. I'm very good at compartmentalizing and could leave the whole story behind in a heartbeat. I've buried my share of friends/coworkers. Had to deal a little with the uncle of one of the dead hands the week of the blow out. I don't attend memorials anymore.

But we are family of sorts here at TOD .

Rockman - thanks for your insight. Our place is over (on top of?) the Eagle Ford Shale in DeWitt County. We're taking the big bucks from the oil company for a new lease. You in a cow pasture anywhere in our neighborhood?

All us local folks are now thinking that wells on dry land, even if they're almost three miles deep, might look better than a mile under the ocean.

Congrats Lauren. Best wishes for future "mail box" money.

Nope...just north of Houston only a hour away from the house. A nice change from those 9 hour drives to Fourchon.

Rockman

It may be a dumb question, but can you explain how the relief well would work? I assume it does not relieve the pressure of the formation, but instead provides upstream access to fix the leaker ahead ot the casing?

Or? Thanks in advance.

Paul

Exactly Paul. They’ll intersect the original hole. A little more complicated then when a well blows out in an uncased hole: hit the open hole and start pumping in very heavy drilling mud under very high pump pressure. In this case they will probably change drilling bits when they get close. They’ll need a metal cutting mill bit to get through the casing. Even when this is successful they will still have to reenter the hole through the original well head and plug and abandon the well permanently. This could take many months but it’s required by law.

From what I can find on the web there appears to be a major difference in what was going on at the time of the explosion.

In the radio interview at Mark Levin's radio show, the caller who claims to have been there at the rig at the time of the explosion states that the cementing was about to begin, not that it was nearly completed as others have said on various blogs.

This is important, not only to determine what happened but for legal reasons in the many legal lawsuits to follow.

Here is the link to the radio interview:

Mark’s Exclusive Interview with a Survivor from the Oil Rig Explosion

So who are we to believe. The caller or others that we read who don't claim to be there but have second hand information?

Is there some kind of dis-information going on here or is it just the normal mish-mash that always follows events like this?

Papa Ray

West Texas

P.S. I was suspended from the blog: Drilling Ahead for asking this question. I have asked why and received no answer.

I believe that you are confusing two different cementing operations. The first was the cement injection at the bottom of the hole to surround the production pipe. That was completed between 16 and 20 hours before the incident, depending on who is reporting. What remained to be done was to pour a second concrete plug at the top of the well, so that the drilling rig could be pulled from the site, and moved to drill another well. A second rig would come in to make the connections to the transport network, and to perforate the well (if it needed it).

Thanks for the comment. Still, would you listen to the interview and see if maybe I'm missing something. My buds and I are really concerned and interested in why there are varing reports on the cementing.

And I'm really interesting why I was banned from Drilling ahead for even asking this question.

The person interviewed would know the difference that you spoke of, wouldn't you think?

Papa Ray

West Texas

Interview here: http://www.drillingahead.com/ Very interesting, consistant with qualified explanations we've gotten on TOD.

Yes, and that is the blog that I got banned from for asking about the conflicting stories about the cementing. The caller on the Mark Levin radio show said that the cementing was just about to start where others say (on the web, all second hand info) that the cementing was almost complete except for the last "plug".

Mark’s Exclusive Interview with a Survivor from the Oil Rig Explosion

My question was who is mistaken or if there was some kind of "disinformation" going on.

Papa Ray

West Texas

My take is that he was refering to the final plug being cemented in (though it's a little vague).

Note: For a good view of a BOP in place, check out the video of a BOP with a live Marlin stuck in it.

I would like just to ask for more details if anybody knows.

- The well was just cemented with the production casing, this production casing can be a liner or a complete column. The most probable in this case is a complete column which has been landed in the subsea wellhead.

- I don’t know the type of this subsea well head Cameron, Vetco or another one?. It has to be kown that for each one a different procedure exists to land and to cement the casing once landed.

- The BOP is above the subsea wellhead, if they where cleaning the riser prior to set the top cap plugs to abandon the well it means that they were confident in the success of the cementing operation and the sealing of the cementing ports in the well head, this is normally tested at the required pressure and you have procedures very tight to follow in case you have a leak!

- Cementing at this depth below sea level with a semi sub (around 18 000ft) is a sensitive operation and the main risk is to destabilize the reservoir pressure by an improper balance of all the fluids you are going to pump in the well. You have also the possibility of a “strong” channeling bringing the cement too high in the well and may be even higher…One of the key of the understanding is to have the logs of the cementing operation which as you can imagine is impossible for the moment (confidentiality etc..)

In brief to understand what happen and why the well started to flow a lot of “details” are missing in the press!

For sure if you clean your riser from the very expensive synthetic base mud for sea water it means that you have finished the tricky part of the work.

I'd like to add a couple of questions:

Does the term "production casing" refer only to the length of casing in the oil-bearing zone which will later be perforated and/or have a completion screen fitted? (Presumably any other casing would be referred to as "intermediate casing.")

Is a drill hole cased along its whole length, or only when passing through weak or porous rock (and water-bearing strata for above-ground drill holes)? If cased only along portions of its length, what are the typical lengths of cased portions?

Are there restrictions on the length of casing that may be cemented in any one operation? I'm thinking that the further the cement travels in the annular space, the more its quality drops off due to dilution and ingress of foreign matter.

You are a nosey little devil aardy. Production casing does imply it's being run over a planned completion interval. And int. csg. is as you say. A hole is cased as needed. Usually have to run int csg when you need to raise mud weight above a level the shallow rocks can handle. There are practical limits to cementing. Some times the cmt is pumped only a certian height up or sometimes all the way to the top of the csg string. Exactly: long cmt jobs are more subject to failure.

Thanks for answering, Rock. And I'd like to add my name to the many others who appreciate the way you give of your time and experience here on TOD.

Tripling in size in three days and it is already HUNDREDS of MILES long. Exxon Valdez spill with 11 million gallons contaminated heavily 200 miles and 1300 miles was affected.

Only 5000 barrels or 220 000 gallons per day, coming from mile deep, oil very dense and easily mixing up with water and STILL tripling in size, seeing from SATELLITE images...that 5000 barrels estimation must be way way too low. By now it should affect maybe 100 miles at best, 1/5th of Exxon Valdez.

As I posted above, others are coming to the same conclusion.

http://fraudonomics.blogspot.com/

"John Amos, a geologist who has worked as a consultant with companies such as BP, ExxonMobil Corp. and Royal Dutch Shell PLC on tracking and measuring oil spills from satellite data, said NOAA raised its estimates to 5,000 barrels a day after he and his colleagues published calculations that showed the original figures were far too low based on the NOAA data. Amos has also previously participated in a joint industry-NASA study using satellite imagines to detect and track oil slicks.

Mr. Amos said the 5,000 barrels a day is the "extremely low end" of their estimates. He said, based on NOAA maps, a more realistic figure is 20,000 barrels a day."

"Oil May Be Leaking at Rate of 25,000 Barrels a Day in Gulf - WSJ.com:

WASHINGTON—The Gulf of Mexico oil spill could be leaking at a rate of 25,000 barrels a day, five times the government's current estimate, industry experts say."

"Asked Friday to comment on the document, NOAA spokesman Scott Smullen said that the additional leaks described were reported to the public late Wednesday night. Regarding the possibility of the spill becoming an order of magnitude larger, Smullen said, "I'm letting the document you have speak for itself."

In scientific circles, an order of magnitude means something is 10 times larger. In this case, an order of magnitude higher would mean the volume of oil coming from the well could be 10 times higher than the 5,000 barrels a day coming out now. That would mean 50,000 barrels a day, or 2.1 million gallons a day."

"A National Oceanic and Atmospheric Administration video, shot as officials coordinated response to the Deepwater Horizon disaster, shows that federal officials almost immediately worried that the oil well could leak up to 110,000 barrels per day, or 4.6 million gallons."

Apples and oranges comparison. Too many variables: Different oil, E-V was contained in a sound, different wave action/wind forces, E-V spill was on the surface, this one is at depth, different water temps,,,, all having differing effects on dispersion. The size of the slick is a poor indicator of the amount of oil released.

Maybe but 5000 barrels per day is one fire truck hose blasting and even one man can handle it. And BP is saying they cannot contain the main leak at the end of the riser?!

I don't disagree that the flow may be much higher than reported. I expect that measuring the velocity/pressure of flow will be the best method of determining this. Until the riser is cut (some reports say this has already been done) and there is a single point of flow established, any attempts to determine flow rates accurately will be difficult. I also agree with others here who have posted that there is little to be gained from providing dis-information at this point. It could make their legal/liability issues worse, IMO.

I agree with ROCKMAN's statement a couple of days ago. Better to say "we don't know".

Exactly, we don't know. So we should not be too ready to discount people like stiv that are presenting figures much higher than the industry is putting out.

BP Moves to Fix a Leak as Obama Warns of Oil Damage May 2, 2010

From the article: "BP hoped to install a shut-off valve on one of the three leaks....But the biggest leak, at the end of the riser pipe, which Mr. Fryar said was the source of most of the spewing oil, cannot be shut off this way."

Something does not add up here at all. If we are talking about 210 000 gallons per day or 5000 barrels, that is about 150 gallons per minute, which is about average FIRE HOSE flow! Yeah, a lot of pressure but still manageable. Fire truck main pump can usually max out in 1500 GPM.

An easy answer Tim Let’s use your fire hose example. Manageable? Maybe with a nozzle on the end of it. But how would you control it if there were no nozzle Put your hand over the end of it? Or maybe your mouth?

Your example is good way to envision BP’s problem: they need to get a nozzle over the end of the pipe so they can shut it off. I know that sounds simplistic but that is the basic problem.

If you want to see how that is done rent the John Wayne movie "Hell Fighters". Really. It shows exactly what the process looks like.

I second the "Hellfighters" recommendation. It's one of my favorite John Wayne movies. As the Rock noted earlier, it is of course based on Red Adair's life.

I was at a presentation by either Boots or Coots, long since forgotten which one, at a local geological society meeting in West Texas about 45 years ago, some time in the Sixties (I was in elementary school at the time). But I still vividly remember the slide presentation.

I think it would be very difficult; IMHO they are asking for more trouble than they have if they 'cut off' the pipe below the BOP, etc.

It sort of reminds me of Engineman 1st Class Brad Stepanak in Down Periscope where he caps of the high pressure water leak in the engine room. If he didn't succeed, the USS Stingray was doomed.

Analagously, if BP doesn't succeed, NOLA and quite a bit of the Gulf coast are doomed. I hope BP can do it. I am not making book on it.

Craig

I do luv that silly movie zap. Thanks for reminding me.

This is a neophyte question, but I'm quite curious - What is meant by the "test" process that is performed with a BOP at depth. My understanding of how the BOP functions (and I could certainly be wrong) would seem to indicate that completely testing the device would necessarily cause the destruction of the well bore itself. In other words, doesn't activating the BOP destructively shear through the casing/steel/whatever else is actually in the well itself? Once it's activated, how do you remove/replace it? Thanks for any info!

I saw this link at Naked capitalism and looked at it. I don't know enough to interpret what I see, but surely someone here will be able to comment on the significance of these things.

http://solanic.com/wordpress/2010/05/02/technical-discussion-of-deepwate...

I DO NOT HAVE CONFIRMATION OF WHAT I’M ABOUT TO SAY!!!!

Did everyone hear that? Maybe true…maybe just BS. But just heard a story re: the displacement of the drilling mud with sea water from the riser. The mud was being pumped into a boat at the rig. Normal procedure. But at one point the boat captain notified the rig his tanks were almost full. But that didn’t match the volume of mud that could have been pumped in the time span.

What this might mean: when you’re drilling and you stop to add a new section of drill pipe you monitor the return mud tank. When you stop your mud pumps, the flow of mud from the well bore should also stop. If it doesn’t then something down hole must be pushing the mud up and out… oil/NG/water or any combination. That’s why you do a “flow check”. To make sure the hole is static. Pure speculation on my part based upon the unconfirmed report of excessive mud pumped to the boat: the well started coming in and no one was monitoring the flow back. There are also electronic monitors to watch for this but they don’t work very well (or at all) during such an offloading op.

But if true this goes a long way toward explaining why the accident happened so fast. As others have mentioned there are procedures to kill a kick or an actual well flow. But those actions are only taken when you know they well is coming at you. As we say in the oil patch: “When you see it coming at you through the kelly (the drill floor) you’re probably already dead.”

Certainly makes sense.

Something happened down hole--cement job & bottom plug failed or casing collapsed--and the rig didn't know the well was kicking (for reasons outlined above), until the water hit, followed quickly by the gas, then oil.

Finally, for whatever reason, the BOP didn't work.

BTW, can you confirm the "Brazil Rule" that "Toopush" discussed, to-wit, that in deepwater Brazil wells they have to demsontrate that the shear rams will cut through drill pipe at depth? And is it true that there is no such rule in the deepwater GOM?

Actually never heard of it before but I'm not really an engineer...just play one on TV...I mean TOD. But I can understand why the industry would resist it. A Deep Water rig might be costing $800,000 per day or more when you add everythng up. I can easily imagine the entire Brazil test taking 3 or 4 days MINIMUM.

Rockman

When I was brasil there was only Petrobras, so not sure if it was government or company policy, but they were basically the same thing. It was actually stated in the contract, that I do know. They are usually long term contracts, around 5 years, and it was a one off test. After spudding the first well and on the first run in the hole after running the BOP, we had to hang off the string, shear and test the BOP. Also they made us cut a brand new joint of pipe, could not use an old.

Then the fun begins, then it was mill and fish the cut joint. If sucessful first time your still on contract. If not, your on down time until you get it.

Petrobras just loved down time.

I don't see why the MMS couldn't implement the "Brazil Rule" for deepwater GOM projects tomorrow morning.

By chance I came across this SHEAR RAM CAPABILITIES STUDY For U.S. Minerals Management Service (PDF)

Pretty technical, maybe of interest...

ETA other MMS reports are here http://www.mms.gov/tarprojects/ I think study #455 is the one referred to by the WSJ article.

--dated Sept 2004.

Invariably it is found that someone has flagged the issue well before a disaster has occurred. 50% of operators would not even allow their BOP to be tested, only 3/6 would have worked in real use. So basically it's down to a coin toss to prevent a major spill! I think the industry and MMS have really fallen down on the job here.

I just got off the phone with a MSM reporter. I urged him to look into the "Brazil Rule" angle.

When it comes out that other countries have much tougher standards regarding BOP's--combined with the WSJ article that the government has had a report for six years highlighting the weaknesses of some shear rams (they highlighted Cameron)--I somehow think that Gulf Coast to East Coast residents are not going to be happy campers.

Let's see now, six years. So that means the report got to our government in 2004, when our President and Veep had one or two ties to the industry. The Bush II administration would have been in no hurry to have drilling on the OCS slowed up because of tougher BOP standards.

Thanks Bob

Looks interesting I will give a good read when I get time.

Here are pretty pictures from Cameron of what equipment they offer for sub sea

www.c-a-m.com/oe01/presents/camdrill.ppt

Perhaps provide a small warning for a 10Mb PowerPoint download ...

The report I read stated that a service boat was en route and close when the well blew, but nothing about one being tied up.

The testimony of a service boat tied up and offloading would be crucial, yet I have seen no mention of said boat.

Alan

Alan, think he had to be near wouldn't he ,because from all accounts they had 'finished displacing the riser with seawater'? Would that much mud be pumped onto Horizon when they'd maybe want to get it off anyway?

There might have been several boats there at the time. When a rig is preparing to leave location there’s usually a lot if very expensive rental equipment on board they want to get off the clock as fast as possible. And they also offload all the mud normally. And 5,000’ of riser would hold a lot of mud so the story is feasible. But that’s why I made a point of noting the report was unconfirmed. Someone might have had such a theory and then after several repeating it turned into fact.

Interesting ,yeah Ghung is right the eyewitness said the ship emergency disconnected.

It must have been a major "Aw Sh@t!" moment for the guys on that boat.

I can attest to that. I was sitting on the back of a workboat about 16 years ago when the bottom blew out of an empty oil tank above me. Now one was hurt but the concussion knocked on my butt. I can't honestly remember what I thought at that moment. Just sat there trying to catch the breath that was knocked out of me. But another example of not being able to outlaw stupidity. They were cleaning the tank and broke for midnight meal. Turned off the ventilating fans and work lights. Don’t ask me why they turned the fans off. I didn’t ask them because I knew whatever the answer was I would have beaten the crap out of them. They came back from the meal break and turned the lights back on first. Even though the tank was empty enough volatiles came off the metal to cause the explosion.

As a comedian once said: “You can’t fix stupid”.

I worked as a tank cleaner at Coryton oil refinery for 9 months. In that time we had 9 accidents where men were hospitalized and some never came back to work afterwards. At one point another lad and I were temporarily blinded for 4 hours by an unknown chemical. I saw one man get crushed by a dumper and another break his leg falling over the heating coils. Looking back on it now I cant believe how little health and safety training we were given.

Some ancient Greek or one of his contemporaries in that part of the world said it first.

"Against stupidity the gods themselves contend in vain."

In the radio interview I linked to above, "James" claims that the service boat was connected and offloading mud. He says they did an emergency breakaway and pulled up about a mile away to rescue survivors.

"From the horses mouth":

http://www.drillingahead.com/video/video/show?id=3116006%3AVideo%3A99439

Is the ultimate goal to cut the riser at the BOP and drop a containment dome over that, or will they attempt to drop one at each identified leak location? How will this be possible considering distance to seafloor?

A matter of record. Dick Cheney is responsible for Gulf oil spill ... He refused to require $500,000 remote shut-off buttons ... http://shar.es/mGoWL

Dasterdly Dick isn't responsible for anything. Just ask him.

Others may disagree: http://indictdickcheney.blogspot.com/

Came across this elsewhere, a tuna fisherman describes the events from his bird'eye view directly at the rig where the tuna were biting moments before the Deepwater lit up. Complete with pictures.

Kheris, great find, thanks for digging this up and posting the link.

It's an eyewitness account from two guys out tuna fishing right below the Deepwater Horizon on the night of April 20th. One of the guys had worked offshore, and from the story, that experience probably saved his life, as he knew what the "kick" they were watching meant, and yelled for his buddy to get their boat away from their fishing spot by the platform ASAP, which they did.

I've excerpted the following verbatim, with spelling/grammar errors as is, from this account that Kheris linked to above.

ROCKMAN; as I read through the story that these two tell, it sure sounds like the unconfirmed report you heard and which you posted around 12:30 pm today, which is that someone on the platform missed seeing the well kicking back at them until the ship reported the disconnect between the tanks full of mud vs. the amount of mud that should have been pumped, is a very plausible explanation. And, when someone up top did recognize the kick, it was too late. Methane was already venting (the eyewitness account of the decibel level is scary), and when power was cut the backup system started up but sparked, and that caused the initial explosion.

Their observations are VERY interesting, and if these two eyewitnesses are right, it was the start-up of the backup electrical power system that caused the initial explosion:

Sounds right Petro. And very sad. Lets see if I cannot throw up my late night dinner now. Thanks loads. LOL.

First post, been checking in here off and on for a couple of years. Cheers to ROCKMAN and other pros for taking the time and effort to contribute.

I read the fisherman's story last night and my first reaction was maybe their boat sparked it? That's a kick in the gut, for sure. I cannot imagine that emergency power would be more likely than main power system to spark; emergency systems should be designed with the idea they would crank up in the midst of a cloud of gas & oil. Not that we're ever likely to know for sure.

The other thing that struck me was the mention of water pouring off the rig (as opposed to drilling mud), so a data point that at the time of blow-out the marine riser had largely been flushed.

I'd like to hear more thoughts on the fisherman's tale.

Given the off-load story, is this the rough sequence of events?

Cementing completed

Mud displacement with seawater began

Something went wrong at the plug or casing, and gas bypassed the plug - nobody noticed

Gas and water surged up the column, expelling mud - nobody noticed

Mudship almost full WAY early -- somebody notices.

Too late, somebody hits the BOP, which is likely at high-flow and high differential pressure

Gas blows through the fittings, showering injected water everywhere

Rig explodes

Oil follows the gas up in some quantity -- who knows the mix of oil and gas now?

Rig collapses, kinking drill string

Oil leaks from rig, string, and riser

So the key questions:

What broke at the bottom of the well?

Why doesn't BOP work at depth?

Why didn't anybody monitor flow rate of the mud, or in the bore?

If the report from BP is true, they had tried to activate the BOP from the rig, and had confirmation to the rig, before the explosion. So for your third question, they might have detected the kick early, but the rams just didn't close off the well sufficiently.

From the eye witness report there was not much time between gas production and ignition, but it's impossible to tell yet when or if the BOP was activated.

Since I live only about a four-to-five hours drive away from the Florida Panhandle, this oil spill, which can better be described as a volcanic eruption of oil, has me weeping more than most of you here. I weep as I think about the untold amounts of death and destruction sweeping across the Gulf. I weep as I think about all of its wildlife being soaked and poisoned to death by oil. And no amount of money in the world can ever replace the incredible beauty of its beaches and the incredible taste of its seafood. :'-(

And even though Dick Cheney managed to beat the rap for creating a needless war in Iraq, I was hoping that I'd have the pleasure of seeing him and other warfare-driven, welfare Queens at Halliburton all behind bars, wearing orange jumpsuits, eating baloney sandwiches and drinking kool-aid for improperly cementing this ultra-deepwater oil rig to the sea floor. But upon further examination, I've come to see that the culprits in this catastrophe go far deeper and much broader than Dick Cheney and Halliburton: the Bush Administration's unwillingness to require all deepwater oil rigs to have emergency shut-off valves, called blowout preventers, and British Petroleum's as well as Transocean's unwillingness to play it safe by having these valves installed on their oil rigs in the Gulf.

http://online.wsj.com/article/SB1000142405274870442350457521203141793679...

I was wrong in saying that Deepwater Horizon lacked a blowout preventer that can be triggered from the rig. I should have said that it lacked a remote control device, capable of shutting down the rig from a distance. The article from the WSJ goes on to mention that both Norway and Brazil require that all offshore rigs be equipped with remote control devices to prevent blowouts.

Unfortunately, if the shear rams are not capable of severing the drill pipe and sealing the well off, it doesn't matter where the switch is (see above).

Cynthia, amid all the technical jargon, you have reminded us there will be much to grieve. It is indeed a Mad World

I just heard a guy on NPR claim that the BOP didn't work because the drill string was still in the pipe. From all else I've read (I know nothing more) it doesn't make sense. I'd have thought they were long past the process of having the drill string in the pipe.

hillco - The terminology can be confusing. Drill string = drill pipe. Casing is run into the hole and cemented. The drill pipe extends up through the BOP at times. The casing is below the BOP.

Rockman,

I am asking this question due to not having the time to read every comment on this thread. I apologize if it has alrady been mentioned or asked.

But, is there not a contradiction or at least some confusion in the stories regarding the riser from the well?

The comment from the story above explaining the possible and actual actions to stop the flow of oil, says and I quote; "However they have cut off the riser to give a better target, and they will do this again before lowering a new BOP arrangement that will “stab” onto the initial structure..."

I am just throwing this out there with no knowledge of the details, but if you cut off the riser at the BOP you are now allowing uninhibited flow from the well. Prior to that point it the flow was partially restricted by multiple kinks in the riser.

While this make sense as the most logical way to implement the plan of stabbing a second BOP device over the old BOP, would this not dramatically increase the flow of oil from the well in the short term? Like unkinking the garden hose?

I have read reports that the flow seems to have exponentially increased over the last 24-48 hours. If the riser was cut off to make the procedure outlined above possible, it would explain the uptick in the oil slick.

Then you wonder why they are trying the containment dome idea if they can just first try to stab a new BOP unit over the existing one?

It almost seems like a contradiction. Or are they trying both?

Just thinking.

That's a fair question SW. But I doubt removing the riser will make things worse. But even if it did it still has to be done. Sounds simplistic but imagine trying to screw your water hose into the faucet with a bunch of junk pile in front of it. The fittings on the new BOP are very precise. Even a piece of metal the size of your thumb in the way could cause the entire operation to fail. And even make the situation worse.

Again, not being silly: rent the movie "Hell Fighters". It gives a rather complete and technically correct idea of how you kill a wild well.

So you don't believe the riser was inhibiting or restricting flow? I find that surprising.

As I mentioned, I understand why it has to be done.

I am wondering why they wouldnt delay cutting the riser until either the containment dome or the new BOP was ready to be put in place. I still wonder which method they are going to use. Is it possible to place the containment dome on top of the old BOP along with a new BOP? Are the two methods mutually exclusive?

The methods to the uneducated yet intellectually curious seem contradictory.

While I probably watched the movie you mentioned with my Dad (big John Wayne fan) I don't remmber the details. I have however closely followed the documented exploits of the Canuck company, Safety Boss...very facinating.

Not really SW. The riser isn't much more than a long metal cylinder with no control valves now. It might be crimped but a crimp isn't going to hold back much pressure IMHO let alone what they might be dealing with. Also, maybe I've missed it, but so far I've only seen oil flowing out of drill pipe.

Yep...over the years I've been drawn towards safety issues. That's one reason I enjoyed my short stint as a well site pore pressure analyst. If I were a good bit younger I might try a switch to saftey.

Rockman, I'm trying to guesstimate the pressures involved. At a depth of 4989 feet, water pressure is 2240 psi. Assuming 18,000 feet of sandstone beneath that at a density of 1450 kg/m^3 I get an additional 11,400 psi of pressure in the reservoir. If the fluid pressure exerted at the wellhead is mostly gas (low density) then the wellhead would be looking at a differential pressure of about that magnitude at zero flow. Does that sound about right?

If the drill hole is filled with oil instead of gas, at a density of 800 kg/m^3, then the weight of the oil column reduces the differential pressure at the wellhead by about 6300 psi to around 5100 psi.

Steel tensile strengths are in the 40,000-50,000 psi range, so a small pipe with thick walls can contain the bore pressure easily. But as I understand it the riser is a large diameter pipe, which will rupture at about 500 psi. So any kink in the riser can't be responsible for slowing the flow much, otherwise the internal pressure in the kinked riser would increase to its bursting pressure.

So I've gotta think that the main pressure drop of nearly 5000 psi is across the poorly-activated, partly-closed BOP shear ram.