BP's Deepwater Oil Spill - After the Storm - and Open Thread

Posted by Heading Out on July 26, 2010 - 10:25am

This thread is being closed. Please comment on http://www.theoildrum.com/node/6783.

The “Bonnie” storm has passed, and the different vessels are not only returned to the site, but are already making progress in returning to operations. As Admiral Allen noted on Sunday

DDIII is now running the riser pipe down. They have 67 joints to complete, they've done 39 of those as of about 10:30 Central Daylight time this morning, need about five more hours to do that. They are planning to latch on to the well around midnight tonight. Development Driller II which was – had drill – was involved in drilling the backup well is returning to site and will start running their riser today.

Q4000 is inspecting the yellow pad, that is the control device that's placed subsea to operate the hydraulics. They replaced the valve on that and they plan to install it later on today and then they will begin preparations for the static kill operations.

He also noted that the pressure in the well has now risen to just over 6,900 psi, while the temperature at the BOP remains at 40 deg – suggesting no flow and that well integrity is apparent. The storm has, however, dispersed and moved the oil, and they are resurveying to find where the threats now lie.

He then gave the current anticipated time line for the kill of the well.

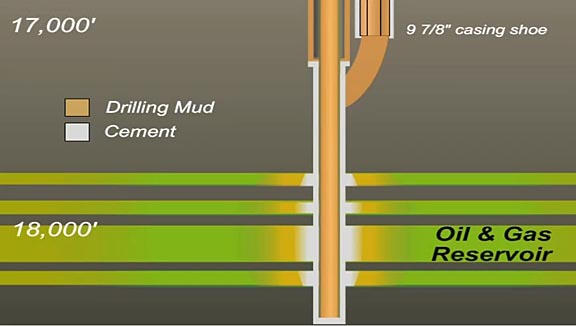

The time line is roughly over the next week. We'll return the Development Driller III, run the riser pipe, latch in, pull that undersea containment device, which they call a packer. They're going to need to circulate conditioning fluids through that pipe line to make sure it's ready what they call conditioning a hole and then some time in the next week they'll be in a position to be able to run that (nine and seven-eighths inch) liner which is the critical path right now to moving – to move ahead.

Once that liner is laid, they're going to put cement in and around it. And at that point the two vessels that were supporting the liner operation, one call the Blue Dolphin, the other is called the Center Line will redeploy and hook up with the Q4000.

This is sometime – this will be sometime during the week of 1 August. And they will set up for that to be able to inject the static kill and during that week of August subject to the (inaudible) I'm sorry the containment pipe being installed and cemented in then we will go to the static kill with the Q4000.

Kent Wells has also now released the animation showing how the different kill methods will take place, and interestingly also showed the section at the bottom of the well that shows the different layers of oil bearing rock in the reservoir.

The animation follows along the process in much the way that I described in an earlier post on the bottom kill, which is now scheduled in two parts. As the Admiral noted, the first part is to case the relief well. Once that is in place, and the cement run, then the top kill will start.

Because the well is shut-in, the plan is that the flow to the surface will be reversed. the flow lines are now passing oil and gas to the surface, the circuits will be reversed to return them to their original condition, and then mud will be fed into the well. Because this can be done a little at a time, it will be, and the pressures will be monitored to ensure that, as the well fills with mud, that there are no integrity problems.

Once the well is full of mud, they may try pumping cement into the well from the top (this is shown in the animation), though, because of concerns over flow control, I would suspect that they will not put the cement in until they connect through the relief well, and they will then do a two stage (annulus and then inside the casing) final kill.

And I should note that, contrary to my concern, the leaks that are being shown again now by the HOV ROV1 are no worse than they were before the storm, so perhaps that is not going to be much of a problem going forward.

Prof. Goose's comment:

Welcome--modified 21 JUL 2010

Thanks for your donations; they have been helpful--be assured that every penny of that will go toward Institute for the Study of Energy and Our Future/The Oil Drum costs, especially towards the servers, etc.

1. The Oil Drum is a special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity is more than welcome.) We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes. Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address. It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up. Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries. That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much. You can find the donate button in the top left hand corner of the main page.

4. If you would like to catch up with what's been going on in the last few days, our IRC channel has been maintaining a FAQ, which is an open source log full of information, links, and such. Check it out: http://docs.google.com/View?id=dff7zmqz_7c6rdwsc9 . Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum (google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum) or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

5. Don't be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. That will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable.

From the previous thread on the new containment system.

A billion dollars and 18 months!! Well, at least that is better than the 24 months I've heard in an earlier discussion. I think if they really wanted to, they could put something together in a few days that would at least keep the oil out of the water. For a simple design, see the thread "Floating flare" at http://groups.google.com/group/stop_blowout. Here an attempt to post an image:

http://commons.wikimedia.org/wiki/File:Floating_flare.png

We could sure use some help from anyone with engineering expertise in this area.

One thing that will be really great about when the well is killed is that then we will be spared these cock and bull ideas for how to kill a well "in a few days" or "cheap".

I don't know what the "Floating flare" is supposed to be, it seems self evident to you how it works but I am sure that it will not. Have you ever been in the open sea? If you had, you would know how utterly ludicrous that thing is.

What really makes me sad is this thing that every idea regardless of how absent of science or engineering thinking, is worthy of further thought. Just because someone makes a picture or writes a statement, doesn't mean it is so.

The other part of this is that it really is there is not any kind of relationship between the boiling fevered and obvious observation that "Something must be done immediately" and the time it takes. Billy Nungasser's near vein busting spew about ideas that actually will do more harm than good is an example. There were good reasons to delay his marine accidents waiting to happen, to block barriers that would have held the oil in if there were a hurricane or other hair brained ideas. SO ... as we decide what to do next for our energy supply, consider this: It takes a long time to clean up, there are consequences and, with deeper wells, the scale of accidents may increase.

Why not this? Consider that actually it really does take this long and cost this much? People with "engineering expertise" (and science expertise) have been working on this and, actually, this is a pretty good time line ... better than was expected. My take away message is that these kinds of groundless speculations have not been helpful, they only spread confusion that would best left in the fetid minds that dreamed them up.

Well Geoffrey, I seldom respond to ad-hominem arguments, but yours is so outrageous, that what the heck, let's have some fun.

First, thank you for being honest about not having any idea what we are talking about. That would have taken all of one click, but then you might run the risk of having to argue against something real, instead of whatever it is you are imagining. If you knew anything about engineering, you wouldn't make statements that it is impossible to build a flare like the one we are working on. While I agree that many of the proposals we have seen actually do more harm than good, that doesn't lead me to conclude that nothing can be done.

What surprises me is the vehemence of your attack. Please be assured, whatever your job is, I mean you no harm. My criticism is directed at institutions and agencies, not individuals. I see that engineers, in particular, have been blamed unfairly for the current situation.

Now, if I could devote just one paragraph to the original proposal, for those who are not interested in reading a flame war. The problem I see with the billion-dollar system is that it will probably never be done, and it will be hard to keep in a perpetual state of readiness for what will be a one-in-a-million chance of failure. Much better to spend a few million on a system that can be kept in a warehouse forever at $1000 a month, and deployed rapidly if it is ever needed.

LOL, since I actually submitted a design to flare the well underwater in the first weeks of this disaster (along with fdoleza independently), I'm not really in a position to criticize another flare design, much. I think one issue that your crew on the Google discussion mentioned was the heat. I recommend looking at these pics to get an idea of how hot this might get. Maybe an addition might be a number of ships spraying water constantly at the flare. Of course since oil will have spilled there will be a big oil slick right there, that might catch fire and blow up the ships if you're not careful, so I'd suggest being VERY careful.

My idea was to flare underwater so no worries about keeping it wet and cooling it down, the ocean does that for free. Keeping it lit, that's another problem. I never took it past the noodling stage myself, would have to run simulations and spend some time with my ChemE's to work out the best oxidizers to keep it going after the thermite gets it started. Fe3O4 would work but I bet there's something else with more O's that's heavy enough to work too.

Your other points about cost are also good. Why spend a billion or so, when 10 million might do just fine? Of course thinking like that might have gotten BP in the quandary they're in now... :)

Nice pictures. That flame really is impressive. One of the key features of our latest design is to get the flares away from the ships entirely. The only thing that needs to be above water is the flare itself. All the pipes and valves are suspended well beneath the waves.

Some spill into the water may occur in high winds, but that is a very small fraction of the total oil flow. The wind shield has some internal flaps that close when the wind picks up. With some cut-and-try experimentation, we should be able to keep a steady air flow inside the shield, even in a hurricane.

We had some discussions on another forum about burning some of the oil at the sea floor. The purpose there was not to dispose of it all, but just generate enough heat to avoid the hydrates, and boost the gas lift in the riser.

Many thanks for the suggestions, and the can-do attitude.

Awesome ideas. That inspired me. What about flaring into a series of giant hot air balloons? The lift generated could elevate a tube up into the upper atmosphere where a venturi could be employed to shoot the exhaust out into space.

If dilution of oil into the ocean isn't good enough, how about disposing of the greenhouse gases into space?

Coriolis, I can't tell if this is a serious question or sarcasm, but I'll give you a serious answer. The question of air pollution was discussed in an earlier thread. The answer is - in an emergency situation like these last few months, our choices are limited. I would let the governors of the gulf states decide if they want the oil on their beaches or in the air 50 miles away. What we can do as engineers, is try to make the burn as clean as possible. The CO2 is unavoidable, but we can reduce the smoke, with all its health concerns. Lifting the CO2 to "space" won't help. The greenhouse effect is the same whether it is released at the ground or in the stratosphere.

Looks like we are approaching our comment limit again. Anyone interested in a low-noise discussion of alternative technologies related to offshore oil spill prevention and response, is welcome to join us at http://groups.google.com/group/stop_blowout.

Geezee take a deep breath and TELL US HOW YOU REALLY FEEL!

Any number of interesting insights into BP under Tony Hayward in WaPo's new story. A sample:

When Svanberg used "small" for "ordinary,"

And the feeling is mutual, Tone. Toodles.

This was also a finding of the CSB report (Baker Panel too IIRC) regarding the Texas City incident in 2005.

http://www.csb.gov/assets/document/CSBFinalReportBP.pdf

See Section 10.2.1 beginning on p. 184.

And to be fair, Texas City & the Baker report brought about a massive undertaking to overhaul internal safety processes for the entire company. bp was in the process of implementing the new program when the blow-out occurred. No excuses for what happened at the Macondo well site, however the new program contains both personal & process components and it appeared to me to have the sincere support of management. I personally incorporated the program into a fairly large seismic acquisition project so have some firsthand experience with it. While it added new required processes to an existing approach that I thought was already rigorous and safe, thereby also adding some frustration and significant cost to the project, we effectively incorporated it into our work and ended up with what I thought was an even safer great project.

bp is a huge company so my take on this topic is that the implementation of the new program was incomplete. It was being "rolled out" in phases in different parts of the company when the blow-out occurred. As it takes time for everyone to "digest", learn about, gain experience with and integrate an approach that was/is a departure from previous approaches the new program was being rolled out over a couple of years.

The portrayal of bp in the referenced article(s) on this issue presents a static and somewhat out of date view.

Agreed. There's been a lot more emphasis on process safety KPI's (like near misses) since these reports came out.

coop,

Military friend on his first tour overseas to GB: It was the group consensus he be introduced properly by a night out to the pubs. Upon arrival at the first pub an english lad exiting the pub sloshes partial contents of his brew on the new arrivals frontside whereas the patron announced; "Excuse me I'm pissed." This brought hearty laughter from the group when the new arrival stated; "Well I'm not to happy about it myself."

"The portrayal of bp in the referenced article(s) on this issue presents a static and somewhat out of date view."

In my travels I have come to understand dialect can be a barrier in mission accomplishment. I considered a guess on the possibility that you mean BP still makes things go boom. I reflected on John Glides comments regarding the repairs on the DWH or the party atmosphere prior to the DWH blowout, explosion, death and injury to crew members. The KPIs are off the chart.

In what manner is the Texas City report incongruent with the current practices of BP?

BP appears to suffer from a cultural problem which employees raised in that system are not able to recognize. This means the safety culture they try to implement is overprinted with the older company culture, which is hard to change.

This problem isn't really safety related, or technical, it's associated with risk assessment and how they assign the cost of failure to their decisions. This isn't about race, religion, or sex.

If I were BP's management, I would investigate these major incidents they have had using high powered psychologists. I got the feeling the engineers working for BP may feel the pressure to cut corners to reduce costs. After all, the Macondo incident seems to have been caused by a chain of decisions, any of which was somewhat risky but all of which, when chained together, turned out to be lethal.

Those applying the pressure are doing so without understanding the consequences, but they have the power to push the buttons, so they push. And they push out of ignorance, which tells me they're likely to be commercial types, rather than engineers or operations personnel. Thus, the conclusion is the commercial side of the community hods too much power, and the engineers and operations types are short-changed.

There's no safety or operational system in this universe able to stop large safety hazards if the people who are running it are doing so under pressure to cut corners. It just doesn't work that way. Which means they have to be able to resist the pressure. And to do so, they need to feel empowered, truly empowered. A team of outside shrinks may give BP's upper management an insight they lack, and help them understand they can create all the systems in the world, but the human beings operating the system have to have their heads screwed on tight.

I suppose an outsider like Bob Dudley may have an insight on how to get this problem solved, but it's going to require time to change things.

There's no safety or operational system in this universe able to stop large safety hazards if the people who are running it are doing so under pressure to cut corners. It just doesn't work that way. Which means they have to be able to resist the pressure. And to do so, they need to feel empowered, truly empowered.

Totally agree, although I'm not sure your proposed solution, ie shrinks, would be powerful enough against corporate culture and financial imperatives. Shrinks are not known to be held in high regard in the rarefied atmospheres of board rooms, I don't think.

Hi fdoleza,

I agree totally, having worked in various industries (not oil) and seen the build up of pressure from the commercial side to make it pay. I alluded to this sort of thing in an earlier post.

Of course one other thing to do is to put in place a 'go straight to jail, do not pass GO' (no million pay-offs and pension pots) for the whole corporate chain of command. If a corporation wants to be treated like an individual person, then (collectively) the people in that organisation should. I know as well as anyone that this is a speculative comment, but unless some serious moves are made against the Realpolitik, things are unlikely to improve - witness the financial clusterf**k still ongoing.

L,

Sid.

Baker Report is here -

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/re...

This has been my criticism of safety regulations as well. OSHA pays close attention and has a myriad of regulations covering personal safety, yet is pretty much ineffective when it comes to process safety.

This encourages a group think where measurement of personal safety is easy - no OSHA violations or reportables and you must be doing great, right?

Unfortunately in reality it is a lot harder than that.

I agree, Safety glasses required while the process requiring the glasses isn't on the radar of the person wearing them.

Rosabeth Moss Kanter of Harvard Biz School:

Lotus ~ Thanks for this. Excellent article. I discovered Kanter a year ago through her writings on the kaleidoscopic nature of creativity. I always appreciate her thoughts.

I did have to smile. There might be a politician or two who could make use of those leadership tips.

I used to work for a company that closed its domestic manufacturing department, not because it was unprofitable, but because it would be more profitable operated out of a third-world country. To help employees cope with job loss (management positions were not affected), the company called a series of special meetings to show them a video -- a cartoon based on the best-selling business book of all-time, "Who Moved My Cheese."

The book is a parable that features mice and "little people" dealing with sudden cheese shortages in a maze. Here's an interesting article on it (random quote):

Here's a clip from the video (couldn't find the full vid).

The "sickening" thing is that business parables like 'Who Moved My Cheese' and the skits produced to communicate them are not intended to "make light of serious things." Just the opposite. A large number of people in high management positions think they're good, effective, and appropriate. These are very shallow people who mean well but are incapable of fully grasping the seriousness of anything.

...except ...time ...title ...salary & stock options...

BULLSHIT

mean? yes

well? for themselves

mean well? i don't thiiiiink so.

+100

Lotus -- Interesting side story about the handrail incident. About 4 years ago I came down from the chopper pad and used one hand on the handrail. Not that easy with the gear I was carrying. And the base of the stairs was a safety officer. He complimented me for keeping one hand on the rail. The hands that didn’t keep on hand on were ushered into a small conference room and were forced to watch the same boring safety films we had all seen many time…FOR THREE HOURS.

The operator was ExxonMobil. There’s an old sailing axiom: One hand for the ship…one hand for you. It wasn’t so much preaching safety as it was telling hands aloft in bad weather to not hang on with two hands…work the sails with one and keep yourself secure with the other.

I remember yelling at tank crewmen: "Three points of contact!" (One hand and two feet for stability is required whenever you are on a tank.) And not caring if the person was an officer or not because I knew that the CO would back me.

I also remember an incident where I screamed at by BN commander and CSM because they had walked between my tank and my ground guide while we were moving into a fighting position under blackout conditions. I had literally missed killing them by a few feet because we couldn't see them. (And nobody ever said a word about it to me afterwards.) If you ever want to know what terror means - try manauvering a tank in total darkness when you know there are people wandering around whom you cannot see.

The biggest about safety is that people tend to focus on individual safety because there are likely a million slip/fall incidents for every DWH disaster. 11 people died all at one on the DWH - but likely more than that have died in simple slip/falls/etc type accidents over the past 10 years.

Trivia note: Despite fighting two wars the leading cause of death for US servicemebers is 'off duty' accidents. (Traffic accidents, sports accidents, etc.)

05b -- Interesting. Offshore the highest body count comes from chopper crashes. Almost zero survivability. Sorta like playing tag with one of your tanks.

There are statistics, and there is reality. I'm hope you're not saying it's safer to be in Afghanistan dodging Taliban bombs than playing basketball at Ft Hood.

Statistically people are safer flying around the world than driving a mile from their house. Its a matter of perspective. Warzone risks may be better known and prepared for (flak jacket, journey prep, hyper alertness) vs. walking around where you feel completely safe because its not a warzone (shorts and t-shirt, leaving without telling people, getting drunk at a bar).

I won't say statistics prove that out, but it is possible.

Edit: Moved To New Window

I am posting this again because some of you guys might want to make use of this information.

This is a list of retiring senators. Since they are stepping out of the ratrace and the pressures of pursuing re-election, perhaps we could cajole some of them into publicly discussing politically unpopular topics, like peak oil.

RETIRING SENATORS - DEMOCRAT

Christopher Dodd of Connecticut

Ted Kaufman of Deleware

Roland Burris of Illinois

Evan Bayh of Indiana

Byron Dorgan of North Dakota

Carte Goodwin of West Virginia

RETIRING SENATORS - REPUBLICAN

George LeMieux of Florida

Sam Brownback of Kansas

Jim Bunning of Kentucky

Kit Bond of Missouri

Judd Gregg of New Hamshire

George Voinovich of Ohio

DEFEATED IN PRIMARY - DEMOCRAT

Arlen Specter of Pennsylvania

DEFEATED IN PRIMARY - REPUBLICAN

Bob Bennett of Utah

They can all be reached through the US Senate portal at www.senate.gov

In the House, their email system has an electronic gatekeeper that is works on zip codes - if you live in the wrong place you cannot get in. IN THE SENATE, however, there is no such nonsense. You can reach senators from wherever.

In the House, their email system has an electronic gatekeeper that is works on zip codes - if you live in the wrong place you cannot get in.

A way around that is to use an address from his area. Then add your own contact info internally. No guarantee he will get it, but it will get by the 'gate-keeper'. I have gotten (somewhat boiler-plated) responses back in the past.

A way around that is to use an address from his area.

I've done that occasionally. Use the zip code from one of the district offices, then fill in your own full address on another line.

lfeather, I don't know if their main topic should be "peak oil". I doubt there's such a thing as "peak oil" anyway. The topic politicians should discuss is "increasing energy prices as cheap oil supplies run out".

WaPo: Apparently cordgrass and wiregrass can take an oiling or two and send new green shoots up through it. But there's a limit . . .

Here's the link for that:

http://www.washingtonpost.com/wp-dyn/content/article/2010/07/25/AR201007...

I question this:

That would be, for example, 400 miles of shoreline oiled 1/2 mile deep, when we are told most of the marshline is only oiled a couple of feet deep, or occasionally 8-20 feet deep. I think the official said or meant 200 linear miles, which would likely be less than one square mile.

I apologise in advance for posting a reply to a thread several days old, but given that I have been absent for a few days I just wished to respond to a few points. The thread in question was started on July 22nd at 10:00am.

Firstly, in response to kalliergo

That is your prerogative. I am not trying to convince you, I am simply presenting the view of someone (me) with over a decade of experience in the industry as to what is being shown in these videos. It is up to you and any other interested observers to collate the evidence, listen to the opinions, expert and otherwise, weigh them up and form your own opinion. In time, you, I, or neither of us will be shown to be correct.

Secondly, in response to boon

Assuming that I am one of the 'experts' you are referring to, I am retaining my anonymity for several reasons. One is simply that I don't want my identity all over the internet. Once it's out there it can't be put back. I may just like it the way it is. Secondly, anonymity allows me to comment freely and openly. Surely that is preferable to having to keep my comments 'on message' with my employer, should our opinions happen to diverge (which so far they have not). If you require proof that I work with ROVs just ask.

Wide variety? Not really. I've seen three basic categories of 'plumes'.

1. Thrusters kick up a sh*t storm from the bottom of varying duration.

2. Wispy 'cigarette smoke'. More interesting. I am not sure exactly what those were, but they were small quantities of stuff, and certainly not coming out at any sort of significant pressure. Wafted about by thruster wash, but yes, I would be interested in knowing their composition.

3. Stuff falling off the vehicle whilst in the cage, specifically the one poor quality video.

Why has 'silt' activity increased? I'd say primarily because of the sonar surveys. Before they started, there was less activity at the bottom.

You would be correct if I was simply shouting 'silt!' without taking the time to have a proper look and make an informed decision, but that is not the case. You have only my word on that, which doesn't appear to be enough for you. There's not a lot I can do about that, even if I wanted to.

You appear to be questioning my credentials. What can I do to allay your fears? Do you need proof?

Out of interest, what is your background? The same question goes to kalliergo. I'll show you mine if you show me yours ;)

Lastly, in reply to avonaltendorf

It is easy enough to see exactly how far the ROV moves due to the swell- just watch the depth gauge during the clip. I quite clearly saw the correlation between the swells and the pulsing 'billows' (which were simply video artefacts). The larger mud billows happen at three irregular intervals as lumps of mud fall off. That's what I see, and I recognise it's not easy to see. YMMV.

The two explanations do 'jive'. Maybe I just didn't explain well enough. The ROV is in the cage with the lights on. The lights shine out into the darkness, nothing shines back, so the camera gain goes full. You can actually see the slight 'billows' which look like a small amount of ambient light, changing as the pitch of the ROV changes slightly in the swell. Mud particles are dislodged. These particles would look brown or grey on your desk, but as they pass through the lights, they appear white to the full-gain camera.

Why burn lights? Why not? ROV pilots rarely care whether they leave the lights on or not. Really, I'm not kidding.

Yes, it's hugely different. Besides, that video was 'enhanced' which made the artefacts quite noticeable.

Links please? Happy to review.

The coordinates of that ROV were presumably the same as the surface vessel at that time. I don't know why it was in that location, presumably it was standing by.

Why has no ROV been tasked to look SSW? No idea.

Sorry for the extra wear I just caused to your scroll button ;)

I enjoy your posts and thank you for your help.

Now let's see where flattery will get me. ;)

Just for curiosity's sake, I would like to know if these are oil seeps. I apologize for the video quality. I have no idea what happened. The actual feed was that greenish tone and fairly clear.

Times of interest:

:28 - :36

1:10 - 1:17

3:53 - 3:58

http://tinyurl.com/2c6uq6x

Ok gmf, that's a tough one but I'll give it a go.

First, we can ignore the orange tone. You say it was actually greenish, but that changed when you captured it, right?

I *think* what I'm seeing is mostly sea floor and some unidentified man-made structures viewed possibly from some distance and height through an out-of-focus camera. The camera appears to be focussed on the ROV tool tray, not the rest of the scene. You can see the ROV rotate from 1:30 to 2:05 and the shadowy stuff moves accordingly, as if it were solid things on the sea floor. The ROV doesn't appear to have its lights on, or al least the shadowy objects are far enough away not to be lit by them. They appear backlit by another light source. At the times you refer to, small particles of something (mud? organics? clathrates? extra-terrestrials?) fall downwards past the camera.

It all made much more sense when I drank half a bottle of tequila and stood on my head.

That was a quick half bottle of tequila.

When I watched the live feed, it appeared that the tool tray was in the foreground and the light was focused on the sea floor. The video was pretty clear, unlike this one. The black bubbles were not falling downward, they were moving up and could be seen emerging from the silt.

Thanks for watching, and I agree...unless you had seen the original this gets pretty confusing.

I was kidding about the tequila, but not about standing on my head :)

Sounds like you were looking at a seep. Pity it didn't capture properly.

Your video is upside down and in mirror image. You have to set your media player: Go to media player, TOOLS, Options, Performance, Advanced. In Advanced, uncheck all the "use overlays". Save that. That should fix the mirror-upside down.

thank you

rovman:

I've found your interpretations of the video feeds to be very enlightening, and reassuring.

I find these videos very hard to interpret because all that most of us have to compare them with is topside, clear air, vision, which is how we normally see things.

I would guess that in training to operate these it takes longer to learn to interpret the video feed correctly than to be able to maneuver the ROV or manipulate its attachments with reasonable facility.

I suspect that most of have had the experience of finding ourselves looking at a totally alien view of something and having difficulty deciphering the detail. I often have wished I had an expert over my shoulder to help me understand what I'm looking at. So thanks for providing that to us.

I can imagine that your interpretations have had the effect of dissolving a few "discoveries." Having had a few deflated by reality myself I can appreciate how that can be disappointing. We all want to make a positive contribution to efforts like these.

So keep up the good work, and thanks for your patience and good humor.

Dave

rovman, no problem with your anonymity or expertise. Someday the ROVs will be withdrawn from MC-252, or the feeds will cease, and public discussion will evaporate.

Best burning them. They blow more often when switched on or off than when left on. You don't want to have to keep hauling your ROVs up to change the bulb. When night diving you leave your light on ALWAYS. If you want to see phosphorescence (for example) you hold the light to your body, you do not switch it off. If people did some diving they would see many of the things that Rovman describes, silt storms, bubbles etc.It gives me confidence in his answers to compare them with what I have seen with my own 2 eyes.

NAOM

Rovman brings up an excellent point I'd like to comment on. There are people here who seem to constantly want "credentials". Some posters here, myself included, work for employers who might not like us commenting "out of school". For my part, I'm a geologist. I know very little about the petroleum industry because my specialty lies in mineralogy and petrology. In grad school, I studied plate tectonics under Dr. P.J. Coney, whose name will be familiar to geologists. I work for an agency of the U.S. Government and have for 21 years. So if I say something about geology, it's an "expert opinion". If I say something about oil, take it with a pound of salt. Thank you.

Thanks rovman, fasanating thread...

I'm totally hooked on the live feeds, best TV since Arrested Development... will surely jones when cut off...

Thinking about the technology, both oily and electronic, it's clear deep water exploration and development would not be possible without the ROV. Especially for dw oil and gas and these behemoth workhorses now on the scene. It seems, like dw drilling itself, we are pushing up against technological limits. It's obvious operators have a hard time with depth perception. I assume this is because they do not have a 3d display or adequate tactile feedback through the stick?

It will be interesting to watch this field evolve as it no doubt will, and develop more autonomous and untethered machines. Meanwhile we should hope that future guidelines and procedures will result in a more realistic picture around what these things can actually do, today.

Number one on my list for dealing with this kind of crisis in future is the use of special ROV subs that can operate one or more ROVs, regardless of the weather above. They could also be used for much needed inspection of all those capped and abandoned wells now in the GoM, for example.

In case you missed it, here's a pic of the USS Jimmy Carter, a US nuclear submarine with ROV support capability...

USS Jimmy Carter (SSN-23)

Click image for the big picture...

Rovman, thanks for all your posts, even this monster ;)

Especially thanks for continuing to remind folks that silt, loads of silt, is the norm in this environment. When I see repeated comments like "Blaming it all on silt being diturbed by ROVs is just as fallable in my opinion as blaming it all on hydrocarbons" I get cranky, but you keep your cool pretty well. With light, fluffy, grimy silt covering everything on the bottom, we should expect to see silt moving all the time, and oil only rarely.

Notanoilman may be right that without experience underwater most people have a hard time understanding the sudden eruptions of dark stuff all over the video screen. Personally, I would rather have skipped a couple of my silt experiences --like freediving a cave in the Caymans (but it seemed like such a good idea at the time). I understand people's fear of catastrophe, and mistrust of BP and the Gov., but I wish they would think for a minute before reflexively dissing someone with relevant experience like you or Shelburn.

I'm as interested as anyone in finding seeps, natural or BP-made, but I'm relieved every time a video link turns out to be ROV blown silt. There is already too much oil in the Gulf, so why the heck are folks so upset to hear, "excuse me, that's just silt"?

A one shot self powered shear ram design. No explosives or hydraulic required! KISS

At the surface, with the ram piston retracted, close off the topside of the rams piston by installing a normally closed valve. Allow air at 1 atmosphere to fill the working side of the piston via a valve, then close that valve. The result is nothing on the head of the retracted piston, 14psi air on the other side.

To actuate the ram under water, simply open the valve on the head side of the cylinder; thus allowing seawater at pressure to compress the air by moving the ram. Size the piston for the required force.

To get full ram travel, add a small pressure container on the air side; size it for the pressure differential desired. This allows for a space to hold all the compressed air outside the cylinder when the ram is fully extended. The larger the container, the more consistant the ram force during its travel.

The ram can be hydraulicly retracted; connecting and applying a hydraulic force greater than the seawater pressure on the bottom of the piston will retract the ram. But again, this is a one time shot until the ram can be brought topside and "recharged" with air. Once retracted, SAFETY is of concern due to the highly stored energy in the air hydraulic mix.

"Patent Application Pending" Sequoia CPE Consultants :>)

My worry with this is that it is subject to leaking. Even a very slow leak could significantly compromise the vacuum side over time. And you have no safe way of fixing this. Lifting the BOP to the surface to empty a leaking vacuum cylinder may simply not be feasible. The cylinder needs to be leakproof across the entire seal of the ram piston, and maintain that integrity for up to six months.

So the competing design :-)

Use a large spring for each ram - I mentioned a Belleville spring as a suitable design. The spring can be compressed by a hydraulic piston that forms part of the assembly. Force from the spring can be transferred to the ram via another hydraulic piston, or even via a mechanical coupling. The advantage of a hydraulic coupling is that the actuation can be performed by a valve here. A mechanical coupling would need a mechanical holdoff and trigger, which may be more complex and prone to hanging up. Another possibility is to use the compressing piston to hold the spring down, and releasing the pressure on that piston causes the shears to close.

The advantage is that the system can be set ready to fire and left. It can't leak. Better, it isn't one shot. The compressing piston can be used to recompress the spring, allow the shears to open, and then the system can be reapplied.

I did not suggest a vacuum. I want 1 atmosphere so that pressure readings can be used for monitoring as I suggest in my follow-up post.

A perfect vacuum would apply a limited ram force while topside, not desirable. The limit would be dependent on the non-displaced volume at the top of the piston.

An inadvertant opening of the top valve while topside will not cause the piston to move; a vacuum would. A SAFETY concern.

Compared to a spring if compressed topside, the air concept does not become "armed" until submerged; again a SAFETY concern.

As for the One Shot concern. Once a shear ram has been actuated, it probably can not be trusted for a second attempt without inspection and maintenance.

Compared to a spring, think KISS!

:>)

I was really only considering that at depth one atmosphere was pretty much equivalent to a vacuum. You can just substitute 1 atm for vacuum in my comments and the rest remains. So no safety issues with a vacuum at the surface.

I would assume with my design you would arm the spring at depth once the BOP has been safely attached and integrity of the system established. The idea of a spring is really no different to any other accumulator, but it has the advantage that it can't leak and can be independent of other control systems. As far as simplicity goes, for the bit that matters, I.e. the function of cutting, it is as simple as it can get.

A container with one atmosphere of air pressure situated in an environment with over 150 atmospheres of water i.e. at the depth of the Macondo well is pretty much indistinguishable from a vacuum. The water (or oil) outside the ram will want to get past the ram seals into the atmospheric charge chamber really really badly -- see the infamous "crab" video for details. Remember that wells are planned for even deeper sites where the pressure differentials will be even greater.

Currently the BOP systems designed for deepwater work use hydraulic rams capable of being driven under normal conditions at 7-8000 psi (as seen on the videos of assorted hydraulic system gauges on the BOP stack), that's about 4 tonnes per square inch. If you presume the shear ram's maximum design requirement is 200 tonnes force, that implies a hydraulic ram with an actuating area of 50 square inches or about 8 inches in diameter resulting in a circumferential seal length of about 25 inches. An "atmospheric" system at Macondo depth could only exert 2200psi differential on the ram or 1 tonne per square inch. To be able to exert a force of 200 tonnes the ram area would have to be 200 square inches or about 16 inches in diameter resulting in a cylinder-ram seal length of 50 inches. The longer the seal the more chance of a leak which is bad.

The existing hydraulic ram systems can be driven from local accumulators with more stored energy than a single-shot system or the rams can be powered from surface vessels in extremis via direct hookups. They can be fired repeately in short order and if necessary they can be overdriven to beyond their design limits by connecting them to a more powerful pump, say one rated at 12,000 psi. A atmospheric system or a spring-driven system can only provide a one-shot capability which cannot be overdriven from the outside. The spring system someone else suggested could be reset remotely but only if there is a working high-pressure hydraulic hookup to the BOP and if that is the case why bother putting a complicated energy-draining mechanical linkage between the hydraulic supply and the ram? KISS.

Nojay

Correct, Overdrive is lacking without surface pumps or accumulators.

As for as seal length computations; piston seal is only of concern during actuation, while piston rod seal is always a concern. But piston rod sizing would be the same for hydraulic and seawater based systems. There would be only a minor pressure differential change during actuation.

The hydraulic based system compensates for seawater pressure via pump capacity as you noted. The air-reservoir does require cylinder area changes to compensate for seawater pressure; this is only in cylinder area, not piston rod area as that is a force withstanding issue. Cylinders appear to be only externally mounted components on a BOP; larger cylinders at shallower depths does not seem to me to problem with deep water wells. Thse two contra-indicative items, as you go deeper pumps need to be more powerful while air cylinders would get smaller, indicates to me that each may have an advantage over the other depending on depth.

But the apparent DWH failure to activate some of the rams seems to me that having a ram that only needs activation and not hydraulics is a good safety net.

Thinking about this BOP design - I think that there is a huge weakness in that it REQUIRES deep water conditions for it to be usable. You can't use this in shallow water, and to test it means it has to be in conditions at least simulating deep water.

It would be much better to have a BOP design that could be used in all offshore applications.

This is where the hydraulic designs are clearly superior.

A shear ram needs to have as consistent a force accross its travel as posible. If the force declines significantly, the design must be capable of producing excessive force initially so that, as it encounters pipes to be sheared, it still exerts enough force to do the job.

Belleville springs and other springs share a common trait. The force they exert is based on spring rates and deflection. A compressed spring exibits a reduction of force as it decompresses. Too bad this could not be reversed!

An air reservoir "hydraulic" cylinder can be designed to exert a much more constant force as the air is compressed by the admission of seawater; a suitably sized external container allows for control of the consistency of the force with displacement. The force of the seawater (at a constant pressure) is offset by the force of the changing air pressure. The air pressure change can be restricted to 1 atmosphere by having an external container with a volume equal to the "swept" volume of the piston.

And no moving parts except the ram piston!

:>)

That was one of the reasons I chose a Belleville spring. You can tweak the design so that over more than half its travel it has close to a constant force. All the other tweaks you suggest can also be used with the spring.

[edit] Actually you can design a Belleville spring so that the force at most compressed is less than the force exerted when partially compressed. It is this non Hooke's Law behaviour that makes it a rather interesting and useful device. So, for cutting a DP in the BOP it could be designed to have close to an ideal force to movement profile.

A follow-up;

Include an absolute presure monitoring apparatus in the air container.

NORMAL condition: 1 atmosphere topside AND submerged. Piston has not moved and there are no leaks. Unit is "Armed and Ready for Deployment".

LEAKING condition: somewhat greater than 1 atmosphere, the amount indicates the amount of leakage; until the amount is significant, operation of the ram is still possible BUT maintenance is indicated. A travel sensor on the piston top would help to determine if the increase is due to piston travel or piston rod leakage.

ACTUATED condition: Based the ratio of the sizes of the 2 air chambers, pressure of the ratio atmospheres indicates full extension of the ram. An intermediate pressure indicates the amount of travel. No need for an ROV observation if the sensors are brought to the drill ship. No wondering if the ram fully actuated; the response should be fast.

:>)

I must be missing something here. If the BOP shearing ram is at 5000’ sea depth the point where the ram leaves the cylinder(interior pressure of BOP =PSI of fluid in riser pipe) will have about 2200 PSI across the cross sectional area of the diameter of the ram or rod pushing the ram. In case of drilling fluid in the riser would be several thousand PSI higher across diameter of ram.

I have seen a well flowing on annulus side and when BOP rams were

Closed on drill pipe the drill pipe was actually blown up the hole by differential pressure on cross sectional area of pipe where rams were closed until a tool jt came up against the rams.

passaloutre

Both the hydraulic and the air chamber rams produce force as a reult of the difference between the force applied on the top of the piston versus the force applied on the bottom of the piston. Large cylinder bore, small piston rod. The hydraulic bottom exit allows for the hydraulic fluid a place to go on activation so that bottom pressure remains fairly constant; botom pressure will probably naturally be maintained across the rod exit so as to make the seals job easier. The air reservoir leaves a compressible bottom "fluid" (air)so as to leave the piston a place to go via compression, pressure change can be minimized; but the rod exit seal sees almost full seawater pressure.

Both must overcome the forces present where the actuating rod leaves the BOP. Yes, this is a function of drilling mud depth. The design of either method must include mud column pressures as well as pipe shear forces required. And of course water pressure.

The Deep Water hydraulic ram only differs from a surface ram in the ambient pressure portion of the computations. Deeper presents much more challenges.

The air reservoir only works for Deep Water rams. Here the reversal of pressure (low inside the piston bottom and high outside the cylinder)is put to use by just compressing air during activation. The air serves no purpose other than monitoring by being a compressible "fluid".

:>)

I appreciate the creative inventive genius in all but these folks have a few days experience on the issue.

http://www.drillingcontractor.org/dcpi/dc-mayjune07/DC_May07_BOP.pdf

"The air serves no purpose other than monitoring by being a compressible "fluid"."

This is scary.

my314tin

scary? What an air chamber? I guess you never saw an accumulator! Or never completely read your referenced document which references the use of accumulators at depth with the current crop of BOP's.

What is really scary is that we continue to rely of BOP designs that have a rather suspect history. Or that we continue with the tried and unproven and their designers (My apologies to the BOP designers, they are really trying their best!) My experience with continuing without an infusion in the form of alternative designs is that there is a tendency to try to "tweak" rather than taking a new look at the problem, starting with the problem definition itself. How often does a poor problem definition influence the subsequent design!

My you are prolific! over 6 index pages of posts in a little over 6 weeks.

:>(

Sequoia,

I guess I saw the comment on air being a compressible fluid and it kinda took me aback.

I am familiar with the function of an accumulator and I wonder how large your accumulator would be in able to store enough air to produce the force to shear a section of drill pipe or even a section of casing. If you keep the mechanism within the confines of a good usable design then how large would it be? How much pressure is required to do the job? I did read and understand the link I posted and the accumulators referenced were hydraulic. The current BOPs use mechanical or hydraulic mechanisms to open and close the rams. I don't think the folks at Cameron have been sitting on their hands for 100 years in regards to BOP design.

If you choose to give your BOP design dimensions and pressures needed to shear the DP then I might come on board. How do you close the ram? How do you open the ram? How do you cycle the rams to insure they are operating properly? How do you control the air pressure of your device? Air over hyd. systems are used for low pressure applications. High pressure gas is scary. It's scary because it's like a bomb in the pressure range you are discussing. I am asking the questions because a patent for your idea requires these to insure no one has already applied for the patent and if you go this far you will need testing and approval also. Maybe you are just interested in patenting your idea? In reading I noticed you placed lots of emphasis on closing the rams. They need to open also.

"My you are prolific! over 6 index pages of posts in a little over 6 weeks."

Yeah I know, I made a donation and wanted to get my monies worth.

In my diagram, if you submerged this assembly, is the upward force on the piston directly proportional to the size of the balloon and does this system adhere to the basic hydraulic laws between the two reservoirs? I do get the point that why not charge an accumulator and then sink it provide grater power. I just like my picture.

TFHG

Having no ballon and only the bottom of the pump exposed would be equivalent. So no, the size of the liquid filled ballon would not enter into the computation. The force on the piston would always be 100% depth related. Once the air space is very small, the balloon will not appreciately change size.

:>( sorry!

As to reservoir hydraulic laws, there are a lot of factors to consider (many unknown or estimated for each reservoir), so I leave that to the reservoir guru's.

SequoiaCPE - nice idea. But study how railroad air brakes work. Finally something I am fully qualified to discuss on TOD. That would work better. But I think I have an even better idea.

You're far better off having a "double acting cylinder" type of design with TWO pipes to the surface. Keep those dudes pressurized with air to a wee bit over the seawater pressure at the wellhead. Remotely operated valve at the bottom to open to seawater (kind of important to flush condensed water out of the pipes periodically, as you'll soon see).

To fire off at full effect, open one of the lower valves to the sea (to limit flow losses) and open the OTHER compressed air pipe at the surface. Rather quickly, one side of the piston is at atmospheric, and the other is at sea pressure.

You don't technically have to open the lower valve, it just limits flow losses.

Say pipe #2 leaks a little. No problemo, thats why its connected to an air compressor. Or vice versa.

Say pipe #2 leaks a heck of a lot. No problemo, that line is connected to a subsurface valve that will open to the sea, in other words pipe 2 will be the subsurface pressure side and pipe 1 will be the atmospheric side. You've got some time to replace hose #2, as long as hose #1 remains undamaged. Or vice versa.

So, you've got a slightly higher air pressure at the wellhead than sea pressure, and theoretically bottom vent occasionally to blow condensed water out. No corrosion problem, no connection problem. You do need to make sure the pipe won't implode when the thing goes off.

On the other hand, on the surface you've got compressed air at subsurface pressure. But thats "no big deal" because its on the surface, easy to maintain.

Exploration wells

I have some questions re fundamentals:

1. How does exploration drilling differ from regular drilling (in deep-water)?

2. Does it involve steel casing or is it simply a drill bit which makes a hole but stays above where they think the oil & gas are located?

3. If all wells including exploratory involve steel casing, do companies file a plan to show how their casing will be constructed?

4. What would that plan be called?

5. Is a BOP necessary for exploratory drilling?

Thanks for considering this.

RickM

In general (site-specific conditions may change details of the ops):

1 - Drilling ops are essentially the same regardless if the hole is exploratory or development. With exploratory holes some ops may be added or removed depending on downhole/formation conditions. With development drilling, most of the guess work regarding drilling conditions is removed and holes tend to be more cookie-cutter.

2 - In most cases the hole conditions (expected and existing) determine the casing schedule (types, lengths, etc. of casing and related cement) used. The hole may be cased in stages or portions of the hole may remain "open", it mostly depends on formation type and subsurface pressure/fluid conditions. When a well is completed for production, the well will have production casing (AKA as "string") run to the producing depth, cemented, and then perforated to allow fluid/gas flow into the production string. How extensive the length of cementing of the production string is a function of the hole conditions.

3 - Although their might be some types of "exotic materials" under research development for casing, the casing used is steel and the anticipated casing schedule are generally part of a well's drilling permit, which are reviewed by trained and experienced engineers as part of the approval of the drilling permit. Planned ops vs actual ops may vary once hole conditions are known and sometimes (read almost always) the casing schedule is modified (usually with regulatory approval).

4 - Casing schedule.

5 - In most cases yes, as it is also necessary on any type of drilling where subsurface pressures (or hole conditions - gas/fluid flow) could have potential for ops or safety hazards.

Thanks very much, Bob, for your prompt response & clear answers.

Very helpful...

- Rick

Rick - An exploration well = a well drilling for a potential hydrocarbon bearing reservoir which has yet to be drilled. Development well = a well drilling for a reservoir that has already been drilled by an exploratory well.

The tricky part about drilling an deep exploratory well (onshore, offshore deep water and shallow) is the rock pressure. This determines what mud weights are required. Being the first well drilled in a area makes this pre-drill estimate very difficult. There are some seismic techniques that can model pressure but the can often be very wrong. While drilling a real time estimate can be made from the log while drilling data set. I was doing this prior to my current gig. If an exploratory well drills into a much higher pressure csg has to be set. Can’t put too high a mud weight against lower pressure rocks,

All pre-drill programs have a detailed csg design. But this is based upon assumptions which can quickly change while drilling. Simply called the csg program. All wells must be drilled with a BOP. As my description explains they are all the more vital in exploratory wells.

Brings to mind a term I haven't heard in years, wildcat. And those that drilled such wells were called wildcatters.

Maybe one reason they were called wildcats was they might bite you. :)

I tried to capture the leaking bubbles, and ended up with over one hundred captures. However, so as not to clog up bandwidth, I noticed something odd. Can anyone explain the rectangle within the circle a ROV focused on (may still be there now, perhaps)? There are bubbles coming from it (there are a few in this image link, below). But what is the circle, and what is the rectangle? Are they looking at the original drill site (where the drill head broke or had a problem, and they abandoned)? I don't know how to read coordinates to know where they are. Thanks for any answers. It is quite clear there is a rectangle in a circle. PS: I am not a scientist, nor technically-minded, hence the "oh my". :)

http://i978.photobucket.com/albums/ae268/onefifty/julytwentysixshapeswit...

The rectangle is probably the 'footprint' of a ROV that sat down on the bottom.

The circle is probably left when it lifted off and rotated to go to the next spot.

Pretty sure about the first one . . . not so sure about the second.

I tried to edit my post, but it was denied.

Anyway, I wanted to insert this question (thank you for your patience and allowing me to ask). I managed to get a few captures, earlier this morning, and although they did not zoom into the well, it appeared (in the corner) as if it had sank to the seabed, or that snow methane hydrate had formed a mound around it. I did the best I could to zoom in slowly in that corner (I'm just curious to know what's going on). I have this zoom in a gif. Is this methane hydrated and/or has the well sunk into the seabed--or WORSE, has the seabed raised itself around the well? Thank you.

http://i978.photobucket.com/albums/ae268/onefifty/julytwentysixSnowJob.gif

@ onefifty:

Good eyes. I did not notice the triangle and circle until you pointed it out. Not sure what could have caused it. Unfortunately, that ROV feed you captured does not give coordinates so it's impossible to say where it was located.

Regarding the depression (or should I say "ditch") around the well bore. I noticed that too and wondered what might have caused it. Several days ago, when we first saw images of Skandi ROV2 collecting gas samples from the same area, the mudline was flat all the way around the well bore. Now, there is a significant depression all the way around the bore. I'm sure there are some here that will tell you it's all due to prop wash from the ROV's but I wouldn't buy that. My guess is it's mostly due to erosion from the gas bubbles, perhaps assisted by the prop wash. I think it's safe to say the well is not sinking.

(Tongue in cheek: When the ROV arrived at the well bore last night to begin collecting its samples, the eel we've all been seeing these past several days zoomed right past the camera. Perhaps the eel has been doing a little construction of his own? Ha!)

As Skandi 2 is sitting collecting bubbles underneath the BOP I think it would notice if it was now below the sea-bed.

Thank you Trip and Undertow. Later on, I'll crop all those captures, in sequence. I have some of the eel, as well! :)

Also, Undertow, did you see this? What's all that white stuff building up? Is that the well being swallowed...is it even the well (or which well?)...

http://i978.photobucket.com/albums/ae268/onefifty/julytentysixDidTheSeab...

It might be an octagon rather than a circle.

I suspect that the rov was rotating through 45 degrees then sitting down again. Maybe for sonar scans or something, though those were 90 degree rotations last time I saw them.

Thank you James and Rovman. That could be. I took over one hundred captures prior to those I showed. I'll have to go back and see what happened (an eel did slither by too). I was wondering if they were trying to calculate if the seabed was rising. It looks as if the well is under a snow mound (I know, I probably am wrong) but it does look that way. Here's something from another camera looking at the well.

http://i978.photobucket.com/albums/ae268/onefifty/julytentysixDidTheSeab...

Here are all the pictures I cropped so far (I can't do anymore today, bad arm, that's why they're so uneven, lol!). Anyway, here's the link to all of them. I haven't gotten to the eel yet, and I have more of the mysterious rectangle inside the circle yet to crop. Have a great day everyone! Thanks for all your help. By the way, is that methane hydrate building up over the well or is the seabed rising?

Bubbles from seabed:

http://i978.photobucket.com/albums/ae268/onefifty/julytwentysixTinyBubbl...

Seabed rectangle inside circle with bubbles:

http://i978.photobucket.com/albums/ae268/onefifty/julytwentysixshapeswit...

Methane rising over well?:

http://i978.photobucket.com/albums/ae268/onefifty/julytentysixDidTheSeab...

Zoom in on "snow covered?" well:

http://i978.photobucket.com/albums/ae268/onefifty/julytwentysixSnowJob.gif

Interesting. I can't claim Rovman's expertise but as far as the bubbles are concerned, they aren't unusual from any seabed. I've seen a lot more than that coming from the mud in shallower water. It usually indicates either rotting biomass or creature activity. There could be clams or who knows what kinds of critters under that surface. Certainly we know there are crabs and eels down there! The clips I've seen of known seeps have a much more regular release rhythm to them indicating a slow leak rather than periodic bursts. I suppose this explains why sampling and analysis is needed.

It appears now, the methane ice is also forming where the bubbles are coming out:

http://i978.photobucket.com/albums/ae268/onefifty/julytwentysixIceBop.gif

A few captures to see if it grows from here.

Is this good or bad news?

Hopefully it's good, if bad then hopefully it's fixable...because I've been very optimistic so far and I'd hate to see our progress ruined.

Oh noes! They put the well through the main square of Atlantis!!! :)

There are a lot of mud mats down there and I have noticed a number of views that seem to show paving which may be the mud mats. The ROV explanation sounds quite reasonable. Small bubbles rising from the bottom are quite normal underwater, nothing unusual there, if that were shallower and sand I wouldn't want to put a hand there as there may be a sting ray or electric ray underneath :)

NAOM

A little history lesson for those who think more government is the answer.

source http://www.asme.org/Communities/History/ASMEHistory/Brief_History.cfm

source http://en.wikipedia.org/wiki/ASME

Private individuals, seeing a pressing need, filled it and governments have merely adopted (co-opted?) the fruits of their labors.

Yes, you are absolutely right. The ASME codes and standards are written in human blood.

The codes and standards are a monumental effort and largely done by volunteers.

The codes and standards are frequently adopted in-total in federal laws and regulations.

I am a proud member of the ASME.

Private development of codes and standards can be a double-edged sword. Sometimes private groups use codes to advance their own products/systems. As a retired P.E. with over 15 years experience in state government implementation of codes and standards I have observed several instances of this. One was a provision in the NY state code that related to "lightning protection".

Short version: The NYS code provision was written so as to allow only one type of system. A vendor applied to have their system "approved" also. A brief survey indicated that, at that time, there was no scientific evidence that ANY system of lightning protection worked. We therefore acted to remove the current code language, allow any system that could be tested and approved, and refer to proper electrical grounding of structures, etc.

Not only did the private entity that had writtrn the current standard protest the potential loss of their proprietary system (and loss of sales of publications) but the state agency that was supposed to assist in the elimination of unneccessary and useless regulations fought the elimination of the code language by noting that we were removing "protection" from the codes.

We don't need MORE gov't. We need BETTER government.

How we get there I'll leave for others to argue for the next century or so.

I helped get "lightning protection" removed from the NY state building code, although it took way more work than it should have. So, I can die happy knowing that I at least swept back one or two waves of the incoming tide.

Amen. Amen. Amen.

IF we need better government, maybe we need qualifications for the voters that elect the unqualified legislators?

Isn't government the most important thing we do these days?

Isn't it strange that we think that there should be NO limits on how dumb or crazy a voter should be, and NO limits on how dumb or crazy a legislator should be, and NO limits on how dumb or crazy an executive should be.

I therefore think we're mostly dumb and crazy, and our version of democracy will crash the system.

But nobody dares to bell THAT cat!

Government is not made up of documents or money. It is made up of people. Government's people may need money, but they are people just the same. We do not need more government, in fact we need less. We need better people overall. The leaders are just a symptom.

moosedog86

Very well said and illustrated. Thanks.

I don't know anyone who thinks government is the answer to everything, nor anyone who believes there should be no government, so the accusation that even some people do either of those wastes a lot of time and energy that could be put to better use.

PS: I presume the suffix indicates that there are, or have been, at least 85 others of you. Are you a family, or just an organization, like the elks? ;)

"I helped get "lightning protection" removed from the NY state building code,..."

That's very clever of you.

May none of your loved ones ever die in a fire cased by lightning.

Or don't you live in NY anymore?

"I helped get "lightning protection" removed from the NY state building code,..."

That's very clever of you.

May none of your loved ones ever die in a fire cased by lightning.

I understood him to be saying that what he got removed was a provision that permitted only one company's brand of lightning protection to be used. Removing that provision meant other companies' brands could be used as well if they met the standards.

The company that made the equipment in the removed code protested, claiming--falsely--that the change had removed protection altogether.

(moosedog, if I got that wrong, please fix.)

I read the post the same. If a code needs product references to explain code instrumentation then the code needs a re-write.

How many confirmed leaks are there and where are they?

Several times I have seen what I thought was oil leaking from below the one we see on Hos.

@ gmf:

The last hard number I heard from Thad Allen was six leaks in the BOP/ capping stack. This is not inclusive of the seeps/anomalies they've been discussing.

You are correct that there is a leak located below the one in your frame capture. It is located on the old BOP in the area of the upper annular. It tends to build up over time, then a blob will break away and float upward, sometimes being seen on the feed of the ROV montoring the leak around the HC connector (the leak shown in your capture).

So how common are such leaks?

Interesting question. I also wonder what these leaks would have been like if they did actually have 9000 psi at the top of the well as expected.

I don't know whether these leaks are common or to be expected. We were bombarded with statements from Thad Allen and BP that the capping stack had been thoroughly tested prior to installation, but those statements abruptly ceased after the stack was installed and the choke fitting leaked like a sieve. Since then, we see all these other leaks springing up and are assured they are of no concern right now.

As for the old BOP, it's been through a lot of stress and abuse. We can only guess that it is leaking because of the disaster, but if the new capping stack was leaking after supposedly being thoroughly tested, it makes you wonder if the old BOP would have also leaked even if they had avoided the blowout (and also if there are other leaking wells out there right now that John Q knows nothing about).

Interesting series of posts at ZeroHedge, dated today.

and in response to a request for "CDOM flouresence in relation to DO2 and the date your vessel departed/returned along with its MMSI",

Interesting series of posts at ZeroHedge, dated today.

Actually not that interesting at all. Just a Simmons supporter trying to make the Simmons meme look good, when all his predictions have turned out to be pure tin foil.(no insult to you TinFoilGuy).

Disagree. He just added

What he's claiming so far cuts into various reports of mile-long plumes. If anything, it makes Simmons look worse.

Wait are you talking about Simmon's assesment of our situation or something else entirely? What are these mile long plumes?

Reuters news alert, beverage spill warning.

Current CEO of BP (BP/ LN) Tony Hayward to be nominated as director of TNK-BP

FTSE

17:03 26-07-2010

Note: this includes Siberia.

For reals?

I haven't seen the actual story appear yet. But I did note this: "CEO Hayward to step down, be replaced by American-sources" and "Investors cheered Hayward's expected departure, sending BP shares up 4 percent in London and New York."

FT.com says Hayward

No mention of Siberia.

The company has ops in eastern Siberia, among other places.

I wonder if he will be based onsite?

NAOM

Remember, Dudley got kicked out of Russia a few years ago, IIRC because he wouldn't "play ball".

If you wonder how politics works in Russia, imagine if the mob in this country totally ran the government.

...except the food isn't as good.

But the vodka and the caviar are outstanding.

His $23M kiss-off pay ought to hold him for a couple weeks.

Caption: "Tony Hayward leaves BP's offices in St James's Square, central London, today. Photograph: Dominic Lipinski/PA"

Ah, Tony, Tony, Tony -- lookit what The Guardian's homepage did to yer name: BP opts to send Hawyard to Siberia

now that is STANDARD RUSSIAN.

http://www.youtube.com/watch?v=dO76_0pQOzc

This is RUSSIAN STANDARD.

Does Southwest Airlines fly to the Ukraine???

Sign me up!!!!!!!!!

Southwest flies to Odessa (Midland) - does that count?

I think they do.

If that were true, Glenn Beck would have started glowing two years ago ;)

We have the Chicago mob running it now.

Nah. Who got whacked or disappeared? No Vince Fosters here. There is history, however. Wasn't there a Chicago mob-Daily-Kennedy conspiracy of sorts uncovered? The current guys just make you Blackberry in your resignation from the side of the road and put their finger in your chest. I would love them to try that with me. I would get it all on video.

No, New Orleans mob Carlos Marcello was implicated in the Kennedy affair.

You are right, Kennedy recruited mobster Sam Giancana to assassinate Fidel Castro and shared a mistress with him, Judith Exner.

http://en.wikipedia.org/wiki/Sam_Giancana#Alleged_CIA_connections

Joe Kennedy SR was a bootlegger (per Frank Costello, who ought to know!! http://en.wikipedia.org/wiki/Frank_Costello ) and stock manipulator http://www.straightdope.com/columns/read/716/what-is-the-true-source-of-...

I agree. I'm very much in favor of a static kill being attempted as soon as possible, but see no advantage to be gained from pumping cement in at that time. Maybe the best approach later on would be to pump in cement via the RW first, then follow it up with cement from the top (where one has gravity on one's side...)?

By the way, I presume that the goal in the static kill is not necessarily to get the pressure in the BOP down to zero, but instead to reduce it to a low enough value (say < 2000 psi ??), such that the pressure of the 5,000 foot water column above it would prevent the well from flowing should the vents be opened.

For the life of me, I still can't understand why they should want to have the casing in place in the RW before trying the static kill. Has anyone got any ideas as to what may have been the reasoning behind this decision?

Mike, Wells's and Allen's explanation was that they want to protect the RW as much as possible from anything that might go hinky in the static kill.

Yes, Allen and Wells both have stressed how close the bottom of the relief well now is to the wild well (4'8" horizontally, iirc).

In his video Wells said that the mud will be pumped via the Q4000 drill pipe. Anybody know if the drill pipe will be within a riser? The capping stack seemed to be lowered on drill pipe alone, but I'd assumed the mud-pumping operation would have the drill pipe enclosed in a riser to deal with possible mud return.

I wouldn't have it any other way. If ANYthing goes wrong up top, you have to rescue the well from below. There's still the possibility that the casing up top is somehow compromised. The possibility is remote at this juncture, but that possibility exists. They know now there's not been a leak of any significant amount into the subsurface. That and the steady pressures from the blowout well doesn't mean there can't be at any point.