Tech Talk - Venezuela, heavy crudes, API gravity and refinery gains

Posted by Heading Out on January 9, 2011 - 6:09am

Because the world market is increasingly having to accommodate crudes that are heavier and less easy to refine into desirable, profitable products I thought I would revisit my discussion from earlier in the series about the limitation on global oil production, due to the need for suitable refineries to process the oil that is produced, before it can reach and be used by the ultimate customer.

I have covered the operations of refineries in the past, but this time I thought I would dwell a little more on some of the factors that relate to the type of oil that is being refined. It is perhaps timely to do so, given that China is moving forward with plans to construct a refinery that will process the heavy Venezuelan crude that, until now, has largely been sent to specialized refineries in the United States that are designed to handle it. In 2008 Venezuela exported 120 kbd of oil to China (out of a total of 1.89 mbd, of which the USA imported 1.19 mbd). This past year the flow to China is reported to have increased to 362 kbd. It might be noted that the recent diplomatic leaks known as the Wikileaks saga has revealed cables that suggest that China was getting some of this oil for $5 a barrel, and then selling it for more on the open market, including possibly to the USA. This could be quite possible since it is also reported that while Venezuela said it exported 460 kbd to China, Chinese figures put the volume this year at 132 kbd.

The largest supply of oil remaining in Venezuela is that in the Orinoco Belt, which the USGS has estimated holds a reserve of some 513 billion barrels. (Which, for reference is about twice the size of the Saudi Arabian reported reserve.) The problem with the oil is that it has an API of 9 degrees. Which is where I need to digress a little and explain to those not familiar with the term, what API gravity is, and the significance of a value below 10 degrees.

In the following explanation I am going to use a couple of examples taken from “Petroleum Refining in Non-Technical Language” by William Leffler, which has some clear descriptions that I cannot hope to improve on, in explaining some of these issues.

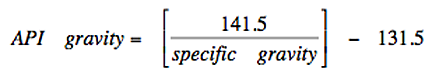

As I had mentioned in the earlier post, the crude that comes from the ground is a mixture of compounds of carbon and hydrogen with the compounds individually having roughly twice as many hydrogen atoms as carbon, and with the higher numbered compounds being heavier. As a way of characterizing the crude at this point, the American Petroleum Institute developed a measure known as the API gravity. The API gravity, which is expressed in degrees, is obtained from the equation:

If you recognize that the specific gravity of a fluid is the relative density of the fluid when compared with water (at 60 deg F in this case), then you will see that with an S.G. of 1, water has an API gravity of 10 degrees. Fluids, such as the Orinoco crude, with an API gravity of 9 degrees, are thus denser than water, and the scale is inversely related to density, so that the higher density fluids such as asphalt, have a lower API gravity (in this case 11 degrees) than lighter fluids such as light crude (36 degrees) and gasoline (60 degrees).

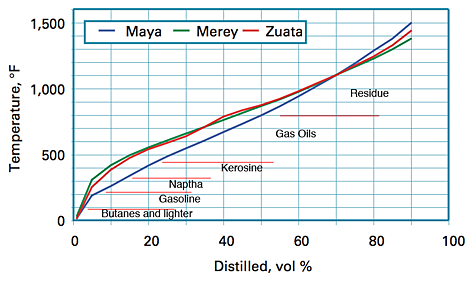

The initial separation of the different compounds in the crude is achieved by heating the crude to about 750 degrees F, and feeding the result into a distillation column, where the volatized fractions of the mix can be condensed back out and separated out on trays at different temperature levels. The hydrocarbon content can thus be characterized by the relative levels of fluid that condense out at different temperatures, and the product is known as a Distillation Curve for that crude. For example these are the basic curves for some of the heavy crudes from South America.

I have added the temperature ranges in which the different fractions of the crude would settle out.

You can see that, there is not, initially, a lot of the lighter fractions available in these crudes., which are also because of this, more viscous and difficult to move around the plant.

To produce those higher fractions the refinery will first remove the lighter fractions, as described above, but then will further heat the remaining crude to the point that the heavier hydrocarbons break down into smaller molecules. Consider the case of the C16H34 Cetane molecule, which will break down into a combination of C8H18 octane molecules; C6H12 hexene molecules and C2H4 (ethylene) molecules roughly in the ratio of 50:38:12. When this happens the volume of the product will also increase. (I am taking this example, and the numbers from Leffler’s text).

The density of the original fluid was 7.2 lb/gal, it now breaks down into the smaller molecule hydrocarbons.

If we consider the original volume weighed 7.2 lb (1 gal) then 50% of that would become C8H18, which would weigh 3.6 lb. However octane is a lighter hydrocarbon that only weighs 5.9 lb/gallon, so that the resulting volume would occupy (3.6/5.9) 0.61 gallons.

In the same way the 38% of the original 7.2 lb would break down into the same weight of C6H12, some 2.7 lb, but hexene has a density of 5.6 lb/gallon. The resulting volume would thus occupy (2.7/5.6) 0.48 gallons.

And the third fraction would be the 12% that turns to ethylene, some 0.9 lb that would, at the new density (3.1 lb/gallon) occupy 0.29 gallons.

If one adds up the three “cracked” volumes the total is now 1.38 gallons, rather than the original 1 gallon, and this is how “refinery gains” are developed (illustratively) within the refinery. To keep the temperatures down during the cracking process it is generally carried out at a lower pressure than atmospheric, since this allows the fluid to boil at a lower temperature.

The heavier the crude then the more complex, and expensive the process of refining becomes. Often even to produce the original crude to the point that it can be pumped long distances, it must first be upgraded to a synthetic crude in an upgrader, located on site. It is this process that the Canadians have found a way to work around, though this is not yet the case with Veneuela. As a result as the different blocks of the Orinoco Basin are being developed, they only come into full production when upgraders have been constructed to handle the flow.

Given the need for considerable processing of the Venezuelan crude, which can also contain other contaminants such as vanadium, it is important to note that about the same time as the USGS was upgrading its figures for the Venezuelan reserve, that country and China were approving a $6-billion joint venture to build a 400 kbd refinery in China to handle that crude. Whether the crude is processed into a syncrude before shipping to China is not clear, but this is all part of the effort by Venezuela to increase exports. (The crude will come from Junin Block 4.)

Veneuela has contracted with a number of other country partners for production from other parts of the Orinoco Basin. Petrovietnam will help develop Junin Block 2, which is slated to have a production capacity of 200 kbd by the end of this year; Italy’s ENI has a target of 240 kbd starting to come on line in 2013 from Junin Block 5, though the refinery to process this into diesel for Europe won’t be built until 2016; Russia will partner in Junin Block 6 to develop 450 kbd at some unspecified date. In addition a combination of partners are to develop blocks in the Carabobo region, with a total production of 800 lbd, with the production to be on stream by 2013, though upgraders for the crude won’t be ready until 2017. The Chinese involvement has now been approved, with a performance period of 25 years, and further the Chinese have agreed to develop Junin 1 and Junin 8 at 200 kbd each, for a grand total of 800 kbd, which will require a $40 billion investment. Should all the investments that Venezuela envisages come to pass, then they anticipate that the country could be producing 7 mbd by 2021.

It is worth noting that the Junin 1 block was supposed initially to be developed by Belarus, but that fell through. However, in a four-party deal, Venezuela has agreed that it would send some of its crude to the USA, if Azerbaijan agreed to send an equivalent amount of its oil to Belarus. Azerbaijan is increasing production and has just reached the 1 mbd mark.

Whether Venezuela will reach the levels of production anticipated, or at the rate anticipated, is still, of course some matter of debate, but it does explain where some of the more Cornucopian projections acquire some of their statistics.

Thanks, I learned from your post.

My take-away is that the price of gas at the pump is likely to rise faster than many expect and that our transition away from petroleum is about to accelerate.

Good thing Nissan is gearing up to manufacture 500,000 EVs per year starting in 2012. Looks like Ford could quickly ramp up their Focus EV quickly since they are using an existing model. This change may mimic the abrupt switch from film to digital....

IMO. It Won't happen

i) the power grid will not cope. German power has said that if just 1 in 10 German households go to an Electric Car that will be enough to crash their grid

ii) battery life & changeover costs will be expensive, decreasing market penetration of EV's. There's a big difference between the cost of a digital camera & a power source for an EV.

iii) EV's will still not replace most uses of oil, even in the personal transport market.

Yes there will be EV's & expect to see lots of electric motorbikes & scooters like in China now. But whole fleets of electric cars jamming our freeways? I don't think so.

Most people will have a few limited choices, such as walk, bicycle, electric bicycle or public transport. And the latter is where society should be directing its efforts, not maintaining individual polluting single vehicle transport modalities.

Sorry to disagree with your dream Bob

i) Two separate studies of the US grid have shown that if there were a way to instantly convert 85% of all existing ICEVs to EVs we have the capacity to charge them during nighttime/off-peak hours. Yes, some neighborhood transformers would likely need replacing sooner than otherwise, but that was the only discovered problem.

Europe is showing itself to be very willing to move away from a 19th/20th Century energy supply and on into the current century. They'll upgrade their grid. We lag behind Europe.

ii) Digital cameras were very expensive when first introduced. I paid around $600 for a compact digital around a decade ago. I can now buy a much higher featured compact for under $100 today.

The price of EVs/EV batteries is simply an economy of scale issue. There are no very expensive components/materials involved. Yes, there is a few hundred dollars worth of lithium in lithium batteries. There is also a few hundred dollars worth of platinum in a ICEV catalytic converter.

EVs should be comparably priced to ICEVs once production levels reach the 500,000 to 1,000,000 range. Nissan is gearing up to be manufacture 500,000 EVs in 2012. (Statements from Carlos Gohsen, Nissan CEO.)

iii) An EV with a 200 mile range (Tesla S will have a 300 mile range) and ten minute rapid charging (MIT has developed one) will serve the driving needs of most Americans. Those who need longer range can use PHEVs, doing the bulk of their driving with electricity.

It would be best if we walked/biked/took public transportation, but it's foolish to think that people will do so in large numbers. We can increase the percent of non-auto travel but not all that much outside of densely populated areas.

People are going to want a personal vehicle which makes travel comfortable and convenient. As long as we can provide them one made from sustainable materials and powered with renewable energy then we will have created no problems for ourselves.

According to the US Department of Energy, there is enough spare capacity at non-peak hours to replace all of the light vehicle liquid fuels with electricity. In several US areas, such as SoCal, that are anticipating high electric car acceptance, Time of Day pricing has already been put in place. While off-peak charging (that is to say, over night charging) will consume more electric fuel resources, the need for more generating and transmission capacity can be avoided.

However, what of the additional fuel required ?

And extra 17% to 20% more MWh. Very few new nukes in the near future. Likewise hydro.

But I frankly believe that a good % of EV owners will recharge as soon as they get home, adding to the 6 PM peak (previously a secondary peak in most areas).

Alan

We are adding wind generation to the grid much, much faster than we will bring EVs to the grid. We are also beginning to roof parking spaces with PV racks and rapidly increase installation rates.

We could even simply shift electricity and natural gas used to extract, refine and distribute petroleum. Apparently we use more energy 'creating' a gallon of gas at the pump than it would take to power an EV the equivalent miles of a Prius.

People will not recharge as soon as they get home if price structures operate against evening charging. People will plug in and the actual charging will occur after midnight. Remember the average driver puts on only 30 miles per day. With a 220vac outlet one can do a 30 mile recharge in less than three hours.

Within a short time smart grids will be able to control charge times for individual EVs so that EVs will be available for peak-shaving charging thus reducing overall utility bills.

People will plug in and the actual charging will occur after midnight.

I doubt it. The price delta will not be great enough for a significant minority at least.

Time of day pricing has zero impact on my cell phone use.

Alan

You can doubt it if you like. But don't try to compare cell phone use time to EV charging time. The desire to call is time constrained in a way that EV charging is not. Few of us are going to sit up until 3am to make our daily calls. But you can bet that if rates are high at 3pm most will cut their calls short.

With your EV you arrive home and plug in. Ver 1.0 charging will be/is determined by simply programming the charging timer in your EV. (You can adjust the settings via cell phone or computer with the Nissan Leaf.)

Are you going to set the timer to charge from 7pm to 10 pm at $0.25/kWh or from 1am to 4am at $0.05/kWh? Well, not you perhaps, but most people?

Ver 2.0 charging will be grid controlled. You plug in with the setting to get you 50%/70%/100% charged by 6am. Then the grid will turn your charger on and off based on price of power on the grid during each 15 minute time block.

If supply is expected to be flat throughout the night then all the EVs waiting for their 'fix' will be staggered in order to keep demand flat.

If power is highly available then the grid might decide to ignore your 70% setting and fill you up in order to load shift away from subsequent nights, and pay you a bit for the privilege.

The sad thing with PV is that they require an alloy of indium/gallium to work. Both, but especially indium, is a scarece metall. The PV revolution will not happen, untill someone either figures out a way to not need indium, or new sources are added.

Well, that is almost true in the case of copper-indium selenide and gallium arsenide technologies. But buck up Bucky, there are other technologies which work just fine.

Go here and click down to #6 - Materials. It will brighten your day.

Oh, and to make those pearly whites flash even brighter, indium is the 61st most common element making it three times more common than silver. As for gallium the USGS estimates that there is about one million metric tons

Perhaps you're confused between occurrence and production/reserve amounts?

All atoms are not equal. They have to come in minable concentrations, or like with gallium, be a by-product from other mines. For example silver is muchly a by-product from copper mines (wich is the reason why old copper items have a high silver content). Gallium is thusly mined in other mines, there are no gallium mines as such.

So the important question is: how much of all this stuff is at places we will actually afford digging out?

How much? As much as we need.

Check my post on graphene panels.

Oh, and there are solar technologies which have yet to make it to Wiki.

The standard material used so far for these electrodes is indium-tin-oxide, or ITO. But indium is expensive and relatively rare, so the search has been on for a suitable replacement. Now, a team of MIT researchers has come up with a practical way of using a possible substitute made from inexpensive and ubiquitous carbon. The proposed material is graphene, a form of carbon in which the atoms form a flat sheet just one atom thick, arranged in a chicken-wire-like formation.

http://www.physorg.com/news/2011-01-graphene-electrodes-solar-cells.html

There's one lab that has produced incredible performance with graphene nanofibers which uses about 1/10th as much active material as normal panels and can be manufactured using standard thin film printing techniques. Their lab cells are converting roughly 70% of the light into power. That's considerably more than the most efficient silicon cells which are quite expensive to produce.

Fell free to now do your happy dance....

Argh! NO!

81% of PV in 2009 is crystalline silicon, another 7% is amorphous silicon.

NO indium or gallium needed.

CIGS (Copper Indium Gallium Selenide/Sulfide) was 2%, CdTe was 10%.

Silicon is the 2nd most common element on the earth's surface.

Wish I could think of a quick newbies guide to PV technologies.

maybe at:

http://www.photon-magazine.com

http://www.ases.org/

http://solarbuzz.com/

http://www.nrel.gov/learning/re_solar.html

PDF from NREL on "does the world have enough materials"

http://www.nrel.gov/docs/fy05osti/37656.pdf

Let me share another development which I read about some time back but just now found on line....

Using arrays of long, thin silicon wires embedded in a polymer substrate, a team of scientists from the California Institute of Technology (Caltech) has created a new type of flexible solar cell that enhances the absorption of sunlight and efficiently converts its photons into electrons. The solar cell does all this using only a fraction of the expensive semiconductor materials required by conventional solar cells.

"These solar cells have, for the first time, surpassed the conventional light-trapping limit for absorbing materials," says Harry Atwater, Howard Hughes Professor, professor of applied physics and materials science, and director of Caltech's Resnick Institute, which focuses on sustainability research.

The light-trapping limit of a material refers to how much sunlight it is able to absorb. The silicon-wire arrays absorb up to 96 percent of incident sunlight at a single wavelength and 85 percent of total collectible sunlight. "We've surpassed previous optical microstructures developed to trap light," he says.

http://media.caltech.edu/press_releases/13325

Did you get that 85% absorption rate? That's, what, 2x as high as the best cells to date? And more than 4x more efficient than commonly installed panels. Four times more efficient means a 4x decrease in mounting and labor costs per project. Plus a lot more power out of a given piece of real estate.

These cells use only 2% of the silicon in normal PV cells and can be manufactured as thin-film which brings a roll to roll efficiency into play.

Put this together with one of the new non-reflective panel coatings being developed and it's a whole new ballgame. Thin film manufacturing costs are already getting close to $0.50/watt and the cheaper materials in this approach should drop the price even further.

Perhaps someone on this site can answer what should be a fairly simple question...

How much electricity and natural gas does it take to extract, process and distribute a gallon of gas?

I've tried some web searches and found sites which claim that there's enough energy embedded in producing a gallon of gas to drive an EV 30 miles or so. But the sites I've found lack any sort of "academic" feel and I don't know how much to trust them.

If these sites are roughly correct then it would seem to make sense to leave all that carbon sequestered in the ground and simply re-purpose the electricity and NG to charging EV batteries.

Any help?

On a related note, I contacted an Italian maker of small CNG compressors (suitable for truck stops a la Pickens Plan) and found that the electrical energy required to compress the NG to CNG at 250 bar/atmospheres was 4% (1/25th) of the energy in the NG.

Alan

That's true. CNG compressors don't consume very much energy compared to the energy in the natural gas they compress. There's nothing technically difficult about using CNG, and it is not particularly hard to implement.

It's just that historically, gasoline and diesel fuel were available cheaply in such large quantities that nobody wanted to bother with CNG.

Given the current price difference between CNG and diesel fuel, though, I think that trucking companies should be thinking very hard about converting their fleets to CNG.

I agree, and I have had some significant hands on experience with propane powered engines;they are reliable and durable and actually cheaper to build than diesels, which require a very expensive high pressure fuel injection system.

There are no significant differences,except for the fuel storage tanks, between propane and ng engines.

The only real holdup to switching long distance trucks to natural gas is business inertia and perhaps the lack of pipelines and fueling stations.Millions of trucks stay close enough to their home base to run on cng for a day,and could be refueled overnight.The necessary tanks can be mounted underneath the cargo trailers;it would not be that big a deal to enclose them in a safety cage similar to the ones used top protect race car drivers.

Heavy duty trucks are highly standardized, and have plenty of access space around the engine-modifying them will be a very minor job compared to modifying a passenger car.

Of course this will require preserving the diesel injection system to provide a source of ignition-a little diesel will be needed, probably less than 5 percent of normal usage;but this also means the driver can flip a switch and run 100 percent diesel if necessary.

My guess is that we have not seen this changeover yet because diesel is still affordable, and because of the reluctance of trucking companies to take on the regulatory authorities and insurance companies, both of which will almost certainly do all within their power to play god.

However, the electricity to just compress the NG is 80% of the electricity to move the same number of ton-miles by electrified double stack rail.

Remember, the 20 BTUs of refined diesel for 1 BTU of electricity "trade" by shifting from trucks to electrified rail.

If one looks at CNG trucks (lower compression > lower efficiency), the options to move X ton-miles appear to be, roughly

Diesel trucks - 20 BTUs refined diesel

CNG trucks - 24 BTUs NG + 0.8 BTU electricity

Electric double stack trains - 1 BTU electricity

Best Hopes for Electric Trains,

Alan

So it sounds as if it might more sense to divert the electricity from petroleum->gas/diesel to EVs and the natural gas to transportation needs that lie in between the workable range of EVs and electric-powered rail.

Well, it is true that electric trains would be the most efficient way to move things by natural gas. There's really no comparison between trainws and trucks as far as fuel consumption is concerned. Trains are much, much more energy efficient.

However, in comparing diesel fuel to natural gas as truck fuel, you have to keep in mind that natural gas is currently trading for much less than oil on an energy equivalent basis.

According to the EIA, diesel fuel is currently selling in the US for about $3.33 per gallon. That is about $0.88 per litre (I'll use metric since I am more comfortable with it), and since diesel fuel contains about 36 megajoules per litre of energy on average, that works out to about $24 per gigajoule.

By contrast, according to the EIA, natural gas for commercial use in the US is currently selling at about $9 per Mcf, and since 1 Mcf of natural gas contains about 1 GJ of energy, that is about $9 per GJ.

So, notwithstanding the relative energy efficiencies, a CNG truck should have less than half the fuel costs of a diesel one.

Rocky,

In Australia for heavy duty long distance trucking LNG seems the be the way to go.

http://evollng.com.au/our_business.html

Higher fuel density and diesel cycle being the main advantage. The trucks end up being duel fuel as they require a little diesel for idle and ignition. It ends up 90% gas 10% diesel. This is a new business but I am sure with the current up swing in the oil price we will see it take off.

CNG is mainly used for local work with the truck returning to base over night and large fuel loads are not required.

It takes more energy, and larger, centralized installations, to liquefy NG than to just compress it. I do not have a good source (does anyone ?) but "I have heard" 20% of the energy of NG is used to liquefy.

US and Australian distances and diversified travel paths are unlikely to be able to support the required LNG facility density (with duplicates for redundancy) without rail transport of LNG to a limited number of truck stops, properly spaced.

It is my understanding that LNG can be used in high compression diesel engines, but CNG is used in lower compression ignition engines. True ?

Alan

Alan,

The LNG plants that Evol are building are not the export orientated multi million ton per year plants. They intend and are building several small and dispersed plants. Currently their largest is a 175 ton/day plant in WA which is suppling remote mine sites with LNG for power production a well as LNG for several trucking operations. A 50 ton/day plants in Tasmania, Melbourne with one under construction in Chinchilla Queensland. As the market takes hold these smaller plants will be constructed across the country. All that is needed is access to a NG pipeline and good power supply.

These small plants have traditionally be used for short term storage and surge capacity in the pipeline networks.

This is the normal practice but, not true in all cases. As I understand it, LNG is still vaporized before use in the engine, which ever type, and therefore LNG could still be used in spark ignition engines.

I believe it comes down to the economics of the LNG being a higher density fuel allows the added cost of the diesel cycle installation to be used where as CNG has greater weight penalties due to heavy wall high pressure tanks that do not scale up well for long distance travel, and therefore are confined to around town type applications and used spark ignition which is a relative cheaper engine conversion.

I see burning NG in a diesel as a distinct advantage. Higher fuel efficiency (guess 20% to 25%) and much lower maintenance.

That CNG cannot be used in diesel is a major strike against it. CNG buses in the USA have been major maintenance problems (disasters in some cases). Reports of major overhauls in just 5,000 hours of operation in some cases.

But what is the energy cost to liquefy NG in small scale LNG plants ? Any data from Evol ? Or others ?

Thanks,

Alan

Alan,

Finally found some numbers for you. You will need to do the crunching.

This is for a 50 ton per day of LNG. The input of 19000 ton of NG sounds strange, I would have expected to see cubic feet, metres, or gigajoules, I am sure you will work it out.

I believe the main problem for CNG for long distance is the weight disadvantage of the heavy HP tanks and therefore cutting into pay load. This has even been noted as a problem for short distance trucking, eg Cement mix trucks.

As to maintenance problems, I have read where the local city bus company (govt owned) only uses CNG on new buses as they had problems early on when they tried to convert some of their diesels. They have been using CNG for 20 years, and keep buying more.

Have fun!

Thanks !!

It is "approximately 50 tons/day". Some boil off from the 52.8 tonnes/day input.

Why not capture and recycle that NG ? EIS says small volumes are "not economic" to recycle, so they flare it, along with NG gas left in empty LNG tank trucks when they are refilled.

Good numbers to crunch !

Alan

First cut is 4.4% of energy of LNG is used by electricity to liquefy. I assumed that 13,000 MW/a meant 13,000 MWh/year (in good engineering MW does NOT = MWh but these are environmental engineers).

H2S is removed from pipeline gas (a very small % of total energy) as well as CO2 in the pipeline gas. I will need to reread to find out fate of ethane and other heavier hydrocarbons in liquification process.

Removing H2S and CO2 will be part of the 52.8 tonnes of pipeline gas/day > approx. 50 tonnes LNG/day.

It is my understanding that imported LNG is pure methane and, in the USA, must be mixed with domestic NG before use in homes, etc. That is, no NGLs (natural gas liquids) are entrained with imported LNG.

No mention of boil off volumes either in EIS.

PS: The adjacent property processes opium poppies into morphine and related pharmaceuticals.

Alan,

I can not comment on LNG into the States but the LNG leaving Australia form the traditional gas fields on the North West shelf contain NGL, ethane and propane for which they get paid a premium. This was a decisions made back in the 1980's when there was talk of keeping the NGL and building a petrochemical plant at the site. The cheap and easy solution won the day and they just left it in the LNG and sent to Japan for them to gain the added value.

The new LNG plants propose from Queensland are from Coal seam Gas and is dry. This has been a point of discussion during the marketing exercise.

Does Trinidad have Petrochemical beside there LNG plant? Don't know but it could be an easy way to answer the question!

Trinidad has an extensive petrochemical and refining industry.

"Petrochemicals based on natural gas became the center of the industrial strategy envisioned in the 1970s to diversify away from oil and export agriculture".

Propane is also shipped separately on international markets, as is naphta.

http://bulktransporter.com/mag/transportation_teppco_providence_propane/

So, unless provisions are made to recover NGLs, just include them in the LNG. Hopefully the truck engines can take a mixture of fuels as they drain their tanks.

Alan

Alan,

As for the Opium, Tasmania is Australia's place for growing Opium for the Medical industry. They feel it is easier to contain on a "small" island than a large open country.

I have heard security is rather high around harvest time!

Tasmania is the world's largest producer of "concentrated poppy straw extract" (the gum extracted from scarring the closed poppy bud, dissolved and then crystallized) with 20,000 hectares under cultivation. About half of the world supply.

Note: This is for legal production. Afghanistan is thought to be the lead producer for illegal use.

Alan

Um, that is a little open to different interpretations ;)

NAOM

Urmm,

That CNG cannot be used in a diesel is a big disadvantage.

Try this : http://www.cleanairpower.com/duel-technology.php

and this for your car (not for diesels at present)

http://www.gasfill.com/

CNG and LNG are one and the same compund. The former is a compressed gas and the latter a liquid. It is the storage vessel that differs.

in both cases the gas in vapour form at the point of injection. LNG also constantly boils off during storage and this must be taken into account. LNG shipping vessels use the boil off methane as engine fuel in DIESEL engines.

Whether or not gasfill will get around to diesel conversion I do not know. In principle there is not reason why not but there is the cost which will be more than a gasoline engine.

Much of the Indian small taxi fleet of Ptuk-Ptuks were converted to CNG a few years back.

Seems like it might be possible to get that energy back by expanding the gas through a tiny single shaft turbine generator. The gas could be preheated using engine exhaust to extract more than 4%. Overall efficiency goes up and tank size is slightly smaller.

A similar idea could be applied to LPG, but would require a pump to achieve high pressure before expanding the liquid.

Details, details, details… No rare earths means no electric cars, solar cells or wind mills, unless you buy them from China.

The "rare" in rare-earth minerals does not mean what you think it does. Look it up.

China does not possess all of the world's deposits of REMs, they are simply the world's processor because they forced other countries out of production via low prices.

We are currently reopening REM mines and processing plants in the US and Australia among other places.

China has a short term monopoly on REMs as well as lithium. I suspect it's about a two year window and then there will be multiple national suppliers in addition to China.

Chile about to release large Lithium deposits: Bloomberg Businessweek http://www.businessweek.com/news/2010-04-30/chile-plans-to-open-up-lithi...

And Bob, Thanks for your information but 100% of EV users will never all charge off peak. To start with a significant percent of the population works "off peak" hours. If 10% of EV's plug in during peak the grid will likely crash. Obviously not even 1% of an EV fleet could plug in during maximum load (hot day, all air conditioners maxed out). CRASH

The lower energy density of fuel for EV's & the lower EROEI of all other electrical sources compared to gasoline will ensure significantly fewer cars on the road in the future. Electric, hybrid or gasoline powered.

And this statement

is actually true in nearly every country in the world except USA, Australia & Canada. They all can't be that foolish. And yes I too have sat in traffic jams in Beijing, Berlin & Birmingham but the percent of public transport users to private car commuters is much much higher than in our car dependent countries.

Our car culture is going to hurt & it's going to change. It is right now.

I don't believe I ever said anything about 100% of EV users charging off peak. I simply gave data for the grid's ability to service 85% EVs during off peak hours.

Now if we find a significant increase in daytime charging (which can't be time-shifted by pricing) then we will add more capacity. Don't forget that we are in the process of a large grid improvement already. Most failures come from dumb switching, making the grid smarter will eliminate that problem.

Just switching from incandescent to LED/CFL lighting and more efficient AC/appliances is going to free up peak hour power/grid capacity.

---

I really don't know how you calculate fewer cars on the road due to lower EROEI for electricity sources since it's actually lower for gas. Take the electricity and natural gas used to extract, refine, and distribute a gallon of gas and you can pretty much drive a gallon's worth with an EV.

--

Been in India, Thailand, China or other up and coming Asian country lately? I have.

The streets are now crowded with private cars and motorcycles. Private, personal transportation is what people desire. You and I might recognize that public transportation is more efficient and walking/biking is better for ones health, but that will not make the vast majority of people give up their desires for their own car/motorcycle.

Lots of people are not going to willingly give up eating meat, heating/cooling their houses, or making any personal sacrifices for the common good. That is just not how humans behave. We have to accept what we cannot change and find ways to save our sorry butts that people will accept.

Better urban public transportation. Better walking conditions. Those will help. EV 'Zip' cars, small battery 2/4 person pods which are limited to city speeds and can be rented along the streets with a card swipe will get some private cars off city streets. Especially if we establish free/very low cost parking lots on the outskirts.

But that sort of system will not work for the 'burbs and rural areas. And many people will not be willing to relocate into crowded urban areas. Already they pay more in both dollars and time to commute in order to live a more enjoyable life.

There was an interesting chart in the post-o-charts, I followed the link, and read some more. My summary (mostly links and pictures) here: http://dr2chase.wordpress.com/2011/01/03/e-bikes-in-china/ .

They're selling a boatload of e-bikes. I am not sure things will converge on cars, partly because their infrastructure won't support it, and anyone running the country would see a clear benefit to avoiding the costs of the required upgrade.

You also have to be careful of eyeball measurement of cars vs other vehicles in a traffic jam; cars take up a lot of space, and the smaller vehicles can still be filtering through.

Also, you have to be careful how you define "private" and "personal". A bike, e- or otherwise, is certainly personal transportation, and though it lacks some privacy, it also lacks the mandatory plate on the back, registration, excise taxes, etc.

Nonetheless, you are right about the fact of resistance to change in this country -- I just don't think it helps to reinforce it. Bikes are personal transportation. People may be able to see you, but they don't have your number.

I've been spending part of most of my years in Asia since 1982. When I first visited India private vehicles were almost non-existent outside of the richest neighborhoods. The doctor might own a bike. Now it's very clear that many people own private cars and discussions with 'common folks' make it clear that owning a car is their big dream (or recently realized dream).

China is now a major market for GM.

I'm currently posting from a private house in Bangkok which only a few years ago had only one single auto for the household. Now there are six resident and five autos. And dreams of moving up to a "Benz". In the 1980s people walked, now when you walk somewhere outside of the city center people look at you as if you are daft.

I fear we must be realistic and develop sustainable personal vehicles powered by cleantech energy. It's something which we can now do.

The sales numbers say that there's a lot of them, but unless they built some really unusual cities long ago, there will not be enough roads for them, at least not if sales continue like this. Are they really going to be stupid enough to repeat all our mistakes, in high-speed replay?

In a word, Yes.

A few older places such as the oldest part of Kathmandu have largely banned private cars (except if you have 'pull' which people with enough money to purchase a car often do).

Other places are building roads and highways while enjoying massive traffic jams. Thailand has now built a fully modern highway from Bangkok to the north (perhaps to the south, haven't been down there lately). Bangkok has a new system of toll roads, owned by the Japanese, to speed traffic out of the city center. They also have state of the art elevated rail (SkyTrain) and a brand new subway system along with an excellent bus system but the street are clogged with private autos and pickups. Interestingly the number of motorbikes is way down from a decade or so ago, I would think because people can now afford autos.

I don't think the future bleak. I think our future cars will be much lighter weight, fully or almost fully recyclable, battery powered using cleantech energy, and self-driving. The latter is important because it will greatly increase the carrying capacity of our roads and highways as vehicles will be able to travel safely with much less space between them.

Keep in mind that Google-sponsored self-driving cars have already accumulated over 100,000 miles of hands-off driving on real US roads. They require no infrastructure upgrades but use existing cues and GPS information to navigate their way through the real world.

A decade to pull EVs, self-navigation, and sustainable manufacturing together in a single package? I think that within reason.

A decade to pull EVs, self-navigation, and sustainable manufacturing together in a single package?

Technically, possible. Socially, not so sure. I suspect a few problems -- one is that unless they are notably smaller than what we drive now (and they might be, it sure makes it easier to save energy, and since the computers will never be wrong, no crashes, so no need for excess weight for "safety", right?), there will be no place to put them, in places like Boston, NY, San Francisco (but there is more parking in "newer" cities, so perhaps Atlanta).

Second, the transition is going to be hard, because of legal issues involved in a robot/human-guided mix. I am sure that these cars will be logging data and video of wherever they go, just to defend the manufacturer/owner in the inevitable lawsuit.

There is a third problem, not widely appreciated in this country, and that is the largest number of people killed by cars, are killed by a lack of exercise. One estimate I read claimed that expected years of life lost by not biking (and by inference, walking -- note that walking is officially listed as a relatively dangerous way to transport yourself, but the deaths are overwhelmingly caused by cars, so that's an interesting way to apportion cause and effect) was 10 times higher than what is saved by avoiding bike crashes. Another study reported that non-bicycle commuters had a 39% higher mortality rate -- officially, "just correlation". This is one of the reasons why I think the rapidly-developing economies are completely bleeping crazy to copy our car addiction; the health care costs done the road will not be happy-making.

I would wonder instead if the self-driving cars, would end up being used for some variety of tinier mass transit. There's fans of some sort of "personal rapid transit" but it still runs on rails, obviously requires infrastructure, obviously less flexible than cars. If cars are self-driving, why not just do away with taxis AND busses, and just carry people in small batches, let people pay a premium for a private car (no delays while it picks up other people), and when they are delivered, it just moves on to the next person that needs transport? This would seem to avoid the parking problem, AND increase efficiency (since de facto carpooling would then be the rule, and because when the "bus" was empty, it would just park itself in the nearest available space, instead of burning fuel to patrol its route).

Another issue is, could these be made quiet enough, and really safe enough, that people would not mind having them in their neighborhoods? For example, here's a comfort standard that is already met by bicycles -- people push baby strollers on a 12-foot wide 2-way bike path, comfortable with bicycles passing them (13-18mph), even in the dark, even when there is snow and ice on the path. Will smart cars be able to meet that standard of pedestrian non-intimidation? What I'm thinking about, is how you might deal with existing far-flung burbs and mass transit (commuter rail) that is just barely making it -- again parking limited, traffic limited, and these are a consequence of station neighbors not enjoying the presence of cars-cars-cars. If these cars were nicer to be around, then maybe rail traffic could handle the long haul stuff better, with these little cab/bus/car things dispersing people at the endpoints.

Size, in and of itself, is not a critical consideration for efficiency. Weight and aerodynamics are the important variables. Neither size nor weight are critical elements for safety. That role falls on design. Lovins has done some very good work on these issues.

As I reported Google has already accumulated over 100,000 miles of driver-free miles on ordinary American streets in ordinary traffic. They were involved in one accident. Their car was rear-ended by another drier while stopped at a traffic light.

Yes, computers do crash, but CPUs are cheap which allows for lots of redundancy. And computers don't get distracted, drunk or sleepy. Computers will react quicker when a bicyclist swerves or a child darts out into traffic. Computers do not get road rage.

The answer for dense city centers might well be slower, smaller rent-a-pods. Self-driven pods could position themselves along streets allowing people to jump in and out as desired, thus allowing cities to restrict entry of non-resident autos where parking was a problem.

There are a lots of ways the details can play out, but clearly we're going to make some major changes in personal transportation in the coming years.

A decade is a long time. Take a look back at what the transitions we've experienced in the past and how quickly they happened. Radio to TV, about 15 years. B^W to color, less than 10. Personal computers from the rare Apple II to common, 10. The internet, 10. Film to digital, 10. Rough estimates, but not all that rough.

There are a lot of possibilities.

BTW, that 10% who work nights (doubt it's that high) can plug in at work and charge at night if the grid really can't handle the extra load on hot afternoons.

220vac charge points should not be expensive to install in parking lots. Initially set them up with card swipes.

Down the road we should have direct talk between EVs and utility companies - "I'm car #98971234 and I want 5kWh of power over the next 3/5/8 hours. Bill it to my account." - type of communication.

Details, details, details… No rare earths means no electric cars, solar cells or wind mills, unless you buy them from China.

It also means no catalytic converters for autos and no fluid cracking catalysts for oil refineries.

"No rare earths means no electric cars"

Not necessarily ...

China's Rare-Earth Monopoly The rest of the world is trying to find alternatives to these crucial materials

Got a reference?

Was this a real study, or some "official" shooting his mouth off?

The Nissan Leaf on board charger pulls 3.3kWs.

Here are some other power draw numbers...

Clothes dryer 1.8 to 5.0kW

Dishwasher 1.2 to 2.5kW

Water heater 4.5 to 5.5kW

I wonder if 1 in 10 Germans decides to take a shower, dry their clothes or wash their dishes at the same time crashes their grid?

Does Germany have a ban on adding more clothes dryers, dishwashers, water heaters to their grid because they are at their tipping point?

(Personally, I smell FUD....)

1 in 10 may be too high (optimistic)

47.27 million cars in Germany ( http://answers.google.com/answers/threadview/id/440396.html also this German site http://www.destatis.de/jetspeed/portal/cms/ (2003 data)

And the German power grid (as of Dec 1 2010) can handle "up to" 1 million EV's (with qualifications).

http://www.businessgreen.com/bg/news/1929297/report-german-grid-handle-m...

I can't find the reference on the 10% of households. Guess he was being optimistic. Or maybe the Germans are like us & have 2 or 3 or 4 cars per household then the figure is in the ball park.

And I would expect the German Grid to be newer, smarter & less reliant on FF than the ageing maxed out USA Grid.

If the Germans can only handle 1 in 47 vehicles as EV's then it is beyond my comprehension how anyone can comprehend 85% of the USA car Fleet able to be charged off the USA Grid.

I'm not sure how you get from your Businessgreen link which states...

The report also expressed confidence the entire national fleet of electric vehicles could be powered by renewable sources, stating that the country's expected renewable electricity output by 2020 of approximately 100 billion kilowatt-hours would be 50 times larger than the amount needed to supply one million EVs.

to your statement that "if just 1 in 10 German households go to an Electric Car that will be enough to crash their grid".

Seems like you link says that by 2020 Germany would be able to charge 50,000,000 cars from renewable energy. That's all their cars, not 1/40th.

If you'd like to understand how we can charge an almost-all American EV fleet you can read this report from the Pacific Northwest National Lab.

http://www.ferc.gov/about/com-mem/wellinghoff/5-24-07-technical-analy-we...

If you'd like to read more try Googling for the Oak Ridge National Lab report which was published, I think, in 2008.

SUNNNV asked for data links for German EV charging. The links I provided are for like NOW ie 2010 & the German grid can only charge 1 in 47 of their cars as EV's. Yes the report says that "with conditions" by 2020 Germany MAY be able to completely charge an electric car fleet. Good luck to them, At least they are planning it.

Your link re an all American EV fleet is for Plug In Hybrids. These are not pure EV's & require much less electricity. This report also gives the 85% fleet conversion which was what your thread was based on. These are not EV's.

My vision remains unchanged ie we will NEVER see 100% of the current US car fleet convert to the same number of EV's. Can't & won't happen. Sometime soon our roads are going to get a lot less congested & we will be sharing them with electric scooters, public transport & bicycles.

Moving on to "Coal & Olduvai Gorge" now. Thanks for the discussion Bob. The transition has begun. One of us will be right. Cheers & goodbye.

There's little functional difference between EVs and PHEVs in terms of routine charging. Few people drive more than 30 miles per day with any regularity and that distance falls within the range of both technologies. When these reports were written it was assumed that we wouldn't have affordable, adequate range EVs this soon and that people would do their first 30 miles or so of driving on electricity.

Our current fleet turnover is somewhere around 12% per year. Very high fuel prices along with rapidly dropping EV prices could speed that up somewhat, especially for the 50% of the population who do the majority of all driving. Regardless it will take a number of years to switch the majority of the American fleet to electricity. We're already upgrading our grid for a number of reasons, there's not a great danger that the grid will not be ready.

However, I do agree that we will "NEVER see 100% of the current US car fleet convert". There will still be antique and collector cars on the road. Some people still ride horses....

KUDOS TO BOB WALLACE - !!! BRAVO, BRAVISSIMO !!

It sure is nice to see rational and holistic thinking backed up with extensive quantification.

Great report. How realistic is 7mbd at any point in the future. I have no basis to judge but it seems optimistic. Canada has been at this a lot longer and in a more favorable environment and they haven't come close to 7mbd.

7 MMBOD of Venezuelan production by 2021 is quite unlikely... review the list of companies and the location of the projects listed most prominently (the Junin blocks). They are all greenfield developments, essentially in the jungle so the infrastructure build out starts with road access, worker housing, utilities and so on... then examine the list of companies - the criteria for selection has largely been political or willingness to lend Venezuela large amounts of money - basically none with any material technical competence in these types of heavy oil projects.

So the scale of developments would vastly outrun the capacity of the country to absorb investment and there will be 'growing pains' as the new entrants learn how to produce these fields, which means delays.

Yes, 7 million bpd by 2021 is completely unrealistic for Venezuela. It is unrealistic even for Canada, and Canada has a much more stable investment climate than Venezuela.

I would guess that 2021, Venezuela will be lucky to still be producing as much oil as it does now, i.e. around 2.5 million bpd. In a worst-case scenario (i.e. political and economic collapse) it may not be exporting any oil at all by that time.

Political and economic collapses are not really rare occurrences for countries in South America.

The information on Venezuela's well known Orinoco oil is appreciated.

The question I have concerns viscosity of that oil and its difficulty in being removed from the ground and pumped. What is the viscosity and does this oil need to be heated when transferred to a storage tank or ship? This will affect the EROEI of the oil, besides the refining process having lower EROEI. Thanks.

My favorite web paper on the Orinoco: The Orinoco Heavy Oil Belt in Venezuela (Or Heavy Oil to the Rescue?) PDF. Do we still need to warn people about pdf files? Had to find a new link for that paper, too; stupid transient internet.

That is an interesting report, although some of the information is data from the mid 1990's and the report appears to be about 10 years old. One thing to mention is that the ongoing Orinoco projects listed in the report show Conoco-Phillips, Texaco (now part of Chevron) and Exxon Mobile as major players in the development of this heavy oil. These companies have all had their oil contracts voided and assets confiscated by Hugo Chavez's government and they are probably no longer involved in the Orinoco heavy oil. So, the planned run up to 7 million barrels per day may take a long time, maybe longer than Hugo's lifespan.

Chevron's actually back in as of Feb 2010, $15B and 34% of a new project with several asian companies holding substantially smaller stakes in the same project. I assume it is orinoco heavy oil but cannot find reference to that. Apparently they think Chavez has learned that he has to play rationally to get the income he needs from oil development. Was hoping some folks with more info would bring it up in this thread and give some color on what is going on down there, but unfortunately not.

Thanks for this paper.

I'm interested in the high sulphur content of the Venezuelan oil. Here in the UK this killed off attempts to burn orimulsion in power stations long ago.

The paper says the following about sulphur:

Where did the sulphur come from in the first place and why has Venezuelan oil got such a lot? - 3.5%-5.4% in Machete it says.

Oil was originlly algae. Sulphur is one of the 6 critical natural element for life (I won't go into the arsenic/phosfor thing here) so they come from the algae. My GUESS is they are stored in the surounding rock, and are sucked up by the bacteria when they need it.

OTOH, often when oil form, it migrate upwards to a higher strata above the source rock.

Is this true?

Wow. Not only are we buying everything we own from China but part of our refined energy supplies as well. OMG.

Still I suppose that's one way for China to claw back some of the USA debt it holds.

If all the Venezuelan treasury would get as a netback is just $5/bbl for their heavy crudes, then Chavez is dumber than I thought--far dumber. Guess that's what happens when you fire all the "experts" in the industry in a fit of "pique".

During my time doing upgrader studies in Venezuela, the calculated Value of the feed to a typical heavy oil upgrader, turned out to be about 60-70% percent of the value of Arabian Light (34 API).

I'm not saying it would be quite worth than now, but I would be astounded for it to be less than 50%, even with today's higher capital costs for upgraders. This means that, with AL at $100/bbl, 10 API heavy oil should be worth at least $50/bbl.

Only six billion for an plant to upgrade 400k bbl/d--I would say 2-4 times this cost. The heavy-walled, alloy reactors, compressors, high pressure/temperature pumps and exchangers required don't come cheap.

7 million bbl/d production with upgrading added over 15 years--impossible--not even half this could be built.

Sounds like a PR campaign for the local population.

Finally, as a person who has done a lot of these upgrading studies, any estimate that there will be a a net volume gain of ~40% of the original crude volume is absurd. Any practical process will have to reject something like 20 wt% of the original crude as useless high-sulfur, high-metals coke or asphaltenes that must be stored forever (or dumped into a deep ocean trench ;-]). Also 10% by weight would come off as fuel gas, including ethylene, that would be burned as process fuel, not recovered as a liquid.

The description of the refining process for upgrading heavy crude given in the article is both trivial and wrong, bordering on being worse than useless.

As you may remember, I used to put a caveat at the top of each Tech Talk that pointed out that I was trying to give a very brief description of technology to lay folk, and that in the process I would likely offend those who knew the real story, since I couldn't cover the complexity of the topic in a thousand words or so, and I would as a result oversimplify. Since my purpose here is a little different I had taken those out. The purpose here was to illustrate how a refinery gain might happen, and not the more detailed process of how the Venezuelan crude was actually upgraded.

Next week's topic will address (briefly) the actual loss in volume that happened at the 4 original upgraders in Venezuela, but not in the detail you have just given (my topic is such that it is almost an aside).

I always thought of "refinery gain" as just an artifact of the measurement used. Since the molecules are cracked and reformed into less dense products than the original feedstock, the volume increases. However, if you measure it by mass, the law of conservation of mass applies and mass in = mass out.

So, if you measured petroleum in tonnes, as the Europeans do, there would be no "refinery gain".

If hydrogen is added chemically from an external source, such as natural gas, then there would be a refinery gain in mass. However, the gains would be dwarfed by the losses as part of the product is burnt to provide energy in the process, and residual carbon and contaminants like sulphur are disposed as waste.

Yes, Venezuelan heavy oil experts are now making great progress in producing more heavy oil everywhere in the world except Venezuela. It's not as if there is a global surplus of experts in this field, and their international employment prospects are excellent. Outside of Venezuela.

I think Venezuela's plans to increase production are completely delusional. They will be hard-pressed to keep their production from continuing to decline, never mind getting it to increase. Their costs estimates are completely delusional, too. They estimate the cost of an upgrader at $6 billion, their Russian partners (who are the ones who would have to design it for them) use a figure closer to $20 billion.

And their Chinese "friends" are paying them $5/bbl for their heavy crude. With friends like that, the Venezuelans don't need any enemies.

In the Canadian industry we would recover the sulfur and sell it on the international market for fertilizer and chemicals, recover the coke and either sell it to the steel industry or burn it for fuel, recover the heavy metals and sell them wherever possible, possibly gasify the asphaltenes and use the syngas for fuel, and probably strip off the ethylene and sell it to the petrochemical industry.

I doubt the Venezuelans would be up to that kind of thing, though. They'd probably dump it into an ocean trench if they couldn't burn it.

They were trying to sell their extra-heavy oil without upgrading to power plants as Orimulsion as a substitute for coal, but they couldn't even make that work after they fired all their engineers. Orimulsion wasn't that popular in countries with air-pollution controls so most of their remaining sales are to China.

Everybody please forgive me for wandering a bit off topic, but the big picture is ALWAYS RELEVANT.

And poking fun at supposedly open minded people who are out to lunch outside their field is always lots of fun.:)

I have remarked here several times before that novels are to be, and are((by those who understand the arts) read as social commentary, rather than as blueprints or engineering drawings.

An author may put forth idiotic ideas on one page, and yet on the next page display an absolutely stunning understanding of other aspects of the nature of society and politics.

I refer doubters and religiously literal minded types to Ayn Rands description of the difficulties of a stereotypical Central or South American govt trying to operate a mining industry seized from its owners.

All that is necessary to make it a dead on caricature of Venezuela today is to change the names and dates.

It's in Atlas shrugged.

Here's an interesting paper on Ormulsion: A perspective on Venezuela's Extra Heavy and Bitumen hydrocarbons reserves | www.vcrisis.com. Found that while looking for a good map of the Orinoco projects, but you'd as well just search Google Images on your own. Also one of the first hits there is a map of the parties involved here which Dave has used in his follow up post, which conveys what a tangled web of companies are/were ganging up on the Orinoco.

My Orimulsion page suggests a five fold capacity increase by 2012 - it's a web version of a paper that was published June '05. That sure didn't happen. The EIA page doesn't even mention the stuff anymore, I notice.

Heavy,

Chavez may not be as dumb as you think, a few years ago there were deals going around where you bought Venezuelan oil for a heavy discount, and sold it on, with an agreed amount as a kick back to reportably Chavez's brother.

I would say they would be very rich brothers by now. I can imagine that China being a much bigger friend than my contacts and would get a much better deal than what I was offered.

No I did not make any deals, but it would have been a nice retirement package.

Ironically, Chinese sales of oil to the US would only increase the amount of US debt they hold. Only a few weeks ago were Chinese exporters permitted to hold USD offshore for as long as 30 days, prior to that it had to be returned to the central bank for conversion to maintain the RMB-Dollar peg much sooner. And once the central bank hads those dollars it is easiet to invest them in...US debt. So depending on how quickly Sinopec or whoever sold the oil turned over the cash in their foreign accounts for another purpose, it likely ended up there.

wot - I can't confirm the $5 but a couple of years ago Ghina cut a deal with Vz: China would build several tankers designed specifically to haul Vz heavy as well as several refineries in China to process it. The Chinese certainly didn't make such a commitment without some pricing guarentee. Maybe the $5 pricing is part of it. But also remember that China has purchased a lot of crude reserves in the ground around the globe...including VZ (I think). In many cases the lifting costs to China will be far below the price of oil. IOW they aren't buying oil and reselling...they are producing their share and selling it in the market place. So yes...there could be many instances where it's costing China $5 or so to produce a bbl of oil and then selling it for $90. That's called the oil biz and that's what I do for a living. This has been, and will continue to be IMHO, a very big difference between China and the USA: the Chinese govt is in the oil biz...the US govt is more a spectator than a player.

I'm wondering how the cost of the refined Venezuela product compares with refined product from the rest of the world? This seems like a pretty big question, given such a huge estimate on heavy oil reserves in Venezuela.

Thanks for the interesting report, a few questions come to mind.

Is the oil hot when it comes out of the ground? Is it shipped hot in the tanker? What % of the contained energy is consumed in processing and how does that compare to light oil. Can process energy be supplied by solar or fission to increase production significantly?

Oil comes out slightly below ambient temperature of the reservoir. Mainly the expansion of natural gas entrained cools the oil a bit, plus some small conductive losses.

Enough heat is left that, as I understand it (correct me if wrong), it keeps Prudhoe Bay oil flowing down to Valdez in the winter without auxiliary heating.

OTOH, API 9 oil is like asphalt. Solid at room temperatures and elevated temperatures or diluent are required to make it flow. An often substantial energy cost.

There has been some speculation about nukes in Canada to help process tar sands, but I know of none in Venezuela (although some talk of two VVERs for civil electrical demand). And not solar either.

During a wet year, surplus hydropower may supply electrical resistance heat seasonally. Basically just install more generators at major dams like Guri to generate from water that is spilled today.

Alan

The Venezuelan extra-heavy oil is from deeper reservoirs and therefore is hotter as it comes out of the ground than Canadian bitumen. As a result it flows a bit better.

Not a lot better though. Their recovery rates using what we Canadians would call "cold flow" is only on the order of 10% of oil in place. By contrast, the Canadian SAGD process often recovers 60% or more using steam stimulation. The SAGD process would probably work very well in Venezuela, too. I think the USGS high estimates of Venezuelan oil reserves must assume that they would use SAGD because I don't see how they would get that much oil out otherwise..

However, as was noted elsewhere, Chavez fired all of Venezuela's technical experts for political reasons, and you can't get SAGD to work without technical experts. Venezuela even has trouble getting cold flow to work, hence the fact that their oil production has been declining ever since Chavez took power.

What I wonder is how they even get such heavy oil out of the ground in the first place? Is it warmer and therefore more fluid down there? I can't imagine pumping that stuff through a pipe.

And regrding Venezuelaand hydro-power: Spring of 2010 showed us what happens when the country has a dty year. Not good at all.

Excess hydropower would be a seasonal (part-time) event even in wet years. Perhaps just produce heavy oil for 4 months/year and then only in wet years ?

Or use surplus electricity when available (low cost, the price of adding generators & transmission) and FF the rest of the time.

Alan

I haven't heard of any speculation you're talking about, but I wonder what the unexpected consequence would be - something like eternal underground fires, just like a coal seam fire but worse. Just burning and burning for tens of years, no way to stop it. The madness will only increase, as the world scrabbles for oil as it dwindles away ... like the blood diamond miners, scrabbling at the earth.

I think the speculation is about NUKElear power plants for heat, while steaming the tar out of the sand, not detonating warheads under ground.

Lesson; do not say "nuke" when you mean "nuclear power plant", it confuses people.

Unless you actuallymeant blowing a-bombs up there, wich seems like an unpresedented bad idea to me.

I may be in over my head here, but I have never heard of an underground oil fire.

Underground coal fires are quite common however, as it is possible for fresh air to reach coal seams thru various passageways in the soil and rock overlying the coal.

Apparently oil is usually too far underground, and the nature of the overburden is sufficiently different , for an underground oil fire to be possible.Certainly there are no access tunnels and ventilation shafts to act as accidental chimneys.

If I am wrong, I have already admitted that I am merely making educated guesses.;)

You are not wrong OFM. If there was a way for the air to flow down, there would be a way for the oil to flow up. This does not apply to coal, wich is a solid. And as the coal burns, the ground above it loses its suport and collapse - new cracks form. Such a fire can eat through the entire coal seem, end to end. You probably know about Centralia.

Well, Canada designs and builds its own nuclear reactors, and Venezuela doesn't.

The proposal to use nuclear power in the oil sands was just a proposal by the Canadian nuclear industry to provide process heat and power to the oil sands industry.

Unfortunately, from the standpoint of the nuclear reactor designers, it is cheaper and safer to use natural gas. There are vast reserves of natural gas in close proximity to the oil sands, so that is likely the direction the Canadian oil sands producers will continue to go in.

If a means of producing clean, cheap electricity could be developed in the area (over and above what is produced by the Guri hydroelectric complex), one could contemplate the use of resistance heaters used downhole, similar to Shell's proposal to recover shale oil in Colorado, Utah and Wyoming.

In the case of Venezuela, the heating wouldn't necessarily have to be intensive enough to crack the oil, only to reduce it's viscosity.

The most abundant source of clean energy in the area that could be used to produce electricity, is Convective Available Potential Energy, or CAPE, which is just residual solar energy.

The Atmospheric Vortex Engine is a device invented by Louis M. Michaud, P.Eng., which can harvest this energy and convert a portion of it into electricity. Solar energy could be collected and stored underground as warm water for use in heating the air when the amount of natural CAPE in the atmosphere is reduced (November through February) See

http://vortexengine.ca

One technical point that was missed in an excellent article - hydrogen is usually added to upgrade heavy oil and decrease the C-H ratio of the products.

Two C8H18 molecules require C16H36, not C16H34. So half the product absorbs one H2

However, two C6H12 and two C2H4 require one C16H32, so the other half releases one H2, but on a 25:25 ratio, not 38:12.

I cannot square the ratios or what I know from other sources - upgraders require lots of hydrogen, derived from natural gas, and/or they generate substantial amounts of petroleum coke (mainly carbon).

The fault may lie in the text you quoted.

Alan

SONOCHEMICAL TREATMENT OF FUEL COMPONENTS

A new refining method using tiny bubbles from cavitation has been developed to recover upgraded lighter-hydrocarbon liquid oil from an asphaltene containing oil material (tar sand, asphalt, heavy oil, shale oil, coal liquids, etc.)

The process involves dispersing particles of the carbonaceous material in an aqueous solution containing an inorganic base (NaOH, Na2iO,, etc.) and/or surfactant at ambient temperatures and pressures. With the aid of sonoication, the inorganic base and/or surfactant will combine with the polar components of the fuel to speed the recovery of upgraded oil material.

Inside the collapsing tiny sonobubbles in an aqueous solution of heavy oil and water, the instantaneous pressure at the center of a collapsing bubble has been estimated from theoretical considerations to be about 75,000 psi (5,100 atm).

Bubble collapse in liquids produces enormous amounts of energy from the conversion of kinetic energy of the liquid motion into heating the contents of the bubble. The compression of the bubbles during cavitation is more rapid than thermal transport, which generates a short-lived localized hot-spot.

Experimentally, cavitation thresholds up to 1000 atmospheres have been obtained. The actual cavitation temperature has been similarly measured as high as 1,000,000C … far hotter than the surface of the sun. The industry is therefore slowly being awakened to this powerfully unique manner and feasibility for large scale heavy oil sonorefining processes.

In this sonoprocess, the inorganic base and/or surfactant will combine with the polar components of the heavy fuel to speed the refining and recovery of upgraded thick oil material. The reaction process essentially removes the asphaltene fraction in the bituminous material by converting it to lighter fractions. In experiments, the process is highly efficient and the reaction time is measured in minutes for the samples examined. The reaction mechanisms are related to principles of sonochemistry as well as membrane mimetic chemistry.

Experimental results from a wide variety of fuel sources, coal liquids, tar sands, oil shale, asphalt and heavy oils all indicate that this new upgrading technology is feasible. The remaining development work leading to any useful industrial operations still need to be followed and completed.

Upon completion of development work, a second generation refining technology may be born with the minimum environmental impact since this new process can be conducted at room temperature and ambient atmosphere and all the processes can be made in modules with enclosed pathways.

P.S - In chemistry, the study of sonochemistry is concerned with understanding the effect of sonic waves and wave properties on chemical systems. The chemical effects of ultrasound do not come from a direct interaction with molecular species. Studies have shown that no direct coupling of the acoustic field with chemical species on a molecular level can account for sonochemistry or sonoluminescence. Instead, sonochemistry arises from acoustic cavitation: the formation, growth, and implosive collapse of bubbles in a liquid. This is demonstrated in phenomena such as ultrasound, sonication, sonoluminescence, and sonic cavitation.

Interesting !

I had wondered about that from years ago.

Alan

I have some trouble believing some of these "theoretical" claims, like the claim of 1,000,000 deg C temps. A temperature this high would cause disassociation of hydrocarbon molecules, but still allow a long chain H-C to break into smaller chains? Sounds doubtful to happen on a large scale. Also, the whole process is supposed to take place in an aqueous solution where the H-C have been mixed with water by addition of Na-OH (sodium hydroxide). At even 200 deg. C the water component would turn to steam and the aqueous solution would be no more. Where is the reference to the research facility and reports?

Furthermore, if the claims are true then what kind of energy input is required by this sonoication (supposed to be high frequency pressure waves?) to create the molecular H-C reorganization? If the EROEI is much less than 6 or 8, then conventional refining processes are more efficient.

"Where is the reference to the research facility and reports?"

Google the title of the post!

We have experimentally verified that the impacting pressures from the collapsing bubbles can be as high as a million psi, validating Al Ellis theoretical work on this subject. This was with an ASTM type vibrating horn apparatus, the more modern pressurized cavitation cells likely generate significantly higher pressures.

Yeah this approach is of interest across numerous branches of chemistry. Its effectively a new way to do chemistry.

Think about the advent of electrochemical processes for comparison. Its that fundamental. Its impossible to even guess just what might be done in Sonochemistry its the biggest fundamental change synthetic chemistry in 100 years. At least in my opinion, however lasers might be considered as competitors. Needless to say things like this simply don't happen often. Fundamentally new routes for synthesis are few and far between.

http://en.wikipedia.org/wiki/Sonochemistry

Now as far as scaling up to be a useful process method for fuels. I have my doubts I've not seen a single example of sonochemistry used for bulk chemical conversions. Its just not a high volume process. For synthesis or dealing with trace impurities its a godsend. As a bulk operation I dunno.

Found this.

http://www.brighthub.com/environment/renewable-energy/articles/7727.aspx It mentions 2000 Liters as industrial scale.

I don't follow the area rigorously but as I said I'm not aware of any sonochemistry done on a scale comparable to your base petrochemical plants much less fuel production. Given the nature of the reaction obviously your fundamental synthesis process's such as making plastic monomers perhaps ammonia synthesis etc all might be revolutionized.

Its not like people are not looking its fairly obvious what the potential is.

http://www.ncbi.nlm.nih.gov/pubmed/11602996

As far as silver bullets go well breakthroughs in sonochemistry are at the top of believable ones.

As I said I don't follow it religously just check from time to time so perhaps someone can give examples of sonochemistry working at the petrochemical plant level. I simply don't know of any such breakthrough.

Particularly compelling in this presentation (very technical, and very educational) is the insight into refinery gains. Most of my past experience has been on the construction end of the refinery... pipes, plumbing, pumps and the like. It is interesting to see how those are used, and why the particular components are what they are! Now, if I could understand the chemistry of it a bit better - but that is coming along.

That still does not speak to EROEI... I have a feeling that the TANSTAAFL principal is going to require payment for all that energy release. If so, where does that come from, and how much are we talking about? If not, what new law of physics are we applying here?

Craig

One technical point that was missed in an excellent article - hydrogen is usually added to upgrade heavy oil and decrease the C-H ratio of the products.