The Future of Cheap Energy: Underground Coal Gasification

Posted by Rembrandt on August 3, 2011 - 9:50am

Between 2000 and 2010 world energy use increased by 2.6 billion metric tons of oil equivalent per year. Of this increase, a little over half came from coal, and 72% of the coal increase came from China. The vast exploitation of Chinese coal, the cheapest source of electricity in the world, enabled western nations to benefit from both cheaper goods and outsourcing environmental issues, and for China to benefit from increasing goods exports and rising domestic consumption. Substantial doubt has risen, however, about the possible duration of this economic miracle since China now produces 48% of global coal and consumes around 3% of its reserves every year. How long will Chinese coal last?

The reserve limits for coal, for China as well as the rest of the world, can be postponed for several generations if the technology to gasify coal underground can be commercialized. Underground Coal Gasification (UCG) enables the access of deeper coal layers hitherto unavailable through conventional mining. Several modern pilot projects have been successfully completed in recent years and commercial projects are underway. This article gives an overview of present developments, the technology of the process, costs to produce electricity and liquid fuels from the syngas, and discusses environmental concerns. The article is informed by the excellent presentation given at the ASPO 9 presentation given by Marc Mostade, Technical Director of Clean Coal, and advisor to the UCG Association. The slides of that presentation can be downloaded here, and the video is available here.

The History and Present Underground Coal Gasification Activities

The technology of UCG is quite old as it was already developed in the 1920s and 1930s in the former Soviet Union. These activities resulted in several pilot plants and five industrial sized UCG plants in the 1960s, but efforts were abandoned as large natural gas discoveries made the process uneconomical. Today of these only the Yerostigaz plant owned by the Australian Linc Energy in Uzbekistan remains. Several trials were also undertaken in this period in Europe, documented in detail at the website of the UCG Association.

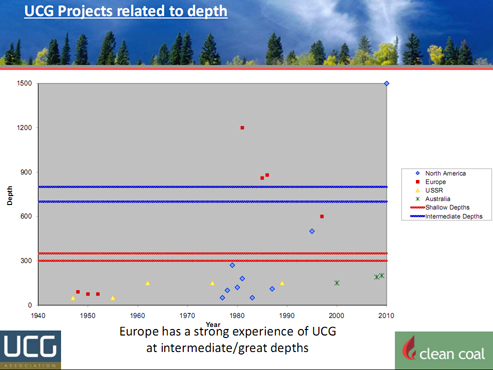

Figure 1 – An overview of UCG trials over time and their depth. Slide from a presentation given at the ASPO 9 Conference by Marc Mostade, Technical Director of Clean Coal, and advisor to the UCG Association.

The technology has gained substantial interest in the last ten years as fossil fuel prices increased and concerns over rising fossil fuel imports in Europe have grown. There are now over 30 pilot projects either operating or in the planning stage in more than 25 countries, including the U.K., Australia, the U.S., South Africa, and China. Of special importance are:

• The 1 km deep 5 MW coal pilot carried out by ENN in China that ran for 26 months. The Chinese government last month signed a 1.5 billion USD commercial partnership with the UK government for commercial development of the technology to be deployed in Inner Mongolia.

• The Swan Hills project supported by the government of Alberta in Canada that should start in 2012 and become operational in 2015. The 300 MW syngas electricity plant is intended to be equipped with a carbon capture and storage facility. The commercial project follows a trial project in the region which successfully gasified coal in-situ at 1.4 km’s of depth.

• The Chinchilla project in Australia operated by Linc Energy which since 2008 was combined with a Gas-to-Liquids plant to produce 20 barrels per day from the UCG syngas. The company is presently finalizing the engineering aspects to begin construction of a 20.000 barrels of oil equivalent per day UCG-GTL plant in 2012. Linc Energy claims it can commercially produce a barrel of oil equivalent at a price of 30 dollars.

The Technology of Underground Coal Gasification

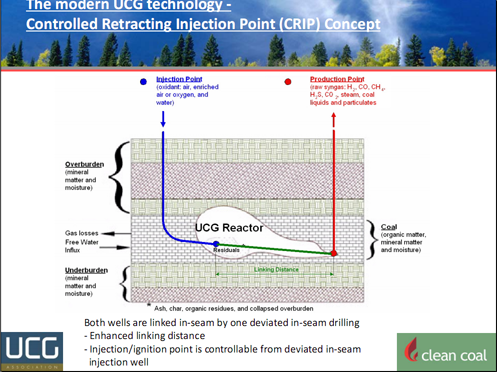

The latest standard of the technology incorporates horizontal directional drilling. To obtain the gas two wells are drilled - an injection well which brings steam and oxygen or air underground to ignite the coal seam and maintain the process, and a production well which pumps out the raw syngas. Previously vertical wells were used which are difficult to connect and limit control over the formation of the underground cavity as they cannot be steered. Today's horizontal wells can be connected using a magnetic target and detector positioned in the tip of the wells. The injection well is retracted along the borehole to gasify the coal which flows to the production well. The process is monitored above ground based on measurements of pressure, temperature, gas flow rates, gas composition at the wells. These are informed by simulations carried out to model the process. The control of the process comes from the injection of the oxidant, as too low or a halting of flows will stop the process.

The produced syngas varies in composition depending on the coal quality and for a standard horizontal two well retractable injection point technique (CRIP) includes hydrogen (11-35%), carbon monoxide (2-16%), methane (1-8%), carbon dioxide (12-28%) and other smaller components. Specific alteration of the gasification system can also result in a variance of the syngas composition. Yang et al. (2008) published about a field test to manufacture hydrogen using a two-stage gasification process with multiple steam injection points to raise the temperature. In the test syngas was succesfully produced with on average 50%+ hydrogen content with a range between 40% to 73%, and both CO and CH4 contents of over 6%.

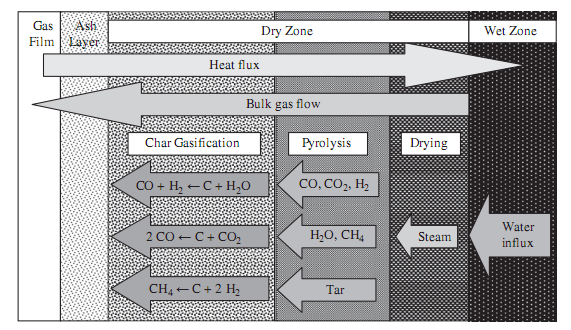

The process itself takes place in a coal seam normally saturated with water at hydrostatic pressure. There, several processes take place including evaporation, pyrolysis, steam gasification, CO2 gasification, and direct hydrogenation, depicted in figure 3. To prevent the “reactor” from collapsing the process needs to take place in modules at a specified length, width, and depth, shown in figure 3. Thereby sufficient structural support is created both via the rock between the modules and by the under burden and overburden, similar to a large extent as the pillars created in room-and-pillar wall mining. Since the reactor is dynamic and its physical conditions depend on the type of coal and surrounding rocks these determine the possible size of a “module”.

More information about the process can be found in a post written early 2010 by Heading Out at The Oil Drum.

The economics of Underground Coal Gasification

Several estimates have been made of the cost of an electricity plant based on UCG syngas. The main physical variables are the quality of the coal, depth and thickness of the coal seam, linking distance of the injection and production well, distance between the cavities, and sweep efficiency. The calculations based on theoretical and actual operations point to a cost range of 1 to 8 USD per GJ of produced syngas. The main cost variation is the usage of air or enriched oxygen for injection, the thickness of the coal seam, and the depth of drilling. The later two factors determine the number of wells that need to be drilled and their required length. Oxygen-blown gasification is preferred in case of adding Carbon Capture and Storage technology.

• The estimate of Marc Mostade of Clean Coal is a production cost of 2.5 to 4.5 USD per GJ of syngas, based on a 800 meter deep 500 MW thermal size UCG plant and a coal seam of 4 to 6 meters thickness at 800 meters of depth. The difference is caused by the usage of air-blown or oxygen-blown syngas. Information about the variables underlying his calculation can be found in his ASPO 9 presentation.

• Based on the Chinese ENN Pilot a total cost of 0.9 to 1.7 USD cents per cubic meters of syngas was documented, which translates into 1 to 1.9 USD per GJ of syngas assuming a higher heating value of 9 MJ/Nm3

• In 2007, GasTech carried out an analysis of costs based on coal in the US Powder River Basin using air-blown and oxygen-blown gasification. These were estimated at a cost of 1.5 to 2.4 USD per GJ of syngas.

• In 2011, the School of Public and Environmental Affairs of Indiana University calculated the production costs for air-fired syngas via UCG in the state of Indiana in the US at 4.6 to 7.7 USD per GJ of syngas for respectively syngas produced via enriched or air, assuming a coal seam thickness of 2 to 3.5 meters at 200 meters of depth or more.

These cost levels are when averaged equal to or below the present day price of natural gas in the US, EU and Asian markets, as shown in figure 4 below. The lower cost range is on par with today’s coal price on a GJ energy basis.

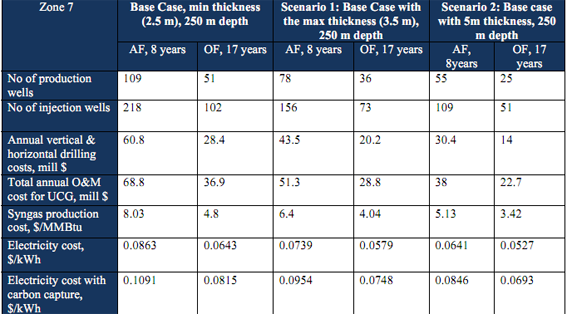

The costs of electricity produced with UCG based syngas were estimated in the study of the University of Indiana and shown to be highly sensitive to seam thickness as shown in Table 1 below. The cost for a seam with 5 meters thickness was estimated at 5.2 to 6.4 USD cents per kWh, and a seam with 2.5 meters thickness at 6.4 to 8.6 USD cents per kWh, the lower and higher value caused by air or oxygen enriched injection. The average cost of electricity production in 2010 in the state of Indiana according to the report was 5.7 cents per kWh, which at present makes exploitation of UCG in Indiana economically difficult since only seams up to 3.5 meters thick are available at depths greater than 200 meters.

Table 1 - Sensitivity analysis of UCG based electricity with and without carbon capture and storage for Indiana. Source: Indiana University

The potential expansion of coal reserves from UCG

There are only preliminary and hence incomplete studies available of how much coal would become available if UCG becomes a commercial technology. The World Energy Council (WEC) estimates that total coal reserves in 2010 amounted to 860 billion including anthracite, bituminous, sub-bituminous and lignite coal. In 2007 the WEC released a coal reserve estimate based on studies from a number of countries including USA, Russia, China, India, South Africa, Australia as well as Europe. These countries and regions combined were estimated to have a potential of 565 billion tonnes of coal accessible by UCG, 52% of today's coal reserves.

These estimates are highly dependent on a number of variables especially the maximum depth of the coal seams extracted using UCG and whether offshore coal is included. For instance, a GasTech study of the Powder River Basin of Wyoming and Montana included only coal reserves at a depth between 152 and 610 meters, and coal seams thicker than 10 meters. In the study it was assumed that deeper extraction below 610 meters and thinner seams would make the process uneconomical. In assuming a 65% recovery factor the study came to 200 billion tons of coal recoverable in the Powder River Basin, a substantially higher figure than the 138 billion estimated for the entire USA by the World Energy Council.

The figures become even more uncertain if also offshore coal comes into the picture which theoretically can be extracted easily with UCG. In the United Kingdom offshore UCG is taking a leap with five conditional licenses granted to Clean Coal Ltd by the UK coal authority in 2009 to investigate the potential for offshore UCG. These could turn into commercial operations by 2014/2015 giving access to 1 billion tons of offshore coal. At this stage the licenses are for relatively shallow offshore sites where the operating plant would be stationed just onshore and directional drilling takes place offshore, but there is no reason for deeper operations not to work unless the cost of the coal becomes too high. If UCG will prove to be economic in a couple of decades a large share of the estimated 3000 billion tons of coal that lie near Norway's coastline could be gasified. After their natural gas reserves are depleted Norway may still remain a gas exporting nation, but then via underground coal gasification.

The problem of carbon dioxide emissions

The major downside to UCG is that by prolonging the age of fossil fuels substantially it would cause human-caused emissions of carbon dioxide in the atmosphere to continue, unless measures are taken to capture greenhouse gasses emitted from UCG syngas combustion. The costs of carbon capture and storage (CCS) from the UCG syngas are expected to be comparable to that of CCS of above ground gasification of coal in an integrated gasification combined cycle or IGCC power plant (Friedmann et al. 2009).

In an earlier post I discussed the IPCC special report on carbon dioxide capture and storage which estimated an additional 0.9 to 2.2 USD cents per kWh of electricity to install CCS at such an IGCC plant. This cost range is similar to an estimate of the University of Indiana that resulted in a cost range of 1.7 to 2.2 USD cents per kWh to add carbon capture and storage to a power plant run with UCG syngas, as shown in table 1 above. The additional costs are plausibly affordable for coal sites with a high seam thickness in comparison to non-CCS based gas power plants, especially in markets with high natural gas electricity costs such as Europe. Therefore, adopting CCS would mean a restriction to use UCG at the most economic sites, reducing but not eliminating the potential adoption of Underground Coal Gasification.

Environmental concerns – groundwater contamination

In contrast to conventional mining, there is no discharge of tailings and sulfur emissions are much reduced as well as the discharge of ash, mercury, and tar because there is no handling of coal involved. There is one important problem that UCG has in comparison to conventional coal mining, which is the hazard of groundwater contamination. Due to a lack of sufficiently high temperatures across the underground cavity, there will be formation of carcinogenic coal tar. In above ground gasification of coal, the temperature can be controlled in the reactor and is kept at high temperatures uniformly to prevent coal tar formation. If the underground cavity pressure is too high it can force some of the syngas and tar into the surrounding formation, thereby contaminating the groundwater. In case of a pilot in Hoe Creek north-eastern Wyoming, groundwater contamination occurred due to the collapse of the cavity roof in which water from a nearby freshwater aquifer mixed with the tar and rock (Bell et al. 2011). Possible suggested solutions are to select coal seams not hydrogeologically connected to surface waters or wells, pumping contaminated water out for surface disposal, re-mediation after gasification, and/or lowering of the gasification pressure were possible:

“Water contamination issues can be reduced by gasifying at slightly less than the hydrostatic pressure. Water will tend to flow into the gasification cavity, flushing flush coal tars into the gasification zone and towards the production well. This strategy has been successfully demonstrated at the Chinchilla test burn in Australia. A low seep rate will provide steam to help gasify the coal. If the pressure is too low, the water flow rate will be excessive; and the heat required to evaporate this excess water will reduce the thermal efficiency of gasification (Bell et al. 2011, p. 107).”

Unfortunately, such measures cannot fully remove all water contamination because when the process is finished, a cavity will fill up with ground water which mixes with remaining tar. This is not that much of a problem as it is a contained spill according to Bell et al (2011) because the unburned coal can absorb compounds from contaminated water and inorganic rocks will buffer inorganic contamination via ion-exchange. That the problem is taken seriously can be understood from problems with the Cougar Energy project in Australia. The project was permanently suspended by the Department of Environment and Resource Management of Queensland in 2011. In March 2010, a well blocked and ruptured at the Cougar site, resulting in the release of chemicals. By May 2010 elevated benzene and toluene levels were measured in two of the Cougar Energy groundwater measurement holes. Platts reports that this amounted to 2 parts per billion of benzene. In a response Cougar has stated it has since tested over 300 water samples which did not show any detection which exceeded drinking water guidelines. Two other UCG companies with projects in Australia, Carbon Energy and Linc Energy, are also under close inspection of the Queensland State Government. Linc Energy was found to fully comply with environmental regulations but Carbon has been charged for two incidents. One of the Carbon Energy incidents related to the spill of process water to a creek; the other related to unauthorized use of process water for irrigation. Neither relate to direct contamination of groundwater, but illustrate the need for government to scrutinize companies on their environmental standards.

Conclusions

The technology of underground coal gasification has been technically proven to work at numerous locations and different depths ranging from several hundred metres up to 1.4 km of depth. So far the economics look promising with costs competitive to natural gas markets and possibly also coal markets. Furthermore, a combination with gas-to-liquids technology would enable the production of fairly cheap synthetic diesel. These possibilities together with the potential to unlock vast new coal seams unavailable via conventional mining make UCG an important technology that could substantially extend the era of cheap energy. There are justified concerns over groundwater contamination that need continuous attention of both companies and regulators. Finally, the technology does not solve the issue of carbon dioxide emissions as it provides only a marginal improvement over standard coal mining, unless implemented together with carbon capture and storage technologies.

References

Bell, D., Towler, B.F., Fan, M., 2011. Coal Gasification and its Applications. Elsevier

Friedmann et al., 2009. Prospects for underground coal gasification in carbon-costrained world. Energy Procedia 1. p. 4551-4557.

Yang et al., 2008. Field test of large-scale hydrogen manufacturing from underground coal gasification (UCG). International Journal of Hydrogen Energy. 33. p. 1275-1285.

This technology is just another way of kicking the can down the road. The potential environmental downside is horrendous as well. Let's get on with powerdown and adaptation instead.

Yea, nice report on a monstrously bad idea. It's morbidly fascinating to watch how unintelligently and unimaginitively our species is responding to resource decline.

This UCG stuff is like a terminal lung cancer patient cleverly figuring out how to smoke through a hole in their trachea. Tragic, sad, and pathetic.

Well said! I had much the same reaction, also quite sad to see TOD going downhill like this.

No need to read the rest of the article, that statement alone is enough to completely discredit the coal industry shill writing it. Dr. Albert Bartlett would be shaking his head in dis-belief right now. How can people be so numerically illiterate?

Cheers,

Jerry

@Jerry McManus

As author of the article I have not affiliation whatsoever with the coal industry, your comment is ill mannered and abusive. In addition your reference to numerical illiteracy it is flawed, a calculation of exponential growth as to Albert Bartlett's calculations would show that the quote of mine you cite is correct, given the coal growth rate we have witnessed in the last ten years and the potential reserves that can be added due to UCG. If you would read the article that would become clear.

Non-related is the moral issue that mamba and dan commented on earlier, which is a different debate altogether on whether we can afford to burn and develop the coal in terms of carbon dioxide emissions. My perception is that we can given the relatively cheap cost of UCG versus other possibilities when including carbon capture and storage. There is no reason hence to discount out the technology a-priori. More importantly, given the cheap cost it is likely that this will be developed any case since that's how our economy works, and hence ignoring it a-priori will prove to be stupid ignorance.

I'm interested in discussion on any perspective but prefer some considerate thoughts. I hope that's a general wish for other folks in this venue of discussion and that you can keep that in mind.

Dan and Mamba are clearly ignorant. They do not understand the most basic of economic principles: cost. The tables have been turned. Dan and Mamba accused Jerry of foolishly not addressing consequences; Jerry now accuses Dan and Mamba of not understanding the basic economic principle of our society: Cost. I beg to differ. I suspect Dan and Mamba are fully aware of how choices are being made.

While Dan and Mamba did not spell out the environmental consequences—other than to say they were horrendous--, I think their argument deserves a hearing. Otherwise, we all should rejoice in love canals—they seemed quite profitable at the outset. Maybe there are costs Jerry should really consider. Maybe, just maybe, we will be foolish if we consider only short-term costs?

My comment wasn't ill-mannered or abusive, but it was a strong statement opposed to doing this. It was deleted. That deletion, if intentional, would seem to be a repudiation of my position and a tacit endorsement by the author or moderator for doing it.

If I had said this practice was the best idea since sliced bread, one wonders if it would have been deleted.

Hi Greenish,

I'm sorry to say I missed your comment.

I'm sure it shouldn't have been deleted, considering your track record here as an old timer.

Hi Mac.

Don't be too sure. It was a post saying "this is a bad idea".

The future habitability the earth for humans and currently extant large species may depend on how much CO2 we inject into the air before we stop being able to extract and distribute flammables at current scales; say the next hundred years or so.

That, in turn, will be determined by how much fossil carbon will remain sequestered and out of reach. Ergo, figuring a way and a rationale to get at deep coal beds economically is bad news for the invisible trillion-or-so human lives which might otherwise exist in the future.

It isn't fashionable to treat those people as real, since any fool can see that the odds of their being born goes down by the day.

I reckon it comes off as "environmentalist" even though that word has been rejiggered as much as "conservative" and I no longer use it; by any reasonable definitions I'm both.

I think it's legitimate to consider the people now alive, and their kids and grandkids; which is what most people do. I also consider subsequent generations. It's valid to hope that the people we know don't have terrible lives. But it's also valid, I'd say, to think about the people who live after them, the earth's carrying capacity and their life quality.

There's financial "economics", and there's the off-books cost of turning the future to a fetid hellscape with anoxic, acidic oceans, leading to actual existential risk for our species versus a few centuries of dieoff which are already baked into the cake.

This site is, or was, about "energy and our future", not just energy. I think I see it up there on the masthead still. I was referring to the "our future" part of that, and noting that it would be nice to have one. I just consider "our future" to be that of our descendants for the next million-plus years, not just the years until our kids retire.

If such a forum allows people to say it's a good idea, one would think it would be allowable to say it's a bad idea, which I did. I respect your perspective and realize that you see both sides of it, I'm just using this reply to restate my position.

Burning more & deeper stuff is clearly a bad idea for the future, making the ultimate carrying capacity lower. It may be true that there's nothing we can do to stop it, but that's a pretty poor standard by which to assess a course of action. I think it would be nice to have a planet that might support 1-2 billion humans instead of 10 million humans after the crash/dieoff.

I have a geology degree and used it working in the oil industry, among other things; if I'm an enviro I've come by it honestly. 60 years of life, study and reflection have led to my current opinions. As it happens, I think the fossil fuel thing has been overdone; and that a hypothetical self-aware species would stop looking for new ways to de-sequester carbon.

best

Take one ton of politically-mandatory energy demand. Add one dash anti-nuclearism. Spread tragically over one commons. Yields: disaster.

Censorship abuse appears to be common on TOD, and is worse because it destroys every trace visible not just to the public at large, but to the author of the censored material as well. Only the editor(s) have access to censored material. I have been complaining bitterly about this for years, and I have still not received some of my own writings back.

The worst thing seems to be that the Powers That Be have authorized censorship for "tone". Anyone with experience in on-line forums knows that it is nearly impossible to infer tone accurately from text. This leads to the use of censorshp in a way which is inherently capricious and abusive.

Yet nothing presents you from saving the material before you post, either. I have rarely seen anything of high value deleted, though in a few cases high noise exchanges with nuggets of gold may have disappeared. Signal to noise is exceptionally high here, though, and that's a good thing. Surely deletion rates of high-value info is a fraction of a percent?

Only a few people seem to chafe under the rules here, and I wonder why do you stay or post if it is so onerous?

When one posts reference- and analysis-heavy replies to a site which claims to hold to the Creative Commons license, one does not expect it to just disappear. I know I didn't. Saving things individually is also very tedious.

A large number of comments, including lots of references and calculations representing hours and hours of work, disappeared from a series of threads a couple of years ago. When I went back to try to incorporate that work into a rebuttal series, I couldn't find it. I thought I was just losing it in the mass of comments, spread across multiple pages per keypost.

I was wrong. That work was, for all intents and purposes, stolen from me. It was gone even from my own comment history, as if it had never existed. I have received neither an explanation nor a return of my work to me. I am still outraged by this.

You've missed the ones who left in disgust. I'm here because I'm hard-headed.

It seems as if a few good folks here are suffering from the delusion that this site is primarily about environmentalism;this is patently not so.

This is an energy site, dedicated to educating it's readership about all things energy and ff energy in particular. and it is to be expected that here you will find the news and the facts in respect to whatever is going on in the energy field.

I suppose these well meaning (?) individuals would like to shoot any messenger arriving with bad news.

That is not a recipe for progress on any front.

I personally am ambivalent about this technology, considering the risks;but it might be the means by which we survive and prevent the starvation of hundreds of millions of people;it might allow us to avoid an energy based WWIII.

Just how big an ecological disaster might WWIII be?

Some environmentalists remind me of preachers and Jesus freaks-i know a LOT all three types.

Well, yea -- it isn't an 'environmental' site, but to separate our quest for energy from its effects on the ecosphere is a very deadly form of autism.

Hi Dan,

In principle, I agree wholeheartedly with your comment.

It's just that some of us seem to think that we should have our ears and eyes and pure little hearts sheltered from any news that does not suit thier environmental agenda-and incidentally, I am pretty much in agreement wioth the typical environmentalist's agenda.

I just like to see a little hard headed common sense mixed in with any and all news and reactions to it......

Wishing will not make coal go away-fighting coal is not likely to make it go away either, but a good fight might soften some of the harsh consequences of burning it.

The most successful soldier or or athlete -or environmentalist- is one possessed of a sound and detailed knowledge his opponent.

Shielding our delicate little ears from news of likely developments in the coal industry is sort of like shielding children from hearing dirty words.

We aren't children, we should be able to handle dirty words and bad news in a level headed and rational way.

We ain't ostriches either-at least, not very many of us.;-)

Too many people can't think about systems as systems, or manage to work unintended consequences into their mental models.

I think this comes out most clearly in thinking about nuclear power. Soi-disant environmentalists tend to be strongly against it, but fail to consider the consequences if their favored alternatives do not yield enough energy soon enough at affordable prices. The results will include continued operation of the fossil-fired plants which are (so many environmentalists claim) the biggest threats to the environment world-wide. (The nuclear threat to people is different; Chernobyl is a wildlife haven, not a desert.)

James Lovelock and Patrick Moore have seen the connections, but the global organizations and their membership remain locked in simplistic, self-defeating thinking.

It's very hard to think about everything at once.

For instance, everybody seems to have forgotten about the threat of nuclear war, even though a nuclear winter wouldn't do much good for us and our environment either. Nuclear power's connection to weapons, and their proliferation, is a significant factor: think Iran.

I think disastrous climate change is rather more likely than disastrous nuclear weapons use, but I still have a hard time getting enthusiastic about nuclear power.

As far as wind and solar power go, I think there's little doubt they'd work well. Similarly, it sounds very likely that UCG with CCS would work just fine.

Will we choose wind/solar, or UCG with CCS, instead of plain old dirty coal?? I think we will to some extent, but I'm not optimistic that we'll do so nearly as quickly and strongly as we should.

Choices...

Iran is not using nuclear power reactors to make weapons. Iran is using uranium enrichment; spent LWR fuel is essentially useless to proliferators, as the Pu isotope ratio is all wrong for weapons. If Iran bought its LWR fuel from Europe or Russia, there would be neglible risk of Iran developing nuclear weaponry.

True. And yet, they're not doing so...

If you want to argue that the NNPT has some glaring defects, I will violently agree with you.

do you foresee any chance of fixing them?

Not my bailiwick.

Where do we have a carbon capture and storage facility that does not leak? Where do we have one of a size and scope that this article suggests that does not leak?

Lots of food for thought here.

It may be that this technology, if it proves to be scalable at a fast enough rate, will extend the so far successful track record of the techno copians and conventional economists who believe that new tech and ingenuity will always save us.

This might prove to be true for several more decades-there is a hxxl of a lot of deep coal out there, and I have no doubt that an industrial economy can run on coal to liquids motor fuels.There is plenty of room for fuel efficiency improvements and lifestyle changes to compensate for the financial costs.

I forsee two major problems however;the first one is that the technology- meaning both underground gasification and ctl - won't scale fast enough to prevent an economic collapse due to the effects of oil depletion and the ELM.

The second one is the one that will put a REAL hurt on us-if it works on the grand scale, ucg will simply allow us to continue bau soo that the coming overshoot crash will be even more violent when it dies arrive.

Of course overshoot includes all the potential and actual ecological and climatic problems associated with ff in general and coal in particular.

So the risk is that we enact the technological fix either too fast, thus perpetuating BAU, or too slow, thus inducing an economic and probably a technological collapse. While I agree with this, I wonder what the chance is that we will get it just right ??. Enough of an impact to induce some long range thinking but not so miuch as to impede our capacity to develop and apply technical fixes.

There are other risks involved, but yes as I see it you have basically got it in a nutshell.

I fear the odds of us getting it "just right " are rather slim;in the continiuum of possibilities, there are likely many, many times as many opportunities to get it wrong as there are to get it right.

However, as Yogi sez, predictin' is hard, specially the future.

There is some possibility that we might avoid a PERMANENT collapse and merely suffer a major dieoff due to resource depletion, pollution , and climate change.

That possibility lies in the fast falling birth rate in most of the world- outright collapse could if we are lucky be confined to the poorer and worst overpopulated areas with the least potential for food self sufficiency.

I am a firm believer in an overshoot collapse, but I don't expect very many people to starve in for instance North America, unless we suffer an outright failure of our govt.I fear anarchy is our potentially biggest problem here, barring WWIII.

Things are going to be very very grim in lots of places though-let's just hope we don't have to fight WWIII in a nuclear armed world.

I don't have any ideas what the odds are, but a hundred years from now there may very well be a billion or two billion people who are living very well and sustainably because they choose to limit thier family size to replacement level or less. Prosperous people have proven themselves to be in favor of small families all thru Western society, and I foresee this trend spreading with prosperity.

My own people , and my part of the country, are mostly evangelical Baptist fundamentalists-the ones who aren't drunks , lawyers, and so forth- and our birth rate is well below replacement- once we get over the demographic hump, our numbers will begin falling fast.Preachers aren't nearly so influential as those who are opposed to religion make them out to be.

Of course there will almost certainly be areas where Malthusian overshoot is occuring and recurring , as it is today in drought stricken Africa.

OFM

After being on a journey of discovery for more than 5 years now, I have come to the conclusion that the real problem we face is not resource depletion or polution or economics. The real problem is population. It is good to see that others get it.

I agree with you that the opportunity to get the timing wrong seems much higher than the opportunity to get it right. I believe that this will act over time to de-globalise the world community. There will be places that manage to achieve an orderly transition to a sustaiable population level. But I fear these will be relatively few. At this time it is not possible to identify a single world government that is actively driving such a transition even though it is likely that the forced transition is only a few decades, maybe only a few years away. Maybe Norway is trending in the right direction.

And then there is the danger that those societies that do manage their own transition will become engulfed in the anarchy that spreads from those that don't.

So then this translates into the day to day problems we face. There will be negative environmental impacts from technologies such as CSG, UCG and nuclear power. But will the extra time bought using these technologies provide for a more widespread transition to lower population and the chance that at least some of the world makes it through. Or will we use the extra time to just gain more momentum before we hit the wall ?

Before natural gas became available in the UK 'town gas;' was produced and distributed as a domestic gas supply. This was

gassified coal, presumably similar to UGC in chemical composition. It was incompatible with natural gas (mostly methane) as a domestic gas source, and the transition in the UK involved modifying every gas burner in the country. It is also toxic, and was a convenient method of suicide for decades.

I think UGC will only ever be used for electricity generation or GTL. We will never us it for domestic supply again.

Does the variable chemical composition of the gas produced cause problems designing burners for it in electricity production?

I echo the worries that it will only accelerate climate change.

Its quite possible to gasify coal to methane rather than CO. If we ever went back to gas from coal for domestic use, thats how it would be done. Either the syngas from UCG would be used to manufacture methane, or the coal would be mined and gasified on the surface.

Coal isn't gasified to methane (there's always some CH4 in the product) so much as the stream is "methanated": CO + 3H2 -> CH4 + H2O

There's a considerable energy loss in methanation, so it's best to avoid unless necessary.

Ralph

I have been involved in some detail in one of the UCG operations in Australia including trying to configure gas turbines to run on the syngas.

While the low calorific value of the gas does necessitate modifications to the conventional gas turbine burners, there is no doubt it can readily be utilised in this way. The basic design of the turbine is standard off the shelf with special burners fited. The low calorie gas burners have been in use for a number of years in the steel making industry where low calorie gas is extracted from both the coking and blast furnace processes.

It is also possible to utilise the gas turbine compressor to provide some or all of the large quantity of high pressure air required for the underground injection. Unfortunately, conventional turbines are not designed for such large extraction of the gas flow, however, I expect that as this process develops over time, that new versions of turbines will be developed that optimise this idea.

It potentially both a savior, and a disaster. The former because it may allow us to more gracefully over several decades transition away fro FF. The later, because without the proper political controls, it will always be cheaper to skip CCS. Without CCS it will create severe problems for hundreds of years. And if the economics is marginal, CCS will be jetisoned in order to make it competitive with NG. So how do we insure that if it is developed (hard to stop) it will be used with CCS?

I agree, it is primarily for industrial use at or near the production site. Mostly electricty gen, although perhaps cogen and desalination, as well as GTL.

The main difference between 30 years ago, when I reviewed UGC while working on surface gasifiers, seems to be that the sorts of seams being used now, are the sort that it was assumed would be mined. Why are such thick and shallow seams now regarded as being better gasified than mined?

Could you expand on how steam is used to increase temperature in the Yang process? Steam is the normal method (the reaction is endothermic) to reduce temperature in gasifiers and I am puzzled about how they can get the opposite to happen.

hot - Just a guess but maybe two factors. Since the process involves drilling wells that cost is proportional to depth. Perhaps a more important tech problem: drilling thru coal seams is actually fairly difficult. They wash out easily and you tend to lose your drilling mud. Most coal rich regions have multiple layers in the section. Trying to drill down to deeper non-minable coal seams might be impractical. I also suspect the difficulty/costs/environmental issues with surface mining and the dangers/expense of deep mining could be aanother factor.

From the next comment down, looks like its actually the type of coal. I am not convinced that lignite is actually the best fuel, but gasification is a good way of processing poor quality fuels so I can see how large, shallow lignite seams become the preferred prospect over higher quality but thin and deep seams.

Hot Air,

You seem to have a good handle of coal gasification, matbe you can help.

The wording that is used for the type of coal that is most suited, is "reactive" and apparently Lignite falls into this category, maybe you can educate me in what other types of coal would be considered "reactive".

As for seam thickness, it appears 2m to 10m ie approx 6ft to 30ft thick. Ash content up to 40% is also not a problem.

Unless you are trying to do some pretty fancy chemistry, more reactivity is always good.

Coals tend to have reactivities opposite to their fuel content. Lignites will tend to be more reactive than bitumenous coal and anthracite will tend to be the least reactive. Ash tends to have a catalytic effect, but the big advantage for underground rather than surface is that you don't have to find somewhere to dump the ash after gasifying the coal.

With a low quality fuel you have to run the gasification at low temperature, because the fuel wont support higher temperatures, so you need it to be reactive. With a high quality fuel, it can support higher temperature operation, so it doesn't need to be so reactive.

Lignite makes sense, and with a lignite target, it has to be reactive. If you happened to have a lignite that was rather less reactive than typical, it would be bad.

@hot air

>Why are such thick and shallow seams now regarded as being better gasified than mined?<

It is unclear to me what you mean with this statement. To my understanding the idea is to use UCG where conventional mining is not applicable. In case of too deep coal, offshore areas, or where it is not feasible due too environmental/population restrictions.

>Could you expand on how steam is used to increase temperature in the Yang process?<

Here are the details from the paper, if you want to know the reactions and more details you can purchase the paper:

"The two-stage UCG is an underground gasification method of supplying air and steam stage-by-stage. In the first stage,

the air is injected. The combustion (reactions (1), (2), and (3)) in the coal seam is initiated, producing a lot of heat, which is stored in the coal seam and results in the temperature increase in the gasifier in a stepwise way and forms an ideal temperature field, which, in turn, produces air gas containing a large amount of N2.

In the second stage, the steam is injected. The decomposition reaction (5) occurs [15] between the steam and the

incandescent coal seam, producing water gas with a high content of H2. Because the decomposition reaction is an

endothermic reaction, the temperature in the gasifier declines. When the temperature in the gasifier declines to a

sufficient degree, the gasification agent is changed to air, and this is repeated again and again.

The two-stage underground gasification technique is dependent on the size of the gasifier. If the gasifier is small, and

the heat accumulated is not sufficient in the first stage, then, when the steam is injected, the heat will be consumed too quickly, lowering the temperature in the gasifier, and rendering it impossible for the second stage to last long enough to sustain hydrogen production. Therefore, the gasifier in the Woniushan Mine provides good conditions for the use of two-phase UCG to produce hydrogen. (yang et al. 2008 p. 1276)"

The point on depth is already answered. It has to do with what people regard as "coal". Being relatively advanced in years, and not having worked on coal for several decades, I tend to think of "coal" as that solid black stuff which you could buy in sacks from the coal merchant and has now been mostly mined and burnt. When coal is mentioned the soggy brown stuff does not spring to my mind. There are indeed thick deposits of the soggy brown stuff not far underground, which would certainly have been mined if they were the shiny black stuff, but being soggy and brown are still there to be gasified.

The soggy brown stuff near the surface is a reasonable gasification target. I just don't naturally think of that as "coal", but once "lignite" is mentioned, it makes sense to me.

The Yang process looks pretty straightforward too. With the extra context I think its just a clumsy translation from the Chinese.

To me this is a major new source of available energy, it uses a current stranded resource (deep coal), it has minimal disruption to the country side, it controls aquifers much more successfully than Coal Bed Methane, or Coal Seam Gas (name depending on where you live) and recovers 20 time the amount of energy than CBM/CSG from the same coal.

As the CO2 is easily recovered at source it can also be easily disposed of down hole. It has been found that a depleted cavity can actually absorbed more CO2 than it produced while under production. Therefore each depleted cavity will become an available CO2 sink for other forms of carbon capture.

The greatest advantage of the easily captured CO2 is EOR for depleted oilfields. There are numerous situations where UCG usable coal is in the same area as old traditional oilfields. Both Linc Energy and Carbon Energy, both Australian UCG companies are starting operations in the Powder River Basin with this purpose in mind. It has been stated that CO2 from UCG is the cheapest source of CO2 available.

The best coal for UCG is actually Lignite (Brown Coal), ie the cheap stuff nobody else wants to use, and quite often nobody has looked for or worried able it unless it is very shallow and thick. There actually are deep reserves of brown coal along the TX & LA onshore coast. Nobody has been interested until now, but if this resource could be converted to CO2 and used for EOR in all those TX & LA depleted fields, what would be the result. Might not turn the world around but should be a profit for someone.

The syn gas produced in usually high in CO and H2, making it idea for GTL to ultra clean diesel, as well making N2 fertilizers. The excess H2 can be converted to electricity by fuel cells at 50% efficiency or just burn it in a CCGT for a simple guaranteed result.

I do feel we will see more UCG in the near future.

Declaration: I do own some UGC companies. (At least I put my money where my mouth is)

pusher - Interesting. The Lower Colorado River Authority has a couple of lignite burning plants just a couple of hours west of Houston. Don't know much about those reserves but the plants (built on top of the lignite field) have been running for a couple of decades. And the lignite sits right in the middle of billions of bbls of residual oil. And most of those wells have been abandoned.

I might have to think about getting into UCG and use the CO2 for EOR. Win/win so to speak.

Rockman,

That is what I thought, when Linc came up with the idea in Wyoming, so I bought a few more shares. BTW Linc actually bought the GasTech leases that are quoted in the post above.

They are also on the hunt in the US to repeat the idea in other states.

The minimum depth of the coal seam needs to >150m covered by an impermeable layer of rock, there were some failures in the 70's when it was tried at a too shallow depth.

http://www.lincenergy.com/information_sheets.php?series=2

The max depth is > 1000m where Swan Hill Canada is currently doing a project at 1400m, though I believe this ups the cost due to the higher HSP and the pumps required to over come it.

http://swanhills-synfuels.com/projects/demonstration-project/

You say that there is minimal disruption to the countryside but what is the risk of getting collapses as coal is burnt out?

NAOM

This question was answered below - thanks HotAir

NAOM,

http://www.lincenergy.com/data/info_sheets/e7-fact.pdf

Here is a ref from the Linc web site. The Linc web site has a lot of information on how UCG works. It is worth a look around.

Thanks, that explains it quite clearly.

NAOM

What happens to the sulpher and other contaminants in the coal? It was always the boast of the nuclear industry that they put less radioactivity into the atmosphere than the same amount of electricity production from coal.

Does this process allow the sulphur and heavy metal in the coal to be extracted efficiently?

Ralph,

If the syngas is going to be used for GTL, then the Sulfur must be removed before it enters the FT process.

http://www.lincenergy.com/data/info_sheets/g2-fact.pdf

Sulphur comes out as H2S, which has to be extracted from the gas, converted to sulphur and disposed of. It tends to be a lot easier to extract H2S from the gas prior to combustion than it is to scrub SOx from the flue afterwards, so gasification should produce less sulphur emissions.

H2S is recovered (along with CO2) in amine-type acid-gas scrubbers. It can be used with CO2 for EOR or re-injected as fuel for gasification.

I heard a rumor of using Microwave technology for subsurface coal gasification from coal. The idea is to place a long horizontal antenna and use the coal bed as a natural wave guide. Don't

have more details.

I question how cheap this energy really is. At the end of the day, this will still be an expensive source of energy - approx. 6 to 10 cents/kWh including CCS according to the range of estimates above. Compare this cost to alternatives, where, unlike fossil fuel sources, fuel is typically free. How much has been spent on R&D for this technology? R&D spent on wind, solar, energy storage and nuclear (where fuel cost is minimal compared to upfront capital costs) has the potential to reduce levelized energy costs well below 6 to 10 cents/kWh as efficiency improves and capital costs fall. UGC, on the other hand, will never get cheaper as it will always entail ongoing expenses to produce fuel working deep underground, which is by definition expensive. With limited resources to spend on R&D, is pursuing UGC really the best allocation? Or is it an attempt by a fossilized industry to get us all to stick our heads in the sand - literally?

@RefuelEnergy

In the present the costs of all renewable energy sources is substantially above 6 cents/kWh, except onshore wind on land in some locations. Not accounting for infrastructure and storage requirements. Your are recycling an unproven theory that R&D developments for wind, solar and other energy sources will continue to develop in the future as in the past. This is based on assuming that all past cost decreases were due to R&D which is not the case (a substantial part has been caused by cheaper commodity costs and cheaper labour) and also ignoring factors which will increase costs of these technologies. Mainly the cost of raw material inputs but also electricity/fuel.

The range of the estimates above to which you refer (table 1) is for a specific region, namely Indiana, which is relatively expensive. If you look at a broader spectrum there is a plausible range at the lower cost end shown by the Chinese pilot and the GasTech calculation, which would translate to 4-6 cents/kWh including CCS.

As to attempts by the fossil industries, the motivations of Linc Energy is partially driven by awareness of Peak Oil. I think it's a concern about future energy availability and far from sticking heads in the sand.

@Rembrandt

The position that R&D has lowered renewable energy costs is not a recycled unproved theory, it is proven fact. The efficiency of both solar and wind has dramatically improved over the past few decades as a result of extensive R&D efforts. You are correct that I didn't mention the increasing scale of the renewable sector, which has also significantly reduced prices recently as production has skyrocketed. As far as commodity and labor prices go, I think you would have a difficult time demonstrating that they have fallen in real terms over the past decade. For example, even in China labor prices have risen in recent years while solar panel prices have fallen.

The graph you posted directly above the table you refer to shows the range of estimates for UCG cost, ranging from approximately $1 to $8 per MMBTU. At the median level of $4.50, the fuel cost alone is 3.6 cents per kWh, excluding capital, O&M and CCS costs. Including an average of 3 cents for CCS as identified in the IPCC report mentioned plus 1.5 cents for capital (assumes $1,000/kW which is also probably low), and we're already at 8.1 cents before O&M. I would view this as a more middle-of-the-road cost estimate for UCG.

UCG seems preferable to mountaintop removal and open pit mining. But why resign ourselves to continued reliance on fossil fuels when we have an opportunity to radically transform our fuel economy and ensure long-term, cheap sources of energy? If you were to compare the amount of money spent on fossil fuel reserve expansion and R&D to the level of spending on the alternatives I think you would find that a remarkable amount has been done in the alternative space at a fraction of the budget of fossil fuels. Coal will only get more expensive as we have to go deeper and deeper to find reserves. That seems like a losing long-term strategy to me.

One excellent alternative that has not yet been mentioned in this post is thorium, which could, with sufficient R&D, provide baseload power at a fraction of the cost of even the cheapest coal plants.

@ReFuelenergy

Thanks for the additional input, here's my reply

You are citing me incorrectly, I stated that it is unproven that the developments as in the past will be the same in the future. I did not say that the developments in the past did not improve substantially. At least that's how I see it.

You are ignoring the most important point I made about the costs of input costs (steel, copper, silver, energy) that will increase for renewable energies which will much less affect fossil fuel technologies, because they are less material intensive. The main reasons for the cost increase (absent of Energy) are the need to mine deeper and relative scarcity.

>Including an average of 3 cents for CCS as identified in the IPCC report mentioned plus 1.5 cents for capital (assumes $1,000/kW which is also probably low)<

Where does the 1.5 cents for CCS capital come from above the 3 USD cents per kWh?

>UCG seems preferable to mountaintop removal and open pit mining. But why resign ourselves to continued reliance on fossil fuels when we have an opportunity to radically transform our fuel economy and ensure long-term, cheap sources of energy? If you were to compare the amount of money spent on fossil fuel reserve expansion and R&D to the level of spending on the alternatives I think you would find that a remarkable amount has been done in the alternative space at a fraction of the budget of fossil fuels<

The main reason is A) stock based resource and therefore B) costs. The opposite of your question is: If we can do UCG with CCS cheaper than renewable energy, why would we do renewable energy?.

Thorium is a straw man argument without proof that it is a workable technology, which so far it is not. If you can provide me with a guest post about thorium reactors and their feasibility than that would be welcomed. For instance similar to the UCG post above.

I confess I am baffled by this and other statements like it. Quite frankly I absolutely do not believe it is true! I wish someone would point me to data, research or studies that include a whole cost accounting of all the materials and energy that go into the entire supply chain of the technology and machinery that is needed to mine, drill, process, refine, transport etc.. of all the fossil fuels that we use to power our current industrial civilization. Are you claiming as a fact that there is less need for steel, copper, energy, etc. in keeping even some of the basic infrastructure functional? Let alone the building out of new rigs, wells, ships, heavy machinery, etc?

If someone has a credible comparison of what materials are really needed for both alternatives and fossil fuel technologies I'd love to see it. And that's even without getting into paradigm and expectation changes that are already underway.

@FMagyar

Your remark is warranted as I made a bold claim and didn't back it up with data. I'm working on an analysis, give me some time. For now

>Are you claiming as a fact that there is less need for steel, copper, energy, etc. in keeping even some of the basic infrastructure functional? <

yes, that's my present expectation.

@Rembrandt

I similarly think you may mis-cite my argument, which is that scale and technology gains will work to rapidly lower costs - as has been shown in the past - most than offsetting any increase in commodity costs. For example, FSLR discloses that its COGS in 2010 was only 53.8% of revenue, or $0.77/W, including labor, manufacturing overhead, etc. indicating that there is room for further retail cost reduction even in a rising commodity price environment. Despite the rise in raw material costs including silicon in 2010 over 2009, FLSR's cost to manufacture on watt dropped from $0.87 to $0.77 year over year. Further, FSLR states:

"By continuing to improve conversion efficiency and production line throughput, lower material costs, and drive volume scale to further decrease overhead costs, we believe that we can further reduce our manufacturing costs per watt"

This illustrates my point that there are more important factors than raw material costs alone when it comes to the cost of renewable energy.

FMagyar also makes an excellent point regarding the use of commodities in conventional fuels. I think we can all agree that the pipelines, drilling rigs, refineries, heavy machinery, etc. used in conventional production all use far more raw commodities than renewable techs.

>Where does the 1.5 cents for CCS capital come from above the 3 USD cents per kWh?<

This represents the levelized capital cost of the plant required to burn the syngas. The 3 cent CCS charge is incremental to the cost of the facility needed to generate the power. I based this estimate at the low end of capital costs required for a new natural gas-fired plant.

>The opposite of your question is: If we can do UCG with CCS cheaper than renewable energy, why would we do renewable energy?<

Even with CCS, this process still emits a substantial level of carbon - not to mention the significant groundwater contamination issue. As mentioned before, there is little remaining economy of scale to gain in the conventional business, while investing in renewable energy - even if it may be more expensive in some forms now - promises to yield a substantial return to society in the form of lower costs.

>Thorium is a straw man argument without proof that it is a workable technology, which so far it is not. If you can provide me with a guest post about thorium reactors and their feasibility than that would be welcomed. For instance similar to the UCG post above.<

Thorium fuel can be used in conventional reactor technology, and can even be used in combination with spent fuel rods helping to solve the problem of radioactive waste storage. While I am not a nuclear physicist, I would be happy to provide a guest post covering a meta-analysis of the topic. If there are any readers here with greater knowledge of the technical side of the thorium process that would like to collaborate I would be interested in linking up.

By the way, while I differ in opinion with regard to some of your conclusions, I appreciate the post and would like to thank you for your well-written overview of UCG.

I'm not so sure. Renewable sources of temperature gradients are almost aways more diffuse than conventional, combustion related sources. The ambient solar power flowing around us results in lower temperature differences than can be obtained through combustion. Generally speaking, a shallow temperature gradient requires a large structure for conversion to a more useful mechanical or electric form. Admittedly, this is neither a rigorous or thorough treatment of the entire system. Are you aware of one?

I'm not sure I fully understand your point - but let me give it a shot. Generally when discussing renewable generation we are not working with thermal gradients to generate power. Wind power is mechanical, while photovoltaic solar converts photons directly into electricity (and waste heat). Solar thermal does rely on the temperature gradient, but it concentrates the sun's energy to achieve a significant temperature difference without requiring a large superstructure to convert that energy collected to electricity.

RE,

Thanks for your reply.

Wind results from thermal gradients in our environment, as does rain. A few hundred watts per square meter is a very low energy flux, compared to that which can be obtained by burning our currently accessible endowment of fuel, be it uranium or fossil biomass. A relatively large superstructure is required to concentrate solar thermal energy for an 1000 MWe electric power plant, dam, or wind farm. While true that PV does not require a thermal gradient, it does require large swaths of land for the same reason. I don't know which requires less raw material on a per Joule basis, and the EROI analysis I've seen is pretty much all over the map, depending on who is doing the analysis. My point is that an in-depth analysis is not so simple, but this simple, first-order treatment does not favor renewables.

Of course, renewable has the advantage of being, well, renewable. Greater questions remain: Which renewable, and how to build it while making the best use what remains of our endowment of potential energy, or which currently inaccessible potential energy source might we exploit, AND what about all of these hungry people?

Ah, now I see your point better. And yes, I would agree that to capture these low-intensity sources that some sort of larger structure is necessary. I read further up in this comment thread that Rembrandt is working on a full cost accounting of the raw materials. I still believe that despite these super structures, renewables will prove to be less intensive on a raw material basis, particularly when including the materials needed to produce and transport fossil fuels. I look forward to discussing this report as once we have some good data it will be easier to understand the difference. We should probably avoid whichever source has a higher cost impact - the trick will be to properly discern all the true costs.

There are 525,000 operating oil wells in the US, and probably 10M abandoned or dry wells. There are 70,000 abandoned coal mines - shouldn't we include those somehow in space requirement calculations?

--

Energy density is a common criticism of wind and solar, when in fact wind consumes very little land - perhaps 1/2 acre per 1.6-3MW wind turbine - much less than other forms of generation, when you include fuel mining and the overall footprint of generating plants (nuclear plants can take up more than a square mile). Rooftop solar doesn't consume any land.

18.5 acres per MW!

The Clinton Power Station is located near Clinton, Illinois, USA. The nuclear power station has a General Electric boiling water reactor on a 14,300 acres (57.9 km2) site with an adjacent 5,000 acres (20.2 km2) cooling reservoir, Clinton Lake. Due to inflation and cost overruns, Clinton's final construction cost exceeded $2.6 billion, leading the plant to produce some of the most expensive power in the Midwest. The power station began service on April 24, 1987 and is currently capable of generating 1,043 MW.

http://en.wikipedia.org/wiki/Clinton_Nuclear_Generating_Station

To this we of course have to add the land use for mining and refining the uranium yellowcake.

Nick,

Yes, the volume of mined material should be accounted for in all cases. How much material is mined for the wind turbine components? How does this compare to the amount of material mined for nuclear?

Footprint should be an apples to apples comparison as well. A 450 MWe nuclear plant will run rain, wind or shine, and is way smaller than, to pick a random example, the 25,000 acre 450 MWe capacity (i.e., on a really good hour) Bigelow Canyon Wind Farm. To use capacity as a benchmark, one must include the capacity factor or duty cycle of the power plant. Another factor against renewables. The nuclear power plant itself is small, and if it is on a square mile site, that has more to do with security than anything else. A nuclear site forest can be logged, just as a wind farm can be farmed. Nobody would really want to live in an area bombarded by turbine blade shadows or security guards. Cooling reservoirs shouldn't count, since they can be and often are major bodies of water.

http://en.wikipedia.org/wiki/Biglow_Canyon_Wind_Farm

How much material is mined for the wind turbine components? How does this compare to the amount of material mined for nuclear?

Wind turbines require more steel and concrete per average watt of output, for construction. The steel and concrete have standard specifications, so they're cheaper than nuclear construction. More importantly, wind requires no fuel - the lifecycle mining requirements for nuclear are very likely substantially greater than for wind. The land requirements for uranium mining don't occur so much in N. America or Europe, but they're real.

The nuclear power plant itself is small, and if it is on a square mile site, that has more to do with security than anything else. A nuclear site forest can be logged, just as a wind farm can be farmed.

That sounds mighty unrealistic: you can't maintain good security with loggers running around. No, a nuclear plant "consumes" land in a way that wind power does not.

Nobody would really want to live in an area bombarded by turbine blade shadows or security guards.

Farmers would strongly disagree (I assume "security guards" applies to nuclear).

Cooling reservoirs shouldn't count, since they can be and often are major bodies of water.

Of course. That's my point: just as it's silly to say that a nuclear plant's requirement of a body of water means that the plant "consumes" the body of water, it's silly to say that a wind farm "consumes" the land between the turbines.

The bottom line: "density" or "diffuseness" is an unrealistic argument against renewables.

@ReFuelEnery

Thanks again for the reply, I am working on an article on the subject (economies of scale, cost decline, input costs for ren. energy) that will be published in the not too distant future. Hope to discuss there further with more data

substance.

I looked a bit into thorium reactors after you brought it up, its interesting especially now that China has ventured into Fluid Thorium. The more "conventional" forms of reactors as pursued by India are probably so interesting in my perception (cost, risks, operation difficulties).

I eagerly await your article and look forward to some good data to digest.

Regarding thorium, I would agree that the more promising forms are the more advanced as they could substantially mitigate many of the items that make building a conventional plant so difficult such as large footprint, NIMBY effects due to the fear of meltdown and substantial red tape. While there is more research that needs to be done, the potential payoff is huge. My concern is that we will continue to shun anything even remotely nuclear-related, and/or allow special interests to continue to block research funding, allowing other countries such as China to commercialize a technology that we invented. Do we really want to wean ourselves off of foreign oil only to rely on China for our nuclear tech?

The MSRE verified the important details of molten-salt fuels, and the final run of the Shoreham reactor proved that over-unity breeding with 233U-Th fuel is possible even with a light-water coolant. (Lightbridge will soon be selling U-Th fuel assemblies for LWRs. I doubt they'll breed more than unity, but they will leave lots of 233U in the spent fuel just waiting for molten-salt reactors to take it.)

Much of what you're complaining about originates in politics, not technical issues. Both the MSR development effort and the IFR were killed by political action, not technical roadblocks; the IFR in particular was killed at a point where it cost more to close (and refund foreign contributions) than it would have cost to run. This is the sort of thing that happens to real threats to the status quo, not technically impossible initiatives like an all-hydrogen economy.

"... the final run of the Shoreham reactor ..."

ITYM Shippingport. :-)

You are correct. Brainf**t!

Refuel:

Assuming the following, which I think are reasonable assumptions today:

(1) We aggressively build out wind/solar.

(2) Nuclear is all but dead due to a combination of escalating costs plus Fukishima.

(3) Shale gas isn't going to be cheap/abundant enough to do the job all by itself.

(4) We do CCS with this.

(5) Cheap energy storage doesn't allow wind/solar to become 100% of our use.

It would seem we need some power sources which can be used as a combination od baseline and dispatchable mode, to make up for generation gaps in wind/solar. Gassification plus CCS, if used primarily to balance out the inevitable supply gaps associated with wind/solar, would allow a fairly longterm sustainable energy future.

Used on a large scale, there might be some issues related to the change of the deep underground layers affected. Will the spent coal layers, contract or expand, leading to either subsidence or rising land surfaces? What other problems might ensue from the widescale use of such methods? Even if we do CCS, it won't capture 100% of the CO2, so there is still climate risk even if we do it almost right.

I think that your assumptions are generally reasonable with a few caveats:

>(2) Nuclear is all but dead due to a combination of escalating costs plus Fukashima.<

Politically, possibly so. Changing the politics of nuclear will be essential to lowering costs. However, from a technical perspective the cost of nuclear is falling as it becomes more modular with smaller footprints. Thorium in particular has the potential to be a game changer - but again, progress is frequently blocked by special interests.

>(5) Cheap energy storage doesn't allow wind/solar to become 100% of our use.<

It doesn't need to. Nuclear will continue to represent ~20% of our generation for decades, hydro 7 - 10% and gas at least 20%. The other half could easily be made up from baseload renewables (including geothermal, wave energy and biomass), and a dispatchable combination of intermittent sources and modern natural gas generation. Demand growth is already more than met by current rates of renewable and gas capacity additions, allowing renewables and gas to take market share from coal. As shown in the link, coal use has declined markedly over the past few years (partially due to the economy, granted).

Either way, while UCG appears to be preferable to traditional generation, I don't see it as necessary for our energy future.

I remember some interesting articles by Heading Out, on long wall coal mining. There was a lot of discussion of how the overburden subsides/collapses sequentially all the way up to the surface of the ground. I wonder what is known about how the underground cavities created by UCG develop and collapse.

I note that the need for an impermeable rock layer is mentioned above. How can one be confident of the continued impermeability of a rock layer if it is subjected to massive differential subsidence? I wonder.

Thanks, Rembrandt, for a very interesting article.

Collapse happens, but not all the way up to ground level.

The rubble from the roof occupies more space than it did in the roof. Around 1/3 of a pile of rubble is the space between the rocks. So if you start out with a 1m high cavity and 200m of solid roof over it, you end up with 3m of rubble filled space and 198m of solid roof over it.

If you had a 5m seam with a 3m impermeable layer over it, you could be pretty sure that it wouldn't be impermeable after you burnt the coal out, but a 3m seam with a 20m impermeable layer is a much better bet. Even though about half its thickness will be in a rubble pile there is still an impermeable layer sitting on top of the rubble after the coal is burnt out.

As the saying goes, "You cannot be serious!!" This is a terrible thing to do. Notice how careful the author and the presentation are to not actually say what they are really doing? They are talking about setting these coal seams ON FIRE and collecting the vapors. This is a recipie for environmental disaster. Having grown up in an area where underground mine fires were common, they are very difficult and extremely expensive to control or contain if it gets out of hand.

Hot Air, yes collapse does happen on the surface. I recommend everybody just Google "Centralia mine fire" to see what happens with underground combustion of coal seams.

I visited a similar fire to the Centralia one, near Cransac in France, many years ago. However these are very shallow fires. The jist of this thread is seams that are very deep, maybe a mile down and hardly easy to connect with the surface.

NAOM

A chamber capped by an impermeable layer with wells drilled into it is easily flooded to quench a flame. That's not the problem. Making resource-cheap and pollutant-costly energy is the problem.

Grin, that's what we thought until we tried to do it. You need the coal seam to be deep enough that the thermally induced cracks, as well as the mechanical ones formed when the roof falls into the cavity are contained well below the surface (to prevent air access, which is the big reason that they can't control the fires at Centralia).. One of the big issues in this process is the control of the fire front, and it is why the dual-bore system is likely to prove the best. We worked on solving some of these problems back in the 70's and early 80's. It is relatively easy to drill a horizontal hole in coal with a high=pressure waterjet stream- and by adjusting the pressure you can actually keep it in the coal. (We were asked to look into developing the "round-the-corner" drill for this because of the problem of keeping the drill in the bottom of the seam - a problem with conventional tools at the time).

We found that if you left a hot spot in the coal no larger than a quarter, then if it was left for a day you might as well not have bothered. Mud works better than water.

I would have thought the problem with cracks would be water getting in or gas getting out rather than air getting in.

How much further does thermal cracking actually go? My assumption was that if you were heating up that much overburden, the process would be not be economic.

If the seam underlies an aquifer, that doesn't seem to be a likely problem. Too much subsidence and it all goes out.

My prescription for that is to dam the valley and flood it, or just dig canals to allow comprehensive flooding of the seam from many points of entry. That might be too expensive for people to consider, but even dry spots wouldn't matter so long as they were isolated and eventually burned themselves out.

@fisherman

You are confusing fires in coal seams that are uncontrolled which occurred through unknown reasons with much deeper controllable fires. Controllable as combustion requires inputs and these can be controlled. The Centralia mine fire is in no way comparable to a UCG process.That doesn't diminish the impact of what this disaster may have had on the area there, but it certainly doesn't relate to UCG.

Here is an explanation on how the combustion is controlled and commissioned.

http://www.lincenergy.com/data/info_sheets/e2-fact.pdf

http://www.lincenergy.com/data/info_sheets/e6-fact.pdf

The claimed low cost of liquid fuel from UCG doesn't ring true. Using air input it seems the exit gas could consist of ~35% nitrogen. That would be a lot harder to capture than reactive components like H2S. Same goes for excessive raw CO2 levels. Perhaps the Fischer Tropsch processor can cope and unreacted gases are vented afterwards.

A couple of years ago Linc drove a small car around Australia displaying some words like 'clean fuel' or similar. A truck carrying spare fuel followed behind. The term 'clean' was evidently a reference to low sulphur not low well-to-wheels CO2 which I believe to be about double that of oil derived fuels. Let's say it's 5 kg well-to-wheels CO2 per litre of fuel. A carbon tax of 3c per kg of CO2 would add 15c to each litre of fuel. That is not how Australia's carbon tax will work initially but it may turn out that way.

I think it's implausible that the onsite CO2 could be captured and re-injected underground. That means the same sedimentary formation happily gives up one gas in a permeable layer then stores another gas in a less permeable layer. I suspect Linc are biding their time until Australia has a liquid fuels crisis at which point environmental concerns go out the window.

Britain used town gas to operate vehicles during WWII, when petroleum was in short supply. The product of UCG could probably be used similarly, though modern vehicles would be much harder to convert than ones with carbureted engines.

The UCG operations would have to be local to the point of use. The heating value of syngas is much lower than NG (very expensive to pump) and nobody would be building a pipeline network during a crisis.

@Boof,

Not sure what the cost figure about UCG you cite. The figure I have heard is 30 dollars per barrel from Linc Energy which is based on their press statements, and doesn't show any calculation behind it whatsoever.

If you have insights as to the costs without a carbon tax that would be interesting. To what extent can it compete with diesel/gasoline?