Tech Talk - Improving Horizontal Well Flow at Berri and Ghawar

Posted by Heading Out on April 30, 2012 - 7:06pm

The very size of oil reservoirs in Saudi Arabia means that as the dominant method of water flooding is used to sweep oil to the producing wells, not all the oil in place migrates as hoped. Some remains in place and this makes up a very significant volume of possibly lost production. This is particularly true in reservoirs such as the Hanifa and Hadriya reservoirs at Berri, where water flooding since 1975 has largely obscured the field. Recognizing this problem, Aramco has increasingly used sophisticated mathematical models of various reservoirs to help locate these remaining pools, searching for oil volumes that could be successfully recovered.

As the models were increasingly able to divide the reservoir into smaller and smaller fractions over time, the presence of these pools became increasingly apparent. Definite proof of their existence then came through drilling. Here again, the change in technology in the use of horizontal wells has allowed the recovery of volumes of stranded oil from thin layers that would have been more difficult to recover had technology not advanced. The first test of this was at Berri where the field modeling was changed from a 14-layer to a 128-layer model, revealing accessible "lost" oil. Five wells were drilled into the region and all yielded oil for a total of 17.4 million barrels by 2007, when the wells were still producing. This capability has extended the life of the Berri field, capturing much of the oil that would otherwise have been lost.

One of the problems, however, in changing to the use of the horizontal wells has been that the well diameter is reduced and as a result the ability to do remedial work on those wells as required was limited at first. The three techniques that are now being aggressively used in these cases include acidizing, advanced hydraulic fracturing, and hydrojetting. And since this latter is an area in which I “wrote the book” and controlled crack growth demonstrations led to the only time I was picketed by a union, I thought I would spend today's post explaining a couple of these developments with fluid treatments, which aren't often as simple to apply as they may appear. Next time I'll finish up with some thoughts on improving hydraulic fracturing, and the possible benefits of using carbon dioxide as the fracking medium rather than other fluids.

The problem of scale in the pumping of fluids into the reservoirs and the flow of oil out is that the quantities dealt with are significantly larger than in most other countries. Flow levels are required to reach over 10,000 bd, both in oil recovery and in the relatively precise location of water injection to sustain reservoir pressures. This led Aramco to adopt horizontal well technology, not only for the recovery of oil, but also in the injection wells that are used to inject the seawater.

Horizontal wells in carbonate are prone to well damage around the borehole due to the drilling process, and this initially limits the flow of fluid through this annulus, or requires a higher driving pressure to inject the water into the formation. In one example, it took an injection pressure of 2,350 psi to drive 13,000 bd through an exposed horizontal open hole section some 8,900 ft long. In order to improve the performance of the well, it was to be treated with an acid bath to remove damaged sections of the wall, and also to eat wormholes into the formation. Where the wells are draining gas, it is not that difficult to bullhead the acid into the well where the acid is injected to allow the well to fill for a couple of hours before being removed. This can be successful in wells where the use of coiled tubing (CT) is limited and flow rates would otherwise not be as high as needed for an effective cleaning. But this requires considerable volumes of acid, and in filling the entire open hole there is the risk of differential attack along the walls, providing an undesired result. The alternative was to use the smaller diameter of a coiled tubing rig and to feed this first to the back of the hole, and then inject acid as the coiled tubing was pulled out of hole (POOH). However, it is sometimes a little difficult to feed the smaller pipe down the open hole all the way to the back because the diameter limits the rate at which acid can be injected. Thus, there was a debate as to which method would be the best to use.

Aramco has used two ways to get around this problem. The first was to use a down-hole tractor to overcome the frictional forces that were otherwise stalling the placement of the CT by overwhelming the driving force before the tool could reach the back of the hole. The tractor has a small series of wheels that are recessed within the tool while it is fed down the well to the point where it is deployed.

When the CT Well Tractor is initially powered up, the wheel sections are hydraulically extended out of the tool body and activated automatically. Each wheel contains its own independent hydraulic motor, which drives the wheels and provides the forward motion of the CT Well Tractor. . . . . . The modular structure of the drive sections makes it possible to change the traction by reducing or increasing the number of wheels needed to drive the toolstring. The CT Well Tractor 318 can provide a pull of 3,500 lbs, which doubles in tandem configuration. This can further be increased to 10,000 lbs by stacking three CT Well Tractors.

The first major test of this was in the 8,900 horizontal section water injection well I referred to above. That section of the well was divided into 16 sections, each of which was treated as follows:

1. First, the treatment interval has to be washed with plain 20 wt% HCl for filter-cake clean up and provide initial wormholes. The main additives to the plain acid are a corrosion inhibitor, surfactant, and friction reducer. Plain acid was used at 10 gal/ft, including additives, resulting in a total acid volume of 77,000 gallons.

2. Plain acid was followed by 20 wt% diesel emulsified acid at 20 gal/ft with a total of 154,000 gallons for the 16 treatment stages. The higher concentration of retarded acid is meant to provide deeper wormholes.

3. To achieve better acid diversion at the end of each pumping stage, viscoelastic surfactant-based (VES) water will be used at 10 gal/ft at a total volume of 7,500 gallons.

4. Finally, water over-flush of 10,000 gallons is to be pumped following the previous 16 treatment stages to break micelles formed by VES. The over-flush contained brine water mixed with 3 vol% of mutual solvent.

The total treatment fluid to be injected in this job is 248,500 gallons; this large acid job is considered one of the biggest stimulation jobs for any well in the Ghawar field.

There were a couple of glitches with running the tool, in that the well had washouts that took a "flying leap" for the tractor to get past and it was not able to reach the last 3,000 ft of the well, which was bullheaded. Nevertheless, after the treatment the flow injection rate for the well was increased from 13,000 barrels of water per day (BWPD) to 28,000 BWPD.

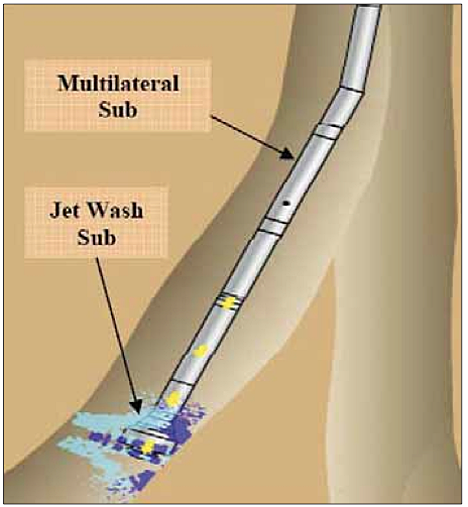

In a consequent test of a multilateral water injection well, some 362,700 gallons of treatment fluid were used to acidize a dual lateral horizontal water injection well with a total horizontal interval of 10,335 feet. Prior to the treatment the well required an injection pressure of 2,100 psi to inject 15,000 BWPD into the formation. After the treatment the two laterals were able to inject 30,000 BWPD at 700 psi driving pressure, and at 2,100 psi the wells became capable of deliving 80,000 BWPD. This saved the cost of adding two additional wells in the neighborhood.

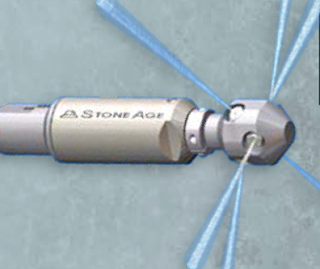

The use of these large volumes of acid carries burdens with it, and in much the same way as the chemical industry has moved to the use of self-rotating high-pressure jets to clean heat exchanger tube bundles and other tubulars, so this tool also became available for use downhole. I am going to use one of StoneAge illustrations to show how these work, since they pioneered a lot of the development of these tools for the industry. (You should also know that I have done a small amount of consulting for this company).

In normal jet cleaning operations, the head would be fixed and the jets would clean only where they impacted along the walls of the tube. But by housing a bearing within the body of the tool, the front head can rotate, and if the jets are turned so that their axes lie slightly offset and angled to the central axis of the head, then the force of water leaving the orifices becomes high enough to rotate the tool (quite fast), spinning the jets across the surrounding surface.

The technique that works for clearing the horizontal sections for water injection obviously also can be used to clean producing oilwells to enhance their productivity. Because the zones that are now being developed are much smaller, as these are often the trapped oil left after a water flood with very tight geometric constraints where the acid must be applied, bullheading is still being successfully used. However, it is in the placement precision of the rotary tools and the total coverage of the interval in which the benefit is becoming apparent. The tool is obviously somewhat more complex than that used on the surface, but operates under the same idea of jet thrust, causing the head to rotate.

Note that because the orifices are larger for this tool, the jet pressure drop across the nozzles required to make it rotate was 1,900 psi, at which pressure the tool was delivering 1.5 barrels/minute of treatment fluid. This dual-lateral well had been shut-in because of formation damage and after treatment, produced at 11,000 bd.

The equally significant number is that the amount of treatment fluid required was reduced by 70%, and that at a 7,000 ft interval, only required 42,000 gal of 20% nitrified hydrochloric acid.

As the main reservoirs in Ghawar are filling with water, it is through techniques like these that the oil left behind can continue to be recovered at a significant rate. But each of those reserve pools in itself is not that large a volume.

But each of those reserve pools, in itself, is not of that large a volume.

It is my quite limited knowledge that northern Ghawar has relatively few of the faults that cause water injection to bypass oil in place, stranding it. One reason is the generally high permeability (darcy) of the rock. But northern Ghawar does have them, and stranded layers of oil.

Everything in Ghawar is super size. Do you have the least inkling of how large these bypassed pockets of oil in place are ?

And at 10,000+ b/day, I suspect that they are drained in a couple of years or so. Any confirmation ?

Thanks,

Alan

PS: Acid and limestone should create quite a bit of CO2. Is that a factor in using acid ? Or is it ignored ?

It seems to me that in order to justify the expense involved, there would need to be maybe 1 + yr production in a pool. A quarter million gallons of acid, and acid mix, etc., cannot be free; also there are equipment losses during any staged injection of this sort, personnel costs, and (maybe, though in KAS I don't know full ramifications) insurace expenses. These in addition to 'normal' operating costs of extraction. All to increase speed of recovery of 'scraps' of remaining hydrocarbons.

No wonder oil prices remain high.

Craig

Zaphod:

Obviously not every well works, some fail within six months others last more than a couple of years but in relative terms the costs are generally significantly less than the gain from the additional oil. But it again this exemplifies that Aramco are designing their operations to maximize overall recovery, rather than to go for instantaneous higher production rates, and it is that philosophy (logical for them) which makes me question the higher production rates that a number of folk are assigning to them in the years to come.

Good thought there... it makes the KSA heads saying they are going to hold on to some for their posterity more believable to me than the ARAMCO spokesmen who claim they are going to increase production and be the resource to moderate world oil pricess. It should also serve as a guide to those who seem to think PO will have an easy out provided more-or-less gratis by our Saudi benefactors. Methinks the Saudi Princes know what they are doing, and part of that is dissembling to willing believers.

Craig

Alan:

Ghawar is permeated with the "Super K" veins that can lead to premature water break through, it seems to be a characteristic of the Arab reservoirs. In regard to the size of the reservoirs that are being tapped, it is hard to get that much information, but it appears that there are some of the wells that only last six months or so, but as they learn better how to manage the recoveries, so the wells are running for a few years. But obviously, if you are tapping into pools that are only a few million barrels in size, and are withdrawing oil at rates of up to 10,000 bd then you are likely only talking about a couple of years or so of production, as you note. Incidentally the original spacing for the wells in KSA seems to have been at a kilometer, though those were vertical wells, and the preponderance now are the MRC and smartwells. CO2 is being used to help foam the acid in some wells since this lifts the fluid so that it more evenly coats the wells, not sure that is still being done now that they are using spinning jets.

A further discussion of the Super K zones in Ghawar:

Reservoir Characterization of Arab D Super K as A Discrete Fracture Network Flow System, Ghawar Field Saudi Arabia (Stanford University - PHD dissertaion - large pdf, 540 pages)

Thanks for the link, Bob! It may take a while to read through, but initially already a very useful item.

Craig

oil guru Pekins today on CNBC said SA maxed out. M. Bartoloma has srange look on her face. it was hard for her to believe it.

Okay it's Pickens not Perkins. Took me awhile to find it because I was searching on Perkins. Finally found it by searching on Maria Bartiromo.

Pickens on Chesapeake Energy

Ron P.

Huge waste of time and money. All they need to do is keep drilling one big hole until they hit the creamy nugat ball of abiotic oil in the earth's mantle. Y'know, the one that Red State prayers keep perpetually full.

Don't you realise all Saudi oil is abiotic? Just check their reserve numbers for proof of that!

By your logic, non OPEC is also producing abiotic oil - reserve replacement 1989 - 2010 is 105%.

False analogy.

Saudi Aramco is clearly lying about their reserve replacements - that does not apply to the totality of "non-OPEC".

Alan

Thank you for expressing your opinion.

Totally. But as I understand it, the earth's outer core is believed to be composed primarily of molten iron and lead. So if iron/steel liquifies at this depth and temperature, then what can the drilling and production pipes be made out of? (NOTE: it will need to remain strong and solid at the +6,000 degrees Celsius temp of the outer core). And this "new technology" piping material will be handling a massive never-ending stream of pure, renewable abiotic oil that will probably be boiling like crazy at over 7,000 degrees Celsius! ...coming directly out of the earth's inner core like it does. Yes, we're technically far outside of the so-called "oil window" so you can consider that tired, archaic limitation as now having been officially slam-dunk-debunked.

BTW, if this oil is at the inner core of the earth, then which nation of the world would be found directly above the inner core of the earth? You guessed it, I'm thinking about American "mineral rights" and I'm hoping that we can still be the first country to claim exclusive national mineral rights to the earth's core (inner AND outer cores both, up to our traditional +100% share and beyond) ALL of IT! - and "first" still counts for something, especially when you are ready to enforce your claims using the largest, most sophisticated military force in the world. Let those big guns do some talking as they warm up the jury on our behalf - and quickly please! Airborne force insertion protocols are fully pre-authorized (pending initial review by POTUS) before the world's lawyers get involved with all of their boring, fine print details of "international law" and the like.

Abiotic oil has been adequately debunked many times. Pseudoabiotic oil is a different topic altogether. Eugene Island, East Texas, LaBarge, Grant Canyon and Jay Field(Tuscaloosa trend - ring a bell ?) may all be examples of pseudoabiotic oil- influx from a deeper reservoir.

Khurias field in SA may be another, better documented case of pseudoabiotic oil influx from a deeper zone.

I'm not so sure abiotic methane and carbon dioxide haven't been discovered in limited quantities, where does helium come from ?

What specific evidence is there for that?

I espouse a new probiotic mechanism for helium formation.

What ? Are you looking for a plug for your own work ? ha !

Khurais Me A River

The chart labeled:

shows pressure recovery from about ’84 to ’90 and again ’95 to 2000 during extended shut-in periods. The pressure response could have been from ‘delayed water influx’ or that pressure response could be from oil influx via fractures communicating with the essentially undeveloped deeper Hanifa and Fadhili reservoirs.

The pressure response in the Arab D from about ’84 to ’90 and again ’95 to 2000 shows pressure recovery during extended shut-in periods, which could be sourced from the deeper reservoirs.

The other pseudoabiotic cases I have cited are based on recoveries approaching and in some cases exceeding 100 % of ‘estimated’ oil in place.

I'm not sure if you are joking or not. If not, could you fill me in on this probiotic mechanism ?

One guy is proposing inhaling hydrogen peroxide for improved health ????

The Arab-D and Hanifa reservoirs are definitely connected by fractures (pressure correlation shows this), and the oil is pretty much the same. They have produced from both since early on, and producing one without the other is problematic as aquifer/injection water could flow from one to the other, stranding oil. They have a few wells which produce from both simultaneously (some in Berri do this as well). Hanifa is much smaller in size. Fadhili? Wasn't tapped before and isn't now, so that says something.

In any case, these reservoirs repressurize when you stop draining them because aquifer water slowly moves in to replace the oil. That very thing happened in Haradh (Ghawar) as well, and nobody suspects oil coming up from below there either.

Microbial-assisted low-temperature fusion (MALF): Theory and experiment

We don't know. I acknowledged that the shut-in pressure response could be due to water influx. There are many unknowns.

Details of pressure measurements and historical water production seem to be lacking.

Suspects is such an ugly word. I for one have 'wondered' if that could be the case. Recall that Saudi Aramco claims 210 Gb of oil in place in Ghawar. I don't dispute the 170-180 GB calculation of original oil in place, although that is subject to and dependent on the porosity cut off used in making such a calculation.

A review of AAPG memoir 78:Petroleum Provinces of the Twenty-First Century may open some eyes or raise some eyebrows about the volume of paleozoic oil potentially generated on the Arabian Plate. See Page 502.

That one is available for preview on Google Books.

For now, we are stuck with eye crossing stares at KSA production, and for me, pondering how (or why ?) Matthew Simmons got it so wrong. I never did trust Dick Cheney.

Do we have any analysis of the He-3/He-4 isotope ratio at individual fields? This ratio varies by as much as a factor of forty in terrestrial samples (measured so far) and there is no single accepted reason for this. The georeactor production theory is interesting. He-3/He-4 ratio over time in igneous rock appears to match that produced by the fuel burn of a hypothetical, natural 3 Terrawatt fast breeder reactor at the centre of the planet, now nearing the end of its life.

Terrestrial He-3 is believed to be primordial (remnant from when the earth was formed), whereas He-4 is formed from radioactive decay (alpha particles). Thus, the ratio will vary with location as there is no necessary correlation between these.

http://www.ncbi.nlm.nih.gov/pmc/articles/PMC152243/

j - The discussion of abiotic oil deals with how/where the oil is generated and not where it has no accumulated. Oil/NG cannot physically exist anywhere close to the temperatures at the depths you're referring to. That's one of the great misleading aspects of the abiotic oil crowd. I've been looking for oil/NG for 37 years and never really gave much thought to where it was generated. IOW my efforts have been entirely focused on where oil/NG, of any origin, has accumulated in commercial quantities. Even the most ardent abiotic believers acknowledge that if there is an abiotic source it doesn't create oil at a rate that would be useful to mankind today. IOW the challenge is still to find where oil/NG has accumulated in economic quantities regardless of their origin.

One useful visual.

Humanity is extracting One Thousand Barrels of Oil per Second !

Imagine that - and being replaced at the same rate by bubbling up from "below".

Alan

PS: Aramco produces well over a hundred barrels/second

for added visual picture that thousand barrels a second as curling wave and humanity surfing the curl, don't know that we and our board are nimble enough to avoid crashing on the reef, it has already been a long and wild ride.

[edit add on] Here is a cool NY Times article on the massive foundation of the fossil fuel wave.

Best hopes for finding a new a wave to ride.

The human race is pumping about 4 million barrels of blood per second!

I was thinking a bit more about the acid-limestone (or is it another carbonate ?) chemical reaction.

What is the acid used ? and the pH (pure or diluted basically) ?

Is the rock mainly limestone ?

Thanks,

Alan

Alan - Not sure which post you're responding to. But the acid typically used in treating most carbonate rocks such as a limestone is hydrochloric. But the exact mixture includes various buffers and other components. For silicate rocks some form of hydrofluoric acid is common. Very nasty stuff.

Hydrofluoric acid is *VERY* nasty indeed !!

It will penetrate below the skin before you feel the burn.

Alan

I'm curious as to how they get it down there without destroying everything on the way. You can't even keep that stuff in glass bottles.

NAOM

One of the ways information gets misread, misinterpreted, misstated, otherwise distorted and repeated over and over.

T. Boone Pickens Dances the Saudi Oil Polka

What Learsy said:

What NYT said:

It is doubtful Saleri said what the NYT printed and Learsey didn’t even print what NYT printed.

Clearly Saleri was referring to resources being 716 Gb, and clearly Saleri ‘wouldn’t be surprised’ if total resources eventually reached 1 trillion barrels, in spite of what NYT claims he said.

It is never good to quote a source that doesn’t understand the difference between resources and reserves. I seriously doubt Nansen Saleri is confused by the distinction.