Getting plowed also happens to coal

Posted by Heading Out on February 18, 2007 - 5:48pm

As I mentioned in summarizing the Conference from last week, it seems as though, whether willingly or not, we are going to be seeing a lot of black coal in our energy future. I have written a couple of technical talks about coal mining in the past, and, if I can, I’ll move references to them into The Book later on today, along with the petroleum ones. (The coal ones are in Chapter 10, the oil production ones in Chapter 3.2).

The Chinese have just bought another longwall mining system, but instead of the shearer that I had described in the earlier longwall piece these systems will use a plow system to mine the coal. So I thought I would explain what those machines are, why it is interesting to see the Chinese using them (and why) and then perhaps close with a little note on fires underground. And perhaps have a little comment on EROI thrown in along the way. The plow also featured in the recent Washington Post story on coal mining.

So let’s drop down into my simplified mine model and see what it is I am talking about. And, since no-one answered my question about the modeling programs, the mine will be empty of workers, and you will have to use your imagination to sense their presence. Which may, fortuitously, be an indication of the future, since more and more pieces of mining equipment are being automated, or operated remotely, so that manpower is less, and less required. And this has some benefits beyond just removing people from areas of possible risk. I was fortunate enough to work with a couple of Dr Charles Hall’s students over last summer who were looking into EROI issues relating to mining. The high energy cost to provide the support needed for personnel was particularly striking in some of the situations that they looked into. And from the EROI point of view, a plow is usually a lot less energy intensive.

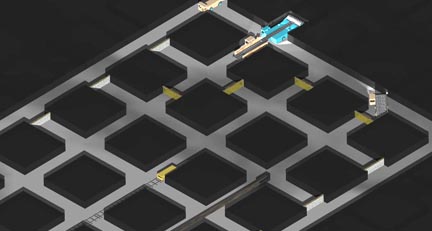

Well my model isn’t quite that forward looking, but let’s start by presuming we have left the surface, and gone down in the cage to the level at which the coal seam lies in the ground. Since the coal, in general, is thick enough so that people can move around within the coal height, the mine is largely developed by driving parallel tunnels away from the shaft towards the boundaries of the property that is being mined. (Note that because coal seams can stretch for many miles) The tunnels run parallel to one another, so that air can be circulated down through some of the tunnels, across the working face, and then back out, through another tunnel, to the shaft that will carry it to the surface. The tunnels are driven in the same way as coal is mined by Room and Pillar mining.

Figure 1 Overview showing the continuous mining machine (blue) loading into a shuttle car

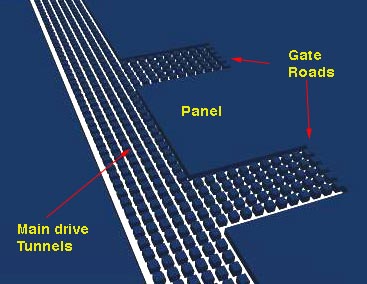

Once the main tunnels have been driven out to the edge of the property, then the coal on either side of them can be recovered. To mine that coal, secondary sets of tunnels are now offset from what I will call the “mains.”

Figure 2 Overview showing how the two sets of side tunnels, forming the gate roads, develop from the main set of drive tunnels that contain the main conveyor belts that will cary the coal back to the shaft.

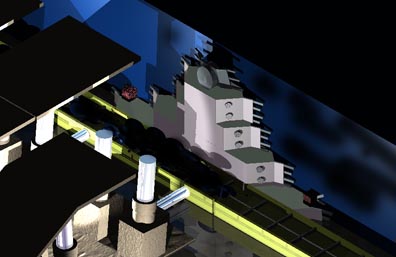

Once this gets to the edge of the area to be worked, a cross tunnel is driven between the two sets of advancing tunnels, which now form the gates to this cross-tunnel, which becomes the longwall face. It is into this tunnel that the roof supports are placed, and then a chain conveyor is installed along the tunnel, and the mining machine mounted to the conveyor.

In the previous post this machine was a shearer, with two rotating drums, one at each end, which had metal picks set into them to cut into the coal.. The drum rotation grinds the coal from the face, generally in pieces smaller than an inch, as the machine pulls itself down the face. In a plow face, that self-propelled machine is replaced with a machine called, not surprisingly, a plow (Hobel in German, since this is where the machines were invented).

Figure 3 Looking at the coal face with part of the shield canopy removed so that the different pieces of face machinery, including the plow and the face chain conveyor, can be seen.

In contrast with the shearer, the plow is pulled down the coal face by continuous chain attached to a winch mounted at the end of the face. The teeth of the plow are pushed into the coal by the thrust from the cylinders that are attached to the roof supporting chocks, on the other side of the conveyor. Every so often, as the plow cuts deeper into the coal, the supports lower the vertical rams, and reverse the action of the horizontal thrusting ram, so as to pull themselves forward into open space behind the plow. This keeps the immediate roof supported, while that behind the supports falls into the open space, as I have described before.

The plow is thus a much more inert piece of equipment (though if you have even seen one bash down a face that is not exactly horizontal you might doubt that word). But it has a significant advantage over the shearer, in that, with the body being segmented, individual layers can be removed. Thus the plow can, more easily, work in thinner coal seams than the shearer can easily be adapted for.

You should note, from the EROI perspective, that the plow does not, usually, break out all the coal by itself, but, as it pulls down the face, so it undercuts the top layer of coal. And in the type of brittle coal in which the plow works best, that top coal will collapse down onto the conveyor under its own weight.

So why is it interesting that the Chinese are buying more plows. Well, generally, when you find one coal seam, you will often find a number stacked, one above the other, in a sequence. Historically the mine owner would look to see which ones were thick enough to be worth mining and the rest would either be left, or would collapse into the waste, and be left as the thicker, underlying seams were mined.

However, by investing in plow systems, these thinner coals can be mined, and taken out before the thicker coal is removed. In this way more of the total resource is recovered and the thinner seams, which would otherwise be lost and abandoned, since their value will not justify the attempt to return later to recover them. It is indicative of the thoroughness with which the Chinese (and Mexicans) are addressing the different aspects of their need for energy supplies.

The second most scared I have been underground was when, many years ago in Germany, I watched a high-speed plow being pulled down a face that has a roll in it, so that the plow came up off the floor and gouged into the overlying rock roof, generating showers of sparks as it passed. (Sparks in mines can ignite the methane that is being emitted from the coal, and which, in the right concentrations in the air, can then explode). The majority of the time it is the hot spot left in, usually a sandstone rock, as the cutting pick from a shearer rubs over it, that has both the temperature and the energy to ignite the gas. The plow can move at up to 3 m/sec, and thus the shoer of sparks can appear (and did) very dramatic, but fortunately the seam was not gassy, and they knew much more about what they were doing than I did. Even so, using machines to mine into rock along a coal face is not only wasteful of energy, but also increases wear, and thus operational costs, and can be a bit more dangerous, depending what that rock is.

Hello HO,

THxs for the keypost.

Using the room and pillar mining method generally leaves what percentage of the coal behind for safety support? 50%? Do other countries' coal mines harvest a higher percentage, but transfer the greater risk to the unfortunate miners? Thxs for any reply.

Bob Shaw in Phx,Az Are Humans Smarter than Yeast?

It depends under what conditions they are mining. In many room and pillar mining operations, after they have reached the boundary of the working, then they try and recover part of the coal from the pillars as they retreat back out. Obviously it is a tricky game to ensure you leave enough to be safe while doing it, yet getting out the most that you can. It has been helped in the recent past by the introduction of remotely operated artificial ground supports (like the shields from the longwall models). It also depends on the Safety Factor used in the design and while the global average for underground is around 50% recovery with the right conditions, equipment and supervision room and pillar can approach longwall in the amount of coal recovered. I checked here and was amused, apropos the post, to see that they don't count coal thinner than 42 inches as a reserve.

i1 i2 i3 i4 i5 i6 i7 i8 i9 i10 i11 i12 i13 i14 i15 i16 i17 i18 i19 i20 i21 i22 i23 i24 i25 i26 i27 i28 i29 i30 i31 i32 i33 i34 i35 i36 i37 i38 i39 i40 i41 i42 i43 i44 i45 i46 i47 i48 i49 i50 i51 i52 i53 i54 i55 i56 i57 i58 i59 i60 i61 i62 i63 i64 i65 i66 i67 i68 i69 i70 i71 i72 i73 i74 i75 i76 i77 i78 i79 i80 i81 i82 i83 i84 i85 i86 i87 i88 i89 i90 i91 i92 i93 i94 i95

Thanks for the interesting post.

It is interesting that the Chinese seem to be trying to harvest the thinner seams of coal. As supplies get more scarce, people will try to make the best use of them they can.

You talked a little about EROI. Where do we generally stand in terms of coal EROI in the United States? It seems like this would vary, but are there any general estimates available for say, current production in West Virginia? Current production in Wyoming? Lignite production?

Does anyone know how much coal can we expect to mine in the United States, with EROI of 2 or more, given current technology?

EROEI on coal--that's a great question. EROEI literally varies from mine to mine, but some rough averages that I came up with, assuming that the coal is used to generate electricity (current average conversion factor of 32.5%)--which 90% of coal consumed in the US goes towards:

This does not include transmission losses. Mining energy figures from the Industrial Technologies Program Mining: Energy Analysis Average energy potential for various coal types:

What are the actual inputs in this case? How much is just electricity (which is sort of interesting in itself in that some fraction of the coal that we mine gets burned to mine more coal), and what fraction is diesel fuel and other forms of energy?

Using your input numbers I'm coming up with totally different results for the EROEI. For example Appalachia Northeast Bituminous:

Energy Inputs (per ton)

Mining: 325,000 BTU

Transportation: 339.1x900 = 305,109 BTU

Total: 630,109 BTU

Energy Output: 24mln.x0.3254 = 7.8 mln. BTU

EROEI = 7,800,000 / 630,109 = 12.4 : 1

This is 4 times higher than your number (2.84). Am I missing something?

Christ, that was a bad mistake, eh? Thanks for catching that--the first round of reviews did not. The updated numbers have been changed in the original post. That dramatically alters the EROEI. Looks like transportation distances trumps all for its impact on returns.

Thus using electrified railroads (instead of diesel-electric locos) will be crucial. The "rule of thumb" is that electrification saves x2.5 on the plains and x3 in the mountains or "conjested, urbanized areas" (measured in BTUs). Part of this comes from not using a small, isolated diesel generating plant vs. more efficient centralized generation and regenerative braking.

IMHO, the latest GE locos cut this advantage somewhat (they may use 20% less diesel). Using coal (less efficient than NG combined cycle) to generate marginal power for railroads will cut it a bit more. OTOH, wind is the source of 44% of the new generation MWh in the US this year (per other TODer whose 2006 #s I reviewed).

Best Hopes,

Alan

Don't feel too bad - think about this quote from the Post - 'In a typical year, the plow will deliver 4 million tons of coal, or enough to fill 350 rail cars.' When thinking about coal, thousands of tons is a good measure - an old collier that could carry 11,500 tons was a good sized ship. Though I can imagine a train carrying that capacity, a single rail car is difficult to grasp, especially after watching a coal train pass slowly along the river we were swimming in last summer (feeds the James - can't remember the river's name) on its way to Hampton Roads, Virginia - at one time (mid-1980s as a quick recollection), the world's largest coal port.

Nobody at the Post blinked an eye, even though coal is part of its regional coverage - Virginia is a coal state involved in world trade, while West Virginia remains an industrial region.

Thanks for bringing up these numbers, the math error is not that essential compared to that.

I simply noticed another glaring mistake, having a lot of experience reading the Washington Post, and his work was good.

Everyone makes mistakes, which is why many eyes looking is good.

Sometimes, I think a lot of people miss the various facts about Virginia and Hampton Roads - not only is the world's largest naval port there, one of the world's most important coal ports shares the same general space.

Energy is not the only use for coal - its role in steel production is fairly critical, and what comes from Appalachia is truly a world class resource still, and generally, it is not burned merely for electricity. This use is not exactly CO2 neutral, but it is much less damaging than burning coal for A/C or Internet access or refrigeration or cooking, or as wasteful - once created, steel is fairly easy to reuse.

One reason Germany retains a coal industry is the fact that German 'Steinkohle' is also useful in steel production - the lignite/brown coal areas have been pretty much retired ('Stillgelegt' - 'left in stillness' is one literal translation).

I think you need to double-check the facts about Germany's coal industry:

http://www.cslforum.org/germany.htm

Several facts paint the exact picture of the Germany electricity generation future:

1) Germany uses primarily lignite for baseload electricity generation

2) Wind and solar power do not displace baseload generation. They tend to displace hydro and NG

3) Germany is phasing out its nuclear plants and it looks like is committed to insist on this madness

4) Currently Germany imports nuclear electricity from France, but it is doubtful this will be able fill the gap for much longer. All indications are that France will be too busy saving the ass of its northern neighbour.

Does this picture need any comments?

Your facts are correct, but what I was trying to say was that the German Steinkohle industry still exists in subsidized form in part because of metallurgical coal (which is one reason why Hampton Roads is such a major coal port). Though I believe that cheaper Chinese imports have led to a serious decline in German production/use of domestic coal/coke in steel production over the last decade. (Some of the old coking plants were exported to China in the 1990s.)

As for the lignite/brown coal, the decline was related to major reductions in the mining of East Germany's very poor quality brown coal (if there is such a thing as sub-lignite, it would fit - I have also read descriptions of it as being one step up from peat) - obviously, other mines with higher quality lignite supply major amounts of coal for power.

The confusion is understandable - what I was trying to express is that coal is not only burnt for electricity, it also has major role in steel production, and much of the coal exported from Appalachia fits more into this framework than electric generation, at least into the early 1990s.

Obviously, Germany burns a lot of coal - that fact was in no sense meant to be obscured, however, it was merely that metallurgical coal / coke / etc. is also a high value use for coal - and German mines receive support in part due to their historical relationship to the German steel industry.

Germany will have a very hard time reducing its reliance on coal, no question. But major amounts of coal will still be mined as long as steel is used, a fact that tends to be a bit obscured in some of these discussions.

GTA,

Dr. Nate Lewis of CalTech has a slide in his presentationhere comparing coal reserves and resources with those of oil and gas. He doesn't address EROI, but the operative phrase is 'given current technology'. Where I work (BC coal industry) the prices were so bad just 6-7 years ago that the government sold the(excellent, electric) railroad, and would likely have sold the coal port if there had been takers. Now the prices are 4x what they were, projects are under development, and more young men are entering the business.

New technology can and will be developed to mine difficult seams, but its a bit of a laugh to think about investing in this just yet. There is plenty of semi-easy coal left, and the possibility of a glut driving down prices will discourage real innovation for another decade. Once oil production is post-peak, and coal demand is steadily high, I expect there will gradually be more remote mining of thin, deep coal, and EROI, rather than over-production, will become an issue.

Longwall mining is responsible for destroying many acres of farmland in Illinois. Once the coal is removed the land can drop a few feet causing the property to be inundated with water during large rainfalls. This is an environmentally damaging practice that many large companies are seeking to use in the heart of the nation’s best farmland.

See:

http://www.no-longwall.com/

http://www.longwall.montgomerycountyfb.com/

There are a number of different factors that have to be considered, some of which were not appreciated at the time that longwall was first applied in Illinois. While I have only enough knowledge on some of the issues to be dangerous, I do seem to have read that there were also issues about changes in the soil compaction, which also influenced crop fertility, that have arisen since they first started mining that way.

HO:

What is your sense of how responsive the coal mining industry could be to rapid increases in demand from current levels? Could Peabody, for instance, increase production by half in just a few years? Or would it rapidly run into the kinds of issues like skilled labour and equipment shortages that currently drag on the oil biz?

Obviously, from reading your piece, modern coal mining is a complex business. But, at the same time, it doesn't seem like Jack II.

There are lots of plans out there, but more coal requires more power plants first, and all parties have memories of the last time that this happened, and how many of them got burned in the 80's. The industry is changing, but that also means that it needs less employees, a plow longwall can produce up to 1.8 million tons of coal a year - an unheard of number thirty years ago (and shearers can produce more). Individual mines can increase capacity, but the planning permission to open new mines, takes a lot longer.

So, if I hear you right, perhaps if the political will was there, it could be ramped up pretty quickly because the resource is in a different stage of depletion and the extractive technology has improved substantially in recent decades.

I've heard lead times on power plants quoted at 5 years. But that probably includes some time for red tape.

Not that I'm personally fond of the idea, but does it not seem like a rush to coal post peak is technically feasible? (assuming, of course, that the technology is there to use the electricity in such a way as to offset the loss in oil and NG).

I'd like to hear what HO has to say on this as well, but I have the data right in front of me in a half-finished paper on coal production in the US, so please forgive me.

I have attached a pdf of my draft first half if you are interested. The short story is that our historical production trends--which are a product of our social, technological, and economic history--do not vary wildly (59% increase in production over 87 years):

US Coal Production, 1890-2005

90% of current coal consumption in the US is already spoken for by electricity generating power plants, and demand in this area is set to steadily increase as over 100 new coal power plants are scheduled to come online in the next 10 years. Per capita US coal production has remained relatively flat over time:

US Coal Production Per Capita, 1900-2005

The interesting side-note here is that federally underwritten loan programs have made over $1 billion available to expand coal-specific railways into the mountains of North Dakota, Montana, Wyoming, and Utah, with hopes to jumpstart stagnating US coal production and a particular eye on the Powder River Basin. Even with this influx of investment (and higher prices as global demand increases--largely thanks to China and the US), I don't think the growth in production is going to be all that out of the ordinary from the historical trend. In fact, the US Department of Energy’s Energy Information Agency (EIA)--someone that I am admittedly reluctant to trust--forecasts a slight drop in coal production for 2006, and another expected decline in 2007, followed by a modest recovery in 2008 (roughly back to 2005 production figures). Even after this, the physical mining of coal--and the expansion is primarily aimed at open pit mining rather than underground--is not a process that is conducive to an overnight doubling (despite what orthdox economists will insist upon).

Hello Seth,

Excellent work--Kudos! I am concerned about worker safety/health and mining community health/safety issues, especially if we suddenly have to rush a quick ramp up of production tonnage. I hope you include some info on this in the second half of your PDF report. I am assuming that open-pit is safer than underground operations for the respective mine-workers, but the coal dust, water pumping residue ponds, overburden piles, flood dangers, etc, cause increased issues for the surrounding community. Any info posted here will be appreciated.

May I suggest you email TOD with a potential keypost?

Bob Shaw in Phx,Az Are Humans Smarter than Yeast?

Great post HO. THX also to Seth for the additional info.

Both postings were very informative. I think we need to pay closer attention

to coal because, rightly or wrongly I suspect we will be using a great deal more

of it in the near future.

Seth,

Thanks for your pdf and the graphs. Just gave it a quick once-over but will give it the closer look it deserves later.

This jumped out at me from the pdf:

However, your production graph shows two periods of very rapid and arguably exponential growth (1890's through to 1914 and early '60's through to early '90's).

Sorry if I missed something obvious.

That's a good point. I include the per capita coal production graph to partially answer that discrepancy. Coal production has historically ranged between 2.5-6.5 short tons per person. In recent years (1979-2005), production has been relatively steady at just under 4 tons per person. With 90% of produced coal going towards electricity generation, and the population rising in the US (we're the only industrialized country projected to significantly increase it's population by 2050), I would hazzrd to guess that all gains made in the coal production arena will barely keep up with growing demand, let alone create enough for CTL or whatever anyone else wants to do with it.

This guess is based largely on a great paper by Richard York, which validates the hypothesis that electricity consumption is a product of demographic patterns more than any other causal variable.

An example might illustrate this better than me rambling:

If we were to magically increase our coal production back to it's per capita levels of 1918 (6.5 tons per person) for this calendar year (2007), we would have to produce roughly 1950 million short tons of coal. We are projected to produce around 1100 million short tons this year. That's a 56.4% increase in production. I just ran a first-difference calculation and created a graph that shows the historical variation in coal production (see below).

Change in Raw Coal Production From Previous Year, 1891-2005

Change in Per Capita Coal Production From Previous Year, 1901-2005

What appears historically are single years of great production increases, followed by years of precipitous declines. If the data are any indicator of production potential, we might be able to ramp up production significantly for a year or so, but maintaining that high level of extraction does not seem possible.

I would also guess that the reason for these huge yearly fluctuations is due to the nature of coal production--mines often stockpile large amounts of coal, which they can release to the market as prices increase and (more importantly these days) transportation becomes available. If they sell their stockpiles, their overall production declines the next year. Historical production data on actual mine output rather than coal sold to the market would be really helpful in elucidating the possibility for a ramp up in coal production (anyone have anything like this?).

This whole thread seems to lack a lot of credibility. The amount of coal available is staggering. Up until about 3 years ago the coal industry was shutting mines down because of the low prices for coal.

It would take some investment and effort to increase coal production, but I simply can't believe that it can't be done with some effort. As a matter of fact, I expect that switching North America to a coal based economy is probably what will happen unless some leadership is shown.

I think that the more crucial question revolves around the effects of burning coal on climate change and the severe air quality problems that doubling coal production would engender.

The burning of coal is, after all, the quickest and easiest way to generate huge volumes of greenhouse gases.

The Toronto Globe and Mail has been running a series on coal production in China. Here is a link to at least one article

http://www.theglobeandmail.com/servlet/story/RTGAM.20070203.wclimatechin...

I suppose that if growth continues unabated for long enough, the US could run into a Peak Coal problem, but I suspect we would all choke to death first.

Ramping up coal production to replace oil resources is short sighted to say the least, but given enough greed I suspect it is likely.

I somehow doubt that we are likely to run into a peak greed problem.

I'm confused--could you elaborate? Where's the credibility gap--me, the data, or my brief analysis? I'd be happy to share my data, and the literature behind my claims is all cited (please check it out).

My contention is that, yes, we have a staggering amount of coal, but abundance does not equal the ability to produce it at any arbitrary rate (which should be a familiar argument). My position is that, when reflecting on the historical trends of coal production in conjunction with projected electricity demands (growing with population and tied to coal generating power stations at this point), the potential for spare coal capacity for anything like CTL is not realistic.

Please keep in mind that I am in no way an advocate of coal--I'm just presenting the data as it is, along with some analysis of what it means for us in the near future. I think we need to take a long hard look at what our future energy mix is going to be if we are to have a realistic understanding of the implications for the future (especially regarding global warming).

1) the technical challenges to building more coal mines and railroads are nothing new. It would be disastrously easy to ramp up coal production. It hasn't been done in the last 10 years because of pollution control provisions and prices of approximately $40 per tonne of coal.

2) we have been practically giving coal away. The whole of the East face of the rockies from the Mexican Border to well north of the Canadian border has easily accessible coal deposits. There are also huge deposits underlying the Apalachians. These deposits have been shut in by pollution control regulations. Not the technical feasibility of getting the coal out.

3) The main sticking point with coal should be pollution and global warming. Regardless of whether or not we could produce coal to run our current vehicle fleet with CTL or whatever other process you like, we cannot afford to run a coal powered vehicle fleet without massive pollution problems.

My main problem with your post is that you seem to get lost in engineering calculations of whether or not we could produce coal rather than how dirty the stuff is. If we can't get the coal out of the ground we would be better off.

Seth,

During those strong growth periods (1890 to 1914, early '60's to early '90's), down years were heavily outnumbered by up years.

Coal production, it seems, can be both choppy from year to year and still grow exponentially -- kinda like GDP. (I'd like to see a study on coal production and GDP).

The choppiness, if it is caused by the technicalities of production, says much more about the need for inventory management and storage facilities than it says about upside supply potential.

I'm no coal shill here. Just trying to get at the facts.

I ran the frequencies of negative versus positive growth in coal production (difference in N due to a lack of population data for 1890-99):

For raw coal production (1890-2005):

Up years: 75

Down years: 40

For per capita coal production (1900-2005):

Up years: 62

Down years: 43

The up years definitely outweigh the down years in frequency, and the trend over time has been increasing raw production with a relative decline (over time) in per capita production, though this figure has remained fairly stationary for the past 25 years or so.

Using the historical data (1890-2005) and the EIA's projections, coal production in the US has doubled [roughly] every 40 years, but, as you stated, it has not been a linear progression. The big spikes in production seem to demonstrate the potential for a more rapid doubling; the years between 1890-1903 (13 years) and 1903-1917 (14 years) are good examples of relatively quick doubling in production. But, coal production languished after these older spikes until another doubling occured between 1973-1990 (17 years). We have remained relatively flat in production since 1990.

Not because the mines ceased to cooperate, though. In fact, during this whole period in question there are massive confounding factors. Like: the huge advent of oil, natural gas, nuclear, and hydro-electicity -- all judged superior to coal and capable of beating it hands down in the marketplace for many uses. And let's not forget the Great Depression and "Silent Spring" and all that followed.

Without a shadow of a doubt, that US coal production graph tells many stories that have nothing to do with what the industry is capable of.

From what I've heard, CTL has many problems. But are we really convinced that a coal production constraint in the next couple of decades is one of them?

US GDP and Coal Production, 1929-2005

There was a good segue on Australia's version of 60 Minutes last night from polar bears on thin ice to the coal industry

http://sixtyminutes.ninemsn.com.au/sixtyminutes/stories/2007_02_18/story...

Something that can be pointed out is that coal mining machinery is often electrically powered by a nearby or dedicated power plant. That must help EROEI. Metal mining machinery in well ventilated mines is more often (not always) diesel powered.

I can't help wondering if thin seam mining will lower EROEI from the need to separate shale from coal with lowered heating value via contamination. If so EROEI under 4 say will come a lot sooner than coal boosters predict. Perhaps we should burn the lot and get it over with.

Just a quick language note - 'Hobel' is generally translated as 'plane' or 'planer,' and though I can see why a translator would use plow/plough, 'planing' is more technically correct, I think, reading the information. Normally, 'pflügen' is the term for plowing/ploughing a field.

A fascinating thread, in an area I had no knowledge of whatsoever. Many thanks to all who have contributed thusfar, and just the sort of information that continues to make TOD invaluable (when it doesn't get invaded by the pillocks of this world)

I agree.

yes, an interesting and informative post and discussion. as an investor, i have not been able to find any (us) coal co.s to put my nickel on. research by others indicates that the industry is highly capital intensive , not unlike tar sand mining (not very glamorous either).

I have heard that China is within 30 years of Peak Coal at today's production rates and 20 years with continued growth.

I wonder if a higher extraction % of the resource is in response to the looming shortfall ?

Are most Chinese coal mines state owned or privately owned ?

Only state owned mines would take a multi-decade view of overall resource depletion IMO.

Any comments ?

Best Hopes for lower annual Chinese coal use,

Alan

Kudos for an informative and useful description :-)

I did not know anything about China's coal reserves or production before a couple months ago (and I'm still not an expert), but I can now understand why industrialized nations are crying about China's lack of accountability under Kyoto. I'm pessimistic. Between the US and China, I'd put money on a melted planet.

Estimated Recoverable Global Coal Reserves

Coal Production by Country, 2005

I think we should be watching coal production in China very closely over the next 10-20 years. Some people have unofficially raised the "Peak Coal" question--does coal production follow a Gaussian curve like oil?--and it definitely pertains to China. Right now, they have about 126,415 million short tons of coal reserves left (though calculation of reserves--just like oil--is problematic) and their 2005 production was 2413 million short tons--this leaves them about 52 years of coal left at current production levels. It will be interesting to see how this unfolds.

China's reserves are based on a 30% recovery factor. The U.S. achieves close to 60%, suggesting that improvements in the sophistication of China's coal mining will yield an increase in reserves.

On a wider point, current coal reserves generally have an r/p of centuries and represent a small fraction of the total resource:

The above graphic is for the U.S. only and gives a good representation of how reserves are not the sum total of coal in the ground. If the proportion of the inferred and undiscovered resources that is extractable is similar to that of the reserve base, then the U.S. will have sufficient coal to last for many centuries, even if use increases due to CTL.

The desirability of this eventuality is another question.

It is not difficult to cite specific reasons for the general volatility of coal since, among other things it has a history of some of the worst labor relations in most countries where it occurs. Thus, as contracts approach closure the mines and powerplants can stockpile coal in anticipation of a strike, and the strikes were often bitter, lasting many months. This in not now as prevalent as it used to be, but for many years it was an underlying cycle to coal production (and there have been a number of good books written on this in the past).

In regard to China, the demand has led to a stratification of their production to a degree (as happened here during the boom time of the 1970's). The larger more productive mines maintain their standards, in general, and because of the way that they mine it is not hard, as an example, to buy an additional continuous miner, bolting machine and a pair of shuttle cars, to increase production from one section to two, using the existing mine infrastructure to handle the additional volume.

On the other hand the increase in demand opens the door for small local mines, where production crews can be a family or a bunch of friends. Particularly where this is in a remoter region, or more isolated, there have been reports in China of local officials being paid off by "part of the action" and in these cases there are quite frequently almost no-one who really knows what they are doing. In these cases, sadly, very few of the proper safety precautions are followed, and there is little in the way of safety inspections.

This is particularly true when mines start to take the coal out of the main support pillars, as they retreat back from the boundaries of the area that they are working in, and where inexperience can be fatal. Similarly if the mines are not properly ventilated, so that poisonous gases collect (which depending on type they can do either at roof level or floor) and with the gases being invisible they can also be deadly. See, for example here

The fact that production is even feasible on that scale (and without massive capital outlay) would seem to indicate a resource that is far from peaking.