Tech Talk: Revisiting Oil Well Pressures and Blowout Preventers after BP's Gulf of Mexico Oil Spill

Posted by Heading Out on May 2, 2010 - 11:01am

I thought that it might be useful to explain where and how at least part of the problem with the Transocean Deepwater Horizon fire and sinking spreading oil across the Gulf of Mexico might have started. I am going to start by repeating one of my previous technical posts, where I explain what a blow-out preventer is, then I will add some comments in an update relating to the current leak.

This post is going to deal with some of the problems that a driller encounters as he reaches the layer of rock (the reservoir) in which the oil or gas is being held. And what I want to talk about is something called Differential Pressure, but to explain that, I need to drag you back to High School for just a minute.

Let's, in fact, go back to Newton's Three Laws. And, for those who slept through that part of the Physics class in school, don't be too ashamed - I have seen the desk where Newton whittled his name, being similarly bored. Let's start with the first law, which is probably the most relevant.

Every object in a state of (rest or) uniform motion tends to remain in that state of (rest or) motion unless an external force is applied to it.

Except that I want to change external force into pressure (which is force divided by area) since it is the way we normally think of it. (Note: I added rest which is a special case of uniform motion since that is specific to the oil we want to talk about). In other words, nothing is going to move unless something pushes it. It is what does the pushing and what does the moving that this is all about.

And now our drill, is down through the casing, drilling the well open hole and using the circulating mud to carry away the cuttings as it continues to go deeper. I had stopped progress last week just before we went down to total depth (TD) of the well, or into the pay. And the reason I did has to do with this differential pressure. But first, the bit about how you calculate pressure.

As you go deeper into the earth, the rock at any layer is carrying the weight of all the rock vertically above it. For rough calculations we generally consider that this rock weighs 144 lb a cubic foot. So that 10 ft down the weight of the overlying column on a square foot would be 144 x 10 = 1,440 lb/sq ft. But through convention we reduce the area that we talk about to a square inch (144 sq in= 1 sq ft) so with this division the weight on a square inch would be 10 lb. A remarkable resemblance to the depth number (grin). This means that we can assume, as we go deeper into the earth, that the pressure on the rock increases by 1 lb/sq. inch (psi) for every foot we go deeper. This means that at 6,000 ft, the rock is under a pressure, from the rock above it, of 6,000 psi.

Now water does not weigh as much as rock, but can be approximated to roughly half the weight. So that, by the same argument, under water, for every foot of depth the pressure goes up roughly half-a-psi. So that at 6,000 ft under water the pressure is 3,000 psi (roughly twice the water pressure in the wand you use at a car wash). Now because we have increased the density of the fluid in the well (the mud) to help lift the cuttings out of the hole it weighs a bit more than water, but for the sake of working the example I'm going to use the half-psi measure for now. We are now at the point where the actual amount that it weighs becomes important.

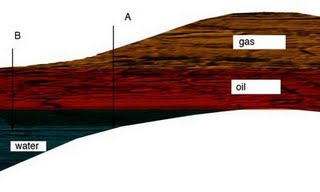

I have made a very simple sketch of the layer of rock that we are going to drill into. In order to trap the oil it is shaped into a dome, and the sketch shows a vertical slice through that dome, viewed from the side. It has a layer of oil in it (the reddish layer), but above that is a layer of gas that has diffused from the oil (brownish), and below it is water (bluish) which may have been there when the algae died and which has stayed with the remains as they turned into oil under the temperatures and pressures deep in the rock. Oil floats on water, and gas is lighter than oil, so we have the three layers. At the moment the well has not arrived and all three fluids are sensibly in equilibrium at the same pressure.

Now why do we need to know this before we reach our layer of oil-bearing rock? Well first let's go and interpret that first law a little more.

If a person on either side of you pushed you with equal force at the same time, you don't move, because the two forces balance out. It is only if there is one force, or if one of the two pushes harder, that you move. In other words, where there are a number of forces acting on a body, it is the size of the difference in pressures, and the direction of that difference, that controls the movement.

Consider, here we are drilling merrily away (and have cased the well near the surface, and hit no more fluids on the way down) and at 6,000 ft. we penetrate the rock that is capping the well, and enter the rock with the oil in it. The oil (in the rock) is at some fraction of the overburden pressure, since it is trapped in the rock, and for the sake of this example I am going to say that it is at 5,000 psi , the fluid in the well is at 3,000 psi, the height of the mud column.

There is a difference of 2,000 psi. We are drilling a hole some 6-5/8th inches in diameter. That has an area of about 34.5 square inches. The total force we have suddenly applied to the bottom of the well (bit and fluid) is thus (area x pressure difference) 34.5 x 2,000 = 69,000 lb (or 35 tons). Oops!

Sadly most catch fire and the rig is destroyed (there are more pictures of such damage at the EIP site). It's called a blow-out, and they still happen.

This is why we approach the oil/gas producing zone of the rock with caution. And bear in mind that the driller that is controlling the progress of this well is at the surface, trying to guide the bit at the bottom of the hole, with, historically, little immediate information to help.

Based on the surveys that brought the crew to the site in the first place he knows roughly how thick the layers of rock are, and probably what rock they are, but the only real information on where the bit is in that sequence, is from the returns (cuttings) that come out of the well, and there is the lag, we mentioned before, while those chips make their way up the 6,000 ft pipe. (This is why Measurement While Drilling [MWD] has been such a relatively recent boon to the industry (though not all rigs have it)).

By monitoring a number of pressure gages the driller can gain a sense of what is happening at the bottom of the well. If he senses that there is going to be a problem, then he can do one of several things, based on the way the well is set up.

The first thing is to increase the density of the mud. By making the fluid in the well weigh more, the difference in the pressure across that face is reduced, and the change in conditions is easier to handle. However weighting up the hole has the disadvantage that it becomes much slower to drill with a heavier mud (it is a poor bottom-hole cleaner among other things). And, if done during drilling, bear in mind that once the heavier mud is added to the well it won't be fully effective until it has had time to get down to the bit and then fill back up the annulus between the drill string and the casing all the way to the surface.

So that is an expensive and slow option. Let us take the game a little more interesting and say that there is a gas pocket above the oil, and that the hole is going to go into the layer at A. Gas will enter the well at the down-hole pressure, but as the bubble rises, that pressure is reduced, and the gas expands, pushing the mud above it out ahead of itself. Another potential source for big-time trouble. And this one (which is known as a kick in the well) happens much faster, so there is less time to react.

How do we handle this? The answer is to invert the problem. Gas or oil flows into the well because the well is at a lower pressure than the fluid in the rock. The fluid in the well is, initially at the pressure created by the depth, and by the weight (density) of the mud in the hole. However, if we put a restriction on the flow of fluid out of the well (such as when you put your finger over the end of a garden hose so that the stream becomes smaller and shoots out further) we can increase the pressure in the well.

For those who want to know why, if the same volume has to go through a smaller hole in the same amount of time it has to go faster. This means it has to be pushed harder. Bernoulli explained it, and there is an animation available that helps explain it.

What it means is that by adjusting the flow out of the hole, the driller can adjust the internal pressure, and thus "kill the kick," or if gets to be too much of a problem, “kill the well”. But it is not completely that simple. Bear in mind that there is all the drilling and rotating equipment on the rig floor connected to the drill pipe at the top of the well. None of this can stand much pressure. So we need to place another piece of equipment between the drilling rig, and the top of the well.

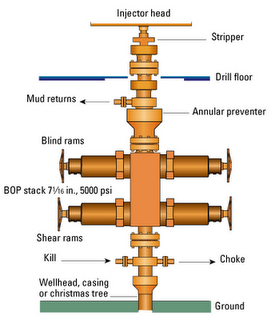

This is the Blow-out Preventer (BOP), which is essentially a ram that very rapidly shuts off fluid flow at the top of the well. These have to be well designed, since they are generally the line of last defense against a blowout, and when they fail as the pictures show, serious problems arise. They also form the basis for the well-known structures, often referred to as Christmas Trees that sit at the top of producing wells. By themselves, however, these aren't enough, since their main function is just to slam the door shut, before all the oil gets out and we have a gusher.

The more critical tools are the chokes on the well. (Below the rams in the picture above). There are generally several, both hydraulically operated and manual (in case the power dies) which are simply large valves that can be turned to increase or reduce the size of the flow path out of the well over to the mud pits. By adjusting these, in real time, the driller can control the well pressure, and thus the dynamics of the behavior at the bottom of the well. And after the rig leaves, an operator can adjust well pressure, and thereby the production from the well and its long-term performance.

If the operator is well trained (and you find drilling simulator equipment in Petroleum Engineering Departments so that students can understand how to do this (I last tried some decades ago) the well pressure will be controlled, so that any kicks can be handled, and the drill can now penetrate safely into the rock containing the oil/gas, which we call the reservoir, or the pay.

Update

The oil spill is continuing to get worse, and there are growing questions that have been raised on what could have gone wrong, and how it can be fixed. I am in the same position as most, in regard to getting information – it comes from news reports, in the main. But there are some points that can be picked out as the focus of those reports switch to the impact that the oil is going to have on the coast and businesses that are going to be severely damaged.

An early story noted that the BOP had recently been tested.

Mr. Hayward said the blowout preventer was tested 10 days ago and worked. He said a valve must be partly closed, otherwise the spillage would be worse.

There are a number of things that can go wrong with a blowout preventer, said Greg McCormack, director of the Petroleum Extension Service at the University of Texas, which provides training for the industry.

The pressure of the oil coming from below might be so great that the valves cannot make an adequate seal. Or in the case of a shear ram, which is designed to cut through the drill pipe itself and seal it off, it might have encountered a tool joint, the thicker, threaded area where two lengths of drilling pipe are joined.

Still, Mr. McCormack said, “something is working there because you wouldn’t have such a relatively small flow of oil.” If the blowout preventer were completely inoperable, he said, the flow would be “orders of magnitude” greater.

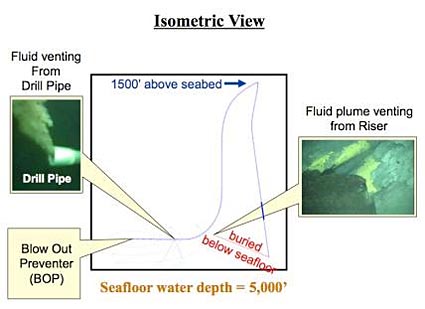

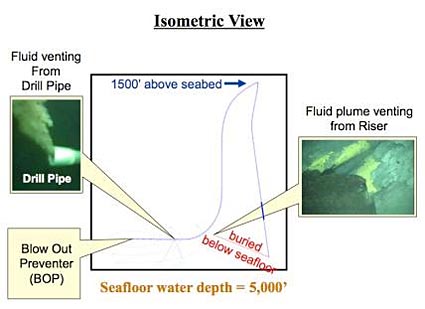

However oil is now flowing through the BOP and out into the water immediately above the well site on the sea bed. When the site was visited by a small remotely operated vehicle with cameras they showed that the riser, the pipe that normally carries the oil from the sea bed to the surface, had kinked over when the rig sank, and oil was coming from three places:

The Coast Guard said it had not detected oil coming from the well Friday and assumed post-accident efforts to activate the blowout preventer “a huge stack of valves sitting atop the wellhead on the sea floor” had been successful.

But later trips by the remotely operated vehicles (ROV’s), discovered oil shooting from the end of the pipe-like riser that had connected the rig to the blowout preventer.

A second, smaller leak was found in a section of drill pipe near the wellhead. That 21-inch-diameter riser had become detached from the rig when it sank. In the process, it was folded over at a 90-degree angle just above the wellhead, which had the effect of kinking it like a garden hose and constraining the flow of oil from the well. It now sits in a long, meandering mess on the ocean bottom. This helps explains why oil was not initially thought to be seeping. , . .

The preferred option, he said, is still to find a way to engage the blowout preventer. That fix, if it works, could be handled in a matter of days, he said.

But if that doesn't work, the other option is to drill a deep “relief” well into the damaged well and stem the flow of oil, though that option could take several months, Suttles acknowledged. He said his team would spend the next several days trying to determine the best method.

The problem lies, in part, with the capabilities of the ROVs and their ability to get access to the well site on the sea-bed.

There is a report from a survivor (h/t Fractional Flow ) that says that the well was shut in and they were going through the process of separating the rig from the well, and moving it off. They began by cleaning out the drilling mud from the riser, replacing it with sea water. However, when they re-opened the valves at the top of the well, the pipe in the well had become filled with gas from the well, under considerable pressure, and this “Kicked” the well as the valve opened. Gas, as the pressure gets less as it moves up the pipe, expands much more than oil. And unfortunately in the process of disconnection, the pressure to hold the gas, which comes from the density of the drilling mud in the riser initially, had been removed as part of the disconnection process.

So the high pressure gas was able to blow all the sea water in the riser out onto the deck of the rig. (This happens extremely quickly, well below a minute) The gas then followed, and as it flowed out of the pipe at the top of the well there was some hot source that caused it to ignite. (This could even be from a static electricity spark). Because of the depth of the well, the pressure in the bottom of the well was in the 30-40,000 psi range.

Part of the problem that arises with flows at that pressure is that any abrasive particles (such as small pieces of rock) will cut through metal at the speeds at which it is carried. (Such jets were used to remove the damaged tops of the wells in Kuwait after the Gulf War, for example). So that it is possible that as the BOP started to function the high-velocity flow may have eroded part of the system to allow some fluid to bypass the plug that the BOP inserted. If that happened then the continued flow would just enlarge the passage again fairly quickly, so that the BOP will become ineffective.

However there are pictures of the leaks available.

Pictures of the oil flows ( Drillingahead )

At this stage there does not appear to be that great a driving pressure for the oil coming out of the well. (If there were, the flow would be more directed horizontally) This suggests that the BOP did at least partially function, and that the passage may have been eroded by the particles in the gas and oil now escaping.

There is a recent report that the accident may have been caused by a poor cementing job by Haliburton:

After an exploration well is drilled, cement slurry is pumped through a steel pipe or casing and out through a check valve at the bottom of the casing. It then travels up the outside of the pipe, sheathing the part of the pipe surrounded by the oil and gas zone. When the cement hardens, it is supposed to prevent oil or gas from leaking into adjacent zones along the pipe.

As the cement sets, the check valve at the end of the casing prevents any material from flowing back up the pipe. The zone is thus isolated until the company is ready to start production.

The process is tricky. A 2007 study by the U.S. Minerals Management Service found that cementing was the single most-important factor in 18 of 39 well blowouts in the Gulf of Mexico over a 14-year period. But at the time of the accident, "well operations had not yet reached the point requiring the placement of the final cement plug, which would enable the planned temporary abandonment of the well," the Halliburton statement said.

However it is hard to see from what is known, that this was a cause in this case.

Some other earlier Tech Talk posts that might be of interest in following the ongoing discussion about the problems encountered include:

Casing a Well

The Drilling Part of Creating an Oil Well

Completing and Perforating a Well

God. Reading through these various detailed technical descriptions really should bring it home to anyone who blithely pontificates about "technology" solving the energy crises just how extraordinarily difficult it is to get this deep water oil and gas up from there. All those media commentators who so casually reassure us that there's nothing to worry about - that there's huge amounts of oil and gas just waiting for us to come along and retrieve it - they really need to study this accident and then shut up until they've got some useful contribution to make.

Tragic though this disaster is it is hugely enlightening for the ill-informed - among whose ranks I would include myself.

Marco Rubio, (R) candidate for FL Senate seat, when asked on CNN this AM if we need to rethink offshore drilling responded; "Well, I think we need to rethink the technologies of offshore drilling." (emphasis his)

Clearly there is a mindset that more, better technology thrown at our energy situation can solve these things. Little acknowledgment that there are limits to our technology. It seems to me that Deepwater Horizon was pretty much a state of the art platform, technologically. Comments certainly invited.

One thing I know about applying technology in their designed purpose is - rather quickly - the processes and language drives to simplification for reasons of cost efficiency and standardization. This is evident in the names given for the pieces of equipment and machinery.

I'm no drilling expert, far from it actually. Although they use complex and relatively advanced machinery and systems, one doesn't have to be a mechanical or electrical engineer to operate these processes. I use this as a benchmark in our designs. If a reasonably trained tradesman cannot easily identify and understand the drawings, then we've missed our mark. I believe this is a common adaptation of any technology in our society. That is, how does it go from concept, to development, to a useful tool.

For those familiar with telecommunications, I think this is the underlying reason ATM (Asynchronous Transfer Mode) never attained the widespread deployment as expected. At one time a large proportion of Internet traffic was transported on ATM but it is complex to implement and could not be made simpler. This particular technology, although robust and efficient, in the end application was not a good tool. (MPLS is proving easier to understand and implement because it lives in layers 3 and 4).

In the case of deep water drilling there appears to be an analogue. I started writing this to chide the good Florida Senator, but have come around to understand what he intended to say but did not have the semantics at the ready. Is the present means of deep water drilling for oil and gas a good tool?

By extending typical drilling methods has it come up against the limits? I'm sure many in the business are taking the time to give it all a rethink. Maybe Dr. Evil wasn't that far off with his (air quotes) Laser...

http://www.whoateallthepies.tv/dr%20evil%20laser.jpg

You know, just mount it on Moon as planned and drill away - brilliant!!

(How are images inserted??)

Bc -- The discussion of advanced drilling tech just reminded me of the Mars landing failure a few years ago. Tens of billion's of $'s of tech history, hundreds of millions of $'s in equipment on the lander. And some of the smartest folks on the planet running the mission. And why did it crash into the surface of Mars? A scientist forget he was setting controls in meters and not feet? Got a high tech fix for that? How about having a recent high dschool graduate double check his numbers.

As Pogo said long ago: "We have met the enemy...and he is us".

That is ironic you mentioned the Mars Lander. I was going to chide you in a post farther down about using metric with all the GPM and lbs/ft. etc. - but thought better of it ;-)

Since moving back to Canada from the U.S. its taken me over two years to get back into the metric swing of things. But, we still use a lot of imperial units, i.e. I just can't get away from MPG versus L/100 km; and, an inch is still the length from the middle thumb joint to the tip.

But the one that drives me crazy is gallons/min, or GPM. Is that U.S. gallons (usually is), or imperial gallons? Of course, we have pumps measured in this all the time.

As an Australian (aka a Southern Hemisphere Canuckostani), we have become indoctrinated with the metric system for a generation. And all of it is okay - length, weight, and volume, except for small measures for which we do not have a handy equivalent - there is no inch, foot, or ounce equivalent - and it is annoying. Saying "He missed the putt by 15cm." or "She is 2.5cm taller than her sister." just don't cut it, sadly. Someone is still 6 feet tall (not 185cm), and a pint of beer is still a pint however - cheers.

Don't worry. Just a bit more of indoctrination and your grand children will be perfectly confortable with grams and centimeters. The entire world already suffered from that, but most countries did so a century ago.

Remember the problems that occurred initially with the Hubble telescope? The lens was cut incorrectly. Out of focus. Very smart people are capable of making very stupid mistakes.

hotrod

To be fair, the problem was a speck of grit in the machining mechanism caused that flaw. It was not human error.

About Hubble:

http://en.wikipedia.org/wiki/Hubble_Space_Telescope#Origin_of_the_problem

Seems like human error to me.

Never ignore what your instruments are telling you.

Definitely human error, not a speck of grit.

If the thing hadn't been precisely mis-ground in a known way, it wouldn't have been possible to fit it with a corrective lens which brought it reasonably up to spec.

I don't know where you got that idea.. the flaw was attributed to an incorrectly assembled measurement device. This error was noticed during testing, but unfortunately was ignored. NASA also failed to oversee the contractor, and in fact could have used a backup mirror that was ground correctly.

Of course, there are failures caused by unprecedented events, e.g. the first metal fatigue occurring in passenger jets. But for the most part, failures are caused by events that are well unknown, standard procedures that are not correctly followed, lack of procedures, and poor management of quality and risks, or combinations of those.

My analysis of failures suggests that even among organizations that are motivated and sensitive to risk, such as NASA, there is a systemic trend that erodes safety standards and moves towards more error prone behavior. This is a characteristic of many failures, where organizational factors are identified as the root cause of failure. The management process that should prevent failures, itself fails, and then it's just a matter of time before a minor incident turns into a major accident.

The implication is that whatever activity humans perform, it is inevitable that major accidents will eventually happen. The only way to alleviate that is only perform activities that have a low worst case impact.

"(How are images inserted??)"

You need an account on an image sharing site. I use www.photobucket.com. Easy to do. Once you get an account, at your homepage you'll see "upload images". Find your image and open it. After the upload completes, click on the thumbnail of your image to open it in photobucket. Once it opens, scroll down and on the left you will see a sharing menu. Pick the html option. You should see "copied" pop up for a sec.

Back in TOD, at the edit screen, just paste the html code into your post where you want it (you should see several lines of gobbledygook).

Try to keep the horizontal aspect of your image under 600 (I usually prefer 500) or the image will run off of the right side. Also, good idea to preview your post to make sure the image loads correctly and that it is the right image. It's not as complicated as it may sound. Remember, images use a lot of bandwidth, and they don't need to be high quality. I usually edit mine down to 100dpi and reduce the size before I upload to photobucket.

Or...

If you're using an image from the internet.

1) Right-click the image, select "View Image" and copy the URL of the image:

eg. http://www.whoateallthepies.tv/dr%20evil%20laser.jpg

Then paste your URL...(except use "<" and ">" symbols instead of curly brackets) into the following simple HTML command:

{img src="http://www.whoateallthepies.tv/dr%20evil%20laser.jpg"}

Width setting is optional, eg. to get 500 as recommended by Ghung...

{img src="http://www.whoateallthepies.tv/dr%20evil%20laser.jpg" width=500}

(Lots of other options on http://www.netstrider.com/tutorials/HTMLRef/commands/img.html)

The result comes out like this when you preview your post:

From what I have read, the production casing had been cemented, with the bottom plug set. So it seems to me that there had to be a failure of the cement job and bottom plug.

I can't figure out why they open the values if the well was "shut-in". Weren't they trying to replace the mud with seawater in the riser? A diagram showing the mud return path might help us arm-chair observers understand the problem. Does it come back up at the BOP (ocean to rock transition) or at the bottom of the pipe where it enters the reservoir? Seems like you would need two return paths: one if you want to sever the connection at the sea floor and a second to handle mud return from the bottom.

Second question: if the valve is closed, can you measure the pressure in the pipe and determine if it is oil or gas? If so, I would assume that this blowout was caused by operator error since they should have been able to bleed the gas in a controlled manner.

realist -- There are actually several flow back channels in the riser. Bottom line: the primary method to control well flow is the heavy drilling mud. The fact they were replacing the mud with salt water tells you they had absolute confidence the well could not flow. They were wrong.

ok, so that points to a problem with the cement that allowed gas in. I find it quite amazing that they can fill cement along miles of pipe and expect it all to cure with a perfect seal. Can it be tested before you start replacing the mud with water?

Or a big patch of methane hydrate that was melted by the heat generated by the cementing or drilling process.

Actually realist bad cement jobs are not uncommon. In fact, so common we have a special tool run down the hole to evaluate the cement: the "cement bond log". Done mostly to make sure you get a good completion later. If the CBL looks bad you shoot holes in the casing and pump more cement into the annulus. This will be a very important issue when the facts finally surface. They also pressure test the cement at the bottom of the casing...called a leak off test. Pressure up until you see the cement begin to break down. Another standard procedure.

If they didn't follow procedure, the lawyers probably won't let them admit it. Let's hope there are mandatory records that can be checked, assuming they weren't lost in the sinking.

The US government/MMS should have electronic copies of this stuff. That would be a very small overhead given the huge investment.

On the other hand, if we electrify transportation, we would not have to worry about this stuff. I think the whole oil project is rapidly coming to a close. Natural decline is going to overwhelm the industry so we probably don't need to make things worse.

"When you are falling, dive" -- Cheri Huber

realist -- I doubt much will be hidden in the investigation. Remember most of the workers on the rig aren't BP employees. That doesn't mean they won't try to protect themselves but there were many independent witnesses there. And no one...absolutely no one... will perjure themselves for anyone. Except for themselves, of course. I doubt any records survived except those that might have been transmitted in real time back to the bank.

If cement was completed 20 hours earlier, the results of those tests should have been sent to shore for approval to remove the mud. Would that kind of decision be made in the field?

Could the standard procedures be unable to detect certain types of flaws in the cement?

As I said in other post, I think the standard procedure should be to wait a day and retest the cement to make sure nothing has changed before removing mud.

realist -- There are thousand of pages of procedures and specs written for every well like this. And following procedures is well documented and, in some cases, both sworn to under oath at the time and witnessed by third parties. that's how critical parts of the process can be. But that doesn't mean they were followed. And there's always some leeway in the inpretation process. As I said a few days ago it's best not to speculate at this time on this incident but I can add that almost all failures like this are typically human error and are related to not following standard practices.

Wow, that is quite a statement. All the more reason to increase oversight as much as the oil companies will not like it.

realist -- I don't think it's been mentioned but the MMS has inspectors flying around the OCS all the time doing planned and unannounced inspections. They also check all then paper work that has been certified. And they don't hesitate to write you up ("get ink") if you've violated regs. And they have full authority to shut your operations down immediately if they think there's a safety issue. Unfortunately the Feds can't be everywhere all the time. And the circumstance when a human error might have caused the type of accident we just witnessed might only exist for minutes. In theory an MMS inspetor could have given them a clean bill of health but then before he took 15 minutes to get to the chopper pad the rig could have exploded. That's just how fast it can go from AOK to deadly.

Agreed, my point is that MMS should have access to all the records to they can reconstruct the events leading up to the problem and take corrective action. If these types of problems are unavoidable (which I think is true), perhaps we should reconsider our energy policy. At some point no amount of money that BP will pay can rebuild the loss to our ecosystem.

The MMS has access to all records all the time. The bad news: records from the last 24 hours before the blow out are gone for good...went down with the rig. But virtually all ops records are emailed in daily by the operator as well as all the subcontractors. And the feds doen't even need a court order: copies of all records belong to the MMS via the drilling permit process. Unfortunately even if we had complete records right up to the second of the blow out we might not see the cause. I understand it can be difficult for folks to accept how quickly matters can turn fatal during drilling ops. I have no idea what went wrong. But it' possible the entire system looked stable and safe with no indications of any sort of trouble just 60 seconds before the well came in. All safety protocols followed and everyone doing their job correctly. That's how it can happpen on the drill floor: you can die before you even know you're in danger. We know this in the oil pacth and accept it. TPTB need to explain honestly to the public that no matter how much they say they will improve safety protocols they really can't promise a repeat of this event will never happen again. Maybe lower the risk but never 100% prevention. As was said long ago on "M.A.S.H": God answers all prayers. Just sometimes the answer is no.

And sometimes God says the rig will blow out, men will die and the environment suffers. Deal with it...we do. Pretending otherwise is dishonest on the part of the industry, gov't and the public IMHO.

According to a whistle blower, BP has a history of failures and lousy records and MMS didn't do much about it. And this is not the first disaster they have had because of shoddy work or procedures. Just one example "On October 25, 2007, BP pled guilty to a criminal violation of the Clean Water Act and paid a $20 million fine related to two separate oil spills that occurred in the North Slope in March and August of 2006, the result of a severely corroded pipeline and a safety valve failure." No doubt there will be accidents no matter how well procedures are followed but it seems they have a history of cutting corners and that is unforgivable in industries that can have such a wide scale impact - deep wells in the ocean, and nuclear power plants certainly fit that description. But the larger question is given the nature of humans beings should we ever attempt such projects that have the capacity to do such harm?

http://www.truthout.org/whistlelower-bps-other-offshore-drilling-project...

here is an excerpt of the article:

oxi -- "given the nature of humans beings should we ever attempt such projects that have the capacity to do such harm?" That's exactly the point I've been trying to make in my own subtle way. No matter the effort no one can promise such an event will never happen again. So a conscious and knowledgable choice must be made by society: accept the risk or stop such efforts. Each side of the argument needs to heard clearly. And then a decision made. Ignoring a risk for self serving reasons just won't cut it anymore. The public is free to cry all the crocodile tears they want about the environment today. But we heard none of that anguish when gasoline was over $5/gal. Drill...don't drill. Doesn't really matter to me. Just make a decision and stick with it.

Given that the public is not fully informed and is deliberately mislead about the nature of the problem facing us I don't think the public should carry all the burden. While I don't hold out much hope for the general public, I do know that they have not been told just how little time offshore drilling will give us. True they could do their own research, but groups like CERA have been deliberately deceiving them. When WWII started the public buckled down and supported the war effort. If they were told an asteroid was going to hit planet earth unless we made a massive effort that would entail large increases in taxes I bet they would agree. So if our government leveled with the American Public they just might surprise us.

By and large however I don't think the public is crying crocodile tears over the environment. Not in my neck of the woods anyway. You cannot trust MSM reporting for a full picture - just because they feature pictures of someone rescuing a gull doesn't mean that my neighbors care about gulls or sea turtles. If an environmental scientist complains about $5 a gallon gasoline, well then your point is well taken.

OTOH The oil industry with the help of MSM has certainly put enough disinformation out there to cloud the issue of Global Warming so that the public is not aware that something akin to an asteroid (in terms of whether the planet is livable for humans) is going to happen to the planet.

I don't want more drilling and I would like to see donkeys become the usual mode of transportation. I am sticking to that.

oxi -- Of course they are real tears...just like the ones rolling down their cheeks for the thousands of our troops and 100's of thousands of innocent civilians killed in the ME. Please don't lecture me about the moral compass of the American people as a whole. Wait a few years when PO starts hurting bad and watch them demand more Deep Water drilling. IMHO just as sure to happen as the sun rising tomorrow.

Just my personal opinion of the American people. Nothing more...nothing less.

"I would like to see donkeys become the usual mode of transportation."

And when and if that happens they'll have to feed the donkeys - and the tradeoff against using land to grow food for people will be far more draconian in a world of nine billion than it was in a world of one billion. Now and then there will be an epizootic among the donkeys that will cause great grief and probably many deaths, as epizootics among horses once did. Oh, and now and then they'll be trampled by the donkeys; IIRC within the last few weeks, somebody here mentioned a one-in-eight lifetime chance of dying in an encounter with a farm animal back in the good old days. The risks being run nowadays pale into utter insignificance compared to anything approaching that magnitude.

So even in your fifteenth-century alleged paradise there will still be costs and risks, not universal peaches, cream, and roses. The zero-risk Utopia sought by environmental (and sometimes medical) puritans will still not have arrived. Indeed it will never arrive, not under any scenario.

No reasonable person could disagree with this, however it seems to me that is not how things actually work in the real world. Oil companies will do their darnedest to produce oil in the OCS or wherever, if they can make a buck out of it long-term. Meanwhile the general populace will continue to live in their Wal-Mart world, and very rarely - if ever - think about the downside risks of oil exploration they so hopelessly depend on. Just a thought.

Cargil -- That was exactly my point. The American public might not say it in front of a camera but they'll accept the possibiity of another such blow out if it gives them the illusion of maintaining BAU. And the politicians will follow their lead. That is exactly how our world works IMHO. Like it or not.

Yes, if the only environmental problem with oil was the occasional spill, I might agree. But the environmental consequences are far reaching. I fear that our generation's legacy will be more about the destruction of earth's life support system than the marvels of the oil industry.

Do we really need to squeeze every last drop? Do we really need to spend our hard earned dollars supporting the Mid East desert economies? After a trip to Dubai, I'm shocked at the irrational nature of their abusive society. We are doing a disservice to the world be supporting them. OCS drilling is a finger in the dike and buys us a few years.

We should be grateful to all of the men that have given their lives to bring us oil, but the time has come to reevaluate our policy and try to save our economy by reducing our addiction.

In most cases they used to run a CBL Cement Bond Log a sonic measuring tool, However I have been retired for 15 years. So I'm no longer up on Standard Op procedures.

Could they run all of those tests in 20 hours? Seems pretty fast. I'm not an oil engineer, but it would smart to test the cement, wait a day and retest to see if there are any growing fractures. Given that cement is such a huge problem, it doesn't make any sense to take out the mud until you are damn sure the stuff is solid.

Who is responsible for testing the cement seal Transocean, BP or Halliburton? I would love to see the emails.

The operator is always responsible. That doesn't mean they can catch every screw up by a service company. But they are supposed to.

Still pretty much the same ops dip. And for the rest of you folks that means the CBL is neither fool proof nor easy to interpret.

As the plan was to temporary abandon the well and they had just finished the cement, they would not have been planning a CBL. Though they would need to do this on their return and before they perferated the well.

A pressure test on the liner is all they would have done, most likely from the top. We are already looking at our procedures to incorperate inflow tests,ie testing from below. It also appears they had a great deal of trouble setting the liner seal which is more likely the failure point than the cement through the shoe track.

http://online.wsj.com/article/SB1000142405274870396920457522063063839762...

Safety Device Questioned in '04

Regulations are ONLY needed when there is bad design. The oil industry is inviting tighter regulation. They will pay 100x more than if they had designed a functional BOP.

Good design is expensive.

I'm trying to work out whether the cement plugs had been set or not.

Is the replacement of mud by water normally done after the cement plugs are in place? And where are the plugs placed?

ETA: I'm also wondering that since the drilling ops was nearly complete and the well was considered "plugged" then perhaps the eye was taken off the ball, wrt to risks of blow out. It seems they had done the hard part and were "wrapping up" when something unexpected happened.

It appears since drill pipe was in hole they had run a liner (casing) hung off some distance from bottom in the last protective string of casing. Liners have an external casing packer and are cemented through liner lap. This connection is then tested by doing a draw down test with a packer in the casing above liner top. If this test is sucessful and there is well integrity the drilling mud can displaced with seawater. It seems likely that there was a liner lap leak or some sort of downhole failure. The fact that the BOP/shear rams did not function or seal compounded the problem.

Bob, I think you're on it, don't know if you had seen this but Halliburten was reported in Upstream as saying as much.

http://www.upstreamonline.com/live/article213877.ece

Good description but there is no way the pressure was 30-40 kpsi at 18,000 total, 5,000' water.

Rockman would be the ultimate expert as he has made a living predicting this but "normal" pressure would probably be around 8,500 psi.

Still enough to handle.

i was a bit surprised about that number, but it was the one quoted by the survivor in that ref you cited, and I presumed he would know something that I didn't and so that was the one that I used.

Fair Enough saw this discussion somewhere else and the conclusion was that the witness said something to the effect that we are working with 30,000- 40,000 psi pressures and not referring to this particular instance.

FF

Thanks for yet another informative report, HO.

The 30,000 psi pressure figure amazed me as well, ignorant as I am about this industry. A scuba tank holds about 2,000 psi of air, and you don't want to be nearby when one of them explodes.

Then I started wondering how far they were from drilling for diamonds. According to Wikipedia, 40,000 psi is about 5% of the pressure employed in making lab-created diamond, 5.5GPa.

Yeah you right. Typical deep well in that are might drill with 15# mud to deal with overpressures. Convert lbs/gal mudweight to psi/ft and multiply by 18,000' depth gives about 14,000 psi (8,500 psi would be hydrostatic pressure, not formation pressure).

Geo - The highest MW I've drilled in DW was 17.9 lbs/gal. And here's a small detail: there is also the ECD - effective circulating density. You might be using 17 ppg mud but you're pumping it down so the added force from the pumps would give the appearence of, say, 17.5 ppg. All well and good but when you stop pumping the effect drops back to the lower weight. That's why when you stop drilling the first thing you do is "check for flow". You literally look to see if mud is flowing out of the well with the pumps off. Not a good sign obviously. One of the first signs you might be taking a kick.

Yeah, there are some deep GOM shelf wells that have used >19# mud. I know you know this, RM, but some folks here might not realize that it isn't just a matter of having enough mud-weight (plus ECD's) to hold the formation pressure, but you can't get too high either - if you exceed min stress in the open hole and frac it, you risk losing circulation, and if that happens faster than you can add mud, you know what happens. It isn't the amount of pressure - it's knowing it precisely that counts - deep wells in that part of the GOM typically have narrow margin between formation pressure and min stress and ECD's are closely monitored.

I would be interested in seeing people here comment on this story that was making the rounds yesterday..

Leaked report: Government fears Deepwater Horizon well could become unchecked gusher

ericy -- it's called sand cut and is a common problem in many producing wells let alone a blow out. A very simple concept: they can cut 2 inch think steel with a water jet carrying sand just like slicing thru a load of bread. But IMHO it doesn't matter: I can't concieve of any way to deal with the blow out at the well head other than getting the BOP to work. And that seems very unlikely at this point. They well will either kill itself or be killed by the relief well. Any other expectaion is grossly optimistic IMHO.

When I was a kid I worked at Coryton oil refinery in the UK. If we couldnt get into a tank because the hatch was rusted shut we would climb on the metal roof and cut a hole with a water jet operating between 3000-4000 psi.

Rockman

could you describe the mechanics of what you mean by 'the well will either kill itself or be killed by the relief well'?

The Ixtoc case history is relevant (although the Ixtoc well was in shallow water). The well blew out in June, 1979, and they weren't able to kill the oil flow, via relief wells, until March, 1980:

http://www.incidentnews.gov/incident/6250

The estimated flow rate from June to March was 10,000 to 30,000 bpd.

The Wikipedia article goes into more detail:

http://en.wikipedia.org/wiki/Ixtoc_I

And that schedule takes it right through hurricane season.

Nate -- When a well is flowing uncontrolled from an open well bore the formation will often flow into the hole and plug the flow off. Called bridging over. Less likely to happen in a cased hole like BP has on thir hands. But the rocks can still flow into a cased hole. This can lead to "point loading" on the casing causing it to collapse and, to some degree, diminish the flow. BP is praying for either scenario right now. Might happen in an hour...might never happen.

I suspect most here already know the goal of the relief well: drill a new hole to intersect the old hole and pump heavy mud down it to kill the wild flow. But even if the well kills itself soon they still need to drill the relief well. Only way to make sure it doesn't start flowing again. A procedure required by Fed regs.

Rockman in your opinion does the possible uncorking of the remaining controls and riser through sand-cutting make the possibility of at least a temporary formation bridge over a little more likely?

Also I am seeing a report from Michael E. Lynch (not Michael C. Lynch of CERA fame for those wondering) http://www.glgroup.com/News/Halliburton-issues-statement-on-Deepwater-Ho... of a Halliburten statement that casing failure is their likely cause. And another in upstream saying they had not put a cement cap in the upper portion of the well yet.

Is this a situation where the production string is cemented and sealed at the formation but with no upper cement plug is set and could then a casing above that lower plug fail and allow the formation to push through that failure to the seawater riser? Is that what they are saying? Isn't that annulus supposed to be packed with cement too?

If I get this correctly, there is no bridge plug, no cement shoe and float, drill string, and there is no top cement plug in the well when the BOP test is done and the mud has been displaced with seawater, (completion fluid in the well itself?) The controls, BOP's and a column of seawater is all that's between the formation and the rig?

Halliburton said the hole was cased, cemented and tested. Therefore there was steel and cement between the formation and the rig. No plugs had been set according to Halliburton. There was a cemented shoe and float.

"Isn't that annulus supposed to be packed with cement too?"

I assume you mean the 7" liner annulus, then the answer is yes it should have been. There was some mention of loss circulation while drilling so may they had losses during the cement job as well.

"BOP test is done and the mud has been displaced with seawater, (completion fluid in the well itself?)"

The liner was tested not the BOP, the pressure test would have been done by closing the BOP which goes to show the BOP was operating shortly before the blow out.

"There was some mention of loss circulation while drilling so may they had losses during the cement job as well."

Thank you Toolpush. When they pressure test the liner, does that mean it has to hold a certain pressure for a given period of time w/o additional volume being added? And it passed that, apparently. What would the psi of the test typically be on a well at this depth?

x -- That's exactly right. They run the pumps up to get an effective pressure of X psi for Y minutes depending on the requirements of that particular test. The test is charted so there should be a record.

Thanks Rockman. Would they use the annular or sized BOP to do the test? Meaning there must be a pipe running through the BOP when the test is done. Then that pipe was likely still there when the blowout occurred, necessitating a shear cutoff instead this time?

OK coffee is kicking in, thanks to you both the lights are coming on too.

x - They actually have "test plugs" specifically designed for testing BOP's.

The Timor Sea blowout last year:

http://blog.skytruth.org/2009/09/timor-sea-drilling-spill-worse-than.html

Timor Sea Drilling Spill - Satellite Images Reveal Extensive Slicks

TUESDAY, SEPTEMBER 1, 2009

http://www.chron.com/disp/story.mpl/business/deepwaterhorizon/6980770.html

'Cementing' of rig's well eyed as possible culprit in blowout

April 29, 2010, 4:27PM

As we have discussed, Halliburton was the cementing contractor on both wells.

When I sailed thru that area in OCT 2009, there was approx. 300 linear miles of thick brown sludge on my course line to Bali

Does anybody wonder what the future will be like ?

It's here already.

That's why I was a bit surprised by the slow flow shown in the picture, given the implication of the very high flow rates that are beginning to appear in the press. But remember that 5,000 barrels a day converts to 145 gpm. At a pressure of 10,000 psi (accepting a high estimate of roughly the pressure Fractional Flow gives) the fluid velocity would be around 1,200 ft/sec. So it would not need a very large aperture to flow the volumes discussed.

At driving pressures above 3,500 psi a liquid flow containing abrasives such as the sand for the drilled rock, can erode metal of more than an inch thick at significant parts of an inch a minute traverse speed. The sand can come from the drilling process or from crushing the rock around the well bore because of the redistribution of stress.

If there was a constriction in the flow at the BOP, however, which generates the resistance that builds the pressure, then as the jet moves beyond that point it would a) cut into any of the pipe ahead of it. b) disperse fairly rapidly into the broader flow that is seen coming out of the well, as the surrounding water decelerates the flow quite quickly (a matter of a couple of feet or so).

HO, given that the velocity of this sand-cut could take out the restriction left within the BOP and riser sections leaking (still attached), what do you estimate a 7" pipe(?) with a length to the formation depth of 12,000 feet could flow in light sweet crude(?) given a reservoir pressure of at least 10,000 psi against a mile of seawater?

I'm just wondering if the worst case 50K barrels a day figure or the 150,000 barrels a day that Undertow linked a couple of places seem more plausible to you based on your knowledge of hydraulics?

The crude is medium heavy sweet. No API# given.

http://www.npr.org/templates/story/story.php?storyId=126424949

Alan

Thanks for the details HO.

Thanks also to all the other oil patch people for the comments about possible reasons for the disaster.

It has been obvious for 3-4 years now that we have been right at the limit of human capability to keep the oil supply flowing (never mind increased) as the "economy" demanded. It was only a matter of time until corners were cut, a mistake made or safety concerns overruled by profit motives. We see the same thing in the coal mines.

I have great respect for the engineering marvels of our day, not just in the energy fields. I would much rather we, as a society, used that knowledge and skill to use energy more wisely rather than trying to increase supply as the primary solution. People in energy related fields are dying because economic models show that to be a more profitable approach than all of us reducing usage by some equivalent amount to maintain a reasonable and sustainable standard of living.

As an added thought the environment is now the front line for our profit driven approach. We are still connected to the ecosystem and we threaten that system at our own peril.

"...all of us reducing usage..."

in the short run for sure... maybe forever... all of us reducing usage... is the simplest technology.

i'm in the technology (computer) biz... daily i'm amazed at the new products... but... i've always said... these things fail at the most inopportune time... and it's never one piece... it's the interaction of several pieces...

i read earlier tonight the first blowout preventer was patented circa 1926...

and this rig had just come off a successful drill...

so there's nothing "new" here... per se... except this particular location... depth... etc...

all technology will have it's failures... regardless of a cell phone dropped call to a space shuttle exploding... and what was that... joint rings combined w/ ambient low temperatures... and a decision not to delay the launch...

there was a similar blowout and spill in east timor sea a year or so ago... nary a word in the press here about it...

at some point the "...all of us reducing usage..." decision will be made... all that remains to be decided is how painful does it have to get first... "it" being the "indirect" costs of spills... mine collapses... slurry spills... wars... et al...

If this is a failure of the blowout preventer, then what exactly fails within the mechanism? Assuming we did hit a pipe connector that was thicker than normal, is the problem a lack of hydraulic pressure to close the rams?, or do the surfaces of the shears crack and fail to do their job?

Does anyone know how long these BOPs stay underwater - I doubt the steel of all the critical components is resistant to corrosion in seawater, so I wonder if corrosion somehow played a role.

What a horrible tragedy with the potential to get even worse.

OIL SPILL RESPONSE PROTOCOL

Another outstand tech report from HO. Mucho thanks.

What follows is not so much tech but potential soap opera with this event.

We have a good deal of discussions about the BP blow out. And there will much more to consider when the details of the events leading to the accident eventually come out. As this tragedy quickly grows to biblical proportions more thoughts regarding the spill response will surface. Following is the general out line of the process. Rather dry factoids but hang in there. The finish may become THE headlines in the near future IMHO.

Every company operating offshore is required to maintain an in-house staff trained to handle the immediate response to a spill. In addition to training they also attend MMS/Coast Guard simulation exercises. But these folks are not involved directly in the physical response. The offshore drilling industry maintains, by Federal mandate, a corps of professional spill responders as well as all the specialized equipment. The industry collective provides all the financial support for this effort. Thus whether it’s BP, Chevron or any other company the same assets are available. The gov’t does not have the specialized equipment or the specifically trained personnel required to respond to a spill. The most valuable asset the gov’t brings to bear is the Coast Guard. The Coasties observe the operations and maintain the safety of the shipping lanes. Unfortunately few folks know what a valuable asset our Coasties are.

I’ve just become involved in OCS operations and discovered a significant change in the initial response structure. Instead of each company maintaining an in-house Spill Response Team (as described above) there are several companies that provide, on a will call basis, a full time professional SRT. This is a big improvement IMHO. Compare it to a local volunteer fire department vs. a fully trained and staffed fire department. Again, the SRT doesn’t handle the clean up it self but directs and coordinates the field effort.

When such events occur the immediate problem is that no one knows exactly what’s going on or how bad the event maybe be. BP has been rightfully criticized for down playing the initial problem. I doubt they were intentionally doing so but failed to follow a basis rule: when you don’t know the answer to the question of how bad a situation is you should just say “I don’t know” instead of going into spin mode. I haven’t seen the details of BP’s call out to the industry’s Spill Response Consortium. But, if I had to guess, they requested a full asset deployment. One could not view the initially films of the rig fire and not assume it wasn’t going to be a major event. And once activated the SRC essentially takes over the process on a somewhat independent basis. Again, they are the professionals and this is all they do for a living.

Some folks have expressed feelings that the response has not been adequate. Obviously this is true. A fault of any response system not designed for the “worse case scenario”. Though I wouldn’t classify this blow out as a “Black Swan” few would have given it a significant probability. Much as the gov’t not anticipating planes being intentionally flown into NYC buildings. This is not defense of the level of preparedness but just an acknowledgment of choices we make. A silly but true comparison: most folks would agree motorcycle rides should wear helmets. But the reality is that more than 50 times as many folks die from head injuries inside a car than on a motorcycle. Thus how can anyone of us justify not wearing a helmet while in our cars? As I said, choices are made every day as to how much is enough when it comes to safety. We have air bags in our cars to protect us from 40 mph crashed but not in our commercial jets that hit the ground at a few hundred mph. Choices and more choices. But as more Deep Water drilling is certainly in our future we will see an increase in spill response capabilities. OTHO, I can’t imagine any level of spill preparedness that would have made much difference. The choice we face, IMHO, is whether we allow such activities at all in the future. IMHO no amount of training or improved safety protocol can promise such an event will never happen again.

Now, for the juicy part of this twisted tale I promised above. BP has gotten some complaints from some administration talking heads regarding their response to the blow out. We’ll likely see more coming out of DC as the story continues to unfold. But they are going to need tread lightly if they know what’s good for them. There are regulations that all OCS operators agree to if they want drilling permits. All companies agree to a very special provision regarding spill responses: the gov’t is required to immediately assess a company’s response to a spill. If the gov’t deems the response to be too slow or inadequate the gov’t is REQUERED to take over the entire effort. Remember from above, the equipment and personnel in the field don’t change in this case…just the management of the event. The prospect of loosing control of such an operation scares the hell out of every OCS operator. Even though the gov’t calls the shots now, it’s the company that still foots the bill. In a small spill that might cost $2 million to clean up in a properly measured response the gov’t might go for over kill and spend $8 million. After all, it’s not their money. Of course, the BP spill is a very different animal from this example. No amount of response could be deemed too much.

But back to the political hot potato. If the administration levees too much criticism against BP and declares their response insufficient then they are required to take over. So instead of a BP spokesman getting before the cameras everyday and reporting continued failure it would be a gov’t spokesman doing so since the administration would be calling all the shots. A few months from now if there are still thousands of bbls of oil flowing into the GOM do you think some White House talking head wants to get in front of the cameras to again proclaim “We are doing the best we can”?

Alan -- Reminds us of the post-Katrina days, eh?

Alan -- Reminds us of the post-Katrina days, eh?

Not really. The USS Bataan (USMC helo assault ship, 600 hospital beds, distill 100,000 liters of water/day, many tons of MREs) was the only US Navy ship in the GoM. She was following over 100 miles behind the eyewall of Katrina.

The Navy's plan was to give first relief to Plaquemines & St. Bernard Parish (British Columbia Search & Rescue ended with the honors there) and anchor at either the US Navy base in the Upper 9th Ward or behind the Convention Center at the cruise ship terminal and evacuate the hospitals with staff onto the ship. Depending on time spent in Plaquemines & St. Bernand, dock late Monday or early Tuesday.

Our Commander-in-Chief diverted the USS Bataan to the Mississippi Gulf Coast and assigned a sister ship (in Norfolk VA) to New Orleans which took 5 days to arrive. According to the captain of the USS Bataan, she was "under utilized" there (an under statement when actual aid delivered is measured).

14 buses were assigned Wednesday to evacuate Gretna (minor street flooding from rainwater only, no power). The collection point was under the Mississippi River bridge on the West bank. Under the bridge (with a dry open road from the center) was the Convention Center. Any New Orleanian that tried to walk to the buses was shot at. They had to wait "their turn" on Friday.

and much more.

So the story of Katrina was deliberate diversion of federal resources away from New Orleans (while spinning for media) and to Republican areas.

Not the case now.

Although we want to booms to protect fisheries and not the Casino Coast. First dibs for us, last dibs to protect casinos.

Alan

I'm not a Gulf Coaster, so I guessed what you meant by "Casino Coast" but used the Google for a quick check. Came up right away with this gem (emphasis added):

So in a region known for centuries for severe hurricanes and storm surges, we had viciously corrupt idiot government mandating buildings to be constructed out over the water.

Great. Wonderful. Blimey, I didn't know that. Who'd'a thunk it? Something new to learn every day. I'll leave off my true reaction because it would block the page to those infamously censorious library filters. Same with respect to the simple fact that said viciously corrupt idiots and slimeballs may well be the ones ultimately telling the Coasties and others mentioned elsewhere on this page who put their lives on the line what to do. Ugh.

So, should it come to pass that viciously corrupt government takes over managing this debacle, then God help everyone affected, since they will find themselves utterly beyond any conceivable other help.

Rockman -- appreciate the clarification about how federal law works, who is responsible and how. Federal law initially puts the burden to respond on the oil companies. This being said, I think it is important to recognize that federal law also provides substantial discretion to the Coasties and MMS about how much, where and how resources are deployed. The regs don't specify how much spill response equipment is required or exactly where it should be located. In making these judgments, the feds rely heavily on industry judgments, in part because as is clear from these circumstances the risks of drilling, and especially deepwater drilling, relate to cutting edge and evolving technology and the feds have no where near the industry's capabilities to assess the risks and ownership of information. But the feds are also very cognizant of the tremendous political power wielded by this industry.

I imagine that the industry figured out the level of spill it was willing to prep for, offered this, and the feds pretty much agreed. I'm not aware of any groups that watchdog this process at a level of technical ability sufficient to make a difference. Has anybody on this list been involved in a public process that questions the type and location of spill response equipment? The enviros might complain, but they don't have the technical or political resources required to change the industry's spill response plan "offers." It would be interesting to see the industry's cost benefit analyses about how much spill response capability to “buy.” Since these resources are not cheap and the costs are split between different companies, it is likely that the amounts were calculated and divided with some care.

Some are fobbing responsibility for this disaster off on the feds because in theory they have ultimate control, but practically, that's not how things work. Wonder how long it will be before the industry flacks start hiding behind the feds: “They only required this much or they shoulda made us do more.” The feds serve well as a whipping boy.

Two different issue HT. First, prevention and preparation. The feds set the regs but the industry certainly lobbies to their own interests. These procedures can be reviewed. I can promise you that the procedures are pretty good AS LONG AS THEY ARE FOLLOWED. But the public, gov't and industry can debate changes going forward.

Second, spill response. The gov't has absolute and complete authority and responsibility to evaluate the response by the operator. The Coasties and gov't contractors do this evaluation. The operator has no lobbying ability in this process. There is no negotiation. There is no appeal. If the Feds don't like what they see they take over ops immediately. Don't need to go to court. Just present the preprinted document to BP and BP sits down and shuts up. Had this fact beat into me at every MMS spill school I attended. It is far from a subtle threat. As I said earlier, it scares the hell out of operators and makes them put forward the best effort they deem correct. There's only two reason for the Feds to have not taken over the effort from BP: they were satisfied with the BP effort or they didn't want to be in charge of a horrible problem. Remember wht I said: it doesn't matter if BP or the Feds are managing the event, it's the same people and equipment out in the GOM doing the work. The big difference is who has to make the daily press conference reporting the lack of progress.

Jim -- Lots of potential reasons for failure. Pressure sensors misread, pressure surge knocks gears out of line, catch a thick dril collar with the rams, insufficient hydraulic pressure due to leaks.

The BOP's stay under water for months at a time except when they are pulled to the surface for inspection. External corrosion isn't a problem per se. The big problem is when seals leak and salt water gets inside. As I mentioned the other day while drilling a well off Africa a few years ago we pulled the BOP up for inspection. Found that a seal leak had destroyed its ability to function. Unsettling to say the least. It was a crappy Russian drill ship. Even worse, got food poisening twice. LOL. Blow outs are one thing... projectile vomiting another.

Could the produced oil and gas flow up the outside of the drill pipe from the pay zone ? Bad cement job several times.

Very unlikely to me since oil does enter the drill string at the BOP and above. I see no reasonable explanation for the transfer of oil from outside the drill pipe to inside the drill string @ the BOP. But I am a layman here.

Alan

If the bottom of the pipe is shallower than the leak in the casing, and as the drill pipe would not contain a float (non return valve) as they had just cement liner and you don't run floats while cementing, then there is nothing stopping the oil flowing up the drill pipe.

If the BOP has partly closed and has caused a retriction if not a seal then this would also push oil up the drill pipe.

The problem with drilling in the ocean is 'Murphy's Law' will kick in someday. We need more energy but the enviroment is more important to our long term survival. Maybe there should be a ban on drilling in our oceans. I say this reluctantly.

hotrod

Let us pause and say a quiet but sincere Thank You for The Oil Drum. I don't know anywhere else, not anywhere, where this quality of information is available to the general public. And a special thanks to you, HO, for a calm, informed, dispassionate description about this calamity. I am grateful this morning, and thanks to you, a tad less ignorant than I was when I went to bed last night.

I'll second that Thank You to HO, ROCKMAN, westexas and everyone else who has contributed to my understanding of how this all works and can fail.

I agree Lee, I know diddly about the oil and gas drilling business and reading through expert comments makes me appreciate the challenges and accomplishments from here on out. I was pleasantly surprised that I could contribute my 2-cents to this discussion.

how deep was the well ? press reports have stated 30,000 ft, others herein are saying 18,000 ft.

IIRC, the total depth is 18,000': 5000' water + 13,000' drilled.

correction edit: xburb posted a graphic showing drilled depth at 18,000' + 5000' water depth = 23,000' total.

http://www.theoildrum.com/node/6417/616553

The Deepwater Horizon is specced to at least 30,000ft Deepwater Horizon and has drilled well 35,000 feet deep, but the well depth here was around 18,000 ft.

I’ll add a little more detail to one aspect HO highlighted: down hole formation pressure estimation. Until year ago this is what I did on the rig: pore pressure analyst. The science behind the process was established decades ago. But as HO pointed out LWD (logging while drilling) has changed the process tremendously. Prior to LWD drilling ops had to be stopped, drill pipe removed from the well and electronic devices (logging tools) run down on the end of a cable to acquire the measurements needed to calculate down hole rock pressures. Often rather late after the time for this critical data. With LWD the logging tools are located right behind the drill bit and send that data to the surface continuously. The PPA is tasked with using this data in our modeling software to estimate down hole pressure. Not a very straightforward or absolute answer to say the least. The answers can be nebulous and sometimes outright contradictory. Like many tech analysis, experience becomes a very key factor. In addition to the LWD analysis we watch the character of the mud returning from the bottom of the well (mud logging). The amount of NG returning with the mud is often key. I would also spend hours watching at the shale shaker (where the rock cuttings are separated from the drilling mud). Changes in cuttings character can give a clue. And the changes in down hole pressures are not always gradual. Pressures can ramp up 5,000 psi in just 100’. One might think the solution is just to always drill with very heavy mud. But if the mud weight exceeds the over burden pressure you’ll frac into the rock (just like they intentionally do in the shale gas plays) and could lose a $100 million hole. As HO pointed out: it’s a game of balance.

You should grasp that being a PPA is as much an art as a science. I’ve worked with drilling engineers that look to me first for help. I’ve worked with others that couldn’t care less what I had to say about down hole pressures. PPA’s are like stockbrokers: always making predictions but not always right. If a PPA isn’t credible in the eyes of the driller it doesn’t matter what he says. More than once I’ve warned of potential trouble coming and was ignored. And then took a kick. A guess what? The driller would as likely be pissed with me about being right than offer an apology. You can go high tech all you want, but if humans are involved it might not help you. When I’ve run into a driller that didn’t want to take my analysis to heart I would always respond the same: ”I’ll be right back…going to get my car keys from my bunk room”. When you abandon a rig you’re only allowed what’s in your pocket when you board the escape capsule. Needless to say that comment usually pisses them off but I’m not there to make friends. Have suffered some minor retaliations for that snotty comment. But I can usually give as good as I get. I know these words won’t bring much comfort for folks worried about future drilling efforts. But it’s the naked and occasionally ugly way the system works. You won’t see such a tale in a Chevron TV ad. But this is the real world with real people making real mistakes that no technology can prevent all the time.

According to the survivor's audio report, they were moving from drilling to production, and had cemented the casing and flushed the mud out with seawater. (pardon my lack of terminology, I'm only an armchair observer)

So the DH project was at its most absolutely vulnerable stage when this blowout occurred.

Actually DYI just the opposite. When first drilling into the formation is the greatest risk. Then it's risky when you're running and cementing the casing. They were in the process of temporarily abandoning the well. The well should have been in it's safest mode. They were in the process of removing the drilling mud from the riser; the very next step would have been REMOVING THE BOP. How safe must you believe the situation to be to do that?

That’s the bizarre aspect: I’ve never heard of a blow out occurring at this point. Needless to say something in the down hole plumbing failed.

Hmm.. by "most vulnerable I meant that without the mud column there wouldn't be the pressure to stop the flow.

So, you must stick some kind of "cork" in when removing the BOP. If you're getting ready for production, there would be a clear path to the formation and the casing is full of lightweight sea water? What stops the flow during that interval?

Exactly DIY. The cemented casing should have been the first flow prevention. In 35 years I've never seen a report of any well coming in at this point. Probably has happened but never heard of it. As they were preparing to temp abandon the well they should have also had a plug (that "cork") set inside the casing. And the well head itself is a system of flow control valves. I don't know the current required procedures but I would bet that casing plug was required before displacing the riser with sea water. What's puzzling is that there are many pressure monitors throughout the entire system. You always know what the pressure is behind every valve out there. A drilling rig is a giant system of hydraulics running hundreds and even thousands of psi. You live and die based on knowing what pressure is coming at you.

OK, I just re-read HO's articles on casing and finishing. I didn't specifically see a step where the BOP is removed, but I can see that there's a _lot_ of downhole technology to control and manage the flow of oil, gas, water, sand, gravel, and steel under extreme pressure.

Thanks to both Rockman and HO, for your clear informative posts on this vital technology.

[edit]: ... and mud.

"and could lose a $100 million hole."

If the mud is to heavy and and the well pressure exceeds the formation pressure then mud will flow into the formation and seal the pore spaces. It also locks decentralized wireline tools to the formation and can cause wireline weakpoint separation and start a fishing operation.

Anyway as I see it that's the reason you loose a $100 million hole.

dc -- And that's one of the biggest challenges in DW drilling. The difference in MW between a blow out and frac'ing the formation can be the difference between 17.2 ppg mud weight and 17.5 ppg. Then consider the complication that the pump pressure can add 0.4 ppg to the effective circulating density. But that's when you're pumping the mud. Stop pumping and you lose that extra back pressure. Obviously balancing can be very tricky

Murphy's Law

hotrod

This disaster is only INDIRECTLY related to the issue of peak oil, which is the focus of The Oil Drum.

But there is no other popular blog that I am aware of where oil industry professionals participate with technical opinions.

Since Deepwater Horizon could turn out to be the biggest environmental disaster in history, I guess I am asking The Oil Drum to give this story special treatment, perhaps with its own subpage.