Deepwater Oil Spill - Top Kill "Stage 2," Junk Shots, and Live Comment Thread

Posted by Heading Out on May 27, 2010 - 4:02pm

New thread, please redirect to http://www.theoildrum.com/node/6538.

The leakage rate is significant (I calculated earlier that it was around 17,000 bd, which lies within the newly reported range of 12,000 to 19,000 bd, and may have been higher than BP were actually anticipating. (Though the leak may also have increased a little as the mud was injected at higher pressures). The operation has already used all the mud on one of the supply boats, and has moved to the second (there is a third standing by so they won't run out). The concern, however is now with the volume of cement that will be required for the seal.

The high volume that is leaking would require that additional amount to the volume needed for the seal itself, and that may be closer to the available capacity of the system that they have in place, or the supplies that they have on site to achieve the seal. If that is the case, one can understand the desire to at least partially plug the leaks in the BOP, and to wait until the mud column fully balances the pressure in the oil reservoir before starting this phase of the operation.

Until this point in the operation the volume of cement required to create an effective plug has not been seen as an issue.

Edit - New Section Added:

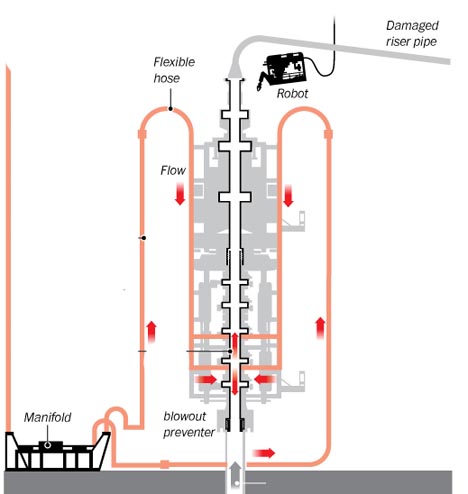

Unfortunately as I write the feed from the leak has moved to look at other things, but the last glance I had seemed to suggest that they have been able to reduce the flow somewhat, though I guess not enough. Just to remind you of the problem, this is what the internal flow path through the BOP looks like:

Now they have to get relatively large particles (larger than the smallest diameter of the flow path) through the feed lines, which have a size of 3-inches, and those of us who pump particles in fluids much prefer that the particle diameter be no more than 30% of the pipe diameter - which is to say in this case an inch. And so if the orifice in the BOP is larger than that, then there is a problem in working out how to get something in there that will be effective, remembering that it has to work through all the flow convolutions of the supply line that has just been installed for the mud.

This posted in the Drumbeat by user BOPE Man. Gail suggested they should post it here but I thought I'd might as well copy it over here anyway for any comments.

http://www.theoildrum.com/node/6514#comment-630672

sorry, i lost track of the number of times "team" was used. this could be an all time record use of the term. sounds like the writings of a mid-manager with upper-manager aspirations.

Any opinion on the validity or otherwise of their thoughts/analysis though?

Somewhere earlier, I read that someone accidentally pushed some button that caused the drill pipe to move and thus strip the annular, and chunks of rubber started flowing with the drilling fluid they were (prematurely) removing from the wellbore. The annular was DAMAGED, SHREDDED, CHUNKING OFF, and the mud logger reported this, even carried some of the shreds of rubber to show to someone, but the blowout was probably well on its way toward happening at that point. By the time the chain of command was consulted and the order was given to activate the BOP, it was too late -- WAY too late. The hydraulic system did not respond. The damaged BOP could not contain the gas/oil blowing out of the well.

That was on 60 Minutes.

Secretary Salazar seemed dismissive of the 60 Minutes "evidence" in testimony (claimed he hadn't even bothered to watch it) but did add that there was some key information about the disaster not yet made public. He said it would all be in a report before the end of the month. I would just like to rule out for certain that the reason the BOP initially "failed" was that it was manually opened.

In another thread here on TOD, a more knowledgable commenter mentioned that he concurred with the expert's opinion expressed on 60 minutes that the annular damage was probably not serious. Apparently the annular's a big honking sturdy thing, not a fragile little flower, and a little bit ("two handfuls") of rubber being worn off the surface by drill bit movement was probably not enough to seriously damage it.

This was also significantly before the blowout.

And the annular isn't the "last line of defense" in any case -- the shear rams are.

But I don't really know anything; I'm just repeating what I've read here on TOD.

The report I read said they were LARGE CHUNKS. As for two handfuls "not being much," maybe the mud logger didn't have a bucket handy to bring more for showing the evidence of damage. I wouldn't dismiss any pre-blowout damage as being "unimportant"...

Especially as BP's internal investigation apparently said that one thing that happened about 5 hrs. before blowout could have indicated a problem w/ the annulars not sealing.

So why wasn't the Company Man on the floor when this happened??

BP official apologetic for not sharing more info about 'top kill'

http://politicalticker.blogs.cnn.com/2010/05/27/bp-official-apologetic-f...

Can anyone enlighten me? Is the mud supposed to force part of the blow off valve shut? Or is it just to provide raw "anti-flow" pressure against the reservoir?

The diagram I reviewed showed mud going inside the blow off valve.

==Until this point in the operation the volume of cement required to create an effective plug has not been seen as an issue==

That seems very hard to believe.

They must have a workplan, based on the analysis of the hydrolics in the system. The large outer leaks are there for everyone to see.

What is their plan for the cement?

They can't really "balance the well", so the plan must be to get close and pump enough cement so either on the way down or they way up it finally hardens and seals the works.

But before they committed to this, they must have done the very best analysis of how close they can balance and how much cement they will need based on the residual movement of the oil/mud boundary.

Right?

Bad news......we are back to golf balls. Its leaking way more than they thought........

Redirect to newer post here: http://theoildrum.com/node/6518.

So, we get the "junk shot" as well as the top kill. It seems a good idea, except that it allows Mr. Murphy a little more room to horn in here.

Does anyone else have a concern that shooting the junk in could make things worse? Is there any chance that it would increase pressure at the BOP beyond its uncertain ability to hold on?

The cement problem seems obvious to anyone with basic knowledge of fluids, so the reason to make the attempt to slow the leakage is apparant (just looking at the video above clarifies that). I'd bet the PTB at BP are sweating right now!

Craig

I am woundering why they dont freeze it off with N2, and remove the leaking riser and clean up top of the BOP ,install new Bop on top..then be able to bull head the kill mud down the hole and why not have 1 of two the rigs drilling relief wells, just shoot for the wellbore up higher and 1 shoot for the bottom....either 1 would releave the pressure off the well to kill it...

The gas/oil coming up is in the vicinity of 450 F - and that will melt (heat up) "your" N2 just like that...... and there is constantly more heat where it comes from.How much and fast can you "counter supply " your N2- and do "you" have the tech readily at hand to actually do this?

I'd go for the junk-shot at this stage - a lot of big junky stuff or maybe just some Chinese plastic toys could suffice.

Haha, Methode_Champagnoise for crude oil!

Anyone seen any eels since they began pumping mud in ? Maybe eels dont like barium ?

New York Times:

Setback Delays ‘Top Kill’ Effort to Seal Leaking Oil Well in Gulf

By CLIFFORD KRAUSS, JOHN M. BRODER and LIZ ROBBINS 15 minutes ago

BP had to temporarily stop its effort to plug the well when engineers saw that too much of the fluid they were injecting into the well was escaping along with the leaking crude oil.

(edit by PG, here's the link: http://www.nytimes.com/2010/05/28/us/28spill.html?hp )

I wonder if they figured this out by looking at the deposits on the wrench the ROV was sticking into the outflow.

Folks here have been asking these very questions since they started pumping yesterday and probably before then.

They must have a *PLAN* to deal with this, right?

The fluid dynamics part of this is modelable with finite element analysis.

The well bore geometry is set and they probably don't know the reservoir pressure exactly. Pretty much all the rest is known or can be estimated within reasonable error. They can insert pressure probes and measure inside the BOP and at the riser holes.

They must have picked the mud density to be able to balance the reservoir pressure with some bias (I don't know if they prefer to have cement plug sink slowly or be expelled slowly). They must have calcualted the residual reate of cement sinking or expulsion. They must have calculated the amount of cement, time of cement pumping, etc., before they begun.

In other words they done their homework, right?

::exhales::

What does 'temporarily' mean?

BTW, did anyone else hear Prez O today? Sounds like he sort of understands the concept of peak oil and energy, and that we need to 'do something,' yet he does not know what to do about it. Of he doesn't want to commit. He needs to learn the definition of leadership.

Craig

Obama said "all the easy oil is gone" and that is why we are going after the oil that is hard to extract and requires much higher environmental risk. He further explained that he acknowledges the oil supply predicament and therefore never advocated the "drill baby drill" scenario. Obama said these technological challenges of oil extraction should be cause for eventually moving to alternative energy sources. He inferred that oil will only get more expensive and harder to obtain.

I heard it live on NPR.

Yes He Does.

See this clip from the 2008 Presidential Forum at Saddleback Church

http://www.youtube.com/watch?v=NKZCrW4g13c#t=0m45s

He just didn't want to say Peak Oil quite yet, but I think BP has forced the issue, and now it's a matter of timing to avoid panicking the public, and leveraging awareness from this mess.

Which is what the main point of the post was all about. It is not a problem with the mud supply, they have more than enough on the three boats and the pumps available. It is likely now that they have reached the point of pouring the plug and they don't have that same capability to supply the needed volume of cement at the flow rates required, if most of it is going to go out of the leaks. They may not have realized this until they went to start up the production line for the cement, and looked at the additional quantities that they now needed, relative to a conventional cement plug.

Thus the need to start blocking those holes.

I would think they better try the junk shot soon before the hole(s) get any bigger. At this point, it probably doesn't matter if they lose the mud already injected into the well, since it appears to be a small fraction of what they are pushing through now.

I mentioned this possibility on the previous thread and was told I was being silly.

My question now involves what happens AFTER they pump cement down the hole.

Seems to me that they have to push the cement down beyond the end of the drill pipe and then sort of "rinse" the cement out of the annulus between the drill pipe and the inner casing. If they DON'T do this, they're going to be permanently setting the drill pipe in place.

I expect that the BOP will be sawed off the wellhead eventually, if for no reason other than to allow forensic examination, and maybe they can fill the drill pipe with cement at that time, but I'm uneasy about what they'll be leaving behind.

If - and to the extent that - there is any leak path from the TD into the well bore below this "upper" cement plug, they will be building an ecological time bomb with a fuse set to go off in a few decades... or centuries.

I don't know how long it'll take, but the casing is still a steel pipe in a marine environment. EVENTUALLY, it'll rust through. MAYBE it'll just be a pinhole leak, but as we've seen recently, even with new steel, high pressure flow can erode small passages into larger ones. I can only imagine how fast this'll happen after the pipe has been rusting for a while.

I've got myself convinced that the only way to safely and permanently abandon this hole is to go back into it - from the top - and do some work down at the impermeable cap layer over the producing stratum. I think the casing should be perforated at that level, and concrete should be squeezed into the concentric annuli all the way from the well bore out to the original rock.

THEN, and IMHO, ONLY then, they can walk away from this hole.

I'd appreciate some feedback on my concerns from some of the guys around this forum who have more (any!!?) experience in realworld oil drilling.

1. The reservoir will be tapped through other wells relieving the pressure.

2. Regardless of what happens here it is only a temporary fix because a relief well will be completed.

Two words: relief well.

The relief well is the real solution. Everything else, including the top kill, is just a stopgap to reduce the problem until the relief wells can be completed.

So the top kill doesn't need to last forever. Just until August (more or less).

(Maybe I should mention that it's not really a "relief well", it's a "kill well", and the purpose of the kill well is to get down below the bottom of the drill pipe and inject enough cement to plug the formation up but good.)

Two dumb questions

1. If they pumped in 30,000 barrels of mud, and the drilled chamber only needs about 1300 barrels of mud to fill up, where did the other 28,700+ barrels of mud go in the last day? Did it leak out the riser?

2. If the mud is a heavy fluid, won't the particles composing eventually just sink to the bottom of the well, letting the gas and oil coming to the top? Is this effect not important because it occurs on too long a timescale?

Doc -- As you probably guessed the rest of the mud went into the GOM.

And everyone: you can stop taking about BP pumping cement into the hole to plug the well. I know it's difficult for most to envision what's going on down there. But this isn't a simplification of the situation: you have a pipe sticking straight up the air and it's flowing 10 gallons per minute out the top. You stick a tube down the pipe and start pumping cement. Question: how long for the cement to harden? Answer: never. The cement is going to mix with the water and flow out the end of the pipe. Honest...I didn't dumb down this example. That's exactly what would happen if the pumped cmt down the blow out if it were still flowing. No one has ever set a cement plug into a flowing well in the history of the oil business. But you can shove a packer down a producing csg string and stop or at least slow a flow considerably. But can't shove a packer down this hole: can't get it through the BOP. And if you could there's drill pipe in the way.

Sorry to be such a downer but I thought BP might have come up with a clever idea they weren't talking about. So far I still haven't heard of it.

Well then, guess I will go get drunk. Bet BP or the Feds can't mess that one up for me.

thanks rockman

Surely not all doom & gloom yet? Could we be better off than before? If they have truly weighed the well down with mud, there should be less upwards movement of the oil from the reservoir.. back off the mud pressure & do junk shot . .. with much less hydraulic hammer than without mud?

Or is your suspicion that the well is still full of oil, and practically ALL the mud went into the GOM? In which case, no extra weight, no lessening of pressure, and more spill as soon as they back off the pumps?

ben

speaking as a novice...the heavy mud which spills into the gulf does have weight. Even just laying on the floor of the seabed, it becomes part of the seabed pressure on the oil below?

Hey Rockman, I have a stupid question. If they can stop the flow and try and pump mud in, why not pump in seawater and do not stop it until the relief wells come in. Does mud have to be in the mix to make it work? Could such a flow be maintained and not make things worse?

That's been my question all along, Rock. Need to stop all movement before the cement will set up. Do they expect to get enough heavy mud down hole to balance the system (weight of mud equals formation pressure) and then push the cement in on top of the mud? Also, why didn't they do a junk shot first to plug the leaks before pushing the mud in?

Why is a lot of people suddenly talking about flows of cement at this stage? I got the impression that the plan had no cement until the well was essentially controlled with mud. Am I missing something?

BP is talking about the junk shot, but as an adjunct to Top Kill.

And then replacing the BOP.

Alan

I'm curious about the "replace the BOP" part. Does that come from BP?

I certainly think it should happen, but I can't figure out HOW to do it. It seems to me that if/when some combination of junkshot and topkill pumping get enough mud down the bore to kill the well, they couldn't lift the BOP and the attached drill pipe (3000 ft?) without reducing the hydrostatic pressure at the bottom of the hole.

If they pump concrete down after the kill mud, they'll lock the drill pipe in place inside the casing. Then the only way to remove the old BOP (unless they can make the shear rams retract) will be to saw it off the wellhead. I'm NOT very confident that they could then stab a new BOP onto the wellhead with the concrete and drill pipe in place and flush with the end of the wellhead.

Finally, unless they figure out some way to pump concrete into the bore of the drill pipe first, cutting off the BOP will leave a pretty unnerving leak path up through the bore of the drill pipe.

All the talking heads are merging, but I believe the "replace BOP" was a side comment by Thad Allen.

I have come to the conclusion that 1) his grasp of technical details is not exactly firm at all times and 2) BP occasional blows smoke in his direction (this works because of #1).

Alan

I'm kind of surprised that another Big Oil Co hasn't made and expert available to the press to keep the technical details straight. BP hasn't stood up on this, and their screwing everyone's pooch on this.

Probably because any other Big Oil Co could find themselves in The Same Position tomorrow, and also because it would just be bad PR to have the name of their Big Oil Co anywhere near "Gulf Spill" in the press.

So what was it that they did in Iraq after the gulf war? Eg. from what I've heard those were top killed, and not exactly shut-in.

??

After the fire was put out mostly they just cut the old well head off and stabbed on a new BOP and put the well back in production (oversimplified I know but that was the basic concept). If this well was shallow and on land same techniques would apply. But the well head is almost 1 mile beneath the ocean, and another 13,000'+ to the formation below. Besides the fact that it's an oil well, there are almost no other similarities between this event and the burning feilds in Kuwait.

OK - NOT top killed...One of my buds at work thot that they were....

Solid explanation. People think if you don't have a library card you can't figure out how tie your own shoes.

Cement won't set if it's gushing out of the riser. They just emptied 20,000 plus barrels of mud into the sea unless some of it filled loose fissures and caverns down the well. Once they lost control of the pressure on 4/20 they mucked us all.

But I'm sure this is a temporary set back and they've got all the neccessary equipment waiting on the ocean floor for the next "event" that will have a 60-70% chance.

Also as soon as Brunswick PR came in around May 1, BP's been shooting false press reports early in the morning relying on the copy to saturate the MSM. Mr. Suttles then releases the official statement at his press conference contradicting the false reports, but the copy and false perception are out there in cyberspace.

They did it when they told us the annular rams were closed. They did when they told us the siphon was sucking up 5,000b a day. And they did it again this morning.

Grin, see I knew you'd need a miner before all this was done.

Getting concrete to set in flowing water is sometimes needed in places where you need to set a support on a wall that keeps falling in. The answer is to add chemicals to the mix that accelerate setting time to that you can spray say 6 inches of material (shotcrete) above your head and it won't fall back on you. So now the trick is to engineer how to do that (and to get the accelerant to act only when you need it). And I think you misunderstand a little of the mechanics of this, because, by pumping in the mud at higher pressure that the oil, they can actually generate a dynamic seal that sensibly stops the oil and gas from reaching the BOP, and can hold an interface if you adjust the pressure and flow rates. Bear in mind they have a lot of pressure and volume capacity available at the pumps that hasn't been used yet.

They only need this plug to hold long enough for them to cut the riser and place the new BOP on top of the old one. How many days is that?

If I'm correct, Shotcrete won't set as long as its kept moving. As soon as it is sprayed and becomes stationary, it solidifies almost immediately. Regular concrete is the same way. As long as it's in the mixer being stirred, it won't set (to a point).

So is what you are saying:

IF they can keep an interface between the mud and hydrocarbon...

then

they can pump cement down thru the mud column and have it set up if you dope the mud enough?

Would that require blocking the upper leaks to get seal?

(i'm confused....and kinda bummed. hoped i'd get home today and this would be a lot better...).

No one has ever set a cement plug into a flowing well in the history of the oil business. But you can shove a packer down a producing csg string and stop or at least slow a flow considerably.

Or to pump cement down thru a string of pipe filled with mud. The cement must be pumped in "on top" simplified And completly displace

(shove the mud down to open end of string.)It must be understood that the ones writing about this are "WORMS" They haven't even reached the weevil stage yet

A conversation between Rock and I that I wanted to make sure got over here from the last thread:

http://www.theoildrum.com/node/6515#comment-631020

And now the big question is whether they have been making things worse as a result of erosion. The holes in the bent riser seem larger to me than they were several days ago. If that truly is the case, then I would think whatever gap/orifice exists in the BOP has suffered similar erosion - the amount obviously depending on the materials surrounding the gap.

That is why it was never going to work and why a top kill is also referred to as bullheading. Without a functioning BOP to impose artificial formation pressure(SIDPP/SICP - hydrostatic of kill fluid)and ability to bleed off expanding gas entrained in the well fluid. 1 bbl mud in, bleed off equivalent volume expanding gas out. BP's lips were always moving.

Thanks, guys. And, a few questions.

When they try to pump the mud down the hole, the upward flow is creating eddies and going around the mud, right? I mean, the problem seems to me to be that even if they pump in cement, the escaping oil and gas makes holes all around it. Or am I totally off?

Once, in the UP of Michigan, I swam in a stream that had been warmed by the local electric plant. It flowed into Lake Superior. As I swam, the upper level was warm... out a ways into the lake there was a layer about 1 foot deep that was warm, and when I moved it stirred the water and mixed the two levels. It did not take much to do that.

If there is an incoming stream that exactly matched in size the outgoing stream, it would create swirls of mixed water. Just like I visualize in the well, as the drill mud mixes with the uprising fluids.

Do you think there is any way to stop this thing other than the two relief wells?

What is the downside of the relief wells? How is old man Murphy going to screw them up?

Craig

Rockman -- not to nitpick, as UR analogy of (what my understanding is of) the situation is very good. I'd just make it that a firm connection of the fire hose to the hydrant can be made... it's just that the hydrant body is leaking at several locations :>)

Realistically

HOUSTON, May 27 (Reuters)

Extending the hydrant analogy, how will inserting the hose lower in the pipe feeding the hydrant have a different outcome from a hose flowing in closer to the top? In this case, what will be different about pouring in cement via a successfully cut relief well vs mud pushed in through the BOP? What will prevent the poured cement from flowing up the well and out the riser before it sets just as the mud entered via the BOP was doing?

Apparently relief wells have been successful in the past - what is the mechanism that allows them to work?

Again, thanks to Rockman and the other knowledgeable posters for bearing with us newbies who are trying to understand the complexities of the situation. We seem to have moved from oil drilling structural concepts to fluid mechanics today.

When you drill a second well you keep it full of mud at all times. Whenever you hit oil or gas you have a column of mud at least as high as the depth of the formation. Since the pressure of the oil or gas is proportional to the depth, the new well does not blow out. In contrast, if you pour mud into a well that is blowing, the mud gets blown out too.

Following all this with interest, its good to have some decent technical details as to what is going on here. I'm particularly interested in the discussion as to how the total weight of the mud in the well column is the key factor in counterbalancing the reservoir pressure and hence mitigating the flow.

However I'd assume that the *rheology* of the mud is also an important issue: viscosity is just one factor here, but for nonnewtonian fluids viscosity depends on the flow conditions, particularly the shear rate. Some nonnewtonian fluids behave almost like solids or plastics at low flow rates, and become liquid over a certain point. There was one comment that these are shear-thinning. Googling "drilling mud rheology" gives very little useful technical information, I assume because most of these muds are proprietary technology.

Now I'm very familiar with pumping slurries around - I work in the mining/mineral processing industry. I've done testing on laterite slurries that look almost like clay, but become very runny when you add a bit of water and start pumping them. They are hell to work with - if you have a pipeline full of the stuff and the flow stops for *any* reason, it just solidifies and no amount of pressure will get the flow started again. So designing a 60km pipeline to transport the stuff means having a huge header tank so that if the pumps stop for some reason, you keep the flow going with water till the pipe is flushed out.

So it would seem that if you got the well filled with mud, the rheology would play an important part in whether it would be plugged.

Could anyone with technical knowledge on the rheology of these muds comment on just how important this factor is?

Good points.

I think there is another dimension to fluid viscosity as well, mentioned by knowledgeable in other threads.

If you ar trying to force the turbulent gas/oil mixture to back down of the BOP and back into the main pipe below, you want to use a "forcing" fluid of higher viscosity than the "target" fluid. Basically, you want to minimize the mixing of the two fluids at the interface. The approach works if you can maintain a reasonably well defined interface between the two fluids (ideally a surface, but could be a volume that is "thin" on the scale of the problem, probably a Reinolds number thing). If you don't and the two fluids mix continuously, you really can't maintain the local pressure differential that makes the whole thing move - you get a mess. That seems to be what we have.

I read here that the mud they use has "several" times the viscosity, but don't remember now if that was several times that of water or several times that of oil.

I've struggled trying to understand just how pumping the mud in is going to push back the oil/gas mix. If the mud is pumped in at a sufficiently high rate and a higher pressure than the well discharge pressure, it will fill the BOP - some will discharge through the holes previously leaking oil/gas, and some forced back down the well casing. Enough going down the casing was presumably meant to plug the well by hydrostatic pressure.

Now the oil/gas flowing up the well has some pressure drop due to friction, and the mixture will have hydrostatic pressure changes as well, it may be 'choked' in the two-phase flow sense - its a complex fluid flow problem. However as you start to restrict the oil/gas flow, the frictional pressure drop will decrease, so the back pressure on the mud from the well will increase. So you need to pump in the mud at higher pressure, but that just means that the quantity of mud escaping will increase. For this to work it would seem that you need a fine balancing act - keeping some flow to reduce the wellhead pressure, allowing mud to flow back down the well and not mixing with the upcoming gas/oil, all the time hoping that not much is being lost at the leaks. It will all depend on how the various fluids interact - if they do mix you are ultimately ending up with a homogeneous mixture that is only going one way - driven by the reservoir pressure.

It seems the key assumption is that there is sufficient restriction at the leaks to provide backpressure and force the mud down. A rather ambitious assumption to be rating the chances of success at 60-70%,

This is my question as well. Do they have some sort of plug ahead of the mud to pack the oil/gas mix down the hole? Like the wad in a shotgun shell? From what I understand, that is not possible b/c the riser is not an open pipe... they don't even know exactly the size of the flows of oil & gas coming up. If it is all in one stream, they would need to push that stream down. If several separate flows through different channels, they need to get them all. That, as I understand it, is why the viscosity is important.

Still, it strains credulity to believe that they can accomplish a full shut down. And, if they don't, they cannot cap it with cement - it won't set if it is flowing; and, if there are streams of material still going around it, not near those streams, at least. Hence, I foresee big holes from the get-go, which enlarge over time. The best case I see is a partial limitation of flow. Maybe that is what they want.

OTOH, the earlier reports after BP announced that they were postponing the TK sounded a lot like they were planning to do a junk shot into the BOP to block the outflow before the restarted the mud.

I don't think these guys have a clue, some times. Not that I have any good ideas. Has anyone tried duct tape?

Craig

Here are the facts as I understand them (apologies if this is a bit lengthy or too obvious):

- the lower part of the production casing (the inner most casing string) has been cemented in place, but the cement does not overlap with the next casing shoe above

- BP report that the blow out has occurred up a casing annulus and not up the main production casing bore. This implies that the cement at the production casing shoe itself is intact and that reservoir fluids are flowing through an imperfect cement job behind the production casing and up one or more of the casing annuli

- to flow out to surface from the annuli, one or more of the casing hangers in the wellhead on which the BOP sits must have failed

- it appears possible then that the main bore in which the drill pipe sits remains full of the mud that was in it prior to the blowout, unless the flowing reservoir fluids are able to reverse down the main bore from the wellhead and out of the open drillpipe (and reported flow rates out of the drillpipe prior to plugging it were very low)

- well kills are absolutely routine and generally have the objective of replacing fluid of a lower density in the well (normally reservoir fluids) with fluid of a higher density (typically mud). The pressure at the bottom of the higher density column will equal or exceed the reservoir pressure and prevent influx of reservoir fluids. The replacement of one fluid by another is normally accomplished by circulating the fluids round the well (for example down the drill pipe and up the inside of the production casing to surface, or in some cases by 'bullheading' in which the fluids in the wellbore are replaced by forcing the contents back down into the reservoir itself. This is always done with the well closed at the top.

- what is different in this case is that the well is open at the top and flowing reservoir fluids through the BOP. The production casing is closed at the bottom but the casing annulus is flowing reservoir fluids. There is no option to circulate fluids in the well, so the bullheading approach must be adopted (and note we are bullheading down the annulus not the production casing or drillpipe)

- when mud is injected into the BOP in an attempt to force the reservoir fluids back down the casing annulus and into the reservoir (and replace the column with mud) most of the mud will flow out of the breaches above the BOP. Mud must be pumped at a rate such that despite these losses, enough pressure is maintained within the BOP to force the contents of the annulus back down the well (ie the pressure in the BOP plus the hydrostatic head of the column (part mud part reservoir fluids) exceeds the reservoir pressure at the base of the well). If the overbalance at the base of the well is quite low, then this displacement process might be quite slow, despite the relatively small volume of the annulus. Frictional pressure losses in the annulus will also be low due to the low net downward flow rate (so flow restrictions due to obstructions will not likely be important)

- its important to realise that from the moment they started pumping the mud and increasing the pressure in the BOP, they have effectively stopped the well from flowing (what is exiting the riser leaks is almost certainly all mud, and no more oil is entering the annulus down below), but if they stop pumping before pushing the mud far enough down to overbalance the reservoir pressure then the well will simply start flowing again

- it begins to look like the venting of the injected mud via the BOP has not allowed them to get enough pressure differential to depress the mud level far enough down the annulus and achieve overbalance, hence the plan to inject junk (to restrict the leak path through the BOP and increase internal pressure)

- if they have actually stopped pumping then it seems likely that they will be starting from square one when the restart, which is fine if they have enough mud and if they get some help from the bridging junk

- I would expect that they would like to achieve static overbalance before pumping cement to follow the mud down the annulus (and lets hope that where the cement goes is the only leak path). But I don't see how they can prevent most of it from exiting the top of the BOP unless they use the static condition of the well to cut off the riser and cap it in some fashion (another BOP on top would do it)

- great news though that the wellhead/BOP package is taking the strain after all it has been through. Production engineers generally get jittery about the wear and tear caused by normal rig interventions, let alone the extremely brutal treatment that this one has received acting as an anchor point for a burning and drifting and ultimately sinking rig, and then a conduit for uncontrolled flow via non-standard paths.

All the diagrams that I've seen (like the one at the top of this page) just show the BOP sitting on top of a single pipe, but from your description things are somewhat more elaborate than this. Is there a more detailed diagram somewhere showing the exact configuration of the various annular casings and how they connect, where the concrete is located, where the reservoir fluids are flowing and so on?

I do have some expertise in fluid flow (as in solving difficult multiphase non-newtonian slurry flow problems for the mining/mineral processing industry in Australia is my main line of work and I fly around the world troubleshooting mineral refineries). So I'm trying to figure out what is going on from the viewpoint of an expert in fluid dynamics. I'm finding it difficult to believe that the top-kill procedure as described can possibly work - but still trying to understand exactly what the procedure is trying to accomplish in terms of the flow and interaction between the various fluids and bits of piping, casing and BOP.

Have a look here:

http://www.theoildrum.com/node/6493

graphics and discussion.

strictly a weight issue, though the viscosity of the fluid does need to be able to suspend the weight of the solids in a static condition, otherwise just precipitates out.

ppg x .052(pressure gradient cu. ft. air.@sealevel) x TVD=conversion of column of fluid to psi (diameter of column irrelevant)

thats correct ...

the viscosity in terms of Newtonian fluids dictates its ability to suspend and transport solids .....the cross linking helps there as well...

what matters here is the weight of the kill mud and the pressure it creates at the oil/mud interface ...16 ppg means the mud physically weights 16 pounds when a gallon of it is weighed under STP

Caveat I was a mud logger--not a mud engineer, and despite the seeming similarity of the titles, they are pretty different jobs. The mud logger tracks the mechanical parameters of the rig, how the pumps are working, where the top drive is etc; the lithology of the cuttings coming out of the hole, and any hydrocarbon content--either gas or oil. The mud engineer actually directs the making and maintaining of the drilling fluid, so things like weight per gallon, pH, filter cake layer, viscosity and gel point were the mud engineer's area.

Having said that, I talked to a lot of mud engineers, I recorded their mud reports and included them with my morning reports, and needed to understand the drilling fluid insofar as it affected what I saw with my gear. So here goes: Drilling mud is made to liquify with the application of shear stress (ie pumping) and gel in the absence of pumping. Precisely how much depends on the specifics of the hole in question. The plan is to have the mud gel when the pumps are off to prevent gas from rising through the column, and to prevent cuttings from sedimenting to the bottom.

If I understand your question, yes the rheology of the mud is very important. If they can get heavy enough mud to the well bottom to balance the bottom hole pressure, and then stop pumping, it SHOULD hold things more or less static. If it can't balance the pressure, the flow from the well will prevent the gelling and defeat the kill. I may be wrong here, does anybody with a more pure fluids background care to sound off?

It seems that they may not have been able to get the heavy mud to the bottom of the hole. I HOPE I am wrong about that. I REALLY hope I am wrong about that.

That's a good answer. It has a reverse non-newtonian behavior, like fancy modern paint - flows nice under the brush, doesn't drip once you are done.

So, the mud would be a great choice if you did not have turbulent high speed flow (i.e. the well was shut in). You could get it to flow into the well under high pressure, and once it filled the pipe, you could rely on its non-newtonian properties to kind of slow down any movement due to residual unbalance of the forces. So you could cap it.

It would appear to be a poor choice if you are working with a turbulent, high speed flow as your "target" fluid. It will have a low viscosity "response", mixing with the other fluid and not able to maintain the local pressure differential needed for the interface to move into the well. So you couldn't cap it.

There is a (NSF Animal Lovers) analogy one uses when confronted with an impossible or futile task: "Its like trying to push butter up a cat's asshole using a hot needle".

Seems to me that the analogy is a *particularly* appropriate one here, with the cat being the well, the butter the oil/gas flow and the needle the mud.

Dimitry, I am a complete layman, but here is how I imagine this, i.e., I don't quite understand what you said. I suppose that if there is a given pressure difference between the space below the shear rams and the space above them, and the open conduits between these spaces have a certain cross section, then you get a certain flow of fluids from the former space to the latter. If you increase the pressure difference, the flow increases. On the other hand, there is a balance of pressures and flow velocities from the well head to the space below the shear ram. If you then force a certain volume (per unit time) of mud into this space, the pressure in this space must necessarily increase until the outflow above and the inflow below have changed correspondingly. As the pressure in this space increases, the outflow to the riser increases, while the inflow from the well head is reduced. Notice that this idea does not depend on the mixing or not of the fluids.

If at a point the flow of mud forced into said space equals the (increased) flow of fluids past the shear rams, then the /net/ inflow from below must go down to zero. At this point the oil coming up through the well head no longer has a high velocity. A zero net flow can be just a zero flow, or the sum of a down-flow and an up-flow. In the latter case, there is some mud going down in spite of the oil still going up. In the other case, there is no turbulent mixing with oil from below, as whatever oil is still in the space where the mud is injected, gets drained from this space.

If the forced inflow of mud is increased even more, some of the mud must go down the well.

However, what remains a possibility (given my ignorance) is that this point is reached only when the pressure in said space is also increased to the point where the BOP or the well head structures are destroyed, or the flow past the shear rams becomes so violent that the erosion is greatly increased, and thereby the cross section of the conduits past the rams increases to the point that the pumps are unable to supply mud fast enough.

If there is an erosion problem but not a too violent one, I imagine the possibility that before the erosion gets too bad, enough mud has crept down the well to add some weight to the column. If at this point the inflow of mud is briefly turned off, it takes some time to accelerate the fluid in the column, and in the mean time the pressure and the flow past the shear rams is much reduced. At this point a "junk shot" will be less violent on the shear rams since there will be less hammer effect when rubber pieces lodge. This is the only reason I have been able to come up with for why the top kill does not start with a junk shot right away.

Any comments?

Replacing oil & gas supercritical mixture with mud will vastly increase the density/mass, and inertia of teh column coming up. We had 16 hours to push out much of the mud (some left) and re-establish flow before the junk shot.

So I like the thinking behind this, but it appears flawed to me.

Alan

My comments above were general in nature. In the specific case, it may well be that they can get the mud into the well head, but not in a way that facilitates driving the oil/gas mixture down in a controlled manner. For that to occur, there must be a defined interface maintained between the two fluids. This condition is aided by the high pressure fluid (in this case mud) being of higher viscosity. As a though experiment, they can drive the well oil/gas mixture easier with molasses than with alcohol, even if we can get both of these with the same density. Drilling mud, unfortunately exhibits the lower viscosity when moving, so when it enters the turbulent flow it is less likely to maintain a fluid interface and drive the oil/gas mixture down. In other words, all things being equal it is less likely to maintain the needed pressure gradient below and more likely to escape above.

Practically, though, in either case one would need the pressure inside the BOP greater than the local stagnation pressure of the oil/gas mixture. If there are internal obstructions that drop the pressure of the oil/gas mixture by the time it gets to the BOP, the internal BOP mud pressure must be greater than the pressure below the obstruction for any flow to start moving down. Since this well appears to be very high pressure, it is a very tall order to maintain this level of pressure with the top of the BOP nearly open.

Finally, since there is turbulent flow throughout the BOP and likely into the well head with lots of fluid mixing and no well defined oil/gas to mud interface, it is unclear how the injected cement can set in this environment. For this to occur, there must be no flow somewhere in the critical area for the cement to be at rest long enough not to be diluted by the flow.

I have not seen this posted here before, but Matthew Simmons thinks BP has filled the wrong hole:

http://www.examiner.com/x-33986-Political-Spin-Examiner~y2010m5d26-2010-...

Can some of the experts here please comment this?

I'm not an expert, but even I can tell that the "experts" quoted in the article are *also* not experts. The giveaway is the ol' "just detonate a bumb down there" as the closing kicker. The floor of the gulf is soft fine mud. Imagine detonating a bomb in jello or pudding -- would that seal anything up?

The oil did come from the "little dinky hole" -- because it's flowing at almost unimaginable pressures. If you don't understand that, sure you may be looking for other sources -- but you're also surely not an "expert".

I would think that BP would know if the riser were still attached to the well head or not.

Simmons is nuttier than a fruitcake.

I've watched the interview with Simmons and Possi that these quotes were taken from. From what I was able to pick out of the conversation, they are making some VERY INTERESTING claims:

1. The riser is still attached to the Horizon and the oil we see coming out of the end of it is actually coming out of a tank somewhere on the sunken drill rig. I couldn't figure out where they thought the GAS may be coming from.

2. We've all seen the two main leaks from the riser (top of the BOP/riser kink and end of the riser) and there was the third leak at the end of the drill pipe before that was valved and shut off. These two clowns are claiming that the REAL leak from this well is somewhere about 6 or 7 miles away from where all those ships and ROVs are working. There was no explanation of how the oil might be traveling from the GPS coordinates where the Horizon was drilling to where they claim it is coming up from the sea floor.

3. Both Simmons and Possi have suggested that military high explosives are an (the?) appropriate solution to this problem. In fact, Simmons suggested that the navy should "drop a bomb down the bore". If we ignore the little problem involving getting any such bomb past the kinked-up riser and/or partially-actuated shear rams in the BOP AND the fact that the inner casing of the well is something less than 10" inner diameter - thus SEVERELY LIMITING the size of bomb that could be shoved down the bore, we are STILL left with the problem that any such explosion would introduce NUMEROUS new leak paths to either the surface or to new reservoirs higher in the geological strata.

From what I understand, Simmons may once have had some credibility in the field. As far as I'm concerned, on the basis of what I've seen him say in the last few days, he's now got about as much credibility as George W. Bush had when he was in the oval office.

Personally, I have MUCH more confidence in what I hear from Heading Out, ROCKMAN, Shelburn, or many other posters in this forum.

Simmon's comments were highly embarrassing.

I'm not an expert, but in my judgment it is complete bunk.

For many years now I have had a good amount of respect for Matt and his collective body of work. Could someone who knows him or at least has met and talked to him tell me why during this event, he's coming off sounding like a nutter? Reason I ask is at least in the MSM this can put all the real work backed up with evidence he has done over the years on PO in jepordy. I know he has never exactly been mainstream but some of what he is saying is directly contradicting what we can see from the ROV's.

I think he is in love with seeing himself on the news channels as a 'talking head.' I mean, he never had this degree of coverage just for PO, and the MSM will listen to anyone on the BP spill, especially if they say something provocative.

Consider:

http://www.businessinsider.com/matthew-simmons-dylan-ratigan-deepwater-2...

He sounds barking mad!

Craig

HOUSTON — BP had to halt its ambitious effort to plug its stricken oil well in the Gulf of Mexico on Thursday afternoon when engineers saw that too much of the drilling fluid they were injecting into the well was escaping along with the leaking crude oil. http://j.mp/dgKQg9

Really?

Stopping the pumping of mud would explain why the leaking stuff turned to a darker brown color last night but not why the LA Times proclaimed success in stopping the oil leak around 8:27 am PDT this morning.

Gentleman,

trying to wrap my head around what I am looking at in the livestream, and it seems you folks could easily help with my noobish questions...

1) I understand we are currently looking at the top of the BOP, and the stuff is gushing out of the attached riser pipe, which is bent & cracked. Correct?

2) Yesterday the TOV camera showed a different place, as I understood the end of the ripped off riser lying on the seabed. It appeared to me that much more fluid was escaping through the end of the riser pipe, compared to the cracks near the BOP. Has anyone seen this angle since the top kill started? Wouldn't that picture give a much better indicator about progress in terms of reducing pressure/clogging the BOP?

Let's not forget who is giving us all the information on how this "top kill" is going...BP...who has not been truthful about any aspect of this disaster. And how many times now have we heard the line "things are moving along smoothly"...first it was used when they were lowering the first containment structure. It failed. Then with the "top hat" container. It failed. Then with the insertion tube. It failed. And now this. And something I'm not sure has been brought up, but what exactly was going on that rig on the hours leading up to the explosion? Why so much disagreement? Why did some of the rig workers predict this was going to happen? And just one more question, don"t these rigs have black boxes, like those on commercial airplanes, and where is that black box?

this is not going well....

they've been pumping for 27 hrs now at avg rate of 19.2 gal/min ......30000 bbl of kill mud out ...this is starting to look like SIDPP/SICP equalization is not going to happen here ......bullheading is not working here folks....

and wellbore has to be exhaling/breathing by now .....

always was a long shot bullheading a flowing well.....can't blame em' for trying though ....

BP really should have been honest with the chance of success here being 50%. I also wonder why they didn't drill a parallel well right away so they would eventually have the scary option of lighting off conventional explosive and collapsing the well hole. Now we'll probably have to wait for the first relief well, unless the plan on starting over with another 50,000 barrels of mud. This is not good news for the BOP. shakes head.....

sucess rated at 50% is optimistic .....the well is flowing here...top kill has a very low chance of success on flowing wells......let alone one thats been flowing at a clip ....

this is the reason is called bullheading ....basically two fronts ...one oil and one mud are duking it out the the fluid interface and each front has momentum behind it and BP is hoping the momentum of the mud will win ....two bulls pushing each other and hence bullheading( little oil field history here)

thank you. the history AND your insights really help make this clearer.

I suppose that in order to "collapse the well hole" you would have to have the explosives fill at least one third of the length of the bore with rock and sand, otherwise the pressure of the oil would just push the dirt out of the hole.

Why not pump the mud in at a much higher rate?

In order to increase the pumping rate, you must increase pressure inside the casing of the BOP and all along the supply plumbing. I'm not sure where the weakest link in the chain is, but I AM sure that they don't want to find out by overpressuring it to failure.

It was mentioned in the previous thread that the mud was water-based, and inferred that it was less toxic. Can it be inferred that the sg of the mud was insufficient to equalize the pressure downhole because of it's less-toxic properties. E.g. - minus barium?

no ..they can change weight of the mud on the fly .....oil based or water based means the delivery mechanism is oil based (diesel) or water ....oil based muds can be significantly strengthened with cross linking polymers to increased absolute viscosity which is the ability to suspend and deliver solids .....what matters here is the mud weight....barite is what is mixed in the mud to increase the mud weight .......

calculating mud weight for kill mud is a basic calculation and BP knows what the mud wight is ....what they have no control over is what direction the mud flows and how much .....same goes for the wellbore ....the idea is to force mud along the well but the mud is flowing into the rocks underground (losing fluid in formation) and so its not going where it needs to go to be effective....

now they cant simply keep increasing weight on the mud arbitrarily....csg and liner burst pressures.....formation pore pressure .....many things come into play ....but i think the biggest worry has to be the BOP stack itself and casing seats ....

Thanks. I had thought that barium was disallowed for some reason.

So if as Rockman and others have said, and this topkill isn't working, considering the amount of mud that has been pumped in, when do you guys think they might let the media in on it? News stations still saying..." everything is going well at this point".

Well, there is a press conference at 5:30 Eastern time.

Well they would probably announce a delay and explain to the media we are looking at our options....The problem is once they stopped pumping that mud the oil is going to come shooting back out again.

I also read on here today that Barry is calling a 6 month delay in deepwater drilling??? shakes head if the oil companies drill 2 relief wells in each location I see no reason why we can't start drilling again. The last thing we need here is another 3000 people out of work.

I reluctantly support the 6 month pause.

1) We need to make SURE the BOPs work ! Another blow-out now would be beyond catastrophic (and yes, it COULD happen !)

2) Lessons need to be learned and implemented. Simply not a two week process.

3) We have *NO* reserve spill clean-up resources. Even a small spill will require taking men and resources off the front line. In 6 months, we will still be cleaning up Lake Palin, but it will no longer be (I HOPE !) an all out desperate effort then.

Alan

Are they going to rip out 4,000 BOP's and replace them? Can any of them cut a tool joint?

They'll be able to drill 10 miles from New Orleans in six months. The wetlands will be gone. But that's kind of want the oil industry wants isn't it.

If there is a one-month delay in all deep-water drilling after each blowout, the whole trade will /want/ to have strict enforcement of the regulations, lest some "cowboy capitalist" company or rig boss take irresponsible shortcuts.

A six-month delay after every near-accident would be even more efficient in reforming the culture of the trade. They would begin hiring large numbers of psychologists to investigate the social mechanisms behind the failures.

New to this BOP oil rig stuff. But just to get a gage on the size of what I am looking at with the live stream. What is the diameter of the BOP head or cap (the white thing with 4 plums coming out of it)? Looked for schematics and looks like a range of about 12" to about 36"

21" before being stretched and bent.

I have a question about the video. What is the scale of the pipes we are seeing and the plumes coming out of the leaks? It is hard to interpret without some idea of the size of these things. Is the pipe 2" or 20" in diameter????

Thanks.

The original diameter of the riser was 20 inches or 22 inches. It is currently bent over in an approximately 90 degree angle and squished a little wider than its original diameter.

It's been noted we haven't seen the end of the riser for a long time. Given that that was always assumed to be the major part of the outflow, I assume that must also be where most of the mud is going. Is there any possibility of blocking that off? I'd think the whole riser is mostly full of mud now, but I don't know if that'd make it easier or harder to block it at the end. On the other hand, maybe it's so buried in mud now nobody could find it.

Seriously, though, at this point could the riser be somehow crimped or clamped off? If pressure is really near zero from the well, it seems it should maybe be possible, and ought to generate more back pressure than, say , patching the holes at the riser bend.

If the end is capped allowing the pressure to increase, the riser would probably spring several leaks along its length because it is damaged. Leaks in many locations would be harder to control than in two locations.

If you look at the video live feed you can now see the tube sparaying the dispersant again(right corner of feed) so the oil is leaking again and it appears to be coming out at an increased rate.

I don't know if that's really dispersant; to my eye the current feed doesn't look particularly different from the stills at the beginning of http://www.theoildrum.com/node/6515 which also have a stream on the right side of the riser. If they really stopped pumping mud, though, I'd guess we'll see black pretty soon.

Weight

the weight of the mud should? Be counter-ballancing the upthrust of the well, but is this a case that we don't have a stable well, or that leaks in the riser are requiring the pumps to run harder that should be? Equilibrium should mean that no pumping is required if a weight balance is reached.

Seems to me the well is not stable.

I suspect the next move is a new BOP head whilst the pressures are low.

Epic stuff. This is gonna make a cracking movie....

Well, that was an incredible amount of tap-dancing.

haha... it's not over yet. bp guy is not in the best mood today.

How is doing this with the Relief Well any easier? After they intersect the well, and push mud again, it will also just go up the main well hole right? The well is flowing, I don't understand why it is any different trying to push against it at the top or the bottom. Same problem. Can someone explain how this is done exactly with the relief well?

The relief well intersects the wild well a few hundred feet above the oil & gas reservoir. It spends 1 to 3 weeks (I have read various times) TRYING to mill through the steel (<50% chance each attempt) on the last foot. Once it succeeds it pumps in kill mud into the bottom of the well and kills flow. Then cemented in.

If relief well attempt to mill through fails, week plus to back up and start over a few feet up or down.

THEN wild well is reentered and a series of concrete plugs are poured in the original well bore.

Alan

OK - was lurking for days and decided to jump in. See my bio for my industry background.

In this case, it's almost certain that the flow is coming up the outside of the production casing string, so you don't want to mill a window in it. Instead, the relief well has to get very close to the old wellbore and establish communication with it.

Once that's done, you can pump like craazy down the relief well and begin mixing heavy mud with the produced fluids at the source. Remember, that the velocities are much lower downhole because the gas is unlikely to be coming out of solution until the pressure is relieved up the wellbore. (I always thought the topkill would fail, because it's like pissing into the wind -- there are so many leaks above the stack that they can't establish enough backpressure to halt the well flow and start the mud going south. If they can get enough bridging with the junk shot, it might have a chance, IMHO)

Anyway, back to the relief well -- As the mud adds hydrostatic pressure, it slows the rate into the wellbore (as per Darcy's law), which means that the ratio of mud to oil increases, which further increases the mud/oil ratio, which further increases the hydrostatic head. This cycle continues until no more oil flows and it's only mud circulating up the old casing annulus.

Once the flow stops, then BP can remove the old LMRP, connect a 2nd BOP stack on to of the old one, open the old rams, and begin permanent P@A operations (assuming its not a casing collapse below the hangar, in which case I think the only option would be to bullhead cement from the top and pump enough of it that if plugs off the annulus between the production casing and intermediate string).

> After they intersect the well

I doubt there was ever any sort of geomag tool run down that hole - they dont have a clue where the wellbore really is down there except from the MWD logs, I'll speculate. If so, then the chances of intersecting that 7" rathole at TD, even with multiple branch attempts is small. Negligible even.

That's why they're drilling two RWs

Surely for a well that expensive they have done a wellbore survey so they have a good idea where the bottom hole location is.

Also in Canadian SAGD fields they use a technology to drill horizontal wells parallel to already existing wells. I don't know the name of the technology but I would think that they could use something like that here to detect the (nearly) exact location of the existing vertical wellbore.

BP was in the process of closing the well, I believe it was exploratory. The exact geometry was likely not interesting enough to make a separate log run. But I'm only speculating here. There are sensor logtools which can detect possible collisions, but my understanding is that their penetration is limited. Accidental intersections are relatively common in complex fields. In any case, it will certainly be a probing process once TD is acheived.

yes...if anything Obama can force BP to do ...is to drill maybe another two wells in case the first 2 don't intersect.......

this will be another drama in august...BP needs to come out cleanly and say there is a good chance the first relief well might not be enough ....this can easily take 2 or 3 tries to do .....

add in the hurricane season and BP has a steep hill to climb from here on forward

According to CNN, the GOM is 4 degrees hotter than normal for this time for year. I think that someone posted a link to Jeff Masters' thoughts about major hurricanes driving the oil and chemical dispersants ashore across a wide area. Because of the oil and chemical threat, can you imagine the scale of the evacuation we would see if a Katrina size hurricane came ashore through the oil slicks?

It would be nice if this were all a collective nightmare we are having, and we could wake up at some point.

Also according to CNN Int. (weather-forecast). They're expecting 19-23 named storms (average 11) and 3-7 major hurricanes (average 2) this season.

Hopefully BP has managed to plug the holes by then. God bless the wildlife and those living in/off that hazard prone area.

I think we need a 'redo' here. 28 years should be about right, but only if the guys at the top get the same redo and promise to do it right this time. Maybe this time we reelect Carter?

Craig

You know, Craig, I voted for 'im. In 1980 too.

But alas, we live in an idiocracy...

BP wanted to only drill one RW. Thad Allen demanded two (I would have demanded four or five !)

This well was almost completed for future production. First class crew & equipment. They knew where the wild well is and RW drillbit sensors can find the exact location once they are within a few feet. Some of this per Rockman.

Alan

They don't have to "know" where it is. They use a powerful electrical field (basically a fancy induction tool) and azimuthal sensors to detect the steel of the orginal well's casing/drill-string. The ellipse of uncertainty on the directional tools isn't as big as you think, so all they do is drill close to where they think it is, and use the sensor to guide them to the original wellbore. Intersecting is easy.

So have I got this correct? The pumping of the mud has stopped as of now, and they are re-stocking their mud to get ready to try it again tonight? And possibly with the "junk shot" included? What is happening or has happend to all the mud they have pumped in so far? Just leaking out onto the seafloor? And out of the holes above BOP?

BP guy says now that they have stopped pumping mud for some time now.

So if the feeds ARE live right now, all what we are seeing coming out right now must be oil/gas!!

Doesn't look good to me....

It seems that for 16 hours what we have seen is the mud being pushed out by formation pressure. An hour or two ago I noticed one of the plumes had changed color (darker), so it seems the mud they pushed down last night has about all been pushed back out. This was likely a test to see if things would hold together and determining pressure requirements before taking the next step (junk shot/more mud/cement). They should have a pretty good idea of what the well pressure is now, and whether the mud they are using is the correct weight.

Hmmmm.. if they stopped 16 hours ago, that means approx. 10000 barrels of mud coming out of the well? Based on a flowrate of 12-19 Kbls per day?

I that possible?

The specific gravity, flow characteristics and friction factor of the mud would be different from the oil/gas mixture. Also, the rate of mud flow back out of the well wouldn't be linear because of the gradually diminishing weight of the mud column atop the oil/gas column (as mud is expelled).

The flow rate of mud would be tough to calculate. They know how much they pumped, but likely not how much actually entered the well bore vs. what leaked out. I suspect that is one of the things they are trying to determine. This was a data collection exercise rather than an actual top kill attempt.

Edit: Suttles just confirmed what I said here. They needed to know how much mud was going down the well. This is why they stopped pumping and waited (16 hours) until the oil started coming out again. He just said that they resumed pumping about an hour ago.

So they pushed a boatload and a half of mud thru a damaged BOP and into the GOM just for a test? Going to be real embarrasing when the junk shot fails because of an eroded BOP.

that's my read. I think they're going to try changes with the materials and the spec grav of the mud, and the pressure--all variables they can play with.

all that mud is probably gone right back out, yes.

you cannot start and stop a top kill on a flowing well......top kill on a flowing well is a one shot procedure......once the mud pumps stop, top kill is effectively over for a flowing well....so essentially what they will be doing if they start pumping again is top kill attempt No 2.....

i think BP engineers have given up ....this was a long shot anyways ...BP is just blathering and will soon announce that top kill has failed completely .....

It will be completely flushed out of the system. The top kill is an all or nothing proposition, you have to overcome the gas-oil flow up the bore hole.

As somebody mentioned before, using mercury and thousands of tons of it would overwhelm the gas-oil stream by the large density differential (i.e. it would not be blended completely by turbulent mixing in the BOP and borehole). But this is never going to be tried and at the end of the day the relief wells are the only solution.

They stopped pumping mud at 11 p.m. LAST NIGHT. It "worked" only in the sense that while it was firehose-on-firehose, things stopped for a moment. This is not working.

I strongly suspect that was a misstatement, and that he meant that the oil had stopped flowing at that time.

No, he was asked a follow-up on it from the Times-Picayune and confirmed there had been absolutely no pumping today. He explicitly noted what we were seeing on the feed was oil and gas. Pumping ceased last night before midnight.

Bizarre. We saw them test the flow and nobody saw any oil on that wrench...

The sound dropped out a couple of times here, so you may be right, but then... what emptied the 30k bbl mud barge?

According to him, total amount of mud was around 15k bbl if I understood that right.

Gah. Now confirmed...

http://us.cnn.com/2010/US/05/27/gulf.oil.spill/index.html

Suttles said that less than 15,000 barrels of mud had been pumped, total.

All he said was they managed to "decrease" the amount of oil and gas coming up while pumping in mud, and pressed about what part of the operation had been a success, he responded "pumping mud in the wellhead". oh dear.

Hmmm. Wonder why they haven't been showing any video from the riser break? To avoid breaking the illusion that the top-kill was working?

I think he said "as of the start of this press conference". So probably a couple of hours ago.

No, it has been 16 hours since pumping completely ceased.

They're talking about this 16 hours on CNN right now.

This really, really sucks.

The problem itself really sucks and now BP continues with this spin. My gosh.

I don't get them. Do they think they are "beyond whatever"..

Suttles is going to be on John King's show. (I think it's 6 EDT CNN)

Hopefully this 16 hour thing will get clarified.

Suttles made it very clear during the news conference... they last poured in mud around 11 pm last night.

Suttles scuttled around and John King's questioning was not aggressive enough (In my opinion)

It was hard to figure out what was going on.

Media furious:

#OilSpill more: BP says it stopped pumping mud into well 16 hours ago, but will pump again soon. Waited until end of business day to tell us http://j.mp/ckHBsq

More action in the live feed again, looks like they prepare for "Top Kill: The Revenge"

Idea. I don't think this is insane...

Could they setup additional mud shots through the riser holes? Maybe with something to partially block the flow, or maybe position it/them at a choke point to maximize effectiveness? Increase push pressure beyond the riser holes to force primary mud down the well.

Get 10-12 mud ships, 3-4 additional mud pipes/manifolds (or maybe 1 if going for an internal choke point or corner). Fire cement into the primary hole (non-riser) if pressure levels allow it.

There will still be considerable outflow for sure (hopefully decreased?). I imagine this could further damage/increase the riser leaks as well (possibly dramatically).

Member for over three years, maybe my third post...

Is there any way in which things are meaningfully better than they were 24 hours ago, or is it only worse because of erosion to BOP/existing leaks and obviously additional leakage.

One less day's worth of oil polluting the Gulf till the relief wells work.

Alan

Only that more people are aware of the dire situation we're all in. Hopefully the response will increase.

Obviously there's about 15,000bb of toxic mud in the sea and many of the leaks have likely enlarged too.

On a completely non-technical note, it is truly amazing to me that all those shrill voices out there who would lead us to believe that the federal government is the the root of all evil are either completely silent now or more likely the same loud voices that are criticizing the feds for not taking a much bigger role sooner.

what has happened essentially is

Top Kill Attempt No 1 failed last night....they pumped 30000 bbl of kill mud in 10 hrs ......thats 50 bbl per min ....or 2100 gal per min .....and if they really had to go upto 2100 gal per min to jam the mud downhole that means they are loosing a lot of kill fluid through the leaks and not enough is making its way downhole or they are loosing ti all in the formation..

going forward for top kill attempt no 2

the only thing left to even try is ....pump junk in the BOP ....hope a few pieces stick and provide enough coverage on the leaks that when they pump mud again it goes downhole....this is the only logical attempt they have

we are in 10% or less success chances range here folks...no mistake

I *think* Suttle said they've only pumped something around 15000 bbl of kill mud.

here's where this thing goes to hell in a handbasket....

and why top kill attempt no 2 will not work ...

if they pumped for 10 hrs and all the time its been kill fluid +oil+gas thats been coming out that means not only was kill fluid able to pass into the formation but the well is breathing now ....essentially there are spots within the wellbore that have pressure communication across the wellbore .....so not only did the kill fluid pass into formation ...it flowed under reservoir pressures back into the wellbore ...this kind of open communication suggests to me there are not problem spots downhole but problem zones ...this is getting tougher and tougher .... (this post assumes the best case scenario that BP was able to stop oil flow yesterday at some point and actually got a column of kill mud downhole....this is a big assumption)

Reactionary dribble.

This has never been done before so far down in the water. How can you predict a 10% chance of it working?

We don't know, no one knows at this point if they are going to be able to slow down the flow of oil and gas to try something else or try to stop it using this method.

They haven't given up on the top kill yet.

Looks like are going again from all the activity. What was that red led gauge for? It read ~2200.

The led gauge and the shot of the 2 round things surrounded with bolts. I've seen them look at those a number of times. One looks like it a pin sticking out. Maybe like a blown fuse.

Steve

Was wondering same thing. They had plugged something in, then twisted the knob, and then the timer started. Not sure what it's for. It started somewhere around 22:30 (or thereabouts).

It dropped to around 2200 and stopped, flucuating a bit, seemed like some sort of pressure gauge to me.

I had the impression that was the control box for the newly-added flexible kill line (the one marked with the "BOP <--" and "--> Kill" lettering).

That ROV definitely switched from "C" to "O" on the valve, so perhaps that LED readout was the pressure gauge(gal/min?) and this action marked the restart of the pumping?

I like Rockman's fire hose-to-hydrant analogy. Except, things are a bit more complicated which, of course, makes his conclusion even more correct. Sigh...

As you can see from the recently added diagram of the BOP and the mud lines, the mud (unlike the water in Rockman's fire hose) can also travel upwards through the center of the BOP. When the mud gets to the center of the BOP, it has to make a "decision": Go down the well bore or go up? Going up is probably the path of least resistance. Because of the holes at the top of the BOP, it only has to overcome the pressure of 5,000 feet of water (and some additional pressure because it has to go through the holes). If it decides to go down into the well, it has to overcome the pressure of the oil and gas which is higher than the pressure of the 5,000 feet of water since we have all seen the gas/oil mixture flowing out of the BOP and the damaged riser.

So, how can we make the mud go down and push against the gas/oil instead of flowing out? Plug the holes at the top of the BOP. Therefore, junk shot. if we could only tell, sorry guide, the "junk" to go up instead of down when they enter the center of the BOP.

Something else that I am not at all certain about. How do we know that they are only losing mud from the top? Have they measured the flow? How can they be sure that they are not losing mud in the formation? Who knows the shape of the walls of the well? One last thing. For the mud to work and form a seal, it has to stop moving. It is a thixotropic fluid and its viscosity goes down if it flows at high velocity or you shear it with counter-flowing gas or oil.

I really hope I am wrong and somebody (who knows better) tells me so.

I also appreciate Rockman's analogy.

What I don't understand - and asked about higher up in the thread - is how a relief well works. Assuming the establishment of a successful entry from the relief well to the problem well, the cement being poured in will have the same choice to make as yesterday's mud - go up the bore or down into the formation? Unless there is some way to put in a solid, as opposed to liquid, plug, it seems it would just shoot up along with the gas and oil. I'm obviously missing something.