Deepwater Oil Spill - the Congressional Illustrations - and Thurs. Open Thread 2

Posted by Heading Out on June 3, 2010 - 9:16am

Please transfer discussion to http://www.theoildrum.com/node/6562.

10:06 PM Heading Out's comment: They have the cap on but it has not gone down far enough to generate the seal, and so there is a lot of oil still coming out from under the cap.

We are now reading that BP says there will be a 12 to 24 hour wait before the new cap is installed. So in this post, I will go back background material I put together earlier, based on material presented in the Congressional Hearings.

I am sure you are still interested in current events as well, so before going to the background material, these are a few news items. According to the New York Times:

A technician involved in the effort said that because the shear cut left the riser with a slight bend, a different cap would be used than the one originally planned. This cap would fit over the flange that attaches the riser to the blowout preventer stack, the large assembly of equipment atop the well that was supposed to seal the well in an emergency but failed to do so.

The technician, who spoke on condition of anonymity because he was not authorized to comment on the work, said that robotic submersibles had to "dress up" the cut end of the pipe before the cap could be lowered. "Everything just takes time," he said.

If the cap succeeds in capturing most of the leaking oil, BP will try a couple of other measures to minimize the amount of oil still leaking into the sea, Mr. Hayward said.

To combat hydrate problems this time around, BP is running methanol, which will act as a kind of antifreeze, and heated water through a hose down into the containment cap.

The Christian Science Monitor reports:

Embattled oil giant BP made headway in containing the gushing Macondo well Thursday morning, severing a piece of riser pipe to make way for a "top cap" device with a garden-hose-type seal designed to siphon leaking oil to surface tankers. . .

Currently, the well is emptying at a pressure of 9,000 pounds per square inch (psi). The pressure of the water at 5,000 feet is counteracting that pressure and bringing the flow pressure at the wellhead to 3,500 psi. For comparison, a crocodile's bite is measured at 5,000 psi.

"The question is, will the pressure of oil going up into the much smaller pipe mean that [it will create] enough pressure to force the oil up and around the oil seals," says Allen. "We won't know until the cap is seated and we can see how the seals are doing their job."

According to the Oil and Gas Journal:

The cut on the riser pipe is irregular, and the top of the riser is leaning about 10º, Allen said. Crews will place a containment cap with a rubber seal on top of the riser. BP has caps available with different widths and sealing mechanisms so that it can use the cap that best fits the cut riser.

“Once the cap is on, there is some chance that some oil could escape,” Allen said. “It could be close to none, it could be some,” leaking out, he said, adding this only can be determined after the cap is placed.

The reservoir pressure is 9,000 psi, and the pressure of oil coming through the BOP is 3,500 psi, he said. The collected oil and gas will go into a smaller pipe, which could increase back pressure and cause oil to leak out around the seal.

Before the riser was cut, federal scientists estimated the flow rate of the spill could increase 20% between the time of the cut and the time that the cap was placed. A team of scientists had released preliminary findings showing the estimated flow rate is 12,000-19,000 b/d although it possibly could be 25,000 b/d (OGJ Online, May 27, 2010).

BP's spill camera is now offering 12 live feeds from ROVs. This is the link I have, but it is not clear how one gets to the 12 feeds.

(These updates are by Gail. The background material below is by Heading Out.)

Congressional Testimony Illustrations

One of the considerable problems that arise in writing about the Deepwater Horizon oil spill in the Gulf of Mexico comes in determining what information that is given is actually accurate. I’m going to assume, however, that when a company provides information to Congress that it is, to the best of their knowledge, correct. Since the illustrations that accompanied the testimony of BP officials is now available, albeit in draft form, I am going to summarize some of this so that, as discussion and later posts require, it can serve as a useful point to find reference material.

This information was presented the Energy and Commerce Committee of the House, on May 24th. (Note that the illustrations have been condensed to fit on the page. Clicking on the image should lead to a larger view on a separate page.)

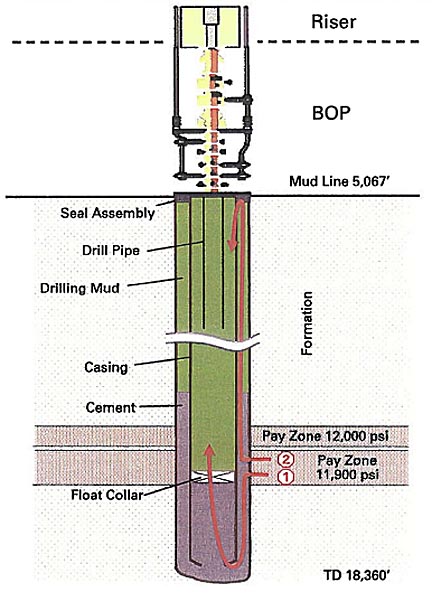

There are several points that I want to highlight, and so I will be taking selected parts of the BP slides to record separate pieces of information. The first of these is where the actual pay zones of oil and gas are, relative to the total depth of the well, and what the pressures are within them. Notice that the pressure at the bottom of the well is about a thousand psi lower than I had been using in earlier posts.

There are several different parts of the overall structure for which more information is available in these slides (and my many thanks to several folk who have pointed me to their existence).

Consider first the Blow-Out Preventer, on which I have focused recently. The exact nature of the different rams is not the same as that illustrated by the paper from which I took the illustration.

The various components of the BOP, from the top are:

UAP – Upper Annular Preventer, used in normal drilling operations for well shut-in, rated at 10,000 psi

LAP – Lower Annular Preventer - down rated to lower wellbore retaining pressure to 5,000 psi.

BSR – Blind Shear Rams – cuts through the pipe and seals the well. 2 rams, one on either side of the drill pipe (DP).

CSR – Casing Shear Rams – non sealing, cut drill pipe and casing, but not designed to seal the well.

The three variable bore rams (VBO) would normally be the following with the functions designated:

UPR – Upper Pipe Rams – Ram packers can close on a range of drill pipe, from 3.5” OD to 6 5/8” OD and seal at 15,000 psi well bore pressure.

MPR – Middle Pipe Rams - Ram packers can close on a range of drill pipe, from 3.5” OD to 6 5/8” OD and seal at 15,000 psi well bore pressure., can also be used to hand-off drill pipe to a maximum weight of 600,000 lb.

LPR – Lower Pipe Rams – A Test Ram that can hold up to 15,000 psi.

The lowest ram did not function, I believe, and there was evidence of hydraulic leakage which has raised questions as to whether, or which, of the other rams functioned. However, as a part of the protocol for the positive pressure test, the drill pipe is lifted out of the BOP, and the BSR is closed to seal the well, while fluid is pumped into the well through the kill line, to raise the pressure and ensure that the cement job had held pressure. That test was successfully completed.

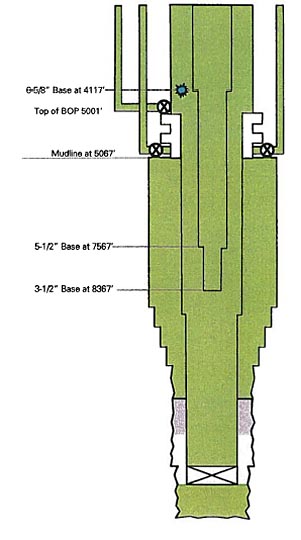

Following the positive pressure test the drill pipe is lowered back into the hole. Note that it is in three sizes, as it goes down the well, with the upper segment at a diameter of 6 5/8” , and the lowest at a diameter of 3.5” extending down to 8,367 ft below the rig.

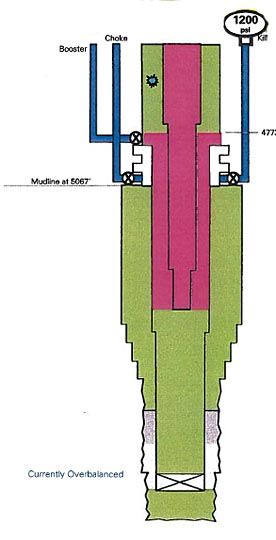

To separate the seawater that is then going to be pumped into the riser a special, heavy mud known as the Lost Circulation Material (LCM) which has a weight of 16 pounds per gallon (ppg) is injected into the well, through the DP, and it circulates from the bottom of the DP back up to the BOP. The choke and kill lines had been filled with seawater, and the kill line pressure gage was still reading 1200 psi. (This takes the time to 16:28 on the 20th April. The green color is 14 ppg mud, the pink the 454 barrels of 16 ppg LCM, and the blue is seawater at 8.6 ppg.

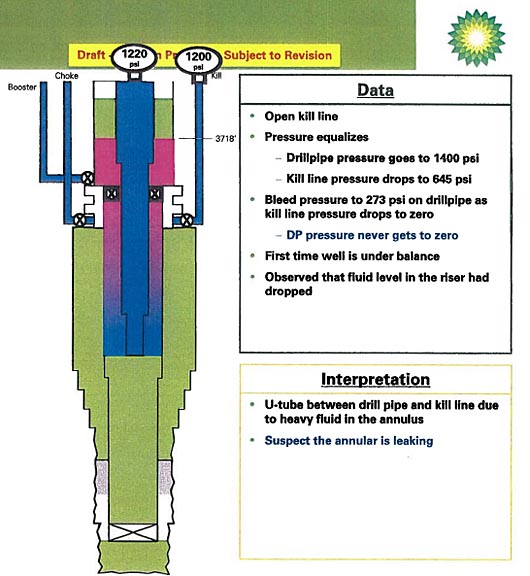

The sea water is pumped into the well and circulated behind the spacing LCM, material. Once it has filled the drill pipe, and started to rise back up the production casing, the pressure rating of the water in the DP is at 2325 psi, and that in the kill line is 1200 psi. The annular seal is closed around the DP, and the pump is switched off. The pressure in the DP (on the rig floor I imagine) is reduced to 1200 psi, to equate with that of the kill line. Once the two are at the same pressure the kill valve at the BOP is opened, but this is where, at around 5 pm the first signs of a problem appear. The fluid in the well, for the first time, exerts less pressure on the fluid in the rock, than the value of that pressure.

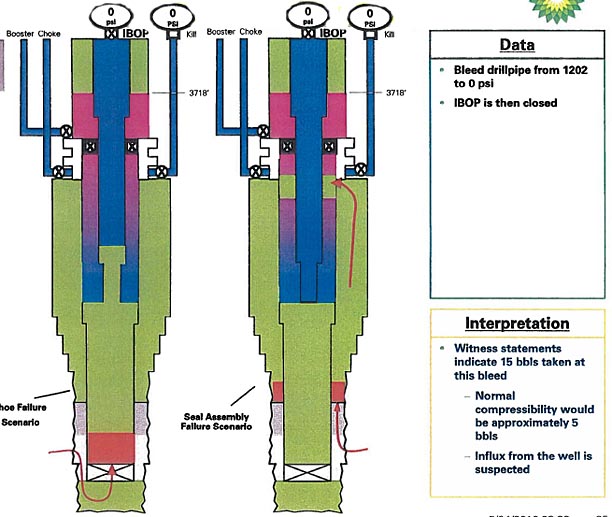

The annular that is leaking is, presumably, the annular seal at the top of the BOP. The term “U-tube” I believe refers to the fact that there is not a pressure balance at the point it is measured. At this point there are two separate scenarios as to how fluid starts to migrate into the well, as the pressure in the DP is bled back to zero. It is now 17:52. Note that the oil/gas flow is shown as an orange arrow and in either case has a path to the bottom of the DP.

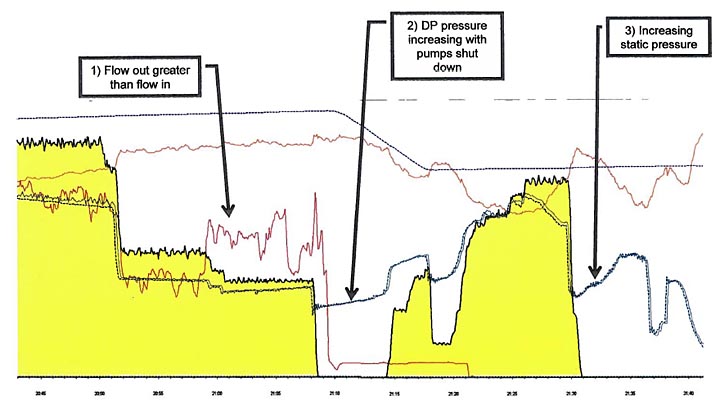

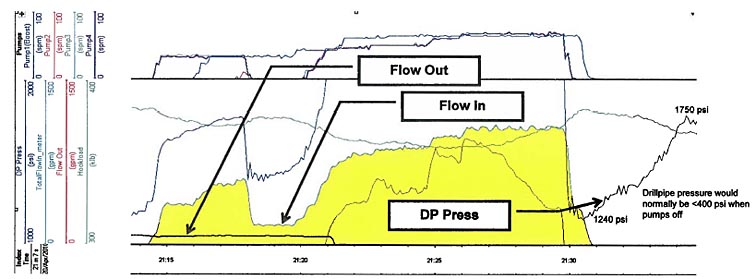

Pressure in the well now starts to rise, fluid is flowing from the kill line (about 3 – 15 bbls, the kill line was closed. Pressure in the DP was monitored and held steady at 1,400 psi, This was the negative pressure test, at 19:55 the decision to continue pumping seawater was implemented, at 20:58 it was noted that the flow out was greater than the flow in. The flow meter indicates that the well is flowing. Pressure in the DP continues to build, even after the pumps are shut down.

The first indications of this flow was 51 minutes before the explosion occurred. Seawater displacement restarted, at 21:14 and at 21:56 the Emergency Disconnect System (EDS) was activated, which should have led the shear rams to activate, and released the riser from the well. It did not work. The gage results leading up to the explosion were provided.

The activation time for the EDS should be 46 seconds. In this time, after the EDS button is pushed, the blind shear rams close, cutting the drill pipe and sealing the well.

The choke and kill line valves are closed and the lines unlatched.

The LMRP is unlatched and disconnects.

The sequence is complete and the rig can move away from the well.

There is no evidence that the EDS fully activated. Even if hydraulic power to the BOP had been lost there was a second procedure, the AMF, that should have sensed the loss in power, communications and hydraulics and closed the blind shear rams. But it required all three to have been lost to activate. It should take 37 seconds. There is no evidence that it fully activated.

The subsequent use of ultrasonics and gamma ray examination suggests that the blind shear and VBRs may have functioned, and could have reached the locked (closed?) position.

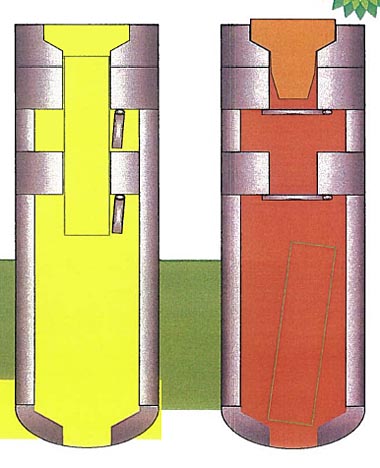

The testimony also showed a simplified version of how the shoe at the bottom of the casing should act to stop re-entry of fluids into the bottom of the production casing. The flappers stay open as first mud, and then cement is pumped down the well. Once the plug reaches the well, and all the cement has been ejected, then the flappers swing back horizontal, sealing the well. (The testimony pictures has the flapper in the wrong place in the middle figure so I deleted it from this copy.)

Prof. Goose's Comment:

A continued sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

Ironically, just as I was going to post this comment in the morning's thread it was closed for comments :-)

I was responding to a comment by ov with a followup by shelburne.

ov said:

sherburn went on to say:

Having focused threads that are open for a long time allows us to keep comments key to the discussion in one place, ensures there will be few repeated questions, and gives us a place for comments containing important links to outside sources to accumulate.

It also means fewer questions will go unanswered (although we are doing a remarkable job now under the circumstances). Knowing the thread will remain open for comments takes the pressure off of trying to keep up.

The most important benefit IMHO, is the thread would become the best ongoing, comprehensive, and credible source for information about its topic available.

I know there are limits to the number of dedicated threads, but perhaps we could experiment with a single thread and see how it goes.

It strikes me that the BP-lead, government-supported response effort is deteriorating into a fresh round of finger-pointing (consider recent attempts to distance our national response from BP's efforts; for example, Adm. Thad Allen just began holding solo press briefings... no more BP representatives).

At this crucial juncture, it appears the entire endeavor is hampered by poor communication and hazy command structure. And Admiral Allen certainly has more to manage than simply following Tony Hayward (BP's CEO) around all day keeping an eye on everything. He cannot be a hands-on manager directly overseeing BP 24-7.

***This begs the question: who is the administration's "point man" is in the BP nerve center?***

Participants in the effort to kill this well clearly bring sharp minds and years of experience to the table. For example, Secretary Chu recently sent a team of 5 nuclear physicists to the Gulf (including Richard Garwin, a designer of the first hydrogen bomb, and Tom Hunter, chief of Snadia National Labs). The skilled pilots of those ROVs all have at least 2,000 hours of flight time and are doing a remarkable job.

Those credentials are genuinely impressive.

But my concern relates to the central decision-making process. Is this a scenario where:

1.) Tony Hayward & BP make decisions, carry them out and public officials are then brought into the loop as events unfold (perhaps even after-the-fact)?

OR

2.) Someone with command authority is essentially attached to Tony Hayward (physically or electronically), getting real-time information and granting approval or tweaking plans before they are executed?

For example (purely hypothetical): Tony Hayward gets a call from the ROV room that the BOP appears on the verge of rupturing. A crucial decision must be made rapidly. Does he:

1.) Make an executive decision, leaving the government to find out second-hand or via phone call shortly afterwards

OR

2.) Have a public official he directly communicates with and says, "Hey, here's what's happening and this is what we want/intend to do. Good to go?" At which point the public official says either, "You're good to go, let's get this done" or, "Sorry Tony, that's not safe, practical or in line with reasonable procedures. Why is this the best option? Have you considered trying X or Y instead? I can approve that immediately while we hash this out a bit more."

This single factor alone may make a world of difference as events continue unfolding in the days and weeks ahead.

Thanks for any guidance, input or additional thoughts on this vital issue.

_If_ US disaster response doctrine were being followed the 'incident commander' for the oil well should be BP. This is because BP is the largest 'stakeholder' and is performing the bulk of the effort.

What gets tricky here is that government agences are loath to give up control to 'civilians.' As a result I see a command structure where the Coast Guard is overseeing operations that they do not really understand.

If I were sitting in the White House this is how I would organize the response:

The response to the oil leak and everything within 5 miles is 'owned' by BP with a Coast Guard laison keeping tabs on the operation.

All 'deepwater' oil cleanup operations are 'owned' by the US Coast Guard.

All coastal oil cleanup operations are 'owned' by the respective state governments.

FEMA operates as a support orginization for BP, the Coast Guard. and each state response team.

The EPA is tasked to _support_ each orginization that 'owns' a response with advice and technical assistance - however the final decision on any remedation or mitigation effort cannot be blocked by the EPA.

Listened to an NPR interview yesterday w/ whatever 'Secy' this is under. Woman, don't remember the name or position.

She said that Gov't gets over-ride or go-ahead on any move that BP makes at this point.

Altho I don't know who, how fast, based on what, etc etc etc.

That may have been Carol Browner, white house energy and climate change adviser. An interview with her, recorded yesterday, was also broadcast today on Morning Edition. Among other things she said

No specifics were given on exactly how that happens.

A transcript of interview available at

Government monitors BP's every move

Audio available at link at the top of the transcript. I heard it this am ... the pauses in her answers aren't reflected in the transcript.

I have not seen it mentioned anywhere, but Mr. Obama has put the director of the Bureau of Land Management (BLM) in temporary control of the MMS. Quite obviously, BLM knows 'diddly squat' about drilling oil/gas wells in 5,000 feet of sea water. I would also add, if MMS had ethics problems (too many lunches with industry), BLM has ethics problems in spades (harassing land owners, and filing false criminal charges against land owners):

Wilkie v. Robbins

http://www.law.cornell.edu/supct/html/06-219.ZX.html

This is like putting the fox in charge of the chicken coop...

Thanks, cactolith. Citations and everything (a recent case, too)!

Not exactly reassuring for the state of affairs moving forward, however...

Please document your assertion that the Dept. of the Interior/BLM is running herd on the MMS.

The MMS did considerably more than have lunch, compliments of "X" oil company.

Several of the employees were busted for snorting coke & crank. Internet porn @ work & partying on the oil companies dime. The same companies that they were supposed to be regulating. There was a serious lack of independence as the oil companies would pencil-in reports only to have MMS fill them out in ink, etc..

I've worked for many a yr. in the WY, CO, UT, ND, MT, & CA oilpatch, & have seen countless BLM personnel, making sure that the blowout equipment was up to snuff & that BOP pressure tests were copasetic, before we were ever able to spud-in.

The Department of the Interior regulatory agency was busted while Bu$h was still in office. The employees w/ the Dept. of the Interior were in the Dnvr. office, snorting cocaine on top of a toaster oven in the break room, w/ oil company representatives & also on many other occasions. The govt. employees were also trading sexual favors w/ oil company reps, as well as accepting gifts, like free tickets to the Broncos & the Rockies, et cetera.

They might have some dedicated & loyal govt. servants in there now, we can only hope.

The SEC employees were downloading porn for 8 hrs./day 5 days/week, on our dime.

There was also some drug use involved. They certainly were not regulating the commodities futures mkt.. Otherwise, they may have caught the criminality, had they been on the job instead of on the dole.

And of course the secret meetings that Dick Cheney had w/ the multinational oil companies to hammer-out a National Energy Policy were somewhat disconcerting. Justice Scalia who had previously gone duck hunting w/ Cheney, ruled that the Shooter didn't have to reveal the names of those who attended the energy policy cabal.

By all rights, Scalia should have recused himself.

Thank you for this great collection of materials, etc. It looks to me like the basic narrative we have previously heard is being proven to a near certainty - the decision to displace with sea water was the fatal step, but occurred anyway despite being poor drilling practice and in the shadow of multiple PHYSICALLY obvious warnings and danger signs.

I see no diagrams regarding the two supposed negative pressure tests that were run. Are there diagrams relating to the negative pressure tests, and the supposed "other tests" that BP testified were their assurance to go ahead with the sea water displacement plan?

Also, the diagram that show an orange arrow penetrating cement dont seem to take into account the earlier diagram they submitted where there was an open path throught the lower annular space to the surface. Which is lying/ wrong?

FOR ALL

Once again the Huffington Post leads the way for exploitive BS info meant to get you to read their rag.

Re: the link from the previous thread wherein their title gives the impression that ALL OFFSHORE drilling had been forbidden. From the very same article:" Kendra Barkoff, a spokeswoman for Interior Secretary Ken Salazar, denied that the administration was placing a hold on shallow-water drilling. "There is a six-month moratorium on deepwater drilling," Barkoff said in an e-mail Thursday. "Shallow-water drilling may continue as long as oil and gas operations satisfy the environmental and safety requirements Secretary Salazar outlined in his report to the president and have exploration plans that meet those requirements. There is no moratorium on shallow water drilling."

I knew the "all offshore drilling is banned" statement was BS...I'm in the process of permitting 5 shelf projects with the MMS as I type.

http://news.yahoo.com/s/ap/20100603/ap_on_go_ca_st_pe/us_gulf_oil_spill_...

WASHINGTON – The Obama administration is blocking all new offshore drilling in the Gulf of Mexico, a day after regulators approved a new permit for drilling in shallow water.

An e-mail Thursday from the Gulf Coast office of the Minerals Management Service says that "until further notice" no new drilling is being allowed in the Gulf, no matter the water depth. A copy of the e-mail was obtained by The Associated Press.

Yeah, MMS started this "rumor"—which was hastily repudiated by officials higher up the food chain at Interior and the WH. HuffPo is frequently guilty of sensationalism and uncritical jabbering, but they aren't the bad guys here.

They're the bad guys for OTHER reasons

(grumble grumble antivaccination nutcases)

Yeah, but you know where that "He's guilty of *something*. . ." path leads us.

Of course, right now, if you proposed tying Arianna and Tony back-to-back and dropping them off the Golden Gate Bridge (where it would be easy for me to get good photos), I'd be hard-pressed to refrain from cheering you on.

Edit to correct dumb typo.

http://preview.bloomberg.com/news/2010-06-03/u-s-requires-drillers-to-re...

Hey RM, Sorry for having linked to them instead of a more official press release, it was the first I'd come across, I should have dug up the AP article instead.

No problem somatic -- half the folks it my office took it the wrong way also. This entire incident is in desparite need of a RCO (Rumor Control Officer).

I hope you have a hip-pocket full of onshore opportunities, if needed.

Unless there is a new NTL that I don't know about... "For the purposes of this Moratorium NTL, “deepwater” means depths greater than 500 feet." - from NTL 2010-N04. So yes everything on the shelf should be fine. That doesn't mean that they wont let those permits sit on their desks for 6 months...

This is an area of my expertise. I've been following the financial press/blogs for 3 years now, as a service for another forum elsewhere. You can't believe Huffpo. Financial Times is as mainstream as you can get, always late to the party with blah commentary. Bloomberg - half the time they're right, half the time they're wrong. The London Telegraph is excellent, as is Zero Hedge. But Zero Hedge had the wrong story yesterday; they should stick to what they're good at, analyzing the capital markets and market action. Once in a blue moon, the New York Times will scoop the world.

don't know how current this is from the FT

Further setback in bid to contain leak

By Ed Crooks in Houston

Published: June 3 2010 19:27 GMT| Last updated: June 3 2010 19:27

BP has been forced to use a less effective method of capturing the oil pouring from its leaking Macondo well in the Gulf of Mexico, raising the risk that the spill will continue to worsen.

With options for containing the oil now almost exhausted, the setback to the latest attempt raises the prospect that the leak may continue until the relief wells are completed in mid-August.

http://www.ft.com/cms/s/0/88c13348-6f35-11df-9f43-00144feabdc0.html

The setback: "BP on Thursday used powerful hydraulic shears to cut off broken pipes from the valves on the seabed. The move was a fall-back after it was forced to abandon an attempt to make the cut with a diamond-tipped saw." FP seems to be using a huffpo approach to headlines.

From previous thread :

Thanks a lot for the info, and is the feedback on their job only based on the video feeds, or do they have somekind of reconstructed 3D views based on position sensors ?

With the disk cutting stuff, sometimes it caught the oil and the view was totally obscured, in that case they just "back out" and wait for the view to clear up ?

this is skilled skilled work

each ROV is piloted remotely from the surface vessel using a cable by a 3 man crew

1 man is the pilot

1 man works the manipulator (the manipulator can have diff tools as attachments)

1 man is the navigator

no there is no level of command as unscrew a bolt or do this.....every movement is controlled top side by the 3 man crew...

there is no reconstructed views ...a few sensors are there but none is a reactive sensor ....all sensors provide feed to the operators who operate even the slightest function on the ROV's

There is no exact rule for the number of hours an ROV pilot needs to have. The level of expertise is the determining factor. Maturity, knowledge of the work and safety attitude are just as important as stick skill. There is usually, but not always, a correlation between number of hours flying and skill.

They are flying a 200 horsepower vehicle weighing 3 to 5 tons and worth $2 million. It is big and powerful enough to do considerable damage if mishandled. Unlike operating a piece of machinery on the surface these act more like a helicopter with pitch, yaw and vertical thrust as well as back and forth and sideways.

The pilot has a large screen TV with a high definition picture (much better than the BP live feed) but no depth perception and usually a considerable distortion due to the wide angle lens. He also has other cameras showing in side screens that he can switch to his center screen if he wants. He has a sector scan sonar that can help him "see" farther and in black water, not enough to work but to keep from running into things.

Most of the cameras have pan and tilt and zoom. Some of the lights are variable intensity and even may have their own pan and tilt.

The manipulators are 5 or 7 function rate feed and require the same level of skill to operate as the ROV itself.

For work like this it is all hand controlled. Parking in a set location is probably the only computer controlled function, but that allows the pilot to relax a bit.

A number of years ago we were meeting with a bunch of Shell people and were explaining that soon we would have onshore live feeds from ROV video and might even have the capability to fly the ROV from onshore. One of the younger Shell engineers said he really liked the idea of flying the ROV around the wellhead from his office. I said that was great but he would have to sign a waiver taking all liability for any damage, the ROV and lost revenues if it was lost or damaged. A Shell VP in the room put a real quick stop to that idea.

BP Feeds on one page: Reality Check - BP Video Center Courtesy Hx3 at Live Feed Oil Gusher GOM at LATOC.

Can/should we confine this thread to the stated topic? Current events are not the focus of this thread except where ongoing investigations and testimony is concerned. There are other threads for other topics....

..."and Thurs. Open Thread 2".

Is there somewhere else we should be discussing general issues at the moment?

My Firefox keeps crashing when I try to watch the multiple feed links. Any suggestions on a single feed link for the best view? Thanks.

you don't have enough memory

1. close & reopen firefox to clear the cache

2. when viewing the full set of videos, pause all but the ones you are most interested in

3. if firefox isn't clearing the cache effectively you can also do start/run/ & type: ipconfig /flushdns

Which OS are you using?

http://mfile.akamai.com/97892/live/reflector:46245.asx

This one works fine in my FF:

http://www.deepwaterbp.com/

I also did the akamai thing with a local html code file. Read yesterday's link for info on that.

Meantime, does anyone have any idea what the manhole cover looking thing below the LMRP is for? Is that just a stabilizer to keep it oriented upright (seems like the cable from the support ship would do that) or is it intended to go inside the riser acting as a kind of manifold?

Enterprise ROV2 shows it at the moment, suspended below the LMRP

I'm using http://mxl.fi/bpfeeds/ (as linked to on the last comment thread), working fine in chrome, but as 7 feeds are working at the moment (out of the full 12) it takes a fairly chunky PC to show them all!

Okay, open thread.... dang. I wish there was a thread for the investigation only. Hard to keep up with a topic when 98% of the traffic is going to be "hey, an eel floated by!"

Drumbeat...come on over...

http://www.theoildrum.com/node/6553

This thread is for current events too. It is hard to have enough threads.

HO wrote this a couple of days ago, and asked us to hold it until there was a "break" in the immediate activity.

Thanks gail. Please, is it possible to have ONE thread that concerns drilling practice/ criminal negligence and the ongoing efforts to find out how this disaster was created/perpetrated?

Yes, the disaster response is important but no, it would not be necessary to do it a second time if we could isolate some of the causes, etc.

Have you noticed the way that intensive ROV-watching affects you, psychologically?

Yesterday there were two incidents that caused me to kinda lose my perspective temporarily:

1) There was a brief and stunningly beautiful scene, just after the diamond band-saw was yanked away, where 2 ROVs, viewed by a third, were hovering in the water maybe 30 or 40 feet away from the BOP top. With all that lighting horsepower, the scene was *very* well-illumniated, best panoramic view I've seen so far. The plume of oil and dispersant from the BOP was horrendous, the clarity of the scene stunning. And for a moment I idly wondered.... what the hell must those ROVs be thinking? ....then I realised.

2) Two ROVs came face to face, and started reaching out their claws and toching each other. "Some kind of ROV mating ritual?" I thought "baby ROVs on the way?"..... after a couple of mins I realised that ROV1 was reaching out to clean the main camara lens of ROV2.

This obsessive observation of the action down there (and I'm sure I'm not the only one.....) is kinda sending me nutty.

Regards Chris

The ROV feeds are certainly captivating. I find myself staring at them for embarrassingly long periods of time.

First time posting here! Have to say how much I appreciate the excellent info on this site, and the actually useful discussions!

I will say: thank goodness my metals lab is much too small to get any of the massive amount of work that is going to be flowing out of this nightmare.

Chris, this must be how primitive people thought of the sun, moon, stars, etc as like "gods" - how we can see so many things as having "human qualities". I think we're wired for that! Babies, as soon as they're born, will fixate visually on anything that appears to be a face - a couple of eyes, a mouth. It's interesting how, from what you write, we interpret actions as "intended" and as empathically motivated. (or possibly warlike - in other cases)

But yes, I caught myself seeing those "arms" as attached to "people" - as not just robotic extensions. So how easily we "connect" - even emotionally - with what's going on.

Robots don't like to be anthropomorphized.

yes, "gotta hankie, mate?"

I say beware spinal-cord life forms, these ROVs are gonna go rogue on us. First clue I'm right, they'll invade and capture your local Toys"R"Us and Wal-Mart-type places, and then spread out to single family homes throughout your neighborhoods.

I caught a glimpse of the little yellow one's stern........Niiice!

Enterprise ROVs 1 & 2 appear to be working on the cap, making some connections (looks like hydraulic tubing) between the cap and the "power pack" (midway station?) that the cap is hanging from.

Feeds are in row 3, the first two from left:

http://mxl.fi/bpfeeds2/

See this illustration for the layout, though it's not to scale:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

Scratch that comment about hydraulic lines. From the illustration, they're probably lines for methanol and hot water.

Looks like no ROVs are working on the riser stub at the moment, but two are working on the manifold/LMRP plumbing. Guessing that means we're going to see a capping attempt soon once the system is prepped. I'm assuming that they'll first try to crank up the manifold to divert off some oil flow and decrease the output at the riser stub... also guessing that they'll start the methanol flow during the attempt to forestall hydrate formation. I wonder what the exact sequence of events will wind up being, going to be a nail-biter.

~15:15 CDT Skandi ROV 1 injecting dispersant with the cut portion of the riser visible.

~15:20 CDT Enterprise ROV 2 attaching a blue hose to the top of the yellow and white top hat 4.

~15:20 CDT Q4000 ROV 1 monitoring a pipe or hose and connector.

~15:24 CDT Ocean Intervention III ROV 2 starring into sea water.

I think the OI 3 - ROV 2 and the Skadi ROV 2 are staring each other down...

High Noon at the OK BOP

An interesting aside is that there are ROVs from at least 4 companies that are usually fierce competitors and highly secretive of their technology and equipment. But here they all realize the stakes involved and are working in complete cooperation.

They were probably all on hire for other oil companies when the blowout happened and they, like many of the engineers and vessels involved in this project, were released by those companies at the expense of their own projects.

I know that BP has the authority, backed by government regulations, to commander anything they need but I haven't heard of once instance that whatever they thought they could use wasn't freely offered.

I really enjoy reading TOD, lots of interesting and useful info, thank you all guys.

Don't know if it had been mentioned earlier, just being curious.. Here comes another sick-minded contraption of an outsider.

The formation of hydrates (or whatever you name those crystals forming from crude in the presence of seawater) had only been considered as a problem. Would it be impossible to exploit this phenomena on our side? The idea is that if we could get access to the DP (that's the hard part I think, even more that now it's sheared to hell - but I can imagine a hydraulically operated gasket that can be lowered into the gusher, on top of the DP, then activated to seal around it) and inject pure seawater in it, this water would flow through the DP to the bottom of the well, forming crystals there, in some time eventually blocking the way of the blowout. Or does that crystal formation happen only with cold water?

Apart from technical difficulties, what is the weak point of this solution?

Here's some great info on hydrates and their habitat:

http://woodshole.er.usgs.gov/project-pages/hydrates/what.html

The problem is that as you go down into the seafloor, it gets hotter. Hydrates/clathrates are only stable at low temperatures. The oil and gas coming out of the well are too hot to permit clathrate formation: they have to cool in contact with water before clathrate can form.

One interesting fact, though, for anyone interested in doing engineering with hydrates: they're about 20 times stronger than ice.

http://www.agu.org/pubs/sample_articles/cr/2002JB001872/2002JB001872.pdf

The Saddest VIDEO Yet Broadcast Of The Effect Of The Spill On WILDLIFE.... http://www.cbsnews.com/video/watch/?id=6544966n&tag=watchnow

"Why should man expect his prayer for mercy to be heard by What is above him when he shows no mercy to what is under him?"

—Pierre Troubetzko

~15:30 Enterprise ROV 2 has returned to the square white open frame object with other blue hoses hooked and dangling from one side. I guess this is a pump or interface for top hat 4.

~15:34 Enterprise ROV 2 has retrieved a hose that was apparently dropped below the square object and returned it to a hook.

~15:39 CDT Enterprise ROV 2 unhooks another blue hose, moves downward and releases it. It continues moving downward until top hat 4 is visible. The square white open frame object appears to be attached higher up on the pipe that comes out of top hat 4.

That "white open frame" is another LMRP from the Enterprise. The top hat is connected to drill pipe or drill collars that protrude from the bottom of the LMRP.

I'm guessing that that white disk is just a shield to help keep gas bubbles from going up inside the riser.

Now that you point this out, I see the similarity in the illustration on the BP site, except that the second LMRP is rotated about 180 degrees in the illustration.

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

Does the LMRP provide/generate the heated water and pump the methanol?

methanol will be pumped from the top side via feed in line

The Enterprise ROV 2 "open frame object" is most likely the cage that it deploys from. This cage device hosts the tether that runs out to the ROV. The cage device is what the mother ship drops into the ocean with a payload cable and various communications cables to link the ship with the ROV.

It is not a ROV cage because it contains equipment (pumps?) and is attached to top hat 4 with a pipe (like a drill pipe). The configuration resembles the following diagram:

I agree with you on the description and purpose.....but I believe what you are citing is what the "Enterprise ROV 1" is viewing. I was citing what "Enterprise ROV 2" was viewing at the time.

Here's a picture of this from about 30 minutes ago.

Yep. That's the LMRP Cap "equipment" cage. What I saw earlier in the day was Enterprise ROV 2 going back to its "support cage" to get something out of a tool tray. Maybe our timing is off on what we see versus post.

I watched the activity at the top of the BOP this morning for a number of hours. They used the shear last night to cut the riser off about two feet above the flange. They spent a lot of time trying to cut what looked like a remnant from the pipe that was sticking out beyond the flange using a large circular saw. They couldn't get a solid enough grip on the saw (although the specs for the Schilling manipulator suggest it's capable of between 500 to 1000 psi). Anyway they dropped the saw 2 or 3 times. Once they tryed to use a smaller one with a composite wheel instead of a steel blade and it broke almost immediately.

When they finally got down to some serious cutting it didn't look like they were making much headway.

Turns out the the remnant they were trying to cut was actually an entire circular section of the pipe that had been cut loose at the bottom and crushed against the other side of the pipe by the shear.(when they took a closer look you could see a different color stream that was jetting through the narrow gap between the crushed sides, that stood out against the darker main body of the flow.

Question: why haven't they tried to just unbolt the remains of the riser at the flange? It would provide a smooth flat mating surface, and should even lift off over the DP which might still be protruding inside?

The answer I've seen elsewhere on here is that the ROVs can't muster the 3,000+ ft/lbs it would take to unbolt the flange.

They no doubt made a guesstimate of which would take longer to implement, trim the rough edges of the riser stub or try unbolting the flange. My guess is that the collective heads all agreed longer to get the torque wrenches deployed and unbolt the flange, assuming they could get the bolts broken loose. Also, I believe the riser stub sticking up may prove of some benefit when they're trying to rattle the LMRP funnel down over the stream of oil coming out, once they get the lower guide vanes started over the pipe, which they will have some visibility to assist them, then the pipe will more or less center the funnel up and keep it from being blown completely out of the flow stream.

There have been constant suggestions to remove the flange bolts to get a smooth surface thinking this promises the best hopes of a seal. This ignores the ways seals normally work. In designing a seal you aim to make the effects of pressure tighten the seal not loosen it. A seal can be made with a gasket compressed between flat flanges but this is the brute force approach. O-rings are normally retained in a groove between the faces to be sealed. Pressure from fluid flowing between the faces, will compress the cross section of the O-ring in the direction of flow since the opposite wall of the groove will stop the O-ring being pushed bodily in the direction of the flow but this compression will cause it to expand in the perpendicular direction pressing against the surfaces that the liquid is flowing along and tightening the seal.

If the proposed collar has a large O-ring that fits over the outside cylindrical surface of the flange and there is a retention lip on the collar to stop it being ejected downward we will get this self sealing effect as the fluid is trying to push axially downward between the outer cylindrical surface of the flange and the inner cylindrical surface of the collar. The O-ring cross section will be compressed axially between the downward pressure of the liquid and the retention lip of the collar and as a result will expand radially tightening the seal between the outside of the flange and the inside of the collar. If the collar is roughly clipped down or if the weight of a mile of riser above it is sufficient to prevent it rising there is no need of any further force on the O-ring and there no need to locate bolt holes or provide any alignment force. Even slight tilts of the collar from vertical will be accommodated.

If a gasket where used on the upper flat face of the flange a slight tilt of flange above a gasket on the flange face will cause a leak and necessitate the use of some extra clamping force.

Thus although the outer surface of the flange is rougher, its geometry makes it a better bet than the upper face of the unbolted flange (if indeed it is practical to unbolt it).

If a reasonably good seal can be made initially it may be possible to inject some quick setting sealant just above the O-ring so that it sets as it is driven through the remaining leaks.

The following has occurred to me as I have learned about the accident.

The BOP (Blow-Out Preventer) has two types of functions - (1)normal well control to allow the drilling to proceed safely and effectively [choke and kill lines, annular preventers, pipe rams, and blind shear ram], and (2) emergency well control [ Casing shear ram, blind shear, annular preventers, also flow control valves]

In the first case, the device is used extensively during drilling activity and well tests and components are subject to considerable wear and tear.

In the second case only some functions are used as part of normal work and some are emergency only (casing shear and EDS function).

The device cannot be repaired on the seabed if a major component has a problem - it must be brought to the surface and this is a lengthy and time-consuming process - maybe a couple of days or more lost time.

Since some of the emergency functions are not needed in the normal course of work a fault could be overlooked or ignored - especially when a job is behind schedule and nearly finished.

A good operator can still work effectively with a device that has some faults or worn parts if he (she) understands the limitations imposed and compensates for those faults. This may allow successful completion of a job with no time lost for repairs which are deferred until after job completion.

On the other hand, in an emergency when the device is under stress and there is little time to react it may simply fail outright.

We heard that at least one of the annular preventers may have been in rough shape, there were hydraulic leaks, battery backup had problems, functionality had been altered and a test ram installed, it wasn't being tested at normal test pressures, etc.

An analogy: A vehicle with a standard transmission and reasonable gearing can be operated with no brakes by a skilled operator who understands how to compensate for this fault - but in an emergency the chance of an accident is rather high...

If the people on the rig had understood that there was a problem with the cement they could have fixed it with normal procedures and would likely have completed the well with no problem. Or even if it started to come in but they reacted quickly enough that might have been able to pull the DP and shut in the well (when it was giving trouble about an hour before the explosion). By the time the seawater began blowing out it was too late and the emergency functions were not effective at that point.

A design that allowed for effective underwater repair by ROVs would seem to be a very good improvement.

In these water depths, I'd bet BOP repair would cost at least a week of rig time.

You have to:

1. Temporarily plug the well with a bridge plug and cement

2. Test that the cement has set

3. Displace the riser

4. Pull the riser and stack to surface

5. Do the repairs & run surface tests

6. Run back in with the stack and riser & latch

7. Hook up the riser tensioners & slip joint

8. Do a set of BOP tests

9. Circulate the riser back to mud

10.Drill out the temporary plug

That's a 7-10 million dollar operation. No wonder they are loath to do it unless there's no other alternative.

ExArc: "That's a 7-10 million dollar operation." Are we talking about BP making choices between fast, cheap and right in managing the operation?

I heard you have a choice on anything in life - fast, cheap, or safe.

But you only get to select two. :)

Long-time follower of this site, but this is the first time I have been moved to comment here. The flow estimates that are going around just seem really incongruous with the images to me, and I mean by orders of magnitude. Just go through the very basic arithmetic here, starting with a benchmark number of 10,000 barrels per day:

10,000 barrels/d = 1,600,000 l/d = 18 liters/second = 0.018 m3/s

Cross-sectional area of inside of riser pipe = 0.16 m2

Do the division, and you find that the given flow rate emerging uniformly from an opening of that size would have a "muzzle velocity" of a whopping 0.11m/s - a tad more than 4 inches per second! This is about 1/4 of a mile per hour, or about one tenth of human walking speed.

Sure I know that not the entire cross-sectional area might be leaking oil at the same rate, etc. etc. But it rapidly merges into an expanding turbulent plume that has a basal diameter about equal to the inside of the riser tube, and expands from there up. There is just no way, even with all the illusions on earth, that the visible plume is moving this slowly. Even at 100,000 barrels per day, your "muzzle velocity" is just over 1 m/s, which is a typical walking speed. Do you really think you could outwalk that massive jet of oil if it were aimed at you horizontally?

Can anyone reconcile these basic numbers with the appearance of a ferociously boiling and rapidly emerging plume? Is there any reason NOT to think that we are looking at something well in excess of 100,000 barrels per day?

Dude, you've completely overlooked gas.

There are very few wells anywhere in the world that can produce 100K bbl/day (most are onshore wells in the Middle East), and that's only possible when they are drawn down hard because at the surface the backpressure is nearly zero.

On this well the flow has to overcome 5200'of seawater, or about 2,500 psi. I would be very surprised to find that this well is flowing more that 20-40K bbl/day.

Note: this well WILL flow more once they run the sring all the way to surface, if they can get a seal on that LMRP top. If not, it's gonna suck in a ton of seawater with it.

This has been covered before, that it's the total volume of the flow. I hadn't seen anyone using a gas:oil volume ratio at depth of 9:1, however. As for overcoming the pressure of 5000 feet of sea water, that is only modestly higher (by 15%) than the pressure of 5000 feet of overlying oil that would have to be overcome if the top of the well were at sea level. BP's a priori worst-case scenario was something like 160,000 bpd for completely unrestricted flow, so they evidently thought rates that high were possible.

Even 20-40K is considerably more than the "20% increase" forecast over the "12-18K" official estimate, unless you just take the lower bound from one and the upper bound from the other.

Frankly, that muzzle velocity looks many times higher than 1 m/s; if it's 3m/s (brisk running speed) and you've got 80% gas by volume you are still looking at 60,000 bpd of oil.

WeLL... A couple of general reasons.

1st - all flow is not oil. It is a highly heterogeneous mixture of oil, natural gases, and formation waters. So not all that is observed is oil or even a fluid which severely limits this sort of "1st order" evaluation of flow volume.

2nd - your flow rates are way off-the-scale for actual production wells in the US GOM which top out (if they are very, very good) at around 12,000 to 14,000 BBls/day of oil (I don't have a range for NG production but it's generally quite large) for initial production rates.

Deepwater production rates run a lot more than 12,000 - 14,000 BOPD. 50,000 is not rare. If 12,000 was the norm we couldn't afford to drill $100,000,000 wells.

You need to check your sources. 50,000 BBls/day is not common and most GOM wells (including Deep H2O) do not cost anywhere close to $100 Million. Just for discussion let say that this BP well was costing $500,000 a day - to be a $100 M well it would have taken 200 days from spud to TD. I believe that the time frame was around 80 days or more like $40 M.

Isn't the 500k figure just the rig time? What about design/engineering, materials, support operations, and sub fees?

yep...avg. total cost in the neighborhood of 1million per day. the rig w/ no people, support, subcontractors, etc etc etc is 500,000 per day.

Actually, DW burn rates are non uncommonly close to $1MM/day and big exploration wells 120 days+. Many $100-150MM wells recently. I remember when a $20mm well was a disaster, but now a sidetrack can cost double that. On rates: 50KBOPD is close to the upper limit, but there are many wells doin better than 30KBOPD.

Ah, I hadn't thought about formation waters. Yeah I can see they would make a big difference as well. What are typical volume or weight fractions of raw flow for them? I'd imagine it is highly variable.

As for the cross-sectional area, since the flow rapidly expands to cover an area about the same as the full diameter of the pipe, its average velocity a short ways beyond the pipe should be about the same as if it were uniform.

The cross-sectional area of the leak is much smaller than the full diameter of the riser pipe.

I've done similar calculations both today and a few weeks ago which come to roughly the same conclusion. However, keep in mind that not all of the plume you're seeing is oil: some is gas, and the fastest-moving stuff is the gassiest. And, as I found out the first time I posted here, some of the gas is *dissolved* in the oil, which makes the whole thing tricky.

But yes. I think 10,000 barrels a day would have been an absolute minimum three weeks ago when we were just looking at the riser in its seafloor crater. Now, we're at *least* several times that.

~ 15:49 CDT There is green stuff coming out of one of the connectors on top of top hat 4. Enterprise ROV 2 does not seem to be interested in the leak.

Johntrask, removing the flange bolts has been asked and answered (impossible to unbolt, impossible to cut through) dozens of times. If TOD weren't so busy keeping the site running with the enormous traffic load they could put it on a FAQ.

All the hydraulic hoses are meant for the manifold sleds on each side of the well. The LMRP is much more complex than the first "top hat" that was lowered, this one has lots of plumbing inside, likely so they can try different things, like shutting down the flow and possibly injecting mud the right way eventually.

Back at the turn of the century they used hydraulic mining. They would dam a stream a mile or so up the mountain and then run 9" pipe all the way down to something like a firehose. This is similar to what is going on here, except there's no hose in place - yet. Just like hydraulic mining, you don't shut off that firehose cannon with a little valve at the business end, they used signals (usually gunshots) to tell the minders at the dam to put a get in place, even then it could take a few minutes for the water to peter out of the pipe.

A picture of hydraulic mining:

http://en.wikipedia.org/wiki/File:X-60072.jpg

Well thanks for the information. I would have thought that it wouldn't have made sense to unbolt the flange before the pipe was cut because the DP might have still been inside, rendering removal of the outlet pipe impossible. However after it was cut the torque values for 17D and 6BX flange bolts for sub sea applications ranges between 376 ft/lbs for a 1-8UN bolt to about 3000 for a 2-8UN bolt which is well within the range of any number of ROV rated power torque tools.

I would think that the increased traffic on this site would be a good thing, unless its just someones hobby, and even then its a good thing.

Is someone around here able to explain to me how it's possible that the BP stock raised ~ + 7% in the last 2 days in NYSE?

People betting on a rally if they contain the leak?

rumor that hayward may get fired/resigned?

Everytime he opens his piehole, BP drops another 100 points.

"Is someone around here able to explain to me how it's possible that the BP stock raised ~ + 7% in the last 2 days in NYSE?"

Two reasons:

The vultures are circling BP, and once it gets cheap enough it is an attractive target for Shell or someone to pick up, liabilities and all

Also at the current share price the dividend pays better than anything else you could invest in:

http://www.marketwatch.com/story/bps-eye-popping-dividend-yield-masks-un...

Well... until they cut the dividend as some are calling for - in order to pay for the costs incurred in this spill.

Possibly it sank so low that some speculators are buying in hopes of a take-over? (I'm no expert, but that may explain some of it.)

By the way, andrea, see here:

http://tpmcafe.talkingpointsmemo.com/talk/blogs/t/h/therap/2010/05/andre...

I publicized your wonderful comment! You're a hit!

wow! thanks..I was very angry ( and I suspect I'll have reasons to be even more angry..)...and tried to leave my thoughts flow out.. sorry for my english...

Your English was WONDERFUL! Your voice, your passion, they came across beautifully! Thank you for that lovely comment. And many, many people were moved by it. Here and at TPM.

Because it went down 14% earlier in the week. The terminology is "dead cat bounce".

BP stock is still down 34% since April 20.

If criminal charges are brought, presumably they will begin with the events that led up to the original explosion. I was wondering when the period of potential criminality will end? If this latest attempt fails (viz. cutting the pipe with shears) and makes the situation even worse, will BP have some sort of indemnity against a charge of criminal negligence both at this stage of the operation and into the coming weeks / months?

Seems logical that everything done since the blowout is in agreement with "the crisis team" that I suppose includes the MMS. So not criminal acts then, but the overall pollution figures are for BP's account, so increased well flow is their risk.

Yes, thanks, Porker. I guess I was wondering whether a government agency can be accused of criminal negligence if it turns out they made the situation much worse, or whether they'll deemed to have *merely* been incompetent. I fully understand this is a unique situation, but someone must be taking responsibility for what's happening now. I was wondering if that's why the U.S. armed forces are staying well out of it, and the British government, too.

Read it before and now just heard on CNN. Theory goes that fireboats using water to extinguish fire sank the Deepwater Horizon. In panic or explosions, watertight doors were open, allowing water from fireboats to fill booms causing an imbalance and the rig sank.

Watch BP to use this and many others in their defense of negligence.

Rockman

I would say you owe me a beer but this came from CNN and therefore mostly likely incorrect and I probably owe you one.

shelburn -- was there suppose to be a link attached?

Rock-

A couple posts up from jay4jet

I'm sorry, but no. You can't blame emergency responders for damage they cause protecting the public from your own negligence.

Besides, what's the alternative? Capping the well while the entire platform is a flaming inferno? You've probably heard about companies like Wild Well Control who do amazing stuff with explosives and fireproof bulldozers, but that sort of operation gets a lot trickier on a floating, burning steel platform.

Honestly, speaking strictly from a safety perspective, not an environmental one, having the rig sink may have made the capping job easier. Watch those ROVs with the diamond saws, cutting metal 2 inches from the oil plume. Not something you want to try in air.

The government (MMS) gave BP approval in many shortcuts performed. Litigation will take years while people and our planet suffer. I was decades before Exxon settled. In the mean time, more outlay from our financially strapped government.

PT: A generation of judges and lawyer may die off before all the civil issues that have arisen between these multiple parties from different jurisdictions are settled and the potential criminal charges brought by the US and maybe state prosecutors and, also, civil cases brought by the US and states reach a conclusion. I think the criminal charges against Jeff Shilling (remember him?) in the Enron case are still on appeal in the US Supreme Court. Think Dickens' Bleak House.

EL: I do remember someone saying that Change had come to America.

COME ON ALREADY WITH THE TOP HAT!!!

Have details been given on how they will manage the flow from the new "LMRP" on topsides? Presumably a big flare, separator train and shuttle tankers?

The Enterprise drillship is equipped with a permanent well testing package. It is Schlumberger equipment, and their personnel are probably out there to handle the flowback.

E ROV I - they were lowering pipe through the bottom of the LMRP ?, ROV 1 keeping the gasket from slipping?

opps, goodby gasket

Not sure about legalities or Criminalities,

But I am sure of one thing!!!

Tony,

you must be making al-Qaida proud!

Humiliating them, more like.

Any theories about why we are seeing two distinctly different colour (and hence composition) plumes from the top of the old LMRP? I'm assuming two separate flow streams, one via the drill pipe, the other via the annulus.

Very limited discussion here about the apparent presence of two sections of pipe within the sheared off marine riser. So far we talked about double cut artifacts, section sheared off in the BOP pushed up by flow, section of DP that brittle failed when the marine riser collapsed and fell, section of liner, etc. Any more reasoned debate?

I just logged in to ask exactly the same question.

I can't believe it's a lighting artefact.

Ben

That's the discoloration I mentioned in this morning's open thread.

It appears to be more of a coherent stream for a few inches beyond the cut end, so I wonder if it might be the end of the DP, which is probably crimped as well, created a sort-of nozzle.

It certainly looked like the drill pipe bent over sideways that the circular saw was cutting off. If so then it could be letting out oil from deep within the well and have a more disolved gas bubbling out as the pressure drops when it squirts out.

Thank you for asking my question. I felt too stupid to do it myself!

To me there appear to be two places the plumes are coming from. So I wondered if there is a flow of dispersant just behind the oil flow.

EDIT: On second thought, I take that back. Now what I'm seeing appears to be from a different perspective. But 2 colors.

I think earlier someone suggested it could be the lights shining and making the colors appear different - due to the perspective of the lights?

I don't know why they AREN'T injecting their dispersant stream into the choke or kill lines, instead of spraying it into the plume. Perhaps the high heat in the pipe damages it chemically.

Does anyone know the answer to this? Can anyone direct me to a thread where direct dispersant injection into the BOP was reviewed and dismissed?

I don't think there would be much difference in total mixing effect fifty feet from the "nozzle" with that kind of turbulence...

More speculation (from a rank amateur): Could the darker plume be oil and the lighter one gas?

Yes :), the well gets it's head pressure from the gas trapped at the top of the reservoir.

Adding this comment to voice my curiosity.

It's clear as day there are two distinct flows: each a different color, each from different parts of the opening.

I'm interested to read what the pros suggest as the origin.

Oil seems to becoming from the drill pipe that is jammed against the casing, light brown, and from the casing, black.

Any thoughts on what Enterprise ROV1 is doing? Just sliped some gasket onto what looks like the Riser insertion tube?? Seems to be over the well flow, might the be using that to seal up the bottom of the LMRP Cap while it fills with methane prior to placement?

This has ALL the feeds ***386 and Dial up WARNING***:

http://bp.isevil.org/

Of-topic: As a Brit, I find it interesting to see how much genuine-looking insider info on what happened when, who said/did what, etc, is in the public domain at this early stage. IANAL and suspect there are several reasons for this, but one is I think the UK law's insistence on not prejudicing trials -- rather than try to screen out potentially biased jurors, the principle seems to be that witnesses mostly stay schtumm until their day in court, and the media are (in theory) careful about what they print and broadcast. That's how I remember it from Piper Alpha, any any number of other disasters, accidents and terrorist attacks of various sorts over here. A lot of the sort of stuff I'm seeing here would only come out at the public enquiry and/or in court in the UK, months or years after the event. (Not saying one way's better than the other necessarily, there are pros and cons to both systems.)

Off-topic: As a Brit, I find it interesting to see how much genuine-looking insider info on what happened when, who said/did what, etc, is in the public domain at this early stage. IANAL and suspect there are several reasons for this, but one is I think the UK law's insistence on not prejudicing trials -- rather than try to screen out potentially biased jurors, the principle seems to be that witnesses mostly stay schtumm until their day in court, and the media are (in theory) careful about what they print and broadcast. That's how I remember it from Piper Alpha, any any number of other disasters, accidents and terrorist attacks of various sorts over here. A lot of the sort of stuff I'm seeing here would only come out at the public enquiry and/or in court in the UK, months or years after the event. (Not saying one way's better than the other necessarily, there are pros and cons to both systems.)

Anyone seen the new plan from BP: http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/06/oil_spill_vide...

Thoughts?

Shelburn....HEEELLLPPPP!!!

James Cameron (because he has the deepest manned subs) sez that 'morons in the gulf don't know what they're doing'.

The comment re: gov't needing independent filming, OK (and let's see - could we use that on a future movie?), but in general to see him saying that everybody working the problem is a 'moron' just sounds like more armchair quarterbacking.

Shelburn - do you know the capabilities of any of his machines?

http://voices.washingtonpost.com./livecoverage/2010/06/james_cameron_cal...

From what I've seen of James Cameron, calling you a moron is basically how he says hello.

To the best of my knowledge Cameron has always used ROVs and submersibles that belong to someone else.

I can only speak knowledgeably about The Abyss where the ROVs and submersibles were on loan from Phil Nuytten the owner of Can-Dive. Phil was and is an icon in the underwater industry. Both on the commercial oilfield and scientific side. He was one of the founders of Oceaneering but has an independent streak and as Oceaneering grew he went back to owning his own company. He is an out of the box thinker who has the chops to know what goes on in the oilfield and he is probably the number one individual BP should have in their war room - and maybe he is as his company was conspicuous by their absence in Cameron's list.

The list of companies he brought in - Woods Hole Oceanographic Institute; the Oceanographic Institute at Harbor Branch, Florida Atlantic University; Deep Oceans Expeditions; the PP Shirshov Institute of Oceanology and Phoenix International - is impressive but only Phoenix has experience on oilfield operations and as far as I know they don't have any capability at 5,000 feet unless it is very recent. Phoenix was a group of Oceaneering employees who "went rouge" and started their own company mostly specializing in deep water sonar search and then backing into oilfield diving.

The Shirshov Institute operates the Mir submersibles and has been doing tourist trips to the Titanic as well as lots of scientific work. They worked with Cameron on his Titanic films and may have connections to the Russian oil industry but I don't believe Russia is doing any deep water drilling.

The rest of the list are strictly scientific and I doubt that between all of them they could come up with any ROV pilots with the experience of any of the people operating the ROVs on site and I can guarantee they don't have ROVs capable of doing the work.

If the goal was to get in the way and make a movie then Cameron is obviously your man, although shooting here is probably a bit more challenging than in a tank in South Carolina.

I have never met Cameron personally but I have a number of friends that worked on The Abyss and I guess to put it kindly they don't really regard him as a people person - although he treated them much better than his own crews.

~17:20 CDT Ocean Intervention ROV 2 is showing a view of the gusher of crude oil and natural gas erupting from the top of the BOP stack. The lights of two other ROV's are in the background and when the lights align, a silhouette of a suspended top hat appears.

~17:26 CDT From the persepective of Ocean Intervention ROV 2 it looks like BP is slowly moving the top hat toward the BOP stack.

~17:29 CDT Top hat 4 is being moved to the BOP stack.

Forgive me if this has been discussed somewhere in the comments, but after reviewing the pic in the other threads I didn't seen anything like what I am inquirying about below.

Does any know what this is? I first noticed it on the "Oceaneering International" feed around 4:15 PM CST. It was visible on that cam for an hour, and now the came ROV is at the LRMP Cap, so it would seem that is the destination. I'll include a screen capture that I took.

I'm wonder if you experts can shed light on what the boxy set of equipment is. The circular white thing seems to be dampening how quickly the boxy platform above descends, but what is the boxy payload? Is this part of the riser 'package'? Sorry I don't have a better capture of it.

It may be the bottom of the LMRP that will be suspended over Top Hat #4, which will hold the "anti-freeze"......see my link above.

see the diagram and comments in threads above - prob pumps, etc it's above the LMRP

Looks like they're getting #4 ready for action, via Enterprise ROV1 and ROV2 cams.

all those hoses and cables are goin to get shoved under and into the top hat when they get it over the flow if they don't move em ??

We're all hoping not. Just one of many sources of anxiety.

Looks like they noticed that too! Best laid plans of mice and men....

dang folks, this feels like final testing of the heating pumps etc, as the LMRP draws closer to the BOP

Cool view from Ocean Intervention ROV 2

Look out blowout - here comes Top Hat 4 [TP4], and he ain't happy....

I love the green fountains from TP4's shoulders - was that James Cameron's suggestions to make it look mean? :-)

More seriously, I'm assuming that it's a flow of warm water with glycol discharged at 100% loss to heat the top of TP4 for reduced hydrate fomation - any other theories?

didn't they say it was hot water and methynol

how much current is down there? any? the illusion is that they're coming in downwind right into the lowered plume (due to dispersants?)

I have lurked around this site for about 4 years and finally signed up after I went to the APSO meeting last fall. Never really posted until this past month.

I have now advanced to the point of actually donating, something I never do in real life.

But this site is a beacon of reason and responsible discourse on energy matters that are either ignored, manipulated or totally misconstrued by the media and politicians and poorly understood by the general public.

Hopefully in some small way we can help spread the word about the end of cheap oil and prepare people for the coming transition.

My heartfelt thanks to Gail, Heading Out, Nate, Leanne, Prof Goose and all those listed on the right hand column, not to mention the posters who have provided me with a free education for the past few years.

I would encourage those who are just discovering TOD to help support this effort which is dependent on volunteers and your donations

100% in agreement. See that Donate button in the upper left corner. USE IT FREQUENTLY.

~17:39 CDT Enterprise ROV's 1 & 2 are escorting top hat 4 to the BOP stack. E ROV 2 is closest. Ocean Intervention III ROV 2 is providing a wide angle view of the action.

Am disturbed to note that TP4 doesn't seem to have any kind of latching attachments, just stabbing guides. Suppose that they are depending on the weight of the assembly, but later stages show this with a top-tensioned, buoyant riser?

:-?

Also, no insulation on the drill pipe coming out of TP4. I know that it would have to be syntactic foam for these depths, but for flow assurance purposes it's a must no?

the "long term solution" will use a different LMRP cap, with 10" thick walls. The top-tensioned buoyant riser is anchored some distance from the BOP.

Kent Wells made a point that THIS current LMRP cap will use some heavy drill collars to weight it down.

video explanation:http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

slides from video in pdf:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

I have a question that pertains to *AFTER* the LMRP/top hat is (we hope) successfully attached to the top of the BOP and sealed the remnant of riser pipe, and *AFTER* oil is (we hope) successfully flowing to the surface....

Would it not make sense to actively pump the oil as fast as possible, in an attempt to, in effect, overproduce the formation and collapse the permeability/porosity? Basically it would be employing bad production techniques on purpose in order to try and kill the well from above...

Is this possible?

If it cant capture any oil, that top hat device looks like it would make a nifty corn liqueur still.

:) Excellent Stvrob. Probably cost a bit more than your average moonshine merchant would be prepared to pay I imagine.

Bill

63: Great idea. Maybe a new career for Tony in the hills? He may need one soon.

Worthless...I doubt it's made out of copper.

I can think of several problems: the flow rate is so high already it may be difficult to pump hard enough to increase it and if they could pump that hard they may actually end up compromising the seal and suck in water, forming hydrates...which would be bad news.

Once the fluids start moving up the pipe to the Enterprise, you will have a negative pressure on the 'seal' at the 'top hat'. No pumping required..... The issue then will be how much seawater can get into the ascending h/c column via the seal and potentially form hydrates which could bung the whole thing up.

Whether it helps kill the well or not, I am sure BP will be pumping this well as fast as they possibly can to offset their billions in losses. I suppose, depending on the deposit, one could reduce the pressure by pulling harder but I doubt it would make any appreciable difference.

My question stands: what then? This arrangement cannot be considered permanent, they have failed at top killing the well and I don't hear anyone proposing another method to plug it. The relief wells may or may not take enough of the pressure off, if they don't there will be little time before hurricane season to address the issue.