BP's Deepwater Oil Spill - The Riser is Cut, Seating the "Containment Cap," and Thurs. Open Thread 1

Posted by Heading Out on June 3, 2010 - 9:15am

It may be necessary to copy over some old comments, if an important discussion was started that could not be continued.

Previous thread introduction has been moved below the fold.

(To learn more about the technical basics of LMRP, please go to this post: http://www.theoildrum.com/node/6531)

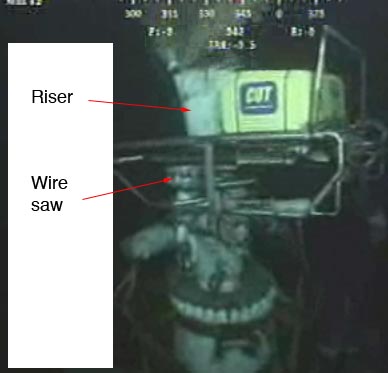

There has been a lot of activity at the bottom of the Gulf, not all of it immediately successful, but all working toward the current aim of being able to field the Lower Marine Riser package. That installation requires that the broken existing riser that connects to the Blowout Preventer (BOP) has to be removed. The bent riser has been exerting some lateral pressure on the BOP, and this might be relieved when it is cut off. To minimize the damage, the first cut is therefore going to be further down the riser, provided that they get the saw "unstuck," which it seems like they might have done, but no word yet on when cutting is to resume.

UPDATE: 5 pm Wednesday: I have added new material explaining how the diamond wire blunted, and how they might have fixed it, but now won't. They are going back to the Shear.)

UPDATE: 1 am Thursday: New plan. They are going to go with the big shears instead of the diamond saw for the cut. I have been intermittently watching for the past couple of hours, while doing something else - they were prepping the Shear, and I think reconnecting the power lines from the Shear to the power pack. Now, I believe that they are lowering the ensemble to the riser on CNN.

UPDATE: 10:30am: The riser is cut, now on to the Top Hat/LMRP/"containment cap," or whatever they're calling it now, seating.

(My post continues after the video. Please click, "There's more".)

VIDEO BELOW FOLD

http://www.cnn.com/video/flashLive/live.html?stream=stream/3&hpt=T1

I described the plan of attack in an earlier post, and what has happened, over the course of today has tried to follow that script. I say tried, because there have been a couple of glitches that developed over the course of the day. The large shearing machine (apparently owned by BTI) appeared on the scene, and in preparation for its use some of the pipes surrounding the main riser (the choke and kill lines) were first cut away using a diamond saw.

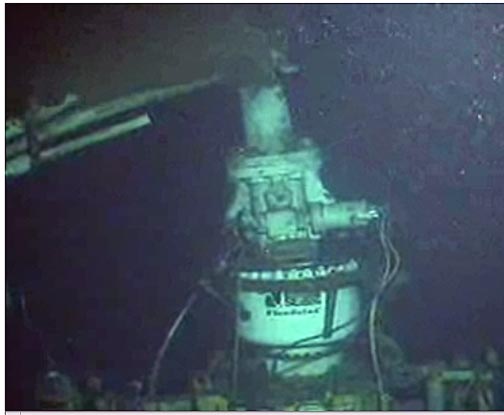

At the same time that this was going on, the wire saw that would make the final cut on the riser had been brought down to the site. The riser assembly has been cleaned of extraneous pipes already, and the wire saw would fit about the flange and below the bend.

It was now time for the shearing machine (which I’m going to call a Shear from now on) to fit around the riser and to make the first cut through the pipe.

Unfortunately the first cut did not appear successful, although there was a cloud of oil and gas released, indicating that the riser was at least breached. There was a pause, and the Shear moved to a new location closer to the riser. Again it tried to shear through the nest of pipes, that now included choke and kill lines. It was not successful, and returned to the surface where it was fixed, and returned to the site. UPDATE 1: Having written this post and not seeing much happening I went off for a couple of hours. On my return (and before Gail posted it), I did not check again and as the notes below show, the Shear worked at 7 pm. At 10:15 pm the wire saw was cutting through the riser. I apologize for the errors.

END of UPDATE 1 UPDATE 2 below> In the meanwhile, a little calculation, based on reports that the White House has announced that the removal of the riser and drill pipe that are protruding from the Blowout Preventer (BOP) of the Deepwater Horizon well in the Gulf may increase the amount of the petroleum leak by 20% when the riser section is removed. There are two immediately obvious reasons why this might be the case.

The first of these is that there is a small amount of oil that was leaking up through the drill pipe that extended beyond the broken riser. That flow was one of the first things capped in the remedial effort. It did not have much impact on the overall flow volume, since the flow merely backed up and increased the flow through the main crack in the riser, but there may be a small increment of flow when this channel is re-opened with the cut below the fold in the riser.

The greater change in the flow, however, will likely come because the riser and DP, while not providing much increased resistance, did raise the pressure on the downstream side of the BOP by about 500 psi. We know that though the pressure down at the formation was at around 12,000 psi, up on the upstream side of the BOP it fluctuates in the 8,000 to 9,000 psi range. The higher resistance on the downstream side, reduces the pressure drop across the BOP by that 500 psi, and the flow rate will be reduced accordingly (the gap size through the BOP is assumed not to change).

However, if the pressure drop across the nozzle was at 6,000 psi in the current condition, (which with an orifice size of 0.6 inches, would give a flow rate of 512 gpm), then raising the pressure drop by 500 psi would only increase the flow rate to 532 gpm, or a difference of 4%--which might suggest that there is something about the drill-pipe flow that was initially capped which we don’t know yet. Alternately it may be that they think that removing the bend in the riser might ease the forces on the BOP, relaxing the metal a little and increasing the orifice size. After all it has only to open up by another 0.05 inches to give the increase in flow that the White House are predicting.

UPDATE 2: Sometime about midnight it appears that the cutting wire stopped moving and may be jammed in the cut, roughly half-way through.

UPDATE 4: On other feeds they are showing that a second cut is now being made by the wire saw, but the camera is further away. BP is predicting that the cut will be completed today and the LMRP installed. But it doesn't look good that they are still working with the Shear, because they can't use that for a final cut, and it implies that they may be having problems with the second cut also.

UPDATE 5: Part of the problem was apparently according to a BP spokesman that the cut through the first half had dulled the blade, so that when they got it restarted it would not cut. (What we do in those circumstances, which are not uncommon with diamond blades, is to run the blade through firebrick, and this erodes the material into which the diamonds have been pushed, and sharpen it. Then we drop the cutting pressure a little.) However, BP's current answer is going to be

The technician said that rather than trying again with the saw, the plan now was to use a large shear to cut the riser. The shear, which is about 20 feet long and nearly 10 feet high, was used to make an earlier cut in the riser about 50 feet from the wellhead. Because the shear will not make as clean a cut as the wire saw, modifications would have to be made to the containment cap that is to be lowered over the cut pipe. But the technician said that even with the switch to the shear and the modifications, he expected the containment cap could be in place by Thursday.

Oh, and I mentioned earlier that an ASJ system had cut through casing and pipes at the bottom of the North Sea. I had the orientation of that cut wrong (at least for the picture below) since in this case it was from the outside in, but I am aware of it being successful the other way. And so here is the picture of casing and cement cut by an ASJ. Sadly it was so long ago - around 23 years, that I can no longer remember exactly the pressure it was cut at, but I believe it was 5,000 psi. And to answer a comment because the nozzle is non-contact, the surfaces it is cutting don't have to be cylindrical.

A continued sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

I had some trouble finding the different feeds BP is providing, but this seemed to work.

http://www.google.com/search?q=site:www.bp.com/liveassets/bp_internet/gl...

http://newsusa.myfeedportal.com/i/LIVE-BP-video-Feed-Oil-Leak-Gulf-of-Me...

Following this is like watching the Three Stooges paint a house.

BP couldn't put another saw blade on the diamond wire saw and remove the uncut half of the riser pipe.

(a) BP is broke and cannot afford another wire saw blade b) there is only one saw blade on Planet Earth and the replacements are on 'back order', c) the replacement blade doesn't fit the saw, d) the blade is fine but the saw itself is broken e) nobody knows how to put the blade on the saw ...)

They go for the sledgehammer, instead. Let's see what folly is derived from using the massive, awkward shear on the riser in the confined space 'Top 'O the BOP'. Maybe they can break off the top assembly and still have the drill pipe and riser attached with millions of gallons of oil spewing ... then the shear can break!

What a pathetic fiasco ...

1 in 300,000 wells but this one makes up for the rest!

Massive amounts of oil streaming from above the BOP.....can't imagine what that will look like after the cut.

Any estimates to what is the total volume flowing out now on a daily basis?

It really is Keystone Coptacular. If it wasn't so dreadfully serious I'd be on the floor. The saw just flew out of the ROV's hand.

ASININE BP STATEMENT OF THE DAY

Caught this on the TV news scroll this morning: head of BP says blow out was a "one in a million" possibility. Everyone can judge after the following short course on completing a well.

Yep -- not going to talk about drilling a well or testing cmt jobs or displacing risers. Completions 101: The well has been drilled and csg run. The drilling rig is gone and you've brought is a smaller rig to make the well produce. You got a perfect cmt job: the oil zone is isolated in the annulus so it can flow neither up or down and discharge into another reservoir (called an underground blow out). But now you want to produce the well but there are two barriers: the steel csg and the cmt. You've removed the original drilling mud and have replace it with an equally heavy clear completion fluid. You go in hole with a perforating gun. It has small shaped charges (around 6 per foot) and you shoot holes (about 1/3" in diameter) through the csg. But you make the charges strong enough to blow thru the cmt also. IOW, you fracture the cmt to make it fail and thus allow the reservoir to flow.

Why a heavy completion fluid? Two reasons: if the back pressure is to small when you perf the surge can damage the reservoir and hurt recover. Can even make the csg collapse. But you also don't want it too heavy either. Typically you use a weight that produces a slightly lower back pressure then the reservoir pressure. Thus when you perf the reservoir it can flow up the well and push the completion fluid out (the well "unloads"). Eventually the well completely unloads the completion fluid and you now have the max PRESSURE DIFFERENTIAL possible. That is THE goal of a completion job: make the well flow.

Back to the BIG IF. If the details are fairly correct then when BP reduced the back pressure by replacing the heavy mud with the lighter seawater they essentially duplicated the effort you make to force a well to produce oil/NG. The pressure drop made the cmt fail just as perforating it would. It was not a "one in a million" possibility that the well would flow...it was a 100% certainty that it would in this circumstance. An undeniable physical law: given a conduit fluid will flow from high pressure to low pressure.

So let's cut him some slack and assume that wasn't what he meant. Maybe he was saying the cmt failing was a "one in a million" possibility. As I mentioned before, cmt failures happen all the time. I would be surprised if they had not gotten bad cmt jobs on one or more of the shallower csg seats in this well. You pressure up on the cmt and if it doesn't hold you go back into the well with a tool (RTTS) that lets you pump more cmt in (a "squeeze job"). Then you test again. And squeeze again if it doesn't hold. I've had to do a squeeze on two of my wells in the last month. So no, bad cmt jobs are not a "one in a million" occurrence.

Maybe he meant not knowing the reservoir was expelling oil/NG up the csg and pushing the drill mud out ahead of it was a "one in a million" problem. Nope: It ain't rocket science: when you shut the mud pumps off the well either stops flowing mud up or it continues. If the mud is flowing with the pumps off then you're taking a "kick": oil/NG/water is coming up the csg. I'll repeat the story of one of my deep wells I drilled earlier this year. When we would stop to add a new section of drill pipe we would "check flow": with the mud pumps off did the mud keep flowing up? How critical is it to pay attention? The driller would check flow. I had the mud engineer double check his appraisal. And then I would have my company man make that 30 yard walk to triple check those two. Had I not been on crutches recovering for double knee surgery I would have made that walk and double checked my company man. We followed this routine for 3 straight weeks 24 hours a day. That's how critical I deem checking for flow. Needless to say I really didn't want to have to jump off that barge into the swamp given my physical condition.

Why they weren't checking for mud flow as they displaced the riser is still an open question. But no, the hands not checking for flow is not a "one in a million" occurrence. It's actually rare that they don't.

OK...perhaps we should have the "Asinine Comment of the Year" award. This latest BP statement should have good shot at it. OTOH they ain't done yet making statements.

"Asinine Comment of the Year"

You would have to eliminate the media from the competition otherwise they will win every award and on one else will have a chance.

Awesome!!! and the truth

The media folks are often ignorant (not that they should be) of pertinent facts and circumstances. BP cannot claim ignorance - or if it does then its in the wrong business.

You have also left out politicians...

Beautiful post Rockman, and so true. Quick question? Is there Criminal Negligence involved? At first I thought so, but think the last couple days its going to be very hard to prove.

I was just reading an article related to that today:

http://www.csmonitor.com/USA/Justice/2010/0602/Oil-spill-jail-time-for-B...

Don't know Iron. Hopefully we wave an legal easgle flying around TOD that can offer some insight.

Here is the basic definition from my state based on the Model Penal Code: "A person who negligently engages in conduct that creates a substantial risk of death or serious bodily injury to another commits the offense of negligent endangerment." A jury, the ultimate decider of facts in a criminal case, will have to decide if the defendant created, and this is the key, a "substantial risk." A jury is composed of 12 citizens chosen at random from the jurisdiction's community. I think thet the basic facts almost automatically create "negligence" in most jurors minds ("Airplanes just don't fall out of the sky.") but it is slightly open to argument. Go to the jury room and start discussing the facts and the law members of theoildrum community. You're the jurors here. You may accept the expert testimony of Rockman and several others as true.

Can you imagine trying to seat a jury that isn't already prejudiced in this case?

Based on the comments I have seen on the TOD, it is hard to visualize.

An impartial jury even

Who in this world hasn't heard about this event unless it is some tribe in the rain forest of South America and isn't being spoonfed the MSM viewpoint of wanton death and destruction of the evironment by BP?

I live in a smallish community where we have had several publicized cases. First, you'd be surprised how little the majority of citizens pay attention to any thing going on outside their small, sitcom universe. Second, the question which the judge asks (I know, I know) is:"Can you set aside your prejudices and what you have heard about this case and reach a decision based solely upon the evidence presented in this court under oath and the law as explained to you by the judge?" I will say this: I have seen and judged several local publicity cases where the community gossip was "Guilty" and the jury has come back "Not Guilty." When I have talked to the jurors, I found they really and in detail thrashed out the evidence presented to them and only the evidence presents to them. Having some scowling dude (gender neutral) in a black robe stare at you while reading jury instructions to you in a authoritative voice wonderfully concentrates the mind. And you know what Churchill said about democracy.

You are absolutely right about the evidence issue. I was on the jury in a murder case earlier this year. The two things that I noticed was that first the case was conducted by the book. I mean down to dotting i's and crossing t's. Nothing was skipped or bypassed.

Second, the police dept was VERY high tech. The photos, x-rays, videos, etc were presented almost exactly as seen on TV. Wide screen, some stuff so graphic that they had to stop a couple of times and excuse the jury (to recover from the shock of it all) for a few minutes.

We concentrated ONLY on presented evidence. Nothing else. Final verdict was guilty. I surely wouldn't want to go thru that again but it was an experience.

Thank you for the informative post.

I followed you right up until you said this:

If the details are fairly correct then when BP reduced the back pressure by replacing the heavy mud with the lighter seawater they essentially duplicated the effort you make to force a well to produce oil/NG. The pressure drop made the cmt fail just as perforating it would.

My question is, if removing the mud is certain to make the cement fail, why on earth would they do it?

I also don't understand this:

Why they weren't checking for mud flow as they displaced the riser is still an open question. But no, the hands not checking for flow is not a "one in a million" occurrence. It's actually rare that they don't.

So failure to check for mud flow is not a "one in a million" -- but it is nonetheless "rare" for them to not check?

I appreciate any clarifying remarks you can add.

Thanks.

Yes it is, not sure what you find hard to understand about this. But that is what people in charge of these jobs are supposed to be doing. From the Company men on down, people were being somehow complacent on this one. Odd that a "Safety" award ceremony on the rig at the very time the rig is exploding would also help serve as another distraction to help setup event just like this.

... and sank on Earth Day. You couldn't write that as believable fiction.

Michael -- Removing the mud would make the cmt fail if it wasn't set at that time or of poor qaulity. I should have been more clear. They thought the hand a good cmt job and thus expected it to hold when they displaced.

Checking for flow when the mud pumps are turned off is THE standard op for looking for a well. That's the point I didn't make so clear. Just aguess but they may have checked for flow a couple of hundreds times as they drilled this well. But the combination of beleiving the cmt was holding and the normal rush to shut down and pack up at this phase probably explains why they didn't follow SOP IMHO.

Displacing the mud with seawater appears (so far) to be one of the critical decisions. I think we understand why they would have done it (to save time cleaning up the well for the completion team, something which you admit can be a PITA), but the question is could they have reasonably determined it was safe from the results of their positive and negative tests. I don't believe we know yet.

Furthermore, there is still a great deal of confusion over who was watching the mud returns, if they were masked by other operations and why they didn't catch any abnormalities. It still could turn out that they were watching the mud returns, but for some reason they weren't seeing what they should have.

Testing the cement early, on what was a questionable method to cement with would be another biggie.

Then not heeding the warning signs they were getting while testing and continuing on as if everything was A OK.

There were other issues also from a well design point of view but doing the above would have set the stage for the big event of the day.

Yes and taking the mud out of the riser was probably the final mistake, actually I think I read it was deeper than that with the displacement. another 3,000' besides the riser if what I have seen is correct.

I have yet to see any questioning along the duration of cement cure time in the investigation. From that, I can only conclude that the cure time was considered sufficient from the facts gathered before testimony. Else, the lawyers missed a pretty big red flag.

The warning signs while testing have been ambiguous at best and no results have been analyzed to my knowledge regarding the positive and negative pressure tests.

What other issues from a well design point of view do you see?

local press reports

"Mud engineer" is a courtesy title. Gordon Jones had a degree in English, not chemistry or engineering. Blair Manuel's brother is a Swaco project manager, put him on the rig to learn the job. Probably paid $50 a day.

Much comment at Drillers Club about this problem. Mudloggers are lowest on the totem pole, but they have vital information about gassy mud returns, lost circulation, return gains. Situation on Deepwater Horizon was worse than usual, displacing to seawater and pumping mud to the Bankston.

BP guilty of manslaughter IMO. Transocean OIM negligent for going along with insane company orders, not supervising drill floor.

avon -- I can't judge Manual or Jones. Don't know either one. It might sound odd but I don't consider their education background as a problem per se. Granted he was just working onshore wells in S Texas, one of the best mud engineers I've worked with had only a high school degree. Like many areas in drilling ops there's little academic training that's directly applicable. Much of the various skills can only be learned on the job. I'll pick an experienced mud engineer with no college degree who is conscientious about his job over one with a Ph.D. who doesn't pay attention to details. Actually mud sales is not an uncommon background for many mud engineers. And vice versa.

And remember what I perceive as the fatal error: not checking the mud returns as they displaced. I can sit a bright 14 yo kid in front of the return lines with instructions to call me if he sees the mud continuing to flow after the pumps are shut off. As I said before I doubt anyone will take comfort in just how easy it was to see the well start coming in.

BTW...Manual was probably making $600/day or more. And that's working 2 weeks on/2 weeks off. So a little over $100,000/year working 26 weeks (84 hour weeks) with 26 weeks off as unpaid vacation.

i think a bright 14 year old might be overqualified. And you have hit the exact point that always scare me about high risk adventures like driving my car in the winter where I live. People, sometimes, for very mundane reasons such as a fight last night with their spouse, just lose concentration and their mind wanders. And people die. Horribly. Know the problem. Don't know the answer, Rockman.

I wonder how many GOM blowouts occurred during some stage of cementing casing, prior to the Macondo blowout, versus all GOM completions that have been made? This would at least give one the approximate odds of a GOM blowout during cementing operations.

Don't know about in the GOM, but my dad told me he finished cementing a well on the choke one time on a land job. He said the well began to kick while they were still cementing, they just closed the rams on it and went on with the cement job.

From what he told me, it was one of those problem wells that they run into from time to time and that was the reason he was there, because the company/operator was afraid of it. He got the job done.

First I want to say "Hi Rock!" and second (this is sort of a public service anouncement to the general public) I want to take another opportunity to clear up that mudloggers and mud engineers are completely different jobs and the only thing they have in common in the word "mud" in the title.

Mudloggers are pretty much low on the totem pole in terms of social respect on a rig IOW it is a fairly sissy job in the opinion of most roughnecks and roustabouts, but the company geologists and such were always interested in what I had to say. To be honest, by the time a hand had risen from derrick hand to assisstant driller they seemed to change, I suspect because they had an appreciation and use for what information we had. This info was about the rock we were drilling, and we got that information by tracking Rate of Penetration, lithology, hydrocarbon shows, etc. Mudloggers are essentially the "minutes takers" of oil wells, and the first trained eyes to actually look at the cuttings coming out of the hole.

Mud engineers made and maintained the drilling fluids. We talked back and forth quite a bit, as what they used for drilling fluid affected what I saw on my gear, and what I saw on my gear REALLY affected the properties of the mud, something they would have to counter as required, by altering the recipe of the mud, and maybe making changes to the mud cleaning system.

Mud engineers get paid more than mud loggers, but back in the late 90s a good mudlogger could still make $200 a day with my company. Of course my company tried to hire only people with Bachelor's degrees in geology--or a long history in the oilfield.

Testimony of Transocean Senior Toolpusher Miles Ezell named the person tasked with monitoring the returns at the time of the incident and stated that he had not been stood down at the time of the incident. The person named was not an employee of Transocean (or BP). To the best of my knowledge that person has not spoken yet.

He further testified that the second negative pressure test and results analysis was done under the supervision and with the participation of Night Pusher Jason Anderson. who was Transocean OIM qualified and also held the positions of Senior Toolpusher and Well Control Instructor. Questioning tried to push him to say that they'd left the "B" team in charge but he most strongly disagreed and said there was no one more qualified on the rig in these situations and one of the best Transocean had. In any case both he (Miles Ezell) and Rig Manager Jimmy Harrell agreed with the go decision and had both talked it over with Jason. That's why Jimmy Harrell was in the shower and Miles Ezell in bed at the time of the incident.

It's still not certain to me that all the people involved in the decision to continue were not correct in deciding that they had a good second pressure test and the earlier anomaly understood and explained. I know it looks they were mistaken because the well blew soon after but is that known for sure? Certainly not from any testimony I've heard. Somehow all concerned were absolutely convinced the earlier anomaly was due to some U-Tube effect (can anyone explain that?). A subsequent second negative pressure test was held for 30 minutes with no anomaly and all concerned agreed the results were good, the reason for the earlier anomaly understood and they could proceed.

Also both Miles Ezell and Jimmy Harrell testified that the reported "argument" was about doing a negative pressure test. Miles Ezell described it as a sort of running in-joke between them rather than an argument because the BP plans never had the negative pressure test and Jimmy always added it. There was never any doubt that it would be done Jimmy's way according to Ezell (as it was in the end) because it was always done his way. Incidentally he further testified that Transocean procedure did not require the negative pressure test either but that Harrell added it as an intended extra safety measure over and above what either company required under the circumstances.

This is interesting. So the OIM added the negative test huh? Was this after they had already broke down the cement job by testing early?

No wonder there is going to be a lot of finger pointing going on between Halliburton, Transocean and BP.

Whichever federal judge is assigned the trial to determine who's liable for what between Halliburton, Transocean and BP had better be young.

Thank you Rockman. Your posts are highly informative and this layman appreciates them.

I have to agree Rockman, thank you for the insight. Forgive me, but I can't find the thread on ideas to stop the leak. 1. Couldn't the cracks in the riser have been welded? 2. Instead of shearing the riser pipe, couldn't we have tried to pinch the pipe more in order to reduce the flow farther? 3. Couldn't a large device like the shear have been designed so that half the jaw served as a large clamp and the other half as a cutter/sidevalve to cutoff the flow. 4. Couldn't an open valve be attached to the top of the BOP (while still open) and then actuated to a closed position? 5. How large are the smaller pipes on the side that they pumped the mud/tire-chunk/golf ball mixture into? 6. Could a strand like material (either a whole bunch of small strands in a bundle or one large interwoven strand) be introduced to the main well pipe via the side pipes? The strands would have to be capable of withstanding the flowrate without tearing and would remain anchored outside the sidepipes (fatter on exterior so couldn't be drawn in all of the way). If so, a group of longer lengths introduced through all of the side pipes might come together at a higher point to effectively clog the pipe at a higher point. 7. Similar to "6", depending on the number of sideholes available, a few strong metal bars/pipes could be inserted through a few of the higher sideholes. Then, bolo-like segments (thinner middle with somewhat fatter ends with a flexible center that would wrap around the bars and would collectively create a clog. I know they've cut the riser and are heading toward LRMP, but if there is ever another incident like this I'll always wonder if any of these ideas were plausible. I'd piss on a spark plug if I though it would help stop this mess and/or clean it up.

The did turn off the pumps, and cheked for mud flow, and there was a significant pressure build-up.

It's described in this document:

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

>> Caught this on the TV news scroll this morning: head of BP says blow out was a "one in a million" possibility. <<

We have had 656 wells drilled over the time between 2004 and 2008 in the GOM, according to the EIA. We have had 1 major blowout (Deepwater Horizon) since the last major blowout (Ixtoc in 1979), so the industry experience is 1 blowout per 31 years, or approximately 1 in 31 * 164 wells, or 1 in 5084. That is a long way from 1 in a million.

It is still not supposed to happen if they follow SOP.

They didn't

Same old shit, new flies!

Quick post on Macondo longer term well flow rates :

I’ve made some basic calculations which suggest (no surprises) that the well will most likely be able to sustain current rates for several months at least, certainly beyond the point at which relief wells are completed later in the year. I’d be very surprised if we are helped out by a reduction in rate due to reservoir depletion.

Material balance reservoir models coupled to well models suggest that for an original oil in place volume of 100 MMstb (million stock tank barrels) and assumed flow rates of 20 Mstb/d (thousand stock tank barrels per day), ie at the upper end of the currently estimated range of flow rates, then in the absence of any active aquifer and using reasonable parameters for other oil and rock properties, average reservoir pressures would decline by around 1800 psi over the 5 months from April 20th to September 20th. This is not enough to cause reduction in flow rate. This would only occur if significant compartmentalisation of the reservoir limited the oil volumes connected to the well.

It is worth noting that based on various oil property correlations, and looking at offset reservoir data, it seems likely that though under-saturated, the reservoir is relatively close to bubble point pressure. When reservoir pressures drop to this level (potentially after 7 – 8 months of production) free gas break-out in the reservoir will increase system compressibility enormously and slow down the rate of pressure depletion, further sustaining well rates. As a potential tiny silver lining however, gas production would increase substantially at the expense of oil. But lets hope they get this well killed well long before then…..

All quoted figures directional and subject to large uncertainty ranges……..

My understanding is that relief well is a misnomer. They are not drilling to reduce pressure. They are simply targeting the trouble spot, and are going to pump as much cement as it takes to plug the well. I am sure that near the target the engineering will get interesting, but at the start, the cement should go in because the reservoir pressure is being bled off by the current blowout. They will also have the advantage of the cement being pressurized to hydrostat at that depth.

Correct BigTuna, they certainly won't be producing from the relief wells, idea is circulate mud up the blowing well to kill it. Cement will surely follow.

If it goes well, it's gonna be a relief to me. [Sorry. Couldn't resist. I'll go the my room now.]

I haven't written about this solution before, because I really felt the leak would have been resolved by the time it got anywhere. Here's a potential solution that maybe someone in the know can vet to see if it has any potential for success.

1. Using the robot subs as control for guidance of equipment, hydraulically excavate the sea bottom around the well's casing, say about 20 feet deep or greater if deemed necessary; or, contrarily, use the subs as guidance, and use some other proven means to perform such excavation.

2. Fabricate a hydraulically driven device, similar to a blowout preventer, but fabricate it in two halves, so that each half can be lowered into place and bolted together at depth.

3. Bolt the two halves together, and attach very high pressure hydraulic hoses or tubing.

4. The device should have multiple cutting edges and slow-moving rams, and should be able to be independently operated, so that if one or more of the cutting edges runs into a drilling steel joint, they can try the next one.

5. Starting from the top-most ram/cutting edge combination in the device, begin hydraulic activation of the cutting edge and ram.

6. If this method is successful, then encase the casing and all the exposed elements of the well in heavy weight concrete for the 20 feet or for the full depth of the hole, whichever is greater.

There are obviously difficulties with this proposed process, the primary one being the lack of visibility due to the materials dredged up. So some means must be developed for that.

I have no way of confirming for myself that this method will be successful, but I think it's certainly worth further investigation. Comments are appreciated.

The problem of excavating around the bottom is not a problem. Part of the ROVs standard tool kit includes mud and jetting pumps, they can excavate a massive hole around the well head given enough time, and they would have plenty of time.

Other problems might include knowing exactly what casing may be in the way and if there are pieces of cement at the location and designing for the worst possibility.

The two halves would be huge as they have to take an internal pressure of up to 15,000 psi when operated.

Bolting can be done by ROVs but it is difficult and extremely time consuming. A hydraulic locking arrange with the the two halves hinged together and lowered as a unit to eliminate alignment problems would be better.

I'm not sure what good the cement would do except hide the equipment so you couldn't monitor for leaks.

This is an all or nothing proposition, if it doesn't work you've eliminated all alternatives except the relief well.

But the real problem is probably the time required. They have to design it (probably well along with that already), then they have to manufacture and test it. For something like this, even working 24/7, I think you are talking at least 6 months.

But, unlike most of the plans put forward, this idea doesn't have to violate any physical laws to work.

Welcome to TOD and keep trying.

Hi all,

I'm thankful to have found this informative and friendly place. The German media report so few details on what I think is one of the or THE biggest desaster of our times.

To be able to follow all these ROV live feeds at once, I use these lines of HTML code saved into a simple feeds.txt file, which I then renamed into feeds.html. Opened in Netscape it shows all feeds in parallel:

---------- start (do not include this line) -----------

---------- end (do not include this line) -----------

Regards,

Martin

The amount of oil flowing from the pipe might not dramatically increase when it is fully open in the same way you experience a spray of water coming from a tap with your finger on it and only get a trickle when you take your finger off. That oil has to come miles via a fairly small pipe so that only when the flow is restricted do you get a high pressure. Fingers crossed anyway.

Martin, your HTML instructions above work exceptionally "well", rendering all other multi-ROV simultaneous cam monitoring methods a complete "bore". A tip of the "Top Hat" to you, sir. d:^)

Thanks for this, Martin. Can you contact me offline at osha@thephoenixsun.com ? Thanks!

Nice and simple.

I was just preparing something similar and thought that there's no point in publishing what I've done after seeing your super simple solution. Here's my take anyway. I've maximized the views and the streams resize proportionally, I've added titles too for the ROVs.

Refreshing/reloading the page after resizing the browser window sets the players to correct dimensions.

It's convenient to save the page and open the resulting HTML file locally.

http://www.sanaracreations.fi/rov-feeds/index.html

Fantastic, thanks! I've created a video wall on my blog page:

Video Wall

Great stuff Martin. Thank you.

G

Thanks, m.ramsch

I've placed this on my site in a clickable form, I hope that's okay...

http://www.josephpalmer.com/ROV.html

I'll leave it around untill this mess is over. (I have more bandwidth than I ever use.)

As another backup capability for ROV feeds this one will only work for Internet Explorer 7/8.

Sorry, no plans on modifying it for not IE browsers. :-|

http://www.americaswatching.com

Here is all 12 of BP's ROV cams from their site

http://www.bp.com/genericarticle.do?categoryId=9033572&contentId=7062605

riser has been removed

Ya...and the cut doesn't look half bad. Not as mangled as I expected.

ya think they could take the shears and squeese the far ends of the flat open?

There was just a view on the Viking Poseidon #1 channel of the cut.

Looked like two squished pipes inside the riser.

Maybe some "junk"?

There is 2 strings of drill pipe in the whole?

Quite apart from dodgy hydraulics, that would help to explain why the BOP shear rams couldn't do their job, AND why annular seals couldn't seal!

It sure looks like two drillpipes in the riser? WTF? Anyone else have an explanation?

I just saw that again on the Viking Poseidon #1 view.

looks like two pipes below the kink,

only 1 above.

I did not see the shearing, but I think it would have squeezed things shut, so the 2nd pipe had to be there before the shearing.

Maybe the shear rams in the BOP did work to shear the Drill Pipe, then when they were cycled, the DP was ejected upwards into the kink. Hopefully the shear rams got closed again.

Unless we're seeing some kind of ring/stub from a cement plug, or part of the metal reinforcement of an annular rubber now turned all cockamamie.

The 2nd pipe looks skinnier than the drill pipe, maybe it's a section of liner or adapter for cementing. Wish I had gotten a screen capture!

interesting and unexpected...

Maybe when the well came in a portion of the drill string down the well was broken off and traveled up into the wellhead area.

http://i618.photobucket.com/albums/tt264/Hx3_1963/Oil%20Spill/6-3-201010...

Thanks.

Maybe because the shears has two arms in the anvil,

the "2nd pipe" is just a stub off the real DP, only as long as the anvil hole is wide like 6" or so, that's folded back 180 degrees and held there by the merest sliver.

that doesnt make sense either. The shear CRAW would take a bite out and leave a short chunk missing - maybe we are seeing the short chunk tho - but i dont think it could be connected

the mystery of the two DPs.... whatever the case is, it seems ONE of the DPs was shorter than the length of the cut to the kink

take a look at the pic techdude posted, and enlarge it in your browser/viewer.

Hard to see for sure, but at the bottom the two pipes might be connect - all it would take is a sliver.

As I work it out in my head, the shear jaw came in from the back (referring to the pic), so it would have hit the left-rear 1st. The 1st piece of DP to shear would be the left-hand - the one that's not so smushed.

The short stub gets sheared off, then folds back 180 degrees into the cavity as the shear progresses.

Since the stub is much weaker than the main pipe (shorter) it is smashed more than the main pipe as the shear completes.

We'll see hopefully they get the riser section to the surface soon, if this hypothesis, or my first one (that the shear rams have cycled twice), or something else happened.

On further thought - you could be right.

The shear takes out a stub, and the flow jambs it up into the riser.

Where is the vaunted erosion? Looks like 1" wall to me.

Broken drill pipe that fell from further up the marine riser as it started to collapse? Production liner pushed up from below? Neither explanation makes much sense to me, but "junk" is a difficult answer too! Junk from where?

Wow the way that well is flowing, I dont think them BOP's are doing anything at all. They better hope the can get something over that now because if its 2 months of that rate, ill be seeing oil up here in Canada.

That flow is nothing like a completely open well, it has some solid restrictions somewhere - downhole and/or the BOP.

There are few closeup pictures of a true open well blowout as you can't get close to them. But heres a couple from a distance.

http://localareawatch.typepad.com/photos/uncategorized/2008/06/26/oil_we...

http://www.civilianism.com/futurism/wp-content/uploads/2009/10/OilGusher...

Well blowouts:

http://asianenergy.blogspot.com/2010/05/what-well-blowout-looks-like-his...

Informative pics from both sites.

It appears the blowouts on Asian Energy site have some resistance as opposed to the early 20th Century pics

Now that the riser is off (and that cut looks nasty - no way they're getting a good seal on that...) why not unbolt that flange and mate something directly to it?

or at least position the top hat WHILE they remove the bolts....I hate thinking that they can just say ok we are catching N % of the oil....we are done till august..

Has anyone answered this question, I wonder the same thing. What mechanical difficulty could exist to prevent this from being the best option? Even if there is still a stub of drill-pipe there, just bolt the new pipe over the top of it. For that matter go-ahead and put a T-valve there to redirect the flow while you bolt up a new riser. When the pressures down-hole are fully understood and in conjunction with the relief wells you then have a ready valve that can be closed.

Why is this thinking wrong? What is missing?

Also why did they orient the diamond cutter aligned parallel with the bending stress....why didn't they rotate around 90 degrees CW so the remaining riser would have a tendency to open the cut and not pinch the line? Was there something in the way?

Viking Poseidon #1 - clear view of 1st riser shear.

only one pipe inside this end.

Link to composite view of all the ROV feeds:

http://mxl.fi/bpfeeds/

condensed version:

http://mxl.fi/bpfeeds2/

The severe bend at the top of the bop may have snapped the more brittle drill pipe before the riser laid over completely and allowed the string to drop into the partially closed bop.

Ocean Intervention III #2 just had a nice view of the BOP - the shear looks pretty good, fairly circular.

The flange must have been good reinforcement.

bring on LMRP cap #2 ASAP.

Surprisingly close/precise cut by the shear. Wouldn't it be worth it now to get the diamond saw back on there to clean up the end above the flange? Should be a much easier cut now that almost all of the riser is gone.

I don't understand how the seal at the cut will be competent enough to allow the pressure to build to a high enough level to push the gas/oil up the pipe to the surface. Perhaps the buoyancy of the gas will help lift the mixture?If my question is valid (I don't have a clue) can surface pumps be enlisted to pull the flow to the surface?

What happens is the external water pressure will push it up the pipe. Oil is less dense than water so the pressure at the bottom of a column of oil 5000' high is less than the pressure of the sea water at the same depth. It is a form of siphon.

Gas coming out of solution will add to that but it isn't necessary.

Rather than trying to clean up the shear cut, why would they not try to fit and seal around the collar (the 2 flanges bolted together)?

a containment dome that fits over the flange with an inflatable doughnut ring at the bottom inflated after the lower edge of the dome is passed the flange...

I assume that the LMRP is suspended by a string of pipe to the surface, hopefully connection to a pump suction. It seems to me that if they get establish that path and regulate the flow, they shouldn't be losing a lot of oil. The jet effect at the shear point ought to be more likely to siphon seawater in than force it back out the imperfect seal.

I would be interested in knowing about the facilities on the receiver ship. Will they let the seawater separate and pump it off, or will they send the whole collection to a coastal refinery? Maybe Texas City? That would seem like an overwhelming thing for a refinery to manage.

SO much talk and focus on technology misses the crucial series of mistakes that led up to this debacle. What we are witnessing is as much a failure of judgment resulting from a system of incentives that perverts the role of technology in many industries.

Just as our government has failed to resist the perversion of the regulatory process from being exploited by the oil industry, the BP managerial system has failed to resist the temptation to pervert their own technological acumen through misplaced attention to financial incentives.

If we don't address how the current balances of industry and regulatory incentives affect human judgment - we are destined to repeat these blunders.

(The above is also known as the "for the want of a nail" rant)

Interesting, nice clean cut by the shear (photoshopped? lol jking) Yes, if they polish it a bit by bringing in the diamond cut to smooth it out it should be pretty good. Wonder why they didn't start with the shears first (maybe the diamond cut loosened it up a bit?)

Jesus... anyone care to guesstimate the flow rate now that we've got one single outflow nozzle?

20 K bbpd seems like a pretty low number...

I'm guessing its less than that. Maybe 7 to 10K/day.

Too low, my call is in the teens, maybe pushing 20. Sometimes the angles where you are viewing the plume can play optical illusions to the true size. Like a Camera trick for making someone smaller in RL look bigger then a person who is actually taller in RL.

Anyhow, the BP vid feed has been down for a while, and Im only getting bits and pieces here and there. Anyone know of a good quality vid site to view the plume from a distance?

Yes, scroll up a page or two, someone gathered all the ROV feeds together into one URL. You can click on the one you want to see full screen.

With the gas entrained, plus the contrasting colors, its easy to overestimate the rate. My thoughts are that the rate didn't increase much at all from cutting the riser below the crimp. Interpretation: Most of the obstruction was upstream of the riser kink.

In any case, did anyone get a screen shot of the riser after they cut with the shears? It sure looked like two pieces of drill pipe next to each other on the part they are now hauling to the surface.

CNN has both Ocean Intervention III #2 - currently above the plume,

and what I think is OI3 #1, currently sawing the little tab the shear left on one side of the cut.

I can't get OI3 #1 on bp's site.

Also Skandi #1 is above the plume, pumping dispersant.

The 12,000 bpd and 20,000 bpd estimates included the kink and the riser, all of which were restrictive. Their estimate was the riser removal would increase flow by 20%.

So, does that look like more than 24,000 bpd? I don't know.

Some video and screencaps, may they be useful: http://pasaudela.blogspot.com

So I had this idea late last night, and I guess it's too late now that the riser is cut off, but ...

There was all this talk about pumping mud and stuff *down* the choke/kill lines, but couldn't you use the same lines, and the same connection to the surface, to take oil and gas *out* of the well? Since the choke/kill bypass the partially-restricted BOP, if those lines can handle the amount of flow coming out of the well, you could reduce the flow out the top of the BOP to a trickle, with no cutting or custom hardware at all.

I believe BP claimed they were going to try precisely that sometime today, goodmanj.

I guess my telepathic powers are working, then. I haven't read the news since yesterday afternoon.

The dual choke and kill lines will be used to pump oil/gas out of the well toward the bottom end (closest to ocean floor) of the BOP, like you said this will greatly alleviate the flow coming out of the now cut riser with hopefully the cap being able to catch the rest of the oil/gas that the choke and kill lines did not pump out. It's a solid plan, and I have my suspicions that this was the final main plan by BP and the top kill was more to get pressure readings (setup choke/kill lines) then anything else.

Overall, good luck BP. These next few hours will make or break you.

The Kent Wells video update that this was described on was posted May 31st.

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

The "Q4000 direct connect" you intuited will take "a couple more weeks" i.e. mid June.

starts at 8:05 in the video.

Then they do the "long term containment option",

a permanent floating riser as option #3, to give them faster disconnect/reconnect during a hurricane.

Yep too late now, instead of the fine smooth cut of the saw, we get the axe approach now.

It sure did take the back pressure off of that saw cut though, if they were to try to finish it to get the smooth cut they said they needed to seal it with the LMRP.

It's my understanding that BP hopes to be able to do that via the kill/choke lines from the manifold.

BP plans to use the choke and kill lines as you suggest.

Hello, I am a Swedish HVAC engineer and this is my first post (excuse my poor english).

About the flowrate right now:

If the inside diameter of the riser is 18" = 0,45 m the area of the riser is 0,45 x 0,45 x pi /4 = 0,159 sqm. If the velocity of the gas/oil gushing out is 1 m/s (about 3 feet per second) it is exactly one barrel per second gushing out. There is 86400 seconds per 24 hours and that makes 86400 bpd. If the gas/oil-ratio is 0,5 there is 86400/2=43200 bpd of oil (if it is liqufied gas).

If the flowrate increased 20% after the removal of the riser there was 43200/1.2=36000 bpd before the riser was removed. And that flow has been gushing for weeks.....

This is my rough estimation. I hope i did my math properly.

And from the bottom of my heart: I really hope they will make it this time.

Oil report from Gulf Shores Alabama near the Hangout @ 101 East Beach Beach Blvd 36542. No visible oil, workers reporting oil visible on surface 7 miles away. We are in the beginning of a thunderstorm with winds of ESE 5/10 mph that are predicted to rise to 40 mph gusts. Estimates put the oil on the beaches within 14 hours. If I see any oil, I will post pictures of it here.

TinFoil I am headed that way to report on this from NOLA. would really help to get some updates, I can be reached at andyimages10001 (at) yahoo.com. Thanks.

I live in the Lower Garden District, within walking distance/streetcar ride of CBD and French Quarter, if you want to meet up. Although I suspect you are on a deadline.

eMail in my bio (just click my name)

Best Hopes,

Alan

Once the relief wells are finished and the well is finally sealed for good, does anyone know if it will be possible to remove the remains of the BOP for a post-mortem dissection? We should try to ensure that some good comes from this debacle--knowing why the BOP failed and designing more reliable equipment to prevent future disasters would provide some benefit.

This is exactly the plan and will be done. The manufacturer of the equipment will want to prove that poor maintenance by the contractor was at fault, not design or other factors under their control. The industry as a whole will want to understand a clearly as possible why this 'fail-safe' device failed.

BP was going to pour cement into BOP and wellhead, remember? The last thing they want is a good forensic exam of their bad well design or the mods that BP ordered to make BOP testing "easier."

Sorry, but this is just not the case. Cementing the well would not have prevented removal of the BOP - and the cementing will be accomplished at some point, most likely from the relief wells.

You can read BP's current analysis of the accident and plan for BOP removal here:

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

Top kill was going to pump cement into BOP and wellhead, remember?

and? This has absolutely nothing to do with removal of the BOP for forensics. The target of the cement was the well in any case, not the BOP.

avon -- unless BP gets a very unusual exemption from the MMS they have to re-enter the well once it's killed and set the appropriate plugs to permanently abandon the hole. They will also be required to recover the BOP and well head as well as cut the csg off below the mud line. Very difficult to imagine them getting such an exemption IMHO.

Good. Let them fry in hell when the evidence is recovered. Eleven dead, 17 injured, 100 survivors emotionally scarred, rig sunk, careers wrecked, worst oil spill in modern history, tools-up moratorium on GoM drilling probably going to cripple ATP and Mariner.

I echo others' praise for your level-headed, unemotional contribution here, Rockman. Me? Just plain pissed off. G&G is gonna take a body slam.

Question for Rockman, HO, Shelburn, or anyone who may wish to comment.

The normal course of action is to shut in the well.

Given the instability of this well, is it possible that drilling a production well to reduce the pressure is a reasonable course of action from an engineering standpoint? Let's leave aside the business, political and emotional components of such a decision if we can. Does shutting in the well leave a higher risk of a future blowout or major seep than producing enough to drop the reservoir pressure to a "safer" level, whatever that is?

Thanks to all of you for your informative posts.

Yet -- Drilling and completing a second well next to the blow out would not solve the problem. Even if the reservoir was a pressure depletion drive it might take several years for the pressure to drop low enough for the blow out to stop producing. And if it's a water drive reservoir (most likely case) the pressure would fall very little if at all over the life of the reservoir.

The most likely way they'll stop the wild well is cut it with a relief well and pump enough heavy mud into it so the back pressure exceeds the reservoir pressure.

Even filled with cement they can do a complete autopsy on it, just a bit more difficult.

Not only possible but required. BP has to reenter the hole and do a proper P&A job which means they have to remove this BOP and replace it with a good one to start the plug and abandon job. Another $100 million + hickey for BP, peanuts compared to their other problems.

Certainly they should examine it, but what is the mystery? From the descriptions I've read here:

* The control line (fiber optic) must be intact to the surface

* It is not able to shear a significant percentage of the materials that are likely to be in it (tool joints)

* It was not even maintained properly, had some some shears removed, and was known to be malfunctioning

If these points are correct, then why would you expect it to work?

Thad Allen provided some discussion of pressures in his press conference today (June 03), but he was not particularly detailed. His numbers do not compare with those presented above. He said there is estimated to be 9000 psi in the reservoir at the end of the well. He said pressures in the BOP are estimated at 3500 psi (reduced as a result of the hydrostatic pressure of the water column at 5,000 feet). Any clarification on these numbers would be welcome!

He also mentioned BP is providing two "technical" press briefings/day on clean-up and operations on seafloor. Anybody know where to find these on-line (presumably they are posting the video somewhere)?

I am assuming they are using the normal procedure of relating pressures to surface (atmospheric) pressure. A few weeks ago the reported pressures were 8,000 to 9,000 psi below the BOP and 2,650 psi above the BOP with an outside bottom pressure of 2,250 psi.

That was about a 6,000 psi drop across the BOP showing a major restriction inside the BOP and about a 400 psi drop across the kink in the riser and continuing to the end of the riser. Probably most of that was due to the kink but up to 100 psi could have been in the elevated loop in the riser if there was a slug of separated gas at that point - which would also explain the constantly changing amount of gas in the flow at the riser end.

If we assume the new pressure readings were taken at the same point as the original ones then this new information of 9,000 psi below the BOP and 3,500 psi would indicate the downhole pressure has probably stayed about the same or maybe increased while the pressure drop across the BOP is now 5,500 psi and may have dropped about 500 to 1,000 psi indicating increased flow.

This would be consistent with continuing erosion inside the BOP.

Not that I would expect BP to have done so, but does anyone know if an ROV has followed the plume to the surface/point where it becomes to tenuous to see/stalls in the water column?

Not sure if I have this right. If it does not follow right please excuse me. High Tension made an excellent post. ( I was writing a reply and then was not allowed to comment!) Many of us took a passing interest technically assuming everything that could be done, was being done. Recently I had a few days off and watched the ROV footage and gathered a little data. High Tension's analysis of corporate response to major threats is correct. I might be a little unfair, but it seems there are one hell of a lot of gadgets on the sea bed and people want solutions that involve playing with them. Stopping a column of oil 3 1/2 miles long and 20" diameter moving at upwards of 20 m/s is not just a case of closing a valve, when there is nowhere else for it to go. The momentum is huge. If the concrete holding the wellhead in, was not fractured before, it should have been after the attempt at the hot stab. The Hot Kill idea of squirting mud down a column was never going to work. You needed to stop the mass of oil coming up first and that was going to take a long time with a massive force and obtaining the reaction to the force was going to be the tricky bit. You look at images of a circular saw being held in a 3d robot arm and wince. Before the first cut was made you knew the blade would jam. Rigid clamp each side, common frame to brace the pipe and hold even when cut, then drive in blade and slice. I watched Kent Wells make a good case for not using the Shear to cut the vertical riser but rather use the diamond blade only yesterday. Many commentators have said "why did they start that side". After it jammed now we see the very thing being used they said they would not use. Corporate think, not critical think. We, without specialist industry knowledge, are wincing too often. However, I don't think anyone from outside is going to be listened to. From my survey of the BP site they have now given up on stopping the flow and are just going for containment. Well head integrity ? Will the BOP and associated pipework lift off if they attempt to stop flow with any sort of device attached to it? I don't know what happens to the flow out of the vertical upriser when the ship disengages in a hurricane. Squirts into the ocean again ?

I wish them luck. Thank you high Tension for expressing what many of us feel.

In yesterdays open thread ExArcoCompanyMan and myself made some posts on the casing design, particularly how it was not designed for well control but merely to get to TD, and how the casing design for the relief well needs to be different than the original well.

EACM http://www.theoildrum.com/node/6551#comment-638210

ov http://www.theoildrum.com/node/6551#comment-638599

I think it is an important subject that gets buried and missed in the daily thread. Could we have a topic on casing design for the relief well? Something that won't fill up in a day with well cam commentary.

Excellent idea.

What about threads for:

1 - Cause of original blow out (including casing design)

2 - Oil containment and subsea recovery

3 - Surface spill control/dispersant issues

4 - ROV live feed and political commentary discussion

Good Idea !

Send it to the eMail address on right border of page.

Best Hopes,

Alan

A subject that really needs expansion to the point of bursting.

note to ov - didn't the MMS approve them using the exact same well design for both relief wells?

Perhaps son. With the drilling history of the blow out well they should have a pretty good idea how to design the RW's. The first well in an area is always the most difficult to design as a rule.

Thanks Rock. X-Arc and ov seem to be saying that well design should be modified, as its defective. It certainly looks defective, but you guys know, not me. Anyway, I guess the worst case here would be if both RWs blow out, this would become an unlikely 3 in 1 million event.

Wow. I'm assuming that the MMS is the equivalent of the ERCB (Energy Resources Conservation Board) up here in Canada. If the MMS has approved the same casing design it looks like they didn't learn anything from the first well. Plus I would think we have to proceed with the possibility that higher formations are being charged up from underground blowout. This has all the makings of burning down another rig.

This is off-topic in regards to the mechanics of the oil containment problem, but I wasn't sure if there has been a discussion about this subject yet here at the Oil drum.

I want to leave the comment here because this site is the best I have seen in terms of really analyzing the many details of the whole larger problem.

So, this comment is not about the oil spill per se, but about health effects, and in particular, health effects at a distance, possibly caused by gases and fumes.

I live in northeastern Kansas. As the crow flies, I am about 800 miles from the well site. I am sixty years old. And for much of the past week, I have been experiencing considerable nausea with no discernible cause.

It is not the same as nausea from stomach flu or bad food. I don't need to throw up, but just feel nauseous. It's somewhat like sea-sickness, but not exactly. Actually, it is the same kind of feeling I used to get on my dad's sailboat when the engine was running and I was in the cabin, when I was a kid. It also is the same kind of nausea I have felt before briefly, after getting a whiff of natural gas or propane.

There is no aroma in the air that I can discern that would indicate that petroleum gases are in this local air. But it seems a funny coincidence.

I have read that when the Empire State Building was going up in 1931, at one point workers on the high steel were pelted with wheat or barley from Nebraska or Oklahoma- a much greater distance than the distance from here to the Deepwater Horizon site.

A breeze from the south might take two or three days from the gulf to my house. So there's no doubt that it is possible, even likely, and maybe certain, that petroleum gases are or will be, before long, in the air over much of the continental U.S.

It kind of depends on the total size of the gas volume coming out of the well.

There has been very little discussion that I've seen in the press about the effects of the gases, how far they will travel, is it a risk for who and where, et cetera.

So, I am looking for estimates about the total size of the gas problem. There are X thousand miles of oil on the water, and a huge, huge amount of gas and evaporaned liquid fractions. These molecules are in the air, somewhere, rather like the "dispersed" oil destroying the underwater world stealth-fashion.

How much gas is there? What gases and vapors is it made of, and in what proportions? Is there enough volume so that it is dangerous to health, despite dilution in the atmosphere?

I know some of it was burned off. I've heard a number of reports of people in close contact with the oil and fumes getting sick from it.

Is it too far-fetched to wonder if the gas from that well could be actually making me feel sick 24/7 800 miles away? I know that at that distance, there would be tremendous dilution. However, if the gas cloud coming out of the hole in the sea is as large as I suspect it might be, maybe it is not unreasonable to wonder if fumes may be affecting me all the way up here in Kansas.

So, I decided to put this out as a topic, and hopefully start a discussion, and find out if other people either close to the well site or at a considerable distance are also experiencing unexplainable nausea.

Thanks for any input.

fisherseye

Is it too far-fetched to wonder if the gas from that well could be actually making me feel sick 24/7 800 miles away?

Yes.

I think worrying about it could make you sick. It is making me sick (I live in the Florida Keys, and I am literally worried sick about what the spill is going to do to my property values and my way of life that involves diving on the reef and fishing.

The major consequences to public health from the Three Mile Island Nuclear Power Plant accident was public anxiety. It is real.

There's a fair body of evidence that the TMI region had some real, scary health effects that seem rather underreported. The following article is a good summary. I agree with your general point on stress.

I can't say enough about how much B.S. there is in that report. The basic claim here is that anecdotal evidence collected by a reporter and a technician level 'expert' is superior in reliability to peer-reviewed literature and a Presidential Commission.

I can't believe people swallow this stuff. It is no different from claims that space aliens built the pyramids.

I'd be less easy to swallow if:

* the EPA didn't lie about the air in Manhattan after 9/11, before even doing any tests.

* the FDA didn't cave to drug companies about drug safety

* the USDA didn't allow CAFOs to feed grain to ruminants and use anti-biotics as a matter of course

* Vermont Yankee's operator didn't lie about not having any pipes under the plant to leak anything.

etc.

etc.

etc.

It's absolutely clear from the technical summary that the TMI instrument air cross-connect with shop air was the issue, but the weasel words now are original cause unknown.

Corporations would rather spend millions on lawyers and get a hit of power than a few thousand on sufficient air compressor capacity.

The evidence wasn't collected by the reporter, although it was obviously compiled by the reporter as a necessary precursor for writing an article.

Hundreds of documented cases of illness and death following the pattern of radiation poisoning in people and animals hardly seems like anecdotal evidence that should be ignored. Just this week BP was claiming that spill workers exposed to fumes were coming down with food poisoning. Is our need for denial that great?

Sounds like you got a pretty fair case for some BP cash. I'd retain a lawyer for certain.

I would look at stress first.

The winds are typically from West to East, so I'd think you wouldn't get much of the fumes.

The poor SOBs on their boats surrounded by slicks are another issue - I cannot believe the EPA/OSHA isn't making BP provide respirators - well, I don't want to accept they aren't anyway.

I think this event is stressful in several ways.

1. it threatens the Gulf fisheries, and livelihoods of hundreds of thousands of your fellow humans. We're social animals, empathic to our fellows, and to some degree nature.

2. we're still in an economic slump, we don't need more bad news.

3. there is a element of suspense and race against time - getting the well contained before a hurricane comes - and who knows what will happen then?

4. there is an element of out-of-control complexity. We'd all love to help - but how? They decided not to use hair boom, their suggestion box is overflowing, you can't drive up to the site and start bailing with your bucket. It's very easy to presume one is individually helpless. (the politicians/wall street have long indoctrinated us to think that, so they can make brownie points/big bucks "helping" us.)

5. At some level, even un-consciously, people have some idea that this is related to peak oil - and that is just too scary to talk about (c.f. Dick Cheney "The American way of life is non-negotiable").

Why are these guys in 5000 feet of water, spending a million dollars a day drilling for oil - what happened to the cheap stuff?

6. We've trusted the "authorities" for so long, and now their incompetence/corruption is getting more and more obvious: dubious wars with profiteering, wall street bailouts, auto bailouts, MMS sex/drug/"gifts"/lax rules/... scandals, sexual predators as priests, ... - are we at the fall of the empire?

Who can one trust?

Here's one link to a peak oil psychology site:

http://www.peakoilblues.org/blog/

Our economy, ecology, psychology and spirituality are all threatened by the implications of peak oil/peak everything.

I'm feeling the stress too.

sunnnv said: 5. At some level, even un-consciously, people have some idea that this is related to peak oil - and that is just too scary to talk about (c.f. Dick Cheney "The American way of life is non-negotiable").

Why are these guys in 5000 feet of water, spending a million dollars a day drilling for oil - what happened to the cheap stuff?

No, that's just a reaction by people who are programmed to think that way. Objective folks have no such reactions. Here's the TRUE message... We're a victim of our own carefulness. Combined, of course, with a human tendency to become complacent. Drill tens of thousands of wells, and one goes wrong? That's odds better than flying commercial airlines, driving your car, or building hydroelectric dams. Why the complacency... It's human nature to forget that very, very difficult things, done with extraordinary means and extremely good knowledge, are still very difficult, and that the consequences of failure are sharp. This happened with space travel, as well. It became so routine that when finally, one of the 80 billion things that could go wrong did, as much of a scientific marvel as they are - bleeding edge technology - we were stunned, shocked, and demanded punishment and were outraged.

Not to suggest in any way that the "solution" is more accidents, but just a simple recognition that with success at things that have the capacity for extreme peril, after a time, we become complacent, that's just human nature.

Political exploiters wish to use it to further their interests, whatever they are, politicians exploit it for whatever gain they can find, to tap into the emotion to try to manipulate people. All are dishonest, and know it. No facts have changed since 60 days ago. Only emotions. I refuse to be emotionally swayed into ceding power over my life to politicians just because they hunger for it. And for those who seek to have them do it for their agenda... I am unmoved. More importantly, I am offended, deeply, by the exploiters. Outraged, is more accurate.

So you are saying that those who accept the idea of peak oil and see a linkage to this event are political exploiters attempting to further their interests?

I'm saying that there is no logical connection. None. Sorry. This is just an accident. The accident is an accident, whether it's the first well, last well, only well, or even if the world has more than it ever could imagine using.

No linkage exists, it is simply people looking for emotional means to advance an agenda.