The BP Deepwater Oil Spill - Cutting Metal Under Water and Tuesday Open Thread 1

Posted by Heading Out on June 1, 2010 - 9:30am

Please transfer discussion to http://www.theoildrum.com/node/6562.

The decision to cut the riser and drill pipe (DP) from the top of the Blow-Out Preventer (BOP) as a first step in putting the Lower Marine Riser Package (LMRP) over the leaking oil well in the Gulf of Mexico is not quite as easy as it might sound to a layman. This post is going to talk a little about a couple of the problems, as well as an alternate way of doing it, and should end with a possibly slightly amusing anecdote.

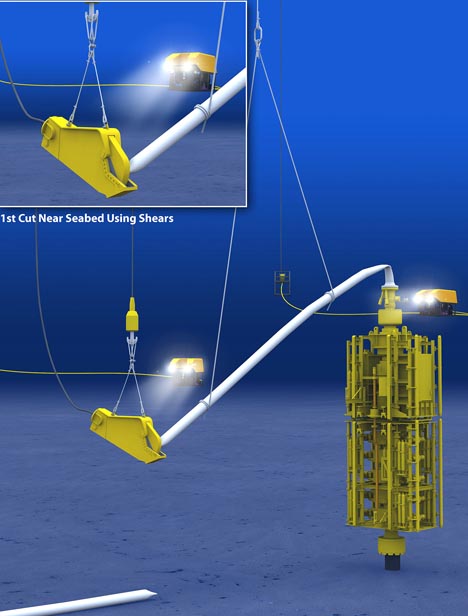

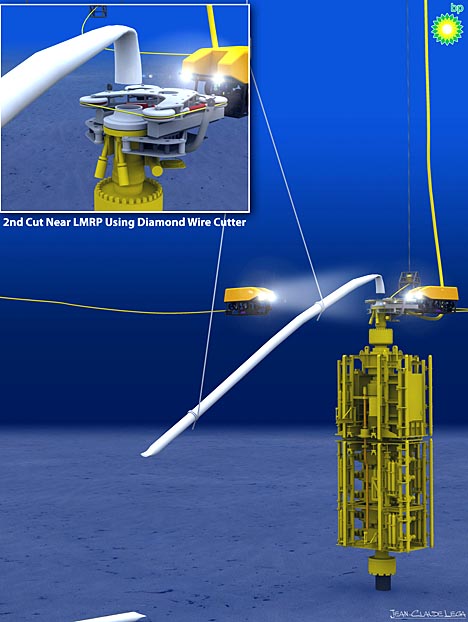

The current plan is to carry out the operation in two parts, first the main body of the riser and contained DP will be cut using a large shearing machine, and then a precision cut will be made with a diamond wire cutter to prepare the surface to act as a support and seal for the LMRP. (Illustrations are below the fold). There are a couple of reasons why this is going to be done this way, and one or two concerns that will need to be watched as the operation continues. (UPDATES At 8:45 am I see that the riser in in the shearing machine, at 9:30 am it appears that they are using a diamond circular saw to cut the choke and kill lines - h/t gel. By 11 am they had the wire saw at the riser, and had started to shear the riser beyond the bend. At 12:50 pm after what may be two attempts to shear through the riser and associated piping the shearing machine has been removed from the riser, and appears to have been taken back to the surface ).

(To learn more about the technical basics of LMRP, please go to this post: http://www.theoildrum.com/node/6531)

Part of the problem lies in the considerable stress that the metal is under, which may make it more difficult to get the precise cut that is needed for the sealing surface. The weight of the collapsed riser on the kinked section of the riser means that the metal is under a considerable stress, and as the cut is being made that stress is going to be released. This is a particular problem if the saw blade is in the cut as that stress releases. As an illustration, large diamond wheels are used in granite quarrying as a way of making the first cut in a new layer of rock. As the quarry works down into the deposit, however, the stress in the rock increases. So that when the diamond saw cuts into the layer, the walls will move in slightly. Now if the diamond saw is rotating until it is removed, it will grind away that small movement and there is no problem. But if the saw is removed, and the cut restarted the next day, then it might be necessary to recut the same depth again, because the walls have moved in that far. The much worse thing to do is to leave the diamond saw in the cut overnight – the walls will move in and pinch the blade and you can’t get it back out without destroying it. Did I mention these blades can cost up to $100,000?

So given that it would be a bad idea to break the diamond wire in the cut, or trap it for that matter, the first step in the process is to take some of the load from the riser by cutting off the majority of the fallen pipe. To make this simpler and since the quality of the cut is not important, this will be done with a large shearing machine.

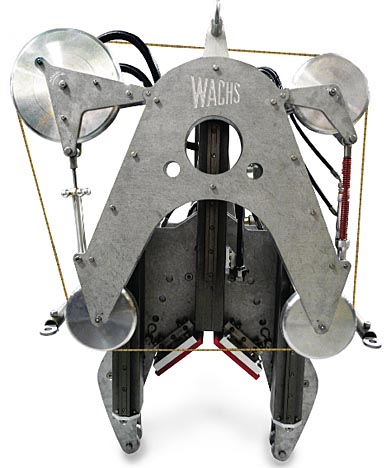

For the second stage in the process the riser and pipe will be cut, at the top of the BOP using a wire saw to cut through both pipes. The diamond wire, which is held under tension in the design, should give a relatively smooth surface that can be used for the sealing surface to the LMRP.

One of the problems in using this tool, which is rather sensitive (in other circumstances we have broken several wires in a smaller model) is dealing with the central DP as the cut is being made, and with the flow of oil and gas past the wire, which can send it into vibration, over the relatively long cut.

The two pulleys at the top of the saw are used, as well as guides, as tools to keep the wire under the correct level of tension.

It is relatively slow to cut, (perhaps 10 to 30 sq ft/ hour, depending on power and blade size) and requires patience to keep the applied loads at the right level (the joy of automatic equipment over manual operation). There are still possible risks, due to the remaining load on the metal being cut as it is being made, since the amount of metal left gets less over time. As a result it is likely that, in the same way as a forester will use wedges to stop the cut closing as he chops down a tree, so small metal wedges will be put into the cut in this case. The only difficulty that this imposes is that it will be difficult to access the central DP and difficult to deal with that, once cut through, since it is within the riser and not accessible. Hopefully it will be held in place by the bend of the pipe and riser, until the wire has passed through it.

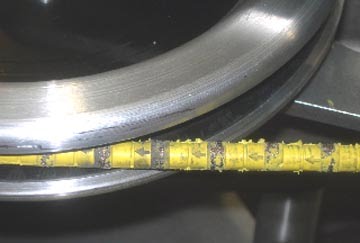

Over the past twenty years diamond wire sawing has become more common as a way of cutting through a variety of materials. It has the advantage of making a relatively narrow cut, and the ability to cut through objects made of different materials, such as reinforced concrete. The cutting wire used to have small diamond particles embedded in the steel of the wire, but in more modern varieties the diamonds are embedded in a plastic such as Teflon, and set as beads along the wire, allowing better cooling during the cutting process.

Now my students will tell you that I have a bad habit of slipping commercials for another technology into lectures, and so I am going to indulge, and mention that there is an alternate technique that could be used instead. And that is the use of a high pressure abrasive laden, waterjet cutting stream. These are becoming increasingly used in industrial manufacturing, although in that use the technique usually involves a different way of adding the abrasive to that which would be used in the current problem. In the conventional way of adding abrasive it is mixed into the jet after the water is accelerated, and, in the right circumstances, we have been able to cut through half-inch titanium with an accuracy of 0.001 inches. Those jet systems operate at pressures from 40,000 psi to about 90,000 psi. In the current case the abrasive is added to the water from a pressure vessel, and the technique is known as abrasive slurry jetting (ASJ). It allows equivalent cutting at about a tenth of the jet pressure (i.e. 5 - 10,000 psi). The tool has been developed for cutting off different oilwell parts from the wells under the North Sea. Because the jet cuts away from the nozzle, it can cut, for example, out from the center of a set of drill pipes, one nested inside the other, and separate them, as one of the last stages in decommissioning a well. It has a problem with range, the jet cutting to a shorter distance as the back pressure in the water increases, and for cutting down to 500 ft (the deepest we have tried) it can be improved to cut large risers by adding an air sheath around the outside of the jet.

One alternate way that is used for cutting tanks and other containers with possibly explosive content is to use a chain crawler around the pipe. This way the jet does not have to cut quite as far through the water.

(And for those who question whether jets would work under this depth, Gulf Oil – as was – used an abrasive waterjet to drill a well down to 15,000 ft back in the early 1970’s but a fire destroyed the equipment and the research was stopped).

To end with the anecdote – which relates to the cleaning of oil rigs for inspection. The problem that arises is that barnacles and a variety of sea creatures and plants grow on these structures, and need to be removed. The historic method of doing this was to give a diver a chipping hammer, and send him down to chip off the offending coating. Now when a diver is in the sea there is not a lot of resistance, and so one has to clamp onto something to develop enough thrust to effectively use the hammer. The only object available is the rig itself, and wrapping one’s legs around a strut works to give the platform. The only problem is that the strut is covered in barnacles – ouch!

So the waterjet industry developed a zero-thrust gun (in other words the cutting jet on one end is matched by a jet of similar power on the other, so the forces are balanced) and the diver does not need to hold onto anything. It was taken out to one of the rigs in the North Sea and given to one of the divers.

He took it, without a word, and disappeared over the side of the rig. He was down underwater using it for about fifteen minutes and came back to the surface. He didn’t say anything, but walked over to the chipping hammer. He put down the lance, picked up the chipping hammer, and walked to the side of the platform. “So long , you son of a . . . .”, he said, and threw it overboard.

It was one of the fastest adaptations of a change in technology around the world that I have seen. Anyway I will talk about using jets for efficient cleaning in another post. Enjoy the day!

A continued sincere thank you to all who have donated thus far. It will help with the increased costs we are facing (see point 3 below).

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes.

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They were really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 400 comments, as it's really unmanageable. Lots of good stuff in there though.

Gosh I love this site! Kudos!

Though I am a nobody and a newbie, I dare to make another suggestion. And therefore I am posting something I've discussed here a bit with a few folks (see comment history here) - something I just placed at the end of the previous open thread (link below):

http://www.theoildrum.com/node/6538#comment-636544

If I have overstepped my bounds, please feel free to delete this. Also, I consider myself one of the troops here - not trying to take over or be handed any authority.

I myself am not a technical person, but I do have time and am gravely concerned about the future on a number of levels - particularly with all this oil spewing and its potential to SPREAD from ocean to ocean. (I will place info for how to reach me if necessary - at the end of my profile, though of course site administrations would know that already.)

I just Registered w/ TOD. I'm very impressed by the technical knowledge on the site, and the BP threads. I hope to contribute, or at least comment soon. As far as I am concerned, the BP accident brings to the front many Human, Energy, and World View issues....that's what has captivated me....that, and the plight of those that live off the Gulf Coast.

Thxs TOD.

I second that.

I'm ready to use whatever little influence I have for putting the case for 3 relief wells, but without the expertise and credentials to make a credible case, would really appreciate those who have them, to post a coherent argument why we need more RWs, so that I/we can send links to relevant folks.

Just trying to do my little bit here...

Just say the word, and we'll cut and paste and send it our friends, congressmen or whoever.

Carol Browner (not sure if that's her name, who is with Obama) stated that she required BP to drill 2 relief wells.

I read that in yesterday's paper and heard it on this morning's news.

She didn't say anything about the halt on the second well due to the BOP being removed, so I don't know if they are ordering another BOP and will resume drilling of the second well?

Drilling on the 2nd relief well has resumed, per Thad Allen at today's briefing.

See explanation below at http://www.theoildrum.com/node/6541#comment-636810

TheraP, We all bring a wide variety of talents to this site. The great thing is the crude oil industry has been around a long time 1859. There is so much written in every detail of the industry from spudding a well to finance. You bring a very important talent to the site and that is the mental state of people in general. The coming days of declining oil reserves and possibly resource wars you may end up being with study of the industry the most valuable person on the site? I believe we are headed for some very hard times with respect to cheap energy producing less expensive foodstuffs in the very near future.

Thanks for being here

Andrew

P.S. What is your hourly fee ha!

Hourly fee? On the web.... I work for free! Just doing my part for humanity. Imperfectly... but with gusto! Very freeing actually.

I'm glad to share what I know. What I theorize. I'm a believer in people working together. So I doubt I would be "the most valuable" - but I hope to add to the mix. I take great joy in seeing the variety of people, how they interact. And yes it's fascinating to see how individual and group dynamics play out over the web or in all areas of business, politics, economics etc.

As you say, very hard times may be coming. We all need to take stock. Live simply. Also, in the end we all have to "let go" - of life itself. Sooner or later. No telling when. The more we face that, the more we may realize that we might as well practice letting go - ahead of time. Scarcity of resources will play out in health care as well. We've burned through way too much in our society! Acceptance, patience, self-restraint, hospitality as a way of life - we need to learn these things as a society.

I look forward to many interesting conversations here. I just love that people work together, without pay, for the common good. I am waxing philosophical as I ponder your comments.

Peace be with you.

Actually, it was a joke about me needing therapy. Not a good one obviously ha!

Yeah, I got the joke. But I turned it around. It was a teaching moment. ;)

TheraP: In re landrew's thoughts, I've been thinking about the 5 stages of grief (loss). Peak oil is about the loss of a way of live embedded in the American psyche. An economist said that America's image of itself is big people driving big cars at high speed across endless open highways. I'm old enough to remember "See the USA in your Chevrolet." I can still sing it. The highway as the symbol of Freedom, "On the Road", the Indianapolis 500 on Memorial weekend, all are woven into all our brains and our behavior.

We are not the only society that has had to cope with the loss of a way of life. And "wanderlust" seems to be deeply embedded in the human psyche, not just in our "on the road" mythology of ourselves. Maybe we need to find ways into the "inner landscape" and take inner journeys. I look at all the ways people waste fuel on pleasure boats and car races and snowmobiles/all-terrain vehicles - just for fun. If we have to give those up, you're right, there will be disbelief, bargaining, anger, fear, sadness - but others will "find themselves" in creativity of all types.

But I begin to see the task here. And I think I'm up to it!!! I have a very spiritual side to myself. And that's really the challenge, I think. To give up childish things - greediness, war (there's a biggie!), selfishness, need to control, etc. - and find ways to enjoy and contribute without having to spend $$$ and fuel to do that. (See my musing in a comment above.)

My pessimistic side sees two wars in this country: Water Wars in the western US where I live. Think LA and Phoenix, Las Vegas (Now with 2.5 millon people! Good God, I used to drive through it in the mid 60s when it had less than 100,000) for water and Energy Wars both played out in national politics. Fuel we can adjust to... maybe. Water also... maybe. Both at once... mixed with a heavy dose of angry populism and conspiracy theories marinated in modern communications and PTSD from loss... I hope the wars remain metaphorical.

Excellent way to put that emotional part of peak oil in focus! Grief, yes, grief is what we will feel. Only after yet another oil shock and this time or soon it doesn't get easier, gets harder to hold on to what was. 5 stages of grief interesting. Thanks EL more to ponder.

I hope our discussions will be about real humans, with their evolutionarily developed human nature, not some idealized rational, far-seeing utopia-dwellers.

I do think there's a possibility of pulling out human society from its nosedive, and I'm sure that if it happens, American ideas of living standards are going to have to move away from energy-wasting pursuits.

Whether the old people in power, and the younger ones moving up can be teased or hammered or cajoled into doing so, without massive war and population decrease, or reduction to living in forts, that's the question.

I think it's not about reduction in energy use so much, as it's about successfully teaching the necessity for it, and pointing the way, through financial means like taxes on carbon, and subsidies for renewables.

Hi ormondotvos,

We can change the world by changing what we teach our children. Most adults lack the ability to understand they don't already know everything, so they are not teachable.

Only problem, it's adults who decide what we teach the children and there is little hope we can agree on the enormous changes in curriculum that will be required.

Sigh...

PriorityX, fascinating conversation going on here.

I usually think of the Learning Curves of adults versus children this way (and I've taught young children as well as done therapy with adults):

Hope is good! Reality is a bite some times. The problem really is the last 10% is worth far, far more than the previous 90%! That is the issue. Barring the miracle fusion reactor which doesn't look likely in the time scale we need. It really is about feeding 7 billion people and what governments will do in order to feed THEIR people? Without cheap oil all of modern ag. is dead. Genetics may be the only way we stay ahead for a few years. My friend the forts are already being built, by many on here :)

landrew: Ponder this. What did the person who cut down the last tree on Easter Island think? And how different are we? Was "Peak Trees" for Easter Island "Peak Oil" for today?

Wait till you get to "peak age"! ;)

Question regarding water jet cutters:

I can see why "back pressure" would be an issue if the water pump for the cutter was located on the surface, but would it not be possible to have a cutter where the water pump was located at depth, i.e. a system where surrounding sea water was drawn, in, filtered, compressed, abrasive entrained, then used for cutting?

obviously power for the pump would need to be supplied from the surface, I would imagine electrical.

Such a design it seems to me would only see the pressure difference between the low and high sides of the pump and should function pretty much the same at any depth, or am I missing something? Is there some property of water which changes at depth which would affect the operation of such a device?

The pressure difference that counts is the one across the nozzle, because the pumps, in general push out a certain volume of water in a given time, and it is the speed that the water is moved through the nozzle that is the effective value. The inlet pressure to the pump has no effect on this, sorry.

I understood this, I think we are having a mis-communication. Let me try another way of saying it:

Assume that all the nozzel's parameters are constants. Then, as I understand it:

A cutter which has the pump at the surface will need more power input to the pump the deeper the nozzle is below the surface to maintain a given flow rate through the nozzle. As the ambient pressure at nozzle depth approaches the maximum possible output pressure of the pump the device will stop cutting.

A cutter that has the pump co-located with the nozzle would require a constant amount of power input to the pump to produce that same flow rate through the nozzle regardless of working depth.

HO thanks for another clear explanation for us non-tech types.

One comment on the jet gun for cleaning rigs. The concept might have been re-invented for that purpose but the first I heard of it was in the story of the salvage of the USS Squalus (later renamed USS Sailfish).

The account described how fire hoses were used to make tunnels in the mud under the sunken Squalus to pass cables under to lift her. The work was slow and frustrating because the back pressure pushed the hard hat divers back out of the hole. The story goes that a USN machinist on the salvage ship made a special nozzle that had back jets to counter the thrust. This worked so well that the holes were completed in relatively no time at all.

We foreigners like to bash you Yanks but stories like this always help to reafirm the respect for your ingenuity and the impressive bravery of those hard hats crawling in the mud under a submarine in 74M of water.

Looking forward to your next post.

Don

Don,

The (high pressure) "jet gun" used for cleaning and cutting is different from a (low pressure) "hand jet" used for excavation/ tunneling under sunken vessels, etc.

High pressure waterblasters operate at thousands of psi, while hand jets run in the hundreds.

Waterblasters that are safely configured for underwater (diver) use are counter-balanced and have long barrels to make it very difficult for the diver to cut themselves, although the diver typically still hangs off on a hogging line of some sort. Using even a well balanced tool is still a rather physical task and the high pressure hoses are quite heavy (imagine using a household drill that had a 3 inch thick electrical cord attached that you had to drag around and pulled on the tool, etc.)

The low-pressure hand jet is typically a fire hose with a t-shaped nozzle on the end for counter-balance and a pump on deck supplies water pressure on the order of 100's of psi, which can blow a glove off of ones hand, but not the hand itself. This kind of setup is "standard loadout" in the commercial diving industry, at least in the States.

Dave

Thanks Dave.

I was talking about the principle applied. The tecnical details are all fascinating.

Very similar to the water jets they use to clean sewers - one jet facing forward to cut through debris, 2-4 jets facing to the rear to push the jet forward/flush debris down the pipe.

Ah, "On The Bottom", the salvage of the S51 in 1925/6. A very good read. I also really liked his account of clearing the scuttled ships from a port in Ethiopia in WWII, "Under The Red Sea Sun". He wrote a few other books too, still in print after all these years!

http://en.wikipedia.org/wiki/Edward_Ellsberg

http://www.edwardellsberg.com/

Great idea, water jet cutting, there must be some reason why the diamond wire is being thought of first but it is generally way to slow with steel products and, as discussed, pinching the wire is going to be very much a possibility. I vote water jet cutting too.

My guess would be that the water jet can't cut deeply enough to slice the drill pipe inside the riser through several inches of flowing oil and gas. That's not a problem for the wire saw. Well, not as much of a problem.

The setup work for the wire saw cut (shearing the riser so it is hanging above the mud) should take compression loads off the cut, minimizing the chance of pinching. And if it does get pinched, lowering the riser stub a little should open the cut. Of course something could still go wrong, like the drill pipe twisting as it is cut.

I have a question related to Marcellus Shale that I'd like to ask, but don't know where to ask it. Should I ask in this thread?

Basically I own a couple of acres of land in Pennsylvania and the gas companies have been mildly interested in digging a well on it. I need to do something with that land and I don't know if the fact that it's sitting on MS (plus incidentally the fact there are some prime cherry trees on the land) makes it worth trying to manage compared to just selling outright.

There are other considerations but like I said I don't want to gum up this thread with personal query. Is there a better place I could ask this question? Thank you.

Rockman, to avoid MOUNTAINS of spam retype email address by using edit key ! wjd2211 at aol dott conn would do it. Otherwise automated bots pick it up !

Alan

Of course, since you replied to it, he can't edit it. But we can do him a favor and flag it (as I did) to make all this go away.

I carefully did not reply to Rockman's post (note no indent between our comments) but replied to the same post he did. He is still able to edit.

WAY too many hours here on TOD. But good point for the newbies.

Alan

Personally, if it was mine I would definitely keep the property and lease it out for the minerals. Surely you can find someone nearby your area to help you with the details so that the oil company doesn't jerk you around on the leasing arrangement.

I know I would keep it. The checks off the royalty can be very lucrative if handled correctly. Plus you say you already have trees on it, that is another plus

I have a little brother who is a land man in Tyler, Tx who did some work for EOG Resources in that area, but not sure what he knows about it without talking to him about it.

Bsmyth, the Drumbeat would be better for this. It covers general topics, many very interesting links to the most recent items dealing with PO, Oil, Energy, and related matters such as AGW and the like.

Enjoy the site! You won't find one much better.

Craig

Put in your contract how clean they must keep your land when all is done. Mud spills; spent tool charges,and crappy trucks will be sent out that leak oil. Not to mention grease and cleaning fluids and pipe dope and diesel. It will be drilling rigs after all. Also if they make a well see if you can get a provision for free natural gas for one single home. Or ranch or farm; whatever. (Yours)

I don't know if they still write contracts like that but they used to.

I've been in the underwater industry (commercial diving, ROV's and submersibles) since 1996 and have used these tools-- including wire saws, abrasive cutters, chippers, and others-- so I thought I would chime in here.

All of these methods (and others) are useful depending on the situation. It is truly "case-by-case."

Cold-cutting underwater using abrasives vs wire saw:

Water jets require the tip to be in proximity to the material; as you back away the energy is quickly dissipated by the seawater. This could be a problem when trying to cut the inner parts of the riser as there may not be room to get the tool inside (one solution is to cut out larger windows in a "wedding cake" or "canoe" fashion. Additionally, to cut the irregular geometry of the damaged riser would require a degree of manipulation not readily achievable by an ROV-- note the strap-on version of abrasive cutter shown by the poster above is fit around an undamaged round pipe in relatively new condition (and yes I know about the removal of the wishbone-shaped members offshore California-- again, a pretty regular geometry). Not saying that it can't be done at BP Macondo, but there are more reliable ways

Wire sawing is not without its drawbacks, but doesn't require intricate manipulation-- other than to set the tool on the work piece-- and once the wire has travelled through it is "proof positive" that the cut is 100% complete. Drawbacks: the wire can get pinched and stuck in the cut-- typically because of compression as the two sides of the cut draw together (hence all of the rigging and preparation). We used this technique to cut a concrete bridge girder a couple of years ago and had to go down every 30 minutes or so to unfoul the wire with a pry bar and re-set the line (didn't have the option of relieving compression with rigging, etc.) In the case of the ROV the worst case is probably to abandon the wire in a failed cut and start over on a new cut.

As for cleaning, again there is also no "one all-perfect tool" for the job. Hand cleaning, pneumatic and hydraulic chippers, whirl-a-wheels, scrubber carts, grit blasters, and yes- waterblasters- all have their pros and cons. Selection of the best method is on a case-by-case basis, although in reality it's usually "work with what you are given." Hence, the propensity for divers to ACCIDENTALLY lose tools from time to time…

Dave

bingo

the dependence of water-cut on distance from pipe will make this a very slow process....and the degree of accuracy required to keep it focused will bring a ROV operator to tears cuz very slight movements by the ROV are normal

whats needed here is a contact cut .....a diamond wire gives that....because once you get a cut going the wire can stay in the groove and the cut can proceed and smallish movements on the ROV will have no effect....

It should be noted that there is a slight current at those depths, the current interacts with the structure, and BP has added a large upwelling in the center of the action, with turbulent results. So ROVs are not perfectly stable platforms.

Alan

Any major cut such as the riser is usually done with a mechanism secured or clamped to the piece being cut to eliminate the current and motion problems.

Last night I observed them (practicing?) with a piece of machinery that seems to fit where they want to make that final, really careful cut - like it was made for that spot. It looks like it goes in and nearly surrounds the site where they expect to cut. I can't vouch for what I saw, but if I'm correct it's one excellent plan for how to do this, because it appears to surround and clamp. (They also had a little fan behind where the robot arm was operating, presumably to fan away the plume if needed?)

I'm so impressed with the work these robot-operators are doing! I cut the people "on the line" slack, but reserve my ire for upper management, who are doing everything (including employing cheney now as a spokesperson - see link below) to obfuscate and misinform.

BP shares down 13% I've just been informed.

http://rawstory.com/rs/2010/0601/bp-hires-cheney-spokeswoman-lead-pr-eff...

TheraP, what do you think the long term physiological damage to the indusry will be? Case in point Three-mile island set us back decades when there were really no leaks offsite to speak of. I get that much radiation every quarter and it has no real effecttttttttt onnnnnnnnnnnnnnnnnnnnnnnnnn meeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeeee

Do you think it would be worthwhile to try to activate the BOP after the final cut is made?

Reasoning: The bent over riser and drill pipe would seem to be putting tremendous pressure and torque on the BOP. Perhaps causing something to be slightly out of round and jamming the BOP mechanics. Relieving

this pressure may allow the BOP to function. What's there to lose?

What's there to lose?

the bop popping like a champagne cork? :)

Depends on if the loss of hydraulic fluid and dead battery situations have been fixed. Otherwise really can't cause much harm. Furtermore, If they get a clean cut They should be able to get something to contain this mess. NO MORE DISPERSANT!

Really can't cause much harm? Hmmmmm, I think it can! Drill pipe shoots out the well bore further damage to BOP, Casing/clamps fall away leaving the BOP open. At that point you have a hole pumping 30-50k barrels a day! That is a very big risk with a relief well still 1/2 months away!

The lessons at the beginning of each thread over the last few weeks are just great. Very well explained with sufficient detail and common sense to help us all to get an idea of what is going on. Thanks so much for the time and care taken by the authors!

1) Have a question about the idea of releasing the shears and what the drill pipe and drill shaft might do. Seems they could either stay in place, fall down or the frictional force of the flow could push it up?

2) Is the drill bit still connected to the drill shaft and is that hollow and if so is oil coming up inside of that as well?

Stay Safe - God Bless - Dave

found a site that has a few different live video feeds on a single page

link

Thanks for the video links

They should clamp on some guides to help guide the arm. I use my other arm as a guide when I'm doing similar things with a cutoff wheel on my car exhaust

perhaps it is merely an issue of scale on the illustration, but:

1.) why not cut off more of the pipe in order to reduce the overhung load that will be acting at the sawcut?

2.)after a manageable amount of teh pipe is removed, why not locate the saw appliance in a position that allows the overhung load forces remaining pipe to work to the advantage of the sawing operration. That is to say, start the cut at the radial location of maximum tensile force (opposite teh overhung load and procede with the cut allowing the dead weight of the pipe to pull the pipe away? wouldnt this eliminate the issue of the sawcut kerf collapsing?

3.)finally this is moving in a direction that I felt was correct several weeks ago, I am curious what all the damaged pipe wasnt cut off directly with a riser pipe then installed to allow the oil a path of least resistance with a minimum of salt water induction. I think this would have gone a long way ~3 weeks ago to buy time on the conventional method to kill the well.

4.) As as theoretical observation, once the pipe is sawed off, why not arrange the riser pipe approach in a manner similar to a modified angioplasty ballon? Insert a riser pipe with an inflatable bladder, the open riser would allow the oil to continue flowing while the bladder is inflated and compressed against the exisitng pipe wall, the riserr could then be mechanically secured to the existing sawed off pipe stub,and subsequently a valve a the surface could be use to manage the flow.

The weight of the severed Riser is being supported by a crane from the surface. As the band saw finishes the cut at the top, the crane can raise the Riser stub slightly to relieve any binding.

In execution, it would most likely be problematic to try and manage,what ~3/8" kerf clearance, with a crane. Use the overhung load of the pipe to the advantage of the cut, and perhaps use a crane rigged to add some bending load in the direction that maintians an the open kerf..

The riser support tether lines won’t stabilize after shear cut. It will sway back and forth under pressure? Install 2 shears, one to cut, other to stabilize during/after cut… like two hands.

It looks like their not going to cut completely thru with the shear, until the saw cut is complete. They can still come up on the load a tad to keep from binding and use the gripping shear for further stabilization.

After shear cut on riser will need forces from multiple directions to stabilize. The oil/gas pressure coming out open end of riser will be like uncontrolled thrust.

Current rig of tether lines provide limited support. Need a more bi-directional setup.

Length of riser remaining is proportional to these forces.

Per BP website, diagram shows shear cut first then diamond cut. Gordon’s post makes sense, understand now. BP illustration is out of sequence.

How will the diamond cut manage the DP cut without sending vibrations/movement down the bore?

I am the one with the

American Wacky Ideas

Wacky ideas to solve the B.P. Gulf Oil Spill

I am pround to tell you I don't think you can be part of the book!

I find this idea fascinating! Cut pipe edges are like razors so the stent would have to be Kevlar or cross-linked pvc or? Love it, it really is somehting you should pursue. Sorry the sinking battle ship stays on the cover!!

My feelings are hurt. I didn't say nuthin' 'bout no stinkin' battleship. The Admiral stole my idea at least three weeks after I first published it. That he stole it is not a shock. The shock is that Admirals read the Huffington Post.

Very informative post, thanks PG.

Is it possible that the wire cut is being used because the well is flowing?

I assume that once the pipe is breached with the initial cut, oil is going to start flowing out and this would create problems for any sort of jet cutting method. I'm guessing the engineers have decided to go with a "metal-on-metal" solution because it offers more control.

Also, I'm hoping that as they start the cut, the weight of the DP away from the cut is going to pull the cut open slightly, and pinching won't be a problem.

The tech talk on this board is the only thing that has made this tragedy bearable. Thanks, TOD.

(Reposting this from last night's thread)

A better, more controllable Video Window:

Bring up Windows Media Player, hit "File | Open URL" and put

http://mfile.akamai.com/97892/live/reflector:46245.asx

into the address block. Now you have better control over the window size. I keep it small on background, then if something good appears click the window and F11 for full screen. (F11 drops it back again too.)

It will drop out when they switch ROV feeds, but just hit "Play" to restart it after a couple of minutes.

Told my daughter it's my new aquarium! :^0

Interesting number offered on NPR this morning. Given they don't tend to take extreme positions their estimate of the total costs for BP for this incident is interesting: will range between $12 - 20 billion. Or about one year's profit. That's a relatively low number compared to the estimated $60 billion lost in shareholder equity. Thus they felt that BP stock might actually be undervalued today. They offered no details on how they came up with that number nor how those costs would be split between the various components.

The impact of Peak Oil will make the shareholders whole.

And the cost of two more relief wells, $0.2 billion.

Alan

Awfully hard to calculate. There are some major wild cards still face down.

Discretionary debarment, for example. I imagine it would be very popular with the public. They want blood. It could range from not allowing them to construct new wells in the gulf to the cancelation of all their existing leases in US territory.

I think NPR pulled the number out of their asses.

It's all going to be about downstream liability so keep an eye on governments desire to remove liability limits on drilling including gas!! The risk reward curve may not facilitate extensive drilling in the future so its my guess these limits will be smaller then the public wants or government itself will need to become drillers.

Either way if taxpayers want oil and gas they will have to agree to pay for clean up cost associated with large and small spills since it will not make economic sense for drillers to take these risks unless new oil sold for large premiums over current market pricing.

BP is dead man walking as a corporation unless they fire Tony and rightfully say he did not have the authority to say BP would cover cost beyond the current cap.

If the government removes all liability limits it will end off shore drilling, and cause 100's of thousands of job losses, and a big increase the cost of petroleum products.

Based on those scenarios, that is what Congress will do. They are mostly a bunch of grand standing jack asses.

Yeah, until the flow is stopped and the well is plugged no one can come up with a reliable guess at to ultimate cost.

And the inevitable decade or more of lawsuits to follow.

...how about a class action suit from all of us seafood eaters? Having to pay more, or do without our GOM shrimp and oysters. We are damaged?

Inhumane denial of Gumbo!

Like it.

And now Robert Reich is calling for the government to put BPs US assets into temporary receivership.

What would they look like by the time they came out?

Thinking about it, there could be an upside for BP. Would the government debar a company the government is running?

Nope, I can't value that stock.

What a ludicrous idea. If you want to get paid off by BP for the damages you need BP's US arm to be a strong operating company with productive assets, not some crippled bankrupt debarred defunct or nationalized operation. This will let BP pay and pay by selling assets at market value (increasing all the time due to increasing oil scarcity), forking over its 8 billion in cash, issuing bonds against its extremely strong balance sheet and so on.

Ultimately this is why (aside from the fact the BP supplies the US military with all of its fuel) you will not see nationalization, debarment, receivership or any other such nonsense. BP is worth far more to the citizens of the Gulf as an going concern than a bunch of leases being sold at fire sale prices by some court appointed government agency.

Do you really honestly expect the brain dead masses to understand this??? The MSM has done their job too well, they want BP punished in the worst way you can imagine.

The OwlGores and Michael Moores are the pied pipers of our day. The torches and pitchforks are out and they are marching up that hill. Lynch mob mentality seems to be the rule now. Got to make them pay for what they did to, "our ocean."

That is our ocean, no need for quotes, and some people most certainly did something very negative to it while trying to make a buck, and possibly cutting corners in the attempt.

I have the feeling that if Michael Moore and Al Gore never existed, folks in the Gulf states might still be just a bit miffed at the toxic soup wrecking their livelihoods, ecology and possibly health.

The fact remains that every coin a boycott removes from BP's fingers is one less coin available for the cleanup. I want a robust cleanup of the Gulf of Mexico. Boycotting BP is counter productive. If they go broke, then they will have no more coins for the cleanup. That would leave it to the taxpayer. The taxpayer can vote not to pay for a robust cleanup.

This has nothing to do with Al Gore and Michael Moore. BP has to pay, so force feed them coins. Instead of boycotting BP, Americans should start switching their allegiance to BP. The cleanup of the Gulf would be robustly funded by whom? Americans? No, it's their gas money. They're going to spend it anyway. BP? Some of it, yes, but they would be joined in funding a robust clean up by ExxonMobil, Shell, Chevron, Hugo Chavez, some Princes, etc.. The coins that normally would be heading to their coffers would instead be flowing into the BP account where the clean-up checks will be drawn.

Once the Gulf of Mexico is cleaned up, do to BP what you want, but please, do not screw the Gulf of Mexico yet again because your outrage wants BP punished this immediate minute. There is plenty of time to punish BP.

BS !!

ANY additional "coin" will go to London and NOT to the clean-up.

BP is as cheap as they come, cutting corners EVERY chance that they get !

Their profits from crude oil production are more than enough to pay what can be cleaned up. Paying damages are what will hopefully bankrupt them.

Humanity would be better served with BP assets dispersed to the highest bidder anyway.

Alan

Er. BP are a publicly traded company, and as such shareholders in the company are all over the planet. I'd be surprised if >50% is held by UK-based institutions (but happy to be corrected, as always, if anyone knows different?) Anyway, "London" as a municipal authority doesn't play the stock market...

Alan, this will be held in court for forty years and the plaintiffs will be scrabbling for food. Hand full of beans and a loaf of bread as a settlement?

Exxon paid nearly nothing after thirty years in courts!

Remember the last 10% is worth far far more than the first 90%.

Speculation on Wall Street is that BP will sell it's Gulf holdings to other majors to avoid any effects of potential disbarment.

Not when they provide the U.S. Military with 80% of its fuel needs.

if you think BP has taken a hammering States side.....BP shares in london have taken a hammering like there's no tomorrow .... 1/3 of BP's market capitalization has been wiped off in the london stock exchange ...and BP's credit swaps on the 5 year have risen from 71 basis points to 176 basis points (essentially it is costing about the same to insure BP's debt right now as StatOil ) ..

i dunno how can BP stock be undervalued right now .... how can stock be valued right now when damages are not close to being certian....no certainity if the moratorium can stand as it is ....what new regulations MMS will mandate and how that will effect operational costs ....

surprising coming form NPR ...NPR usually is like UN ...mild on everything but the BBQ sauce

I don't follow BP. I wonder if they have been buying up their own shares like ExxonMobil has?

Exxon paid out around 3.8 billion in 1990 dollars when their annual profit was around 5 billion. Also, it is believed that Exxon was insured. It has been reported that BP is self-insured.

BP is defiantly self-insured..no question here

BP just like Exxon just like any large oil corporation will buy back shares when running excessive profits ...this helps with times when times are lean ....rmrb the oil business is highly cyclical ....old oil hands of the 80 know this all too real

Well, if this numbers is correct it seems like the BP man on the rig responsible to rush the well to completion to save some money and maximize profit for BP did a teriffic job.

I still think their total liability is 10 billion as per the Congressional actions post Exxon Valdez? It was 75 million. Most likely it will be the civil judgments that kill them. But twenty/ thirty years down the road waiting people will take the 100$ and feel lucky. Don't you love how Congress stands up for the little guy ha!

I saw it mentioned that it would take 4 days. Is that how long it will take to get the cap on? How long does it take to get the oil piped up to tankers after that? Or is it 4 days for both the cap and the oil re-direction to be done?

I think the kink is restricting the flow more than they think......after that cut, watch out!

I’m curious… is there enough pressure in that pipe to cause it to violently straighten after they sheer off the majority of the riser?

No, the velocity goes up. I believe the pipe is 1/2 wall. I still think the location of the drill pipe will be important.

I read the press release on BP's site this morning. They are going to use the top kill manifold and lines to hook up to the new LMRP to bring the leaking oil/gas to the surface. This should speed things up a bit, because its already there and just needs to be attached to the LMRP. They actually started all of this on saturday, so sometime Wednesday would be best case(roughly four days) for having the oil being collected by a surface vessel..........."if"........

Here's an excellent tech talk by Kent Wells posted yesterday on the use of the manifold as one of the three planned paths to capture oil until a RW succeeds, including one that can be quick released and restarted after a hurricane. The plain LMRP cap comes first - the other two begin implementation later this month.

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

VERY EXCELLENT tech talk. Maybe this link should be posted up at the top at the bottom of the lead article? Does BP do these regularly? If so, it's pretty apparent that most talking heads on TV aren't spending 20 minutes to watch.

If Rick Sanchez of CNN watched this he wouldn't sound like such an idiot.

He's done a couple ... they're listed under "Response in Video" in the left hand column on Gulf of Mexico Response on the BP site.

It would be helpful if he did one on how the relief well is intended to work. He sure is a better spokesman for BP than Suttles, Hayward or Dudley.

The live video is showing cutting tools quite unlike those shown in the article above. Looks like a diamond blade circular saw to me. Wondering if anyone knows diameter of this saw?

They just succeeded in cutting one small pipe outside the riser, wondering if anyone knows what this particular pipe was/is for???

I believe the two smaller pipes are the choke and kill lines. They used the same circular saw to cut those away at the BOP yesterday. The wire saw is already installed over at the BOP - they will probably show it later when they start that cut. I think that the smaller lines were going to interfere with the shear and needed to be cut first.

A few snapshots of what happened this morning:

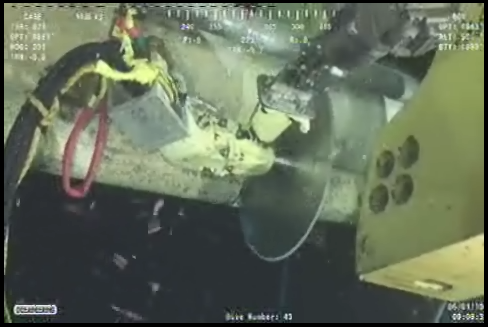

Shears in place:

Cutting of smaller pipes:

General view of shearing machine (BOP in the back)

Saw in place on top of the BOP:

Seeing that this will probably fail just like everything else BP has tried thus far (a bottom kill is probably the only thing thats going to stop this) And seeing that the coolest part about this whole disaster is watching these ROV's operating under a mile of water, can't we just wait out the completion of the relief wells and set up steel cage matches between these ROVs. Atleast we could be entertained while watching the Gulf become a dead zone.

As a technically oriented citizen..looking for reality between BP's "no problem" and other's "disaster for the entire region"...

I read the area of the Gulf is about 600,000 square miles and oil/dispersant is toxic at something like 100-300 parts per million. Do the math and we're only talking very roughly 10 cubic miles at this concentration. Thus, it seems completely false to claim major damage to the (entire) Gulf ecosystem. Oil on the coastal areas is a very different situation for sure. But this perspective seems completely lost from what I read about it all.

Don't misunderstand me though, I personally think this is an unacceptable accident, BP is negligent and this should not have happened if "things were right".

Makes me wonder too if dispursal isn't a great mitigation far from shore. Also, use of the word "clean-up" really bothers me. The only possible responses to **oil on the shore** offer mearly less severe damage. There will never be any "clean-up".

I disagree. Nature always cleans up. We may not be satisfied with the length of time she takes, or the changes in scenery she allows. What does she care?

In the meantime, mechanisms are needed to cause money to circulate in the Gulf region.

Make work schemes to remove some of the gunk is one such mechanism. It also might help save some plants and animals, which might make give nature a small boost when she is in the process of repopulating the oil-struck areas.

Soon though, the whole of the affected areas should be roped off. A no management area. No interference in nature's work.

My advice to people wanting to rush to the Gulf to help out is to stay where you are and work to stop the acidification and warming of the ocean. This is a bigger problem than the BP spill, and can probably only be overcome, at least partially, by increasing the disincentives to burn fossil fuels. Carbon tax, drilling/mining restrictions, corporate liability -- these are some ways to help the lifeforms, including us, dependent on the Gulf of Mexico and all the worlds oceans.

A four part series on the state of the world's oceans: Look for the title One Ocean. http://www.cbc.ca/video/#/Shows/The_Nature_of_Things/ID=1451865820

Extinction(s) and/or toxicity based in an eco-chain - assuming we're looking at that - doesn't/don't really get 'cleaned up' as it were, although I agree eventually the sight and smell of the oil and dispersants will subside.

Nature adapts. She creates a new steady state, and that becomes the new 'normal.' Species die out, others adapt and change (perhaps to new species, like Fred's deadly oil snake). Numbers adjust, predation settles down to sustainability and, welcome to the new world.

Of course, what happens in one locale will impact other systems as well, until the entire planet is altered. It is natural, though, and that's what counts. Isn't it?

I don't know if I would exactly call it a 'clean up,' though.

Best of luck for a clean new world.

Craig

I suppose we shouldn't be cluttering what is another excellent discussion of technical issues wrt to efforts to control the blowout. But...

I don't know if we're on the same wavelength. I am saying that as natural as our species' smartness is, we're not smart enough to 'direct' or 'manage' nature's adaptive process.

The best we can do is to stop digging ourselves into a deeper hole. So let's be glad that grownups are doing their best to staunch the spilling oil from the BP disaster. But let's not forget that ocean acidification, warming and expansion are even bigger threats to our well-being.

If you've got the time, and if you can access the video from your region, the One Ocean series is very informative. Of particular note is the way in which some fisheries in New Zealand's waters were reestablished. People were kept out. Nothing else was done. The result: abundance.

We're right on the same wavelength on this.

Just remember, here in Technocopia, progress is our most important problem.

Craig

Potentially wiping out entire fisheries, chains of species, encouraging bacterial and algal blooms, or killing off grasses that allow wetlands to exist/not erode (and create a barrier area that protects areas further inland)... this is neither natural nor normal. We're not talking about speciation or gradual adaptation here, we're talking about one day the fish larvae and wetlands roots systems can live and the next day maybe not so much.

The world's fisheries all already teetering as it is. There's a "peak protein" problem there that deserves (maybe has?) its own website(s) like this. Aside from an issue like whether or not manatees are just going to have to adapt to ingesting oil emulsion in one generation or become collateral damage in BP's avoidance of paying for some equipment and procedures they would be required to be using in other parts of the world, there's the little problem of humanity feeding itself. And the comparitively smaller (!!!) problems of wrecking the Gulf's economy, changing the way of life for hundreds of thousands of decent folk and rearranging Louisiana's coastline.

This is a human-created catastrophe and I don't think even top oceanographers have a handle on yet, but there's really nothing "circle of life" about this. On the human scale it's like the difference between the process of aging and getting run over by someone who was gabbing on their cell phone.

No argument that this is a man-made catastrophe. Leaving aside the questions about the naturalness of the greed and laziness that has led us to the deep water in search of low entropy, the question for me is whether humans are up to the task of managing the 'recovery' of the imperilled eco-systems. I see no evidence that we are. The best we can do is to keep ourselves contained elsewhere, while nature does the job.

While we're waiting, let's focus on ensuring that when everybody scurrying around the planet today is dead some accessible hydrocarbons are left for our progeny. And that our progeny will not be overwhelmed with the repercussions of acidified, warming and rising oceans.

I just don't want every concerned citizen focussed on getting the gunk scooped out of the Gulf and it's shores, while Exxon, Shell, BP, Peabody, etc are working non-stop to weaken the resolve of legislatures everywhere to impose tough new conditions on hydrocarbon extraction and to effect the necessary transition to an economy minimally dependent on hydrocarbons.

Bravo! Bravo! Well said my friend! Nature does the least damage. Oil has been here longer than we have. Light solvents are evaporated leaving heavier and heavier oil and tar. The ultimate cat cracker!

Water Jet vs Diamond Wire

I think if you look at the specific task you will find that water jet has little, if any chance of working, certainly in any time span measured in days or weeks.

1 - A water jet system works very well of flat plat or round pipelines where the distance from the jet to the material being cut can be precisely controlled. In this case the pipe may well be out of round, even a half inch of distortion or bent area could keep the jet from making a complete cut. There are numerous protrusions, standoffs, other pipes and even the bent over riser that make it difficult to install a guide and to allow room for the jet head to keep in continuous close contact with the metal. This alone probably eliminates the water jet system in this case. These problems also apply to most existing mechanical cutters.

2 – Water jets cannot cut something inside another pipe, like a drill pipe inside a riser. Leaving another major problem to solve.

3 – Delivery of the jet water supply must either be from the surface or from water near the riser. In the first case I would suggest calculating the losses from 1 mile of supply hose rated to over 20,000 psi and all the joints in that line. We used to have major problems just getting that kind of water pressure delivered to 500 or 600 feet for divers. Incidentally, the abrasive water jet used by divers to cut steel like the rebar in concrete pipe weight coating operate at lower pressures in the 20,000 to 30,000 psi range and use a larger volume of water. The water supply could be delivered through drill pipe as it is for cutting casing in a well but I think the only available drill pipe is tied up in supporting the LMRP overshot and to use that drill rig would probably set the project back a couple days.

If the water is supplied locally it will require a lot of horsepower. A pump package can be made up to hook to the ROV which supply up to 200 hydraulic horsepower. I think a bigger problem will be designing a system to filter the water going to the jets. Even a tiny amount of the debris floating in the water will quickly erode the jets rendering them useless, ie a 3 to 4 hour trip to the surface to change them out. While I’m sure such a filter system can be designed and fabricated I doubt that it is off the shelf and will take a lot of time to design build and test.

Supplying the abrasive is another problem. If supplied from the surface it is my experience that the weight of the slurry in the supply line in 5,000 feet of water will probably screw up the feed control system. So probably the abrasive would have to be supplied by the ROV which could certainly is feasible, but I don’t know if there is an off the shelf system to do that rated to 5,000 feet.

Water jets are slooooow in relation to diamond wire.

The diamond wire cutter is an off the shelf system that can be used at 5,000 feet. It is specifically designed to cut a variety of materials that may be deformed, under stress and of unknown configurations and dimensions. It has been proven thousands of times and was an instrumental tool in cutting up the over 100 offshore platforms that were sunk during Katrina and Rita. Those members were deformed and often under extreme stress.

There are problems that may affect the diamond wire cutter.

The cutting wire can bind up but because they are small diameter and due to their design they can cut 360 degrees around the wire they can usually cut their own way out of a bind as long as the wire does not stop. In this case it appears they will cut from the side opposite the hanging riser. After the riser is sheared all they have to do is lower the load a couple inches to allow the weight of the broken riser to open up the cut and help avoid binding.

Visibility will be impaired somewhat as soon as the wire cuts through the skin of the riser. That has no effect of the diamond wire saw but means the ROV will not be able to see the cut as well.

I believe the worst problem will come when they try to cut the drill pipe. At this point they can only assume the drill pipe is jammed solidly by the rams in the BOP on the bottom end and kinked inside the riser at the top end. If this is the case and the drill pipe does not move more than about an inch it should be able to cut it clean. If the drill pipe is not secure and drops it will probably break the wire and they will have to recover the saw, install another wire and try again. Considering the kink above and the rams below I think they have a reasonable chance of cutting it the first time, especially since the stress on the drill pipe is probably trying to open up the cut.

Shelburn:

1) It depends on the system, with an air shroud we have cut metal up to 12 inches from the jet, and some folks in Japan have cut 30 inches of reinforced concrete - it is a matter of the system you use.

2) No I have photos of several pipes inside one another and with concrete in between, cut from the center.

3) As I mentioned at the top Gulf first used abrasive water jets in drilling down to 15,000 ft nearly 40 years ago. With abrasive slurry the differential pressure across the nozzle need be only 5,000 psi, and the supply problems with abrasive - which is is the single fluid flow down to the nozzle - is not an issue. You are confusing abrasive waterjet cutting with abrasive slurry jetting and they are, to a degree, different animals.

I am not necessarily saying that it would be better here (the range with that back pressure is beyond what we have cut against, though we have drilled against higher back pressures than that) . I would agree with you on the problems with the wire, but as you say all they need to do is replace the wire (though that will take some time - wonder if they have a backup machine on site).

HO

1 - Have you considered the problems of having an "air shroud" at 5,000 feet? Either you have to have a shroud that completely and continuously seals against the material being cut or you have to have a continuous supply of air from the surface at about 3,000 psi to overcome friction losses and bottom pressure, and is capable of supply 150 cuft of air for every cubic foot of air lost at depth. That will probably be a massive amount of compressor capacity, hoses, etc.

2 - Do you have any pictures of pipes inside pipes that were jet cut when the inside pipes were surrounded by liquid fluid? Small air filled pipes embedded in concrete act much like a solid object. In this case you probably have a few inches of oil and super-critical gas between the inside of the riser wall and the drill pipe. Or pictures of fluid filled pipes bigger than a couple inches that were cut from one side?

3 - Abrasive water jetting is commonly used by divers but the pressures are usually about 20,000 psi. I don't know as much about ASJ so I won't dispute your claim that 5,000 psi might be enough pressure. I still think the problems of surface supply are real. A clogged or damaged jet is a 3 to 4 hour delay to fix it, any adjustment to flow rates, pressure, slurry inclusion, etc has to wait a considerable time before the change is seen at the jet so ideally all adjustments have to be made at the wellhead which means the slurry entrainment would need to be there.

I don't think the back pressure is nearly as much of a problem to overcome as all the logistical items. I think, with the exception of the problem of trying to cut the drill pipe, all these problems could be overcome with several months of R&D. Cutting the drill pipe would probably require cutting a window in the riser large enough to install a separate cutting jet system to cut the drill pipe.

Basically not a practical solution compared to an off the shelf system specifically designed for this kind of situation - deformed fluid filled members under high stress.

1) Yes I thought about the pressure, once had a 3,000 psi air compressor, never had the nerve to run it up to that pressure though. And the overall optimal air:water nozzle has not been developed for these conditions.

2) When we cut with water between the metal, we weren't using metal pipes but a top layer of metal then a gap and then either another layer of steel or a stepped metal plate that incrementally moved the cutting surface half an inch at a time away from the nozzle. It was done in a pressure tank under water so the results weren't that pictorially interesting - hence the pipes and concrete comment, which showed the cut better, but you're right it is harder to cut through steel water steel than steel concrete steel at depth.

3) Nozzles should last about 30 - 40 hours and the only problem is control of the abrasive size to make sure that none of it is going to bridge in the orifice. Abrasive can be suspended to ensure it is evenly distributed through the flow, and concentrations adjusted at the pressure injector. Then you are just controlling the flow and pressure through the pump. As Gulf showed, it can be done.

(And for a mischievous moment - perhaps it might work better than a certain metal shearer? - grin , actually if the machine were sized right, for this operation, probably not, but we'll never know.)

In drilling the relief wells, is there an intermediate solution where they can intercept the well at a lower depth? I would think that this option would at least enable the recovery of some of the oil and potentially increase the effectiveness of a top-kill, top-hat, junkshot, LMRP procedure to work. Even multiple smaller bores could be deployed; does such technology exist? Intercepting at a lower depth would also increase the probability of hitting the main well too. Is this not a feasible option due to the high pressures potentially leaking through the ground?

jed -- They have to intersect the blow out well at approximatelly the same depth as the producing formation. Otherwise the higher pressures in the reservoir will cause the shallower rocks to fracture and destroy the RW.

Hey!The RW wells haven't failed ... yet! I bet those fellers are working their tails off.Good luck and be safe all you rig hands! Also, the cutting of the riser is,basically,a salvage operation.I am sure they have some pretty darned good people addressing this phase.

Instead of some hard to handle cutting saw they should just use shape charges to cut the pipe just like demolition teams use shape charges to cut steel girders with.

Well, one isn't even being dug, so I'd call that a failure, meself.

I was thinking that too. How can they be holding up the second relief well? How can our government be letting them? I get that they wanted to pull the BOP and move it over to the spill area but are we to believe that there aren't any other available BOP's out there?

Please someone here correct me on this. Are they really talking about a relief well that will bore into the existing well hole diverting the existing oil flow from the original well or are they just drilling more bore holes into the existing oil reservoir-?

I think it’s the latter.

A relief well to bottom kill the damaged well.

http://www.upstreamonline.com/multimedia/archive/00031/Montara_well_repa...

The relief well, when/if successful, will intersect the blowing well and be used as a conduit to kill the flow.

See explanation of the process and a diagram of the two relief wells in relation to the original well at http://www.bp.com/genericarticle.do?categoryId=9033657&contentId=7061734

There are discussions of the process in earlier threads.

they are talking about boring into the existing hole to pump mud and cement in to kill the well.

Note the intersection depth is slightly above the reservoir.

May 30th relief well pic:

http://www.deepwaterhorizonresponse.com/go/doc/2931/575179/

why won't BP put the full sized graphic up on their site?

See at 11:23 in the May 31st video from Kent Wells re relief wells, "the ultimate way we'll kill this well":

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

n.b. this image is big, and I cannot figure out how to make scroll bars around it.

Note by Gail: I fixed it so the whole image would show. (Added width="100%" tag.) Click for larger image.

Been scanning comments, this seems to be the most important one. Talked with an ex BP engineer today who said the relief well is something they can do. It seems amazing that they can actually intersect one well with another, but its been done before. They have 6000 ft (vertical depth) to go with MC 252#2. For all those living on the Gulf Coast - this can / hopefully will really work.

Also picked up in a comment that suspension of MC252#3 was temporary so that the drill ship could off load a spare BOP, and that drilling that well has recommenced - clearing up some confusion.

Also pick up a bit of BP bashing - sure some guys and the company have screwed up big time - but my take on all the failed top down effort is that BP has to be seen to be doing something / everything possible, and I think / hope they are - even though chances are very slim - while the relief wells drill.

And to Rockman - geologists will one day inherit The Earth - cus only we understand how it works.

That's just great Euan...we get to inherit it after BP screws it all up. There's goes our security deposit. Thanks bunches.

Rockman:

"we get to inherit it after BP screws it all up." But only you can save the Blue Bell factories!

After a few thousand years it will all be back to normal.

How about EDM. A servo keeps the distance constant and the arc would love the fluid.

You're not going to do EDM in salt water, ECM maybe but it'd be really slow.

With all the political theatre and watching our president live right now.. He disregards the most important statement.. “Let us pray”

Coast Guard Rear Adm. Mary Landry has been replaced...guess the government got tired of her parroting the lies coming out of the BP's b.s. machine.

http://www.deepwaterhorizonresponse.com/go/doc/2931/576995/

God's speed and good luck to the 8th District.

Important piece of explanatory analysis that relates to the problems in the GOM:

http://www.youtube.com/watch?v=8-QNAwUdHUQ

Oh thank you Blue Moon. That clarifies everything.

Looks like they just tried to clamp down on the pipe and then backed off .. what's producing the power for the shear, the HPU (~110hp) aboard the ROV or something else?

So. let us introduce explosives into this monumental task? With an already damaged BOP below it? Hmmm..... am not too sure about that.NO. I like the wire and cutoff saw procedure much more.

“So. let us introduce explosives into this monumental task?”

There is no oxygen down there to feed an explosion. A shape charge would just cut the pipe in two just like they cut steel girders in two. And the mechanics needed to cut the pipe would be minimal.

Most, if not all, explosives have their own oxidizers. (Think depth charge)

Ummm,

I'm not sure the shock wave and associated vibrations would be all that wise to introduce at this juncture. Unpredictable results at 5,284 ft. are not worth the day or two difference between shaped chg and diamond saw. Besides, diamond saw should be a relatively clean cut, whilst c4 style is jagged at best.

Another raw noobie/first time post here. I know it has been said before, but it is simply impossible to extend enough thanks to all of you long-time and sustaining posters, for your kindness, tolerance, and willingness to educate those of us who have come here from other industries, not even aware of the breadth of technical mastery that we don't (and can't possibly) have. I certainly have learned more in the last week than I thought possible, and I also will be opening my wallet to help a little bit. This is an absolutely invaluable resource.

Nothing concrete to add, no suggestions to make, other than to extend my thanks to all of you for your efforts. And, I suppose, to observe that the closing of the shear jaws around the riser bundle at 5000 feet down is fascinating beyond comprehension.

Kudos as well, and a vote of thanks to all the operators of the ROVs and the remote gear, who are without a doubt bringing their absolute professional best game to this disaster. I literally can't imagine the stress and pressure to perform perfectly that they must feel...

Why not simply rough cut the riser directly below the bend to eliminate the binding issues?

My guess? (Not an expert!) They have to cut it far enough from the BOP so that the falling pipe ("riser" for the purists) doesn't hit the BOP.

Underwater ops update: 1:02 PM EST - Source - live video

About 20 minutes ago the operators applied force to the riser with the sheer (the one that is there to cut the riser) but then this halted without making a cut. Not clear if they are waiting for something else to be ready or if the sheering is having problems.

A couple of minutes ago the sheer was re-opened and moved a short distance, and they appear to be trying to cut at this new position.

The way the observation ROV is being manoeuvred, someone is very interested in exactly what is (or isn't) happening with the sheer.

Worst-case is that the sheer is not capable of cutting the high-spec riser pipe.

Earlier today the ROVs were trying to cut one of the two auxiliary pipes that run along the riser, using a circular saw, but eventually they gave up.

underwater update 1:12 PM EST

The sheer has been opened again, and the observation ROV is looking in detail at the (failed) cut. Does not inspire confidence.

Since the sheer doesn’t eat away at the material the way a saw does, wouldn’t that mean the sheer is working against both the strength of the pipe and the pressure of whatever is in the pipe?

Update 1:30 EDT (thanks Blue Twilight - typical UK mistake)

The shear is probably not affected by the internal pressure, as this is probably only slightly higher than the external pressure.

Now they appear to be trying in a third location. Here is a picture of the dent after the second try (if I can get this to work), for those who missed it on the live feed

I think your time zone is EDT since your time marks are three hours ahead of mine in MST.

An earlier view shows this to be a BTI Services model (not sure which one) : link to their page :

http://www.btiservices.com/index.php?page=hose-reel-support

Based on the known diameter of the riser pipe, it looks like they're using the smallest one. I'm no metallurgist, but is 1500t of force enough to shear through 2x .875 steel?

What's happening to the big shear? I've seen it close on the riser package, close far enough to dent it, then open back up again. It appears to only have cutting teeth at the very end of the jaws, is it going to have to take multiple "nibbles" of the riser to cut it? If so, the the first grip seems like it was a mistake.

Not a scientist or an engineer but it appears as if they may be taking a few test bites right now ( for what reason, i don't know). Either that, or this giant shear is totally failing.

Are they cutting the smaller lines first?

I don't know what they're waiting on.

Just lowering and closing as I write this - another fit test?

But see the pictures:

http://genesisattachments.com/product_detail.aspx?ID=378

It can nibble at the end, but there are blades all across.