BP's Deepwater Oil Spill - Capping the Riser - Part 1 (Cap on, but leaks) - and Open Thread 3

Posted by Heading Out on June 5, 2010 - 12:24am

Please transfer discussion to http://www.theoildrum.com/node/6572.

Update: It is still too soon to know how successful the new cap will be. Spillage of oil was apparently expected by design, initially. As the system is adjusted so that more oil can come from the top, less spillage is expected. Updates on the amount of oil being collected will be provided only every 24 hours. The first estimate is expected tomorrow morning. The ship doing the processing is set up to handle 15,000 barrels of oil a day, so that is the upper limit on the amount the system is set up to handle. - Notes by Gail, based on this afternoon's press conference.

This post describes what leads up to Heading Out's statement at 10:06 PM that they have the cap on but it has not gone down far enough to generate the seal, and so there is a lot of oil still coming out from under the cap.

The vertical section of the riser was cut, using a Shear, at 9 am Thursday morning.

The oil and gas are rising vertically, from the top of the riser, the drill pipe (DP) and the saw cut in the side of the riser (just down from the top of the shear)

At 8:30 pm, the ROVs maneuvered the latest version of the “top hat”, variation 7, of the LMRP over the top of the LRA. As the new cap was lowered into place, it was surrounded by clouds of oil and gas, making the actual progress of the event somewhat difficult to follow. The new variation had been finished yesterday, to accommodate the changing upper surface of the remnants of the well.

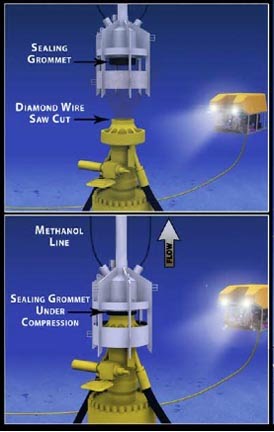

The Lower Marine Riser Package (LMRP) was first connected to the riser, and to a methanol feed that would help, between them, to inhibit the formation of methane hydrides when the gas came into contact with the surrounding cold seawater. It was then slowly lowered to the site, and across into the fountain of oil and gas, and down over the top of the riser.

The initial attempt halted after a while, and by 9 pm the situation was, for while static. The cap was sitting apparently on the rubber seal that had been designed to fit between the LMRP and the flange, but the amount of oil that was leaking out of the bottom of the LMRP was still a considerable amount, even though some of the flow was also being bypassed through ports on the LMRP that could later be closed.

The question now arises as to whether the LMRP could be lowered sufficiently that it could seal to the flange surface, since it was no longer possible to get the seal needed on the upper surface of the riser, given that it had been distorted by the Shear which had cut the bent riser away.

There was a pause, while the engineers had a bit think for over an hour. Looking at the cloud of oil coming out, it does contain small white specs that could be either methane hydrates or drops of the dispersant. And now, at 10:30 pm, there is a little more action.

For those who may not remember, this was the initial plan as it was proposed.

So far it is not quite as simple as the sketch would suggest. But I will put this up, and then update, as changes appear.

At 11:12 PM Central Time, we received an e-mailed press release with a statement from National Incident Commander Admiral Thad Allen that the cap was in place.

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

BP says they collected 1810 BBLs in the first twelve hours of operation. It appears the leakage flow around the cap has reduced somewhat, so they may have meen able to ramp up the flow some. They aren't saying what the recovery rate is at this time:

http://www.bp.com/extendedsectiongenericarticle.do?categoryId=40&content...

Presumably they will start to produce through the existing choke and kill lines soon, as stated in the last technical briefing. Maybe they can begin to collect the majority of this stuff and save a chance for the Gulf.

That's consistent with their previous siphon, which topped out at 5 kbd (if memory serves) before they stopped it.

shelburn: "Lots of potential problems and a lack of information." Thank you. Your sentence says it all.

This analysis of the casing and wellhead failure was posted at end of last thread and is too good not to comment on.

http://www.theoildrum.com/node/6560#comment-640962

There are a number of points raised here that need to be considered in the casing design of the relief well. Is there anyway of finding out what the casing design for the relief well is based on the drilling license, or something?

Good question.

From memory I recall hearing that the casing program for both relief wells were to be the same.

I was looking over at http://www.deepwaterhorizonresponse.com/go/doc/2931/543771/

BP got the permit for the relief well on April 28th. Then the next notice of significance was on May 15th.

"The Development Driller III, which will dig the first relief well, is lowering the blowout preventer stack and riser. The report depth was nearly 3,000 feet as of 7 p.m. EDT on Friday, May 14. After initial review by MMS, BP revised and resubmitted the Application for Permit to Drill the second relief well, which will be undertaken by the Development Driller II—which is on location and making preparations for initiating the drilling process. "

May 16th "MMS reports the Development Driller III, which will drill the first relief well, has finished running blowout preventer (BOP) stack and riser and is currently latching the BOP to the wellhead for the first relief well. The Development Driller II, which will drill the second relief well, is on location and is making preparations for initiating the drilling process and performing BOP maintenance."

May 20th "The Development Driller III, continues to drill the first relief well at approximately 30 feet per hour. The Development Driller II is being prepared to receive the blowout preventer, following which it will begin drilling the second relief well."

May 30th "The Development Driller III and Development Driller II continue to drill the first relief well to a depth of 12,000 feet, and second relief well to a depth of 8,500 feet, respectively."

May 31st "The Development Driller III continues to drill the first relief well to a depth of more than 12,000 feet—10 days ahead of schedule—and is beginning to angle the well at 35 degrees. The Development Driller II has drilled the second relief well to a depth of 8,650 feet."

And that's about it for news on the relief well. I wonder what the revision on May 15th was all about. The way things are going we will soon find out what the design is after its been cased.

The analysis ov refers to is quoted below the dashed line.

The source is from elsewhere on the web. The author feels the need to preserve his anonymity.

For those wishing for a tight seal at the riser to LMRP joint, the problem is becoming clearer.

The well integrity seems to be 'compromised' to the point that any increased back pressure above the BOP could cause an even more catastrophic and entirely uncontrollable blowout... at least as I understand things presently.

Peter B.

---------------------------------

"The following is my theory on what happened on April 20th. I have listed factual information to the best of my knowledge, and base this theory on 33 years of experience working on these rigs, with 16 years working as a consultant worldwide. The contractor (Transocean in this case) typically does not do anything without direction and approval from the operator (BP in this case). I believe that there was nothing wrong with the BOP, or the conduct of the crews prior to the catastrophic failure. If any operator drills a similar well using the same flawed casing and cement program, the same results will be very possible.

The well was drilled to 18,360 ft and final mud weight was 14.0 ppg. The last casing long string was 16 inch and there were 3 drilling liners (13 5/8", 11 7/8" and 9 7/8") with 3 liner tops. A 9-7/8" X 7" tapered casing long string was run to TD. The bottom section of casing was cemented with only 51 barrels of light weight cement containing nitrogen, a tricky procedure, especially in these conditions.

The casing seal assembly was set in wellhead and pressure tested from above to 10,000 psi. Reportedly, a lock down ring was not run on the casing hanger. The casing string was pressure tested against the Shear rams, only 16.5 hours after primary cement job. A negative test on the wellhead packoff was performed.

The rig crew was likely lead to believe that the well was successfully cemented, capped and secured. Normally a responsible operator will not remove the primary source of well control (14.0 ppg drilling mud) until such conditions were met. However, the crews were given the order to displace heavy mud from riser with seawater, prior to setting the final cement plugs. They were pumping seawater down the drill string and sending returns overboard to workboat, so there was limited ability to directly detect influx via pit level. This is the fastest way to perform the displacement operation, and the method was likely directed and certainly approved by operator. There was a sudden casing failure during this displacement procedure that allowed the well to unload, with ignition of gas and oil. Evidently, the crew was able to get the diverter closed based on initial photographs, showing flames coming out of diverter lines.

It is likely that pressure built up between the 9 7/8" and 16" casing under the casing hanger, due to gas migration from the pay zone. Based on reported mud weight, the reservoir formation pressure is in excess of 13,000 psi. The pressure building in the cross sectional area below the casing hanger would have increased casing tension and caused casing to collapse and part (rapidly separate) at a connection, probably a joint or two (50' or 90') below wellhead. The collapse pressure for 62.8 ppf 9-7/8" casing is +/- 10,300 psi. However, the collapse resistance of casing is considerably reduced in presence of axial stress (i.e. tension). Engineers - see formula from API bulletin 5C3, section 2.1.5 and run the math. The well then came in violently through parted casing and caused the blowout. Without lockdown ring on hanger, the casing hanger and joint(s) were slingshot up into BOP. That would explain why all components of the BOP are unable to seal or shear. The parted casing section remains across all BOP ram cavities and probably all the way up into the riser.

Shortcut #1: Running a tapered long string rather than a liner with 9-7/8" liner top packer, followed by tieback string and pumping heavy cement all the way to seabed. Perhaps the original permits for this casing program were based on a planned appraisal well, and changed midstream to a producer well, then hastily approved by the complacent or under-staffed MMS. This tragic shortcut may have saved about 1.5 rig days.

Shortcut #2: Insufficient time was used to cure the mud losses prior to cementing the open hole reservoir section, depending instead on using lightweight cement to prevent losses to the formation.

Shortcut #3: The nitrified primary cement job. This is difficult to pull off, even under ideal conditions.

Shortcut #4: Hanger without lock ring may have used due to the previously unplanned long string, and to avoid waiting for hanger with lock ring to be fabricated or prepared.

Shortcut #5: No cement evaluation logs were performed after a job with known high calculated risk (mud losses to formation). This shortcut may have saved 8 hours of rig time.

Shortcut #6: Pressure testing casing less than 24 hours after cement in place can expand the casing before the cement is fully set. This shortcut can "crack" the cement and create a micro annulus which will allow gas migration.

Shortcut #7: Displacing 14 ppg mud from 8000 ft MDRT with 8.7 ppg seawater, less than 20 hours after primary cement is in place. How many tested and proven barriers can you count? I count zero satisfactory barriers. Industry standards dictate that at least two tested (to maximum anticipated pressure) barriers are in place prior to removing the primary source of well control (weighted mud or brine)."

-----

I would say that it should be mandatory to have the last intermediate casing string run all the way to the wellhead and for the wellhead to have the proper lockdown rings and seals to isolate the intermediate string from all higher casing strings up the well.

One thing missing is the consequence, if any, of rupture disks - 1/4" vent orifice.

During Top Kill, BP put just north of 10,000 psi into the BOP, and they think they lost mud at 1000' below the wellhead because of a failed rupture disk. I guess if the rupture disk didn't work, then the casing system lost part of the design's safety factor.

Another is the issue of the open annulus on the Halliburton concrete plan (an 0&G professor looked at it and thought the error so glaring that he thought it must be mistaken - which could be the case.)

The post is pretty much ROCKMAN's basic tutorial for newbies, less the hot sauce.

The 28" casing is 1250' below BOP. If all the casing strings were rammed up into the BOPs like indicated in article above then there might have been migration out that way. That is really close to surface.

Or was the rupture disk in the 16" casing and they know it was at that depth because that's where it was? That wouldn't necessarily migration into the formation at 6000' but still a tense situation.

I had some hope for awhile that something could be done from this wellhead but now I'm pretty certain that won't happen until after the well has been killed through a relief well.

"During Top Kill, BP put just north of 10,000 psi into the BOP, and they think they lost mud at 1000' below the wellhead because of a failed rupture disk. I guess if the rupture disk didn't work, then the casing system lost part of the design's safety factor."

Will that impact the ability of the relief well(s) to kill the wild well with mud?

Peter B,

I agree with most of your analysis but there are other pathways to explain the loss of well control.

I don't have my casing manual to hand (retired) but with gas pressure at the well head in the 9 5/8 annulus would a burst not be more likely in the outer strings? Then we would have a shallow blowout and a bigger mess.

The combination of events to have a blowout inside the casing does seem improbable viz; failure of the primary cement job/failure of the casing float shoe/failure of lower cement plug/failure to notice well coming in from depth. Your explanation would only require the failure of the primary cement job.

It is however becoming clear from BP's methodology that there is something they are not going public on and I agree that it is probably the integrity of the wellhead area. My instincts are aroused by:-

1. The attempted top kill consisted of an extended period pumping mud across the well head (never going to work on a flowing well) before any attempt was made with LCM to bridge across the rams.

2. Given the phenominal display of technology available on the sea bed no attempt appears to have been made to get the BOP stack functioning.

3. The current extremely timid approach to diverting the flow up the riser.

4. The decision to go wiith a soft seal on the riser cut rather that attaching a new BOP/valve on the top flange which would be classified almost as standard practice in this type of incident.

We have all been under pressure to do things quicker fortunately my morose nature always enabled me to tell the investor/owner/manager to get stuffed.

Ken B

Ken, I believe they think the casing failure was in the 16' casing that made up the outer wall of of the annulus in the area around 1000' below the wellhead - not really, I don't think, any different that the 60' to 90' mentioned.

BP has said they do not think the well is flowing up the production casing.

Casing and Cement and enlarges enough to read the fine print.

If the flow is not coming up the production casing then it is coming in at the annulus at the base of the 9 7/8" intermediate string, which has liner hanger chains back to the 16" which is to wellhead. There are lots of o-rings and weak spots that can pop along the way. Right now the production casing is more of an obstruction than anything; if the wellhead had integrity it could have been the best shot at cementing off the shoe.

>>It is however becoming clear from BP's methodology that there is something they are not going public on and I agree that it is probably the integrity of the wellhead area.

Ixtoc. What happened there is that they did indeed seal the BOP with a junk shot. 3 hours later, the well blew out beneath the sea floor and began flowing out around the well head. They reopened the BOP in a hurry after that.

The platform at Ixtoc partially collapsed on top of the well. I suspect that the bending loads on the upper part of the well broke the casing there. I don't know how much support the seafloor mud would provide to the casing, but I would assume not much.

The bending moments and compressive stresses generated by the sinking of the Deepwater Horizon could be quite impressive, perhaps enough to do damage to the upper part of the well. I suppose the question is how much load could the riser and drillpipe put on the BOP and upper casing? Perhaps enough to cause failure?

It's not just the sinking of DWH. Before that it exerted two days of sideways pull on the riser. I don't know how much longitudinal flexibility the riser has and how much wind and current was there, but I can imagine a 50.000+ ton rig bouncing on the waves pulling rythmically sideways on the riser. Not pretty.

Didn't they say the BOP was also at a 10 degree angle? That would fit right in this picture.

Peter B.

A rather frightening and disturbing comment; about only half of which my layman's brain can follow. Couple of questions:

1. Is no one regulating BP?

2. Is this same shortcutting and disregard for established procedure happening at other wells????

ov -- The anticipated csg design would have been submitted with the drilling permit application with the MMS. But I don't think such info is posted. But the gov't could release that data if they chose to.

Bedtime thought: "It's too soon to tell." Zhou Enlai/Chou En-Lai, in 1968 when asked by Henry Kissinger whether the French Revolution (1789) had been good or bad for France.

E L:

"Bedtime thought ..."

Thanks fer nuttin'. Now I can't sleep.

Please forgive my armchair quarterbacking... I'm just a tech geek, auto enthusiast, computer geek, and operate a wireless internet service. Just so you know, I make NO claim to "superior knowledge".

However, I'd like to run something past the nice folks who DO have experience in the field.

First, cap design... Could the cap not be sealed, not by a rubber ring, but by a lead ring around the circumference. This lead ring would deform as the cap is forced down over the flange, and squish such that the upper edge and circumference of the flange would seal tightly against the riser flange, and then be held tight by spring loaded hooks that pull the cap down tight over the flange.

Second, the cap would be SOLIDLY sealed against leak and intrusion. Now, to make sure you do not push any great additional pressure against the BOP and wellhead below it, this cap would be equipped with blow off valves. These are large flow, spring loaded valves which flow out, but not in, and hold pre-set pressures before opening. Like, 100 psi, or 50 psi. This would allow any future surges to be relieved outward, so as to not sustain any pressure spikes against the wellhead.

Third, the cap would use a pressure regulating Blow Off Valve set much lower than the relief valve, so that there's ALWAYS a small positive pressure inside the cap.

Fourth, above the pressure regulating valve (large disc, spring loaded, 18 inch diameter, that can flow big time when opened) is a manual shut off, and then above that a vent valve, and then a removeable coupler to the pipe to the surface.

When the cap is placed, both BOV's can be forced open. This means NO inside pressure, and the spring loading would place TONS of pressure against the side and top face of the flanges, to keep the lead seal securely smashed into place and sealed.

If there is a surge, or if the ship above needs to disconnect, the blow off at the well head will vent pressure until the top is re-opened or the flow catches up. Water will never intrude, because there is always positive pressure inside when no "stack" is in place above, and when the pipe is disconnected (move ship due to storm, for instance). When the pipe is reconnected, it can be lowered full of sea water, connected, and then blown down with air, pumping the sea water out until it reaches the vent valve above the one-way "positive pressure regulator) type valve in the top hat. When it's blown down, the manual vent can be closed, the ship can open up for oil, and the shut off valve above the "regulator/check" valve opened.

This could gaurantee no pressure surges, would stop water intrusion, would accomodate variable flow, and prevent clathrate formation inside the "hat", since it's sealed against water.

Rundown... sealed, waterproof, and if any tiny leaks remain, generally always under positive pressure when the pipe to the surface has to be opened.

Not one of the experienced folks.

Sealing has been discussed for days. It is a serious technical problem. In your approach, sealing with lead on the sides would be not really feasible - you would need terrific forces to seal securely with a metal seal on a ~30-40" diameter flange - damaging to the BOP. The sealing approach that has been mentioned a lot is through a semi-standard gasket to the top of the existing BOP flange, after the 6 large bolts that hold the old riser stub are removed, itself apparently a very difficult endeavor.

If you are going to seal, it then doesn't make sense to have a small pipe to the surface - a large one allows for higher flow rates and no pressure increase in the BOP, a good thing.

You can have all kinds of valves, relief and splitters, etc. somewhere above the BOP. And a quick disconnect for hurricanes and emergencies.

This approach puts a lot of risk topside. Essentially, you couple a producing facility (with people) to a wild well, with no opportunity to throttle it back. You can have a system to divert the flow quickly back into the ocean in an emergency, but to try to "produce" from this type of well is considered very dangerous.

So the current "cap" is a safer, decoupled system and provides for a lower flow rate to the ship, but can be safely closed off, without significant concern. It will not take all the oil from the wellhead, however.

My contention is that in a national emergency the risk decisions should not be made by a single company. It should be a national decision. There maybe companies out there that would take the risk of coupling to the well, in order to take all of the oil to the surface.

Producing from a wild well ... interesting.

I am wondering when BP is going to hook up the BOP gusher to a pipeline to the coast and thence to a refinery. Oil is oil, right?

Cut those bolts off that flange you morons!

This is actually the simplest solution to all the problems. Use a 36" pipeline with an adapter, I bet there is one or two large pipelines in the area underwater that Macondo can be connected to. The refinery can handle large flows of crude mixed with gas and salt water, they can toss in the oily pelicans, walruses, $10/hr laborers and dolphins while they are at it. No more leaks, BP makes money and Obama gets the glory. No nukes involved. How much does some pipe cost?

Auto use is saved and America can get back to work.

I'm surprised nobody here on TOD has thought of this before ...

Can't toss in the laborers, their bones be all crunchy.

But refineries like crunchy, they're good at cracking.

We have been told the bolts (3 and 7/8") ave very difficult to cut.

There were several suggestions for hydraulic tools.

I was wondering if the H4 hydraulically driven collet head can simply be removed by powering up the lines?

Someone posted it is problematic if it is canted more than a few degrees, but I am not sure if the previous head angle was not due to a lower flex joint.

It looked from pix of a day ago that the riser was bent inside the LMRP and BOP. The collet head was pushed up against the side of the LMRP cage.

That would make it hard to get a good connection to the top hat, seawater will certainly be sucked into the siphon as whatever back pressure they have on the floating line is reduced. The current rig appears little better than the ill- advised siphon.

By putting a flange connection they could slack off the bolts allowing a one- inch gap or slack between flanges. Add a rubber gasket between the flanges. Believe it or not, this could be cut by hand saw and chisel out of an old tire. If well pressure differential increases at the top of the wellhead the top hat would rise off the flange and pressure would vent through the gap between the flanges. If well pressure is reduced by the suction effect of fluid flow, the top hat would sit down by weight on the flange and suction would draw the two mating surfaces together against the gasket.

More flow, more suction, more pressure on the gasket meaning less chance of seawater entering the riser.

The new riser/LMRP and top hat would be a gravity relief valve. The bolts on the flanges would simply keep the parts in alignment in three dimentions as well as limit the amount of venting.

As for unbolting the flange, use of a hydraulic impact wrench would do the trick, after all the parts were bolted together in the first place! By humans with an impact wrench, not by the Almighty Gods.

http://www.imperial-newton.com/hydraulic+torque.htm

It seems as if the production phase will begin in earnest when sufficient capacity is gained through the choke and kill lines. I have to agree with the cynics who suggest that BO has little desire to kill this well if they can make some coin off it.

It seems to me pretty silly not to at least try and see if the bolts will begin to move. One at a time. If the first one you try will move an eighth of a turn, good, stop. Then try the next and so on. As soon as you come across one that won't budge you know there may be a problem but you won't have made the situation any worse by loosening any one bolt.

I wonder if one of the flanges is threaded or if they are attached by only by nuts. If it's only nuts then we're not really talking about undoing bolts so much as undoing nuts!

Since some comments by James Cameron got a lot of press, and also since the same questions seem to be asked here over and over, I thought it would be good to report what he actually said, both in the original statement that the quote was taken from, and also in an appearance on Hardball where he elaborated.

Here's a transcript of that appearance with guest host Chuck Todd, just my own transcription from the video, any errors my doing:

I think this is good to clarify for several reasons, one being that it's just been repeated that "Cameron called them morons", and the other because so many people here keep posting the same ideas that he refers to basically, drawings about how to secure the cap with clamps and so on.

I have a lot of thoughts about the whole safety and environmental impact issue, but what's clear is that almost no one just watching all this as a amateur really has the slightest idea about all the actual considerations involved, though they've been explained by experts here from time to time which is invaluable.

Having said all that, my thoughts on the safety issue are these: We're hearing about how difficult this all is, how it's like trying to thread a needle in LA while standing in Moscow or whatever the imagery is, and I'm absolutely certain this is all true. We're dealing with remotely-operated vehicles in insanely inclement conditions a mile underwater-- all of this is clearly true.

However we need to hear all this when drilling is being debated, not just now. In other words, when the decisions are being made by the country at large, that's the time that we need to hear more than "Oh there are safeguards in place so nothing can happen". We also need to hear, then, about how insanely difficult it is to fix them if a problem does occur.

My two cents, IMHO, etc etc.

Oh and here's a link to the video of the above:

http://www.msnbc.msn.com/id/3096434/ns/msnbc_tv#37518189

LOL, I'm just wondering why James Cameron has ANYTHING to say on the topic? I seem to recall his best talent is to create fiction.

That being the case, he should be convening with BP's PR team now and lawyers later...

Yeah that part wasn't important to me, what was important is that, since his comments got a lot of press, to show that once he sat down with professionals he learned just how complicated it was.

Saying that this is simply irrelevant ignores the fact that about 90% of the posts here are along the same lines as "it's a plumbing problem, just put a cap on it for Pete's sake", which he's exposing as a non-serious, ill-informed way to think about it. That was the point.

I suspect that's not his only talent. Most of us aren't limited to one.

In any event, Cameron, like all of us, is affected in more ways than we can count (and for every minute of our lives in this industrial society) by the issues under discussion and the consequences of the decisions made. That means he has a stake, and should have a voice, in the discussion.

I think he graciously, if perhaps belatedly, recognized that the problems involved in controlling this well are beyond his knowledge and skills. That sort of thing happens to most of us, now and again. I'll bet even you and I occasionally vote on issues we don't thoroughly understand.

Good points. I don't even think that belatedly is really fair. The quote everyone was hearing was from this clip where he was obviously saying "Look, as we all watch it on TV we naturally wonder if they know what they're doing, but as soon as I investigated I realized that they did".

He was relating a story about already having changed his mind, even in the first widely-publicized statement.

It's this sensationalism-oriented news media we have, chopping off quotes, grabbing the most provocative sound bytes, that's the problem.

It's been said more than once that what is happening here is on par with space flight, as far as operational complexity is concerned.

Most people no more want to know the details than want to see dead heron chicks and bloated, oily dolphins.

The technicalities, while fascinating (to me anyway), are irrelevant.

This is a money issue. Corporate oil is beholden to the shareholder. Governments' direct oversight and control has been voted out of office over the last 3 decades or so. The short answer to prevention of material release is a question:

What is the cost burden that a corporation will face, wherein an event such as this one automatically indicts the corporation of acting outside of shareholder's interests? An event of this magnitude should theoretically appear so prohibitively expensive that no corporation could risk the event taking place.

This could be something as simple as posting a 10B dollar bond on every drill site. Mistakes need to be too costly to make; corporate decision making will follow suit.

Yeah and anyone holding BP shares should be ashamed. BP has murdered workers, families, the environment and our planet.

‘Morons’ was my thought many times as I watched….

1) Cutting off riser was bad idea, but what do I know.

2) So called teams of professionals were not ahead of the game in staging

3) Not completing the job using diamond cutter

4) Using shear to cut and deform flange, scared the hell out of me

5) How they tried to cut the tab off after shearing, tools required not available

6) When cutting complete, looked like some ‘hack’ worked on it

7) The tangled hose mess before dropping containment cap

8) Now they have more flow than before

This is not a slam against ROV operators, but the big wigs running this show.

A lot of Kabuki theater eh? Or so it seems. Very strange.

As some might remember, I had put up a solution page for Deepwater Horizon. I've now updated the site to address a much larger issue, the oil driven world we live in and my solution set and vision on how to move beyond.

It is dense, version 1.0 but complete and replete with meaning. A world changing vision.

Please dive in. TOD's audience is precisely the people I want to engage.

www.squareandc.net

Regards.

Alanfrombigeasy was suggesting in the other thread that as oil-eating bacteria consume the Gulf oil spill, they'll consume oxygen, creating a new anoxic "Dead Zone" phenomenon. This phenomenon occurs every year in the Mississippi delta area, but perhaps the spill could make it worse.

Interesting idea, but as far as I can tell nobody's done the chemistry to figure out if the effect would actually be significant. After all, there's a *LOT* of water out there.

So I just did. Here's what I found: keep in mind this is back-of-envelope.

Petroleum is basically repeats of CH2 of varying lengths. Some molecules have a few extra hydrogens, some have less, but the typical C:H ratio is 1:2.

Let's take the worst-case scenario, and assume that metabolism totally oxidizes the petroleum. Either the petroleum-eaters themselves do this, or they use petroleum to build biomolecules, which oxidize when some other organism uses the bacteria for food. The schematic reaction looks like

CH2 + 1.5 O2 = CO2 + H2O

1 mole of CH2 weighs 14 grams; 1.5 moles of O2 weighs 48 grams. Therefore, the ratio of petrolum consumed to oxygen used is 1:3.4.

Using a "your guess is as good as mine" well outflow rate of 20,000 barrels per day, the petroleum supply is 2.7 million kg/day. This could potentially consume 9.3 million kg of oxygen per day, or 420 million kg so far.

In the subsurface Gulf of Mexico, "normal" oxygen levels are typically around 5 mg/l; decrease to 1 mg/l will kill fish and other organisms.

To decrease oxygen levels by 4 mg/l, we need to remove 4 million kg per cubic kilometer of water. Using the flow rates above, that means that, if it's entirely consumed by bacteria, the BP oil spill could potentially create an oxygen "dead zone" at a rate of 2.3 cubic kilometers per day, or 100 cubic kilometers thus far.

For comparison, a typical summer Gulf "dead zone" covers about 15,000 km^2 over a depth of 10 meters, for a total volume of 150 cubic kilometers.

The upshot: if totally oxidized in the water column, the oil spilled into the Gulf so far could create a new anoxic "dead zone" similar in volume to the one which already plagues the Gulf of Mexico. However, it would probably have somewhat less ecosystem impact since it's farther offshore, in deeper water, covering more depth and less area. Still, Alan's suspicion is right: it's potentially a big deal.

That sounds and "feels" as if it might be in the ballpark (way outside my field of expertise, but am basically scientifically literate).

Are you familiar with the surveys the Walton Smith Science Party, from the University of Georgia, et al. is conducting?

See:

http://gulfblog.uga.edu/

Oh, I should mention one important caveat: we have very little information on how much water the petroleum is mixed into. The math above assumes a worst-case scenario: if the oil is mixed into 5x as much water, the amount of oxygen depletion will be too small to affect marine life; if the oil is mixed into 5x less water, the anoxic zone will be much smaller.

Still, this back-of-the-envelope calculation suggests that there's enough oil to have a significant impact on the redox state of large parts of the northern Gulf of Mexico.

Kalliergo, thanks for the link to that blog. I'll point out this figure, which shows a significant decline in oxygen levels in areas with signs of petroleum. It's nowhere near enough to kill fish yet, but there's plenty of petroleum left to be eaten.

Thanks for doing some numbers and adding facts to the issue.

You must have missed clarity's post and my reply yesterday in the natural seeps thread:

http://www.theoildrum.com/node/6552#comment-639009

They guessed (low) on the hydrocarbon:oxygen ratio - you did the numbers as reasonably as I for back of the envelope calcs.

You numbers check out - yes, it is a concern, locally at least.

From the 643 x10^15 gallons in GOM I get 2.44 x 10^6 cubic km.

So 100 km^3 is "only" .000042 of the GOM.

But to the animals that find themselves in the hypoxic mess, stressed is stressed and dead is dead.

Also, Rabelais et al (thanks for the link) assumes 2 ppm as the threshold for the onset of hypoxia,

so things are a bit worse from that standpoint.

Fortunately, a lot of the spill evaporates soon.

Unfortunately, a lot of the methane stays dissolved, and I haven't bothered to calc that, since I've lost track of the Gas Oil Ratio discussion from weeks ago, and too depressed to look for it, fearing the methane might be even worse.

Fate & Behavior of Deepwater Subsea Oil Well Blowouts

http://www.mms.gov/tarprojects/287.htm

Some more links on O2 in the GOM:

A blog from Dr Samantha Joye, who helped break the issue:

http://gulfblog.uga.edu/

A paper on winter water mass distribution in the GOM

It has some graphs of oxygen distribution by depth.

http://www.terrapub.co.jp/journals/JO/pdf/5005/50050559.pdf

n.b. their numbers are in winter, so colder water == more O2 capacity.

More papers than you'll want to read on:

Physical Behavior of Oil in the Ocean

http://www.mms.gov/tarprojects/120.htm

Thanks to both of you. I know they're busy out there, but dropping Mandy Joye a short note might be appropriate.

From CNN:

>>> On Thursday, Allen acknowledged "some anecdotal reports from research vessels from universities that have found dense plumes or what they believe to be plumes under the water.

"We're in the process of taking samples and trying to figure out what they are," he said. "They're denser than the water, but we're not sure whether it's oil or not." <<<

http://www.cnn.com/2010/US/06/04/gulf.oil.spill/index.html?hpt=T2

Having been following Dr. Joye's and her colleagues' reports, I think I'd bet that it's oil.

I agree that this calculation is broadly correct, but in my opinion it is far from clear that petroleum degradation will be complete. I remember reading a publication that implied that mineral nutrients are the limiting factor in oil-devouring microbes growth.

So it could well be that oxygen levels will fall only so much until further depletion is stopped by lack of nutrients. Wish I could remember which journal it was - probably Environ. Sci. tech., I'll have to look it up.

Good analysis, thanks!

There is another difference between the the oil spill and the annual hypoxia from agricultural runoff. The agricultural runoff flows down the Mississippi and is most prominent in the shallow waters and at the surface. It occurs because the fertilizer causes the plants and plant-based microbes to grow like crazy. But plants produce oxygen - right? The problem is a second order one. The microbes that consume the plants also go into overdrive but they use oxygen, and this round is what wins so in the end oxygen is depleted and all oxygen using organisms die. The plant-based decline also occurs as plants consume all of the other nutrients and sunlight.

So, it's a classic overshoot and recover phenomenon. On the positive side, shallow water is quickly refreshed and the plant based organisms eventually return the system into balance.

The problem with the oil spill is that there is quite a bit of oil at very low depths. Microbes will consume the oil, using oxygen in the process, and a dead zone results. But the healing process is much more difficult. Deep waters don't churn as much, so getting fresh oxygen thousands of feet down takes a very long time. And, since it's dark down there, plant-based organisms can't do their part.

The flow has changed and unfortunately not for the better. BP is spraying the dispersant.

It would seem they either lost or decided to throttle back the siphon line.

I have a Q for avonalterndorf.

Short form: Could you describe for us what you saw re the sea floor I believe recently? You seemed to think it backed up the Simmons claim, which if true I imagine anything else discussed here about this incident pales in comparison.

I tried to open the link you posted at the time but I couldn't get a functioning page. Someone seconded the sighting I believe a lot earlier today..?

There hasn't been much follow up on that from anyone else and to be honest your description at the time was understandably terse. What did you see and was there any sense of scale? Just hydrates? Spewing up or just raining down? In (a) cluster(s) or distributed over an area? Any actual visible oil/gas mix? It's not clear to me what you saw exactly let alone how that'd be interpreted correctly.

I think if you fleshed that out it'd be good. I've been following the threads so closely lately in hopes there's be some follow up on that, supportively or debunking. Seems (extereme understatement) important.

I second that request quzmasterchris. I too have been hoping for followup and or extrapolation on that story.

As to how important it may or may not be, I do recall a week or so ago stumbling into some info regarding a good number of "seeps" in the floor of GOM. I do not know if that is of any relavence.

I have twice looked at the feeds avonalterndorf suggested. Both times, by the time I was watching, the ROV's had moved or ascended. I saw nothing of interest.

So, please do tell us more, if you can. And, if anyone has screenshots, we'd all really like to see them.

herc 6 was on the floor late last night for about an hour...instead of dispersant ops it said something else ops...dont know if that is helpful

I looked at it, ROV was handling another big yellow item. It had a big pipe opening at the top like the top hats. But it was different, it appeared to be bolted together lengthwise. My first thought was it might be a top hat which could be assembled over the BOP upper portion, don't know if it might be called "hinged". I really do not know what to make of it, not proposing anything, just describing what I saw only because you asked. It is very difficult to grasp the SCALE of anything in these pictures, there is seldom a frame of reference, is it big and far away? is it close and small?

did it look like anything in the Q4000 direct connect?

(page 7 of the Technical Update):

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

Or the bottom of the long term (pg 8).

They're extending the hoses to use the top-kill manifold to allow some of the oil/gas to go up to the Q4000 drillship, since it already has a connection from it's pipe to the pressure hoses.

I guess they want it further from the DE when they're both flaring stuff.

explanation at 08:05 in the technical update of May 31.

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

It's not clear to me what you saw exactly let alone how that'd be interpreted correctly.

Agree. You're either dead wrong, or on to the biggest news since the rig sank. Carl Sagan is in the back of my head, saying "extraordinary claims require extraordinary evidence". In particular, what did you see that makes you sure you're seeing petroleum, and not silt kicked up from the bottom by the ROV's thrusters?

Enterprise ROV2 is spending considerable time staring close range at the H-4 hydraulic coupler. I bet they read The Oil Drum and are considering finally removing the entire upper junk.

A quick thanks to all the industry experts who have helped bring clarity to an incredibly complex situation. Your help in understanding the situation has been, in word...Priceless.

A question looking forward to RW intercept and the "bottom kill" process.

If the source of well failure is NOT the bottom shoe and is instead a casing failure far up the well string close to BOP, will a "Kill Pill" be effective in sealing a breach in the tapered string seal far upwell without the benefit of mud weight in the exterior of the tapered casing? Put another way is there enough volume and access (thinking cementing barriers) for mud weight to be effective if leak is outside of the production string and venting at top of anulus near BOP? (As per scenario 2 in HO post on congressional diagrams yesterday early AM).

Not to play worst case scenario, but how would you get mud up between casings with cement barriers limiting flow path?

==BP Chief Operating Officer Doug Suttles told U.S. TV networks the containment cap placed on the well pipe a mile below the ocean surface "should work" by capturing upward of 90 percent of the gushing crude. He said it would take a few days for the system to reach full performance.==

I would agree. If they can capture this high a percentage, the operation would be well worth it. I gave them a 50%+ as a criteria that would be considered very worthwhile.

At this point, though, with well over a day of operations and barely a 3.6 kbd rate achieved (25%, maybe) and a recently noticeably increased bottom leak rate, with the "Cap" jumping on the BOP again, I would assess their declared goal as aspirational at best.

That they never went for the proper solution, as you have been pointing out for a while now, by removing the riser at the flange says that they were never serious about capturing 90% of the oil. All the claims that removing the bolts is "impossible" is a load of rubbish. They could have ground them off even if it took a week (clearly using circular saws at this depth poses no challenges).

It is not surprising that they are capturing about as much oil as they did inserting the 4" pipe into the riser a while back. Without a proper seal the oil will not converge into a constriction.

anyone catch that blob BOA just flew threw

what depth are those two?

This looks like the mystery burst disc, Patented by Dril-quip

An interesting point to me is that this well was planned an "exploration" well, yet it looks like then were planning on it being a producer from the beginning.

Greetings from a physicist from Germany, and many thanks for this great amount of knowledge made public!

I have one question: Did they ever try to pump compressed nitrogen down the riser pipe? This should displace all water in the pipe, and after the water is displaced they could depressurize the pipe again and at the LMRP-cap an almost vacuum of minus 150bar (ca. 2000psi) would suck in everything. In principle you could create this way a "blow out" from the damaged riser to the sea surface by replacing heavy seawater with light air.

Even klathrates should be destroyed by this pressure difference.

Greetings for a rocket engineer in oily America!

BP's video said that they plan to do that and I suspect they did do that to start the flow, which they started, albeit at not very impressive numbers.

Keep in mind that a turbulent, multi-phase flow, like one coming from the well is very difficult to channel and contain into a single, narrow pipe.

I hope they succeed, but have grave doubts.

Yes - That was the original plan for placing the top hat.

that was their plan, per this video on the BP site:

(in the "Response in video" section).

It's a silent video:

http://bp.concerts.com/gom/lmrp6_060310.htm

Shows pumping hot water, use of methanol, and pumping nitrogen pumped down the drill pipe to keep it free of water. Once the cap seated on the BOP, they show the oil displacing the nitrogen.

As Dimitry says, it is generally believed they purged the riser with N2.

Many, perhaps most, of our best independent experts here believe this assembly should be able to capture a large fraction of the O/G flow and, eventually, lose relatively little through the loose seal between the cap and the cut-off riser stub. And their arguments make sense to a non-specialist with a scientific approach to analysis.

However, Dimitry's concerns about turbulence and a multi-phase flow aren't easy to dismiss, either. And we're 24 hours or so into this exercise and I don't believe the escaping gusher is reduced in volume. Indeed, right now, it looks worse to me than ever. Of course how it "looks to me" is entirely subjective, but... I don't think overconfidence is warranted here.

Anyway it would have been very astonishing if the experts hadn´t thought about nitrogen, so thanks for the video!

Turbulance is surely the biggest problem. If the hat is small, you have extreme turbulances, if the hat is large you have methanhydrates. Does not seem to be easy to find the optimum inbetween without any experience. I don´t know if there readily is simulation software which can do chemical bonding and hydrodynamics at the same time.

For what it is worth, I expect the "top hat" to be overwhelmed by production. The capacity of the Explorer and the 6" pipe from the top hat are less than production and they will only get a % of that production. Perhaps half at a wild guess.

Future production from the choke and kill lines (higher pressure below the BOP restriction (or what is left of it after sand erosion)) going to a second vessel may get the large majority of production.

One needs to remember that "production" is oil, gas and likely some formation water.

Alan

Something else bothers me here. Don't oil wells usually produce water along with the oil? If that is the case then hydrates will form as soon as the temperature gets low enough. Gases cool when they expand, so the 6000 psi pressure drop across the BOP should provide substantial cooling. That could overwhelm the methanol injection and clog the pipe.

Maybe that's the reason the leak looks a lot worse for the last hour.

I agree, it looks much worse now than it did for the last 4 or 5 hours. There appeared to be some visible improvement earlier this evening.

Past performance is not indicative of future results...

I have noticed the same. When I went to bed the leak had clearly decreased, but now it seems to be as large as it was when the containment system was just lovered into place yesterday.

Steinar

Sometimes - but not this early in their life. If there is water in the formation then it will below the hydrocarbons.

Also, a lot of the water that comes out of some wells is water that has been pumped down into the formation. This is done with older wells in order to boost the production of the formation.

I agree with Exadios, hopefully it's not producing much/any water at the moment.

I don't think we've heard an official gas-oil ratio number,

so it's hard to say what the "bubble point" of the methane is, and thus where in the system bubbles start to appear. Only then can their expansion cause cooling.

And note that some of the gas will still be in solution in the oil phase, and won't contribute to cooling.

And the hot oil would heat the gas up a bit.

Obviously, within the riser it's not forming hydrates, or over 45 days it would have slowed down.

Out in the chilly sea-water, at "only" 2250 psia, is a obviously a different matter...

As A Curious 54 year old Please Could Someone Tell Me What Percentage Of(SEA) Water Would Be In The BP Estimates Of BARRELS OF OIL COLLECTED.....Presumably They Are Collecting Oil AND SEA WATER.....So Surely The TRUE FIGURES HAVE TO BE FURTHER DILUTED So To Speak?

There are a number of ground rules you should understand:

A - the safety of the several hundred men working directly above this well is an absolute priority.

B – the laws of physics must be obeyed, not my choice, just immutable fact.

C – If what you do increases the spill you haven’t done any good.

D – cost is no object, well maybe if it is $100 million or over, but then BP would pay $100 million in a heartbeat if they could stop this spill.

Your points -

1 – If you have a better way to keep the oil out of the water than “producing” it, ie getting it into a tank on a ship; I’m eager to know what it is. Bringing the oil and gas to the surface in an uncontrolled fashion is just starting another blowout with the almost certain probability of explosions, fire and death. It has to be brought to the surface in a safe manner, with minimal risk to personnel, and that means piping it into processing and separating equipment, in other words producing it.

As discussed previously in these threads the commercial value of the oil recovered is peanuts. If you considered only the direct cost of recovering the oil without any of the environmental or economic damage, it is still far greater than any possible value of the oil recovered.

2 – I would assume that if there was a way of increasing the processing capacity on the Discoverer Enterprise then BP will have done it. A lot might be done now that they know the make-up of the flow from the RITT. In addition they plan to start “producing” (that is the proper technical nomenclature) from the choke and kill line to a second vessel. If you watches the video feeds last night you saw an ROV holding the handle of a valve that was blowing oil straight up in the air. The choke and kill line are each the size of that valve.

3 & 4 – If you are going to attack my work please at least do me the courtesy of reading it first. If the well head to BOP connection was to break you would increase the spill as much as 100% and greatly increase the difficulty to catch and recover it. The same for a major shift in the BOP internals. And if there was a rupture on the casing below the mud line then you have the worst case scenario, a totally uncontrolled blowout from below the mudline, probably twice as much as there is now and absolutely no way to recover or stop any of it until the relief well is completed.

All of the equipment and piping down there saw pressures during the blowout that might have been double their working ratings and the entire stack and wellhead were yanked on for two days by the rig before it sank. They are in an unknown condition.

By the way, one of the alternatives recently discarded was to attach another BOP on top of this one which would allow a complete shutdown of the well. That was rejected by people who have much more detailed knowledge of the condition of the BOP, wellhead and casing than any of us. The only logical reason to not put the second BOP on was the possibility it would make the situation worse.

The top kill and junk shot may have either contributed to the overstress or gave BP and the MMS some indication that things were not right. I know there is a group, including experts on this board, that didn’t think they should even try the top kill or junk shot due to the safety concerns.

5 – Anchoring the wellhead is a great idea but let see how practical it is. The hold-down force required is about 3,000 tons using a minimal 25% safety factor.

If you used the minimum number of anchors to achieve stability and save time you would need three. These would have to be drilled as the depth to even reach rock is over 1,000 feet and to reach solid rock and set a 1,000 ton capacity anchor would probably require about 2,000 to 3,000 feet of drilling. Luckily we have a drill ship on site and we could use high strength drill pipe as the anchor string, I believe it is capable of a 1,000 ton axial load.

Of course during the drilling any ongoing oil recovery operations would have to cease. There is only room for one drillship, and to setup, drill, install and cement the anchor in 5,000 feet of water would probably be at least one week per hole. Allow another week for the initial mobilization, design and fabricate the first anchor and a final week to install the rigging, valves, and so on – all with ROVs. So a best case of about 5 weeks, during 4 of which there is no oil recovery. Your choice.

*****

People have a right to be angry about the blowout and the spill.

They have a right to be angry about the lack of preparation for emergenvy intervention in 5,000 feet of water.

From what I have seen they may have a right to be angry and frustrated about the onshore clean-up, at least as presented by the media.

But there has been nothing "cutesy" or “fussy” about the effort to stop the blowout or recover the oil. That perception is being fostered by the media and politicians who don’t take the time to understand anything about what they are saying, never bother to admit when they get it wrong and continually malign and disparage the engineers, technicians and offshore hands working trying to stop the leak.

They bring in “experts” who don’t know the pointy end of a boat, have no underwater experience and don’t know anything about the oilfield. The greenest of offshore diver/tenders can pick holes in their statements.

Publicity hounds like James Cameron jump on the band wagon and call people morons without the slightest understanding of what is involved.

If the American public were given the facts and the media took the time to help them understood the immense engineering and operational challenges presented by trying to control a 10,000 psi blowout in 5,000 feet of water they could actually have a portion of this disaster that would be positive and something they could be proud of.

It’s an undertaking that dwarfs any emergency engineering project that the US has had since Apollo 13. In size and complexity it even dwarfs that.

As long as I’m slagging people I won’t leave out BP who could have opened this effort up to the world, warts and all, and shown what an amazing effort it is.

To paraphrase an earlier post:

“For every complex problem there is an answer that is quick, simple and wrong”.

Forgive me if I seem to be coming on pretty strong but tonight I learned that most of the vessels and rigs working on this project have turned their TVs off. The crews working to control this well were getting so depressed and demoralized watching the misinformation, slander and outright BS from the media, politicians and instant experts that it was starting to affect their work. Believe me those people out there who have been working 12 to 14 hours per day, every day since April 20 doing everything they can to stop this spill don’t deserve this. Very few are actually BP employees, almost all are subcontractors.

Three men, a least one who used to work for me, were on the Deepwater Horizon when it blew up. They did not even go back to shore to see their families. They went straight to an ROV support vessel to try to get control of the BOP. I repeat - THEY DON'T DESERVE THIS.

Incidentally, I’m not from the oil side, I spent nearly 40 years in the underwater service industry from heavy gear diver and diver welder to project management, engineering and most points in between. Before I retired I was running worldwide operations for the largest diving and ROV company out there so I actually know whereof I speak

As about 90% of all the deep water work in the world is for offshore oil I was forced to learn a lot about the oil industry, and I still learn everyday courtesy of people like Rockman and the other drillers on this board.

Along the way I worked in the North Sea and lived in Aberdeen so I also know the true meaning of “with all due respect”.

I had a few martinis tonight in honor of an old friend who died this morning, martinis were his favorite, but I hate them – so I quit, I’m off to bed.

Very nicely put. And sorry to hear about your loss.

I had always been told the reason all decisions are made on the drilling or production floor is that the first area to blow .. tends to make safety somewhat more a concern since your bad decision will blow your own ass up and this includes the client. Not to say that bad decisions/calculations are not made but to think that someone is going to totally disregard safety when they are sitting on top of something that can explode is assine.

Never worked for a drilling company, my offshore projects were on the production side, subsea trees, topsides and spars. Once they were engineered, built and installed my job was complete but my health did not allow me to be there for "start-up" on the rig.

Ah, the things we do for our friends.

That was a helluva good post, and rather restrained, considering. Anyone here who has felt the need to criticize or insult the folks fixing this problem ought to read it through a couple times.

On a lighter note, the bright side of bucket's post is that "gasketing...[with]...Interlocking heavy concrete pads, with multiple packing structures, etc." is at least another couple pages for landrew's book.

oilfield brat: I've been trying to get into landrew's book, but I haven't succeeded because he's such an inconsistent dip. I offered him sinking a quantum battleships consisting of photons and creating a black hole to suck the oil up out of the leaking well (he claims to have worked on that Large Hadron thingy, you know), but he just keeps ignoring me. And he thinks he's knows how to write a book. Give me a break. He's just science's answer to Kitty Kelly.

Not having been in the oil industry (other than one year freezing my ass in Norman Wells) I've avoided commenting on some technical matters but it does seem to me that one can dismiss some of the criticisms for being absurd on simply based on knowing humans.

Take the whole "just unbolt the damn flange and make a tight seal" foot stamping:

We know that they were planning to install a second blow out preventer. So they believed it possible to part a pair of flanges somewhere.

Yet they don't do so.

Thus they are such either dribbling idiots that they've not realized that they can do it as part of this operation too or they don't think the benifit justifies the cost.

I find the second a wee bit more credible.

As has been explained, there are good reasons for not wanting a tight seal, including protecting those above and the well below. Unbolting could be a non-trivial procedure. Break-free torque can be an order of magnitude greater than tightening torque- especially after the assembly has been wrenched and especially as some super Locktight is reportedly used in such assemblies. If you think folks are frustrated now just try them after three weeks of breaking off bolt heads and drilling bolts.

Time is critical. I'd wager that the current effort is judged to be the fastest way to a seal that is good enough.

People who don't realize that "with all due respect" is an insult are irritating.

If Americans had been told repeatedly that a leaking well in 5000 feet of water produces an engineering challenge that eclipses the Apollo 13 challenge by a long shot, what percentage of Americans would have supported drill, baby, drill?

This is a hell of a way to learn about the engineering challenges.

We simply don't want to hear this apologetic s**t when everything has hit the fan.

shelburn: "If the American public were given the facts" Yes. But there is a very nonscientific problem with BP here. BP's top British officers are used to working in a different "informing the public" environment in Great Britain. British corporations are not expected to release and do not release much information to the public in Great Britain in the aftermath of a disaster. Most information about a disaster, which the public in the US feels it should know, is kept private until a public inquiry at a later date. One of our British friends, who is familiar with the release of corporate information to the public in GB, can explain this a lot better than I can. But I do know GB has a different set of expectations and standards for the release of information. And Hayward grew up operating in that environment. Such are the difficulties of international corporations working in a national environment different from their native environment. Facts are knowledge in the scientific community, but facts are money in the business community and facts are the weapons of power in the political community just like guns are. And if I have a gun and you don't....

Edit: I apologize for not expressing my sympathies to you about the passing of your friend. I hope he had a good and satisfying life.

I found your post very enlightening as I've been puzzled over BP's lockdown on information flow.

Oh yeah, after decades of "money is time" you guys are all "victims"?! No friggin way, you GUYS caused this s**t with your swaggering "texas" style c**p. Compared to North Sea, I'd bet even you would say, it is from a different PLANET, when it comes to safety.

And compared to Pluto , your ice is dripping ...

Cool down oke ?

Quite hard criticism:

http://dailyhurricane.com/2010/06/my-industry-should-be-ashamed-of-itsel...

"..Very early on in my career I learned that the industry I had chosen, though I loved it, was dominated by the macho myth of big iron, big rigs, wild wells, and wild men. I was swept up in it myself, pushing my own personal limits; my efforts propelled me quickly up the ranks, but my aggressiveness was one of the causes that lead up to my losing battle with the pit fire. Rules were made to be broken, and money was A-1..."

Wondering something about the oil coming up. I keep hearing about the temperatures of the oil 5000 ft down. What temperature is it at when it gets to the tankers at the surface? Is the tanker above the LMRP just a feed to other tankers? How is all that oil off-loaded?

temperature:

depends on how much gas is in the oil.

Free gas bubbles expanding will cool things, and could

cool them a lot. But they're pumping warm surface water down the riser around the drill pipe they're using to bring up the oil. So the final temp is probably close to the water surface temp - which I'm being too lazy to look up since I'm headed to bed soon.

The "tanker" above the LMRP is the drillship Discoverer Enterprise.

specs:

http://www.deepwater.com/fw/main/Discoverer-Enterprise-61C17.html?Layout...

description:

http://www.deepwater.com/fw/main/Discoverer-Enterprise-141.html

It has an oil storage capacity variously spec'd at 125,000 - 130,000 bbls.

It will be emptied into tankers as needed, by hanging a big hose over the side.

Wow. The Skandi ROV1 just finished a close inspection of one side of the BOP down to the well head. Wow. No hydrocarbons evident. ROV2 is hovering over the package and doing a 360 around the well. The camera is filled w/ shadow covering the middle--clearly an oil-gas mix is spewing out from all sides below the "top hat". BP is trying to attempt a fire hose to fire hose connection w/ the outlet 5,000 ft up through a small pipe. Getting the majority of this well contained is going to take a whole new level of engineering. Hopefully that happens before the relief wells arrive.

Well I used to be a big fan of Obama, but he seems to have completely lost the plot to me.

As a leader he needs to identify the critical problems, which are the oil leak and dealing with the slick on the surface, and focus on them. What I expect to hear from him is "I approve/I don't approve of BP's plans to deal with the crisis"...if he doesn't approve he needs to say why and what should be done. I also expect him to be saying to BP "What do you need? you say what you need and I will make it happen". He should not worry about cost, he can always get that back from BP afterwards.

It seems to me that Obama doesn't understand how to deal with a crisis and that is really worrying. He says he is responsible and the buck stops with him, but he clearly doesn't believe it. He is wasting time blaming BP, that contributes nothing to stopping the leak or keeping the coast free from oil. We have to wait for the enquiry to find out what really happened and who we should blame, we shouldn't prejudge that, for now Obama please focus on the critical problems.

But i rather agree w/ his statement that BP is able to spend big bucks on ads and dividends, but nickle & dime the clean up workers and the GOM fishing industry

The left wants Obama to throw a tizzy fit, take over BP and turn it into a windpower enterprise. The right wants Obama to ummm... fly in with his cape and tights on so they can use him as target practice (actually I think the right doesn't know what the hell they want from the government). I don't know... maybe he's about where he should be on this issue.

Obama may be as misinformed as the rest of us. First it was the cofferdome, then the mini-cofferdome, then the top kill, then the junk shot, and now this -- and I may have missed a few.

On every occasion we were led to believe there was a good chance of either stopping the leak, or capturing nearly all the oil, only to find out there was an abysmal failure within hours (except for the time we were kept in the dark for sixteen).

Now we have seen the results of this and it looks like another fiasco.

Until yesterday, I was still under the impression that this well could be capped. Imagine my naivete. I actually thought terms like "top kill" meant something of substance.

Now the experts here tell us it would be too risky to cap the well and we are now being told on this board by the experts that this engineering debacle is far more challenging than Apollo 13.

How on earth is any politician supposed to make intelligent decisions when kept in the dark? Is it any more likely he's being told what is going on than we are?

I wish Obama would do more as well. But what could the President have done during Apollo 13 to save that mission? Not much.

Someone mentioned that it looked like a hack job was done on the riser with the shears, I didn't get to see that and I checked around for some footage but could find any that were working (a lot of the live feed cams I got to don't work.) Anyhow I thought the diamond saw was doing a good job making a pretty smooth cut too,how far did they get? I thought it was about 1/3 of the way. It reminded me of cutting through 4 inch no hub pipe with a sawz all, guess what happened frequently? the saw blade broke; do you know what I did? I put a new blade on and finished the cut! WHy didn't they try replacing the blade at least once and see how much further it would go, they could of worked there way around the cut and if they got at least another third of the way through before the blade broke again and if it did they could of went for a third blade. The cost of $100,000, I think that was a figure I saw, doesn't seem like a lot for a billion dollar plus botchjob remedy.

The idea of a lead gasket sounded good too, I picturing a hub type end with a lead gasket retained by a lip that would fit tightly around the neatly cut riser,a strap similar to a no hub connector could increase the seal if the hub was able to be compressed. We'll see how what they did turns out, maybe they should of tried the diamond saw again and even the circular saw they cut the smaller pipes with could of been used to saw any nub remaining when the cut was almost completely through.

I realize how much skill and knowledge is required in drilling operations but c'mon when the tools they are using are analogous to everyday power tools and workshop hand tools and they are trying to connect to a bent pipe with basically whatever pipe fittings that the engineers working on the job think will be the best then basically they are doing a mile deep plumbing job trying to connect to a super high pressure flow. Maybe next time they should cement the hole with 2000 gallons of JB Weld and give it the full twenty four hours to cure! LOL

2:14 am PST, 4:14 CST

Seeing more yellow of the side of the LMRP cap on

Enterprise ROV2.

Looks like the cap may be jumping around a little bit,

but the ROV is for sure, so even when I hold up a pen to reference the LMRP cap against the BOP (which hopefully isn't jumping around!) I'm not sure home my the LMRP cap is bouncing.

Would be nice to have the cap made with 10" thick steel walls - guess that's a month away:

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

Hope it gets here before any hurricanes do.

Skandi #1 still spraying dispersant.

Skandi #2 looks like moving the dispersant hoses and manifolds around.

'night.

I'm fearing this is starting to look like a failure. How may hours is it since the top hat was deployed? Didn't they say it would take 12 to 24 hours to establish maximum flow after deployment? I think we should be about there now. So with all that oil still leaking under the top hat I'm getting very dubious to this top hat solution if nothing changes very soon.

Steinar

Good article in today's Times on what to expect

http://www.nytimes.com/2010/06/05/us/05capture.html?hp=&adxnnl=1&pagewan...

As a European, I've been following this insident closely, as I belive the impact of the disaster wil cahnge the way we look at oil as our primary engeysource.

I'm stunned with the lack of foresight within the oilindustry. As oilcompanies drilling in europe work under more strict rules as to prevent situations like this, it's unbeliveble, at the US allown BP to do deep sea drilling under less restrictions than we do in europe.

I hope, that goverment will now force the oilindustry globally, to establish and pay for at taskforce to handle oilspills and blowouts. Develop teniques to collec oil from the sea, develop new safety regulations, and focus more on protecting the environment, than on profit.

I also hope, that when this mess is finally cleared up, some time next year, that the US bann BP from operation entirely in all of the united states.

Having gone through a lot of material on this incident, it stands clear to me, that BP officials skipped several "normal" procedures" to save time (money) and thus cretated the possibility for this disaster.

I my mind it also stands clear, that the wellhead / BOP are so damaged, that plugging the well from above is not an option.