BP's Deepwater Oil Spill - The Saw is Stuck, Working on the Riser, and an Open Thread

Posted by Heading Out on June 2, 2010 - 9:19am

Please transfer discussion to http://www.theoildrum.com/node/6562.

There has been a lot of activity at the bottom of the Gulf today, not all of it immediately successful, but all working toward the current aim of being able to field the Lower Marine Riser package. That installation requires that the broken existing riser that connects to the Blowout Preventer (BOP) has to be removed. The bent riser has been exerting some lateral pressure on the BOP, and this might be relieved when it is cut off. To minimize the damage, the first cut is therefore going to be further down the riser, provided that they get the saw "unstuck."

(My post continues after the video. Please click, "There's more".)

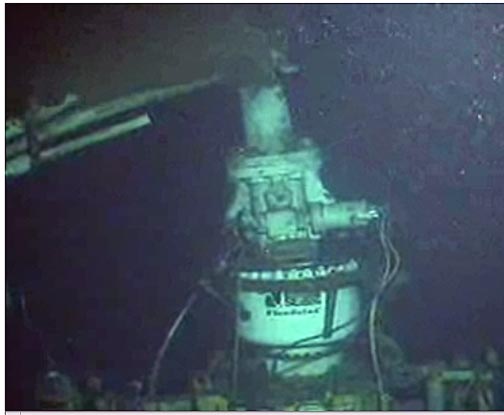

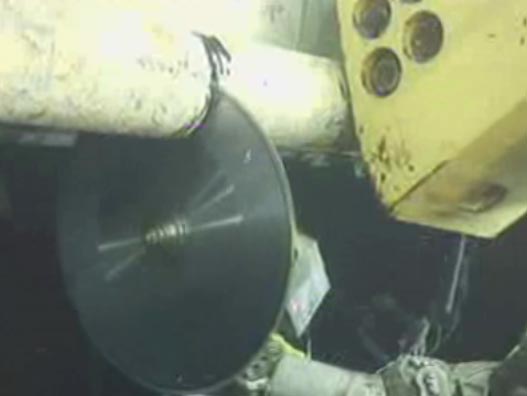

I described the plan of attack in an earlier post, and what has happened, over the course of today has tried to follow that script. I say tried, because there have been a couple of glitches that developed over the course of the day. The large shearing machine (apparently owned by BTI) appeared on the scene, and in preparation for its use some of the pipes surrounding the main riser (the choke and kill lines) were first cut away using a diamond saw.

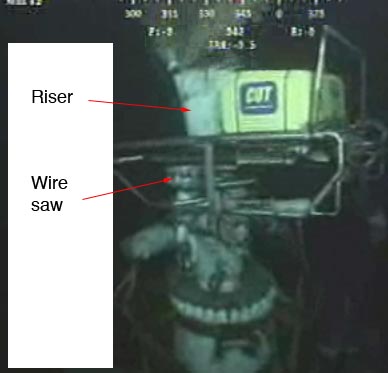

At the same time that this was going on, the wire saw that would make the final cut on the riser had been brought down to the site. The riser assembly has been cleaned of extraneous pipes already, and the wire saw would fit about the flange and below the bend.

It was now time for the shearing machine (which I’m going to call a Shear from now on) to fit around the riser and to make the first cut through the pipe.

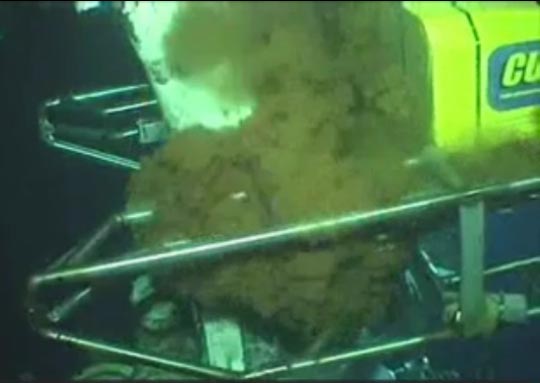

Unfortunately the first cut did not appear successful, although there was a cloud of oil and gas released, indicating that the riser was at least breached. There was a pause, and the Shear moved to a new location closer to the riser. Again it tried to shear through the nest of pipes, that now included choke and kill lines. It was not successful, and returned to the surface where it was fixed, and returned to the site. UPDATE 1: Having written this post and not seeing much happening I went off for a couple of hours. On my return (and before Gail posted it), I did not check again and as the notes below show, the Shear worked at 7 pm. At 10:15 pm the wire saw was cutting through the riser. I apologize for the errors.

END of UPDATE 1 UPDATE 2 below> In the meanwhile, a little calculation, based on reports that the White House has announced that the removal of the riser and drill pipe that are protruding from the Blowout Preventer (BOP) of the Deepwater Horizon well in the Gulf may increase the amount of the petroleum leak by 20% when the riser section is removed. There are two immediately obvious reasons why this might be the case.

The first of these is that there is a small amount of oil that was leaking up through the drill pipe that extended beyond the broken riser. That flow was one of the first things capped in the remedial effort. It did not have much impact on the overall flow volume, since the flow merely backed up and increased the flow through the main crack in the riser, but there may be a small increment of flow when this channel is re-opened with the cut below the fold in the riser.

The greater change in the flow, however, will likely come because the riser and DP, while not providing much increased resistance, did raise the pressure on the downstream side of the BOP by about 500 psi. We know that though the pressure down at the formation was at around 12,000 psi, up on the upstream side of the BOP it fluctuates in the 8,000 to 9,000 psi range. The higher resistance on the downstream side, reduces the pressure drop across the BOP by that 500 psi, and the flow rate will be reduced accordingly (the gap size through the BOP is assumed not to change).

However, if the pressure drop across the nozzle was at 6,000 psi in the current condition, (which with an orifice size of 0.6 inches, would give a flow rate of 512 gpm), then raising the pressure drop by 500 psi would only increase the flow rate to 532 gpm, or a difference of 4%--which might suggest that there is something about the drill-pipe flow that was initially capped which we don’t know yet. Alternately it may be that they think that removing the bend in the riser might ease the forces on the BOP, relaxing the metal a little and increasing the orifice size. After all it has only to open up by another 0.05 inches to give the increase in flow that the White House are predicting.

UPDATE 2: Sometime about midnight it appears that the cutting wire stopped moving and may be jammed in the cut, roughly half-way through.

UPDATE 3 I went to bed and have just checked the comments and it does not appear, at 8:00 am that the saw restarted, and finished cutting the riser. At present the ROV is looking at the end of the riser, and the Shear. Oil and gas from the cut seems to be coming up around the end making it indistinct. Does anyone have a better version of what went on overnight?

UPDATE 4: On other feeds they are showing that a second cut is now being made by the wire saw, but the camera is further away. BP is predicting that the cut will be completed today and the LMRP installed. But it doesn't look good that they are still working with the Shear, because they can't use that for a final cut, and it implies that they may be having problems with the second cut also.

Oh, and I mentioned earlier that an ASJ system had cut through casing and pipes at the bottom of the North Sea. I had the orientation of that cut wrong (at least for the picture below) since in this case it was from the outside in, but I am aware of it being successful the other way. And so here is the picture of casing and cement cut by an ASJ. Sadly it was so long ago - around 23 years, that I can no longer remember exactly the pressure it was cut at, but I believe it was 5,000 psi.

This is Prof. Goose's comment:

A continued sincere thank you to all who have donated thus far. It will help with the increased costs we are facing (see point 3 below).

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes.

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They were really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 400 comments, as it's really unmanageable. Lots of good stuff in there though.

Thanks for your helpful (and sane) coverage of this mess.

(The check is in the mail. Really.)

Thanks very much for the kind remarks, and the support. I am putting this comment here to get it ahead of some of the comments below which related to the use of the Shear and the start of the wire sawing. We unfortunately missed both of those but are watching now.

A question does arise, it seems as though the wire is cutting through the middle of the flange below the riser, not sure if that is the optics, or if that is correct. But if it is correct it might allow a later flange to be bolted, and sealed to that surface.

It's cutting just above the flange in the riser.

HO, it is cutting just above the tops of the bolts, not through the flange - this could be clearly seen when they stopped sawing for a bit just after penetrating the riser.

"...it seems as though the wire is cutting through the middle of the flange below the riser, not sure if that is the optics, or if that is correct."

It's the optics of the moment. In the earlier shots of the sawing procedure (before much of the saw was obscured by flow from the cut), it was clear that the cut is a few inches above the flange bolts.

I presume you'll be editing out the duplicates soon.

I PayPalled some $$ to make up for my dangling on your server tit so much ...

I just reviewed the Kent Wells lecture 13 minutes long with the various "solutions" including the floating riser pipe with quick disconnect at 300' below surface of water, to minimize movement from hurricane waves.

It occurred to me that if they disconnect the retrieval ship, then the oil/gas mixture will have to go somewhere, since it seems to be conventional wisdom that the riser, etc. can't hold the static reservoir pressure of 8000-13000 psi (estimates seem to vary).

Perhaps a mechanism could be set up to dump the gas lower down, right after it comes out of solution, to minimize the high velocity kicks. A simple Klein bottle should do it (-;

I have seen pictures of enormous floating rubber bags used to transport oil somewhere. Why couldn't one or more of them be moored subsurface, and cleverly valved to release the natural gas to a surface snorkel and leave the oil.

During a hurricane, flared or unflared gas would be dissipated rapidly, and the oil, free of the expanding gas, would be a relatively smaller volume.

Post-hurricane, the oil in the storage bags could be pumped, and the bags readied for the next foul-weather event.

Anyone up on these storage/transport bags? NO reason, of course, why a barge couldn't be sunk and tethered, and the flotation automatically maintained to balance its weight. Lotsa barges around these days, some pretty big.

Lotsa clever automated gadgets for maintaining flotation, level, and position.

Glad to see they used my giant suspended shear idea ;-)

In earlier posts I have suggested that the natural gas is our friend here. It is about 40% by mass in the leak. This highly compressed gas at the leak would create a tremendous gaslift effect if the leaking oil and gas were directed into a pipe that runs down to the leak from a salvage vessel.

As you said, "...expanding gas". That is what makes the gaslift work, so we don't want to remove it from the oil. We want to use it to capture the leaking oil and gas.

Some seawater would also enter the rising flow and must be keep to a minimum, but it should not cause the gaslift to fail. You can search the earlier threads on this topic for my handle Windward to find more details of this technique. I have asked the experts to comment, but so far none has taken the time to do it.

I'm not only aware that the expanding gas gives lift, but that it also gives too much lift on occasion, and that is called a "kick".

Since it's a problem, why not have a solution?

Regulators are simple enough mechanical feedback devices. Your dependent variables for this one would be surface delivery speed/pressure, and how much gas to bleed off.

I'm thinking the same mechanism that makes sure your gas water heater doesn't see delivery line pressure, but only 11" water column.

No one wants the gas, right?

Yet, you must bleed off the oil gas mix at exactly the rate the broken BOP lets it out, so some regulation of flow couldn't hurt...

I think a rubberized fabric bag of sorts could indeed work, but it needs to be very strong. It should not get too large; perhaps a day's worth of oil per bag? I'd vote for a "tensioned membrane" structure such as is used for hangars (http://www.rubb.com/). I agree that the gas could be vented at depth.

You state:

"Only snag is that this might move the pressure in the hydraulic hoses and fittings above their design level (e.g. a 5,000 psi cylinder being asked to operate at 7,500 psi - the cylinders might be safe, but what about the hoses?"

I would point out that the design level is psig, not psia. Since "psig" is referenced to ambient, which in this case is roughly "2,300 psi" per your article, there should not be any problem with either the cylinders or the hoses.

Agreed. Ambient pressure should have little effect on the hydraulics. In fact, it will reduce the differential between internal hydraulic pressure and external pressure. It's less likely that a hose will burst at that depth.

No while you are partially right on the hoses, (I realized that about half an hour after the post) it is only partially, if the power pack is on the surface and they are sending the pressure down a hydraulic line. You are I believe not correct on the cylinders since in this case is not the rating that is the problem but the differential pressure across the larger piston.

Hoses at the surface would be susceptible to blowing out while those below would not. The curious thing in a situation like that is expansion of the line itself. When possible, hydraulic line is solid so that you don't lose anything to hose expansion...with a mile long hose though that's by necessity flexible - woo, just a little expansion of over a mile of hose would make that super "spongy" and take some fluid.

If they are indeed pumping the hydraulic fluid all the way from the surface (to deadhead at the shear, I presume), there will be expansion of the line. However, this should not affect the pressure at the bottom of the stack if it is deadheaded and not a two-hose loop going back up to the surface. Does anyone have a schematic of the fluid loop?

And if they are pumping over that distance, hopefully their reservoir would have enough capacity to handle the "sponge" effect. This isn't like your car brakes, where you get a lot of entertainment if they're spongy. Here, that may slow the rate of the cut, but as long as full pressure eventually reaches the shear it should still go through. And they could always go with a higher-rated (pressure-wise) flexhose at the surface and use lower ratings at deeper depth. Or is it really a one mile long single piece of flexhose?

A question: As said here and elsewhere, between now and the time when the relief wells are ready to seal the well, there's a danger the well could fail, that it's possible the casing could be blown out of the well, leading to a greater catastrophic gusher of oil than now. Also, the relief wells may not work, as has also been stated here. If so, what then? Would the only option then be to drill production wells with the goal of emptying the reservoir as a way to stop the flow?

The casing is secured to the drill hole (rock below mud muck 1000' below wellhead) with cement that did not fail or may have failed in small area near bottom, IMO. Cement inside casing (at hangers?) and probably lowest cement plug have failed causing oil/gas to go up liner and drill pipe. BOP and casing should stay where they are regardless of what happens above BOP, hopefully.

Now I am confused. In the other thread posters seem to be saying that shears worked and riser was actually cut - and they saw it on live cam. Now this post suggests that shears did not work yet. Who's right?

The shears worked, now they are cutting off the riser at the top of the BOP.

So the blog article is out of date? It was posted at 10:30pm. Oh well.

More of a recap. They finished shearing the riser (about 20-30 feet from the top of the BOP) around 7pm central. Then started cutting off the riser at the BOP about an hour later.

We're posting about this stuff the minute it happens in the Live Feed Oil Gusher GOM thread at LATOC, if anyone's interested. They look to be about 10% of the way through sawing off the riser.

BP says the LMRP will be deployed later this week - any thoughts? I was under the impression the LMRP would be slapped on right after hacking off the riser top; one of the LATOC posters said he saw it on the feed, too. Update on Gulf of Mexico Oil Spill | Press release | BP

In the technical presentation, Kent Wells described two different methods, with the first method to be tried needing a surface on which a big gasket-like device needs to mate onto a pretty well machined surface. My impression was that they were going to cut, then machine, then lower.

The second containment device was more of a sleeve that would fit over the upper flange of the BOP structure. I am not sure what the sealing mechanism is to be - they showed a huge ring made of 10" thick steel!. If there was some sort of elasto-polymer to be set into the ring, it seems based on the geometry and the nature of the upward pressure drive, that the latter would be easier, in that it requires a less machine surface. What was unclear is how this sleeve would seal. If the issue is keeping seawater out [to reduce hydrate formation?] They could create a decent barrier to seawater input on the 2nd device with a variety of relatively simple structures. But, that is just armchairing it ....

There were multiple attempts at shearing. It's the third attempt after cutting away the parallel kill and control small lines that the CRAW shear was successful.

Here is the video of the successful 3rd time. http://www.youtube.com/watch?v=wuNJCa4DfU0

Notice in the youtube that the small pipes have been cut away.

and making good progress so far. I was curious about the orientation. They are not exactly cutting from "behind" the bend. If I was using an axe that's where I would be...

Definitely moving from right to left, so as it falls to the left, the string won't get caught. I'd say at this rate at least three hours or more to complete the cut.

Do you think they simulated the cutting topside (without the oil & gas) before trying it at 5000 fet?

PDF on wire saw operation, for those interested. At the moment they look to be putting in a new blade, feed is a static shot of the side of the riser.

I was away from my computer for a couple of hours and missed the success of the Shear and the start of the wire saw cut. My apologies, I have corrected the post as of 10:15 pm Central time.

With all my concerns about this / that not going to work, I have come to realize…

I don’t know squat. Thank you Father

My first post.

I'm a chemical engineer and my brother is a 'riser designer' working off the West coast of Nigeria for a big French oil company. His first comment to me 5 weeks ago was 'that thing is gonna piss oil for months'. I guess he was right. It'll be interesting to see if the latest containment idea works.

BP will be a hero on its own screw up

I'm a non technical newbie, nobody....Wikipedia lists historic oil spills.

Very few from well blow outs, very few.

Most are from tankers.

So your brother probably knew ....

There continue to be distinctly different colors. Other than lighting, what are some plausible explanations?

Mud? Two distinctive pathways?

OK, I'm reposting in new thread b/c it could be fun if we keep it somewhat clean:

BTW, I have a lot of respect for the ROV operators, how many are there total and what are their shifts like...they have to be going 1/2 nuts.

Dialog is being written on freenode #oildrum

Actually it is freenode #theoildrum

Oh crappola...there is a strong plume coming straight at the wirecutting saw now and through the body of the thing. Hope that does not effect the machinery. At least there is plenty of oil lubbing the wire right now.

I noticed that also ..

The plume of oil/gas is jetting directly at the drive

unit ( yellow box ) of the saw .. If it packs up perhaps

the ROV operator can use the circular saw to finish the cut ..

Triff ..

I noticed a pair of deflector pads earlier, which probably addressed that problem.

I looked it over as best I could for an hour or two while they were looking around. I don't see any reason why the oil jet would be any problem, other than difficulty seeing.

Is it me, or has the pressure behind it dropped to minimal? Compared to the highly forceful jets I was looking at a few days ago, this seems like there's little pressure at all.

There was a mention by someone during the Top Kill operation that the pressure at the top of the BOP was about 400 psi above ambient, and I think the bottom of the BOP is about 5-7000 above ambient. Didn't someone calculate the BOP opening as 1-2 square inches?

It could be that the pressure right at the point the oil is exiting the pipe has fallen off substantially simply because the saw is creating a constantly growing opening for the oil to pass through.

This might fool the eye but the volume of the leak would either stay the same or increase.

Why do they not unbolt the flange that appears to be beneath the diamond saw cut and bolt on a new riser?

I wonder to what effect the oil lubricates the diamond saw. (probably negligible but still adds time and/or force on the diamond wire)

Are you saying that down in the BOP, the well is flowing through a hole only 0.6 inches across?

There has been speculation to this effect - no one really knows, but the higher the pressure gradient the more fluid can pass through a small hole. HO had a lead post with a formula and a spreadsheet a day or so ago.

If that's the case, it makes you wonder why they would not try junk shot after junk shot. On the other hand, with the pressure involved, I have zero intuition as to what materials would hold.

I posted a couple of "stop the flow" suggestions earlier but I now believe that the engineering taking place is beyond the realm of simple suggestions.

Therefore, I am turning to what next.

The end result of this calamity, outside the oil industry, will either be a return to daily life as usual or some changes in behaviour.

I suspect that most of the Oil Drum's long time readership/membership believes that lifestyle changes from reduced energy availability are inevitable.

I also note that the US government has started punitive ( i.e. criminal ) procedures.

These procedures are probably inevitable. I hope that they are not also the political path of least resistance to a political exit.

If the American political leadership does not take steps now to initiate lifestyle change, the lives lost on board the DWH will have been lost in vain, as will the lives of the helpless animals and the generations long livelihoods of coastal residents.

After the well is killed, the news media will forget the disaster ever happened. If longer term efforts to prepare for the inevitable power down are not started now, they will simply not be started at all.

I would like to suggest that the Oil Drum take the lead. I know the site is primarily about oil and its production and not the social consequences of same.

Therefore, would it be possible to start a parallel theme in the banner with a title along the lines of "The Gulf of Mexico Oil Disaster and the Urgent Need for Lifestyle Change"? If this theme is successful, it could eventually result in a sister site.

I believe that many of the people who have come to The Oil Drum looking for information about the Gulf calamity would also be interested in the need for social changes that the disaster so clearly exemplifies.

The American political leadership needs to know that the American people will not be satisfied with fines, jail terms and "better" regulation of the oil patch as an acceptable outcome of this horrendous disaster.

Do the readers here believe that the Oil Drum could/should play a role as a lifestyle change leader as well as an oil industry information leader?

I post here and I watch the news, but I am planning to move. That is my personal reaction to this disaster. It is a damn shame too, this land has been in my family before Alabama became a state.

TF, my wife and I have been discussing the possibility of moving as well. We live in Mobile about 40 miles from the ocean and 10 miles west of the bay. I have a hunch though that many people (that is, those who can afford it) may have the same idea though. Especially those that live on or close to the water. Quite likely property values in So Baldwin county will drop like a rock and likely even affect places like Fairhope and Daphne. For sure the economy at the beaches will be miserable. Not sure how Mobile itself would be affected.

But then, move where? My family has lived in Ala for many generations. Tough decision that.

JochK: I think we may be on our way to a new category of internally displaced persons: "oil refugees."

It would be sweet if I could pickup some waterfront from the panic party. Always a silverlinning somewhere.

OTOH, you could both take the view that your families have been in the same-old same-old ruts for far too many years, and it's time for a fresh bright start somewhere else. Lots of people have moved throughout history - including during recent history - and have prospered, and enjoyed it.

Avoid cold places, and it could be a great opportunity for change and renewal!

I was trying to figure out if your statement was sarcastic or stupid. Couldn't really see any third alternative.

Forced lifestyle change, for political purposes, is not possible. We should have learned this from the old Soviet Union, who tried many ways to force lifestyle change upon people, and it never worked. In the end, it simply created tyranny and suffering. If people hope to exploit this kind of event to force political change upon the nation, the end result cannot be anything good at all, but will end up with monstrous disaster. The key, as always, is to ALLOW change to happen naturally, to ALLOW alternate forms of energy to be created. As usual, the politically motivated cannot find an answer, as they use politics to attempt to divine an answer to practical problems. Instead, the answers have to come organically, they have to be generated by, wait for it, free enterprise - and by people finding ways to supply needs economically.

Does leadership have a role to play in the allowed changes or do they just "happen" naturally?

Are the lifestyle changes coming anyway with Mother Nature providing the not "for political purposes" changes in Her own way?

It seems to me that sitting back and waiting for the allowed change makes the fundamental assumption that there is time enough available for the changes to come forth. Some would tend to disagree.

Wonderful paean to laissez-faire government, and if times were good, it might even work.

But as the upper classes refuse to learn, when times get hard, the government has to convert from following to leading.

Hence, FDR.

I remember hauling coffee cans of fat with my little red Radio Flyer wagon to the collection spot on base during WWII.

People changed, a lot. They worked long shifts at low wages, bought butter, gas, tires with ration cards.

The only job the government has is to honestly confront the very real war with natural laws that the very real sex and status drives have caused.

End of message.

If the "government" converts from representing the people, to controlling them, then absolute disaster will follow, with a 100% chance of complete and absolute failure.

And what if you're wrong, and the market-driven way is to simply sacrifice us proles to the pollution, steal our pensions to build giant survival domes for the rich, and party on in a depopulated Earth?

That was how the Western Roman Empire fell, with Rome's elites reinforcing their private manors and converting their slaves to serfs to ride out a Dark Age because they didn't want to pay taxes anymore.

...up to a point, Lord Copper.

http://en.wikipedia.org/wiki/Fall_of_the_roman_empire#Theories_of_a_fall...

The sort of lifestyle changes that would have a direct impact on oil consumption is the following. Development of public transport and interurban and intraurban rail networks, redevelopment of cities to facilitate walking and biking (this means obvious things like building sidewalks, creating pedestrian and bike pathways, but also perhaps less obvious things, like fostering higher density residential development (with inadequate residential density, public transport is not viable economically) and penalizing low density development). Consumption is easier to change than are energy sources, but consumption of oil based fuels can only be reduced if it is possible to live using a car very little. Right now it's possible in the US in only a handful of cities, e.g. NYC, Chicago, Boston, etc. It's not a question of allowing or forcing changes - the government's task is to steer and guide.

You said "the government's task is to steer and guide". No, it is not. It cannot. Government is 100% completely incapable of doing so. Any designs on doing this are more gauranteed to fail than attempting to leap a canyon in two steps. Government does not and cannot make decisions about practical matters, since it always makes decisicions based on political whims, and thus, will be completely invalid. Academics, theorists, think-tanks, etc, are useful in looking at ideas, but they cannot be given the decisions, the decisions must be made by those who live with the results, and thus have a feedback loop which prevents bad decisions from being sustained. To be relevant, a person buys a vehicle they can't afford the fuel for. Eventually, they "learn" and change direction. When government makes a mistake, it simply forces the situation. It subsidizies unsustainable public transportation, for instance. If it were organically worthy of doing, no such subsidy would be needed. There is no "learn" mode. It simply becomes more and more diametrically opposed to what works, and instead, attempts to force, either by economic confiscation, or by mandate, the unsustainable. Eventually, as we have all found out, and we can see, by simply reading the news concerning our debt levels, failing economies like Greece, etc, that unless we learn and reduce our governmental controls and dependency, the entire world will fail economically, which, of course, is a disaster which will make the gulf oil spill seem like an irrelevancy, in the scale of disasters. No "planned economy" has ever worked, nor will one.

For all government's massive numbers of people and rules and regulators, the events of this oil spill were never predicted. Instead, our solution lies in the hands of the people who actually do the work, and creatively think up solutions. They WILL succeed, the question is how much time has to go by and how big the damage will be. Put Congress in charge, and in 50 years, we'll still have a leaking oil well with no end in sight. Gauranteed, 100% without reservation. I've watched Congress for nearly 30 years claim they're going to balance the budget. They cannot do what the average, uneducated, dumb-as-a-brick schmuck can do and does do when the need arises. In other words, for how many decades have they promised to conduct some simple math and balance the budget? And can't do it? And you deign to tell me that these utter and complete incompetents can "guide and direct" our economy, energy needs, and future. I'll accept that answer right after you put a gun to my head and pull the trigger, but NEVER before, as all empirical evidence says the idea is so fantastically absurd it falls into the realm of unicorn riders and moonbeam propulsion.

From CNN White House Correspondent Kelly Wallace

September 27, 2000

Web posted at: 4:51 p.m. EDT (2051 GMT)

WASHINGTON (CNN) -- President Clinton announced Wednesday that the federal budget surplus for fiscal year 2000 amounted to at least $230 billion, making it the largest in U.S. history and topping last year's record surplus of $122.7 billion.

http://archives.cnn.com/2000/ALLPOLITICS/stories/09/27/clinton.surplus/

Yup, when ol' Bill changed accounting methods and added Social Security contributions to current income he balanced the budget. The government didn't change the accounting methods back - and a few years later they've spent even that. Now they're spending loans from our grandchildren. That's leadership?

The accounting change was done decades earlier, by Richard Milhouse Nixon if memory serves.

Under the same accounting method, Clinton left a $200+ billion/year surplus. 8 years of R control changed that to a $1.3 trillion deficit and the biggest financial crisis EVER left for an incoming President (1933 for FDR was almost as bad).

Best Hopes for keeping the R's in a small minority for a few decades,

Alan

Mark K: Impressive political rant. So what's your solution to peak oil's aftermath? Or is Peak Oil just another unicorn and moonbeam of the sadly deluded. Let's hear it.

You state your believes quite emphatically, thus they must hold true in your in your geographical zone of knowledge.

However, from Vancouver, Canada, to Berlin, Germany, governments on all levels have and do steer and guide, of the people and for the people, the structural changes needed for post peak oil.

I'm very saddened to know now, that you live in a zone that made you bitter, because no change, never ever, can be initiated there.

I could not have stated the case better myself. Those who advocate that some amorphous government should lead and decide should take some time and read "The Road to Serfdom" by a Nobel prize economist.

There are no Nobel prize economists

I think the "Road to Serfdom" may run through 200 West St.

Such pathological hatred of government has made America great! (That's a joke ... in case you inhabit an irony-free zone). Hope you enjoy the next tea-party!

This is the bit I especially like ... yes sir - leave the world-wide ruins of the oil industry to the good ole oil industry to fix. What a clever plan!

Haven't you heard: the logicians missed an important rule of deduction: A sentence that contains an auxilliary verb in capitals is true, with no other evidence or reasoning necessary. All that messing around analysing at past behaviour and future plans is wasting time, just hitch your wagon to capitalisation and you WILL be envied by all for your correct predictions.

Haven't you heard: the logicians missed an important rule of deduction: A sentence that contains an auxilliary verb in capitals is true, with no other evidence or reasoning necessary. All that messing around analysing at past behaviour and future plans is wasting time, just hitch your wagon to capitalisation and you WILL be envied by all for your correct predictions.

The sort of lifestyle changes that would have a direct impact on oil consumption is the following. Development of public transport and interurban and intraurban rail networks, redevelopment of cities to facilitate walking and biking (this means obvious things like building sidewalks, creating pedestrian and bike pathways, but also perhaps less obvious things, like fostering higher density residential development (with inadequate residential density, public transport is not viable economically) and penalizing low density development). Consumption is easier to change than are energy sources, but consumption of oil based fuels can only be reduced if it is possible to live using a car very little. Right now it's possible in the US in only a handful of cities, e.g. NYC, Chicago, Boston, etc. It's not a question of allowing or forcing changes - the government's task is to steer and guide.

Good idea.

I think lifestyle change will be enforced by GoM no matter what we want, however. And TinfoilHat isn't alone. Thoughtful individuals who live along the GoM or adjacent to Gom areas are assessing the possibility of involuntary relocation. Those of us with family members who are in the age range for reproduction, very young, very old or ill have to consider the longterm environmental impact on human health. I don't know about anyone else, but I learned an unforgettable lesson from the sequellae of Agent Orange, DU and the contaminants to which humans have been exposed as a result of GWI & II.

Discussing the teratogens that have been released into the environment as a result of DWH is as depressing as discussing the carcinogens. Better to focus on Dsaw and CRAW.

I'm a mechanical engineer with interests in nuclear and solar energy in Nevada. Having spent years going over the proposals of solar and green advocates, all with a bias towards a low energy lifestyle, I can tell you they are literally insane. We need more energy, not less and I am not going to live in the dark ages. Solar has so many deficiencies that it is simply not practical as a substitute for an oil, nuclear, coal and natural gas energy mixed economy. Hydrocarbons are the most compact way to carry hydrogen, forget the hydrogen based utopia. We can certainly change our utilization mix of fuels to capture higher efficiencies, but the idea that we are going to cut energy usage by 50% or more so we can live shivering in a green utopia is not supported by the physics of energy systems nor the needs of civilization.

"We need more energy"

Fusion? Zero-point? More of what we already have? Where is your "more" coming from?

"Oil, nuclear, coal, and natural gas mixed economy"

Pretty much what we have now. No?

"Not supported by the physics of energy systems"

Agreed, you only have to look around to see that's true. I assume you are stating, although you haven't said so explicitly, that the current status can carry on into the foreseeable future. With or without oil, nuclear, coal and natural gas?

"Needs of civilization"

That would include SUVs, 747s, strip malls and suburbia?

"We need more energy, not less. . ."

Yes, we do. But it's rather unlikely that we're going to get it, on a per capita basis, with 6.824 billion (and counting) humans on the planet.

". . .and I am not going to live in the dark ages."

Perhaps not. That may well depend, however, upon how long you live, and upon how much more than your "equitable share" of energy you may be able to secure.

stuwaymire: It sounds to me that you have no time for the concept of Peak Oil, eh?

The trick with dark ages, they might not ask permission.

Do you think mothernature cares what you want? Just because you want more oil doesn't mean it is there. I think a lot of people are going to learn real fast over the coming years what that truely means. Some people seem to have no concept of what the word "NO" means. Perhaps our free-lunch society also now believes in "unlimited" oil.

The last time we found more oil than we used per year was 1984. The situation has only gotten much much worse. If you don't understand that, ask yourself why Saudi Arabia has the Chinese putting up acres of solar power farms to run their desalination plants. Perhaps they know something about their oil reserves we don't.

I don't have too. If there is one thing the Saudi's have it is an abundance of desert sun, no reason not to put it to work. And with their money I am sure they can put it to fine use

I guess I should have added why should they waste their oil on that, when they can sell it for lots of money?

"We need more energy, not less"

Yeah, and I need a date with a rich and beautiful woman who will completely fall in love with me and keep me in the style to which I deserve. Doesn't mean I'm gonna get it.

Pete Deer

Thank you, and Amen

We can easily get by with a BETTER lifestyle than is prevalent in Nevada with less than 50% of our current energy.

Europe has a better lifestyle (no obesity epidemic and they live longer and fuller lives) with half the energy we use.

You are *SO* wrong on so many levels, that your attitude will lead us straight into the dark ages. Except we will be seating in the hell of a planet we leave behind.

Alan

Let me give you some "Physics'.

Moving freight from trucks to electrified double stack container trains trades 20 BTUs of diesel for 1 BTU of electricity.

Transit Orientated Development housing has about 1/3rd the VMT (vehicle miles traveled) of US average. About 30% of Americans want to move to TOD today, but they cannot becasue there is not enough T for the OD.

Building DC Metro saves over 100,000 b/day. Expanding it could save an extra 150,000 b/day. We could use at least ten times the Urban rail that we have today in the USA (10 x NYC subway, etc.)

Nevada has *WAY* too many people.

The American Suburban lifestyle is doomed due to post-Peak Oil.

"Nevada has *WAY* too many people." And way too little water. Another "PEAK" thingy.

"political leadership does not take steps now to initiate lifestyle"

Your kidding right? We live in a highly complex interwoven economy. To illustrate how difficult that would be, let's just take a simple example: Say we wanted to reduce Oil use by no more pleasure driving on Sundays, and cut down on Tourisim and Vacations. Here's what would happen:

- Every hotel chain would be down your throat telling you about the resulting drop in business, their bankruptcies, and how many employees are going to loose their jobs. Every restaurant the same thing. Every rent-a-car company the same thing. Every vacation park the same thing. Airlines, building contractors, etc.

Just that one small change would cause massive economic damage. And you think our pliticians will vote for this on their own? Not a chance. Political suicide.

Lifestyle changes happen when they are driven by economics. It is money that causes real change. Now those changes above will come, but they will happen when people no longer have the money for pleasure driving or vacations. Or the price of fuel is just so high they can no longer afford it.

I wasn't expecting to add anything further but I've done a some work where it comes to sustainability. Short answer: the great majority of people don't care. They are in general capable of blanking anything that would imply what they would see as a downgrade in their lifestyle. Anything. Trust me, put peak oil figures (or anything relevant) in front of them and they will literally have erased what you told them in a few seconds and become angry into the process.

Frankly I've come to the nightmarish view that there will be a bulk die-off of humanity and it will be violent and horrible.

I used to see people as rational. No longer. The evidence has overwhelmed me, I am left bleak and empty by what I fear is coming that could be prevented if only for a little forethought.

But, yes, it's always worth one more try. I am an optimist.

Absolutely not!

I think what makes this site so civil is that it concentrates on providing fact based information. The moment you get into "life style" changes advocacy you enter the political realm and the discussions will become vitriolic. Much better that we leave the TOD as a place where people can get their facts and the disputes with regard to those facts and take the advocacy to some other site.

.

As a long time (almost 5 years) TOD member with several thousand posts and several lead articles, I disagree. Lifestyle changes *ARE* discussed here and the consensus is that they will be required post-Peak Oil.

Some disagreement on what changes (different strokes for different folks) but we do discuss them here quite a bit.

Best Hopes,

Alan

Unfortunately, we have discovered here in the US, it takes disasters/catastrophes (oil embargoes, terrorist attacks, oil spills, etc.) to force us to make lifestyle changes. And even this change is always temporary. Due to our short memory, we revert back to bad habits after awhile. We are reactive creatures, not preventive in the least. That mentality must change very soon if we want to get through the next few decades intact.

Dear Heading Out (Dr Summers, I believe) and Gail the Actuary and everyone else on this open thread,

First, I am a newbie and can offer no technical feedback to your discussions. The reason I write: many folks have been trying to come up with a non-toxic 'oil-eating' solution to help the Gulf and the coastal shorelines begin to recover from this catastrophe.

Has anyone else posted a discussion about Elastol, a polymer that melds with oil and renders it into scoop-able ribbons which, I believe, can be re-processed to safely remove and then utilize the oil?

Youtube link:

http://www.youtube.com/watch?v=99ufSms6Jv4 and http://www.youtube.com/watch?v=qftiSOMiB-g

Second, has anyone else posted a discussion about oil-eating Microbes? Here is a link to a YouTube http://www.youtube.com/watch?v=8VfypUzx1tI that explains its mechanics.

I just hope I won't be laughed off or banished from this incredible site because I'm earnestly asking these questions. In the wake of a woeful dearth of information officially being reported by BP and the joint task force, I feel as if TheOilDrum and its members are the only ones who understand and can explain what is going on.

Again, thank ALL of you for your insights, your obvious skills and your patience with newbies like me. True scientists willingly work together to solve a problem. That's what I see here on this site, not PR spin. And I'm grateful.

-bleuz00m

The video is a great oversimplification, and uses a lot of terms incorrectly. I'm trying to find a more scientific version of the treatment but haven't found it yet.

Bioremediation is a common tool for lots of chemical clean-ups. It isn't as perfect as the video shows; there isa lot of research for finding and modifying oil eating bacteria, and as far as I know they can't eat as much or as quickly as the video claims.

There are a lot conditions that bacteria require for effective growth and digestion. There are a lot of potential side effects from using any living organism into a new environment, and many of these bacterial have been genetically modified to improve their functionality/survivability.

The big thing is that the bacteria need other nutrients and oxygen to grow. For a big spill, the bacteria could deplete those other nutrients or oxygen completely, killing other things in the sea even more effectively than the oil. Bacteria do produce their own wastes which can be toxic to other creatures.

The scary part about bacteria is that they easily exchange genetic information with other bacteria, especially in environments toxic to the bacteria. Sections of DNA can even switch between completely different bacteria species. What that means is that when you release modified bacteria into the wild, they can start to gain new abilities and give their abilities to other bacteria, with unpredictable consequences. For instance, if the bacteria pick up a set of genes that causes them to infect fish or shrimp; or if a type of bacteria that already can do that picks up the ability to eat oil, and gets a huge boost to its growth from the oil in the gulf.

Most bioremediation I know of is of the type where the natural bacteria in an environment is encouraged to grow by adding nutrient and oxygen; OR a "foreign" bacteria is allowed to act in a controlled environment that can then be sterilized upon completion of the remediation.

You probably know of stories about introducing invasive species of animals or plants to new environments, such as rabbits in Australia, sheep in Iceland, the "killer bees", fire ants, etc. The same kinds of things can happen with microbes, only microbes have incredibly fast growth cycles and evolve very quickly.

Those are some reasons they haven't just dumped miracle microbes all over the gulf. They may eventually do it, I really can't say, but hopefully they will give it very careful thought and have a backup plan for if the microbes get out of hand.

Thank you, Thane, for your learned insights!

And, if I may, I'd like to post your reply to the friends who suggested it. Do I need to request clearance from anyone else here on TOD to do so? I'm not sure what the policy is and want to honor its guidelines.

Yes, we don't really know how these proposed microbes would behave 'in the wild,' and your points -- and great concerns about existing bacteria intermingling with unforeseen and possibly more dangerous consequences -- are well taken. Hmm.. a quick fix, executed in haste, can wreak more havoc than the original problem had inflicted, sadly.

Though this may seem flippant, I mean it sincerely: as you described the possible concerns and dangers of using microbial intervention, what came to mind was the ill-advised use of kudzu as an erosion control plant in the Southern states. Or the inadvertent introduction of the Asian carp and zebra mussels and how they has now overtaken some US waterways' delicate balance.

Again, thank you for your detailed explanation, Thane! If by chance you are on Twitter, I'm ' bleuz00m '

-bleuzoom aka Amy

At one point in my career I worked in this field. You make a very important statement here:

The Exxon Valdez spill had some fairly extensive use of the first approach used.

The fact is that engineered bacteria are very rarely if ever competitive with naturally occurring bacteria. This has a number of implications - it is very hard to culture engineered bacteria in sufficient quantities - either the culture gets taken over by something introduced by contamination or a mutation occurs which results in something much different than intended unless extreme care is taken.

In any case as far as I know the only EPA approvals for use of genetically engineered microorganisms (GEM) have been in limited field trials.

Of course this spill might encourage some wider use of GEM.

For the reason I stated about I seriously doubt if we have to worry about engineered bacteria taking over an ecosystem. What is there already has been competing tooth and nail for its niche for billions of years and it will overmatch anything artificial.

People have been trying to sell 'selected' bacteria grown on various refractory substrates into various types of waste treatment industries. Generally they are regarded as hucksters for simply it does not work for the reasons stated here.

Larger organisms evolve MUCH more slowly, meaning that an imbalance due to introduction of a foreign organism into an isolated ecology without predators to control it will create an imbalance for a relatively long period of time.

Ultimately I have some serious doubt that GEM will ever be effective in remediation. If you want to degrade a particular refractory compound in your system I suspect the best approach is to introduce a naturally occurring bacteria with the known gene. If that gene is useful it will migrate through the rest of the bacterial population.

I think the video is founded on a scam. I can easily see why officials would like to have a quick solution and I'm not blaming them for getting excited. However, there just isn't any chance in the world that a packet or two of dessicated bacteria could revive and consume 1000X their own weight in oil in just a few minutes. I suspect that the company that ran the "experiment" was pulling a fast one.

That said, I'm a whole lot more enthusiastic than Thane, above. As far as I could tell from the video, the bacteria were all isolated from the wild. (No genetic engineering involved. Even if there was, there are perfectly safe engineered bugs.) They do reproduce and evolve rapidly, but you and I have been surrounded by rapidly evolving bacteria since we were born. Same ol' same ol'. Thane is correct that any useful form of bioremediation will lower oxygen content in a given volume of water. If that volume is full toxins from an oil leak, it may be best for the environment to have the bacteria do the work and get the job done quickly. No one is suggesting that its a perfect solution, and I'd be happy to bow out to anyone who has such a solution. But in the absence of perfection, a period of mild anoxia may be an acceptable price for removing the oil. (A University of Georgia researcher - named Joye, I believe - says current measures of O2 partial pressures in the plumes surrounding the Deepwater Horizon site show decreases of 5 -10%).

What happened when the video showed them adding bacteria in the open Gulf? I suspect that the excited officials were witness to the phenomenon of dilution more than anything else. It is conceivable that the fire hose used to distribute the bacteria also included some nutrients (phosphate, nitrates, trace metals, etc). That could conceivably encourage the oil-eating bacteria that are native and already at reasonably high concentration to increase their numbers. But that would take quite a lot of time. Depending on the water temperature, I'd say at least days and probably weeks to get dense enough to consume significant quantities of oil. It's harsh, but if I was running a bio-remediation scam, I know that I'd sneak in a little detergent into the "bacteria mix". Detergent would have the rapid effects that the Texas officials described.

I'd certainly recommend that researchers try isolate as many different species of oil eaters (oleoclasts), grow up great whomping volumes if at all possible (scale-up is a terrible terrible problem). The lets do like Texas and try them on the blackened beaches. This time, we should be certain to set aside certain parts of the beach to be untreated, so we can see if the treatments are any different. Sure, there would be some problems. We would want to ask immunocompromised individuals to stay away. We'd have to warn neighbors that their literally stinking beaches would probably stink even worse, for a short while. We may have to run out hoses and sprinklers to deliver enough nutrients for the bugs to have a chance. But compared to the problems they're having in Alabama right at this moment, these are small sacrifices indeed.

Yeah, I don't want to sound too down on the idea, only that its got to be very carefully considered so that the cure isn't even worse than the disease. I suspect the video is a scam too, but I just can't find anything to say one way or another.

I am sure there are companies itching to try their bugs out. There are a lot of researchers that work in bioremediation.

Yeah, I don't want to sound too down on the idea, only that its got to be very carefully considered so that the cure isn't even worse than the disease. I suspect the video is a scam too, but I just can't find anything to say one way or another.

I am sure there are companies itching to try their bugs out. There are a lot of researchers that work in bioremediation.

The plume researchers had reported as much as a 30% oxygen depletion in the plumes. The was preliminary though, and may have as much to do with the methane in the water as biological depletion.

Here is Samantha Joye's blog for doing the plume research, it is a very good read. http://gulfblog.uga.edu/

Since this particular pipe is on live video, we watch as if it's the only oil leak in the world. Apparently the routine oil leaks in Nigerian pipelines put this one to shame. But they're not on TV. We only pay attention when something breaks in our backyard.

It's amazing just how intricate, extensive and expensive our worldwide network of gas and petroleum capillaries actually is, and how totally we depend on their routine delivery of vast quantities of fuel to us through every minute of every day.

All those pipes and flanges .. just like the ones we're peering at here. It's a wonder that it all works as well as it does.

Sent earlier today to Secretary Chu and BP:

----------------------------------------------------------------------------------------------------------------------------------

Dear Energy Secretary Chu:

I am writing to you as a concerned citizen with a technical suggestion on the process to mitigate the effects of the current Deepwater Horizon oil spill in the Gulf of Mexico. I am not an oil industry engineer, however, I do have 25 years experience in the aerospace and mechanical engineering field working for one of our nations larges defense contractors - Raytheon Co. My technical expertise is in structural analysis - I have had an opportunity to work on high pressure sealing of non-standard surfaces for an innovative defense related project in the past.

I have been following the attempts by British Petroleum engineers to cap, siphon and kill the well and have been educating myself on the specifics of oil industry approaches to well piping and pressure control. I have also been following some of the valuable live video footage of the repair attempts. As the information has become available from the various attempts and my observations and back of the envelope calculations have evolved, I would like to propose a well containment strategy that I believe has not been fully considered by the current containment team. I apologize in advance for not always using the proper oil-industry terminology, but the approach is simple enough to be understood in general physics terms.

By this time, it should be known that the main flow restriction in the well hydraulic system is what the oil engineers would term "downhole", below the Blow Out Preventer (BOP). It is likely to reside in the compromised cement seal between the casing and the well bore. The exact location of this flow restriction or restrictions is of importance to the relief well intercept locations, however the important thing for well containment is that it is below the BOP collet connector top flange. The main pressure drop in the system is occurring "downhole", so that the static pressure at the BOP outlet flange is quite low, likely below 1000 psi and probably in the hundreds of psi range. British Petroleum engineers already know that from the failed "top kill" attempt - if the main flow restriction was above the mud injection points, they would have been either fully or significantly more successful in creating enough pressure inside the BOP to drive the well flow back into the well bore/casing. The "top kill" experiment has demonstrated that the flow restriction at the bent and broken riser pipe above the BOP flange and the riser pipe itself is relatively low. The experiment also shown that the BOP has not leaked at the elevated pressures of the "top kill" internal mud flow.

The current plan to attach an unsealed or semi-sealed "cap" on top of the cut riser pipe (above the flange) incurs the risks associated with removing the mild flow restrictions above the BOP top flange, but doesn't capitalize on the potential benefits. I agree with the BP assessment of potential 20% increase in the oil flow after the riser pipe removal; this assessment is in agreement with a low level of flow restriction afforded by the removed piping. I think that this risk is low in the context of the potential for collecting most of the oil, while relief wells are drilled. The other risk is the separation of the drill pipe, which may lead to increase/unknown interaction with the BOP shear blades. However, the unsealed or semi-sealed "cap" approach will allow some or significant amount of oil to escape, and, more importantly, will allow for hydrate formation that scuttled the first capping attempt. My proposal does not increase the risk to the BOP or increased flow rate over that of the "cap" approach, but offers potentially full oil containment and removal (at least outside the hurricane-type emergencies).

I propose that the riser pipe is either unbolted or cut at the BOP collet connector top flange (or the hydraulically activated coupling is used to decouple the riser pipe flange, if it is still operational). Recent underwater camera video has shown the amount of damage in the riser pipe above the top BOP flange. It is considerable and plastic deformation starts right above the flange. It will be extremely difficult to fashion a pressure tight seal between the BP collector "cap" and the plastically deformed riser pipe end. However if the cut is made at the flange (or the hydraulic collet is used to separate the joint), a flat and reasonably true surface can be created that will be much more conducive to a true pressure seal. The best solution would be to uncouple the hydraulic coupling, however, since the drill pipe is likely still in the riser pipe, the coupling may be non-functional. The next preferred method is to unbolt at the BOP connector top flange - this maybe difficult due to thread sealing and the large size of the bolts, but apparently not impossible for a modern ROV. Finally, a diamond rope cutter can be used to cut through the bolted interface, allowing the riser pipe flange to separate from the BOP top flange.

The reason why one would want to change the place of proposed riser pipe cut is that the flat surface of the BOP top flange will be much easier to seal against, using either industry standard collet connectors or, alternatively a custom high pressure gasket that would seal against in imperfect surface of the BOP top flange if enough pressure is applied between the two surfaces. The latter can be accomplished with the current set of flange bolt holes or a custom connection scheme. There are specialty gasket materials that would be useful in this application, and I am sure the oil industry has the preferred solutions. We have successfully used Grafoil, a paper made from layered graphite, due to its remarkable non-newtonian flow characteristics under high pressure. Given that we now know that the static pressure inside the unrestricted (or currently mildly restricted BOP) is relatively low, the requirements for this gasket are not extraordinary. The lower seal on the collet connector appears to be a flexible coupling - it is expected to straighten out, once the damaged and bent riser pipe is removed. Alternatively, another flexible coupling perhaps with a correct angle built-in can be utilized at the lower riser pipe end.

If you now have a surface you can seal against, you can look at this well in a very different light. The oil company paradigm, and legal requirements surrounding the blown out well are such that using production techniques are not rigorously considered during deliberations on the containment methods. Once you can truly seal against the top flange of the BOP, you can shift that paradigm and consider using production methods to actually contain ALL the flow. We know that the BOP exterior structure is solid - it has survived the collapse of the original riser pipe package and has not leaked during the higher internal pressures of the "top kill". This is actually as it should be - as a structural analyst, I am confident that the loads associated with the maximum moment from the riser collapse, coupled with internal pressure is one of the BOP design teams critical load cases. This even has demonstrated that the design/analysis team has done its job and the BOP has indeed survived its critical loads.

Since the BOP exterior structure is solid and the top flange can now be truly sealed, we can consider bringing a production rig, which can lower another riser pipe package to the now open top flange of the BOP. The flow in the well right now is estimated to be approximately in the range of the processing capability of the large production rigs. Removing the current bent riser may increase the flow 20%, however, the overall flow rate is still manageable. Attaching a new riser pipe to the flowing well is risky, with a jet of oil/gas coming to the surface, however, the production rig is configured to accept a high level of flow by design, unlike the Deepwater Horizon system which was exploratory. Minor amount of flow restriction can be used to reduce the flow rate at a cost of small increase in the BOP/riser pressure, or a flow divider can be used in combination with two production rigs to accept the high level of flow as is. In either case, all of the oil/gas coming from the well can be processed securely, without releasing it into the marine environment. The pressure in the current BOP can remain as low as it is currently, or can be increased judiciously, while remaining safe. Quick disconnect connector will be required at some point close to the current BOP top flange as part of the new riser package, so the production rigs can be disconnected during a hurricane or other emergency.

The method proposed above allows to safely collect all the oil currently escaping into the Gulf of Mexico using production rigs to collect and process the oil. It is likely that more than one production rig will be required to process the amount of oil the well is currently expelling, if the desire is to keep the pressure on the BOP and the well casing as low as possible. In addition, this system would have to be disconnected in a hurricane or other emergency, however almost anything that collects the oil would also have that weakness. Since the well can no longer be safely capped at the wellhead due to concerns about the quality of the casing seals, oil would escape into the Gulf, as it is doing now. However, this proposed method would collect the oil in its entirety outside the emergency periods and do it without additional pressure increase in the BOP. I am sure the current law prohibiting production from blown out wells can be looked at flexibly, with the method outlined above considered containment using production technology. British Petroleum, without a doubt, would chose to offer any proceeds from the oil gathered during the containment process to mitigate financial losses to the people living in the Gulf coastal regions, mitigating any political criticism.

Regards,

Dimitry XXXXX

Senior Principal Engineer II

Integrated Defense Systems

Raytheon Company

528 Boston Post Road

Sudbury, MA 01776

------------------------------------------------------------------------------------------------------------------------------------

I also wondered why BP did not just unbolt the flange, too - it does give a flat sealing surface. Maybe they will try that after cutting off the current riser / drill pipe.

But I think I saw a pic of the containment hat they plan to mount over the pipe - I don't think they plan to bolt it down. So it might just be a repeat of the first top hat run if they get hydrates again.

Unbolting the flange would get nowhere.

The bent or kinked drill pipe is inside the riser and would prevent riser from moving off BOP. DP is not severed since oil was gushing out its open end before it was plugged in order to get oil from end of riser, and that activity was stopped several days ago when top kill was tried. Only way to sever DP is to cut through riser and DP.

After that the riser flange could be unbolted, but why do it? The LMRP is designed to have some give in the joint with the BOP in case the new riser has to move or flex, IMO. Also I question the integrity of the BOP housing, as the top is canted over about 10 degrees indicating some deformation and yielding of main body. I would worry about BOP body bending more and maybe cracking or partially breaking joint at the well casing, if 5000' riser were bolted to this compromised BOP.

The drill pipe had very little flow at its end and was capped quickly. The entire leak-flow has been within the riser from the area they are now cutting. The riser is connected to the LMRP by a flexible joint to allow for some motion of the drill rig above. The BOP stack itself is not bent.

The entire leak flow was not from the riser they are now cutting. About two weeks ago BP claimed it was getting more than 1000 bpd from the insertion tube they were using at the end of the broken riser after they plugged the broken drill pipe.

If the BOP stack is not bent, then why is the lower barrel shaped portion not in vertical alignment with the top flange? Explaination please?

We will see how much is coming out of the drill pipe in short order, after the remaining riser and drill pipe fall away when cutting is finished. Video will hopefully clearly show velocity of each leak path.

The top is on a flex joint. That's why it's canted.

The BOP body is just fine. It hasn't seen anything it hasn't been designed for. It hasn't leaked at the high pressures of "top kill" and it will easily survive the connection of a new riser pipe.

Their vacuum cleaner can't substitute for a real seal. Whey do they seal these pipes at all? So they don't leak.

If you don't want a leak you seal a pipe.

It's a lot easier to seal a flat flange with a nice Grafoil seal to an upper flex joint, than to have a weighted contraption with a rubber boot, which can't seal a water hose.

I understand the need for a flex joint, especially with the 5000' long riser bending from forces at surface of ocean.

I don't think the riser needs any "vacuum cleaner" as the pressure at well head is a couple thousand psi above sea bed pressure. If the riser pipe (not a production pipe as I understand) taking the oil/gas to the surface is not able to take over pressure then the grommet will act as a release valve. Maybe better to have a leak at joint than riser pipe blow out?

Are you looking for info on how to make this letter more compelling?

Here's a good general rule. If you're writing to someone who's never heard of you, you have 200 words to make your point. Tops.

I'm with goodmanj. I think if you really want this proposal considered, you would need to:

--shorten the letter

--lose the words "concerned citizen" and "suggestion" because EVERYBODY's a concerned citizen with a suggestion

--go straight to "I propose bolting the x to the y with z, which will allow a tight seal and collection of the entire stream of oil using production techniques. There may be some legal/PR problems with using production techniques on this well, but surely these can be worked out, as it's in no-one's interest to have oil in the GOM even if BP pays every cent of its fine...."

--go heavy on your engineering expertise--only list what's pertinent, forget the "I'm not a...but" and get some people from this site to sign off on the idea

These are all just writing tips--I might not know a flange from a firecracker without a few minutes to think about it but I can write a darn good letter.

I agree with Erica. Start with a c.v. (leave out any negatives... state what you do and background, degrees, etc.);

State the problem.

State briefly a summary of novel aspects of your suggestions.

Offer details in resonse to request.

KISS.

Craig

I would like to hear Energy Secretary Chu speak at a news conference, and like to know who the other professionals are that are offering advice or guidance behind the scenes in the command center. Thinking that news conferences could be made from their camands operations center?

Will one of the experts if they know suggest short training certificate programs That BP will accept for Hazmat and toxic waste removal. The way I figure it if i spend 4-8 weeks in hazmat school?

Will Bp hire me? I'm not doing anything right now(unemployment) and would be eager for the work, also does BP issue you a 1099? My accountant wants me to steer clear of them if possible.

Not sure if anyone else caught this, but last night, in the middle of the night, I happened to be awake for a bit. And I caught them practicing for this current maneuver. While they were practicing, you could also see a cage or whatever from which the TV camera must be doing its work. Anyway, they have a fan in there. Thus when they show views of the places where the oil is spewing, I'm guessing they can blow the fan, which allows for a bit of a view of the saw spinning, and I think we just saw the results of that for a short while.

I was there for the dress-rehearsal, I guess. They practiced with the big claw thing. Maneuvering it. And then with this current contraption that's holding the top of the BOP.

I'm guessing at the point when this thing is nearly completely cut, they'll use multiple fans to blow the oil away enough so they can see what they're doing.

Then again, what do I know?

These are all speculations from a rank amateur in these matters - based on my observations of what appeared to be a trial run.

Has the wire saw stopped making progress or is it just my impression?

If it's a 21" pipe with a 9" pipe inside, the first 6" will go quickly, the next 9" slowly, and the final 6" quickly again.

I hope the flow does not dramatically increase as the saw cuts through the drill pipe (DP), but that may be the case.

We know that drill pipe below the BOP is a clear path for oil flow down to 3200'.

We know that BOP did not function properly (annular seal compromised, low pressure in accumulators, low battery voltage, shear ram very possibly tried to cut through DP collar). So, if the blind rams (maybe two or three sets on this BOP?) did not have the force to smash the DP shut, or did not even activate, then the drill pipe might not be restricted as much as everyone thinks.

The main restriction in the DP may be the bent portion in the riser. The drill pipe at this point may have also cracked besides kinking as it is hard steel and has a high elastic range and low yield range. Thus oil may be flowing out of DP here but still has some restriction as it may not be broken off. If DP is completely broken off here without much kinking then cutting DP will not increase flow much.

Based on my experience with seeing pipe failures (smaller sizes of 1" to 4") I would guess that DP is not completely broken off and is partially closed by kink but has also cracked here. The riser probably helped support the DP as it bent over and caused it to bend in a larger radius. This would preclude DP breaking off completely. So if I am correct and the BOP did not reduce DP to a small sliver of an openning, then cutting DP may increase oil flow larger than 20%, perhaps maybe by 50%.

All of this is just based on my interpretation of data presented here at the oil drum.

But there was always plenty of oil flowing out the end of the DP, too. It wasn't so restricted that it wasn't flowing out there. How much flow was there relative to how much is at the cracked open kink, I do not know.

Excellent point. The steel in drill pipe is alloyed for a different regime altogether than the riser pipe.

And since you mentioned this, it has bothered me for the past couple of weeks: Transocean testimony...

"Newman told a US House inquiry that the battery in the yellow pod showed 18.41 volts during an initial test. The charge is slightly above the minimum 18 volts required under manufacturer Cameron’s specifications, Newman said.

A second test showed that the battery was able to transmit 26 volts, Newman said."

OK I'm not a nuclear brain surgeon or anything but I have a pretty good understanding of battery chemistries and Ohm's Law. There is no way a battery tests at 18.4V and then at 26V unless in the latter, it was open circuit voltage. Which, when driving zero load, accomplishes zero work. Duh.

This is the kind of crap that convinces legislators unfamiliar with the hard sciences. Why the hell didn't some unpaid college prof tasked as "science advisor" leap up and challenge them on this?

Dan

Good point, Dan.

Batteries can have good open circuit voltage, but due to internal resistance of plates that are in bad shape, the voltage at load can go very low when current starts to flow. Thus, battery may not have operated the solenoid valves that make rams in BOP operate.

how is the rov footage not a 'made for tv' movie? they can capture 10k/day, best? a tenth of the total flow? this is like wile e. coyote chaining up the front door of the house, pounding in crossbeams and nails, while the entire blown off back end of the place is completely exposed to the elements. this is bath tub theater. the real action is 1,000' below the surface.

http://online.wsj.com/article/SB1000142405274870487560457528013357716426...

if the mud is escaping into the rock, the oil is escaping into the rock.

I know we all said that last week. It was like trying to put air in a tire that has a whole in the sidewall. But they gave it a heck of try.