BP's Deepwater Oil Spill - The Saw is No Longer Stuck, Working on the Riser, and Wed. Open Thread 2

Posted by Heading Out on June 2, 2010 - 9:20am

This is a repeat of the earlier post, because of the large number of comments.

Note Wednesday afternoon updates at the bottom of the post!

There has been a lot of activity at the bottom of the Gulf today, not all of it immediately successful, but all working toward the current aim of being able to field the Lower Marine Riser package. That installation requires that the broken existing riser that connects to the Blowout Preventer (BOP) has to be removed. The bent riser has been exerting some lateral pressure on the BOP, and this might be relieved when it is cut off. To minimize the damage, the first cut is therefore going to be further down the riser, provided that they get the saw "unstuck," which it seems like they might have done, but no word yet on when cutting is to resume. (At 5 pm Wednesday I have added an UPDATE explaining how the diamond wire blunted, and how they might have fixed it, but now won't. They are going back to the Shear.)

(My post continues after the video. Please click, "There's more".)

VIDEO BELOW FOLD

http://www.cnn.com/video/flashLive/live.html?stream=stream/3&hpt=T1

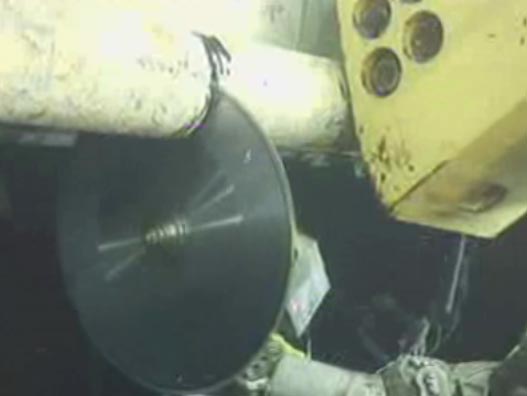

I described the plan of attack in an earlier post, and what has happened, over the course of today has tried to follow that script. I say tried, because there have been a couple of glitches that developed over the course of the day. The large shearing machine (apparently owned by BTI) appeared on the scene, and in preparation for its use some of the pipes surrounding the main riser (the choke and kill lines) were first cut away using a diamond saw.

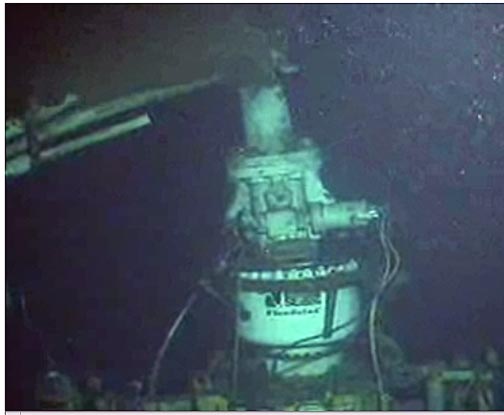

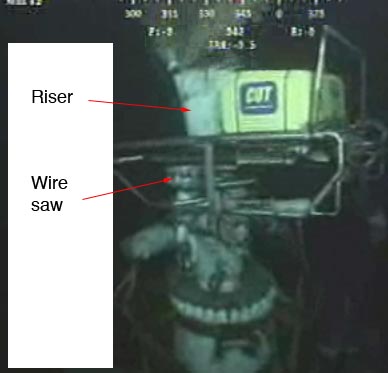

At the same time that this was going on, the wire saw that would make the final cut on the riser had been brought down to the site. The riser assembly has been cleaned of extraneous pipes already, and the wire saw would fit about the flange and below the bend.

It was now time for the shearing machine (which I’m going to call a Shear from now on) to fit around the riser and to make the first cut through the pipe.

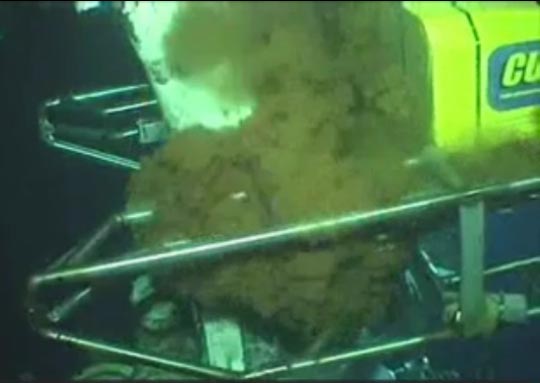

Unfortunately the first cut did not appear successful, although there was a cloud of oil and gas released, indicating that the riser was at least breached. There was a pause, and the Shear moved to a new location closer to the riser. Again it tried to shear through the nest of pipes, that now included choke and kill lines. It was not successful, and returned to the surface where it was fixed, and returned to the site. UPDATE 1: Having written this post and not seeing much happening I went off for a couple of hours. On my return (and before Gail posted it), I did not check again and as the notes below show, the Shear worked at 7 pm. At 10:15 pm the wire saw was cutting through the riser. I apologize for the errors.

END of UPDATE 1 UPDATE 2 below> In the meanwhile, a little calculation, based on reports that the White House has announced that the removal of the riser and drill pipe that are protruding from the Blowout Preventer (BOP) of the Deepwater Horizon well in the Gulf may increase the amount of the petroleum leak by 20% when the riser section is removed. There are two immediately obvious reasons why this might be the case.

The first of these is that there is a small amount of oil that was leaking up through the drill pipe that extended beyond the broken riser. That flow was one of the first things capped in the remedial effort. It did not have much impact on the overall flow volume, since the flow merely backed up and increased the flow through the main crack in the riser, but there may be a small increment of flow when this channel is re-opened with the cut below the fold in the riser.

The greater change in the flow, however, will likely come because the riser and DP, while not providing much increased resistance, did raise the pressure on the downstream side of the BOP by about 500 psi. We know that though the pressure down at the formation was at around 12,000 psi, up on the upstream side of the BOP it fluctuates in the 8,000 to 9,000 psi range. The higher resistance on the downstream side, reduces the pressure drop across the BOP by that 500 psi, and the flow rate will be reduced accordingly (the gap size through the BOP is assumed not to change).

However, if the pressure drop across the nozzle was at 6,000 psi in the current condition, (which with an orifice size of 0.6 inches, would give a flow rate of 512 gpm), then raising the pressure drop by 500 psi would only increase the flow rate to 532 gpm, or a difference of 4%--which might suggest that there is something about the drill-pipe flow that was initially capped which we don’t know yet. Alternately it may be that they think that removing the bend in the riser might ease the forces on the BOP, relaxing the metal a little and increasing the orifice size. After all it has only to open up by another 0.05 inches to give the increase in flow that the White House are predicting.

UPDATE 2: Sometime about midnight it appears that the cutting wire stopped moving and may be jammed in the cut, roughly half-way through.

UPDATE 4: On other feeds they are showing that a second cut is now being made by the wire saw, but the camera is further away. BP is predicting that the cut will be completed today and the LMRP installed. But it doesn't look good that they are still working with the Shear, because they can't use that for a final cut, and it implies that they may be having problems with the second cut also.

UPDATE 5: Part of the problem was apparently according to a BP spokesman that the cut through the first half had dulled the blade, so that when they got it restarted it would not cut. (What we do in those circumstances, which are not uncommon with diamond blades, is to run the blade through firebrick, and this erodes the material into which the diamonds have been pushed, and sharpen it. Then we drop the cutting pressure a little.) However, BP's current answer is going to be

The technician said that rather than trying again with the saw, the plan now was to use a large shear to cut the riser. The shear, which is about 20 feet long and nearly 10 feet high, was used to make an earlier cut in the riser about 50 feet from the wellhead. Because the shear will not make as clean a cut as the wire saw, modifications would have to be made to the containment cap that is to be lowered over the cut pipe. But the technician said that even with the switch to the shear and the modifications, he expected the containment cap could be in place by Thursday.

Oh, and I mentioned earlier that an ASJ system had cut through casing and pipes at the bottom of the North Sea. I had the orientation of that cut wrong (at least for the picture below) since in this case it was from the outside in, but I am aware of it being successful the other way. And so here is the picture of casing and cement cut by an ASJ. Sadly it was so long ago - around 23 years, that I can no longer remember exactly the pressure it was cut at, but I believe it was 5,000 psi. And to answer a comment because the nozzle is non-contact, the surfaces it is cutting don't have to be cylindrical.

Wed. UPDATE: The wire motionless in the slot at 12:30 am

Wed. UPDATE: The wire was apparently stuck for a number of hours and they may have changed the wire, and then restarted with a second cut. BP is still predicting that the cut will be completed today and the LMRP installed.

Wed. UPDATE 2 (5 pm Wednesday): Part of the problem was apparently according to a BP spokesman that the cut through the first half had dulled the blade, so that when they got it restarted it would not cut. (What we do in those circumstances, which are not uncommon with diamond blades, is to run the blade through firebrick, and this erodes the material into which the diamonds have been pushed, and sharpens it. Then we drop the cutting pressure a little.) However, BP's current answer is going to be:

The technician said that rather than trying again with the saw, the plan now was to use a large shear to cut the riser. The shear, which is about 20 feet long and nearly 10 feet high, was used to make an earlier cut in the riser about 50 feet from the wellhead. Because the shear will not make as clean a cut as the wire saw, modifications would have to be made to the containment cap that is to be lowered over the cut pipe. But the technician said that even with the switch to the shear and the modifications, he expected the containment cap could be in place by Thursday.

This is Prof. Goose's comment:

A continued sincere thank you to all who have donated thus far. It will help with the increased costs we are facing (see point 3 below).

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes.

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They were really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 400 comments, as it's really unmanageable. Lots of good stuff in there though.

OK, given BP's falling stock price, here is the sixty four billion dollar question. It could be twice that by the end of next month.

Piping 101 always acknowledges that piping will fail and that the best piping designs with failure in mind and engineers for failure at the best spot rather than the worst.

When I look at the riser I see that it was bent in the worst possible place, within a couple of feet of the BOP.

Piping 101 says you never want a leak near a valve or a joint if you can do anything to prevent it. Those are by far the hardest to repair. If you can design it, you always want to engineer the most vulnerable part of the pipe to have a good long straight section of pipe on both sides of the vulnerable point.

BP would not be having near the nightmare it is if it had twenty good feet of straight pipe coming out of the BOP. With twenty good feet of straight pipe, this leak would have been much more manageable.

So the megabucks question is:

Why wasn't the first twenty feet of riser a 36 inch piece of pipe with a 21 inch reducer? If it had been, the riser would have bent above where it was reduced to 21 inches. Then there would have remained a twenty foot piece of straight 36 inch pipe that could actually be used to effect repairs. Slipping a larger pipe over the 36 inch straight pipe with a an open valve would have possibly allowed for a very good seal by clamping and then the valve could have been slowly closed.

I can find nowhere on this forum where someone has addressed what I believe to be a very poorly designed riser. The few extra bucks it would have cost to make a twenty foot section of larger diameter pipe would have been minuscule compared to the overall cost.

Why am I wrong, if I am?

You're not wrong but you are missing the situation.

Your idea is based on the an incident where they had a blowout (due to human error), AND the BOP didn't function, AND the Emergency Disconnect didn't function, AND the rig sank, AND it sank in such a way that the riser kinked over. For starters this is the first complete BOP failure that resulted in an uncontrolled blow out in the gulf of Mexico in about 30,000 wells. I'll let you calculate the odds required for all the other ANDs.

Its a bit like deciding that since there is a chance in a million that a house will get hit by a tornado that the plumbing should all be designed to withstand a tornado, even if the rest of the house is gone - by god - the plumbing will be intact.

You know, that is d@mn good question and a question for Transocean and all other deepwater marine drilling companies and the manufacuturers they procure the marine riser from. Transocean is responsible for the marine riser design and installation. The marine riser on 5th generation MODU's is far more sophisticated then it's earlier brethern. The choke and kill lines have been increased from 4-1/2" to 6-5/8" OD, likewise, wall thickness has increased but the bottomline is modern risers c/k lines have a minimum 4-1/2" ID to minimize friction pressure during a kill procedure. The larger line of course add weight to the system. These deeper marine risers also incorporate multiple auxillary lines for the multiplex, power fluid systems and typically a booster line. These additional lines also add weight to the marine riser system. The syntatic foam bouyancy modules attached to marine riser helps to alleviate tension requirements at the surface but most rigs have in excess of 2.5MM lbs tension capacity on their riser tensioners.

If the saw blade has seized due to interference with an internal structure (such as the DP), would it not make sense to leave the blade in place as a stabilizing force, and proceed with a new cut nearby? There are several ways for the DP to move here, but if it is jammed by the blade, that movement might be better restricted. I'm a bit skeptical of the theory of the kerf narrowing and pinching the blade based on the depth of cut, which appears to be < 50%.

And thanks to all who make this the only site worth reading on the topic of this exceedingly difficult problem.

I would think the DP is not necessarily centered inside the riser. Lots of random pressures on it during the collapse. It could have bowed to one side or the other and been frozen in place when the riser kink crushed it.

If the shear around the tube would be closed -just before it would cut it- then the flow resistance would increase significantly. In my former post I claimed accidently the opposite, sorry. Does someone of the experts here know why they don`t do so ?

The mechanical stress - that is, the force exerted by the weight of the bent over pipe, is far higher and more important, than the pressure inside the pipe, as compared to the outside of the pipe (psig). They simply need to lift the pipe by 10 to 20 feet, to re-bend the kinked over section, and then lower it, to provide force on the area around blade to open the kerf, instead of closing it.

If the blade is stuck due to a bit of DP rattling around inside, then about all that needs to be done is to reverse the wire direction a few times and pull it backward. If that pipe moves that easy, it will shift around and release the wire.

I suspect that they may end up lowering the shears and lopping off even the pinched over parts, and then sawing the last little bit.

For those wishing to cut down on the "noise", and if you are using Firefox, add-on Greasemonkey. Then download todban.

A little history. An Oil Drum contributor wrote this script 3 or so years ago to cut down the noise from obnoxious trolls -- one of them was BUI (blogging under the influence). Obviously, trolling is almost non-existent now, but there is still too much noise for me.

Hope this of help for some of you.

thank you.

Yes. Thanks, very much.

I have two words:

UN BOLT

i was wondering about that as well. it would seem the bolts would provide as good a potential for connection as you are gonna get at this point. Of course you still have the DP to deal with.

Dimitry. I worked four years as a roughneck. Those bolts were put on with tremendous force, there's nothing you can do 5000' underwater that will "UN BOLT" them, other than cutting them off. Once they are cut, we have another issue, the inside AND outside the annulus oil / gas flow. I think everyone (yourself included) underestimated the psi forces we are dealing with here, and BP themselves seemed concerned enough that they sat and stared at the slit for some time.

[real time] I see they've removed the CUT machine either they are bringing to surface for repair or intend to reposition. My guess is it is headed for surface. Meantime we suspect the shears didn't cut the pipe as they were supposed to because of the DP inside. Where the collars and threads are in the drill pipe it is exceptionally strong. I have a book around here with the relevant numbers for DP meant for surface drilling, I'm guessing underwater at these depths they are at least twice as strong. If by bad luck where they chose to cut the riser pipe they came across ANOTHER set of threads? Ouch.

If they can't unbolt them, they should cut them.

If they ever want to actually seal against this flow, they will need a flat sufrace to seal against, not an oval deformed pipe.

The weighted riser would make a very poor seal, ESPECIALLY if the BOP interior pressure really IS higher than we thought.

If they are concerned about DP interior pressure, lifting the riser slightly would have given them some access to the DP. They could have drilled a small hole and taken a pressure reading.

Why would the drill pipe have significantly more pressure than the riser pipe? They would seem to be exposed to the same pressure below.

If the casing structure is compromised below the BOP they don't want to obtain a hard seal and stop it.

Imagine the same problem, but under 20m of nice seabottom mud.

Three words: "Drill Pipe Inside".

There's a pipe *inside* the riser, and both pipes are folded over together at the kink. Unbolt the outside pipe, and the inside one still holds the whole shebang together.

Hmm... Use the CLAW to shear both pipes below the kink. If not enough torque can be put on the flange bolts with an extension pipe, then just cut them, above the flange, or at the mating surface - either way, don't try to cut the riser and the drill pipe at the same time. Then pull off the riser stub. If the drill pipe is not rock stable wrt the riser, then any saw will bind, as another post has mentioned.

Sorry for my very manyfold post. This side is the last time nearly inaccessible for me and I didn`t know that each reload caused a new posting. Please -one of the admins- remove these posts (excepted one). Thank You !

No worries, Plasma. When the server hangs, it happens. We'll get 'em.

Hopefully we'll have the new server in place soon and things will get back to normal. *sigh*

Prof. Goose, I'm sure I'm not just speaking for myself when I offer my humble THANKS! to you and all the others who keep TOD going.

:-)

Outside of the depth of the water, there is nothing 'rocket science' about this. It's basic repair that any plumber or mechanic can deal with.

I seems the well- meaning and highly experienced rig personnel are taking orders from some idjut in Washington or London.

There is a flange with a bunch of large bolts holding the riser to the TOP of the BOP. Doesn't anyone have a couple of spud wrenches and an impact tool?

If that won't do, cut the bolts with the saw and be done with it!

The saw wire is probably bound up with the drill pipe; if the drill pipe cut angle is different from the riser cut angle the two cuts will fall out of alignment and the saw wire will bind.

Wanna duplicate this problem at home? Take three 2x4s and stack them on top of each other. Try to cut all three at one time with a saw. The 2x4s will shift around pinching the cut. Cut one thing at a time. This is basic 'Construction 101'.

Remove the bolts, remove the riser then deal with the drill pipe.

I also thaught about cutting the bolts than the riser. Why don`t they try just to screw the bolds or at least to cut them ? As a result there would be a proper flange where another valve etc. could be mounted.

Yeah, what's with that idjut in London or Washington. I just tried your 2 by 4 experiment. Put one foot on the wood and you're fine. So somebody talk to the idjut and tell him to get one of robots to step out of the sub and stick his foot on the wood. Simple.

This is obviously about a bunch of inner idjuts who made a secret short bet on BP.

You must be right. It has to be Washington messing with these people. Oil drillers can't be this dumb. I would want it well documented "who' gave this order. This looks ridiculous.

Several folks have explained why the drill pipe makes unbolting or unlatching the LMRP/BOP rather difficult, but it doesn't seem to be getting across to everyone. Maybe this experiment will help:

Go out in the yard and stick your arm out. Have someone stack 4 or 3 car tires from your shoulder right to your wrist. Grab the top of the chain link fence.

Now think of your arm as the drill pipe, the tires as the BOP, LMRP, and flex joint. Imagine a crumpled riser pipe sealing your hand to the fence. Now try to unbolt, unlatch, and remove the tires WITHOUT taking your hand off the fence.

Hope that helps visualize the problem and make it clearer why the wire saw cut is being done now --right about at your wrist.

Thanks, we get it.

They will need a flat surface to seal against if they ever hope to collect this oil and bring it to the surface. They will likely never seal to whatever is left of the bent riser after all the hacking is done.

I have been arguing for a couple of days that they should separate at the flange. That's the surface they will have at least some hope of sealing against, and they can bolt to it, creating the required interface sealing pressure. The "weighted" cap will never seal - especially if the interior BOP pressure is underestimated. It maybe higher than a few hundred psi but I still contend it is not greater than 1 ksi. They will need a good gasket (the kind that won't fall to pieces as they try to seal against high speed flow), but it is doable.

If they separate at the flange, they can hopefully lift the riser a bit, so they can cut the DP directly. If they get really lucky, they may pull a good deal of DP out, maybe all of it - they may get pressure assist.

What they are doing now gives them all the risk, but only part of the benefits. I think it is the wrong choice.

Once they get the cut finished with the wire saw (I am assuming they will) and remove the riser and drill pipe they can still decide to cut the bolts and separate the riser base from the LMRP. I personally thing that cutting off the hardened bolts may well be a more difficult task than most imagine - may require some kind of cutting torch - and would rate the attempt with the wire saw as the better first step in any case. They may be afraid to use the shear right up at the kink because of the stress it could put on the BOP stack and there may be clearance issues too. There may also be clearance issues that restricted where they could mount the wire saw for its cutting operation.

Having the drill pipe in the center is a headache I am sure. It is possible that it is bent over between the kink and the annulars down in the LMRP and may be stiff enough that it is preventing the gimbal cap from straightening like they wanted.

All these operations take time and they have to coordinate with the surface 5,000' above. Think about positioning that shear suspended from a ship on the surface. Everything is a bit like slow motion and having the live feed gives the illusion that "they can just do something - take some action" - quickly, but they can't.

Dimitry -

For safety reasons they can't have a a solid seal until they have control of the well. If they have a problem on the Discoverer Enterprise they have to be able to shut off the flow and it has to be able to escape at the bottom. A vent at the surface with the expanding gas would essentially be a blowout.

They will need some leakage to be sure they are not bringing in seawater which could plug the pipe with hydrates.

With the oil and gas going up the pipe the buoyancy and gas lift should lift way more than the leakage so the problem will be throttling it back so they don't pull in seawater.

A soft wide elastimer, even reaching over the side of the riser should be a sufficient seal. Unfortunately they just show us general sketches with no details.

The picture of the "ASJ cut from the bottom of the north sea" has pipe inside a pipe with concrete between, it also looks unbent. Unless I'm mistaken this is not the same situation as we have here.

unless I am wrong - (possibly very likely) this is a pipe with in a pipe no cement between the two.

This looks ridiculous to me. Aren't we talking two damaged pipes bent on the topside and pinched inside the BOP?

Why would you even attempt to cut both pipes simultaneously? Who can predict the forces on the inside pipe. Imho you are asking to have your saw pinched trying this the way they are doing it. I would not attempt this with a hacksaw and standard water pipe in my home shop the way they are doing it.

they should take out a ring of the otter pipe or cut wedges out of the outer pipe to relieve the (most likely) different stress angles between these two pipes.

This would take a long, long time but having your saw stuck is doing nothing at all.

At 1:40 PM EDT and watching the spill cam, it looks like there is a ROV hooked to the saw with a cable. Then, they gave the saw a good tug to the side and the saw is now disconnected from the riser and hanging below.

E. Swanson

The FOX cam was from the ROV on the other side. You could see the ice caked aroung the DSAW frame. Maybe it was not stuck but just frozen and needs to thaw out.

The entire rope saw assemble was just yanked, rather violently, by a ROV away from the the riser. Once it let go the whole ROV tipped downward making for some pretty dramatic footage.

Now the feed is showing the business end of the rope saw and the cutting rope is no longer visible between the pulleys. All cutting has now been stopped in prep for the LMRC

Before proceeding again, what would be the problem with using ROV with saw attachment to make 3 or 4 parallel "relief" kerf cuts in the riser above the diamond saw kerf. Maybe at 1 to 1 1/2 inch spacings. The cuts do not need to go all the way around...maybe 1/3 or less...but with several small cuts, you could create an emergency flex joint, so to speak, which might prevent binding.

Great Site.BTW. As a suggestion, is it possible to list at the top of the current thread a list of the most frequently watched video feeds, as a reference for the new and uninitiated to the site specifics?

Do ROV operators have 3-D / stereoscopic view?

Rgds

WeekendPeak

There has been a lot of R&D that direction for many years but as a general rule - no

I'll echo the sentiments of others: TOD is the only site worth visiting for accurate, timely information on the spill response. It's become my new favorite site, because the ratio of meat to fat appeals to the tech writer in me. I'll gladly contribute via PayPal.

I've been wondering about the upper LRA flange, where it mates with the riser. Is there a reason why the riser pipe has to be cut instead of just removing it altogether? I see a rotary servo on the LRA just below the flange, attached to a gearbox that appears to drive some mechanism just below the flange. Is that mechanism the reason why the flange can't be unbolted? Or does the flange itself play a role in retaining the DP? I can certainly understand the desire not to send the DP rocketing skyward. But if there is no technical reason not to unbolt the flange, I'd think it would be a perfect surface to receive the new LMRP.

Great question. Given that they seem intent on cutting the riser, I'm wondering if the LMRP has been fabricated to fit over the riser and the riser only.

I have been arguing that for a couple of days and even sent out a plug for that approach to the EPA/DOE/USCG.

Oil engineers have postd on previous days the links to the schematics of the top portion of the BOP, which is apparently an industry standard collet connector, hydraulically activated. It is not clear if BP has or has not attempted to use it. In may or may not be damaged. The canting of the BOP collet connector is due to the use of the flexible joint at the lower junction.

The bolts we have been told are exceedintly difficult to remove at depth. They can be cut, though.

The DP, which is suspected to be inside the riser pipe and bent with it above, may or may not be pinched by the semi-closed jaws inside the BOP.

If it is, than removing the bolts, MAY produce significant pressure forces on the DP from the flow restrictions afforded by the bent riser. To mitigate against that, BP can drill holes above the flange to allow for lower restriction.

I don't think that DP forces are a significant concern. The body of the BOP has seen this and more and held. The intenals don't work anyway.

Hard to believe BP does not have another diamond wire saw on hand at depth and ready to sub for the broken one. Small investment.

didn't someone say yesterday that those blades are 100k?

Heading Out was talking about the large circular blades used in rock quarries yesterday, in the context of sticking saw blades in a cut:

http://www.theoildrum.com/node/6541

From having used smaller diamond wire saws, there's no way to change the blade by ROV. It would be interesting to watch a video of people changing the blade.

tech manual link someone posted yesterday:

http://www.wachsco.com/productmanual/WireSaw_08-051-MAN_R0-0309.pdf

edit to specify ...diamond "wire" saws...

It looks like the wire has to be threaded through and around various moving parts. Hard to believe they can do that at depth amd by remote control.

Yea, bad planning any way you look at it. Even if the tool had to be made, they could have and should have made 2, and had the second staged on bottom. The wire has been toast for 12 hours now, and it's just now coming to the surface for repairs or replacement.. if the intention is to try again. Thad Allen seemed to think there will be another attempt.

I think the saw, and what looks like its power unit, is being hauled to the surface, tracked by the ROV.

Here comes the circular saw again...

I'm trying to visualize (fingers to temple ... hmmm).

Three madhouses: 'Mission Control' in London. President Obama's 'War Room' (is there any other kind). Operations/communications in Discoverer Enterprise (who named that ship, anyway? George Soros? A pension fund manager?).

In each case there are hundreds of people all yelling at once, running around with sheafs of paper(s) in their hands. Inscrutible noises come out of 'squawkboxes' mounted on the walls. A balding. middle- aged dude with a telephone in one hand and a 2way handset in the other stands bored and annoyed in the middle of the maelstrom.

Absolutely nothing is getting done. Most of the noise is from salesment pitching 'guaranteed' products. "Here's Mr. So- And- So which Acme Company and he has a contract to provide a hydraulic deepwater dewatering comistofizer, he spoke with you yssterday, remember?"

"No! Get him out of here!"

The wire saw salesman has sold the wire saw to a BP manager in Turkey and now saw company operators are running it from a satellite link that they have hooked up to a PC. They are using an X- box controller to run the saw. Nobody told them about the bolts which they can see on the computer screen. They both look about 20 and have never worked a day in their lives between them.

"Saw's stuck," sez a secretary to the bald guy while walking by with sandwiches.

Bald Spot turns slowly and looks calmly at the two. He then issues a long string of unprintable - and unrepeated - curses at the them and their mothers.

Meanwhile, on the Discoverer Enterprise, people are milling around trying to look busy while relaxing at the same time. The same inscrutible noises blare out of squawkboxes mounted on the bulkheads. An important looking dude with a military haircut responds to the unintelligible noises when there is a break. His plastic hat is on the table along with hundreds of plastic coffee cups, spoons, wrappers, pieces of paper with sketches on them, flyers, girlie calendars, a hammer and a box of Oreos half- eaten. Down one bulkhead and up the opposite are dozens of computer monitors. Half of them have the same feed that is up top here and the rest are tuned to Bloomberg.com. (One or two have porn but who cares?) Up on deck the three or four hands actually required to be doing something desultorily wind and unwind long choker cables around and about on the drill floor. Until there is something to lift or lower, there is nothing to do but count dead fish floating on the water.

Meanwhile, back at in Washington, the President sits with his hands behind his head in the Oval Office pondering his political future. A door opens and a ferret- like creature scurries in and over to the President and whispers something in his ear: Treasury Secretary Geithner ... "Saw is stuck, sir!"

The Defense Secretary and chief of staff turn toward Geithner with ill- disguised contempt on their faces. "It's Geithner's fault the saw isn't working," says William Gates to Rahm Emmanuel. "If Barry would only fire that goddamned little weasel," replies Emmanuel.

"We ought to just nuke the problem and get it over with!"

"Not yet, let's see if we can pin the blame on people we don't like. Problem is, we need BP, so far all the blame is on them!"

"Forget it, Emmanuel, the military has the final solution to this oil problem and that is to use overwhelming force. We can fix blame, later."

"Whom do you have in mind?"

"Look you're too hard on Geithner, let's let in all fall on Ben Bernanke! Everyone hates him even more than they do BP!"

They look over and see Obama has nodded off. There is a large photograph of Marion Barry on the President's desk.

Okay, this is ridiculous. Somebody posted here a few days ago saying that the ROVs should have proper tool-to-robot interfaces of the kind commonly used on CNC mills.

I just watched an ROV drop a tool for the sixth time in 24 hours, and I have to say HELL YES. They're bobbling tools, clumsily shifting them from hand to hand, trying to align screwdrivers with the axis of wrist rotation, it's nuts.

The paradigm for ROV tool use seems to be "human construction worker". You have your tools hanging on straps from your tool belt, and when you need one you grab it in your hand.

The paradigm should be "Evil Dead II". At the end of the ROV's wrist should be a socket with a locking connector and hydraulic power supply. The ROV has a caddy full of tools mounted below its camera. When it wants to use a saw, it takes its gripping hand off, puts it in the tray, and plugs in the saw hand.

Following up on your comment, it seems to me that we have robot operators who know how to make a robot do certain movements. But they may perhaps not be skilled as mechanics. And therefore they have no means or no experience base with which to cope, other than wait for new tools or whatever.

Since they have these mud mats (or whatever they're called), from the loss of that first saw, I had assumed they would put down mats for the robots... so any dropped tools would (ideally) fall on a mat and be retrievable. You mention other ways to make sure tools don't get lost.

I'm fascinated in some ways by the fact that there seem to be people with a great deal of skill devising the methods and the machines, as well as doing the operating. But somehow.... real-world mechanics, whose experience is crucial, it would now seem, to the ultimate success of this mission, were never consulted. As a result, it's one improvisation after another - based upon small, inadvertent errors, that might have been foreseen and either prevented or would have had pre-positioned solutions already down there - easily at hand.

"real-world mechanics, whose experience is crucial, it would now seem, to the ultimate success of this mission, were never consulted"

Also, the particular sawing job at hand is much like tree falling with a chain saw. Tree fallers have many good strategies for avoiding getting their saw stuck in the tree trunk. Notching, etc. I'm not a tree faller, but my daughter works for Forest Service and has friends with whom I've talked.

IMHO, they should have started their cut from the far side in relation to the bent over riser. Then slight adjustments in the support for the remaining bent over riser would torque the area where they are cutting. If the bottom of the cut is under tension, cutting will progress much faster, and pinching the say is very unlikely to happen. Now, with a cut started to the right of where I think they should have started, I think they should resume work opposite their original cut. That original cut will relieve compressive stress on the metal where I recommend the follow-on cut.

I suspect they need some kind of consultant to literally help the teams work together. Because things seem to be falling through the cracks. It reminds me of how they realized - many decades ago now - that some crashes of airplanes were due to cockpit crews not working together - specifically to pilots not understanding the need to listen and work together, rather than simply issue orders. They found that the pilots had personalities which were not conducive to "cooperation" but to issuing orders. I'm wondering if something similar is going on here. If the BP corporate structure is very top-down, if those "giving orders" fail to heed the experience of those carrying out the orders - if there's a lack of teamwork in some areas.

I'm sure many people involved in trying to solve the problems are experts. I have do no doubt about it. But WHO is coordinating communication? To me that's a crucial role that may be missing here.

I have sympathy for the problems being encountered. But they may be missing "communication" while focusing on engineering and so on.

Just a guess... I hope they learn the right lessons here! It's not only about engineering. Human relations play a huge role!

TheraP, Do you think most structures like these where there is a need for command and control with so many different skill sets? The national lab I work at operates in many of the same ways. Is this the only way this kind of group can operate? Oh no I think I am like that come to think of it ha!

I think the idea was to start from the near side (the 'pinched' side) with a constant upward pull on the free riser end from the surface. It's a lot easier to maintain a constant upward force than to try to transmit *downward* force from the surface to the riser. Plus, they had to attach chains to the free side anyway to ensure that it can be pulled out of the way, so it's killing two birds with one stone.

Now that they've moved to the other side, I'd expect that they would need to weight down the free end of the riser somehow to ensure a good anti-pinch force, and then "catch" it if/when it starts to fall free.

All of this is complicated by the pipe-within-a-pipe deal, of course. It seems there's not a good solid mechanical connection between the pipes, and pulling or pushing on the free riser end doesn't necessarily result in a matching force on the inner drill pipe. So the drill pipe caught the saw blade.

(Also, it seems like the drill pipe must have been crimped over pretty well by the bend, because cutting into it released the present big jet of crude. I'm guessing the limited leaks in the riser we saw before we coming from the outside of the riser pipe, not from the inside. The inside of the drill pipe isn't *completely* closed by the crimp, since they were collecting from it w/ the RITT. But it sure seems like there are two separate pressure environments to deal with here.)

Yes, I've been wondering about this, too. If I were going to make a precision cut just a few inches down from an acute-angle bend in a pipe (double-walled, I now know from reading TOD-- thanks, you guys!), I sure wouldn't try to do it with 200 (2,000?) feet of pipe hanging off the bend!

Wouldn't most people (mechanics?) at least lop off the excess pipe so you don't have to deal with its dangling weight as you attempt to thread a wire saw around and through various obstructions, all the while juggling tools from robot hand to robot hand? Is there a technical reason that's not possible, or not a good idea?

Having worked in the ICS in Houma for about a week, one thing that I can say with accuracy is that those command rooms tend to have a lot of people in there who have been working 12-15 hour days for 4-6 weeks now, fueled by good southern cookin' and way too much Mountain Dew. They are a bunch of really smart people, and I don't think (and didn't see any evidence of) that there is a lot of ego clashing or other dysfunctions, but I do think that their cognitive and decision-making abilities can and should be legitimately questioned. They all WANT to do a good job, but the question may be whether or not they are capable of it. I'm not pointing fingers or making accusations, but I do think it's a real concern.

I'm also not sure why the seem to have limited themselves to two hands...in principle you could have some to immobilize the ROV and still have a few free to do work with.

But I think that what we're seeing these people do right now with ROVs is pushing the envelope and inventing new techniques on a daily basis - and you WILL see a huge amount of work put towards developing new solutions to working at depth over the next 6 months, if only because I don't think that the recent ban on drilling will be lifted until the techniques and equipment are developed and demonstrated.

Would those be R8 or MT5 in the carousel? You know, it worked with Ash's hand in Evil Dead II for one reason: IT'S A MOVIE. Issues like dirty mating surfaces, water introduced into the make/break hydraulic fittings, corrosion of electrical contacts, etc. aren't normally covered in the 1:42 of theatrical wizardry.

Schilling.com makes some awesome stuff - very likely with machining centers much as you suggest - so I doubt they just "missed" this idea.

Geez everyone, can't you just accept that a) it's a hard problem, b) things don't always work out like you expect and c) there's no time to trace down EVERY possible problem path and make sure there's a contingency. If you did that before working on your car, you'd never get anything fixed, much less started.

Dan

I accept this is a hard problem, too hard to be solved by two dweebs and an X-Box controller.

I accept that things don't work out like they were planned. Hmmm, who planned this stuff, anyway?

I DON'T accept that there is no time. What happened to all the time that occurred while this well was being drilled? Obviously, nobody thought to have a contingency plan in case something went wrong.

Adm. Hyman Rickover was faced with similar challenges of running (primitive) nuclear reactors onboard submarines. What to do when something goes wrong? Improvise with chewing gum and coat hanger wire?

Rickover sat down with teams are calculated in advance any conceivable problem that might befall his reactors and crafted step- by- step protocols and tools to deal with them. The protocols became manuals that all reactor operators had to learn completely and follow religiously. Shortcomings in the protocols were addressed as they appeared. The process of dealing with reactor issues was to follow the book. The book had all the answers because of the time taken in advance of operation to prepare for problems and deal with them in abstract. Like oil wells, reactors are physical things than have characteristics that can be mapped.

The outcome has been an almost flawless operating history of reactors on US Navy ships.

Contrast this with BP's systems approach. Almost everything attempted on Deepwater Horizon was done in an ad- hoc manner outside of safe and sane procedure. Unlike the Navy approach to hazardous environments, the management structure on the drill platform was factured- probably to give BP veto power over all phases of the operation. When the process failed and the well blew out, the BP systems approach was to lie to the press and pray the problem would fix itself.

With the obvious failure of that approach the 'Plan B' has been to drill a desultory relief well (with a second only after public insistence!) while entertaining the media with a clown- show of inept diversions including cutting a pipe two inches above a fuc&&ng flange! Like the 'Top Hat', the 'Kill Shot', the 'Junk Shot' and the rest the idea BP promotes is that they are 'doing something'; looking busy while praying the relief well works.

What is 'Plan C'?

What has happened over the past MONTH has been nothing but publicity stunts: one obvious fiasco after another. There is no mitigation procedure or advance preparation, even though well blow outs have taken place since the dawn of oil exploration. With most of the new oil production slated to come from deep water or other hostile work zones, it would simply be common sense for BP to prepare equipment, procedures and control strategies that work properly in the intended environment. It's worked for the Navy and would work for BP if they had taken the time to study and prepare.

The people who work for BP have a responsibility, too.

Man, I need to stop trying to be funny on this forum. I guess it's because I'm joining the conversation along with a ton of other newbies, every time I try to be witty people think I'm an idiot.

The "Evil Dead" thing was a joke. I'm well aware that making powered tool interfaces work outside a clean room is a huge technical challenge: in fact I posted something pretty much identical to your comment a couple days ago.

I'm not saying that this is easy, or that nobody in the business has ever had this idea, or that we shouldn't do what we can with the tools we have. I'm saying that this is a great problem for some bright young engineers to work on.

(Pssst: first thing to do is put ROV interfaces and tool sets on the BOPs and LMRPs not just the ROVs themselves. Some self- assembly capability needs to be built into these wellhead items. Explosive bolts on critical parts is another item that would be useful. Sockets also need to be installed onto the BOPs so the ROVs can mount themselves on the BOPs torgue various parts and not be subject to reaction forces.

ROVs also need an 'eye probe'; a vid camera + pressure/temperature/flow telemetry that is at the end of a long rod or fish tape with an LED lamp so that inspections can be made inside piping without having to wait for disassembly.

If a telemetry probe was available on one of the ROVs, a crewman could insert the probe into the crack in the riser and determine where the oil/gas is gushing from.

I can buy a similar item to examine inaccessible spaces for about $100 @ Home Depot.)

Hello everyone,

I asked the other day and have been closely following TOD i'm UNEMPLOYED! Since this is a close knit industry can one of you guys ask some people over at BP how I can land a job on one of the clean-up crews? I have no problem taking whatever hazmat certs where I live so BP doesn't even have to train me!!! Thanks pay rate, tax, IE W2 1099 any info would be super!

About the riser pipe I have done plenty of tree work, and we use a little device called a WEDGE! What you do is slam it into the crack so the saw doesn't get stuck!!! DID ANYONE THINK OF THAT??? Now they have a real problem I suppose they can shake (wiggle) the riser with the cables they have supporting it.

Newbie. Test post.

Newbie here. Sorry if I'm busting any etiquette rules here but I have a few questions for someone knowledgeable about relief wells and their use to plug out of control wells. I don't intend to take away from the current conversation about the riser/DP sawing work. I'm a civil engineer and do not have a good understanding of deep sea drilling. It's my understanding the RW is being drilled vertically for x number of feet and then diagonally to it's final position.

1. How is the RW drill monitored and accurately guided to it's intended destination

2. Is the RW intended to actually intercept the well casing or is it intended to enter the reservoir just below the inlet to the out of control well

3. What if the RW misses it's mark; can it be re-directed

4. Explain the process of pumping mud/concrete, whatever material is used, to stop the flow of the well? How can the plugging material be simultaneously placed down the RW and in to the out of control well while resisting the flow of gas/oil up the relief well?

5. Is the use of RW's at this depth and apparent reservoir pressure a routine thing, i.e., what are the realistic chances of success with the RW?

I have a great deal of respect for the rig hands, technicians, scientists, engineers, ROV operators, etc that are working their hearts out trying to solve this complex problem. TOD is a great site; very informative.

Thanks.

I asked question #1 the other day and someone replied "google for directional drilling" and that got me started. It seems that it's now possible to put an electric motor down-hole to drive the drill bit directly, through a kind of flex joint, so that establishes the ability to drill along a curving path. Okay, so how do we know where the drill pit is pointing? It's also now possible to put some instrumentation down-hole along with the drill motor, and that may consist of both gyroscopes and magnetic field sensors, which allow the operators to know (in 3D) where the drill is pointing. Okay, now they just need to find out where the original bored hole is located. Presumably it was "surveyed" while it was being drilled, plus it has steel walls so where the relief well gets real close maybe they can detect a magnetic anomaly.

It's a mud driven motor, powered by the drilling mud pumped down the drill pipe.

An electric motor would have a hard time with the temperatures downhole (this well is "cool" at 180 deg.F).

Also, it has to generate several thousand ft-lbs of torque in a 4-6" diameter body, while resisting the applied pressure on the bit. And remain reliable in a hot/salty-wet/oily/gassy generally nasty environment. The electric logging tools have a hard enough time down there.

Then there's the issue of running large power cables down hole.

If those were individual segments, the connections would be a source of unreliability. If it was a long cord, one would have to deal with it AND the mud conduit going thru a snubber to block well kicks.

There's been some work done with electric motors in conjunction with coil tubing units, but nothing commercial I've heard of. Also some work with signal conductors on each joint of drill pipe, but that's still futuristic.

Right now people mainly just use pressure pulses to/from the Bottom Hole Assembly to control things.

There's a cut-away drawing here:

http://www.roperpumps.com/down.htm

Some discussion from a while back - one of Heading Out's tech talks:

http://www.theoildrum.com/node/5776

search in there for mud motor

A good place to start is from May 30:

http://www.theoildrum.com/node/6533#comment-635139

not just my comment, but those above/below, especially the link to Rockman's comments

some limited info on guiding:

http://en.wikipedia.org/wiki/Logging_while_drilling

http://en.wikipedia.org/wiki/Measurement_while_drilling

n.b. Bottom Hole Assembly is the drill bit, a mud motor, the directional stuff, the LWD/MWD stuff, and any drill collars to weight/guide the BHA

http://en.wikipedia.org/wiki/Mud_motor

http://en.wikipedia.org/wiki/Directional_drilling

http://www.glossary.oilfield.slb.com/Display.cfm?Term=bottomhole%20assembly

good technical glossary from SLB (pronounced schlum-ber-jay)

http://www.glossary.oilfield.slb.com/default.cfm

good illustrated glossary:

http://www.osha.gov/SLTC/etools/oilandgas/illustrated_glossary.html

2) they'll intercept the casing.

3) yes, they'll have to back up a few hundred feet and go again per Rockman.

4) the mud pumps

http://www.osha.gov/SLTC/etools/oilandgas/illustrated_glossary/mud_pump....

can develop many thousands of psi, they used 10,000 psi during the top kill. When the pump pressure, plus weight of the column of mud inside the pipes, plus its velocity is greater than the downhole pressure, mud/cement flows in.

5) AFAIK, relief wells have always eventually worked, modulo some mud volcano things. While drilling to these depths in deepwater is not completely routine, I have no doubt that the well will be killed. How long the wait is, who knows, it won't be over until it's over.

They may do it in 3 months total, it might take 6 or more.

Lickmeister,

There are various techniques associated with directional drilling. These include the use of "Steerable Downhole motors" or rotary steerable drive systems near the bit. The Drilling motors are hydraulic motors powered by the drilling fluid being pumped through it. The motor has a bent housing so that just pumping will turn the bit. The remainder of the drill string can be oriented with the inside of the motor bend oriented in the direction you wish to steer. This cuts the hole preferentially in that direction. When you calculate that you are on track, and wish to go straight, the entire string can be rotated for straight drilling. With the Rotary steerable devices, a pad is oriented and pushes on the string just behind the bit to cause the well to deviate in that direction.

Measurement while drilling systems are used to take surveys for positioning. These include a set of orthogonal magentometers and orthogonal accelerometers to deteremine the well's inclination and azimuth will drilling. The survey information is passed back to the surface via a mud pulse telemetry system.

By using the survey of the existing well, and computing a path to intersect it, the well can be planned and then from the know surface position, steered into a collision with the existing wellbore. You know the measured depth (path along the well bore) based on measuring each joint of pipe as it goes in to be drilled.

The systems as a whole can get you within several feet of the objective. On a relief well, I am not 100% expert, but think you drill, try to hit the target, get as close as you can, if you miss(measured depth is past where you should have hit it, then plug back with cement, side track just a little, and try again. eventually you will hit it. One of the reasons it could take so long.

The thing is that when they intercept the well, they have to have their drilling fluid weighted so that it will balance, or be slightly greater than the flowing well. They can then use heavy fluid to balance the live well to formation pressure, thereby reducing the flow to 0. The live well would then be balanced at the correct pressure and under control. They would most likely trip out of the hole, drop off the motor and mwd, run in with drill pipe, then pump cement to cover a substantial section of the well above the high pressure zone, effectively sealing it.

It will be a very difficult process but eventually they will get it. Question is, how many problems will they encounter in the process.

My biggest concern is that they come in to shallow, have a section of open hole at a balanced weight for that depth, hit the live well which would increase the pressure causing a kick on the relief well. Weighting up to fight the kick, could potentially frac the formation and introduce lost circulation. That would make things tough to control.

Hope this helps,

ej

1) Rockman claims to just use his immense mental powers. Less talented drillers use as above, with magnetic sensing for the last few yards. This area is known for high iron concentrations in the rock, which reduces accuracy.

2) the RW will intercept. Issue is flow between rock and steel or inside steel.

If inside steel, one to three weeks milling through the steel, odds of success/try <50%, Fail, back-up, lose a week to ten days (if lucky) and try again a few feet up or down.

3) Yes, week plus lost to backtrack and restart. To mill requires 50% of steel diameter to be exposed to drillbit.

4) BIG mud pumps and LOTS of mud ! "Loss of circulation event". Just keep pumping and pumping and pumping till you fill it up and get "mud returns" back topside.

5) First try by first RW, maybe 20%. By April 20, 2011 99% by April 20, 2012 100%

BIG reason I have been pushing for four RWs going at once ! (Rockman says 3 if BP was paying his salary).

Alan

PS: Check out some other articles here. Good one ending with "the end is nigh" 4,000 word article, I think I put up one of my better responses.

Best Hopes,

Alan

I believe the answers are:

1. GPS then magnetometer for the final bit. Also see Drilling deviated wells and Turning an Oil Well and Down-Hole Motors

2. Intercept the well casing.

3. Yes.

4. See Casing a Well.

5. Yes. Almost 100%. Eventually.

But I am not an industry specialist, just someone who has done a lot of reading.

The problem is how the hell do you insert the wedge into the drill pipe INSIDE the riser?

Two things:

1) It occurs to me that BP is now in charge of dismantling its own crime scene. "Interesting, that."

2) I submitted right down near the bottom of the previous thread to this my bid to make the cover of the Bad Ideas Submitted by Laymen Americans book, although I think for a number of reasons it's not that insane. And we got bumped to this thread before anyone could say how off the mark I am.

Instead of lowering a heavy milk carton-shaped "top hat" for containment, I was thinking a geodesic dome frame "surround hat" (with a skin that inhibits crystal formation, if possible?). The dome would be open at the bottom, the icosahedron panel with a small footprint just a bit larger than the riser.

The top panel would have a riser equivalent attached to move the flow to the surface. The general idea would be a dome about twice the height of the riser to try and get the flow near the center of the dome. I have no expert knoweldge of fluid dynamics but it seems that letting the riser spurt into the center of a spherical structure has to disperse some pressure. It might in this case have been better to leave the riser longer in order to support injection into the center of a dome with a larger capacity.

I believe this shape is the best for handling internal and external pressures - certainly better than a rectangular prism. Maybe instead of simply relying on the weight of a top hat itself to keep it from flying away, there could be some active force brought to bear on the top and sides of the dome to try and keep it centered, or maybe it could be anchored with weights that could sink into the mud at other locations. Inn general these structures are pretty light for their volume.

If all we're looking to do is contain/syphon the spillage until the well can be killed, this seems like a better solution than the top hat.

Presumably the tapering in the bottom half of the dome would keep a lot more oil from escaping than a flat bottomed rectangular prism.

If you're guessing I'm a little too familiar with the works of Bucky Fuller, you're correct.

Feel free to tweak or ridicule, I just can't imagine this working less well than that heavy Top Hat box.

What they're trying to do now isn't a top hat, or even the tall containment structure that they first tried a few weeks ago. Those have the problem that cold sea water gets into them and aids in the creation of the crystal hydrates.

The LMRP "cap" they're preparing for is more akin to the female end of a garden hose, except without screw threads. The gasket inside will hopefully make a fairly tight seal with the cut end of the riser, and since not too much water will get in, hydrates are less likely to form.

Thanks for the explanation. I suppose what I'm saying is that I don't see taking the risk of the backpressure of trying to seal this thing if the only goal right now is containing the oil and not killing the well (other than through relief well(s)).

Let the thing spurt into a larger vessel that (I'm assuning?) disperses the well's pressure(s) and pump out of that. I'm thinking this should A) contain the vast majority of oil/gas being spewed and B) basically doesn't seem to risk putting pressure downpipe and potentially causing any worse damage. In fact they may have been able to do this without making cuts that are theorized to be increasing the amount of oil being spewed temporarily.

A geodesic dome just seems like the best structure for holding a volume of liquid in place, and they take (my understanding) much greater pressures than something with right angles.

They probably should've been working on a big source point container that spreads the pressure over volume instead of trying to cap the well at great pressure at a small point starting weeks ago. I mean, if it's true that this well is never going into production and we just want to suck up the spillage...

It will fill up with methane clathrate just like the milk carton. Formation of clathrate is dependent on pressure, temperature and the presence of water and methane. A coating isn't going to help because clathrate formation will occur in the bulk phase.

While a dome of this nature is elegant, cost to construct it are high because of the complexity of the shape. Low weight isn't an advantage here.

I was once on an icefield research project. It being the 70s the outhouse was a geodesic dome. It was perched over a 5000' cliff and an icefall.

The wind kicked up and it rose, spinning high in the air until it disappeared forever.

Your dome's departure might be even more spectacular.

BP better start shaking those support cables and if need be lower the broken riser back to the sea floor. Leave about 100-200 feet of broken pipe left for-re-attaching the support cables (I understand the riser pipe is thick as hell) but this may be the only way to free-up the saw! Once you do that the existing riser that is left will be light enough so you can shake the riser and free up the saw!!

Obviously none of these guys worked construction when attending college.

As I read the comments here, I'm reminded that much of what we're seeing done is being done by engineers. Not people who turn wrenches and get dirty and beat stuff into submission, but engineers. Not to defame engineers, mind you, we'd be in a heck of a mess without them. But, please, people, don't forget that what we're looking at, is ROV operators following directions from engineers. Having issues with a stuck saw is not really an engineering problem. But it's not an ROV operator problem, either. So, how do you combine the best ROV operator with the skills of a plumber, mechanic, fabricator, oilfield roustabout, and a technician? Sad to say, I don't think you ever do.

In the course of developing the Atomic Bomb, during WWII, the need to refine uranium presented a problem, in that every material except nickel was dissolved by the caustic gases created during the processing. What was needed was a refinery, and one that would withstand the corrosive effects. Engineers decided that it should be made from pure nickel. Problem, they could never create pure nickel, and the entire world's production could not be harnessed to supply the massive amount to build the project. Chrysler was asked to assist in the project, and within 3 weeks, a solution for the problems that been utterly unsolveable by the engineers and scientists was devised and implemented. It took only a few days to figure out the approach. What was it? They simply nickel plated a plain steel condenser on the inside. It produced pure nickel surface and was completely coated. Required very little nickel, too. Point being? Practical experience in problem solving is essential.

Are there lessons to learn? Yes. Will anyone be in a place to learn them and change things? Those of you in the industry, ... You tell us.

I think this trade already exists, and it is called rigging where I came from. Crane operators have most of the same skill set as an ROV operator.

The Chrysler story is nice but it should be noted that the nickel plating observation came from K T Keller, head of Chrysler at the time, who was most definitely an engineer.

Your comic book description of engineers is a silly stereotype Most likely it was an engineer who figured out the nickle plating solution - the problem was too many research scientists.

After the jeans I wear at work get too ratty, then they go into the pile used for projects at home - right now my "good" jeans pile is getting pretty small. Mechanical work, metal work, plumbing, carpentry, masonry, wiring - I may not be a pro in every area, but there's not much I can't fix, and I know many other engineers with similar practical skills.

Scientists think up stuff but can't make it work.

Mechanics hit things with hammers.

Plumbers....well, nevermind.

Engineers solve problems and get things done.

;-)

Also said tongue in cheek

Dad had a saying:

"Last week I couldn't spell engineer, now I are one"

Vanity license plate seen in NJ:

IRNGNER

Engineers from the 30's and 40's were not the engineers of today. They all started as mechanics and machinists, and then got further education and apprenticeship. Notice, I made no slur of engineers, I pointed out that people who had real world experience at problem solving in a practical way, were able to use the knowlege of the theoretical, to accomplish things those without that experiential knowledge could not. One of my friends over the years, was an engineer for Oldsmobile. One of his projects in the barn was a car he designed and built from scratch. He literally designed EVERYTHING and hand built a performance car from the ground up. Knowledge, combined with experience, is a potent enabler.

However, the skill required to be a good ROV operator is going to be the primary concern above that of being a good experienced "handyman". I'm sure these guys get very good at everything they do over time. Frankly, they look pretty darn skilled to me. Imagine, sitting at the controls, with the entire world watching you work, knowing the disaster unfolding in front of your eyes, and some boss, with tired eyes and a rather shortened fuse from being constantly berated by irate management above him looking over at you and you knowing instantly... "I realize the world is watching what you do, you have now become the face of BP world wide, though your face has never been seen. YOu now represent the company to the world, who is tuned in to watch you with critical eyes. So, now that you're going to save the company, save the world, save the environment, and save a billion or two dollars... Could you hurry up and get the damn job done right...the first time?"

I would NOT want to be in that chair, even if I were good, and experienced. For a whole universe of reasons.

I am no expert on oil drilling, but I have cut a pipe within a pipe before (on land, with a hack saw), and the solution seems rather obvious to me.

This should work with the rope saw or a wheel saw. The secret is, don't cut both at once.

Cut through the riser and perhaps 1" further inside. Reposition the drill 30-60 degrees around the riser, on the rope saw just enough so one end hangs in the previous grove, with the circular saw perhaps by just walking it around the pipe. The intention is to cut the riser and NOT the drill pipe.

Ideally this would start 90 degrees off from the kinked over pipe, go around the back side using the weight of the pipe to keep the cut open, then when they get under the kinked pipe (75% cut) lift with a crane to keep it open.

When done, you have a cut riser pipe with the drill pipe intact inside. At this point, there are a number of options:

1) Drill pipe is broken at kink. Lift the riser off, so you have a cut riser with another 10' or so of drill pipe extending up. This is the easy way. A short tug after the cut will tell you if this is the case or not.

2) Bring down Mr Claw. Claw through the riser and drill pipe 2-3 feet ABOVE the cut. Since the riser is cut the riser below the drill pipe should be safe, the claw can cut through the riser that will be lifted off and mangle it all it wants and on through the drill pipe. Lift off the rigged bit, then you would have to slide off the short crused segment of casing with the ROV's. That may be tricky, but shouldn't be too bad.

3) Once it is cut all the way around lift at the kink enough to keep the kerf open, then go back with the wire saw now having to just cut the drill pipe. Ideally they could get it open a half inch or so, which would prevent binding.

I suspect #2 is the easiest. #1 and #2 leave the drill pipe extending past the casing cut, but I think that is likely to make the next step easier. They are going to slide down a new casing with a seal, once past the end of the drill pipe most of the oil will be directed up, allowing them to lower it the last 1-2 feet in a much more controlled way to attach the seal.

Trying to cut through both, particularly with a wire saw, will not work. The drill pipe is going to move vertically inside the casing if only a little bit, most likely from being forced to one side from the kink and having the pressure relieved as it is cut.

All of this has me wondering, would not a plasma cutter rotated around the pipe (in the method I describe) have been faster? They work underwater, but I don't know what the depth does to them...

That approach is one I've been tempted by but haven't been able to come up with a way of doing it so you get a completely clean cut with the tools we've seen, due to having to reposition the saw.

However if you came up with a rig that would allow the saw to smoothly orbit the pipe during your final cut it might work.

Cutting a pipe and a pipe within it at one go is bloody near impossible unless they are held together with absolute rigidity (and even then if there is stress that will cause then to shift as they are cut) or you are using a torch or a water cutter.

What I'd do is cut completely through the riser twice horizontally with several inches between the kerfs. Then make two vertical cuts on opposite sides of the rise that connect the kerfs. The band between your horizontal cuts will then fall away and you'll have plenty of room in which to cut the DP.

Once it is cut you move lower and make a the final smooth cut. (The lower cut you made previously was messed up by the intersecting vertical cuts.)

Solution:

1. Remove or cut bolts from the flange.

2. Use shear to cut riser and DP below kink.

3. Lift remaining stub of riser away from flange.

4. DP stub should not be a problem but if it is cut it with circular saw.

5. Attach new riser package to flange.

This is starting to feel like one of my weekend home improvement projects:

1. Cut off the riser and drill pipe as rough as you want between the kink and the riser flange. Use any crude method, but NOT EXPLOSIVES. A clean cut is not needed.

2. Unbolt the riser stub from the flange and remove. Take to the surface to put into the Museum of Engineering blunders.

3. This should leave a stub of drill pipe sticking somewhat straight up through the flange. It will be somewhere in the middle of that huge plume of oil.

4. Drop a new annular BOP down onto the flange. Use an extension below the BOP if you need to. Also, you might want to try a Hydril this time.

5. Bolt that sucker down good and hook up the hydraulics.

6. Run some 5" tubing down into the throat of the open annular BOP. The tubing goes to the drill ship.

7. Close the new annular and start metering all that oil and gas that comes up to the drill ship. NO SMOKING PLEASE!

I think that everyone who has done plumbing work wants to do it that way.

The BIG BENNY will be a real flat surface at the flange with a big bolt hole pattern around it to actually SEAL against, so you can bring ALL the oil to the surface.

The BIG RISK would be to take this oil stream safely at the surface into processing rigs, which you may need two large ones of, in order to process the amount of unconstrained oil/gas coming out.

For folks who know - if a pressure tight seal with a large riser pipe can be made to the BOP, can a production rig or two safely swing into production mode, starting with a live flow at time zero?

Now that does sound risky...

And you would have to let it spill during the hurricanes...

I don't think BP is dismantling it's own crime scene, everyone already grasps the magnitude of the crimes committed here, whether Holder can make anything stick is the real question. Let's make sure the bureaucrats at MMS are also targeted, and also all consultants that bribed them with gifts.....This thing is like a giant spiderweb and we should want every fly trapped in it cooked.

The LMRP should have a specially made heating coil built into the inside of the dome instead of pumping methanol into it.

I don't think BP set the riser cut properly as theY were cutting the pipe needed to be dragged in < > direction and this is why most of the riser pipe had to be eliminated before the cut was made. Great that BP has all these engineers, they also need contractors familiar with tree work......shakes head.....I think the Army should take over the hive now so a clear chain of command exists. Obviously Tony Hayward is cracking under the pressure. We need a general in charge of the HIVE just as the USA did with the Manhattan project.

TONY HAYWARD CRACKING UNDER THE PRESSURE

http://www.youtube.com/watch?v=MTdKa9eWNFw&feature=player_embedded

It Lives! Rotors on the right side of the cutter appear to work. Left side not so good.

HO or anyone else: Can we confirm that there was anything/nothing inside of the riser pipe that was sheared?

Again, Johhny Appleseed would have cut the riser from directly behind the bend, not on it's side...

There suddenly seem to be a lot of 'why aren't they doing *this*,' comments, with an implied or explicit 'the idiots' included in the post. I'd like to suggest, especially to new people here -I'm one of them- that there is a more productive way to think about it.

I've noticed many of the same things others have commented on - that they aren't doing a lot of things that seem obvious to me. Why don't they wedge the cut open? Why didn't they just unbolt the riser? Etc. Some of them, at first thought, make the guys seem like they are... well... not that bright.

BUT. These guys making the decisions, these guys doing the work we're watching, every one of them know a hell of a lot more than I do about what the situation is, they have a hell of a lot more experience than I do, they are spending a hell of a lot more time than I am thinking there way through the problem, and they have hell of a lot more on the line than I do. They are not, none of them, idiots - they can't be, or they would not be there, now, doing this.

So, when we see them doing something that surprises us, rather than jump to the conclusion that they don't know what they're doing, perhaps we might entertain the possibility that WE don't know what we're talking about. If they decide not to unbolt the riser, perhaps stop and think why they might have made the decision not to do that. If they don't try to wedge the cut open, stop and try to figure out why they might not do that.