Deepwater Oil Spill - Sealing the Cap and Jet Pumps - and Open Thread 2

Posted by Heading Out on June 5, 2010 - 9:15am

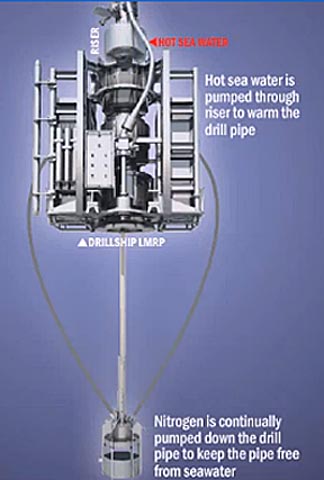

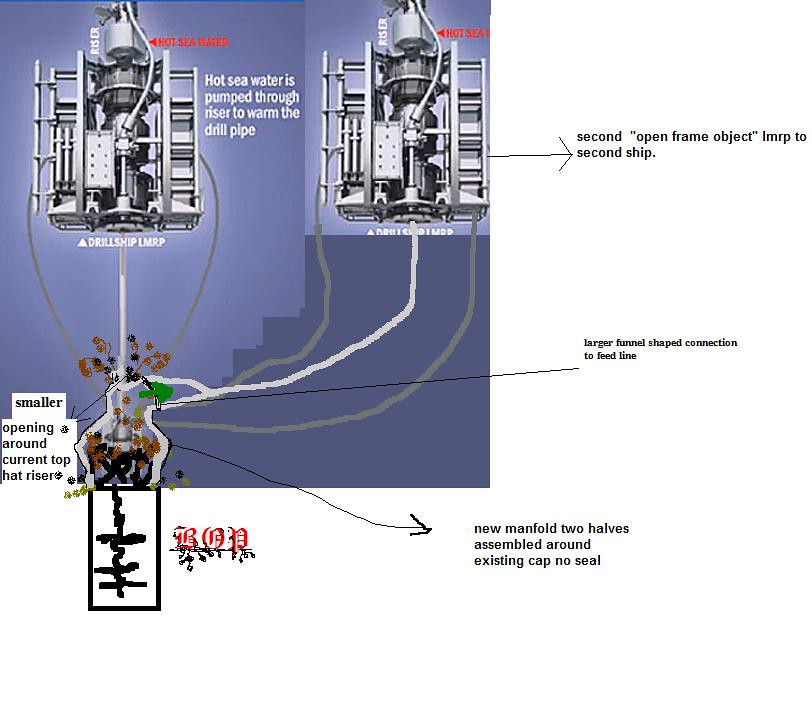

There has not been much change down on the sea bed where Thursday evening BP were able to put a cap onto the short riser section coming out of the Lower Riser Assembly (LRA) that sits on the Blowout Preventer (BOP) at the top of the well. I have looked in a variety of places for information on steps forward, and did discover that there is a second assembly above the cap, that I had seen, but had not been able to recognize until watching the video on capping available at the Deepwater Response site. It is here that the methanol is sent down to the cap to make sure that no crystals form within the cap. So for those who wish to keep the right names for the right parts, take note. UPDATE: I have added a request to the end of this post. UPDATE 2: And have now found where to look, thanks!

And given that I was calling the cap the 7th generation LMRP when it was (as the big 4 on the side of the yellow structure showed) neither, means I need to take my own message to heart. In this post I am going to talk about the seal under the cap.

There are four ports on the top of the cap, that continue to allow the oil that is flowing into the cap to flow back out while the cap was initially positioned, and to reduce the flow according to BP's plans, until the system has been checked out to ensure there are no unforeseen problems. BP only slowly raised the flow rate up the pipe when they first started using the Riser Insertion Tool (RIT) starting out with a flow of around 1,000 barrels/day and then ramping it up, at the time reporting that flow ramped up first to 2,000 bd and then up to 4,000 bd. However they later rescinded the latter number and dropped the maximum flow level to around 2,200 barrels a day. Oil and gas have started flowing up to the drillship at the top of the riser where the oil is separated and stored, and the gas is being flared. (This was taken during the flare from the RIT operation).

However the flow out of the RIT was monitored, and higher rates have now been reported.

On May 25, 2010, at approximately 17:30 CDT, the RITT logged oil collection at a rate of 8,000 barrels of oil per day, as measured by a meter whose calibration was verified by a third-party. Based on observations of the riser, the team estimated that at least 10% of the flow was not being captured by the riser at the time oil collection was logged, increasing the estimate of total flow to 8,800 barrels of oil per day. Factoring in the flow from the kink in the riser, the RITTI Team calculated that the lower bound estimate of the total oil flow is at least 11,000 barrels of oil per day, depending on whether the flow through the kink is primarily gas or oil.With the full flow now being emitted through the single confluence of the riser and BP flows at the top of the remaining riser section on the BOP, a full estimate of the leak will, no doubt, not be long in being announced.

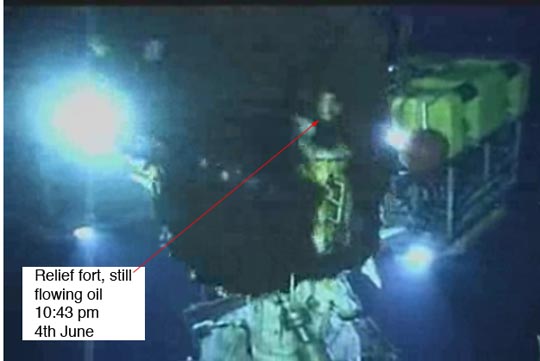

The high volume of flow means that there needs to be cautious progress in capturing all the oil and gas and sending it up the DP. However there is still a little communications conflict, since there were some reports that the taps bypassing the oil/gas would be closed later today, however at 10:43 pm the Enterprise ROV 2 was still showing an open port.

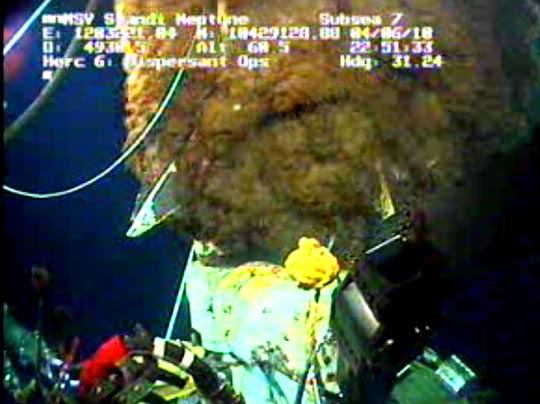

Oil was also leaking out of the bottom of the cap, which is, even when almost all the oil is being recovered, likely to be a good thing in small quantities, somewhat less than this.

Why is this? Well the way in which the Shear was used to cut the end of the riser and DP means that it is likely to be impossible at the present time to get a good strong seal around the chamber between the flow into the cap from the BOP and that out into the DP up to the LMRP.

When a stream enters a chamber through one port, and exits through another, both of relatively small size, then the jet will create a vacuum in the chamber, which pulls fluid from the surroundings into the chamber and carries it, with the jet fluid into the second port. I am going to embed a short video of a commercial down-hole video and am not endorsing anything but the animation shows you how the jet pump works. (And the flow in the Gulf is easier than that shown here ).

The reason that it is critical in this operation is that the fluid outside the cap is seawater. If the jet pumping action were to become too efficient as all the oil flowed from one passage to the other, then the “jet pump effect” would draw cold seawater into the chamber and the problem of hydrate generation and blocking of the flow path would be back to block the cap, as it did top hat. By not getting all the flow into the second pipe it should be possible to drop the suction in the chamber to the point that a little oil still leaks out (treated with dispersants) but the majority goes up the well. Getting this right should prove an interesting exercise. (But isn’t calculating this what the “best and the brightest” – Dr. Chu’s team - are there to do?) And it is not nearly as simple as it might at first appear, being able to capture almost all the oil, without getting the jet pump effect bringing in the seawater that would stop the flow.

Flow control is achieved, simplistically, with a valve at the top of the riser on the Enterprise. By adjusting the flow the valve effectively controls the pressure at the top of the riser and thus also at the bottom.

Incidentally in other circumstances jet pumps are neat tools. One of my students developed a high pressure one for use in lifting high-level radioactive waste out of nuclear waste storage tanks (you want to minimize water use, and do this by upping the driving jet pressure). Worked like a charm, when used in the real tanks. They are also used as remote inexpensive pumps in mines, lying in depressions where water can collect. The water collects, a float valve lifts and the jet flows, sucking the water away. As the water disappears, the float drops and the jet switches off.

Oh, and for those who have ideas on how to deal with any part of this problem, the Government is stepping up the ways in which you can get funding. The process goes through the Federal Business Opportunities Webpage where there is a Broad Agency Announcement on the subject. It would be more fruitful to contact them.

UPDATE:BP are slowly increasing the amount of oil taken up the drill pipe from the cap on the BOP. They have announced that they will give an update on the daily flows measured.

BP announced plans to provide a daily morning update on how much crude is being collected by their oil drillship Enterprise as the oil company struggles to contain the massive oil spill in the Gulf of Mexico.Although Toby and Bendal in comments have stated that BP have raised the flow rate up to the Enterprise to 6,000 bd, from the 1,000 bd initially ( which included 3 hours when the system was shut down) so far I can’t find a reference for this, so I would appreciate the help of readers in finding where these numbers are being posted so that I can make them available to the general readership, who often don’t read the comments.

Prof. Goose's comment:

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we are bringing online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a pretty special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Do not be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

Professor!

I'm wondering if there is any plan to put a big-ass pump between the cap and its riser. A straightforward servo loop (a.k.a. feedback loop or control loop) could regulate the speed of the pump so as to hold the average difference in pressure between the oil in the cap and the water outside the cap to be zero. No differential pressure, no oil going in and no water going out. It's a "virtual seal". Not completely different from a "virtual ground" at the input to an opamp wired up in an inverting configuration and its + input shorted to ground.

Now, even with an average differential pressure of zero, the turbulence of the oil means there will be a lot of mixing (some oil coming out and some water going in). So you still have to maintain a bit of excess oil pressure to keep the water from going in (and then freezing).

Maybe there's a pump already in the LMRP? If so, has it been turned on or not?

I am just so frustrated to see this huge friggin gusher coming out of the cap and Thad Allen shedding no light on the problem at all.

Interesting way to think about it, not sure you could build a BAP with enough "frequency response". Perhaps a "capacitor" (a pressurized tank) before the pump input to cut some of the HF noise.

But yes, I like it -- obviously, the rate regulation is going to track better, the closer it is to the leak. I'm not sure you need a BAP regulator, either -- put a "capacitor" on either side of the regulator, and just adjust the regulator (a valve of some sort) as quickly as necessary to keep the water out and minimize the oil loss.

(I'm not an oil professional at all, but EE, that's much closer to home.)

Here's two paragraphs from an article in the NY Times today:

First of the two makes no sense, as he seems to be saying that if he CLOSES the vents, which of course would INCREASE the oil pressure relative to the water outside, that "water would rush in".

2nd of the two makes more sense but is in direct conflict with the first!:

And this guy Allen is running the show for the government? Holy crap!

SO GET A PUMP IN THERE! WHAT ARE THEY THINKING?

god help us all.

http://www.nytimes.com/2010/06/06/us/06spill.html?hp

more likely the reporter making a mistake in the 2nd and mispeaking in the first

And this guy Allen is running the show for the government? Holy crap!

And you get upset because you take the reporter seriously and did not even try to get the source material instead? com'n. Don't be lazy. It is internet age and it is easy. This is what Thad Allen said this morning... If you heard even one conference call from this guy, you should figure out that he has full command of the information and he is telling the truth as much as he know.. He does not sugar coated any answer.. we have the right guy on the helm...

http://www.deepwaterhorizonresponse.com/go/doc/2931/593199/

Q: Is the cap (inaudible) well (inaudible) to be working (inaudible) doing what it's intended to do so far?

ADMIRAL ALLEN: Yes, with a couple of caveats. When we put the cap down, there are four vents on the cap to allow oil to escape that's not going up through pipe. What you want is, you want to keep oil in the containment cap and not let water in because when water gets in, you form a hydrate.

And so what they're slowing doing is—they're increasing production up the well bore, that's in a ship on top. They're flooding off the gas and they're actually producing oil that will be shifted to (inaudible) just like it would any other (inaudible) production capacity.

They want to raise that up in the maximum amount possible on a daily rate basis and then slowly start turning off those vents where the oil is coming out of right now and they're still going to have seawater coming in.

Ultimately, because we don't have a perfect cap on top of it, there is a rubber seal that connects the containment cap to the marine—the riser pipe, because we didn't get a smooth cut with the diamond wire cutter so we had to use (inaudible) more—less elegant seal with a little bit of (inaudible).

So what we're trying to do is minimize the amount of leakage, and ultimately go to full production. It comes out—it's forced down around those rubber seals because we can't accommodate all the pressure through the production line going up. And we're going to have to get to a full rate of production in that pipe before we know what the exact steady state is in the well for any kind of leakage we may see around that rubber gasket.

To combat that, we have installed equipment down there, where we can use undersea dispersant to try to disperse that oil at the source and (inaudible) much on the surface. In the meantime, we're going to continue mechanical skimming, controlled burning, and we're trying to limit, if at all possible, any dispersant application on the surface because we’ve used so much up there— more than was ever contemplated in a (inaudible) this size.

And as you know, we were—we've reached a million gallon threshold on dispersant. There's some public concern over the implications of dispersant. It's preferable to use a dispersant rather than have the oil because the toxicity is much less. But we are mindful that there is some toxic impact of the dispersant. We're trying to focus that on the subsea area where the oil's actually coming out the riser.

....

....

Thank you, Admiral Allen. At yesterday's hearing, you said that the hope was that those vents would start being closed during the day yesterday. Are all the vents still open and if they are still open, why?

ADMIRAL ALLEN: Well, if the vents remain open. We will get an update from British Petroleum. They will have that later on. They're going to remain open until they can stabilize the pressure and the rate of the production level. They're adjusting—making adjustments to the systems and making sure—they don't want to increase the production rate until it's safe to do so, but we will make (inaudible)

Apparently the hydrates stick to the inner surfaces.

I wonder if lining the collector with Teflon would help?

So why do you need a pump? Just use the control loop to modulate the valve at the top of the riser.

Maybe they are doing that now?

Just cut back on the pressure differential until you start getting water.

Two reasons. Maybe just one.

1. The weight of the column of oil and gas inside the riser has to be less than the pressure of the oil coming out of the BOP. If this is indeed the case, then fine, you only need to increase the pressure in the riser and you can do that with a valve.

2. By trying to use the control loop to modulate a valve at the top of the riser, one is then necessarily including the riser full of gas and oil in the control loop. This would complicate its design and one would also need to slow down the control loop enough so that the delay that this column adds to the loop doesn't result in an out-of-control loop.

Now that I think about it, put the valve (instead of a pump) at the bottom of the riser and modulate it with a control loop such that the differential pressure between the oil in the cap and the water outside the cap is zero (as before).

That does seem to be the simplest solution. But 1. above would have to be true for that to work. And if 1. is true then why is there so much oil gushing out from around the bottom of the cap? Are they restricting the flow at the top of the riser (at the ship)?

Yes - they are restricting the flow at the top of the riser. They NEED to put at least a little restriction on it in order to have enough pressure to vent the gas away to the flare boom.

You can be certain that they will be opening the valve on top of this riser

S-L-O-W-L-Y to be sure that they can handle what's coming out of that pipe. Failure to do this could VERY EASILY result in another explosion, fire, and/or sinking of the processing ship.

terrifying

If a pump is better than a valve??, IMHO a VFD (variable frequency drive and thus variable speed) pump is quite feasible. The key to variable pressure output and flow is variable speed, and this tech. is common/well advanced - can be sorted in a day or so, if not hours. A few electrical issues with voltage/cable size/switchgear, transformers, etc.

I've engineered several of these for offshore production platforms for export pumping/compression, but not a problem to adapt for driving a large submersible pump. Flowrate is no problem for a an engineered submersible as these can handle the flowrates in question (over 5,000 cu.m/hr) as a standard design - used for lifting seawater topsides for process coolers. Note 1 cu.m ~ 1000 kg ~ 1 ton.

Of course this normally takes months to engineer & build, but probably there is one sitting inside BP's warehouse as a spare. They (Flowserve/Clyde Union aka Weir) make these units in corrosion resistant materials such as Super Duplex SS or Ni-Al-Brz designed to go for the long haul. I think you could knock one up from scratch in cast iron in a week or two if you were motivated.

The people I used to know in BP (North Sea) would get this done if it was considered viable.

Seems that a BAP would help should help reduce the pressure in the LMRP hat, which still seems to be floating and waving around from the pressure of oil and gas exiting the BOP. The rubber seal must be taking a beating. I would be building a collar to clamp and lock the LMRP firmly onto the BOP, which has already been suggested somewhere in the comments. Seems as though the fins on LMRP might have been designed with this in mind as they would provide an easy surface to lock around and provide downward force as the collar was tightened. And perhaps a collar could help seal the bottom of the LMRP.

don't be shy of going back and reading threads, esp shelburn, bb51, rockman, others

it's been repeatedly said that they want some leakage

1) to prevent seawater from entering, and

2) the casing below may be compromised and they don't want full pressure on the BOP in case something blows out worse, elsewhere

Is there a link to a condensed list of all the proposed ideas and the pros and cons of trying them? Also is there a link for a set of plans and rumored X-rays for the BOP? This would really be helpful for us out of the box idea people. There are many sharp minds on this site but grouping the solution ideas by category would help the discussions and problem solving. Getting full access to the ideas being floated by the crews at the site would be really great, even a live full time feed from their war room would be riveting TV. Like American Chopper on overdrive.

Hi brooksbot01,

Sorry, no is the answer to all your great questions.

Thanks PriorityX

I wish that would change but I know how fast these ideas are coming and going. I have added a few more follow up details to my direct power to rams idea. http://wiki.therobotgroup.org/wiki/GulfWellFixes . After reading that there may be damage to the BOP making it not able to handle the full pressure, I added a few steps of reinforced concrete around the BOP to beef it up and weigh it down a bit. Now I read that there is concern that there is a casing leak about 1000 feet below the BOP. I mean geez, can this get much worse? I wonder if the rams were closed and the casing leaks would they be able to force enough cement down the mud hoses to fill it all the way down past the leaking casing to seal it?

My fellow Americans,

I was digging through some old LIFE magazines in the White House attic and discovered this ad, from 1972:

http://4.bp.blogspot.com/_lfibbBnlKt8/S_uU1FnWQUI/AAAAAAAAA0g/NxSkZOMzsp...

Sort of takes you back to a bygone era when anything seemed possible...

It is now simply too late according to the Export Land Model. I will probably be the last U.S. President, if I am re-elected. We had a pretty good run, and I hope you are one of the few who survive.

Signing off,

BHO

a repost for those who haven't seen this yet

The New York Times posted a link to The Oil Drum today in an article on peak oil:

http://www.nytimes.com/2010/06/06/us/06peak.html?hp

In reponse to bucket and photon:

--------

[-] bucket on June 5, 2010 - 3:59pm Permalink | Subthread | Comments top

photon --

If what you are suggesting is a verey big accumulator (container / collecting vessel / tank) down at the sea floor, and then pipe (prob quite a bit bigger than 6" -- but that can be worked out) running up to a manifold just below sea level (diver depth - forty feet under surface) that processing vessels could "plug into" with big hoses -- then I am with you.

It would be somewhat unfortunate that the riser has been cut off the BOP, because the bent over riser would have delivered the oil horizontally to an adjacent accumulator, while still giving chances to see and work around the well head with rov's. As things are now, there is a connect onto the BOP problem, and a work around the well head problem. But those aren't the end of the world. And getting the accumulator is mostly a question of finding something of things suitable along the GoM coast, dragging it out, sending it down the 5000 ft to the bottom.

Hurricane comes, processing ships gotta scoot, you end up opening a valve to dump instead of accumulate, pipe, process, and ship, but it would seem to me that's the exception rather than the rule, and in a couple of weeks tops, you are handling all the oil.

--------------

Better yet, get rid of the pipes and hoses.

What if you sent down very large tanks. Something with a bladder, so that you can have sea water on the outside of the bladder to use for ballast to send the tank down. When the tank is at the bottom, warm up the sea water to regulate the temp inside so you don't crack the tank with the warmer oil. Then has the oil flows in, it fills the bladder and displaces the sea water until the tank is full of oil. Hook some chains on it and wench it up to a barge.

This would also give you underwater storage that could stay in place in the event of a hurricane and you wouldn't have to keep spilling more oil.

As I explained in this comment:

http://www.theoildrum.com/node/6549#comment-638058

in response to:

http://www.theoildrum.com/node/6549#comment-638008

there would be no need to winch it up with force

(though one might want to use a winch to back it up).

The oil is buoyant, and wants to go up.

n.b. the "permanent riser" thing is coming at the end of the month:

start at 9:20 in this video if you're pressed for time, otherwise it's only 13:10 and loaded with info.

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

FOR A FULL DAY'S OUTPUT AT 19,000 BARRELS PER DAY,

you'll need a container 99'x100'x10' high, not a particularly big Mississippi barge. Also not a particularly big rubber bag nowadays.

Calculation as follows: There's eight gallons in a cubic foot, and 42 gallons in a barrel, or 5.25 cubic feet per barrel, so 19,000 barrels is 99,750 cubic feet. 10x99.75x100. A third of a football field, ten feet high.

Three bags would hold three days, probably long enough for a hurricane to pass through and the waves to calm down enough to allow access for pumping.

Don't tell me the US Government can't generate such a storage capacity. It probably has such bags in Iraq right now.

f'rinstance:

MPC is a prime supplier to the U.S. Armed Forces of flexible water storage tanks, ground cloths, fuel bladders and berm liners. We supply flexible fuel tanks in 3,000, 10,000, 20,000, 50,000 and

210,000 gallon capacities (4 bags a day)

including bladder tanks and berm liners to specifications ATPD 2262, ATPD 2264, ATPD 2265, ATPD 2266, and PD53048.

http://www.mpccontainment.com/military-applications.shtml

You'd need a way to separate out the gas first, or your bag would very quickly become a balloon and then pop.

Gee, I wonder how you could do that?

Too bad gas isn't lighter than oil, so we could vent it out at a predetermined pressure from the top of the bag...

I wish you'd put some thought into these putdowns.

Well, you didn't mention dealing with gas, so I did. Now would a pressure mechanism work -- it's not so much the pressure as the volume that is an issue.

How would you keep the hurricane from blowing the bags away? I doubt you're going to keep them underwater given the differential density.

"How would you keep the hurricane from blowing the bags away? I doubt you're going to keep them underwater given the differential density."

I'm patenting a concept called a mud anchor.

A fuel cell would float with 15% of its volume above the surface. If a ten-story rig can be controlled, so can a low-windage bag of oil.

Please remember we're talking about multi-layer milspec fuel storage cells here.

The gas pressure relief is set to less than the burst pressure of the fuel cell, psia.

This bag idea sounds good to me. I presume you'd best only fill them to no more than about 70% of their rated capacity so you need to have a few available.

I guess they would try to float as oil is lighter than water, so you'd need some pretty big anchors to hold them down. Big rocks with steel eyes in and plastic coated cables should do that. And no need to let them go to surface till you're good and ready. Could really be a winner for buying time this one. Has anything like it ever been tried in shallower waters?

Wouldn't your rocks sink? It's my understanding that the seabed at the site is unconsolidated highly organic muck with little to no bearing strength.

Ok, use longer cables.

If I may gently ask that people take the time to follow links when given, to reduce the noise on this fine site.

In

http://www.theoildrum.com/node/6549#comment-638058

I show how (only) 5000 bbls of hydrate has 300 tonnes lift.

Oil would have even more lift.

It would take weeks to engineer and construct a system to safely deal with that, and it would present a risk to surface ships in the (crowed) area to have hundreds of tonnes of force suddenly hit from below if a bag suddenly broke loose.

Much safer to use a continuous flow, as the 3 systems (one in place, two more coming) that BP is/will use over the next month:

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

Some FAQs would be nice, but if/until such time as that happens, please try to use the search on the site. And, follow given links to previous answers.

The site is having growing pains due to the BP crisis, and duplicates just lengthen the threads unnecessarily.

It's getting tiresome answering the same question over and over.

Sorry. Still not convinced though that bags are totally out of the question. Sure there are big difficulties. Probably won't be solved this time round. But worth keeping in mind for next time.

And there's sure to be a next time.

PS:Thanks for the hint about the search box. I didn't realise it limited results to TOD.(dumb)

The demise of BP? I hope so! Another repost from the NYT:

"BP accounted for “97 percent of all flagrant violations found in the refining industry by government safety inspectors” — including 760 citations for “egregious, willful” violations (compared with only eight at the two oil companies that tied for second place)."

http://www.nytimes.com/2010/06/06/opinion/06rich.html?ref=opinion

* Another newbie - yes I have read many of the old posts until my eyes became bleary. I sent the following idea for progressive containment/capping to the Deepwaterhorizonresponsewhoevertheyare.com perhaps to clear my conscience and provide some other approach than what I see has been almost embarassing. So w/o bashing other engineers trying to tackle this monster - here is the proposal, since posted to Google Docs: http://docs.google.com/present/edit?id=0AZem4TKHdv82ZGdzcGszNzVfMzM2OXN4... I had intended to assemble this onto the top of the BOP but reading about the concern for complete pressurized failure of the entire assembly if it is summarily capped suggests (if there is room under the BOP) to add the split coupling. I was hopping up and down when I noted the wire saw had only cut 1/2 way thru the pipe above the BOP when it became stuck - this is an element of the proposal: could they have read the note I sent? Maybe/No - then the rest of the pipe was peeled off. I hope this spurs other thoughts. If not I tried..

* The Internet coverage and your website in particular help to educate, encourage and perhaps provide new ideas to expedite solutions. Thanks!

Landrew,

I don't think this one is going to make the book just another "Cap it Off"'er.

To all newbies:

Try to do something special with your Rube Goldbergs (RG's)! You want it to stand out or it is never going to get into the book; how is your RG going get noticed next to the "nuclear explosive rotated sinking battleship screw" or " giant chemical resistant extra heavy duty underwater condom with reservoir tip" if you don't at least decorate your contraption with some garland, mirrored disco ball, laser light show or somenthing? Show some enthusiasm for the damn thing!

Mine invention of the day would borrow the workings of the Dyson vacuum to separate gas and oil. The riser tube would suck out of the "dust bin" at the bottom, and any venting below the skirt would come from the "vortex exit". It would be self-driving by the flow of oil and gas out, perhaps with a bit of nitrogen jet from the surface to help it along.

IF it worked, you'd adjust flow to where you were always venting gas but not oil, and not sucking water. Basically using the expelled gas a buffer fluid.

A larger cap might even be able to have a float guage at the water/oil line that could control venting to manage pressure at the bottom, and signal the surface controller as well.

Vortex separation has been used for a long time in industrial plants to seperate gas/liquids.

Mines Better !

Run a big-assed pipe down there and pump down oxygen - then Burn Baby Burn.....

Bill

Tunaholic: Look. I've tried to get into his book. I've suggested quantum battleships created out of quarks and constructing a black hole in my backyard to suck all the oil out. I think it's personal. landrew just doesn't like me. Sob! On second thought, maybe he likes my ideas. :)

ever seen the movie "The Secret"?

think good thoughts

AnotherEngineerWatchingInHorror,

I think you should have put the pic on page one, not page six. I did my best to get the gist from the text, and I was thinking "pictures, pictures, give me pictures!"

Anyway, I have seen a few similar ideas posted here and I have to say whoever the guys are reading through the 20,000 ideas posted so far and trying to sort out which are viable have my sympathy. If they really are doing their jobs they must go home with a splitting headache at the end of the shift.

At least when they get to the two or three I've submitted they can assess each one in less than a minute, because I've expressed my idea in two or three sentences. If they like it and need more, they've got my number! And I won't charge them for the first half hour as a special introductory offer.

So, I'd suggest you re-submit with a neater drawing and put "see drawing attached" right at the beginning of your description.

A story about a fishing village

http://www.washingtonpost.com/wp-dyn/content/article/2010/06/04/AR201006...

Alan

Krewe of Dead Pelicans

http://www.neworleans.com/community/cityvoices/408585.html

A half mile from home, but I need to get other stuff done :-(

Surely not the last

Alan

Posted this on the other discussion board but it's worth putting here. If people don't care for the suffering of others, they usually care about themselves. Unless you grew up in this area (which I did) it's hard to understand how badly they felt when they had to post this advisory. Follow the link to the ADPH and then look at the CDC "handout". Consequences for everyone, equal opportunity suffering.

http://www.gulfshores.com/issues/ "The Alabama Department of Public Health has issued a swimming advisory for waters off Gulf Shores, Orange Beach and Fort Morgan. A swimming advisory means individuals are discouraged from swimming in gulf waters or in bay waters immediately adjacent to Fort Morgan. The beaches are OPEN and visitors are still welcome to sunbathe and walk the beach, but we suggest they swim in a pool or enjoy our many off-beach activities. To read advisory information and frequently asked questions, visit the Alabama Department of Public Health website."

I liked the part about feel free to form your own "wing".

how many wings does a dead pelican have anyway?

(gallows humour - I've stared at ROV screen so long now, that when I look away, I feel vergio...)

Quote landrew from prev. thread:

"This will change how we do business in the oil business. I personally believe we will demand a relief well be drilled at the same time development/production wells are drilled as a safety factor."

Good. Hope it pushes the price up high enough so people have to think before they push that pedal.

"Good. Hope it pushes the price up high enough so people have to think before they push that pedal."

++++++++++

Then it would only be the government rulers and those they subsidize who will able to use energy. What a wonderful idea. Become a toady or live in the dark.

"What a wonderful idea. Become a toady or live in the dark."

Billions don't even have that choice. Otherwise we wouldn't be dolefully passing the hat for solar-powered hut lighting all over the Third World.

Sad commentary: When the kids bring home their OneLaptopPerChild, the family uses it for house lighting to save the candles and cooking/lighting oil.

The laptop cuts down on breathing problems by cutting down on burning candles, etc.

The solar cookers also cut down on breathing problems by reducing cooking with dung, charcoal or loose twigs.

Also cuts down on deforestation by charcoal production.

Yeah but you miss out on the good flavor of dung smoked meat that way.

I hope it pushes gasoline prices at the pump to $7/gal--Diesel to $8/gal, and I hope they stay there for 2-3 years. The same people screaming for all offshore drilling to be shut down will once again be crying.

I was thinking something more in line with $10/gal would have more of an effect.

On the other hand I am hoping govt would also begin to see the folly of not allowing the growing of industrial hemp for the oil to make biodiesel, as well as other useful products from the hemp hurds and bast. They are too hung up on the similarity of appearance between it and marijuana/cannabis however. So we are denied the use of a very useful crop, that grown in the right locale can yield 3 to 4 crops per year without the use of fertilizer and needs very little in the way of rainfall to grow.

8/9 dollars a gallon already here in UK. Not too sure, not paid for any the last eight years. At least not directly.

some will, but it's going to happen either way that oil becomes unobtainium. Might as well get adjusted to higher oil prices instead of continuing to build our lives around the idea of cheap oil forever and then hit a brick wall when we can't afford it....er excuse me hit the brick wall HARDER.

At $7/gal, people will be screaming for oil rendered from baby fur seals and panda livers.

A quote: "In the US, when oil reaches $19.99 a gallon, oil executives will render their children to sell the oil." I think George Carlin said it.

I feel like a petro engineer explaining downhole problems ...

Expensive fuel is already happening. It's been happening for ten years. It is causing businesses to fail and increasing unemployment. More expensive fuel causes the remaining business to slow to the point where even more more busiesses fail and more people lose jobs. The outcome is less money available ... to buy fuel and to maintain commerce. It adds up to a vicious cycle, an energy- debt deflation cycle.

As relative poverty expands the price level where fuel is too economically costly ... drops relative to it. In 2008 the price level where this took place and markets effected was $147 a barrel. Last month it was $87 s bsrrel. What will be the price level of demand destruction be next year?

Relatively expensive oil to date has made the world that much poorer. Prices drop but peoples' incomes drop faster. The process is accelerating.

The isn't a goddarned thing the money administrations can do about it, either. Fuel is more valuable than the work/business/commerce that can be done with it. The oil speculation dominates - at a relatively low nominal price level - because oil is now too valuable to use (waste). Instead of using, oil is hoarded: stored underground or in tank(er)s.

Or its proxy - the US dollar - is hoarded instead. Compared to other things dollars are valuable priced in oil.

Returns on the use of oil must be greater tham the cost of oil, regardless of the number price. This is not possible as the infrastructure for returns on expsnsive inputs has not been built. Our sprawling empire of waste cannot afford anything other than cheap inputs in order to be profitable.

Sorry, but we are already past the point of no return.

Since the price of dollars in crude makes dollars valuable, the outcome is the rejection of credit, non- dollar currencies and other derivatives in favor of US cash. We Yanks, Brits, French, Chinese, Mexicans, etc. are indeed Greece, in fact the whole world is.

Mark my words in the near future fifty cents will be real money!

The writing is indeed on the wall, and it ain't pretty.

Hello Deadman, In the Netherlands we pay $7,2/gal right now. I see no extra baby seals hunting going on right now ;-). And besides that, our whole country is one big traffic gridlock even with these prices. I think we have to go to $30/gal or even better: $50/gal to bring the relentless driving addiction to it's knees here ;-)

Roger from the Netherlands

What is the cause of your animosity towards people, so that you'd wish to destroy our economy, just to satisfy your blood lust to hurt people?

What's more damaging to the economy: regulations and restrictions, or turning the entire planet into Easter Island?

Depends. Are we talking about economic damage done during *this* election cycle, or further in the future than that?

Are we reaching the limits of the steel used for drill pipes, sheer rams, and other well components?

Granted, I am not a mechanical engineer; I am just a metal artist who loves to do tig welding for art http://www.allyn.com is my artistic journal.

However, I am aware that mild steel (which is what I think most well components are made out of) is not as strong as stainless steel (I know that stainless is much harder than mild steel when it comes to cutting).

What if the rams in a BOP were made out of stainless steel or something like tungsten carbide, which are harder than mild steel. Would that make it easier for them to sheer through drill and casing pipe?

What if the sheers that they tried to use to cut the riser were stainless steel or tungsten carbide? Would they have been able to cut through the riser easier?

On the same note, are the cements they use for plugs at the end of their capability at the pressures involved in deep water drilling?

Should we be 'thinking out of the box' for the plugs, pipes, etc used for these depths and pressures? Like, for example, stainless steel plugs that are in quarters or sectons that can be pushed down the pipe in pieces and assembled at the bottom by robotic and then put into place. They would have to be machined so they fit precicely between the drill pipe and the casing.

As we go deeper and deeper to find oil, I can only guess that the pressures will get greater.

Will we have to re-think the materials and ditch mild steel and cement for something else that can withstand the pressures of greater depths?

Truly,

Mark Allyn

The most stainless type ie marine type - 316?? is not very hard. Tool steel for drills etc is high carbon, heat treated I think. This rusts easily. Very high tensile is Maraging steel etc. I am also not a mech eng but I used to work in a steelworks!

Sc of lc steel is around 137mpa

316l is around 115mpa

mc > ss

duplex is a good steel and is well used in the industry.

Long term , ss is sucseptable to stress corrosion cracking frim clorides < 316 grades .

High chrome/nickel steels have the ultimate strengths...

Hi Mark - cool stuff you do. I just took a TIG class at The Crucible in Oakland, CA.

Anyway, I don't think the material limits are reached, and most of the steel in things like the BOP is alloyed for toughness and corrosion resistance. And one can buy thicker casings if one isn't so cheap.

As far as the BOP shear/blind rams in this case: many issues:

(1) low battery in a control pod

(2) hydraulic leaks down at the BOP

(3) failed application due to loss of power at the surface.

(4) inadaquate testing (search for Brazil rule here on TOD)

(5) what I consider a faulty design assumption.

(and more, see the BOP stuff in:

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

The faulty design assumption is that the blind/shear ram will only be used on pipe, not on pipe joints.

This presumes that during a blowout, one has time/presence of mind/rig power/... to controllably close a pipe ram, back it off a bit, run the drill pipe down (or up) to seat on this ram, close it, then activate the blind/shear ram.

There's a reason ejection seats in jet aircraft are as simple as grab and pull and eject - during an emergency, things are going wrong in ways that are not planned for or plan-able-for in all cases.

This issue is also one of ram power, so they would need larger cylinders/higher pressures in the blind/shear ram as well.

But it's all doable.

Just a matter of will and management attention and clear thinking. I'm reminded of the Titanic "we had as many lifeboats as the rules required" - sure, but the rules were written when "ships bigger than ..." were 1/4th the size of the Titanic. How about a simpler rule: enough lifeboat seats for everybody on board.

How about a simple BOP shear/blind ram rule: it can shear anything (above the Bottom Hole Assembly)?

There are other issues, e.g. some new drill pipe is bigger/stronger than old BOP's shear rams.

Some relevant reports from the MMS. Each TA&R report has one or more .pdfs associated with it.

Review of Shear Ram Capabilities

http://www.mms.gov/tarprojects/455.htm

Evaluation of Sheer Ram Capabilities

http://www.mms.gov/tarprojects/463.htm

Reliability of Subsea Blowout Preventer Systems for Deepwater Applications--Phase II

http://www.mms.gov/tarprojects/319.htm

More info on a variety of subjects at the MMS tarprojects

(n.b. slow loaded due to less than optimal applet use)

http://www.mms.gov/tarprojectcategories/

Best solution I've seen to the pipe joint versus shear ram problem?

Have two shear rams farther apart than the longest joint. One or the other will hit bare pipe.

They already have that, only one set can be across a tool joint. That is why they already have two sets in the stack.

It is a big unknown at this point in time, as to why they were unable to shear the drill pipe and there is much speculation that the final casing may have been shot up into the BOP stack by the force of the blow out. That is a very real possibility. But will not be able to be analyzed until the well is dead and they are doing the final P&A operation on the top and the BOP stack will be removed. They will be able to analyze a lot of things at that time.

This leaves the integrity of the well casing in question and the reason why they are afraid to just try and cap it by force and then have a much bigger problem they they do now. At least now there is some containment through the stack, if they can just rig the riser to capture more of the output. Which so far they seem to have been unable to do that.

Wireline

On the previous BOP test there was an exemption for not operation the casing shears. To me that means they were not operationial and every body knew about. The fact that BP hae not madw a noise about, means they had signed off on it.

If these were in operational order I am sure they would have cut anything required. Even if they did cut they do not seal. The cut pipe would need to be lift above the blind / shears before closing.

As I understand it, they gave up trying to close the shears very early on.

I know there are big risks of making things a whole lot worse in shutting off the flow but if it was possible to close those shears a little bit further ,preferably gradually, would you do that?

I saw somewhere a diagram of the shear ram which looked as though they could be operated by bolts.

If the drill pipe is stuck in the jaws keeping them apart, could they ease them off to let it drop out, then close them up gradually?

I suppose not, or they'd have done it long ago.

casualwatcher

Yes they did give up early, the Blind shears did not close, that is where the discussion about tool joints in the rams came from. There has never been any comment about the casing shears to my knowledge, except on the BOP test sheet where they did not even funtion test them due to an "exemption"

If you look at the sheared riser section containing the cut dril pipe. It looks like two lengths of drill pipe side by side.Looking closer I believe it is the 9 7/8 casing doubled in a fig of eight and the left hand side containing the dril pipe. This is the reason the blind / shears did not shear.

Operating the shears by bolts is a surface rig BOP, not sub sea.

As has been discussed before, due the rupturing of the burst disc in the 16" casing they no longer want to close in the well as this will cause a sub sea blow out, ie blow out on the outside of the casing directly to the seabed.

The cause of action from here is to collect as much oil as possible and wait for the RW to do its trick.

Not true.

There is a casing/drill pipe shear that cannot seal and a drill pipe shear/blind ram that can seal,

per the presentation BP made to the House Energy & Commerce committee:

http://energycommerce.house.gov/documents/20100527/BP.Presentation.pdf

They are right next to each other in the stack.

see page 7 and/or page 40.

per these MMS reports, tool joints are often extra long to allow for re-working and there are no standards for joint length; and in any case, if an automatic shear and LMRP release sequence is activated, there is no opportunity to correctly position the tool joint.

Review of Shear Ram Capabilities:

covers the sorry state of testing, lack of requirement to shear a joint, etc. the short ("mini") version.

http://www.mms.gov/tarprojects/455.htm

Evaluation of Sheer Ram Capabilities

the expanded, updated version.

http://www.mms.gov/tarprojects/463.htm

The tensile strength of X80 grade drill pipe is ~500 -> 800 MPa.

Well cement can withstand pressures of 20,000 PSI and ~250C. To put that in context waterproof building concrete is around 4000 PSI.

Another seafloor survey, bubbling and quaking

http://mfile.akamai.com/97892/live/reflector:46566.asx?bkup=54013

Be patient, let your eyes adjust, tip your laptop screen a little

yes, and look at Q4000 ROV I - mud at the moment, but a bit ago it looked like dispersant being sprayed at a bubbly place ...

eh, i think its just a low resolution illusion

So why is an ROV staring at the bottom? Watch the venting.

well, let's just hope its not what it might be .... if you get my drift.

which ROV is that? - I cannot get the akamai stuff to display.

The Q4000 ROV1 looks like it's moving hoses in preparation for the Q4000 direct connection.

And doing so in a hydrate snow storm.

info on Q4000 direct connection at 08:05 in the May 31st tech video:

http://bp.concerts.com/gom/kentwellstechupdatelong053110.htm

and avon is looking at poseidon ROV 1

Unless they can shift BOP valving to pull from above the shear/ram constriction, I'm not sure these lines will help much. If they're pulling from the high-pressure side of the BOP, which is where I understood is where the mud was intended to go, then this will get a LOT of oil but not help much for the leak.

Thanks a bunch for off topic

Off topic? How? The topic is the choke and kill lines, right? I'm trying to understand why they want to connect them?

avon's post that started this thread was his suspicion of ocean floor leaks, then I noted that the only ROV I saw on the floor was dragging hoses around, perhaps for the choke/kill line Q4000 direct connection.

From the top-kill graphic:

they can only pull from beneath or within the BOP.

But if any of the lower rams are closed, then they may be pulling from a lower pressure side.

n.b. the shear/blind ram is the top ram, under it is a casing shear that cannot seal, then there are pipe rams that can seal around various diameters of pipe.

I haven't heard if they know where exactly the pressure reduction in the BOP is though.

So - I guess they figure by getting a lot of oil, they'll reduce flow above the BOP, so they can:

(a) throttle that back and make it more controllable

(b) have something to suck up some oil if there are issues with the DE and when they do the switch to the new/heavy cap for the long term containment option.

If any of y'all are wondering where the ROVs are working, you can see the location and recent track of any of the ships involved by going to:

http://www.marinetraffic.com/ais/

Click on the Gulf of Mexico block on the world map, zoom in to the spill site, then use the Go To Vessel menu in the bar on the left.

All anchored at the spill site at the moment (boring), but yesterday the VIKING POSEIDON took a trip about 12 miles SSW and stopped 4 miles south of the spill site for 4 hours.

Note: sometimes the vessels disappear even though they are still out there

This is the second time I've seen Poseidon ROV on seafloor

N: 10430530.17 depth: 4934 looking down ~45 degrees

E: 1202546.55

Screenshot of another ROV dive to seafloor 08:40 CDT today

assuming this display has depth in meters, not feet

heh, and look at enterprise rov 1 - that black bit is expanding/contracting

no location data, swam to the surface

How about some captures so that the rest of us can see this?

for reference,

12000bpd is roughly the size of one of the storage tanks (80m od x 20m high) at whiddy island.

Whilst it's a FUCKING BIG TANK ( I've stood in the middle of one !)

it's a drop in the ocean wrt the GOM.

But. Over 6 weeks, it's a lot of oil...

i just don't understand why people are using a number of 12,000-20,000bpd. by bp's own admission, the flow is 60,000 or higher (testimony in front of congress and numbers provided to the coast guard as reported here:)

http://www.publicintegrity.org/articles/entry/2123/

this is bp's own estimate, finally made public.

let's deal with the actual crisis, instead of the pretend crisis that all of you bp apologistas have adopted.

is there 60,000bpd coming out of that riser? or is there a leak below? choose your horse wisely.

Probably because this is not an unconstrained blowout. It is in fact heavy constrained (with at least one large pressure drop at the BOP, and possibly another obstruction in the well), just not very well contained.

It's bad enough, but it could be considerably worse.

Around 19:10 CST, the flow from underneath the cap looks like the most I have ever seen. If BP is recovering anything, the amount going into the water column is still huge :(

Are the gates at the top of the cap corked by now? I don't see a top-of-the-hat rover pic anymore?

It's still a lot underneath, but I'm not sure it's more than yesterday. The hat isn't bumping around, so maybe it's fitted a bit tighter and the oil is squirting out a bit?

not an unconstrained blowout

However, it is evolving towards that. Continued sand erosion of the BOP is (high probability) reducing the pressure reduction there. And the post-BOP restriction has been sawed off recently (only 400 psi though).

The down hole well restrictions ? God, the Devil and perhaps BP only knows.

Alan

As demonstrated above, it's really necessary for TheOilDrum to put the current numbers in consistent terms. I think people are dragging up hypothetical numbers from weeks ago, despite the current estimates. Endless noise results.

PLEASE CORRECT THIS, SENOR GOOSE!

kimyo: We don't know how much is coming out of the riser, and we don't know if there's a leak below. The 4/23 estimate of production from a "full blowout" was obviously based upon early calculations derived from projections about the reservoir and the well design. Further, whatever this horrendous gusher is, it doesn't seem to be anything like a "full blowout." Thank Mother for small favors.

The only remotely reliable (emphasis on "remotely") estimates I've heard were from the gov-sponsored independent panel that set a range of 12-19kbpd for the lower bound, before the riser was cut.

Take the middle of that range, add the 25% that gov/BP optimistically estimated cutting the riser would add to the flow, subtract the 30% or so that they are now (optimistically, again, IMHO) estimating as the percentage being captured by the cap. Where are we? 14-15kbpd still flowing? At least? Maybe. But we just don't know.

Starting flame wars and beating up on the oil patch guys won't shed any light on this situation. Everyone here is perfectly capable of playing that game, as I tried to illustrate in a post responding to one of the flames from the *other* side in the last thread. We all know how to do it, but it's a waste of bandwidth, on the net and in our heads.

Please, people, couldn't we put the politico-religious wars in their own threads?

They are using 12-19k because that's what they have from a panel of experts brought in by the government.

But you knew that, right?

i know that the 12,000-19,000 number is the low range of the estimate as reported here:

http://www.huffingtonpost.com/2010/06/03/gulf-oil-spill-latest-fed_n_599...

attack the huff post if you like , but 'unknown unknowns' is a quote from that panel of experts.

attack the wsj as well, cause they report a casing breach at 1,000'.

you really think they have this well under control? there's no mud circulating, right?

"Casing breach at 1000ft"

That would explain a lot, and is not at all to be unexpected. I would not be surprised at all to find out there were several casing failure points.

Anyone know offhand what the geology is at 1000' below the wellhead?

Mud dominated system. Maybe a little shale, a little sand.

Thank you sir.

Here is one picture out there"

'http://s372.photobucket.com/albums/oo164/Tunaholic/Deepwater/?action=view¤t=GOM20Oil20Spill20Figure_2a.jpg

Can you translate? This means, perhaps, that high pressure oil+gas has a conduit to 1000' below the sea floor, with the possibility of venting directly into the ocean?

Yes, unquestionably. The blowout is in the raw hole (annulus). Upthread I documented seafloor venting again.

"you really think they have this well under control? there's no mud circulating, right?"

I don't think anyone here thinks this well is under control. Very few think it will be/can be until a kill well is successful.

There is a massive amount of oil spewing into the Gulf, causing very grave damage to the environment and the economy—both, perhaps, on a scale most have yet to imagine. As Alan suggests, it seems entirely possible that it could get much worse before it gets better.

But, tossing around old, speculative and unsupported numbers does *not* help make the case I think you want to make. It makes it easy for people who *want* to disagree with you to discredit your arguments and annoys those who already feel attacked or presumed guilty by association with the industry. Bad strategy.

Most of the oil guys here would likely agree with your assessment of BP's lame public relations campaign and their (probably not entirely intentional) misinformation flow. Very few of them are even close to "apologistas" for BP's fatally-flawed practices. They want this gusher stopped and the mess cleaned up, too. For some of them, their jobs depend on that. And they *really* don't want to see this happen again, ever.

Finally, they know *way* more about what's actually going on and what might be done to fix it than the rest of us. Working together, if we even hope to understand, seems essential.

Is there a link for that WSJ story? I can't find it.

Those are the only numbers from a remotely authoritative source available. Huffpo and the other various sources on the internet can whine about them all they want, parse the language of the reports, etc. but they aren't exactly supplying any qualified alternative estimates. All they are doing is presenting sensationalism for their own benefit.

So unless you have some basis for an alternative numerical estimate that is as fact based as the Flowrate Team's work, you are not adding anything to this discussion.

Until then 12,000-19,000 is what we've got.

As far as the wsj and the breach at 1000', that has already been discussed here by people with far more experience in this area than you, me or the wsj.

let's deal with the actual crisis, instead of the pretend crisis that all of you bp apologistas have adopted.

heh heh, I think one of us does not want to read the release before jumping to conclusion:

a full blowout could result in a spill of 64,000 to 110,000 barrels per day

This is the estimate for a full blow out.. right now we have the BOP sitting in the middle restricting oil/gas flow. So we don't have full blow out (yet)..

If you "wisely" believe the current amount of oil leaking is 60,000 bpd,

I've got a horse that I would like to show you.

It is amazing how quickly BP was able to get that Stephen Chu on the coverup team. Do you know how much they had to pay him to keep the 60,000 bpd number a secret? Probably a pittance compared to BP earnings. That must be why it has gone unreported as everyone will believe the Nobel Prize winner expert that Obama put in charge. BP solution - just buy him off and Obama too.

"If you "wisely" believe the current amount of oil leaking is 60,000 bpd, I've got a horse that I would like to show you."

@Augustus:

You didn't respond to his well-chosen technical points about obstructions. Please do so.

My post was response to kimyo at 8:00 pm. tdhere is no mention of obstruction in that post that I see.

The point is that all of the numbers reported have always been estimates. BP has always stated that the only real solution is the Relief Well. No one knows what the leak number is, not BP, certainly not the Coast Guard as they have no experience in this field, and the reporters seem to find the "noted scientist" of the day who wants some publicity. In the end it will not matter how accurate the estimates are or were. It is what it is and will need to be cleaned up.

Maybe because we can read and you can't. Careful who you are calling "bp apologistas" Mr. Running Around With His Head on Fire.

As you will see from your own link, it says "a full blowout."

Which is precisely the case we would be dealing with if that BOP wasn't restraining flow.

We know there is quite a pressure differential between the wellhead and pressure at the top of the riser mount - and let's hope it stays that way. (8.300psi at wellhead, 400psi at the riser mount.)

Using the oil leak counter at this site:

http://www.wkrg.com/gulf_oil_spill/spill_cam/

I have no idea if the counter is correct.

Using that number, roughly 6,500,000 cubic feet or 150 acre feet of oil has gushed out since the start.

Way to go, BP. Heck of a job. And this is just a downpayment!

Did anybody else listen to the BP investor briefing? While not a lot of technical info, there was some. (Other prospects, etc.) Anybody chose to comment on the tech aspects of this call?

rellio: From The Spokesman Review via Google: "[Hayward] telling them BP would have money left over for a dividend after covering the spill costs." Make of that what you may in the context of some of Hayward's other pronouncements.

It seems allot of folks are introducing ideas that misses the fact that this drill pipe is also prone to leaking at the subsurface below the BOP. That's why they've nixed the idea of any type of cap that completely cuts off the flow pressure. When they tried increasing a resisting down pressure with the top kill they saw gas pluming through the sea bed around the drill pipe.

Something went wrong with the drill pipe casing below the sea floor.

There is supposed to be a cement plug at the bottom of this set up and I don't see how there could be one.

If the flow can't be plugged at a good distance below the sea bed then at this point all they can do is redirect the flow.

In reguards to the narrative and image @ the head of the page:

Not to sound rude but I'd hardly call what's depicted in the image a 'leak'.

This has been the pattern here for a while now. Every mickey mouse "fix" by BP is presented as a serious engineering solution. First it was the 4" pipe inserted at the end of the (now gone) riser pipe that was to "suck up the flow" and now it is the 6" pipe in the LMRP cap combo with an exposed leakage area 50% or more of the 6" pipe cross section. Somehow the high pressure turbulent flow will shove itself into the 6" pipe instead of the path of least resistance. That they mangled the riser removal and chose not to attach a new riser-valve assembly to the top of the BOP says it all. Supposedly it is "impossible" to remove some bolts at 5000 feet even though run of the mill circular saws can cut through the piping without issues. They could have drilled the bolts off if they wanted but clearly they did not.

I suspect that they know that the there is damage below the BOP that renders any attempt to divert the flow pointless since this is Ixtoc part II. Note that they were careful not to repeat the mistake in that case of junk plugging the BOP. I hope that one of the relief wells hits its target by the end of August. But in the real world we'll be lucky if they manage to plug this disaster by the end of September.

Have you ever tried to do a field engineering fix? You are limited by resources on hand, you can send out for more, but can't be used until in hand. I suspect that they have some very good engineers on the problem and their choices would be self-evident giving the information they have at each point in time. I've been there multiple times and learned not to be hasty in my criticism.

The bolts are probably very high-alloy steel as opposed to the riser. The cuts in the riser made with the "run of the mill" diamond circular saw are not dimensionally critical. The bolts will have to be cut nearly simultaneously right at the flange. If one sticks, the pressure could bend and tear the flange - back to where you started.

If it was possible, unlatching the existing LMRP would be easier. There must be a good reason for not doing so, as that is what was supposed to happen during the emergency disconnect procedure.

If we are to believe yesterday's figures, 6.15 gallons/sec are escaping. Agreed, that's not a leak, but our perception is distorted by the billowing gas.

(Based upon the statement that they are capturing about 1/3. 19.000 barrels used as basis for calculation, which is the figure they have given.)

cmrosko,

Yes there is supposed to be a cement plug at the bottom of the well and it is supposed to extend up the outside of the final casing string. It is the failure of that plug that caused the blowout. The cause of the failure is not exactly determined and may not ever be known, but there are a lot of good explanations in the previous threads.

TOD on casing and drill pipe and casing and cement

BP doesn't think the flow is coming up the production casing which means it is coming in around the top at the wellhead seals then back around through the drill pipe which is 3000' below the BOP. It's possible that pressure has forced the casing strings up against the bottom of the BOP.

The rupture disk is at the liner hanger seal, is set to burst before the casing bursts, because even if you don't have a pressure seal you still have the casing integrity to support all the strings that are hanging off the end. Looking at the casing schematic I don't see a liner at 1000' below BOP, but that's about where the base of the 28". Or maybe they meant the liner hanger for the 16" which could be 100' below BOP judging from the picture.

The BOP is already choking back the flow by 6 K psi, and the formations could be taking the rest. Downhole who knows what kind of flow paths are outside the casing.

I sure hope they have a better casing design for the relief well seeing as how it's probability of hitting these high pressures is pret near 100%.

What if the bottom 7" casing, plug and all telescoped up to the BOP.

Do you think the 9-7/8" is still where it should be?

If there is no casing at the bottom how will they guide the RW. Can they aim at an empty shaft?

Donner

I think that is a possibility. There wasn't much for cement down there, 50 bbls I heard, and with mud contamination from the two diameter wiper plug how much of that was good. There are two 9 7/8" strings, one that is the top half of the production string (with 7" to TD), and the other that is the intermediate casing liner at 17,168' but which is hung into the uphole strings the 13 5/8 having a burst of 8 K psi. I think this string is still intact but that it is blowing out at one of the weak spots further uphole.

I'd like to ask if the (current, perceived) greater risk (or fear) of introducing back pressure above the BOP is that the BOP itself might 'blow' (out of the wellhead)... or whether a blowout might (or is more likely to) occur from the casing breach below the BOP.

Could there be any hope that 'entombing' most of the height of the BOP in cement (to hold it in position) might allow a wider range of options 'above BOP'?

Thanks for your time.

Peter B.

-----

Unfortunately, any such 'entombing' would quickly run into trouble. The seabed around the wellsite is soft squishy mud. You couldn't make it support the weight of any significant concrete structure, so the weight would have to be held by the well casing and the structure that currently holds up the BOP.

This foundation is NOT overly robust! It has already been subjected to loads it was NEVER designed to withstand. We're lucky it has held up as long and as well as it has.

Adding any more loading to this structure would not go down in history as a brilliant engineering maneuver!

I recently read a post by Activated05b on the closed thread about relief to New Orleans after Katrina that is just about 180 degrees contrary to the facts.

http://www.theoildrum.com/node/6564#comment-641430

I will dilute any further claims by him on any subject 50:50 with NaCl.

Alan

Were you on the relief convoy, too? That would be a very big co-inky-dink.

If you wern't with that convoy to know how they were chosen and prepared, perhaps some NaCl would help you too. Don't overdose.

I was not part of a convoy - I was in the Operations section for a TF HQ.

Yeah, I agree Activated went a little over the top. There were enough roads open into the city that the police and Guard had trouble keeping people out. Maybe his commander over-reacted and ordered that selection policy, but it surprised the heck out of me. I've never heard or read a similar story from others in the Guard.

ahahaha...5 yrs down the line FEMA still won't admit that FEMA just squatted over new orleans and just took a giant dump on the Big Easy.....

It was a systematic failure of an organization if there ever was one

I would say his was a little over the top, my 81 y.o. mother and her 80 y.o. boyfriend, who is a semi-retired project manager for BOH Bros., made it from Folsom (north of Lake Pontchartrain)to the levee break two days after the breach. He was called in and she went to help relieve the drive back.

Ah - so you were in a tent on the tarmac on NAS New Orleans?

Care to tell me which TF you were part of?

OK, Activated, this is making more sense now. Your first post sounded like a general statement on the whole city.

Thanks much for your service at the NAS, y'all did amazing work in primitive conditions.

The refugee traffic was the result of a police blockade; one of my best buds had an M-16 shoved in his face, while holding a baby, just for trying to walk a few blocks more to his house. I hadn't known that the Gretna and Jefferson Parish cops were also blocking aid from getting in to NO.

As for the "unmarried volunteers", I believe you --the rumor mill was WAY over the top about the violence; stressed out a lot of rescuers and residents for no good reason.

From the video, I've noticed that they have not yet reached the critical stage on the chimney effect plan where seawater was going to be sucked into the LMRP cap assembly, or created so much differential pressure at the bottom that the riser might implode. Taking it nice and slow I guess, no hurry to get those images of roiling crude off the air.

This looks like their steady state solution to me. They stated quite clearly they DONT'T want the seawater in there at all. The only way they can have it without a seal is with a significant amount of oil continuously pushing it out. They have to run it with a positive cavity pressure, not negative one.

Success is in the eye of the beholder. BP says that they are very happy with the result.

Since BP has committed itself to a siphon system from the beginning, they have been improving the result, with the third attempt maybe breaking the old record of 25% they achieved with the horizontal straw. Maybe 30% this time, maybe 40%.

Lets just get used to it. This is what a "successful" oil recovery looks like. Most people really are not looking at the underwater video, so the headlines that say things are pretty good is what they see.

I now think that BP has decided early on that coupling directly to a wild well is simply too dangerous and they will not do it. Since BP is really in charge, the country has to live with that decision.

the country has to live with that decision because at the given point IT IS the best decision.....you put back pressure on the BOP stack and f*ck it up then you really have an uncontrolled gusher spewing out who knows what volume of HC's.

armchair quarter-backing is easy ....

the engineers have to take their time adjusting the flow....too quick and either you get hydrates or you get fireworks top side.....

it may escape most peoples notice but they have to flare an enormous quantity of NG topside in an environment where the whole bloody place is covered with OIL .....the poor guys at the wellsite are sitting on a sheet of oil with naked flames flaring the NG ....you get the picture....they are having to water down the oil continuously which is about the best they can do ...a slight letup and you have the perfect conditions for the bigest 4th of July fireworks anyone has ever seen..

give the guys their due...most people would wet their pants if they were taken to the wellsite right now ...I don't understand how every joe schmuck thinks they have this thing figured out...

anybody who knows anything about this operation and is not involved at the wellsite is thanking their lucky stars that they are not there including myself

I don't understand how every joe schmuck thinks they have this thing figured out...

Because we are joe schmuck and we watch a lot of movie and TV that everything resolve neatly in 1 hour with a half baked solution.. So we think that the blow out problem has a simple solution. I am a layman and have been reading through most of the thread in the last few weeks. It is a full display of why US competitiveness is down the drain. Most of the posts are pretty arragont. It is one thing not to know the problem, it is quite another thing to not even bother to research the issue and just pretend that they know the answer... How can we compete with other countries if we refuse to learn ...

XO -- no i didnt mean it in that sense....my point was the engineers know what they are doing and they need to work very carefully with the choke because of what the downside risks are if they hurry this....

we have a group of incredibly brave workers out there working their asses off ....personally I was of the thought that LMRP would never work and I've said so plenty of times even on TOD even before they got the operation underway .....but to criticize what is being done out there as a lot of ppl have done the past day or two on TOD without understanding what is going on is not necessarily a good thing...

I have read plenty of posts the past two days ridiculing the current operations from folks who don't understand half of what is going on and I don't appreciate that .....

ridicule BP or the govt ..thats fine....but for ppl to sit online and ridicule the guys running operations at the wellsite is beyond ridiculous ....those folks are taking a very high risk in the current wellsite environment and deserve nothing but respect and admiration....

anyways I apologize if my post came out condescending .....it was not my intent

anyways I apologize if my post came out condescending .....it was not my intent

No don't be. I think you hit the problem right on the head.. I have the same feeling as you. I read all the post trying to learn more about the problem. But instead get a bunch of half baked solution proposed by novice that don't even try to understand the problem. Regardless of what is the root cause of the blowout, I think the response so far are the best that we can hope for. And I believe BP, their engineers, and all the subcontractors are doing the best job they can. They are limited by the state of the well, equipment availability, logistics and schedule pressure.. I wish all the arm chair quarter can put themselves in one of these guy position before they start to criticise their effort.. They deserve a round of appluad

aliilaali, your comments are sane and useful. Thank you for them.

If the engineering was so brilliant this never would never have gone on so long. Redundancies would have been built into the design, and contingencies developed before any accident of this type occurred. If that is cost-cutting on the oil industry's part, then they should pay. If a profession doesn't want to be criticized then it should demonstrate competency in action, not theory.