Deepwater Oil Spill - A Longer Term Problem, Personnel - and Open Thread

Posted by Heading Out on June 12, 2010 - 9:30am

The comments on this thread are now being closed. Please take discussion to http://www.theoildrum.com/node/6593.

The recent take-up of oil through the cap and the LMRP to the Drillship Enterprise was at a daily rate of 15,400 bd.

For the last 12 hours on June 11 (noon to midnight), approximately 7,835 barrels of oil were collected and 15.7 million cubic feet of natural gas were flared.

• On June 11, a total of approximately 15,550 barrels of oil were collected and 31.2 million cubic feet of natural gas were flared.

• Total oil collected since the LMRP Cap containment system was implemented is approximately 104,300 barrels.

• Operations were stable..

The Loch Rannoch is on its way, as, possibly, is the Toisa Pisces.

This latter is a Well Testing Service Vessel (WTSV) Dynamic Positioning ship, which has systems for the reception and processing of fluids from well completion, stimulation and repair. For those interested in well flow rates, that measuring capability is among its capabilities.

• Reception of the products from the well via flexible hoses connecting the well to the production system installed on the ship.

• Process and separate water, wasted and un-wasted chemicals, gas, crude oil and solids. The water will be stored in the WTSV’s tanks and later re-injected into industrial waste well or offloaded to a processing facility onshore.

• The crude and gas will be measured in quantity and quality. The combination may be returned to the export line, or if this last is not available, the gas will be flared and the crude stored in the WTSV’s tanks to later be exported to an onshore or an offshore offloading terminal.

• The solids are stored in containers to be disposed to shore.

• Crude ranges are from low to high (12 to 43 °) API. Pressures up to 10,000 psi at the well head.

It has been suggested that it might arrive on site on the 19th June. The Loch Rannoch should arrive a few days earlier, releasing the Drillship Enterprise, which, I suspect, has other things that it might now be doing.

The Toisa Pisces was formerly a cable-laying vessel, and is not a Floating Production, Storage and Offloading unit (FPSO).

My main topic for this post, however, is not the possible change is the fleet over the well, but rather some thoughts on how to avoid this happening again. There were likely a cascade of several errors, each of which alone would not have led to the disaster, but cumulatively they did. So how do we stop it happening again?

In some ways the problem is similar to that the Mining Industry faces after more than twice the number of deaths (29) at the Upper Big Branch Mine in West Virginia in April. In both cases, there were safety concerns reflected in the numbers of citations that the companies had received relative to other companies. So how does one install a different attitude in those who work to produce the fuel that we all need? To a degree, it has to be done through the imposition of regulations that enforce the concept of safety in daily working life. Included in those regulations should be the appropriate recommended practices for carrying out different tasks in the operation.

But even with those regulations in place, they are only as good as the enforcement of them. If my memory serves, you could not become an Inspector of Mines in Britain during the National Coal Board years, unless you had a First Class Certificate of Competency (which is the examination that allows you to manage a mine). The standards of education and training for inspectors must be high, and they need to require a reputable image.

The problems, in part, for both industries, are that the fossil industry historically has been cyclic in nature. Often driven by the price of oil, when that price is high, there are lots of jobs, and both coal and oil boom. The price falls, times get tight, and lots of folk get laid off. It has happened more than once in my career, as we have students go from having many job offers, to students coming back for graduate degrees because there was no work in the industry. The employees that are laid off go find work in other, less cyclic industries.

And so when the next boom comes around, they are no longer available. Furthermore, the teaching departments at the Universities have closed. It is as a result of this boom and bust cycle that there is a dearth of middle management in many companies that work in the fossil fuel business. For many years, they were not hiring, and the folk that they now need as long-time trained and experienced individuals do not exist in large numbers.

The number of both mining and petroleum engineering schools have fallen, and student enrollments, until the recent rise in the price of oil (the $140 one) were bringing other departments closer to that action. At one time, for example, Leeds University in the UK had one of the largest mining departments. At that time, it was housed in a building that was funded by those in the Industry in 1928. That building is now occupied by the Art Department and somewhere – not quite sure where (this from the alumni office and the secretary in the building that houses the remaining odd faculty member) – there is still someone that teaches the odd course (he was out). There is only one other Mining School in the UK, and it studies hard rock mining at Exeter (used to be Cambourne School of Mines).

It is hard to criticize University leaders, who must look to where the students are, and which faculty hire will bring the best return to the University. In recent years that has not been within the ability of the fossil fuel departments, and so they are closing – though the demand for their product is now rising again.

It is one of those interesting items to note that the latest reviews of world oil supply are beginning to suggest, increasingly, that the world is approaching if not past the point of peak global oil production. That will require more mining and petroleum engineers, though at places like Leeds (my alma mater), they will likely only be able to produce the modern version of Thomas Hair, to record the modern version of his “Art of Mining,” rather than the subjects of that art.

So what does all this have to do with regulation and responsibility? Well, it is very difficult to maintain high quality folk in industries that go through severe manpower cycles. When regulations are severely enforced under one administration and then almost neglected in another, either because the industry is in disfavor, or the apple of the administration’s eye, it is hard to keep the regulatory inspectorate that is a vital part of running a safe industry. The regulations should be fair, be strict, and must be enforced by individuals that have been properly trained to a high level of understanding as to both the technology that they are reviewing and the consequences of error.

Historical evidence is clear that Universities cannot be left alone to provide that education, and supply those individuals. The National Mine Health and Safety Academy at Beckley is a start in the right direction for the mining industry, but there are other changes that must be made, in the investment in research into new technology, in the general attitude to those who work to provide the fuels that we need (and will continue to do so).

Treating the industries and those who work in them as pariahs is not the way to solve this problem.

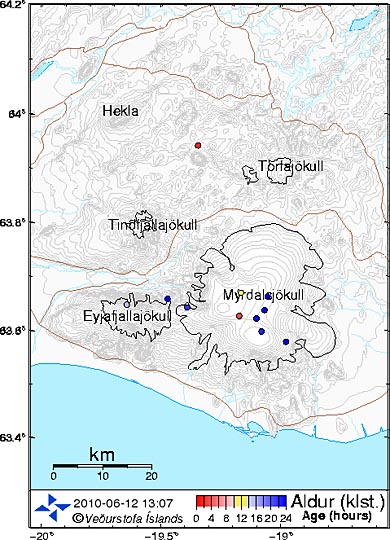

Oh, and not to get anyone excited, but for the first time in the recent past there is some earthquake activity under the Myrdalsjokull glacier in Iceland, the home of the Katla volcano. The map shows the age of recent earthquakes. Eyjafjallajokull is the site of the currently active volcano.

Prof. Goose's comment:

A continued humble and sincere thank you to all who have donated thus far. It will help us pay for the fourth server we brought online to accommodate the increased traffic. (See point 3 below.)

1. The Oil Drum is a special place. We strive to maintain a high signal to noise ratio in our comment threads. Short, unengaging comments, or comments that are off topic, are likely to be deleted without notice. (to be clear--engaging, on point humor and levity, more than welcome.)

We are trying to perform a service to the public here to coordinate smart people who know their stuff with other people who want to learn about what's going on. Promotion of that ideal will be the criteria by which we make our decisions about what stays and what goes.

Flame wars, polemic exchanges, and other content deleterious to the community will be removed, either by an editor or by the community through its moderation process.

2. If you see a problematic comment USE THE COMMENT MODERATION SYSTEM--see the "Flag as inappropriate" and (?) beside it? Learn more there. If you see comments that are questionable after you've done that (that aren't being removed), let us know at the eds email address.

It is up to this community to enforce the norms we have established here (a high signal to noise ratio), keep. it. up.

Our guide to commenting at TOD can be found here: http://www.theoildrum.com/special/guidelines . Please check it out if you are unfamiliar with it, but it is essentially 1) citations welcome (if not necessary), 2) be kind to others, and 3) be nice to the furniture.

3. We have gotten a lot of queries whether this bump in traffic is adding costs to keep the site functioning. Truth is, yes, we are incurring added expenses from these events. It is also true that we try not to beg from you very often as we are not the types to bother you with constant queries.

That being said, if you are inclined to help out, your support is always welcome and very much appreciated. To those who have already given, thank you very much.

You can find the donate button in the top left hand corner of the main page.

4. If you have come here to vet your plan to kill the well, understand that you will be queried on whether or not you have read the other 10 previous comment threads and all the myriad plans that have already been run by the kind folks in this room; if you have actually read all 10 comment threads and still think your plan has legs, well, then maybe yours really is the one that will save the Gulf of Mexico.

This is not to say that well considered questions about current attempts and modifications to those attempts are not welcome; they are. But try to place them in context and in what's actually going on, as opposed to your MacGyver dream solution where you have a 10 megaton bomb, an ice pick, and Commander Spock at your side.

5. Also, if you're looking for live chat to talk about the ROV/LMRP video, etc., and are IRC capable, go to freenode, the channel is #theoildrum

(google MIRC and download it; Hit the lightening bolt and fill in your info; select the server as "freenode" (it is in the server list), hit connect; when connected type /join #theoildrum)

or you can get there just via a browser: http://webchat.freenode.net / Just enter a nickname and #theoildrum in the boxes; then when connected type /join #theoildrum)

6. Don't be afraid to go back and read the last couple of open threads yesterday and today before you start on this thread. They are really good, and will likely catch you up if you have been out of the loop for a while. We shut down threads when we get to 300-400 comments, as it's really unmanageable. Lots of good stuff in there though.

The Loch Rannnoch is a shuttle tanker - normally employed on BPs Schiehallion field in the UK West of Shetland. Capacity stated as 850,000 bbls.

It doesn't have any processing capacity - unless BP have done a super-fast retro fit (unlikely), so its role will be limited to storing or transporting stablised crude.

BP have an entire navy of tankers which could be sent in http://www.bp.com/managedlistingsection.do?categoryId=9019823&contentId=... - however the Loch Rannoch is equipped for offshore loading, which I guess makes it the best choice.

Bill

What sort of position-keeping capability does the Loch Rannoch have? Most tankers ship oil terminal-to-terminal, tied up to wharfs while the transfers occur. They are usually moved around the port area by tugs. In this situation where the Enterprise is continually manoeuvering in open water to keep its string and the cap centred over the wellhead, tying up a tanker to it would severely crimp its position-keeping abilties. A smaller barge is less of a problem to cope with.

If they're expecting rougher weather in the future then having a tanker with its own position-keeping thrusters alongside the Enterprise would mean they could continue operations in sea conditions that might otherwise require a shutdown and temporary abandonment of the wellhead.

The Loch Rannoch has full dynamic positioning. It is used west of Shetland for offloading - some of the roughest water in the Atlantic.

However, there was an incident last year when it collided with the offshore loading buoy. Some damage done, no injuries or oil spilled that time.....

Bill

If you look at its picture here:

http://www.bp.com/sectiongenericarticle.do?categoryId=9019903&contentId=...

You can see the little round marks on the bow, just above the waterline, forward of the Plimsoll mark,

that look like little propellers.

Ships that have bow thrusters (and thus have the mechanism for dynamic positioning - tho' possibly not the automatic control system) have these marks to tell tugboats not to position themselves in front of the thrusters.

The page on BP's site doesn't say it has full DP capability, but other sources imply it does:

http://www.marin.nl/web/Ships-Structures/Merchant-vessel-Work-boat/Shutt...

http://www.onepetro.org/mslib/servlet/onepetropreview?id=OTC-10905-MS&so...

FYI - if you missed the reference further down the thread, a new tech briefing posted:

http://bp.concerts.com/gom/kentwellstechnicalupdate061010a.htm

slides:

http://www.bp.com/liveassets/bp_internet/globalbp/globalbp_uk_english/in...

And Adm Allen has mentioned its DP capabilities a couple of times during his daily briefings, indicating that as a specific reason for bringing it over from the North Sea, so that it will be able to safely stay near the Toisa Pisces.

A UPSTREAM article that another poster linked to a few days ago mentioned that it wasn't clear whether the Loch Rannoch would be used to transport the oil to a terminal or whether, due to Jones Act restrictions, it would transfer the oil to another tanker to be taken to a refinery.

Allen has been asked at least twice recently about the Jones Act in general - both times he has replied that to date he has not received any requests for exemptions, but would certainly consider the need to apply for one. If the Loch Rannoch might need one, it's surprising one isn't in the pipeline already.

I wasnt familiar with the Jones Act until this post, but man what a canb of worms that legislation is! The road to hell is paved with good intentions, and I can totally see how the protectionist impulse has destroyed competition to the detiment of users of the cargo fleet. Jones Act seems at face value a great idea, but not if you actually have to pay to use a US cargo vessel!

I would like to know, how much money BP can net on each bbl pulled up this way. I mean the simple net (direct costs) per unit, not taking into account the additional financial pressures etc. (And even if not a profit, still better than zero gross return as in lost oil.) There's no reason to waste (in so many senses of the term) the oil if it can be used, but remember that only weeks ago we were told BP could and would only kill the well, there was no point in talking of pulling some up from this well? Could thinking of the benefits of the latter approach have influenced their decision making?

BTW the latest claim going around in right-wing circles is that the current approach is what BP wanted to do first, but "Obama blocked them." I don't think he even exercised any power at all esp. in the early stages, and wonder what formal power or agencies have anyway. Maybe he should, but I suggest a post here to clarify the governments legal and logistical situation (again, if necessary) about the leak disaster.

BTW there is no reason to resent their making money off this collection if they can. They might as well have money to pay for this with. That's also why it is stupid to boycott BT. First, it hurts the franchisees, who didn't know any better and why take it out on them? Second, we should want BP to have a decent income stream, the better to pay fines, compensation, etc. I sure don't think much of their recent big payout to shareholders (was it really a 9% cut of profit?) which looks like evading cash on hand to pay damages etc.

BP have said in a press release that they will use the net Revenue from the collected oil to create a wildlife fund.....

" As part of its commitment to restore the environment and habitats in the Gulf Coast region, BP today announced that it will donate the net revenue from oil recovered from the MC252 spill to create a new wildlife fund to create, restore, improve and protect wildlife habitat along the coastline of Louisiana, Mississippi, Alabama, and Florida. The creation of this fund is over and above BP’s obligations under the Oil Pollution Act of 1990.

BP’s net revenue from the sale of oil recovered from skimming operations and the well containment systems will be deposited into this newly-created fund. At this point, BP cannot predict the total of amount of net revenue that will be deposited into the wildlife fund. The amount of funding will be contingent upon the amount of oil collected during operations and the price at which the oil is sold. BP will provide regular updates on the amount of proceeds being deposited into the fund. "

Source - BP Press release 9th June.

Before you start cheering about the wildlife fund getting "the net revenue from oil recovered", you had better find out what kind of bookeeping is involved.

Will royalties still be paid?

Will the donation count as a "taxable deduction"?

Who will lose the tax revenues?

Will the "gross" or "net" be used as a tax deduction?

Who will operate this "newly-created fund" and get paychecks?

jal

You gotta love these guys:

Notice the caveat; "net revenue". There will obviously be no net revenue. Perhaps this "advertisment" should read:

Indeed BPie is trying to hide the number of their slices. Let's focus like a damn laser on their assets and take them to make things good for us all, we'll all be better for it and a lesson will be learned by the other oil vampires.

The US government is talking about a fine of $4,500 per barrel of spilled oil. The current market price of oil is under $80 per barrel. Compared to the fine, everything else is a rounding error.

Well, it's worth knowing about IMHO. And I see comments that the collection ships can't process - sure I would figure that, so where is it going? BTW I wonder if BP even has the money to pay such a fine, once the total is figured up with latest figures and the long delays. BTW what percentage of the gushput (I'm just playing with coinages, sorry) is being collected? From what I hear it may be around half -?

This is one of the fall outs that nobody ever noticed from the de-nationalisation of the coal industry by Mrs-Thatcher-The-Milk-Snatcher. The mining villages have gone to hell in a hand basket, particularly around Nottingham, but nobody missed management, all long retired to wherever you retire to in the UK (probably Torquay).

There is probably nobody left in the UK who can manage an underground coal mine. This includes the geologists, well-head management, inspectors, etc. Plus there is probably nobody who can do the budgeting, planning and business plan for the day-to-day running, and most importantly ... put together a business plan to raise the money in the City to do the job.

As if anybody cared.

I'm sounding like Alan From The big Easy ranting against Bush Pigs and Tony-Twit-Of-The-Year.

Incidentally, thanks to Peskild, Alan from the Big Easy, Trailman, Deseng, etc for their help on who has the tightest offshore drilling regulations.

A minor point on the TFA:

The main reason the UK schools of mining are mostly gone is that 99% of the coal pits our coal mining industry was 99% shut down after the miner's strike in 1984. e.g. http://en.wikipedia.org/wiki/Mining_in_Wales#Coal_mining -- actually Wikipedia seems to be missing an article on the history of coal mining in the UK.

A question for the insiders here:

Is there really such a shortage of processing capacity in the gulf that not having a sufficient amount yet or for weeks to come is justifiable?

Aren't there rigs in the gulf that could have been leased?

I find this bizarre and, if the capacity was available, maybe the clearest example of gross negligence in the whole affair.

I'm guessing it is rooted in some sort of anti-science, anti-outsider denialism, and the fact that such has now become habitual for the corporation and many in the industry. And it bit back.

Requirements to have far improved intervention, recovery and processing facilities on hand in the Gulf would seem likely to be the kind of regulation put in place after this disaster as part of any permission to resume drilling in the deepwater.

This is a good question which has not had much airplay to date in TOD (apologies if I am wrong, but I have struggled to keep pace while holding down my day job).

It may seem odd to the outsider that there are numerous FPSOs around the world with processing capacities well in excess of 100,000 bbl/day - including a number currently not in service - and yet the vessel actually deployed is limited to some 18,000 bbl/day. But the key point is that all FPSOs fitted out for production duty are moored, and they use flexible risers to get the fluids to the surface. A mooring spread in 5,000 feet takes up a huge footprint which all other vessels involved would have to dodge around. And you could not lower and position a containment hat on a rigid riser like you can from the Enterprise.

Thus the actual subset of vessels which (a) have even modest processing capacity and (b) have dynamic positioning and (c) use a rigid riser is in fact quite small. They basically exist to do extended well tests, where there is no real benefit in being able to handle more than 20,000 bbl/day. "Full size" FPSOs are not dynamically positioned because this burns huge amounts of fuel to keep station - and why do that when you can moor it?

Ironically, when I first started to think about vessels which could handle a higher rate than the Enterprise, I thought of the Seillean. This was built in the 1980s by a forward-thinking operator in the North Sea to tap into small fields via one or two subsea wells with a rigid riser and DP. They sold it on in the 1990s. For the past few years it has been working for Petrobras in Brazil in around 5,000 ft water depth. But its capacity is 20,000 bbls/day, not much more than the Enterprise.

Oh.... and that "forward looking North Sea operator"? BP of course. Bet they wish they had kept that in the toolbox.

Is it possible to have a supplemental processor?

Perhaps divert some of what has come up the riser to another ship or add an additional port to the cap to which a flexible hose is attached?

I think that would be the only practical way to do it. But to do the modifications in-situ on the Enterprise to allow it to pipe onwards to another ship would not be trivial. And if you took it back to port you would be spilling the full volume in the meantime. The other ship would also have to be DP, and the flexible mid-water transfer pipe between them would have to allow them both to weathervane, and kept in a safe configuration so it doesnt overstress - not trivial either.

The flexible pipe ported off at the containment hat to a second DP vessel a mile or two away would get around the problems above. But think about the momentum change in the fluid heading off to the side at the hat, which is currently sort of "floating" over the BOP. Would be a horizontal counterforce of many tons which you will have to resist somehow. And maybe in the process stuff up the successful collection you are already getting.

None of these things are insurmountable, but engineering them "on the fly" takes time. I would guess BP have explored all these options, and hopefully a few more along the same lines....

If I am not mistaken the new system they are working on will rely on flexible hoses for delivery from a subsea riser with a buoy. Timeline - July to get this engineered and deployed.

Thank you for the thoughtful responses.

Matched ports 180° offset?

Or bolt the thing to one of the now available bolt holes?

It is the psychology (or madness?) behind the failure to scramble additional capacity if there was even a theoretical chance of connecting it that fascinates me.

They have a crisis that threatens the company, from very early had multiple acedemics saying that the flow estimates were low and they don't take an obvious action just in case.

A refusal/inability to believe it is as bad as it is?

A belief that those giving are acting only due to an anti-BP, anti-oil agenda?

Very strange.

Brains in an extreme failure mode.

Would recommend Kent Well's latest technical update:

http://bp.concerts.com/gom/kentwellstechnicalupdate061010a.htm

Main problem, no matter what solution you use, ultimately have to have surface processing capability. Surface processing capacity (dynamically positioned) has limited availability in the industry. Note from the video, the Q4000 doesn't actually have processing capability, they are building/installing processing equipment right now on the deck live in the Gulf which is why they haven't started using it yet.

The video does show the longer term solution splitting the flow at the BOP (with new "overshot" tool sealed cap) to 2 new processing ships that are en-route.

Not sure I'd want a high pressure multi-phase flow line connecting ships at the surface (still has to come through the Enterprise initially, would have to shut down enterprise for modifications to do a connection before the seperation equipment on ship, and then would have risk of running a high pressure flow line running explosive gas/oil mixture between dynamically positioned ships).

On connecting a flexible hose to the cap ports at the BOP -- need some way of sealing hose (doesn't appear to be any flange or sealing mechanism on outside of port currently), then need 1 mile of high pressure hose & a ship that can process the flow. The industry has exactly this type of high pressure flexible tubing ("coil tubing units"), that can easily bring sufficient length of flexible tubing of up to about 3 inch lines (assuming have ROV to guide/connect the line somehow). But ultimately run back into surface processing cabability limit right now.

The best shipyards in the world to make these type of modifications are in Louisiana. In late April/very early May, they could have pulled in a spare ship and made such modifications.

Given a 24 hour/day, 7 day/ week schedule (and I promise you the workforce would have been motivated !) they would be ready by now.

No excuse !

Alan

There's never an excuse for anything.

Evil dooers must pay until the 7th generation for destroying "our gulf".

Also: LOL

Just as BP has apparently been slow to bring in added capacity, Adm Allen et al have been slow in recognizing the lag. Allen is finally beginning to ask for more.

Earlier this week Rear Adm James Watson (on scene coordinator) gave BP a 72 hr deadline to define their plans for increasing capacity and supplying redundancy. BP COO Suttles replied with an outline on 6/9. His reply here (pdf)

Watson found that reply unsatisfactory and on 6/11 gave BP 48 hours to come up with something more acceptable. Watson's reply here (pdf).

(the choke line will be used by the Q4000, the setup that BP's Kent Wells said (pdf) would begin testing this weekend. The kill line is slated to be used by the Clear Leader, a setup that Suttles writes won't be ready until mid-July.)

Counting the cost of drilling down deep

THE ecological catastrophe unfolding in the Gulf of Mexico has failed to discourage the Rudd government, which has granted oil and gas explorers permission to drill deep off the Australian coastline.

The latest federal government exploration releases confirm a trend towards deep-sea drilling, offering explorers blocks largely around the 1000-metre mark.

''The problem is if you screw up in a highly productive rock formation, the consequential flow is automatically very large.'' Mr Bourne said the remoteness of Australian offshore fields from any oil industry centre made an accident likely to be even more damaging. ''A dynamically-positioned rig would take several months even to get it to Australia before it could begin drilling a relief well. An immediate moratorium on deep water drilling now would be straight logic.''

Last August, when the West Atlas rig blew out in only 77 metres of water in the Timor Sea off Western Australia's Kimberley Coast, it still took 75 days to plug the Montara oil well.

http://www.smh.com.au/environment/counting-the-cost-of-drilling-down-dee...

5/5/2010

Western Australia's battle for offshore oil

Crude Oil dropped by 27% in 2009

http://www.crudeoilpeak.com/?p=1425

I got to say, but this posting exemplifies the wrong way to do it in my opinion; more regulation, more enforcement - it only makes it worse.

The problems with this approach are:

1) no set of regulations can deal with every eventuality and every circumstance, so there are still plenty of opportunities for the dumb process follower to do everything required, and still have an accident. By the book makes for dumb.

2) the more complete the regulations, the more onerous and the more inappropriate in particular circumstances. Net result is that people get used to shaving off the corners of what they are supposed to do, because it makes no sense. Then they shave a bit more and eventually you still get the accident because they don't agree with or respect the rules. This also promotes the behaviour where the regulators impose regulations to ensure that their will always be transgressions, so they can always point to the company as failing, even if the regulations are stupid (its not our fault, look at the thickness of the regs...)

3) the more enforcement, the more time consuming and annoying it becomes, the more things are hidden from the enforcement team (who become 'the bad guys'). No practical level of enforcement will catch even half the transgressions of the rules anyway. Net safety goes down.

4) the more regulations, the more enforcement, the more it costs, the less drilling is done - with far bigger systematic effects than the accident rate risk.

5) you will still get accidents, no matter what. Its in the 'risk sea' where you don't know, can't know what's going to bite you - just that it will happen no matter what. Better to realise and cope with this reality.

A better approach?

a) DON'T tell a company how to maintain safety. Tell the company that they have to define their own approach to maintaining it, describe it to regulators and prove it. Also tell them they are responsible for it. That way if something goes wrong, they are automatically in the frame for failing to ensure safety, whatever they actually do. They then have to prove they couldn't have foreseen it. This general approach is much better, more flexible, more effective and rewards innovation.

b) address the systematic issues with how drilling is conducted, to make the entirety more 'fail safe', as well as cheaper and more attuned to the post peak world. They have been doing the same basic thing for 100 years, they need a revolution.

c) create INDEPENDENTLY a service which only aim is to prevent leaks and close down accident sites. Don't give it to the oil company, have it government administered (and probably paid for)

d) state that the majority of the board of any dangerous or accident prone industry have to be qualified engineers, and make sure the accountants and lawyers in such organisations are kept on a leash. Arts grads, financial types and PR make poor board managers for such structures, for a variety of reasons that include safety.

BP is currently on the hook for their failings. So giving them more rope would have made this spill less likely?

I suppose we should give the financial industry more rope too

Corporations don't make decisions based on the public interest. And sometimes they don't even make appropriate decisions for their own interest.

You're missing the point of making them responsible. If you give them a thick tome of regulations, you create the situation where they shave them and can point to following them as being safe.

If you make them responsible for what you care about "being safe", not following words, you get a whole different, better, behaviour.

Be careful. They ban people here for suggesting "responsibility" instead of more words on paper.

To: garyp

I believe your item "d" is on to a basic part of the problem. BP unless they have changed radically since my last direct experience with them is a prime example.

BP often considers "Qualified" engineers to be someone who is not a "Degreed" Engineer as the equal of a truly qualified engineer. I have worked with "nondegreed engineers" who in their areas of competence were very good but they were not flexible and often poor at seeing the bigger picture. Fifteen or twenty years as an operator in a refinery or on a drill rig does not give one the background to be a "Qualified" engineer no matter what the BP job title.

The second part of the puzzle is that Managers who do not have technical degrees tend to look down on the engineers and disregard their advice. Part of this is due to giving unqualified people the job title "Engineer" and part is an attitude that looks down on technical jobs.

Ultimately I suspect these two related factors played as big a role as BP's penny pinching in this blowout.

That happens everywhere, its a core reason for failure across the piece really, you would have thought they would have learnt from Germany.

The stories I could tell.

You also have to consider the effects that 'engineer syndrome' has on the non-engineers who have to work with them. Have you ever met a degreed engenier who did not think that he knew more about your (non-engineering) specialty than you do?

That's a tired old canard. Yes, there are engineers who are respectful of non-engineers' knowledge and skill.

It may be a 'tired old canard.' But it still is more common than not to encounter it.

Considering the number of let us say 'creative' solutions to the blow out that are in circulation it seems to me that the reverse is more common.

I work every day on systems that are audited as described in (a). This requires a lot of my company's time and effort to explain what we're doing to the auditors. The auditors don't have the technical expertise to properly evaluate what we tell them and they don't demand the access they'd need to our day-to-day activities to validate that we do what we tell them. This is for some relatively simple systems that are not safety critical.

A safety system that gives freedom for the operator to design their own procedures would have to be conducted against a background of industry best practices and with some by-the-book, strictly-enforced requirements for gathering and creating safety-related data that does have to be enforced by the book. Examples of these requirements include a couple of things for which BP seems to be in trouble already: periodic inspections of equipment (inspecting North Slope pipelines for corrosion?) and completing as-built drawings so they're available to guide inspections and for troubleshooting when something goes wrong.

If the operator feels the need to hide routine activities from inspections there's either something wrong with the safety standards or there's something wrong with the operator's attitude toward safety. It would be great if there were a way to structure positive incentives such that everyone working for the operator saw safety as their first priority. If that's not practical the rules have to be enforced using guaranteed access for inspectors and fines big enough to get the operator's attention.

Why wasn't this extra capacity out there a week ago when the cap was installed? This whole exercise has an ad hoc, they're winging it feel to it. Where are the adults?

Roughly 5 weeks ago, when the first processing ship Discovery Enterprise, of 15,000 b/day capacity arrived, I called for a sister ship (or comparable capacity) to also be on-site with provision made for a 3rd (of perhaps smaller capacity) to be brought in on short notice.

Just common sense, if one looked at the various flows and uncertainties involved, but this would have cost BP more money "up front".

Alan

Alan:

Don't you sometimes feel like Cassandra - always right but nobody ever listens to you?

Frustrating?

The commentator snowball earlier in this thread pointed there are not that many drillships with gas/oil capability around. The units which can deal with more than 15-20,000 bpd tend to be rigs which need to be moored since they don't do active position-keeping the way the Enterprise can and setting up rig mooring at a depth of 5000 feet could take weeks, all the time preventing the current capture of oil that is being achieved.

I don't think the Enterprise is configured to transfer raw oil/gas from its riser valvegear to another processing ship or barge laid alongside, it can only store and trans-ship processed oil from its tanks. That means the bottleneck is its separator equipment. Adding another processing drillship similar to the Enterprise to the fleet would mean modifying the wellhead cap to take two risers, one for each drillship. This would make keeping the cap located on the wellhead pretty much impossible as the two ships would have to be able to move independently.

Five weeks ago there were four/five potential production points. The choke & kill lines from the lower part of the BOP and the three leaks from the riser (the end point had a valve attached to it by ROV that was closed but could have been opened and produced directly).

Today, it appears quite possible to produce the choke and kill lines directly, without leakage (combine both lines on one ship or divided on two ships.

There are significant issues in producing the top hat to two ships, in series or in parallel. IMVHO, possible. I would be inclined to a "Y" a few feet above tophat (before gas expansion becomes a bigger issue) and parallel processing.

The easiest solution though is to to take the largest ship (by processing capacity) in the world (BP pays whatever it takes to shut down whatever production it is currently producing) and attach it to tophat and move the Discovery Explorer to the choke and kill lines.

In five weeks, ANY ship in the world over any offshore field (that could fit through the Panama Canal) could be there today. All it takes is an open BP cheque book !

Alan

BP appears to have a perverse corporate culture. Instead of pursuing the goal that economists assume they follow--long-run profit maximization, BP appears mainly to be interested in short-run profit maximization (plus acquisition of reserves for the longer term). For example, think how arrogant it was to cancel their insurance three years ago and self-insure. In the short term this action improved their bottom line, but in light of what is going on now it is clear that this was a bad decision that will greatly decrease long-term profit. Similarly the corporate culture of hurry up and pinch pennies and skimp on safety precautions may help in the short run, but in the longer run it does not maximize profit in the dangerous and risky oil drilling industry.

In other words, BP management has done a poor job for their stock holders. I hope the stock holders will protest and vote proxies to get rid of all of BPs upper management and perhaps some or all middle managers too. BP needs to change its corporate culture (perhaps to resemble the one at Shell) in light of the current ecocatastrophe.

"BP needs to change its corporate culture (perhaps to resemble the one at Shell) in light of the current ecocatastrophe."

Interesting recommendation. Could you elaborate on Shell's corporate culture?

I don't think BP's structure is at fault. The problem is with the corporate culture--culture which is embodied in the beliefs, values, perceptions, and habits of their managers. Hence, get rid of the managers and hire better ones.

From what I've been reading on TOD, Shell has been a model citizen, insofar as an oil company can be a world citizen. Apparently Shell has an excellent safety record, and I believe the company is quite profitable. If it were not profitable it would be failing its shareholders, and by being an ethical and responsible company they contribute to their long-run profitability.

I see no conflict between a strong emphasis on safety and long-run profit maximization.

In the short run you can be like BP and skimp on safety and boost your share price for several quarters, but in the long run, sooner or later, you get the Macondo gusher.

Oil spills escalated in this decade

Now as I believe BP produces a lot more offshore oil than Shell in the USA, it seems from the above that Shell had more spills per barrel of oil produced than BP between 2000 and 2009. Someone correct me if I'm missing something - although of course when things go wrong with BP they do seem to go spectacularly wrong. Also it seems that everyone has been spilling more in the last decade.

Anyone know the source for the MMS data listed by USA Today? Is it available on the MMS website? It would be interesting to see the table of spills per company plotted against production.

I should have used Exon as an example instead of Shell. Exon has been highly praised by Alan.

Actually, that was Rockman that praised Exxon safety (he thinks it may be attributed to post-Valdez).

Locally, Shell has a good reputation both as an exemplary corporate citizen (especially after Katrina !), refinery operator just upriver, offshore design (know some engineers doing that, DO IT RIGHT ! is the motto, redundancy etc.). Also one good report on offshore production safety by Shell.

No specific feedback of offshore drilling by Shell (BP was known as "cheap" before April 20, so "nothing" is probably good). I do know geologist that got fired by Shell after three dry holes in GoM.

Best Hopes for the Good Oil Companies,

Alan

And there are still spills going on since Ivan -the Hurricane - 6 years and counting.

http://www.youtube.com/watch?v=vWHLrcxLVkg

IMHO - It's not just the Oil Patch's problem, but all corporations on the open trades market are running this way. I was a tech with a technology leader back twenty years ago, that was bought out by a larger company it was in debt to. The new management group had no experience dealing with our operations (they ran plants; we were a sales/service outfit), but their bean-counters immediately scrapped our forward-looking two year plans, and put us on a three month - all due to the market analysts drive for increased profitability.

'Twas said they wouldn't spend a dollar on Tuesday they couldn't get back by Friday. Another thing that got extended was Accounts Payable, moved from 30Days Due to 90Days. Tell you, that really pissed the folks off at HQ when they discovered that the bill for Janitorial Services had been delayed, and they ran out of bathroom tissues!

Not sure, but it looks as if Shell is not beholden to the US/UK market forces as much as most others are. I know that here in the NE US, Shell tends to be on the higher side for pricing compared to most other big name fuel outlets.

Thanks for the info. :^)

Data is interesting.

In 1996, the International Organization for Standardization (ISO) developed the ISO 14001 Standard: Environmental Management Systems - Specification with Guidance for Use, which outlines the components of an effective environmental management system. Lloyd's Register Quality Assurance Ltd. (LRQA) is set up to conduct a third party assessment of a company's operations integrity systems. LRQA can confirm if compliance with ISO 14001 is fully in place throughout a Corporation, has reached a high level of maturity in implementation and is promoting continuous improvement.

Do you know if Shell is in compliance with ISO 14001 and has been audited for such by a third party?

I have often wondered about this very thing. I think part of the problem is that a corporation is set up to protect its shareholders from responsibility, even when the corporation engages in what should be considered at the very least, criminally negligent behavior. At the very worst shareholders are only faced with a loss of stock value. They don't ever get to feel the true pain of being punished for the actions of their corporation's malfeasance. The corporation enjoys the rights of personhood, and the share holders hide behind it and get off scott free! Maybe if shareholders were actually held accountable in some way, say hefty fines and the loss of voting privileges, they would be more inclined to make sure there were real changes in the corporate culture.

So in my mind its a bit of a chicken and egg problem. Any new management can't really change corporate culture to the degree that might be necessary. They are beholden to the need to produce profits for their shareholders.

To me new managers would just be akin to new flies swarming over the same old sh1t! The essential fly, sh1t relationship, probably would change all that much...

If stockholders (owners) were not shielded from liability you might as well close down stock markets and give up on capitalism because private ownership of the means of production would become VERY unpopular and there would be no way for a company to raise money to go into business.

Then we would have only socialism (public ownership of the means of production). The problem with that is that allocation of capital works much better with capitalism.

You say that like it was a bad thing...

BTW personally I do not see any of the currently existing *.*ISMS continuing as the operating paradigm far into the post peak oil future.

Especially if unbridled corporatist capitalism or state sponsored socialism, for that matter, continue to show themselves incapable of protecting the commons. Once the commons becomes sufficiently compromised in its capability to sustain capitalism, socialism or any other "ISM", it all becomes moot.

How many more ecological disasters it will take to make all of our current systems inviable, I'm not quite sure, but it ain't lookin good...

I think Gail's latest post is probably a better place to discuss this issue.

http://www.theoildrum.com/node/6591

I for one no longer believe in the systems we have now have in place.

Best hopes for a more sane and sustainable paradigm!

Thanks for the pointer to Gail's article.

And what is your alternate system for providing capital to companies? Do you really think that any 'retail investor' would ever dare to buy even _one_ share of stock in a company if it meant risking the loss of everything he has? What about the peoplem with 401k's?

Under your system the only people who would become the owners in companies would be the ultra-wealthy who can afford to buy enough stock so that they have an actual 'voice' in the company.

"They don't ever get to feel the true pain of being punished for the actions of their corporation's malfeasance" Have you ever had one of the stocks you own go bankrupt while you own it? The punishment is worthless stock. It has happened to me. It's plenty painful, I can tell you.

Oh the pain! Held Superior Offshore only managing to sell half and then the 5$ fee for sell worthless ouch! What was I thinking? I bought that on BO selling his drill offshore than didn't happen until a year later. BO's big plan of nat. gas and my owning worthless Blue Dolphin ha! Come to think of it buying GM when he said we stand behind GM, then lent them just enough to file ha! I need to stop trading on the upside until BO is ousted from office.

That wasn't my point. My point was to rebut the idea that an investor should be liable in exess of his investment if a company fails or faces fines in excess of it's assets.

For example - you invest $100 in XYZ inc which fails the next year, and you discover a lien on your house for the your 'share' of the liability in excess of the company's assets after bankruptcy.

"They don't ever get to feel the true pain of being punished for the actions of their corporation's malfeasance" Have you ever had one of the stocks you own go bankrupt while you own it? The punishment is worthless stock. It has happened to me. It's plenty painful, I can tell you.

A poor job for which stockholders? For twentysomething Wall Streeters whose computers hold shares for three seconds or maybe occasionally three days - or for some other group of stockholders. It seems like it's always possible to goose the share price now at the expense of something later. After all, the future hasn't happened yet, so you lack perfect information about how to build it into the current price. Indeed, if you object to some such action, you may not even be able to demonstrate that it's giving away too much of the future for the sake of "now".

three seconds=three microseconds or maybe occasionally three days=3milliseconds. You cannot believe how fast these people trade now.

I do not have a link but I have read that computer trading now creates the liquidity in the stock market. Some linked SPARK computers make trades in nanoseconds. Computer trading programs operating in nanoseconds were suspected to be the cause of the mysterious instant crash and almost instant rebound, the so called Flash Crash, several weeks ago.

Interesting that there still isn't a definitive post-mortum on that 'little glitch'. A black box run with black magic it seems.

It wasn't a 'glitch.' What happened was that automated trades began cascading on each other.

A very common practice is for day-traders and other short-term investors is to set up an automated trade to sell a stock if the price drops below 'x' dollar amount. In addition some institutional investors have automated 'sells' based on index prices.

This works just fine as long as there is not a lot of volitility in stock prices combined with a market correction. Since the market was correcting (stocks with inflated prices dropping to more realistic levels) and there was a lot of volitility - several stocks all hit preselected 'sell' points at once. As each investor's stock hit the sell trigger - it drove down the price of the stock (supply and demand) which triggered more 'sell' points. Normally thise would be offset by the people/institutions that had preselected 'buy' instructions if the price for a particular stock hits a certain poinjt. This did not happen because due to the market corretion most people who normally ould be buying were stiiing on the sidelines waiting to see where everything would settle after the correction.

The reason that the price drop only lasted about a half-hour was that people began recognising that there was an issue with stock pricing and not in stock value and began grabbing up 'deal of a lifetime stocks.' This buying began driving the prices of stocks back up until equalibrium was once again reached.

BTW - I missed out on the chance to buy a normally $50 dollar stock for less than $3 by only about three minutes. By the time I had jumped on my computer, logged on to my brokerage account and imput my 'buy' orders - the whole thing was over.

Lets see a link to a definitive analysis - rather than some traders opinion.

Here's your link:

http://seekingalpha.com/article/206223-the-weirdly-rational-flash-crash

Of course - since you cannot tell the difference between a 'trader' and an 'investor' - I suspect aht you may not understand the information. (Maybe you should find out what a 'trader is before you _assume_ that I use that type of investment stragety.)

And if you had read my previous post where I described how I think the tax laws on sotck investments should be changed - you would have know that I am absoklutely not a 'trader' since those recomendations would actually shut down the 'traders.'

BTW do you really think that I am going to invest most of my net worth into the stock market and not pay attention to what is going on?

"So while the volatility we saw on May 6 was crazy, and the speed of the drop was unprecedented, it seems to me that the stock market didn’t break, during those 15 minutes, quite as much as conventional wisdom says that it did. There were a few genuinely crazy individual prints, but overall, something seemed to be working."

So this is your idea of a definitive explanation?

I warned you that you wouldn't understand it.

Hint: Look at the chart and the spreadsheet.

Here is a quote and link to the offical SEC report:

"generalized severe mismatch in liquidity, as evinced by sharply lower trading prices and possibly exacerbated by the withdrawal of liquidity by electronic market makers and the use of market orders, including automated stop-loss market orders designed to protect gains in recent market advances;"

(Says the same things I din only in more precise language.)

http://www.sec.gov/sec-cftc-prelimreport.pdf

Any more comments?

You are citing an opinion as definitive analysis. What part of the preceding sentence do you not understand?

"generalized severe mismatch in liquidity, as evinced by sharply lower trading prices and possibly exacerbated by the withdrawal of liquidity by electronic market makers and the use of market orders, including automated stop-loss market orders designed to protect gains in recent market advances;"

My, now that is a significant improvement from the masters of transparency and efficacy at the SEC. My hat's off to those wizards.

Spot on EL! 80% of trading today is High Frequency Trading. That isn't much of a market. That 80% is between five banks!

The problem is that our current tax structure penalizes long-term thinking and encourages companies to manage with a primary focus on the quarter-end results. This is because institutional investors tend to hold stocks for periods of less than one year.

The Bush changes in capital-gains rates were a baby step in the right direction. However we need to change things around so that we begin encouraging shareholders to hold on to ther stocks for at least three years.

In specific - I would change the following:

Brokerage and trading fees cannot be claimed as expenses. (This makes frequent trading more expensive.)

50% tax on all capital gains on assets held less than one year.

35% tax on all capital gains on assets held more than one year but less than two

20% tax on all capital gains on assets held more than two years but less than three

10% tax on all capital gains on assets held more than three years

15% flat rate tax on dividends.

If you do this then everybody will be planning on holding on to any particular investment for at least three years. When the majority of the stockholders are looking three years down the road - management will alter their practices to also focus on that three year time frame.

The dividend tax cut is to encourage companies to pay dividends. (Dividend paying companies typically operate in a more conservative and risk-adverse mode in order to ensure that they can continue paying that dividend.)

Great ideas, but you'll never see them come to fruition. The folks that have the liquid cash are the short-term traders. We all lose. :^(

I remember you calling for that Alan. I was impressed by your foresight. And have been impressed by it every damn time you mention it, which is not often enough. Also we need a minimum of 12 relief wells, not the paltry cheeeeep ass 2 that BP are (allegedly) drilling.

God, I pray that I look the fool when that first relief well slides in on the first try, ahead of schedule !

Best Hopes for RW #1 !

Alan

Would it be a good thing to require the regulatory as well as the corporate people to serve an apprenticeship of some kind,that is, on the drill floor,at the long wall or down in the pit?

How about they do time cleaning up tar balls and pools of oil on the coast or in the marshes? Or maybe spend a little quality time with dead wildlife pick up teams. They should get a better look at what they have created, and killed.

GW -- I Understand your thoughts. But I've run such field trips before. Folks just can't pick it up fast enough. In a way a little bit of familiarity can be counter productive: a false sense of how drilling ops run when there are no problems. And besides, I've seen very experienced hands make very dangerous choices when the financial motivation was sufficient.

via deepwaterbp.com here are the links to each of the BP vessels - The link takes you to the vessel main page and in the left margin there is a link to "Itineraries History", which with a couple of exceptions has been removed but if you click on the Current Vessel's Track link the vessel position will appear on the map.

OCEAN INTERVENTION 3

VIKING POSEIDON

BOA DEEP C

SKANDI NEPTUNE

Q4000

DISCOVER ENTERPRISE

TOISA PISCES

LOCH RANNOCH

DEVELOPMENT DRILLER 3

Onlooker, many thanks for your links to the Ixtoc blowout and Operation Sombrero in a previous thread. I noted them in my post early this morning at

http://www.theoildrum.com/node/6590#more

which is now closed. If you missed this post and have the time to read it, I would like to have your comments. If you have none, I will assume that I am persona non grata here. Best regards.

I don't know about anyone else but when I went to that link I only got every fourth page. Could only get the first and last page of the sombrero operation article. May be the reason for no comment.

Donner T, I had the same problem, so I requested a copy of the book through interlibrary loan, "Offshore Pioneers: Brown and Root and the History of Offshore Oil and Gas."

The other link had the full text of the document, and you can download it for free:

http://www.scribd.com/doc/32237183/Ixtoc-1-a-Case-Study-of-the-World-s-L...

this is the link to the JQuest comment string http://www.theoildrum.com/node/6588#comment-647701

As I recall Top Hat dominated the news cycle for a week in early May followed by Top Kill just before Memorial Day weekend. Both of these were media spectacles and I think it is safe to day that from the first indications of a leak back on April 23 the American media, government and BP downplayed the gravity of the situation. There were reports of a cover up that were redacted in some British papers as early as April 29. Spokespersons for BP and "experts" such as Vernon Asper made the media rounds in those early days and clearly downplayed what was happening (here is a link to an interview with Vernon Asper (MP3 audio about a quarter of the way into this free podcast on Bloomberg.

JQuest refers to the false and misleading information disseminated by the media, government and the companies involved. I certainly recall BP denying the existence of Plumes right up to the point that a scientific panel confirmed their presence. The media downplayed the environmental impact throughout the month of May e.g. very few pictures of oil soaked birds. And now just recently we have the controversial use of dispersants receiving the endorsement of the CRRC in what appears to be a major compromise (cave) to BP.

Perhaps the most controversial issue has been the flow estimates. From no leak to 1,000 b/d to 5,000 etc. It is hard to believe that BP did not have an idea of the flow from early on. It is equally hard to believe that the government with its vast resources did not have an idea of the flow. Both BP and the government had reason to downplay the numbers.

Then there are the numerous reports of the media being turned back by private/government security. Meanwhile another issue is emerging in BP's significance in the UK pension system with 14% of all dividends paid in the UK originating with BP.

Add to that concerns about a breach in the casing and the wild theories that Simmons has postulated. Then there is the conspiratorial ideas that some have floated that this is part of the climate change agenda.

Was Top Hat a cynical ruse foisted on the media to keep the public distracted? I am not sure what the motivation would be but I do find it interesting that the efforts to contain the leak have been sequenced in slow motion rather than prepared for concurrently. Even the ramp up of processing capacity is going to take another six weeks. It is like the media and the public are being fed tiny bits of hope until the RW is in place.

I think that the enormity of this disaster is yet to be fully grasped (or maybe some do grasp it, I'm thinking Sec. Chu for example), whatever, the implications of this will be as far reaching as any event in recent years or even decades.

Onlooker, good summary of the situation. BP and its government and media enablers know that propaganda works. Certainly I was fooled by Top Hat. It seemed like a reasonable concept. When it failed, I accepted the story that it was because methane hydrates plugged it up.

No one on this site questioned that story either, until JQuest put up his post. What he is suggesting, with credible evidence, is that Top Hat was designed to fail. Does no else here find this to be a subject worth investigating? If there is just a 1" diameter hole in the cap on Top Hat...well, I went over this in my earlier post.

If Top Hat had been designed to succeed...

I shall soon have a copy of "Clathrate Hydrates of Natural Gas" by E.D. Sloan, Second Edition(1998). There might be something interesting in it.

"No one on this site questioned that story either, until JQuest put up his post. What he is suggesting, with credible evidence, is that Top Hat was designed to fail. Does no else here find this to be a subject worth investigating? If there is just a 1" diameter hole in the cap on Top Hat...well, I went over this in my earlier post."

Actually I did but from a rhetorical standpoint. It doesn't matter if the hole is 1" or 6". If Top Hat captures all that can be processed topside then hole size is a moot point. Does JQuest feel cheated by his utility company if he discovers an orifice in his gas line at home?

I think for most here the problem has been identified BP will not be able/allowed to state the over used cliche' "I'm not your problem, I'm your solution".

If there is a design flaw to discuss then it's probably within the parameters stated by Alan from BE. The lack of processing ships could be solved by retrofitting. That being said does that resolve the DW problems of the industry? Posting processing ships at every drill site is one solution but not a very economical one. Alan made a statment in an earlier post regarding the Valdez incident being vivid in the memory of....( and I don't remember verbatim) but I'm sure it's not everyone because if it was this (current) BP distaster would not happen. There's a piece of my heart in the GOM. I grew up there and I have many good memories. One vivid memory is the first time I saw the distruction caused by hurricane Camille. I've come to understand that natural disasters pale in comparison to manmade disasters especially in terms of recovery.

What is the solution? Most of Rockman's posts have focused on proper inspection, follow thru, reading and interpretation, following plans and industry guidelines. I mention his posts again because I abhor shoddy work practices in any field. If you are on an oil rig and you are triming procedures to meet deadlines then you just trimmed you way into an unsafe zone. This applied to any industry.

That Viking Poseidon is a beauty. I've been on the Boa Deep C - the bridge has couches and wood floors. You have to take an elevator to get to the galley. Pretty "high cotton" for this oilfield scumbag.

For All

It’s a quiet Saturday morning, coffee has been brewed and the dog let out. And I feeling a little more full of myself then usual so I’ll offer a quick and easy method of greatly reducing the risk of all future offshore drilling that won’t cost the tax payers one cent. Additional it would get the oil field workers back on the job, kick the cash flow back into the service industry and reduce the loss of royalty revenue to the taxpayers.

The original thought was offered as much for comic relief as a practical solution: hire engineers formerly employed by an offshore operator to monitor their safe drilling practices. The idea produced a number of funny anecdotal stories of former employees in a number of industries who have very sharp axes to grind. They would jump at the chances to impose strong safety recommendations that were ignored (and sometimes mocked) by their former employers.

The serious proposal: First, develop specific criteria for the safest drilling procedures. This would take no time at all. Most companies already have very detailed safe drilling protocols (SDP) already developed. How well any one company follows its SDP is another matter. Second, have independent inspectors monitor how well any company is following the SDP especially at critical phases of the operation. Can the gov’t make offshore operators do this? Of course, they do it right now. Many here now understand there is a gov’t regulation that requires BOP’s be tested on a regular basis. These tests are done by private companies and are paid directly by the operators for providing this service. But the analysis by these companies is reported directly to the MMS. If the MMS doesn’t like the results it has the immediate authority to shut down the drilling ops. And how honest are these BOP testing companies? They certify their results under both civil and criminal penalties if they misrepresent the facts. Everyone can judge for themselves how well such a system might work.

So now I’ve incorporated Rockman, Inc. I’ve recruited about 80 consultant engineers. They are all experienced but not the most skilled hands out there. No need to hire the most expensive folks available. Remember they aren’t developing drilling proposals or making those tough judgment calls: they are “watchers”. Consider my background as a well site logging consultant. I sit in a Schlumberger logging unit and watch them log the well. I’m responsible for hole safety and quality control. Could I run the logging unit? Not if my life depended upon it. Way above my pay grade. But I can shut them down in a heart beat if I don’t like what I see. Same situation with my SDP inspectors. They don’t have to have the skills to do a job but can readily tell if it isn’t being done properly.

The cost to the operator? Minimal despite their complaints. The SDP inspectors need not be onboard everyday. Just at critical phases: cementing ops and testing, running casing, displacing riser, setting plugs. Just a guess but on a 80-day well they could be onsite 20 days. Two SDP inspectors working 12-hour towers. They chopper in and out as required. My inspectors would get paid $1400/day each. So the costs estimate for the model above; $1400*2*20 days = $56,000. Cost to drill a typical DW GOM well: $800,000/day*80 days = $64 million + $60 million (casing, mud, etc costs) = about $120 million. Percentage for SDP inspection: about 1/20 of one percent. Companies can bitch but who’ll will take them seriously.

But can the public trust these supposedly “independent” SDP inspectors? Did I mention that as owner of Rockman, Inc I get 20% of my consultants’ fee? Pretty standard cut for running a “body shop”. So what do I make: 80-days per well = about 4 wells per year. Assume 30 rigs drilling DW GOM. So $56,000*30 rigs*4 wells/year = $6.7 million/year. My 20% = $1.3 million/year just sitting in my office sending out invoices. So what would I do if I caught one of my SDP inspectors playing footsie with an operator? I would nail his b*lls to my office door as a warning to the other inspectors as a warning.

Pure speculation, of course. But how would have the situation developed on the BP well if Rockman, Inc. had been onboard? The cmt pressure test would have been rejected out of hand. Either re-cement and get a valid test or the rig is shut down. Displacing the riser? The mud returns are closely monitored or the rig is shut down. BOP in good working order? If the SDP inspectors don’t agree than the rig is shut down. Could Rockman Inc. eliminate all risk? No. But it’s unlikely we would see what’s happening in the GOM right now.

As you can see I meant it when I said I was feeling really full of myself this morning. But I’ve sat in the company man’s office a number of times and listened to concerned hands being over ruled on safety issues because of monetary considerations. In such situations I couldn’t open my mouth let alone change the course of events. All I could do is follow the standard practice when you become concerned about well safety: go to your bunk room and put your wallet and car keys in your pocket. That’s all you’re allowed to take into the escape capsule with you. And I’ve done that more times than I care to remember.

BTW: Do I think there’s much of a chance of such a program being implemented? No.

Where do I sign up?

I had the same question ;^)

Yo Rock.

This is sort of what I was trying to get at below. A group of professionals doing the oversight, using soild clear standards. Incorporate revisions of SDP standards on a continued basis. Is there any country where such a model can be used? It is as you point out, mostly an academic exercise, as the chances of such an effort are close to zero. But the people of whom you speak would have a short term financial interest in doing the right thing, and almost ALL former oil and gas folks want to see the industry continue, safely, and profitably. I doubt that a lot of outsiders realize this, but most of these folks would want to do the right thing.

Hey Rock, sign me up!

Reminds me of construction inspection services provided by engineering firms for civil engineering works, only it's operations inspection. I like it.

Rockman: Don't give up on your idea. The BP blow out and related consequences may have raised the calculated $$$ value of human lives as a commodity for deep water drilling.

Me neither. It would necessarily involve a push from government, which is unavoidably run by politicians, who are far more about the theater that keeps them in power than about mundane substance. Their instinct is always to make a grand show of doing something by piling on ever more rules, never mind that the rules already in place were already well-overdone - if only the sensible ones were followed. A program of mundane day-to-day involvement just wouldn't produce the sorts of maudlin, heart-wrenching, or spectacular videos that keep people scared, agitated, and demanding that power-mad politicians do something no matter how awful the unintended consequences. (Recall that according to the pundits, President O hasn't made enough of a show of anger to properly agitate the baying morons.)

Maybe where this really all goes is that the zero-risk-at-all-cost ideologues keep the moratorium going on and on and on, the resulting increment in balance-of-payments issues helps re-tank the economy, the bloody tourists can't afford to show up in their former numbers, and by 2017 President Palin is elected to "fix" the problems. Sigh.

It's like the once-proverbial broken record - the "system" just does not seem to accommodate learning and it's hard to see any way to change it so it could. Sigh again.

That's sad, because it seems like something like this program needs to be on the minimum ticket to drilling a single new well, nearly anywhere. Politically speaking, it's not going to go down very well if the industry simply says "Oh -- sorry 'bout breaking your Ocean. Bygones. We'll just be ever more careful in the future."

Still, I expect everyone in the industry has been shaken by this disaster. I wonder how many heated discussions have been resolved by invoking "Another Deepwater Horizon".

BTW: Do I think there’s much of a chance of such a program being implemented? No

Why not?

The public is screaming for changes that will lessen the chances of future disasters and this sounds like a very practical and effective one.

Surely if the industry supported it (or didn't fight it tooth and nail) it could happen.

A small minority are screaming at likeminded comrades. The majority trust that this was an accident, being dealt with by the authorities.

Suspension of disbelief is essential. Let's agree we're being told the truth. No ROV ever visited the Deepwater Horizon wreck. Nobody would switch video to green to block ugly images.

I've been a Resident Engineer on several big construction sites. It's not safety-related, but the task is similar to a safety inspector. You certify that the work is done according to the drawings and specifications, and you sign off the quantities on the payment certificates each month.

If you are working with a responsible, financially sound contractor near a large centre with alternative contractors available should this one screw up, it's not a problem to demand that things be done by the book.

When you are stuck in the middle of Namibia with an incompetent contractor who will go bankrupt if you don't sign his payment certificate and there is no one else within 200 km to take over, and the client needs the job finished to generate an income, you turn a blind eye sometimes.

If you are not experienced and you demand things be done a certain way because that's what it says in the specifications, and a gnarly guy with a hard hat and years more experience than you says, "But we always do it this way," what are you gonna do? (Householders get this a lot when dealing with builders.) Often you have to make a decision on the spot because big expensive machines stand waiting, so contacting someone senior in Head Office is not an option. (I'm talking of pre-cellphone days.)

And anyway, on a big site, there are a thousand things going on behind your back that you just have to trust the contractor is doing OK. You can't be everywhere at once.

What it comes down to is building a good working relationship with the contractor, so that he knows you won't take sh1t, but you're not going to be a dogmatically by-the-book a-hole, either.

Going back to DW GOM drilling, when something is costing $800,000/day. it's going to take an inspector with very large cojones to demand that it be shut down. The contractor will always suggest persuasive strategies to satisfy you while keeping his production going. In the back of your mind there's always the thought: What if they can prove I was wrong in shutting them down and I have to pay damages? These things are usually resolved by negotiation.

Additional suggestion: How to change the incentives.

Currently the same entity pays for the safety up front, and (more or less) pays the damages if there is a blowout, as collects the profits if there is not.

Mandate that all operator companies contribute to a body that oversees the safety (among other things, choses between Rockman Inc and its competitors), and bears a good chunk of the burden if there is a blowout. The participating operators have a say on how the body is run. This counters the whining about government involvement leading to inefficiencies. On the other hand, this way Shell (say) would have to worry about BP having a blowout. Shell would see downsides only to safety shortcuts (except when similar shortcuts benefit their own operations). But the psychology of shortcuts is very different if you have to worry about ten other operators taking more shortcuts than yourself, and so the participants would be far more interested in controls and supervision systems that actually work.

There should be some coziness/leverage resisting requirements. One safety contractor couldn't have a "too big to fail" proportion of its contracts with one operator and inspectors should rotate to different operators (thus also gaining a gut-level sense of best practices).

Rockman, Inc, sounds a lot like NR (Naval Reactors):

http://en.wikipedia.org/wiki/Naval_Reactors

I work with folks who have told me something about how this organization works: When a NR inspector is on the Captain's ship, the NR guy is God.

NR inspectors are often enlisted, and wear civilian clothes, but his word is law, his words can stand the ship down...doesn't matter if the ship is skippered by the most decorated, biggest, baddest golden boy in the fleet, his name is mud if the NR inspector says so.

There are no-notice inspections...

AFAIK, we haven't lost a nuclear-powered ship since the Scorpion in 1968, and previous to that, the Scorpion in 1963.

The Russian quality control seems less effective, judging by this list of USSR/Russian nuke sub sinking that are public knowledge:

http://en.wikipedia.org/wiki/List_of_sunken_nuclear_submarines

It is possible to tighten up this offshore oil drilling enterprise...but the inspectors have to be lifers, and beyond the reach of politics...DW drilling would cost more, but such is life.