In Situ retorting of oil shale

Posted by Heading Out on July 4, 2006 - 8:39pm

Mining shale, however, is fairly expensive, both in terms of energy, and hard dollars. At the same time, once the oil is extracted, the spent shale has to be disposed of. That costs more money. Considering all these potential expenses and potential problems, it is therefore not surprising, from the beginning, that the idea of trying to create the initial retort in the rock, and making that transition to oil in-place looked as though it might be a winner.

OK so accepting that we can't use nuke's can we do this on a smaller scale ? What will we need. Firstly we still need some sort of cavity in which to start the fire, and to allow it to spread. Then there has to be air fed to the fire to keep it going (and this will require that boreholes be drilled down into the area to sustain the air flow). And then there has to be some way of getting the mobilized oil out of the ground, so that it all doesn't end up being burned down there.

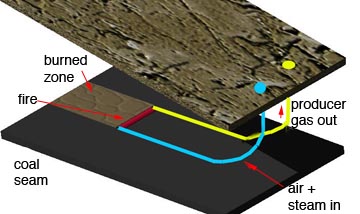

It is an idea that has been suggested for a number of different energy sources. For example, back in the 1970's tests were carried out at Hannah, WY to see if coal could be gasified in place. It had been thought that the natural joints (bedding planes and cleat) would be enough to allow air to reach the fire from an adjacent borehole, but in the field it was found that horizontal boreholes were required to control the flame front. A recent experiment along these lines is being carried out in China.

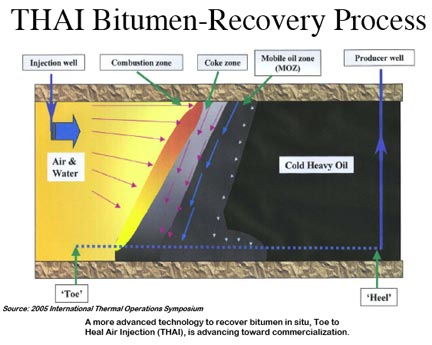

As also has been mentioned in comments up in Canada the toe-to-heel air injection process known as THAI is being tested by Petroleum Equities(pdf file). And I have taken an illustration from one of their talks to illustrate the process.

See also Commodity Mine. As you can see, this is a variant on the coal idea, except that with the oil sand being thicker, it is possible to use a vertical well to feed air into the flame front. The process gets its name from the fact that the oil is recovered through a horizontal well drilled (the blue dotted line) under the zone being processed. The heat, and presence of steam, lowers the viscosity of the bitumen, so that it flows down to the well, and the fire, and recovery process migrate from the toe of the horizontal well (initially under the vertical one) back to the heel (where the horizontal well swings from the vertical). The process has been described more fully at green car congress, and is being tried at Whitesands, where, the first test is underway.

The Pre Ignition Heating Cycle (PIHC) at the WHITESANDS pilot project has commenced its initial start up with steam injection into the vertical injection well. The PIHC phase is programmed to continue for approximately 90 days with steam injection in the first vertical and horizontal well pair. Air injection in this first well pair will commence when the bitumen around the vertical injection well has been sufficiently mobilized. Once combustion is initiated in the first well pair, we will begin the PIHC phase for the second well pair. All three well pairs are expected to be on production by the end of 2006. We are also evaluating the potential to initiate a test of our CAPRI<sup>TM</sup> technology later in 2006.(From Petrobank pdf file).

It might be helpful to insert a slight digression here. In a normal oil refinery, the heavy oils, or residuum, that come out of the bottom of the initial fractionating column have almost no light hydrocarbons left in them, and so are sent to a a Coker, where at a temperature of around 1200 degrees, the final hydrocarbons are driven off, and cracked into lighter fractions, leaving the carbon residue known as coke (or petroleum coke to distinguish it from that made from coal). From my youth I can tell you that this is a much harder fuel to start burning than conventional coal, since it no longer has any volatiles left in it. Thus, for example, even after the intensity of the fires in the Kuwaiti oil field coke was deposited around the burning wells and required barrels of C-4 to break it up, so that the fire fighters could reach the top of the well, put out the fire, and replace the fixtures. The reason that I mention this is that Petrobank intend to burn this coke as the source of heat for the reactions (so that they don't have to use oil or gas product - which can be recovered). This is going to require that a lot of air be supplied to the burning zone to sustain the fire - over the full face of the burn. I'll come back to that in a bit.

The situation with the oil shale is a little more complex, since the structure of the rock is tighter than that in Alberta, and the oil has to be heated to a significantly higher temperature before it will transition and move. The first underground experiments were carried out by Sinclair, in 1953 and 1954. (So we are back to paper references -see Ref 1 at the end). In those days drilling technology wasn't as advanced and so, for the first experiments, they drilled a hole near the outcrop of the shale, and then created a crack from the well to the outcrop by pressurizing air in the well until the rock fractures (a simple variant on hydrofracing a well). By adding sand the crack can be propped open so that air can get into it. It took a couple of tries to get it working, but they were able to start fires in the oil shale at the well, and then by continuously pumping down air, carry the fire along the crack. The heat of the fire changed the kerogen to oil, in the same way as with the retort, and oil was seen coming out of the crack at the outcrop. The rock around the well was, however, fairly fractured from being near the outcrop, so that air passage to encourage the flame to progress, was possible.

I had been asked if there was evidence of shale expanding during this process, and bearing in mind that there is some additional fracturing during burning, the conclusions to the first tests are worth quoting.

Under field conditions - particularly if the operation requires high pressures - volumetric conformance and thermal efficiency can differ significantly from model predictions. The burning zone probably will expand to more closely follow the retorting isotherm and shorten heat transfer distances. In addition, convection may become significant. To illustrate, shale retorted under simulated overburden pressures in the laboratory does not spall or crack as it does at low pressure. Instead, a consolidated rock having high porosity and low permeability remains after pyrolysis of the kerogen. Bulk volume is greater than in the un-retorted state. It is possible that some of the injected air will move through this permeable matrix of spent shale to more fully utilize the fuel content of the spent shale and accelerate heat transfer to raw shale over the rates computed from the mathematical model.Coring of the oil shale as a precursor to the aborted nuclear shot at Rio Blanco (Ref. 2) showed that at depth the shale appeared to have considerable jointing, which would be a real help in any in-situ retorting method, as Socony anticipated (Ref. 3). When looked at under a microscope the retorted shale also had a number of voids, left by the volatized kerogen, that provided some permeability to the shale (Ref. 4).

It is the presence, or absence of cracks, voids and other passages that the controls the success of conventional in-situ retorting of oil shale. Cyclic hydro-fracing or air fracing of the shale can induce a series of fractures around a well bore at depth, but these are going to be relatively narrow. There is not the mobility of the structure that one can anticipate from the oil sands. Further the environment has to be heated to a much higher temperature to induce transition first to the bitumen and then to the crude. In the tight rock that exists under pressure at depth, the only path that air has to the fire is from boreholes drilled to that depth. (In contrast with close-to-surface conditions where ground fracturing will open cracks to the surface). With the cracks being relatively narrow the air that must be supplied to the fire must be at a relatively high pressure, and in considerable volumes. Without an underground cavity, into which some of the rock can displace, or a means for removing some of the rock to allow multiple fractures of the shale, and fracture opening to allow air access, starting and sustaining a large underground fire will be a significant undertaking.

Unfortunately also "Lean shale tends to be brittle, fracturing under stress, while rich shale tends to be tough and resilient, resisting fracture by bending, and tending to yield plastically under stress." (Ref. 5) This is going to make it harder to grow the cracks where we need them to be.

The other problem with in-situ retorting is controlling the flame front to go where you want it. It is hard to control where the fractures go underground, and the path that the air takes, to make sure that all the shale is retorted, so much more air has to be pumped underground than might be needed otherwise. And this is where it gets frustrating because, though it may only take 260 Btu to raise a lb of shale to 900 degF, (Ref. 6) and that can come from the carbon content of the shale (the coke above), getting enough air there and having somewhere for the released oil and gas to go can take a lot more energy.

For example if two wells are drilled, say 500 ft apart, and a crack run between them, then the air to the burning front, and the flow from it, is gong to be limited by the width of the crack. These processes are relatively slow. A model of the process (Ref. 7) has shown that it can take 10 years for the front to move from one well to the next. During that time air has to be continuous injected, and the volume of air required, for a barrel of oil recovered can be calculated. Depending on the temperature at which the air was injected (since it shouldn't cool the fire) it can take between 24,000 scf (standard cubic feet) and 86,000 scf/bbl. To get that air into the fire effectively it would have to be pumped into the well at 2,500 psi. (A conventional air compressor runs at around 120 psi). To generate a flow of 50,000 barrels a day was found to require an air compressor system run at 272,000 horsepower. To cut a longer story short, this turns out not be economic, at 1968 costs.

Hmm! Well I am not quite finished, but perhaps this explains in part why Shell are using heaters, rather than fire. I will try and conclude, with a short discussion of that, next time.

The series also includes:

Where it is

Mining the shale

the nuclear option

nuclear field tests

Ref. 1 Grant B.F. "Retorting Oil Shale Underground - Problems and Possibilities", 1st Oil Shale Symposium, CSM, 1964.

Ref. 2 Stanfield K.E. "Progress Report on Bureau of Mines - Atomic Energy Commission Corehole, Rio Blanco Country, Colorado", 3rd Oil Shale Symposium, CSM, 1966.

Ref. 3 Sandberg C.R., "Method for recovery of hydrocarbons by in situ heating of oil shale", US Patent 3,205,942, 1965.

Ref. 4 Hill G.R. and Dougan P. "The characteristics of a low temperature in-situ shale oil", 4th Oil Shale Symposium, CSM, 1967.

Ref. 5 Budd C.H. McLamore T.T., and Gray K.E. "Microscopic examination of mechanically deformed oil shale," 42nd Petr. Engrs Fall Mtg, SPE 1826, 1967.

Ref. 6 Carpenter H.C. and Sohns H.W. "Application of above ground retorting cariable to in situ oil shale processing", 5th Oil Shale Symposium , CSM 1968.

Ref. 7 Barnes A.L. and Ellington R.T. "A Look at in situ oil shale retorting methods based on limited heat transfer contact surfaces", 5th Oil Shale Symposium, CSM, 1968.

Shell's in-situ method involves electric heating rods in bore holes. Here's a modest proposal: how about supplementing these heaters with spent fuel rods from nuclear power plants? (Not forever, just for the 3 years of heating). These rods are presently just heating "swimming pools" at each plant, waiting for a permanent disposal location. After all, this in-situ retorting is just an acceleration of nature's slow cooking from earth's natural radioactive heating.

I guess the answer is Shell's electric heaters are hundreds of feet long and maintain 700 degrees, neither of which is achievable with spent fuel rods.

I also think this is the case... I suppose spent fuel rods are lower than 100 degrees Celsius, otherwise the water in those pools would have boiled off.

In full operation inside the reactor the maximum surface temperature is about 600 deg F or a bit more than the boiling point of water at 2200 psia (lower for BWRs).

There is no practical theoritical limit on nuclear spent rod temperature but spent fuel assembly loses heat emissions exponentially.

In practice, high purity water is required to prevent corrosion and/or scaling and subsequent failure of the cladding.

Real-world spent fuel pools need external cooling for a few months after fresh spent fuel is added but soon reach an approximate equilibrium with their evironment. Water continues to be circulated but more to maintain purity and clarity than for heat removal.

Using spent nuclear fuel to extract kerogen is not feasible.

But you knew that.....

The vision if fuel rods plugged in the rock riminded me of the natural fission reactors that existed back in the time when U-235 was more abundant. I wonder if something similar could be feasible for oil shale, with kerogen acting as a moderator and a coolant, but this sounds too much a pie in the sky to contemplate with.

A safer bet would be a dedicated reactor producing steam or molten metal for the heaters.

Probably electrical heaters would be the method of choice but I'm sure both methods would need detailed engineering studies for the particular site before a clear decision would be made.

As to embedment of spent nuclear fuels in rock, Yucca Mountain spaced the assemblies to keep rock temps below 300 deg C (if memory serves) but it took decades to reach that temp. The key is that rock in mass is a poor conductor of heat.

Spent fuel assemblies give off heat of maybe 1 kW-thermal after a year or so. I suspect it would liquefy the kerogen but it would take decades and that would make it non-commercial. Plus you would be expected to retrieve the assemblies and move to someplace permanent.

Better to reprocess the spent fuel and return the unreacted uranium and plutonium to the power reactor fuel cycle.

I have a couple of questions:

Where does all the CO2 generated by the controlled burn end up? In the atmosphere?

If a nuclear explosion is used to generate heat to cook the kerogen, does that eliminate the CO2 generation? Seems like it would. Obviously the geothermal processes creating oil at 10,000 feet aren't generating volumes of CO2 in the process.

Thxs for the info. I am assuming you read my earlier link on how Nevada gold mining wrecked the water table and riverine habitats, basically for eternity, in the Humboldt Basin. LOTR: "My precious, my precious...!" SAD.

My belief is that shale mining, by any methods illustrated here and in earlier threads, on the mind-boggling scales proposed, will severely disrupt the habitats in these states. I was hoping an expert hydrologist would elaborate here on TOD to say that it is either a problem or not: so I remain confused from lack of data.

Perhaps the next thread on oil shale could investigate mining versus possible enviro-degradation, and the tradeoffs involved, starting with H20? Thxs.

Bob Shaw in Phx,AZ Are Humans Smarter than Yeast?

We seem to be willing to go to amazing extremes to not raise the CAFE standards.

Almost any sort of underground in situ process, be it in situ bioremediation of toxic waste sites or oil shale projects, is going have an inherently high level of uncertainty, at least initially. it goes with the territory.

However, I think that once some significant operating experience has been accumulated, they might be able to pull it off, albeit very inefficiently. But for now, efficiency is secondary to the primary goal of getting some signficant quantity of good stuff out of the ground. Improvements will be made.

My hunch is that if in situ is not going to be feasible, then brute-force mining of the stuff is not going to be

feasible either. My bet would be on in situ. I just can see moving all of that overburden to here and there and back again.

It's less than ideal, but isn't everything?

Let's talk instead about the timeframe and the potential for large-scale production. This is not discussed here. Only experiments with long lead times.

Aside from the impact on the environment, ignoring that too, what kind of window do we have for replacing decline rates in big but old fields all over the world? C'mon HO, what's the deal? How much will "oil shales" contribute to daily world production by 2012? 2015? 2020?

Naturally, you see my point. I need to be convinced that we are not talking about pipedreams. Your technical posts on the subject are fascinating. I would prefer to talk about the envisioned timeframe, the potential recoverable resources as a function of time and whether the financial, manpower and logistical (technical) resources will be available to make the miracle happen.

Actually I've come increasingly to the conclusion that we can not prevent major oil supply disruption with any alternative approach. In fact sour heavy crude won't even work. Were not only addicted to oil but were addicted to light sweet oil.

Right now were not even capably of timely switch over of our refining capacity to handle the heaver crudes since light sweet has peaked. This will get far worse before it get better if ever. This refining disruption actually over shadows overall oil production and in fact by the time we get this strait we will be pass peak oil. Once we start in terminal decline its impossible to bring online the millions of barrels of day of production to stay even much less reverse the decline. I'm sure all these alternative resource will have there own refining issues just like the orinco heavy oil, tar sands and other heavy oil deposits.

Sure we can refine it but we need special equipment.

The point is I think we are already past the real peak which is the maximum of oil and refinery capacity for the oil which was light sweet. Were never going to gain with difficult to refine heavy sour oils and depletion much less bring online things like oil shells in the volume needed to offset depletion.

Finally the problem is not oil supply its major and pernicious disruptions of the oil supply.

I think RR should have more information on this issue.

So the above commenter is right in the sense that exotic refineries take a long lead time. If the peak is between now and 2010, it may be too late.