From Qurayyah to Khurais: Turning Water Into Oil

Posted by JoulesBurn on March 23, 2012 - 11:11am

|

Synopsis: A poignant little film about someone taking a lot of precious seawater, piping it miles into a parched desert, and forcing it into the ground. Oh, and then poking a bunch of holes in said ground and collecting the ooze that comes out. And separating said ooze into crude oil, bad smelling gas, and assorted other liquids with a whole lot of fancy plumbing. A bit slow occasionally, but this, plus a strange score choice ("Nomads of the Tibetan High Plateau"), forces the viewer to ponder the meaning of it all. In 3D animation. |

|

| Shorter synopsis: This video is an animated flyover of the Khurais Crude Increment Program in Saudi Arabia. Interesting stuff about oil production. | |

OK, so this is more of an educational film. But by watching, you will learn the following:

- How crude oil straight out of the ground is processed prior to being shipped around the world.

- How Saudi Aramco takes seawater from the coast, treats it, transports it, and injects it into the ground, thus helping to force the oil to the surface.

- A few interesting tidbits about the Khurais and Ghawar oil fields.

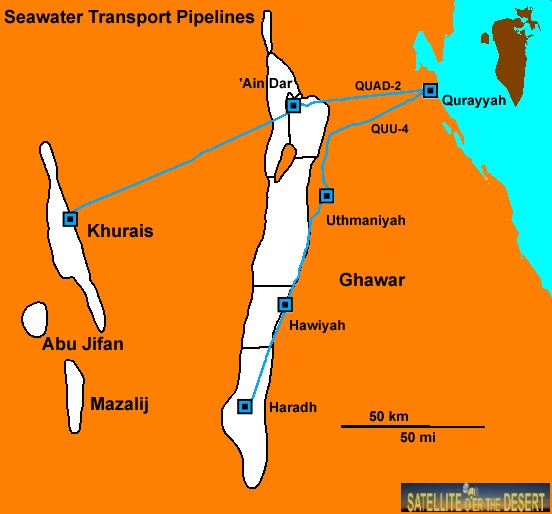

- How to correctly pronounce several Saudi Arabian oil place names.

The 23-minute video (in two parts) is an animated flyover of the Khurais Crude Increment Program, which was completed in 2009. I reported on Khurais prior to its completion. The fields of Khurais, Abu Jifan, and Mazalij together now have a reported capacity of 1.2 million barrels of oil production per day. This project required drilling new production wells plus peripheral water injection wells. Water for the injection is pumped via pipeline from the Arabian Gulf, specifically from the Qurayyah Seawater Treatment Plant, which is also used to provide water for injection into the Ghawar field. Some of the new capacity of Qurayyah was slated for Ghawar. The video covers upgrades made at Quarayyah and Ghawar as part of the Khurais project, as well as showing the workings of the Khurais Central Processing Facility.

Well, enough with the spoilers. Watch the video. There will be a quiz afterwards.

Part 1: The Khurais Central Processing Facility

Part 2: From Qurayyah to Ghawar and Khurais

Supplemental Information and Observations

Location of Facilities

Shown below are the locations of the various facilities and pipelines discussed in the video. The 'Ain Dar Water Injection Plant actually appears to be located in the Shedgum area of Ghawar. The Haradh WIP is located adjacent to Haradh GOSP-2. The new pipelines were generally laid next to existing pipelines, and the new pipeline from 'Ain Dar to Khurais follows the E-W Crude Pipeline that runs between Abqaiq and Yanbu on the Red Sea.

| |

|

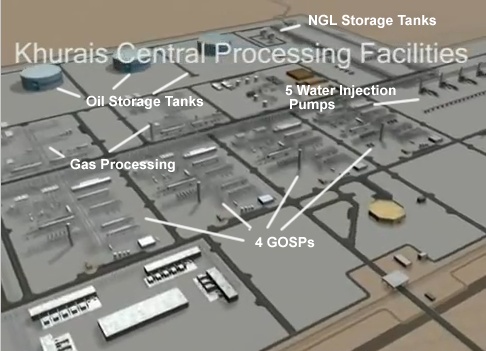

Khurais Central Processing Facility

The Khurais project is novel for Saudi Arabia in that nearly all of the processing happens in a central location. Instead of having gas-oil separation plants scattered around the field, they are located next to each other and connected in parallel. This arrangement is enabled by the fact that all of the Khurais producing wells employ downhole submersible pumps, helping to push the oil from each well to the Khurais Central Processing Facility located up to 100 kilometers away.

| |

|

Qurayyah Seawater Treatment Plant

Below is a Google Earth view of the Qurayyah plant in 2010. The upgrades are in the south (toward screen bottom) end, and the two added pipelines (QUAD-2 and QUU-4) supplement the four existing prior to the Khurais project. Before 1974, the Qurayyah site was a sandy, remote beach. By 1978, it was supplying Ghawar with 4.2 million barrels of seawater for injection. Check it out on Google Maps and note the security around the perimeter.

| |

|

Peripheral Water Injection Explained

Below is an animation (repeated from here) showing how peripheral water injection is used to help get the oil out of a reservoir.

|

Production and Water Cut in Ghawar and Khurais

The amount of water being injected into Ghawar has been of interest on this blog for many years. The video threw a lot of numbers out there regarding how much water the upgraded system can deliver, but it is not always clear when the upgrades alone or the total system are being referred to. But it seems we have the following:

- 2.36 MMBD (million barrels per day) of new water supply is arriving at the Uthmaniyah facility via the new QUU-4 pipeline, adding to that supplied by the three existing lines (QUU-1, QUU-2, and QUU-3)

- A total of 2.52 MMBD of water is being (or can be) injected into the Hawiyah area of Ghawar at 2820 psi. The oil production capacity of this area has not been specified, but it has been assumed to be about 1 MMBD.

- A total of 1.99 MMBD of water is being (or can be) injected into the Haradh area of Ghawar in 135 injectors, also at 2820 psi. The oil production capacity of this area has been stated to be 0.9 MMBD. The figure of 135 water injectors, if true, would mean about 25 more injectors have been added over the last few years, based on previous counts in satellite images that I have done.

- At about 17:00 into the video, it is stated that the water is injected into Haradh at 2500 psi and that the yield is 1.6 barrels oil for every barrel water. That pressure figure (at least) seems to be a mistake, as it is inconsistent with the above values (which are in turn consistent with the Ghawar field operational pressure for many years). The 1.6 ratio is certainly not consistent with the assumed production capacities and the amount of water. The same figures are repeated later after discussing injection into Khurais, and it becomes clear that these apply to Khurais and not to Ghawar, as 2500 psi is sufficient to pressurize Khurais. Perhaps the video has not been edited for final release to theaters.

- The QUAD-2 pipeline is delivering 2.14 MMBD to the 'Ain Dar Water Injection Plant and on to Khuais.

Certainly an unknown quantity is the amount of produced water (from the oil wells) being fed back into the system for reinjection in Ghawar. At 9:26 in the video, a figure of 636 thousand barrels per day of water is given for Khurais. This might be the current capacity for this, but Saudi Aramco recently said:

KHURAIS, the single largest addition to oil capacity in Saudi Aramco’s history, is now producing around 1 million barrels per day (mbpd), field production manager Yousef Al Furaidan says. ... On the other hand, Al Furaidan says it can pump far above nominal capacity. “We can produce up to 1.4 mbpd because this field is considered a virgin field, still at the beginning of its production life,” he said. The facilities can handle the higher production levels as they are designed to deal with a 30 per cent water cut, while the water cut now is virtually zero, he says.

30 percent of 1.2 million is only 360k, so there is an inconsistency somewhere. That report also said this:

Decisions about managing spare capacity at Aramco fields are in the hands of reservoir engineers, but at Khurais, the state oil giant always tries to maximise output from the main field, Al Furaidan says. The two satellite fields, Abu Jifan and Mazalij, together produce 160,000 bpd. They have higher production costs than Khurais, and will be kept idle if not required, industry sources say.

And regarding gas and NGL production, there was:

According to data from the central processing centre, Khurais was exporting 31,900 bpd of natural gas liquids. It was also producing 290 million cubic feet per day (mmcfd) of gas, although Al Furaidan says it can reach 330 mmcfd at full stretch.

Raw gas production is proportionally lower, but NGL production is rather low (80k expected for 1.2 MMBPD oil) Where are those liquids going? It is possible that (much) more NGL comes from Abu Jifan and Mazalij such that when they are shut in, overall NGL production declines substantially.

Bottom Line

It gets a bit old watching fluids flow through pipelines, but there were some nice touches, such as the worker at Qurayyah turning pages and the sea critters in the Gulf. One thing missing from the story was what goes on in Khurais in between the water injection and the wet crude processing. Saudi Aramco has yet to reveal how the field is laid out. So I will -- in a future post.

Oh yeah, the quiz! Question: how many seahorses were in the video?

Joules - Very nice presentation. It's difficult to describe complex technical issues without losing the viewers in the details. Often better to make generalizations than allow the technology to obscure the take away points.

I will offer one detail I think is important for folks to understand. The results of a water injection program vary greatly between a new field and an older one. As long as there is a significant aquifer under the oil column that readily moves upward as the oil is produced there's little benefit in water injection. But most water drive reservoirs don't have sufficient aquifer support. If a new field falls into the less efficient category it's critical that the injection program start as soon as possible. As the water front moves upward it will leave residual oil behind oil behind even if there is a very efficient drive. This residual can range from 15% to more than 50% of the oil in place. That oil can be very difficult to recover regardless of how much water is later injected. The illustration is a tad misleading in that regards: it implies there is no oil left behind as the oil/water interface moves upwards. Even in the most efficient water drive reservoir that's far from true.

Older fields, like Ghawar, are a different situation entirely than a new field like Khurais. The last phase of the illustration, where the oil production has been squeezed down to a relatively small area, better represents mature water drive reservoirs like Ghawar. In this case the water is being flushed through those areas of residual oil saturation that the water front has passed through many decades ago. In general terms Ghawar would be called a water flood with Khurais classified as pressure maintenance. PM programs tend to be much more efficient/profitable than WD programs. It's not uncommon for a strong water drive reservoir to produce commercially even when water cut reaches 99%...especially with current high oil prices. But that also means such a field that might be producing 1 million bopd is also producing 80 to 100 million bbls of water a day. It takes a great deal of energy to move that much water through the system. And a significant infrastructure as this post illustrates.

The efficiency of a water flood of an older field also varies greatly with the nature of the reservoir. One of the difficulties with fractured limestone reservoirs is that the injected water will preferentially moves through the fractures instead of the rock matrix. Thus much of the oil in the matrix isn't "swept" by the water. Something of a good news/bad news tale. Older fields like Ghawar will give up their residual oil but only very slowly. I have no doubt that Ghawar et al will be still producing oil 100 years from now. It may only be a small fraction of the current rate but if the economics support the lifting costs it will be producing long after everyone reading my words have passed.

And that leads to a point I'm will keep beating. There may be as much oil left in the ME as some estimate and maybe even more. But the amount proven reserves left in these fields is not the basis of PO. It's all about the recovery rate of those reserves. One day the URR of Ghawar Field may exceed the most optimistic estimates. But IMHO most of that production will be of no benefit to anyone living today...even a young child.

Here we go. First, Ghawar and probably most of SA is operated at a 'gravity stable' rate. So displacement is very efficient. That is one reason why I roll my eyes when posters claim that recovery at Ghawar will be 40 % of OOIP, most of which has already been produced.

Also Khurias is not a 'virgin' field, but was produced in the '80's. Joules previous post on Khurias showed that pressure recovered during shut-in periods. Khurias has been shut-in for nearly 20 years. So either water incroachment is restoring pressure, or the field is pseudo-abiotic(I am only about 99% joking on that).

That reminds me, I need to look at the film about 2 more times and re-read all the rest of the referenced posts before commenting again.

I think "gravity stable rate" is overstating it, as (as Saudi Aramco has discovered), certain facies of the reservoir (usually at top) were more or less cut off from the waterflood as it moved through, and getting that "attic oil" to come out is a bit problematic. The water front moved faster than it was expected to based on models. There is another reason for that, though, and I will address that in a future post on why Saudi Aramco says they can achieve an even higher recovery rate.

Well, yes. If the reservoir was produced completely 'gravity stable', then the water production rate would be zero until it goes immediately to 100%. I understand that these are a heterogenous reservoirs and production is not ideal.

I also know that SA uses a giga-cell reservoir model with about 44 years of injection history match (at Ghawar) and 61 years of production history. Because of SA's superior reservoir management, I am confident that SA's recovery will exceed any average recovery for giant carbonate reservoirs proposed by Simmons or anyone else.

It's a water flood when it is your backyard.

Great piece of information, Joules. There is so much information here and the potential for greater confusion, or should it be obfuscation ?

I propose that before anyone comments, that they study the film about 3 times with liberal use of the stop and replay buttons. A sort of beta viewing where fundamental questions are addressed. I know it won't happen, wishful thinking.

For example:

I could be mistaken, but at that point i believe the discussion is relative to abu-Jiffan and the ratio is 1.6 barrels of water produced for every barrel of oil. If this is true, then the water cut is 62 % (1.6/2.6). I wonder what is going on with abu-Jiffan ?

I will re-view the film, and the problem may resolve itself.

Thanks for the film, Joules. Where did you come by it ?

The water cut is the fraction of produced oil that is water. If you have 1.6 water in for every barrel of actual oil out, coming out is one oil and 0.6 water, so water cut is 6./1.6 = 35%.

Part of the problem (or perhaps not a problem) is that these numbers seem to be design specs. That and some comments in an article linked in the post suggest that they were expecting water initially, but perhaps 600kbpd water is what it is currently designed to handle (eventually). But I think it applies to all of Khurais. I don't think they would have tacked a satellite field onto the project if it was going to be mostly water.

The video just showed up one day in a Google search.

[edit] Check out the YouTube channel of the guy who uploaded the video:

http://www.youtube.com/user/r0ckheadz

Is that you, ROCKMAN?

Definition of water cut

http://www.glossary.oilfield.slb.com/Display.cfm?Term=water%20cut

Yes. The "1.6" in the video is the amount of water injected, not the amount produced along with the oil.

Sorry Joules, got wrapped up in the comments and did not follow all the numbers presented.

I re-viewed the film, and I now believe the quoted figures are 1.6 barrels water (injected) for each barrel of oil produced and the reference was to abu-Jifan sub station.

If 1.6 barrels of water are injected and 1 barrel of oil produced, the water cut is 26%. Here's how: 1.0 barrel of stock tank oil occupies 1.25 barrels of oil in the reservoir(approximately, from memory). If water injection and oil plus water production are steady state, 1.6 - 1.25 = 0.35 barrels of water are produced. Then the (produced) water cut is 0.35/1.35 = 0.26 = 26 %.

I should have taken my own advise and re-viewed the film. The 1.6 barrels of water for 1 barrel of oil produced refered to are at 19:20.

The same graphic also appears at about 17:00.

Yeah, I neglected the volume factor.

But the Abu Jifan substation is just for electricity. There is not very good registration between where the captions appear vs. what is happening on screen. There is considerable lag.

Note that Khurais has a gas oil ratio of 274, compared to 400-545 for Ghawar.

Joules, thanks for a fantastic article. The video was very informative. It is interesting that about twice as much water is injected as oil that is retrieved. Of course when the water is injected, it goes in every direction and not all goes into the reservoir.

What I found very interesting was the little the little jpeg cartoon labeled "Peripheral Water Injection" and the little button you can click on making the oil reservoir go from full to almost empty. Surely they used Northern Ghawar Depletion Levels as a model for this little cartoon.

Ron P.

Ron, that's my (Flash) cartoon, showing how vertical wells get watered out.

You are correct about the water going everywhere, and that needs to be kept in mind in comparing the Ghawar injection amounts as well.

One thing that always strikes me about these 'dazzling' industrial creations: 10 guys with shoulder rocket launchers could take the whole thing down in a few hours. ...Good riddance.

dan,

from my experience in the military, including operations (being on a crew of a formidable, well-recognized, and enduring machine designed to kill folks and break their things in an organized, government-mandated and authorized fashion, following LOAC [Law of Armed Conflict]), and including plenty of formal and informal study of these matters, I think you underestimate the ability of facilities to be rapidly rebuilt after hostile perturbations.

no doubt a lot of effort can be brought to bear to fix critical broken components, though inventories of replacement parts in remote, non manufacturing regions could be stressed, and possibly very quickly.

If I recall the US Civil War was the first to rely heavily on high tech transport-railroad. Tearing up and rebuilding miles of track the other side had just tore up was a daily occurrence, but compared to oil handling facilities that was stone age stuff. How well did the Germans deal with the targeting of their oil infrastructure In WWII? I know they had serious fuel shortages at the end of things but bombers were hitting oil facilities from nearly the start. I do know the huge bombing attack of Black Thursday that was meant to cripple the ball bearing industry just ending up decentralizing it making it a much tougher target-kind of like Iran's nuke facilities.

Greetings wise ones! This is my first post, so please bear with me. A bit of history first. I'm a plant operator / foreman in northern Alberta, Canada. I have about 25yrs experience in various plants. The video was great, and I have worked with almost all of the equipment mentioned other than the sea water treatment (not much coast line in Alberta). The primary field that I spend my time at, is a very old field. It was established in the 1960's and has a water flood driving the formation. Consistent cuts of 95%+ and produces a fraction of what it once did. Moving the water around and re-injecting it is one of our biggest issues. The other field that I am partially involved in, is a new field that has a very tight formation and is injecting water to for Pressure Management. What is interesting is that the new field has seen huge decline due to unexpected fracturing from the injectors to the producers. So the formation is not sweeping like to old water flood is. Pressures are similar to what the Saudis are using. This is what I would expect of their field within 5 years (IMHO). Their volumes are so HUGE compared to anything that I have seen, and there is no indication of distance, so who knows? The next 10years will be very interesting in this industry.

Carbonate?

Fracturing is an issue in Saudi fields including Ghawar, Abqaiq, and Khurais. They spent quite a bit of effort mapping out the fractures in the crestal area so as to avoid crossing one with a horizontal producer. In my previous post on Khurais, I had some info on the reservoir characteristics.

http://www.theoildrum.com/node/3694

In the Shedgum area of Ghawar, they had wells in the middle of the field water out within days due to a fracture providing flow from an aquifer hundreds of feet further down.

The most interesting part of your article is the graph showing re-pressuring of formation after water injection was introduced. The part on gas injection was good too. We have people, at this very moment, running the numbers on gas re-pressuring of this old field. I'm looking forward to seeing what is finally decided upon for infrastructure, and what the results will be in a few years. The long term view is what it's all about, and that's why I like reading the articles you guys write. Like candy for the brain. Keep them coming!

Frozen North, welcome and I hope you post often.

Concerning your new field's decline rate, I don't think that is really surprising. As you suggest most of the swift decline is due to the water not sweeping uniformly. The fracturing of the reservoir creates a path of least resistance for the water to flow from the injector well to the production well, leaving a lot of oil untouched.

However looking at the world's giant fields it appears that the larger the reservoir the slower the decline rate. Garwar, for instance, produced for decades at around 5 million barrels per day before beginning to decline. Now of course the decline is rather swift but only after decades of hardly any decline at all.

Also, looking at the Gulf of Mexico production it looks like that the deep water fields are declining at a much faster rate than the shallow water fields or onshore fields. The pressure in them I suppose is much higher, creating a much higher flow rate at first. This, perhaps, gave them an original estimate of of a much greater reservoir size than was actually there. But the deep water GOM fields are declining at a rate of about 20 percent, over twice the rate of the shallow water fields, if my observations are correct.

That being said, you are an oil man and I am not, and that is why I hope you post more often. But I have been studying world oil production for about ten years now and that is my two cents worth, for what its worth.

Ron P.

It's always a wake up for me when I convert the numbers on here, compared to what I normally see (bbls vs M3) and so with that, I am still trying to wrap my brain around just how big and impressive some of the Saudi, Russian, and other fields and production are. I do believe that there is a lot that happens behind the scenes, and a lot of the numbers that companies issue can be cooked. And I would imagine this is the case with some of the countries out there. Especially in the middle east. I have been on the wrong end of a "pump and dump" and so am looking at the American Rhetoric on fracking with some skepticism. What I have learned in my career is: Every company has huge plans, and only a very small few come anywhere close to said plans. Zones that were once left cased because of being uneconomic, are now what are being pursued. There appears to be a lot of money being spent on less and less production, and there will be a lot of disappointment of production numbers in the next couple years. There will be some wild swings over resources. Ever play a game like age of empires or command and conquer? The last 3rd of any game like that becomes a fight over resources. And it's always ugly for someone. I don't intend to be that someone, and that's why I appreciate the work you guys put into gathering this info and posting it. My view of all of this is small, but I put my pants on one leg at a time, just like any CEO. Knowledge is power. Keep it up guys!

"precious seawater" ?

Is the world running short of seawater now?

heh.

Ironically, they are actually making the situation better (in a small way). The Arabian Gulf is suffering from the effects of all the desalination plants. The Gulf waters are rather shallow on average, the evaporation high, and the recharge from freshwater rivers or the ocean is rather low. The water entering the Qurayyah plant is almost 60 ppt saline, compared with 36 ppt in the ocean beyond the Gulf - the latter being similar to the value in the Gulf before the desal plants were put in. By drawing a little water in and burying it, a bit more comes in through the Strait of Hormuz. By contrast, each added desalination plant makes it that much worse (expensive) for the existing ones.

There has been quite an assortment of Mysterious Sounds in the news lately, and maybe its just me, but I keep hearing this persistent sound as if the "bottom of a barrel(s)" are being scraped. The "scrapers" are seem to be employing very sophisticated sound dampening techniques to make sure that distinctive sound isn't being heard too widely...

I am aware of the often heard brine discharge concerns on *land*, the impact on *land*, and the possible impact of allowing brine to be dumped back in the ocean untreated. That aside, wow is it that even a large number of desalination plants can change the salinity of the Arabian Gulf, even slightly?

Look at the results of this Google search.

or this article:

Desalination threat to the growing Gulf

"peak salt" - the notional point at which the Arabian Gulf becomes so salty that relying on it for fresh water stops being economically feasible.

Joules, if I were you I wouldn't worry so much about peak salt. When the Greenland ice pack melts, the Strait of Hormuz will widen, the desal plants will be inundated, and normal salinity will be restored.

At the rate we're going, it won't take all that long. Patience.

Look at the results of this Google search.

You may or may not have a point, but responding in such a way is sure sign of a weak (or often manufactured) argument. For example, look at these results

Google search!

Google search!

The National link points out the problem caused by dumping brine waste back into the Gulf, as did I. There's nothing here about the negatives of desalination itself.

No, it's just a sign that I get lazy after awhile. And I wouldn't concur that the search terms "desalination Arabian Gulf" would be leading one to a predetermined conclusion that it is a bad thing. I didn't think about it until I started coming across many articles in academic journals pointing out the problem.

I'm not slamming desalination here, just pointing out that the sum of all the plants operating in the Gulf (and dumping the brine back in) is definitely affecting the salinity level. I did not exactly say that was the problem, but I assumed that was obvious. Apologies if there was any confusion.

Suggestions on where else they should dump it? The volumes are orders of magnitude higher than the Qurayyah plant is pumping inland.

Suggestions on where else they should dump it? The volumes are orders of magnitude higher than the Qurayyah plant is pumping inland.

http://en.wikipedia.org/wiki/User:Benavides.a/Sandbox

The volume of brine from all the desalination plants in Saudi is on the order of millions of barrels per hour. If they paved all Saudi Arabia they would not be able to use all that brine.

Ron P.

Yes, ~1 mbph, of which ~3% is salt/brine.

Since salt is approximately 3.2% of the mass of sea water that still comes to about 10.5 million pounds of salt an hour. I'd be happy to see just how much saltcrete that produced a year, and just how long it would take to pave Saudi Arabis with it >i>?-)

I did read that saltcrete is being replaced by saltstone--I'm guessing they might both be a good building materials, if steel rebar were not required. But carbon fiber reinforcement is still quite expensive I believe.

But carbon fiber reinforcement is still quite expensive I believe.

Basalt http://www.basalt-rebar.com/ is now the "hot ticket" as rebar these days. And priced about the same as Iron.

(and with the topic being water use and oil - the off topic http://www.waterdefense.org/ showed up on Corbert Report this week. They are a US centric org however.)

Pump it down an old abandoned oil field somewhere? If they have no abandoned one, can't they not just sacrifaice an old worn out low performer for the cause?

That is not a viable solution. The volumes are like millions of gallons per hour. There is no field great enough to hold all that. And at any rate, the oil fields are hundreds of miles away. They would have to pipe the brine all that distance, then use a lot of electricity to high pressure pump the water into the ground with no return. Are you serious? Do you think they would go to all that trouble when they could just dump the brine back into the Persian Gulf. Err, the Arabian Gulf. That is a sore spot in Saudi Arabia. There it is known as the Arabian Gulf, not the Persian Gulf.

Ron P.

Another heh; now I have the answer to the snap quiz. That's a very saline environment, so zero seahorses. The upper salinity limit for the seahorse found in the Arabian Gulf, Hippocampus kuda, is 50 ppt, they die within 24 hours at 55 ppt. Sure enough, a recent environmental impact statement for the area doesn't mention them in coastal waters but does confirm that the salinity at Qurayyah is over 55 ppt.

There were six, I think.

And true to form, the video is contradictory, references are made throughout to barrels water per calandar day, and the graphics show mbod ? million barrels oil per day ? Maybe a subliminal message ? But what subliminal message ?

Okay, I follow the story this far: Seawater is transported overland to Khurais Central, 100 km from the Gulf. After its journey to the depths, it passes with oil through a desalter (3:48 timestamp "to remove the water and salt").

But then what? Are the salt and water re-injected as salt water again or is the salt isolated there and sent outside the environment? If so, where outside the environment?

No. The salt is never isolated, after the salt water is separated from the oil it is still salt water, it is never just salt.

I don't know what the water cut in Khurais is but say it is 30%. And if Khurais really produces 1.2 mb/d of oil then the well would produce somewhere around .4 mb/d of water. This salt water is then mixed with the 2.7 mb/d of seawater from the gulf and re-injected into the perimeter of the reservoir.

Ron P.

@3:19, the wet crude flows into the High Pressure Production Trap, which separates the (salt) water and gas from the oil. Some salt remains, and this is removed in the Desalter. Produced water (mostly from the HPPT) is mixed with incoming seawater and reinjected.

And to think it used to squirt out by itself. I wonder if they included the production of this video in the EROEI.

What I want to see is "barrels of oil per fresh desalinated drinking water" stats. At some point that's going to get scary.

Thanks for the video.

Dumb question here; I see a lot of processing steps that involve compressing gas or pressurizing liquids in large quantities. Which requires a bunch of power.

Since the stuff coming up out the well is about the same pressure, is there any equipment currently being used to extract power out of depressurizing the product liquids?

High pressure oil, gas and water are separated in the high pressure separator (trap in the video). Gas taken off the top of the vessel consists mainly of methane, ethane and hydrogen sulfide.

Water is removed and eventually re-injected. The vid uses the term 'salt water disposal' - possibly because it is injected into a dedicated series of wells -compatability problems may develope if mixed with sea water.

Oil and entrained gas is dumped to another separator. Gas from this stage is compressed back up to the first stage separator pressure and sent to the gas plant - for recovery of ngl's, water vapor and hydrogen sulfide. Oil from this stage is 'stabilized' and desalted before going into storage tanks.

I don't know of any field processes extracting power from pressurized gas although it is possible. Pressure is maintained as high as practical prior to further processing which typically includes additional compression. There is not much power to be extracted from the liquids because the liquids are essentially incompressible.

Oilfield operations are typically not highly efficient- as an example the flaring of gas worldwide. The hot Arabian desert sun helps some, as heat is sometimes needed to separate residual water from oil. In some areas, tanks and other vessels are painted black to absorb as much heat as possible. Saudi Aramco's tanks seem to be painted silver-grey.

If the above figures are correct, and we can assume they are: 9MB/d injected @ 2850 psi, average water-cut 30%, production ~ 5MB/d, 4250 ft wells, Ghawar and it three satellite fields are still producing with and ERoEI of over 60:1. Probably the highest in the world. The Saudi claim that 75% of the field can be extracted may very well be true.

With 38% of the world's fields about to go into terminal decline and be shut-in, Ghawar could still be producing its 4+ MB/d. --- At least we know where WWIII is most likely to start!

I tried to figure out who made this video but was not sucessful.Ther person who posted it has a bunch of music videos on Youtube and other sites as well as a couple of other PO-ish videos.

Does anyone know?

Rgds

WeekendPeak

I have no idea what video you are talking about? Apparently you are replying to a post but started a new thread instead of hitting "Reply". The "Reply" link is there for a reason, people should learn how to use it.

Ron P.

looks great..sounds great..OIL