Stranded Oil Recovery and American Energy Independence

Posted by Dave Cohen on October 13, 2006 - 10:54am

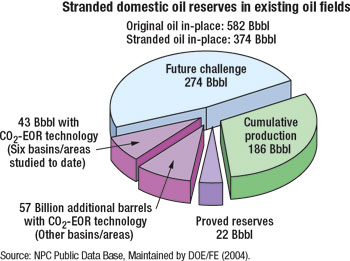

Figure 1

However, the problem of declining domestic oil production is not due to a lack of resources. We still have nearly 400 billion barrels of oil that is being left behind, "stranded". This is because our primary and secondary recovery methods recover only about one-third of the original oil in-place from our domestic oil fields, [Figure 1 above].Let's talk about what's going on here, considering the impact it will have on future U.S. domestic oil production and energy independence.Numerous approaches are being tried to recover a portion of this "stranded" oil. The one with the highest, but still unrealized, potential is using CO2-enhanced oil recovery (CO2-EOR). Twenty years ago, enthusiasm for this idea was high.

An important distinction I've repeatedly tried to make is that huge reserves numbers don't matter much. We are interested in production flows that affect the world's economies. See Stuart Staniford's Do Oil Reserves Tell Us Anything? and my answer to a comment by Leo Drollas, Deputy Director and Chief Economist for the Centre for Global Energy Studies, Reserves Growth and Production Flows, for some background. Also, HO has written about stranded oil in How carbon dioxide improves recovery. In what follows, you are going to be seeing some really big resource numbers which, for the uninitiated, might be miscontrued in toto as commercially recoverable reserves. So, hold on to your hats.

Undeveloped U.S. Oil Resources

From the World Oil article:US oil, while in the midst of transformation, provides about 7 million bpd of petroleum production. In 2004, this made the US the world's third largest oil producer, behind Saudi Arabia (10.6 million bpd) and the Russian Federation (9.3 million bpd). While US oil production has declined somewhat in the past five years, with timely implementation of policies and actions noted in this report, this decline can be reversed.While a mature hydrocarbon province, the US still has large volumes of undeveloped US oil resources in-place, totaling 1,124 Bbbl. Of this, 190 Bbbl is estimated to be technically recoverable with conventional technology, and 210 Bbbl using EOR, Table 1. This resource includes undiscovered oil, stranded light oil amenable to CO2-EOR technologies, unconventional oil (deep heavy oil and oil sands) and new petroleum concepts (residual oil in reservoir transition zones below the traditional oil-water contact).

Table 1. Original, developed and undeveloped

domestic oil resources (summary)

Figure 2 -- click to enlarge

If you are doing a double take—or checking your math—rest assured that Kuuskraa has just stated that the United States has 1.124 trillion barrels of oil resources in-place. Of this, 190 Gb are recoverable with conventional technology and 210 Gb with EOR (enhanced oil recovery) techniques. As usual, the devil lies in the details.

Looking at the table and other parts of the World Oil article, I call your attention to the following items.

- Undiscovered oil is based on the MMS estimates for the OCS (Outer Continental Shelf) as described in my Deep Ocean Energy Resources -- A Critical Analysis. It is particularly noteworthy that 60 Gb (billion barrels) of this oil—which does not yet exist—will be recovered by CO2 injection EOR.

- Conventional primary and secondary recovery technology yields 119 Gb from the chimerical 360 Gb of undiscovered resources, while 71 Gb comes from an estimated 210 Gb of reserves growth in existing fields—the tally is 190 billion barrels.

- Kuuskraa notes both in the article and in this Office of Fossil Energy fact sheet that U.S. "oil" production is 7.24/mbpd (2004). This represents NGLs (1.809/mbpd) + crude & condensates (5.419/mbpd).

- You may be surprised to see that the U.S. contains large heavy oil resources, amounting to 100 Gb OIP (oil in-place). Of this, 18 Gb have been produced in shallow reservoirs (< 3000 feet), most notably using steam-based EOR in the old Kern River Basin fields in California. Kruuskaa's study estimates that 20 Gb might be recoverable by applying thermal EOR—introduction of heat into the reservoir by means of steam injection drives, soaks and perhaps SAGD (Steam Assisted Gravity Drainage) to decrease the oil's viscosity. However, most of this heavy oil (45 Gb) resides in "reservoirs that are too deep for efficient thermal EOR application."

Further advances in heavy oil recovery technology will be required to efficiently and economically recover this large volume of deep stranded heavy oil. Development of more advanced technologies involving horizontal wells, low-cost immiscible CO2, and advanced thermal EOR technology could significantly increase recovery of this otherwise stranded oil. Joint US and Canadian efforts targeted at developing more effective technologies for producing deep heavy oil would be valuable to both countries.

Therefore, only 20 Gb of this resource is adjudged as being potentially recoverable—this depends on thermal EOR technology that is in the early stages of development. Looking further on the bright side, there's little need to worry about disturbing the permafrost anymore.Particular emphasis needs to be placed on evaluating technologies that could help recover more of the underdeveloped heavy oil resource in Alaska. Advanced oil recovery technologies, such as miscibility-enhanced CO2-EOR and CO2-philic mobility control agents, will be essential for recovering more from the largely undeveloped 25 Bbbl heavy oil resource in Alaska, in the Schrader Bluff, West Sak and other formations, without disturbing the permafrost.

- You may also be surprised to learn that America also has tar sands—now called "oil" sands, of course. Take that, you Canucks!

The domestic oil sand resource is substantial, on the order of 60 to 80 Bbbl of OOIP. While it is distributed widely, the bulk is concentrated in five states - Utah (19 - 32 Bbbl), Alaska (19 Bbbl), Alabama (6 Bbbl), California (5 Bbbl) and Texas (5 Bbbl). Uncertainty exists about the quality of the oil sand in Utah, reflected in the wide range of estimates.

Given the great uncertainty in Utah—I myself have also always regarded Utah with some ambivalence— Kuuskraa throws in a mere 10 Gb of potential oil from sands into his estimate, noting that recovery will be aided by more R&D and lessons learned from Canadian applications of SAGD and VAPEX (Combination of solvent and heat).

As both Figure 1 and Figure 2 indicate, the largest share of recoverable stranded conventional original oil in-place comes from application of CO2 injection EOR in the various basins. The lavender-shaded part of Figure 1 indicates that 100 Gb of oil will be recovered—a nice, round number. Let's focus on this part of Kuuskraa's study.

CO2 Injection for Enhanced Oil Recovery

CO2 EOR is viewed as an increasingly important technology for recovering stranded oil and sequestering carbon dioxide. See my story on the Weyburn pilot project for some background. Here are Kuuskraa's remarks on the technology.... widespread application of CO2 and other EOR technologies could raise the average national oil recovery efficiency to nearly 50%. More advanced CO2-EOR and other EOR technologies, such as gravity stable CO2 injection and horizontal wells, could improve the recovery efficiency of stranded oil from domestic reservoirs. Miscibility enhancers, conformance control agents and advanced immiscible CO2-EOR technology could extend the application of CO2-EOR to reservoir and basin settings now excluded from further development. Extending these technologies to recovery of Residual Oil in the transition Zone (ROZ) would add additional volumes of recoverable oil. Successful pursuit of advanced EOR technology will be central to achieving the 60%+ national oil recovery efficiency goal established by DOE/FE for its oil technology R&D program.Whether CO2 EOR (flooding) is miscible (blended) or immiscible depends on the reservoir temperature and pressure. Figure 3, from Enhanced Recovery Through CO2 Flooding illustrates miscible CO2 flooding as envisioned for the Natural Gas Systems, Inc. (NGSY)/Denbury Resources, Inc. acquisition of the Delhi Holt-Bryant Unit (Delhi) in northern Louisiana.

Delhi is a potential carbon dioxide ("CO2") tertiary flood candidate. The Company initially has estimated that this field has an estimated net reserve potential from CO2 tertiary floods of up to 30 to 40 million barrels of oil equivalent ("MMBOE"), net of the projected reversionary interest based on a $60 oil price.

Miscible CO2 Flood

Figure 3

As you can see, the idea is to drive the blended CO2 and oil from the injector well on the left toward the production well on the right. The project will be economical subject to the pilot start-up costs, the price of commercially available CO2 and a $60/barrel oil price. This text and graphic from Oil Field Screening Study for CO2 Sequestration and Enhanced Oil Recovery in the Illinois Basin explains miscibile versus immiscible flooding.

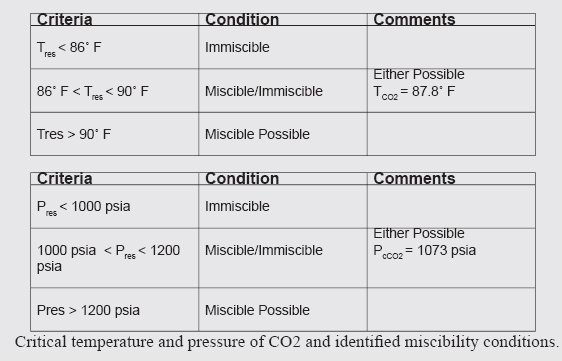

Conditions for CO2 EOR: Miscible vs. Immiscible

Defining plays of oil reservoirs as miscible or immiscible is important in determining the potential for EOR during CO2 sequestration. The use of miscible describes CO2 and crude oil that become a single mixture under certain temperature and pressure conditions via the mass transfer of intermediate hydrocarbons (C5 - C12) from the crude oil to the CO2 phase. Immiscible describes CO2 and crude oil under conditions where there is a distinct and identifiable separation of the two fluids. Mass transfer exists in immiscible CO2 flooding of the oil reservoir, however, there is a CO2 rich phase and a crude oil rich phase.The critical pressure (1073 psia) and temperature (87.8 deg. F.) of CO2 are important to determining miscible and immiscible potential of oil reservoirs. For miscibility to occur CO2 must exist as a critical fluid (i.e. dense phase, liquid-like, supercritical CO2); this is only possible for reservoir temperature exceeding the critical temperature of CO2 and reservoir minimum miscibility pressure (MMP; which increases with temperature and is at least equal to the critical pressure of CO2).

Immiscible conditions exist at reservoir temperature and pressure generally less than the critical temperature of CO2 and temperatures above the critical temperature when reservoir pressure is less than the MMP pressure. Under immiscible conditions, liquid or gas-like phases of CO2 are possible. The charts to the left and above illustrate these criteria for assessing im/ miscibility conditions of a reservoir, with a +/- 2 deg. F. and approx. 1000 psia "window" where either condition of CO2 EOR may be possible.

Figure 4 -- Click to enlarge

Miscible CO2 flooding is the standard technology used in current production. An ARI presentation by Michael Godec, Opportunities for Producing the "Stranded" Hydrocarbon Resources of Louisiana (powerpoint) indicates that immiscible CO2 EOR using large volumes of CO2 is a "state of the art" technology (slide #20) which would "enable nearly 3 billion barrels [in Louisiana] to become economic (at oil price of $25 per barrel and CO2 cost of 5% of oil price)"—as opposed to only 430 million economic barrels that could be produced using miscible flooding only. It is hard the reconcile the $25/barrel oil price cited by Godec and the $60/barrel price used by Denbury.

Even more "advanced" CO2 EOR includes gravity-stable CO2 injection and horizontal wells as cited by both Kuuskraa and Godec. All I know about it is that the DOE awarded ARI and Kinder Morgan a 3-year $5,119,103 contract to investigate it in December, 2004.

Advanced Resources International Inc. (Houston, Texas) will investigate gravity-stable CO2 injection at the giant Permian Basin location in West Texas. The goal is to increase oil recovery in the Scurry Canyon Reef field, which has the potential of an incremental oil recovery on the order of 53 million barrels of oil. Detailed reservoir characterization will be performed, and actual CO2 migration will be assessed by time-lapse crosswell seismic surveys to compare to predictions based on reservoir simulation.Finally, there is Stranded Oil in the Residual Oil Zone (ROZ). The elementary geology is shown in Figure 5. The study (a large pdf) is by L. Stephen Melzer of Melzer Consulting, subcontracting to ARI and DOE. The text below the figure is from the Executive Summary.

Figure 5 -- Click to enlarge

The presence of an oil bearing transition zone (TZ) beneath the traditionally defined base oil-water contact (OWC) of an oil reservoir is well established. What is now clear, and as established by this study, is that, in certain geologic and hydrodynamic conditions, an additional residual oil zone (ROZ) may exist below this TZ. This zone may be extensive, thick, and filled with a residual oil that may be recoverable using CO2 enhanced oil recovery (EOR). These thick residual oil zones exist where nature has waterflooded the lower portion of an oil reservoir.Melzer's extensive study covers the geology and some commercial demonstrations of the technology in the Permian Basin of West Texas and New Mexico. See the document for details. Another Melzer Consulting document—CO2 Flooding—describes the history of CO2 EOR in the U.S., including the original project at Wasson (West Texas) and subsequent developments both in the Permian and elsewhere. Concerning the costs & benefits of standard miscible CO2 injection, the author W.H. Leach states:Past investigations of the origins and presence of these naturally-formed ROZ's have been hampered by two limitations: a general lack of interest in these intervals, as they would add little or no additional oil during primary and secondary production; and, clear preference for avoiding drilling into these residual oil transition zones to avoid or reduce the production of water.

CO2 flooding is not for everyone. Start-up costs, coupled with waiting time for flood response, discourage any number of operators. Furthermore, the condition of the infrastructure of many older fields makes enhanced recovery impractical due to re-equipping costs, and this can be particularly true in the case of corrosive CO2-water mixtures.As if to highlight these remarks, Norway had considered CO2 injection for tertiary recovery in the North Sea. However, the Norwegian Petroleum Directorate (NPD) conducted a feasibility study which concluded that CO2 injection [is] too expensive and too risky.But, for the patient firms with the requisite engineering skill and a deep pocketbook, CO2 flooding can offer lucrative rewards.

There are several challenges that must be surmounted before CO2 injection for improved oil recovery can be implemented. CO2 injection is technically feasible, and the potential for increased recovery is substantial. However, the threshold costs for establishing a delivery chain for injection of CO2 are so high that other methods of improving recovery emerge as being more attractive for the licensees at this time. CO2 for improved oil recovery is capital-intensive, at the same time as production will take place over a long period of time.The Norwegian findings should weigh heavily on those evaluating Kruuskaa's much more ambitious plans for recovering stranded oil using CO2 EOR in the United States.

Future Production from Undeveloped Resources

Kuuskraa told the house members (June, 2004) thatAn aggressive, successful initiative [using CO2 EOR] could add one million barrels per day of domestic oil production by 2015 and twice this by 2025, helping maintain a viable domestic oil production and service industry and improving energy security. Several efforts are underway in the geologically most favorable reservoirs. For example, Anadarko Petroleum has started CO2-EOR in three Wyoming oil fields that are projected to add 50,000 barrels of oil per day by 2010. Kinder-Morgan is conducting a CO2-EOR project at SACROC in West Texas that is expected to have similar results.U.S. oil production (crude + condensate) has declined 20.8% in the last 10 years (since 1996) and stood at 5.121/mbpd in 2005. If the next ten years show the same overall decline percentage, production will stand at 4.056/mbpd in 2015. Adding in the expected 1 million barrels per day from CO2 EOR, given an aggressive initiative, 2015 production would still be less than it was in 2005. A realistic assessment of future U.S. production that includes reasonable projections about existing field declines (for example, the shallow-water Gulf, Prudhoe Bay), new fields (like Thunderhorse and Tahiti in the Gulf) and potential future production from new basins (such as Jack and the Lower Tertiary of the Gulf) is still missing. However, there are other amazing initiatives in the works to increase America's oil production and "energy independence."

If you want to see the really big picture for future North American production, look at North American Energy Freedom from the U.S. House Committee On Resources.

Description |

2010 |

2015 |

2020 |

2025 |

2030 |

| Alaska Onshore | .35 | .95 | 1.80 | 2.40 | 2.60 |

| Alaska Offshore | .15 | .30 | .80 | 1.20 | 1.50 |

| Heavy Oil/Tar Sands | .00 | .20 | .60 | 1.00 | 1.00 |

| Oil Shale | .00 | .40 | 2.00 | 3.00 | 4.00 |

| CO2 EOR | .30 | .80 | 1.20 | 1.70 | 2.00 |

| Canada | 1.20 | 2.50 | 3.95 | 5.10 | 6.10 |

| Grand Totals | 2.00 | 5.15 | 10.36 | 14.40 | 17.20 |

Efforts to Increase Domestic Supply Could

Yield an Additional 17.20 Million Barrels

a Day by 2030

[editor's note, by Dave Cohen] Conveniently, the data above includes production numbers for the Great White North, which, as far as I know, has already achieved "energy independence". However, given NAFTA, the House committee apparently has a keen interest in these territories. Most of this so-called "Canadian" production comes from the province of Alberta, which might as well be considered the 51st state as far as U.S. policy goes. The rest comes from those "Canadian" outer continental shelves. The document is silent about Mexico, which, the last time I checked, was in North America. Imagine that.

What are we to make of this remarkable tabulation? The numbers of immediate interest—those mentioned by Kruuskaa—are sourced from his studies. CO2 EOR shows a 0.3/mbpd increase over the current production of 0.2/mbpd. The 2015 production shows an additional increase of 0.8/mbpd—mostly in accord with Kuuskraa's testimony in 2004. If you thrown in the heavy oil & tar sands, the tally stands at +1.3/mbpd 10 years out. As for the other numbers, these can be the subject of future posts. For example, the ever-warming Arctic—making the region more amenable to oil E&P—contributes heavily to the Alaska projections, as does a dubious addition of 0.3/mbpd by 2015 from ANWR. Others here at TOD, including HO and Robert Rapier, have written extensively on the oil shales. See the "energy freedom" document itself for the sources of these numbers and a more detailed breakdown.

As is usually the case, the further one goes out in time, the rosier the picture becomes. A comprehensive analysis of these production numbers is beyond the scope of this post—suffice it to say that, looking 10 years out, I am skeptical about the stated production increase of 5.15/mbpd from the U.S. and Canada. The 0.4/mbpd from oil shale and the inclusion of ANWR production would seem to be dead giveaways. Not even Shell has ever set such an expectation about production from oil shale. Extraordinary claims require extraordinary evidence. Finally, in the 2010 timeframe, there is little or no help outside the Canadian tar sands increase of 1.20/mbpd. This number, too, appears suspiciously high.

The bottom line is this: regarding oil production,

these idealized projections do not serve as a realistic pathway toward "energy independence" for the United States. Indeed, the view here is that weaning America off oil imports is now, and on any timescale we care about, a fiction. The inclusion of Canadian production by the American congressional committee under the guise of "North American" energy freedom is shameful. Concerning the long range estimates out to 2030—if you choose to believe them, then you can just toss those Hubbert Linearizations right out the window. And to think that the purchase of Alaska from Russia in 1867 for $7,200,000 was called Seward's Folly! ![]()

As the Nobel Prize winning physicist Niels Bohr said, "predictions are hard to make, especially about the future." 17.2/mbpd —11.1/mbpd from the U.S. alone— by 2030? There's only 24 years to go. And although it is generally a mistake to automatically project past trends into the future, if we go backward in time whilst trying to remember what was happening 24 years ago—

8.649/mbpd (crude + condensate)

American Production in 1982

And A Big Hello! from The Gipper

Dave Cohen

TOD Contributor

davec@linkvoyager.com

(How does one "tip"? Well, you can either submit the link to your favorite link farm (reddit, digg, etc.) or link service (/., fark, boing boing, metafilter, stumbleupon). For the former, you click the little icons under the title of the story (and under the word "tags"). The fourth and fifth icons are to reddit (the alien) and digg (a person with a shovel). Both require that you set up an account (on reddit, that takes two seconds, on digg, a little longer). Then you hit the up arrow beside story (reddit) or "digg" it.)

Well done as usual! I just did a quick read and will have to study the links in much more detail later, but my gut feel is that the low ERoEI and high environmental costs will preclude most of this from ever happening. IMO, conservation and mitigation is the far better alternative.

Bob Shaw in Phx,Az Are Humans Smarter than Yeast?

You're very right about the DOE projects. Did you ever look at the fireflood at Saratoga, Hardin County, Texas operated by Mobil? Plunging oil prices in the late '80s did for that one.

There are a huge number of faults and reservoirs, and at least 28 producing sands. It was drilled to a very high well density by numerous operators. I did a lot of work there in 1984-1986, and the operator I was working with drilled about 20 frio wells in the field.

Mobil had the biggest lease in the field and got a grant and started a fireflood. For the non-industry types, thats where an operator pumps air in the reservoir and sets it on fire because heat makes oil thinner and the combustion gases help drive the oil through the reservoir rocks, about 1200 ft. deep and small acreage, less than 500 acres. They got production up to about 2,000 barrels a day by my recollection, and changed the oil from old oil to new oil under the Windfall Profits tax,plus got DOE Grants and Tax Credits.I don't remember what the cost was, but, the lifting costs were not cheap. And it was a couple of hundred wells-they had a large crew working for them-20 or 30 pumpers and technicians. Plus engineers, accountants, investor relations flacks, human resource folks, ect., all of the expensive supernumeraries of a big oil company.

I bought a ten acre lease next door that had five wells and new tanks, the operators had just walked away and left it when prices fell to $12 a barrel and raised $20K by hook and crook and got the lease up to about 10 bbls a day of production. We operated it for about a year, then sold the wells. My investors all made some money, but I figured out my net was about $5 per hour and a heck of a lot of gray hair and much experience. And with prices at $60/bbl I wish I had the lease back, the wells will still pump a couple f barrels a day, and have for the last 20 years in the oldest part of a field now over 100 years old.

So, in conclusion, I just don't see how big companies are going to raise US production by redeveloping old fields. But I think there is lots of oportunity for small operators here on the Gulf Coast to make a good, honest living pumping the dregs. Bob Shaw is right, conservation makes the best economic sense, but its important to recover what'sleft.

Its not a new process, companies have been commercially using it for 30 years or so. CO2 also occurs naturally in some fields. At Spindletop in Jefferson County, Texas the gas in the cap rock contained 25% CO2 naturally and the shallow 1200' wells blew in at an estimated 100,000 bbl/day and flowed for 2 years. This was in 1901 and is considered the start of the Gulf Coast oil business. There is an article in the Bulletin of the American Association of Petroleum Geologists in about 1906 that describes this and is very interesting. I don' think its available online but Rice University in Houston has a copy.

But don't expect this to be cheap oil. Every prospect has to be examined on a well-by-well basis for the economics, and it will favor independents with low overhead, the Majors can't support huge overhead with hundreds of thousands of stripper wells. But, I expect them to sell off the remainder of their production in the next ten years or so as they would get rid of most of their political problems by doing so and declining world production will have hugely higher lifting costs.

Texas and Louisiana are full of fields that were drilled and produced before production methods allowed even a 30% recovery. I think many operators could raise production of many of them by 10% or more by reentering wells and side-tracking to recover attic oil, starting waterflood and using other methods like microbiological enhancement of the resercvoirs to lower gravity. But, it will require a lot of land, geological, geophsical and engineering work, and all of these talents are in short supply.

So the big question is what is the production rate using these methods? I'd have to guess you would also be producing a lot of water or a lot of C02 or both. In other words your looking at a non-oil cut that's fairly high.

I could be wrong but I don't see production rates very high

with these methods.

So I see very expensive operation and low production rates.

Also I think once these solutions become competitive the decline rates of most of our major fields will be significant.

Finally considering the main use case would be for transportation and the cost of road maintenance and fuel in a expensive oil environment I think the overall economics is no longer positive. Expensive oil acts like a sales tax taking a percentage out of each transaction and road building and maintenance uses a lot of oil products.

So expensive oil impacts our current transportation system in a number of places.

Extraction Costs

Road building maintenance costs

End user fuel costs

Tax base ( more money going into fuel )

At some point their is a point where the overall EROI for oil based transport is low enough its not worth it.

This could be as high as 3:1 returns.

Btw ethanol etc all suffer the same problem that's why I ignore the debate. We can afford to maintain roads with expensive oil. Once you look at the big picture its cheap energy that's critical for our road based transport system.

It should not be that hard to figure out a number at which the whole system is not worth pursuing and I think you would be surprised at how low the number is once its a long term rising cost. I don't think the system is viable at even 60 US dollars a barrel for twenty years much less the 100 plus needed to really make these projects viable. With cheap oil the economy could grow using oil/roads and right now at 60 I think the overall cost is now negative. We aren't crashing now simply because we are still using roads that were built with cheap oil but this infrastructure decays over time.

So if I'm right we are already toast and the miles of road in the US will decline and decay from now on and it will be fairly steep since roads especially in the north need to be resurfaced.

http://www.redwoodcity.org/cds/engineering/roadways.html

I'd say the climate in redwood city is very good for roads and they claim a 20 year life time I'd assume it could be much lower under other conditions say as low as 10 years.

So even with todays oil costs your proabably looking at having a extensive road network for less then 40 years.

Every single road in existance today will at best need to be resurfaced in 20 years using energy sources at least as expensive as today. So assuming they were laid at 20 dollars a barrel and oil contributed say 20% to the cost we would reduce our road miles. Since 60 dollar oil would be 60% of the cost. 60-20 = 40% less roads for the same orginal cost.

And in the next twenty years the same so in 40 years we will have at best 20% of the road surface we have today.

Add in the fact that this is conservative and oil will probably rise to 100 or more a barrel and we should lose a significant amount of our road surfaces within 10-15 years.

The key is how much new oil is used or burned to build a mile of road. I don't think 20% is low since you have to consider all places that oil is used this would include equipment manufacturing worker travel etc.

So unless these recovery methods can get the price of oil back down below say 40 a barrel at most they don't matter.

I would like the electric car advocates to describe the road maintenance future.

They don't need subsidies; the process should be commercially feasible with world oil prices at $30 a barrel. The energy balance is favorable; under a conservative life-cycle analysis, it should yield 3.5 units of energy for every 1 unit used in production. The process recovers about 10 times as much oil as mining the rock and crushing and cooking it at the surface, and it's a more desirable grade. Reclamation is easier because the only thing that comes to the surface is the oil you want.

OH NOEZ!!

Keep in mind, they estimate you can get a billion barrels out of 1 square mile of oil shale. There are 1000 square miles in Colorado alone. And the EROEI is about 3.5 to 1, far better then corn based ethanol and better by some accounts then cellulistic ethanol. If its economically feasable to do this on a large scale...

Sincerely,

Jack Abramoff

(Cellblock - pretty comfortable, actually)

Shell will know more in three or four years.

1 million barrels a day, using electricity, needs 10,000 MW of new powerplants, if it works...

100 acre production area would require 3,000 (sic) wells, spaced 8 feet (for frost wall) to 30 feet (heating) apart.

World oil shale production is 12,000 b/d, that's 1/10,000th of global energy.

Read more at http://www.aspencore.org/images/pdf/OilShale.pdf

Actually it does not matter to much electric ethanol oil etc.

Since your going to have to collapse your cities anyway back

to walkable and use electric rail/trolleys/subways for travel.

At best your talking about local runabouts sort of like glorifed golf cars maybe but no one is goin to pay for parking lots. Which leaves you with taxis as maybe still viable.

Of course you still have other types of transport that may be gas/electric powered.

Actually this is how the asian cities used to work till recently you had bus( many electric) rail/subway. And you

used taxis for short distances away from the main lines.

Or "luxury" longer city trips.

But once you figure out most roads are toast they don't really matter all that much since no one will be driving normally.

Since we won't be able to maintain or build a extensive road system my best guess is we will move back to paving stones for city roads. And use trolleys to move around the city.

The idea is that with our current computer capabilities we should be able to build a rail based private trolley that can drop you off and move on its own into a parking structure. The route it drives unattended can be fenced to prevent pedestrians sort of like touching the third rail on a subway or walking in a tunnel dumb thing to do.

In fact these mini trolleys may be fully automated.

Its like having your personal rail car back in the 1800's.

The nice thing about rail is the rest of the road surface can readily be paving stones. I'm sure concrete will be bad news then so using paving stones helps CO2 emissions also.

I think unlike the 1800's personal trolleys should be viable

in the future. Laying the rail etc will still be expensive and so will parking so I think you will still have far denser cities then we have today and few will have the personal trolleys that they own although they may use a private taxi version often. The catch 22 is of course if you make the city dense like we need too you can't find a place to park and congestion is horrible so there is a balance.

http://archives.seattletimes.nwsource.com/cgi-bin/texis.cgi/web/vortex/display?slug=roads08m&dat e=20061008

As the price of fuel goes up the amount of traffic on the roads will go down. The roads will get rougher and speed will eventually decline from lack of maintenance. A road at 70 mph has to be much smoother than one traveled at 40. So eventually we will have light electric cars traveling slowly on a much shrunken maintained road network. With less pounding, the roads will last longer even with limited maintenance. It is possible that road durability can be improved significantly by adding, say, teflon to the top coat. A small electric car will be much less wide than current SUVs, so we would only need about one-half the road width we currently use. Whole lanes of our roads could be set aside for electric bikes. Electric bikes can currently travel 20 miles at 30 mph on SLA batteries. NIMH or Li-ion batteries will soon be able to double the possible range for electric bikes. This is possible today if you want to pay for it. Electric bikes are a serious mode of transportation that is here today and that we will need lots of in the future. It is a matter of shrinking and maintaining our road system to fit the real needs that we will need to adjust to.

One problem with CO2 recovery: does this not contribute to Greenhouse Gas Emissions if the CO2 is not obtained from an already existing source such as a power plant? Also what happens if the CO2 migrates into water supplies? The users of water wells may find their water tastes like seltzer water and that is acidic.

One wonders how long NAFTA will remain when it's a choice between adherence or Canadians going without heat.

In short, it's time once again to remind people of Matt Savinar's speculation that the US may eventually invade Canada.

The other factor was the agent they tried to send across to bomb LAX on the Millenium evening. Who was caught by a US Customs Agent-- when they jumped on the car trunk to check for hidden stuff, he hit the ground, and they realised they were on to something more than an ordinary marijuana smuggler.

Periodically I think that the US will bring in Plan Columbia on British Columbia, the marijuana smuggling has gotten so bad.

If I recall NAFTA correctly, it basically says the US and Canada are one energy market. The energy flows are north and south not east and west.

What I see as more likely is BC & Alberta either form their own country, or join the US in some way (imagine BC splitting in two, with the coast and Vancouver Island joining Washington State, and the inland joining up with a new Washington State east of the mountains, capital-ed in Spokane).

Precipitating that, or following it, Quebec becomes Republic du Quebec, creates its own equilibrium as the Hydro power breadbasket of New York and New England.

That leaves Ontario, Manitoba, Saskatchewan, the Maritime Provinces dangling in the wind. Maybe Man and Sask go with Alberta, or maybe not-- northwestern Ontario has often talked about merging with Manitoba, which is actually much closer than the provincial capital (Toronto).

The precipitate factors would be Quebec separating, or a Federal power grab for the Alberta oil sands royalties.

The US doesn't need to conquer Canada, as culturally and politically is pretty much a colony and it has set in concrete its access to Canada's natural resources. Not politically correct to say that (as a died in the wool anglo-phile, monarchist Canadian from Satan's den aka Toronto) but nonetheless how I see it, from the perspective on t'other side of the drink, sipping Gin and Tonics in the motherland.

I have mixed feelings about CO2 sequestration, at least in the way that it is usually proposed. It is usually proposed as a way to recover oil, not just to sequester CO2. If you sequester the CO2, but then produce more oil than you otherwide would have, to a certain extent you are canceling out the greenhouse gas reduction by later burning the oil. If this is a substitute for burning a more greenhouse intensive fuel like coal, then you have come out ahead. But how do we know it is substitution as opposed to supplementation and just a way to try to indefinitely extent our easy motoring lifestyle?

In our abundance mentality society, most of the so called alternatives to conventional oil are not really alternatives but just a way to increase supply and let demand do what it will.

While alternatives could be a positive thing, I think that they need to be proposed in the context of an overall ceiling in carbon production with a reduction of that ceiling over time. With a ceiling that is managed with a market of carbon credits, then perhapswe could take some of the politics out of the debates regarding the carbon efficiency of each alternative. Set a goal and then let the market decide the optimum mix of the various alternatives.

CO2 which is back produced in the wells can be recirculated into the reservoir, thus limiting the emissions to air, though I think that CO2 EOR schemes to date don't really have this as a major driver. The main reason to separate the CO2 is economic - it costs too much to lose.

It is unlikely that the operator could negotiate the same contracts today with either the landowners or the other operators who unified their operations under Oxy in about 1970. Natural gas is worth too much money for the other operators to contribute gas without some type of compensation.

I have no figures, this is top of my head memory work, but it raises some interesting questions;

1.) how much CO2 does it take to lift a barrel of oil?

2.) how much energy does it take to seperate the CO2 from the fossil fuel electric plant stack?

3.) at what cost per BTU does this become uneconomical

So I wonder, have any of you engineer types done research on this that can yield an EROEI figure ? Robert, Engineer Poet? This is quite possibly another ethanol type of solution, barely economic. I apoligise in advance for my Liberal Arts education that leaves me struggling on more than a simple calculation.

Memmel, in answer to your question about how much oil is going to be produced per well, thats a good question. I'm sure it varies depending on the field and the formation characteristics and the stage of production of the field. I doubt anyone can answer you with a general figure. And about CO2 sequestration, the CO2 is injected compressed as a fluid. If it starts breaking through the wells are being pulled too hard. Thats what Elwood was talking about earlier up the thread, this leaves oil stranded. I do know the maximum economic rate can be calculated by Petroleum Engineers and once again is variable. Also, most oil tanks are airtight in order to capture the natural gas in solution in the oil, so recapturing any CO2 should not be a problem but it will require more energy to reprocess and reinject the CO2.

you asked how much energy to remove CO2 from a power station stack? Two options either process the fuel to remove CO2 beforehand (pre-combustion technology) or take the CO2 from the exhaust stack (post combustion). Lot of development on both of these now no clear winner.

For gas fired plants post combustion removal is probably the way to go - ie from exhaust stream - circa 15%+ efficiency loss in power generation (ie. 75mw+ for every 500mw el generated)

For coal fired, IGCC (syngas / H2 production) could be the winner - don't know the details but also not the most efficient coal firing technology (35% vs. 45%?). IGCC processes the coal upgfront to give you a CO2 stream. This avoids having to process the exhaust stream which volumetrically is much bigger than a gas fired station for the power generated.

I googled...

pre-combustion CO2 removal

...and the first link I found was to a description of the good old Syngas process. In Syngas the carbon ends up in a carbon monoxide molecule; but what do you think happens to the CO eventually? It ends up bonded to two oxygens, i.e. it becomes... CO2. This applies whether you use the syngas directly, or whether you use Fischer-Tropsch to get liquid fuels (which then get burnt in... oxygen).

You're not "removing" CO2 - you're just adding intermediate stages of molecular rearrangement, normally to get the fuel into a more industrially convenient phase (gas or liquid). If you follow the carbons through the process, they always end up as CO2 once everything has been burnt. Why shouldn't they? It's the energetically most stable configuration...

IGCC is a syngas production system - the important thing being that the syngas can be treated to extract most of the CO2 prior to combustion (acid gas removal).

The gasified fuel stream is smaller and at higher pressure than the exhaust gas from the turbines and CO2 content higher. This makes the extraction system more efficient.

The reason I linked this to IGCC is that for coal is this one of a few ways to get an integrated CO2 removal system for a coal fired power station without taking a very big hit on efficiency.

IGCC process with co2 capture

Peak Oil doesn't mean the end of oil, but it is the end of cheap oil. We've used about 50% of the worlds economicialy recoverable reserves in the hundred years of the oil age, and demand and population have grown so we will use the rest cheaply produced oil in the next 30 years or so.

What I like best about this blog is that the people who post here examine in minute detail and generally fair minded thoughts the various positions on energy policy and useage. And there are experts from all kinds of scientific and economic disciplines, and journalists like Dave who wrote his and industry folks like me. Its a great dialogue. Ther's also a few nuts and trolls, but this is the internet.

So welcome to the site, and keep reading. The more people that understand the issues and think about possible solutions the better chance we have of finding some real answers for the world.

(the availability issue can be solved if you have 2 gasifiers).

However the capital costs are much higher. If we had proper charging for carbon emissions, then the same case that is made for nuclear, could be just as well made for IGCC.

But at the moment many of the power consumers groups in Ohio are suing AEP to prevent it building an IGCC, because their power rates would go up. To my mind, AEP is just preparing for the future, but of course no one wants to pay for it...

- Hot

- Dilute

- Low-pressure

- Dirty

- Corrosive (if there is sulfur in the coal or oil)

and in the case of coal-fired power plants it's pretty much where you don't want it because you build said power plants either near coal basins or downwind of cities, not near oilfields.EP is right that H2S is another good miscible solvent for trapped oil, but forget about injecting into old wells (the kind you tend to find in depleted fields) unless you want the ha$$le of retrofitting them with the exotic metallurgy (tubing and liners - oh, and flowlines and compressors and all the rest) that would let you handle that stuff. And won't combustion leave you with SO2 anyway?

It's even worse for transportation fuels because your (hot, dilute etc.) CO2 is coming out of the tailpipe of a car or out of a jet engine at 30,000 feet. Let's see you capture that for injection into a petroleum reservoir!

This is why sequestration will always be a niche business relying on advantaged sources of CO2, penalties for emissions, or tax breaks. I doubt if it will ever reduce mankind's emissions of CO2 into the atmosphere by even as much as a single percent - and emissions are growing by what, two or three times that much per year. Looks like we could be spending billions to buy ourselves a 6-month reprieve from Global Warming, guys!

Greenfuel has algae which tolerate hot, acid conditions. These would be capable of feeding from the cooled stack gases of a conventional powerplant, but would presumably do just fine with the stack gases leaving the HRSG of an IGCC plant.

The future of sequestration depends on carbon taxes. When it becomes less expensive to dump carbon underground than into the air, people will do it. It's not overly difficult, and certain forms of sequestration (enhanced oil recovery, terra preta) can actually pay dividends.

ie same problem as waterflooding.

Looking at the Carbon Sequestration report, if you can use that CO2 for EOR, then sequestration might well wind up costing you nothing.

http://arch.rivm.nl/env/int/ipcc/pages_media/SRCCS-final/IPCCSpecialReportonCarbondioxideCaptureandS torage.htm

Want to see somthing that is even 'neater'? Fly High!!

I saw the kit idea earlier I think they are on the right track. One of the most important things over time is to come up with generation technology that very cheap to deploy. Kites are much cheaper then advanced windmills. I think they are still to high tech in the design. For example they use a electronic controller for the kite where the right answer is probably a simple fluidic control in the kite.

http://en.wikipedia.org/wiki/Fluidic_logic

These can be printed.

Next they are using a large central hub and I think they need

to consider a much smaller cheaper array of little hubs with say two or four kits attached.

And finally they are going for a rotating motion which is not the natural motion of a kite. A kite pulls so a piston

like motion is more natural. The kite can pull on the up swing and dive to cause the down swing.

Or maybe you could get this motion with a long rod mounted so it rotates about the center. A sliding weight is also on the rod so when the rod goes over vertical the weight slides down to the other end. A kite would be at each end of the rod. Then you need no controls since the sliding weight will

switch which kite is pulling against the weight. Maybe the kite needs to be attached to the weight not the rod.

Or one to the rod and one to the weight :)

Not a lot different for the oil well rocker pumps.

Or something like that you get the picture. I'm not a mechanical engineer but I don't think you need the complex rotating mechanism they described.

In the long run I think designs that have the best cost per

power generated and are dead simple to build will be what we use for power.

So the long term winners seem to be.

1.) Kits not windmills

2.) Plastic solar panels and simple evaporation based collectors or solar towers salt ponds.

3.) Wave/Tidal hmm don't know of a simple solution but

again something based on sliding is probably the right answer.

Wave action could be captured saw with a simple buoy that

slid up and done a linear generator anchored to the sea floor. Instead of trying to capture the electricity you could generate hydrogen and when the bag was full go by and pick it up. Or in the case of sea water there is enough co2

that you could generate methane balloons and periodically come by and collect or once you have methane its easy to contine and synthesis methanol or something else. The idea is if these are floating offshore you don't want to try and run electric lines so some sort of coversion to chemical energy with a few collections a year may make the most sense. With the hydrogen or methane blimp it could fly itself to the collector and would not survive storms well. Liquids would be easy to store in a bladder in large quantities but would need collection of course they might also be automated. The nice thing about some sort of buoy is you can also of course attach solar panels and kites so you get all three sources for the price of one.

Microwave transmission to a central receiver is also possible

but I'd wonder about the environmental effects. If the power

is low enough it would actually work the best I think.

Of course toasting a few seagulls probably won't hurt anyone :)

In any case I think that developing cheap electrical generation devices like this allows you to consider "wasting" the power doing conversion to chemical and I think the overall cost would actually be the same or less than the cost of advanced oil extraction or CTL. I'm not saying it allows a car based economy but we still need fuel for airplanes and plastic and other uses. By using barren desert land and the ocean for generators we are not wiping out our topsoil for fuel.

If the generator is cheap then the EROI for these types of devices is much higher then growing crops for energy.

And if they can be made of plastic you can use the remaining oil/gas for plastic production taking advantage of the price and switch later to natural organic sources for plastic.

I think that if the goal is to raise crops to make plastic devices which then can be used for many years to produce energy the EROI is far far higher then burning the organic back to co2.

So I see CTL advanced extraction cellulose to oil as quite reasonable routes for manufacturing value add chemicals but not fuel except for things like airplanes where you have little choice. If you think about it and we actually only used organic fuel where we absolutely had too then we have plenty of oil left.

Come on, has anyone been a kid?

They are not talking about the kite spinning. The spin is the kit tacking upwind around the generator. Sorry for the confusion. The kite itself can perform all kinds motion just I don't agree with trying to tack into the wind or I don't think its required.

A sliding weight or other mechanical process at the bottom can translate a constant pull to rotary motion. You may have to dive the kite to get past TDC but I don't think so if you couple two kite together that are out of phase on the crank.

So all you need is the kite is attached to a lever when it is lifted past a certian point a weight on the end of the lever slides down and say the kit is attached. The rod drops

the weight slides back out so the kite is back on the end it

lifts and the process repeats. A rachet can be used to collect the energy on the up stroke and it free spins on the down stroke allowing the rod to drop.

Since the kit on the weight is no at the center of the rod its not going to keep the rod from dropping.

So you end up with a lever like motion.

Think of it this way.

You have a pole with a kite attached at one end which is also attached to crankshaft for a piston.

The kite has a weighted ring like a fishing pole eylet but it slides down the pole.

When the pole is facing towards the groud the ring slides out moving the kites pull out the pole to the end.

The kite pulls the pole up causing the ring to slide end.

The pole drop and you restart.

I'd just like to underline the fact that these people studying EOR usually talk of reserves. What we want to know is daily production numbers.

Even if the numbers given by the U.S. House Committee On Resources come to be true, 2 Mb/d doesn't seem to change much the whole picture.

Isn't this what we really really want? Shouldn't we be celebrating? Our economies are growing, but we've cut fuel consumption! Without any viable government initiative to do as much! And if OPEC passes its cuts, then the high prices that forced the cuts should probably continue!

Sorry, but this seemed really exciting news, and really good at that, so I just thought I'd share it...

It's WAY too early in the morning to be faced with such a large, horrifying image of the co-star of Bedtime for Bonzo.

P.S. - I heard Nancy got blacklisted at some point. Is that true?

Holy crap this is superb stuff. One question though. Someone asked above about the CO2 getting into the atmosphere. How is it that CO2 doesn't seep through porous rocks? I mean high pressure CO2 gas injection has to push some of it into the surrounding rocks/earth and get into the atmoshpere somehow right? Or has this been addressed and is a red herring?

has a bit of info (although is not focused on EOR per se)

http://www.colloqueco2.com/IFP/en/CO2site/presentations/ColloqueCO2_Session1_02_Socolow_PrincetonUni versity.pdf

has a couple of slides.

There is a lot of research going on in this area however some basic points are......

a) injecting into an old (depleted) hydrocarbon reservoir is a good starting point as this trapped oil or gas and as long as you don't exceed the original reservoir pressure the seal is not too likely to fail (though some seepage over geological time is likely).

b) injecting into an aquifer - research from projects such as Sleipner (Statoil, 5-10 yrs 1million T/yr) has shown that the CO2 will form into a 'front' which slowly migrates away from the well. Can be seen on 3d seismic. If the acquifer formation comes to surface then the CO2 will escape so it is important to understand the formation over a wide area in detail.

Other issues - CO2 forms carbonic acid - disolves away the rock matrix for sandstones making a path to the surface. This is a hypothesis - not proven to date. Have also heard that CO2 also likely to precipitate out in the formation over time too.

Well, not quite. It's not been looked at a lot, but I'd say that what is there doesn't look promising.

http://www.uic.com.au/nip83.htm from their good buddies the World Coal Institute. Claims of a mere 15% power penalty seem more theoretical than actual. Have they even decided yet where FutureGen is to be built? Yet it seems like everyday politicians tell us clean coal is just around the corner. I'm wondering if carbon capture based EOR is all a diversion to stall decisive action on GHGs.

A 2000 US study put the cost of CO2 capture for IGCC plants at 1.7 c/kWh, with an energy penalty 14.6% and a cost of avoided CO2 of $26/t ($96/t C). By 2010 this is expected to improve to 1.0 c/kWh, 9% energy penalty and avoided CO2 cost of $18/t ($66/t C).

Figures from IPCC Mitigation working group in 2005 for IGCC put capture and sequestration cost at 1.0-3.2 c/kWh, thus increasing electricity cost for IGCC by 21-78% to 5.5 to 9.1 c/kWh. The energy penalty in that was 14-25% and the mitigation cost $14-53/t CO2 ($51-200/tC) avoided. These figures included up to $5 per tonne CO2 for transport and up to $8.30 /t CO2 for geological sequestration

From your source.

None of these figures sounds prohibitive, and put CSS on a level playing field with nuclear, particularly as CSS will get cheaper as we know more.

My mental rule of thumb is that we are moving towards $100/tonne carbon ($27/tonne CO2)-- whether by tax, or by permit. About $600 on a flight London to Sydney. Whether that will be enough to do something about global warming I don't know.

(a good rule of thumb is nuclear is 8 cents kw/hr. Nuclear generators of course quote much lower figures like 1-2 cents, but these avoid counting a number of the costs that have gotten nuclear power to the current state (Price Anderson Act, R&D subsidies from government, future waste liability etc.). Every nuclear programme in the world had unforeseen delays and was over budget. Now that real interest rates are lower, the capital cost of plants is less of an issue.

There are reasons to think nuclear might fall to 6c kw/hr, with a stable third generation technology and no unreasonable planning delays (aka no public demonstrations, civil disobedience and multi year public inquiries).

Of course, CSS is also likely to have the same local objections, although undersea oil fields less so.

Biofuels are trendy. CO2 injection is virtually unknown.

6 weeks ago, Statoil admitted it was sequestering CO2 in the North Sea only because it was making a lot of money doing so:

Nothing has changed since. And this is a country that actually has a place to dump their carbon.